1. Introduction and Motivation

Micro/nanoelectromechanical system (M/NEMS) resonators have been widely used as mass sensors in the “More-than-Moore” paradigm because of their enhanced mass sensitivity as a result of their miniaturization down to the nanoscale level [

1]. The operation principle relies on the gravimetric sensing provided by a resonant frequency down-shifting when loaded with a mass. These devices have been either operated in open- or closed-loop arrangement to obtain self-sustained oscillators capable of tracking real-time frequency shifts. Previous works based on NEMS resonators fabricated with specific technologies have reported mass sensing resolution as low as yoctograms (10

−24 g) [

2], as well as real time detection of single proteins [

3]. Additionally, other works take advantage of well-established commercial technologies such as CMOS ICs to design and fabricate fully integrated CMOS-MEMS solutions; i.e., the MEMS resonator and the CMOS readout circuitry are monolithically integrated within the same die, achieving a mass resolution in the range of atto-grams (10

−18 g) [

4]. However, such an outstanding mass resolution comes at the cost of considerably small resonating structures whose effective surface for target–sensor interaction represents a limitation when sensing gas or detecting larger-sized particles. Therefore, in addition to mass sensor enhancement, distributed mass sensing is gaining increased interest given its application in volatile compound sensing. The work in [

5] reported a mass resolution per unit area in the order of fg·cm

−2 for a specific fabrication technology without integrating readout capabilities. In the same line, in a previous work, we designed and fabricated a resonant platform providing mass resolution in the order of pg·cm

−2 by means of a CMOS-MEMS monolithic solution [

6]. Other published works offer specific applications such as relative humidity measurements [

7] or inkjet pico-liter droplet deposition for real-time calibration and future aerosol detection [

8].

All these structures are suitable for a large number of potential applications in the biological, chemical and medical fields when coated with the proper layer materials that provide specific capabilities—for example, cancer biomarker detection [

9]. The objective of adding specific coating materials is to functionalize the resonator for it to capture specific volatile organic compounds (VOCs), enabling the development of a new M/NEMS biosensors generation for the biomedical domain due to their increased effective interaction surface. Some strategies arrange several individual nanoelectromechanical sensors in an array configuration [

10], while others consider larger surface resonating structures such as cantilevers [

11,

12], film bulk acoustic wave resonators (FBARs) [

13], capacitive micromachined ultrasonic transducers (CMUTs) [

14] and membrane resonators [

15]. Increasing the sensing element surface improves the sensor–target interaction, and it also eases the functionalization process that requires the deposition of polymer coatings or other materials that must adhere on top of a micromachined surface. Such a deposition is performed through a variety of methods, such as airbrushing [

12,

16], ink jetting [

17] or spin coating [

13]. The accommodation of a functionalization phase into commercial technology is not a straightforward technique and, in fact, very few works combining a CMOS-MEMS resonator with a functionalization polymer are available [

18].

Miniaturized gas biosensor characterization and tuning involves experimental setups for gas mixing and delivery that require a careful analysis to account for the fundamental physical mechanism by which gas flow impacts the resonant structure behavior. Very few works detailing experimental practices for sensor calibration and operation are available. Various flow sensor designs based on MEMS resonators are available detailing that, among other effects, the well-known solid–fluid drag force impacts the resonator quality factor due to induced mechanical losses. The work in [

19] characterized the change in capacitance for an in-plane capacitive MEMS sensor caused by the drag force generated from a gas stream. Another project developed a gas flowmeter based on a sail-shaped resonator working as an oscillator with a CMOS amplifier on a PCB connected to a flow chamber, obtaining a resolution as low as 0.2 mm/s [

20]. Finally, a self-oscillating cantilever also proved flow sensing capabilities both in dynamic and static modes [

21]. In any case, a detailed analysis of the impact of gas flow on a microelectromechanical resonator response remains an open topic. This is because the intrinsic disturbances that modify the resonator response (which occur also as a result of the specific characteristics of the resonator) when the VOC flow interacts with the sensor surface remain to be experimentally characterized in detail. In this sense, this work is focused on analyzing and evaluating the impact of a fluid flow on a MEMS plate resonator (see

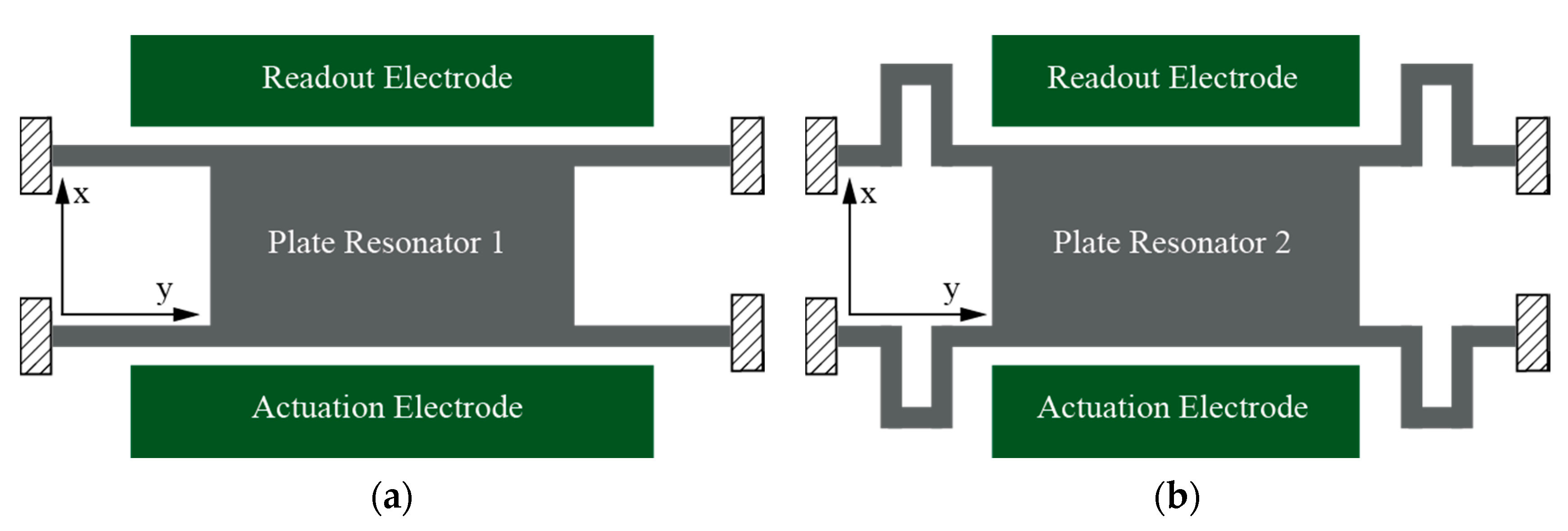

Figure 1a) based on analytical and experimental evidence, while designing and fabricating a new topology to diminish this impact (see

Figure 1b).

This paper is organized as follows:

Section 2 details the design and fabrication of the complete system, while

Section 3 presents the physical mechanisms for which gas flow can modify the frequency of a micromechanical resonator.

Section 4 details the setup used for the gas delivery system and presents the experimental results of flow sensitivity for open- and closed-loop topologies. Finally,

Section 4 also presents the temperature sensitivity measurements and a comparison with other designs, and

Section 5 summarizes the whole paper and provides the main conclusions.

2. Design and Fabrication

The mechanical resonators used in this work were fabricated on CMOS 0.35 μm commercial technology with an additional final step performed at our lab facilities consisting of a post-CMOS mask-less wet-etch to remove the sacrificial oxide underneath the structure by using a commercial etchant; further details about the fabrication process were provided previously [

22]. The technology used had four metal layers based on an aluminum composite with a TiN film; the top one was used as the resonator structural layer as it provided the larger thickness, thus resulting in a larger capacitive coupling [

6]. The resonators were electrostatically actuated, while the readout scheme was capacitive, sensing the motional current generated by the resonator vibration. The whole system illustrated in

Figure 2 monolithically integrates the MEMS resonator together with a CMOS readout amplifier circuit to obtain a CMOS-MEMS full-custom oscillator with quasi-digital sensor output.

Two anchor geometries were designed, fabricated and tested. The geometric parameters for the two structures are given in

Table 1. The plate resonator (PR1) depicted in

Figure 3a was designed specifically for gas sensing incorporating a large sensing area that provided a high mass sensitivity per unit area [

6]. A re-designed plate resonator (PR2) with the same plate area but incorporating folded flexure anchors was conceived to mitigate the impact of fluid flow effects with respect to PR1, while also reducing the temperature sensitivity (

Figure 3b). Folded flexure anchors offer an additional degree of freedom displacement in the horizontal dimension (

y-axis in

Figure 1) not having its elongation constrained, which helps in improving fluid flow capabilities and temperature sensitivity. In addition to such benefits, resonator PR2 also exhibits a similar mass sensitivity per unit of area with its counterpart PR1, as indicated in

Table 1. Such sensitivity (

) is computed by means of the resonance frequency (

), effective mass (

) and platform surface (

) following Equation (1) [

6].

4. Experimental Setup and Results

Most experiments involving gas management use a calibrated source that is further mixed with a carrier to modify the gas concentration driven to the sensor being characterized. Other techniques take a solution of the desired analyte through which the gas is passed getting saturated by the analyte. Next, further mixtures can be performed to obtain the desired concentration. Most of the works published in the literature [

12,

16,

18,

26,

27,

28,

29,

30] use a similar gas injection system as the one depicted in

Figure 5 to characterize resonator-based gas sensor. To the best of our knowledge, a detailed investigation into the impact of the gas flow phenomena (without considering any analyte–sensor adsorption nor chemical interaction) on the vibrating mechanical structure is not available. To conduct such an experiment and provide a systematic way to properly characterize resonator-based VOC sensor structures, we ran our experiments using dry air constituting an inert gas to guarantee minimum chemical interaction with our sensor structures. We designed and fabricated a gas chamber, whose schematic and dimensions are depicted in

Figure 5c, that minimized the fluid flow direct impact over the plate resonator. This was accomplished by directing the inlet flow towards a lateral wall instead to the resonator itself.

The CMOS-MEMS resonators were characterized by both open- and closed-loop self-excited configurations to obtain an accurate description of the various effects induced by the gas flow. The flow tests were implemented using the experimental setup shown in

Figure 5 that consisted of a gas supply (dry air) that ran through two digitally controlled mass flow Bronkhorst El-Flow valves to investigate the impact of gas mixture transients. The two valve outputs were mixed and fed into a sealed test chamber, where the resonator was electrically driven and measured while being kept at constant temperature. A gas outlet from the chamber was driven into a bubbler to avoid backpressure having the whole system continuously monitored by a computer. The open-loop tests were performed with a Keysight E5061B Vector Network Analyzer (VNA) to obtain the electromechanical transmission coefficient, while the frequency real-time tracking when operating as a self-sustained oscillator was done by means of a Frequency Counter Pendulum CNT-91.

4.1. Impact of Gas Flow

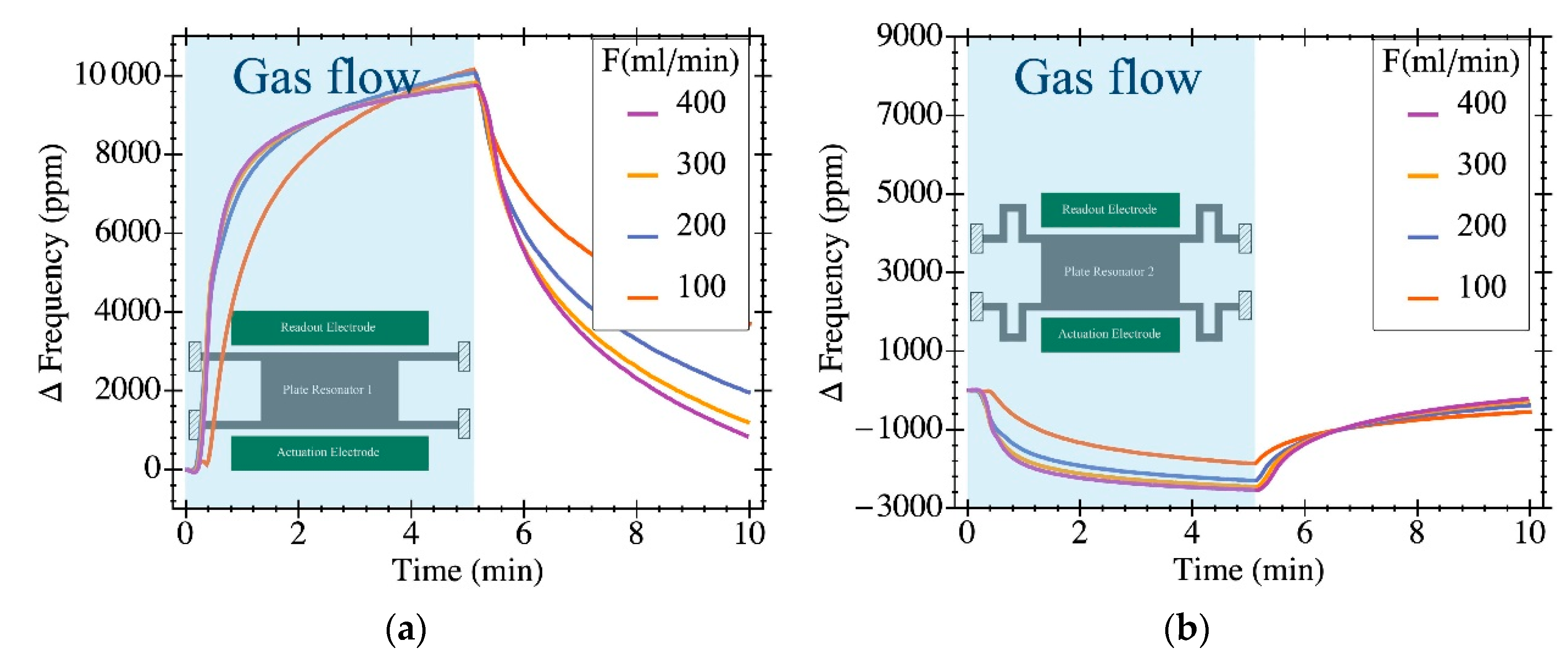

In the first analysis, we injected various flow rates to our two resonant structures to determine the impact of such flow on the resonant frequency.

Figure 6 plots the experimental results obtained when the gas flow ranged between 100 mL·min

−1 and 400 mL·min

−1 in steps of 100 mL·min

−1. The minute-range transient response obtained was clearly attributed to the gas flow stationary stabilization into the chamber since the resonator response to an external disturbance takes a few seconds given its micrometric-scale dimensions. Data show a dissimilar response for the two structures both quantitatively and qualitatively. The PR1 structure resonant frequency increased while the gas flow was injected (light blue background portion of the graph) and restored to its initial value once the gas flow was removed with a relative frequency variation of 1%. However, the PR2 structure, with the folded flexure anchors, experienced a frequency variation in the opposite direction (decreasing) with respect to PR1 exhibiting a much smaller (below 0.3%) overall variation. These results suggest that the relative dominance of the non-linear spring-hardening and softening counterbalance in a considerably different manner for these structures due to the shape of the anchors.

In the second experiment, we investigated the impact of gas flow-relative transients on the resonator response. We programed an overall constant mass flow of 300 mL·min

−1 while varying the relative aperture of mixing valves valve 1 and valve 2 while passing dry air coming from the same source.

Figure 7 reports the experimental data obtained for the resonant frequency of PR1 and PR2 structures when valve 1′s aperture was toggled from closed state to 10%, 20%, 30% and 40% aperture (valve 2 was settled to (100%—valve 1) aperture to guarantee the overall constant mass flow). Results show that PR1′s structure exhibited a relatively larger transient flow sensitivity with sharp frequency shifts followed by a transient recovery period. PR2′s structure exhibited a much lower transient flow sensitivity, thus being less impacted by gas flow transients. The perturbations induced by the gas transients do impact the resolution limit for these structures when used as gravimetric sensors since such frequency fluctuations are not caused by mass deposition or overall flow-rate variation. This means that the limit of detection for such sensors depends not only on the structure itself, but also on the gas injection method. In this sense, results in

Figure 7 show that the PR2 structure is much less sensitive to these undesired transient effects, with a 10× reduction in frequency shift representing, a priori, a better structure for gravimetric-based VOC sensing.

4.2. Impact of Operating Pressure

To determine which of the mechanisms described in

Section 3 dominates the frequency variations observed, we ran an additional test in vacuum conditions since the pressure at which the resonator operates impacts its resonant frequency through the variation of the quality factor

as stated in

Section 3.1 Figure 8 shows the relative frequency variation of the CMOS-MEMS oscillators when changing the operating pressure from high vacuum (<10

−3 mbar) to ambient air pressure. It is shown that PR1 exhibits a frequency variation in the opposite direction than the one measured for PR2. The frequency change in the opposite direction for both structures is consistent with the results shown in

Figure 6 where the influence of a fluid flow shifts the resonance frequency of PR1 to higher values, while in the case of PR2 it moves to lower frequencies.

If these divergences were to be caused only by a change in

value, both structures would present a frequency shift in the same direction; i.e., when toggling from air to vacuum conditions, the frequency change should point towards larger resonance frequency for both resonators given the increased value of

(see

Figure 8) according to Equation (4). This is not the case for PR2 as it experiences a downshift of the resonant frequency due to the dominating effect of the spring-softening effect as stated in

Section 3.3 As for the PR1 structure, its frequency shift when changing from vacuum to normal air pressure conditions is in the order of 10

4 ppm (as shown in

Figure 8). According to Equation (4), such a frequency shift would require a value of Q ≈ 5 in air, while the actual value derived from experimental data when fitting the open-loop response is Q = 190. This indicates, as stated in

Section 3.3, that PR1 with clamped anchors experiences mechanical spring-hardening, and that the primary cause for its frequency increase is due to an increase in its oscillation amplitude up to the non-linear regime caused by a larger value of

as a result of the vacuum conditions.

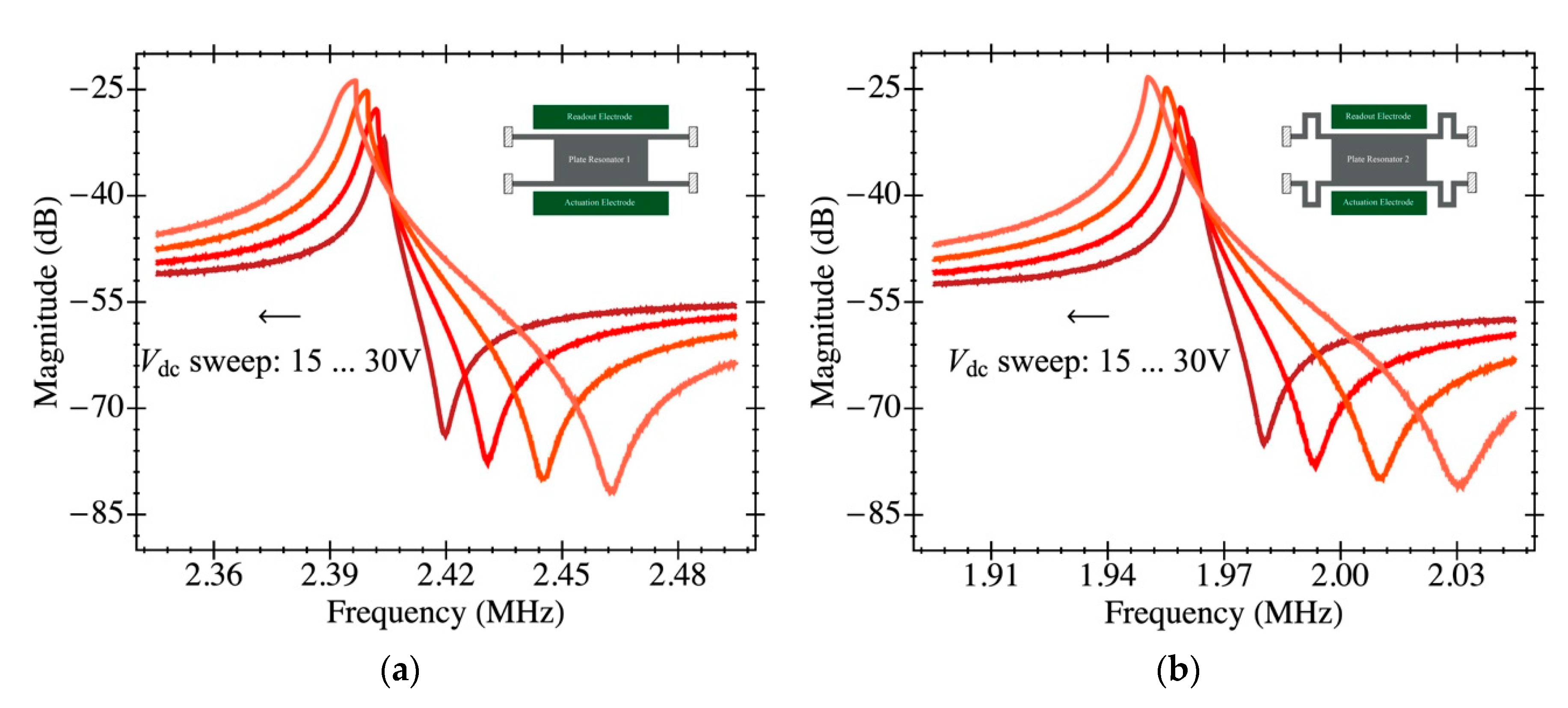

To further verify these dependencies, we ran the open-loop experiments shown in

Figure 9 where we measured the system transmission coefficient for a large enough input power (2 dBm). Such measurements visualize the well-known non-linear frequency shift already described, being in full agreement with the self-oscillation test.

We ran an additional experiment to determine the impact of pressure increase on each structure.

Figure 10 reports the open-loop behavior for both structures measured at 1 atm and 2 atm environments, showing the same tendency for the two resonator types—a frequency decrease with increasing pressure. Such a decrease is caused by a

factor degradation with increase in pressure for both structures. These results indicate that the behavior observed for the experiments shown in

Figure 6 and

Figure 7 is not caused by a relative pressure increase induced by the fluid flow, as overpressure impacts the frequency shift of both structures in the same direction. This dissimilar behavior shown in

Figure 6 and

Figure 7 is due to the interaction of the folded flexure anchors with the environment fluid, mitigating the vibration losses.

4.3. Temperature Sensitivity

Temperature was carefully measured by including a thermal probe in the PCB design together with the IC connections to characterize its time evolution within the sealed chamber. Any gas delivery system is suitable for inducing local temperature variations caused by thermodynamic effects as a consequence of a gas expansion as a result of relative pressure changes or thermal differences between the gas supply and the resonator circuit.

Figure 11 shows the thermal variations during one of the flow rate experiments, obtaining a temperature variation below 0.1 °C in the whole range. The impact of temperature on the resonant frequency was determined through a thermal calibration procedure obtained as in [

31], where the IC was placed into a climate chamber with a constant relative humidity of 40% during a temperature sweep while acquiring the resonance frequency. Experimental results are given in

Figure 12, from where the thermal sensitivities were computed to be −2430 ppm/°C for PR1 and −115 ppm/°C for PR2. The thermal insensitivity of PR2 vs. PR1 represents a dramatic improvement of more than one order of magnitude due to the folded flexure anchors. The temperature-related relative frequency change was 243 ppm in the worst case for PR1 and 11.5 ppm for PR2. These results conclude that the differences in frequency shifts experimentally measured during the gas flow trials were not due to temperature variations, and demonstrate that the PR2 design represents a significant advantage for a gas-sensing platform as it provides lower temperature variations. Interestingly, the measured temperature coefficient for PR2 was closer to the state-of-the-art results reported in [

32] using the same technological approach, but with an active temperature compensation system that increased the overall power consumption.

4.4. Gas Flow-Induced Stationary Deflection

The reported experimental data support the notion that the root cause of the frequency drift induced by the gas flow was caused by the drag force exerted on the resonator, inducing its deflection. If the solid–fluid interaction is large enough to deflect the resonator out of equilibrium, it enters the non-linear stiffness region (see

Section 3.2). If mechanical spring-hardening is the dominant mechanism (as happens for PR1 from

Figure 4a), then when the structure is deflected by the fluid flow, its stiffness constant increases together with the resonance frequency, as shown in

Figure 6a. However, if the dominant mechanism is not the spring-hardening (resonator PR2 in

Figure 4b), then the resulting frequency shift after the gas stream is applied is much smaller when compared to PR1 (see

Figure 6b). To thoroughly confirm these claims, one can relate the static deflection caused by the fluid drag force to the required change in the stiffness constant to provide a quantitative verification. For the PR1 structure, it is easy to find that the 1% change in resonance frequency (observed in

Figure 6a) requires a 2% change of its stiffness constant. According to Equation (7) and the non-linear model in

Figure 4, such an increase in the stiffness constant requires a resonator static deflection of 90 nm from the zero-deflection equilibrium. From Equation (5), and assuming a turbulent regime for the fluid flow, the drag force-induced deflection obtained is 30 nm, which is in the same order of magnitude as the computed value. Notice that an accurate estimation of the induced force is not feasible due to the turbulent nature of the fluid under test, and the non-linear model supported by COMSOL simulations might not provide full matching with the measured device because of fabrication stress, tolerance, etc.

5. Conclusions and Discussion

The reported experimental results highlight the impact of gas flow on the frequency shift of MEMS resonators caused by the fluid induced drag force without considering any chemical interaction. Such experimental data match perfectly with the analytical expressions. Our results show that the geometrical conditions of the structures supporting the resonant plate are capable of alleviating the disturbing effects of the solid–fluid interaction by reducing the spring-hardening effect as much as possible. Experimental data highlight that a calibration procedure of the overall experimental setups used for resonant gas sensors is mandatory to determine the final resolution of the overall system. The fabricated and measured CMOS-MEMS plate resonators specifically designed for gravimetric gas sensing monolithically integrated on-chip together with the readout amplifier operating as self-sustained oscillators show that the folded flexure anchor geometry mitigates this effect. The net result was a 5× reduction in the gas flow impact on the MEMS resonators’ frequency response conceived as mass distributed sensors for VOC monitoring. Moreover, we found the frequency shift to decrease with the fluid flow, i.e., the frequency variations were tinier for lower values of the flow rate only for the folded flexure geometry. A thorough analysis of the phenomena related to the resonance properties modified by the gas stream is supported by the experimental data of both under open-loop and closed-loop topologies.

Additionally, our work also shows that the folded flexure anchors provide a dramatic improvement temperature sensitivity close to 20× that of the already existing design, achieving −115 ppm/°C. Such a result is obtained without the need of adopting active temperature compensation schemes and using a single metal layer resonator to keep the mass sensitivity as high as possible [

6].

The main contribution is the derivation of a method to diminish the impact of a gas course over the resonance properties of a MEMS resonator by anchor re-design with the consequent gain in overall gas sensitivity. Additionally, we proved that the very same shape also improves the temperature sensitivity of these resonators. Both aspects are key in the design of gas sensing structures since a transport system needs to be implemented for sensor calibration, thus inducing both temperature variations and gas flow impact.