A High-Strength Strain Sensor Based on a Reshaped Micro-Air-Cavity

Abstract

1. Introduction

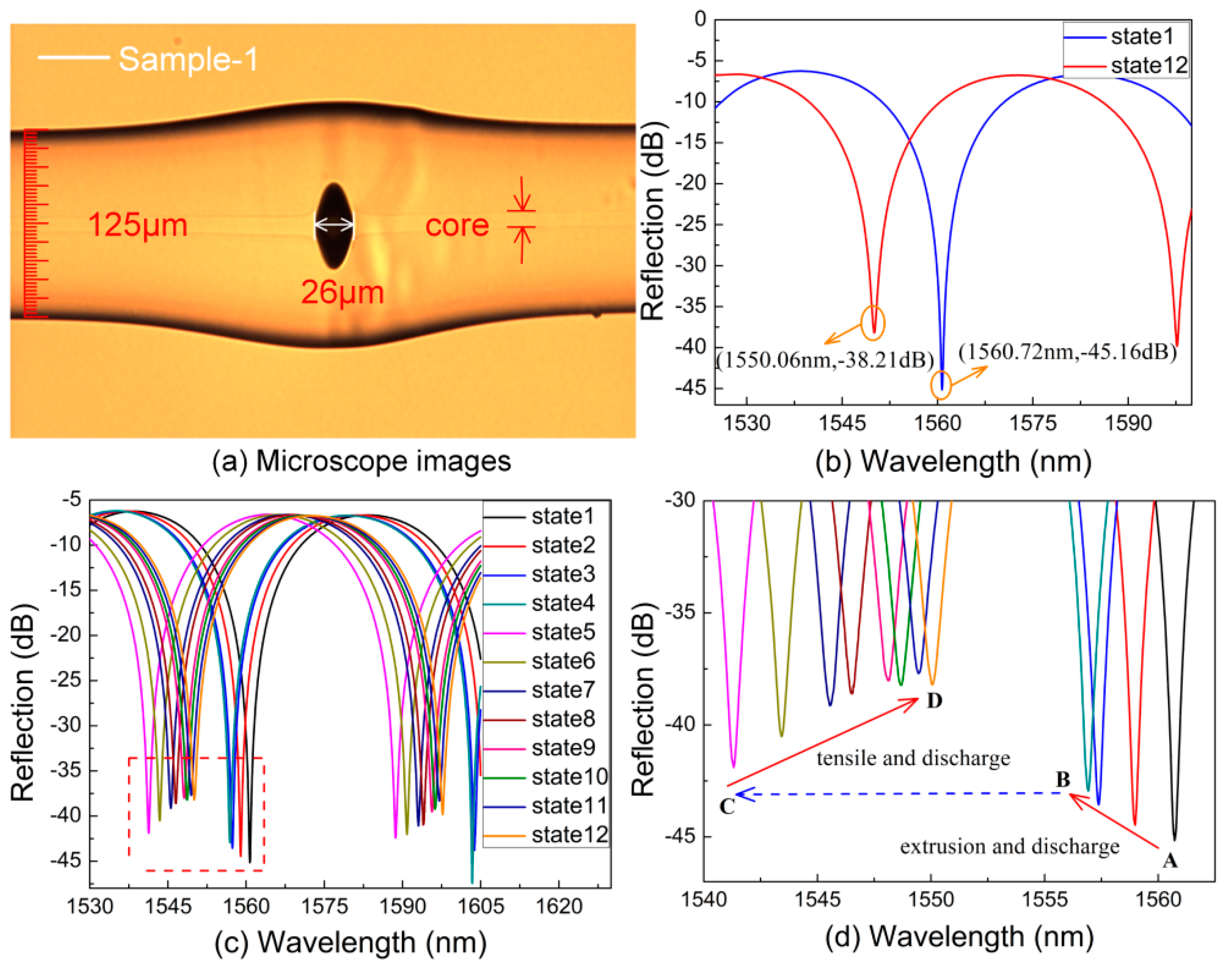

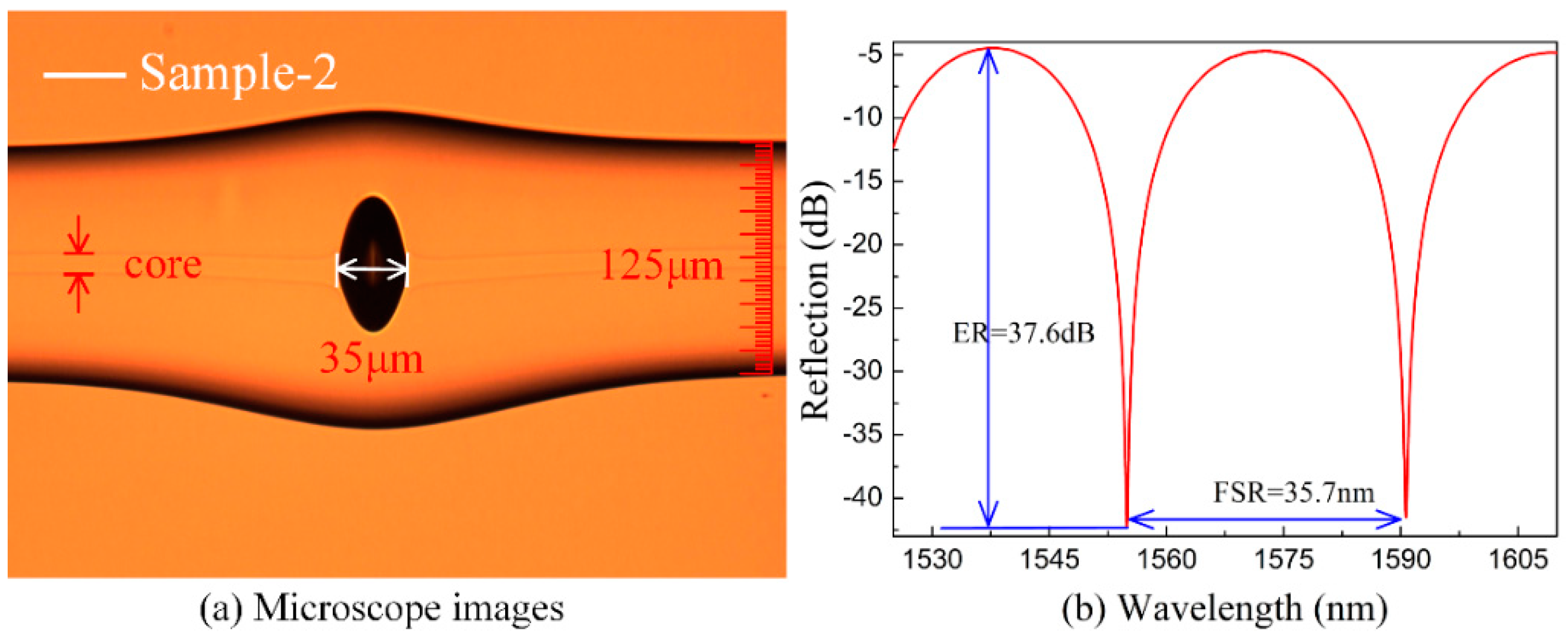

2. FPI Dip Wavelength Customization

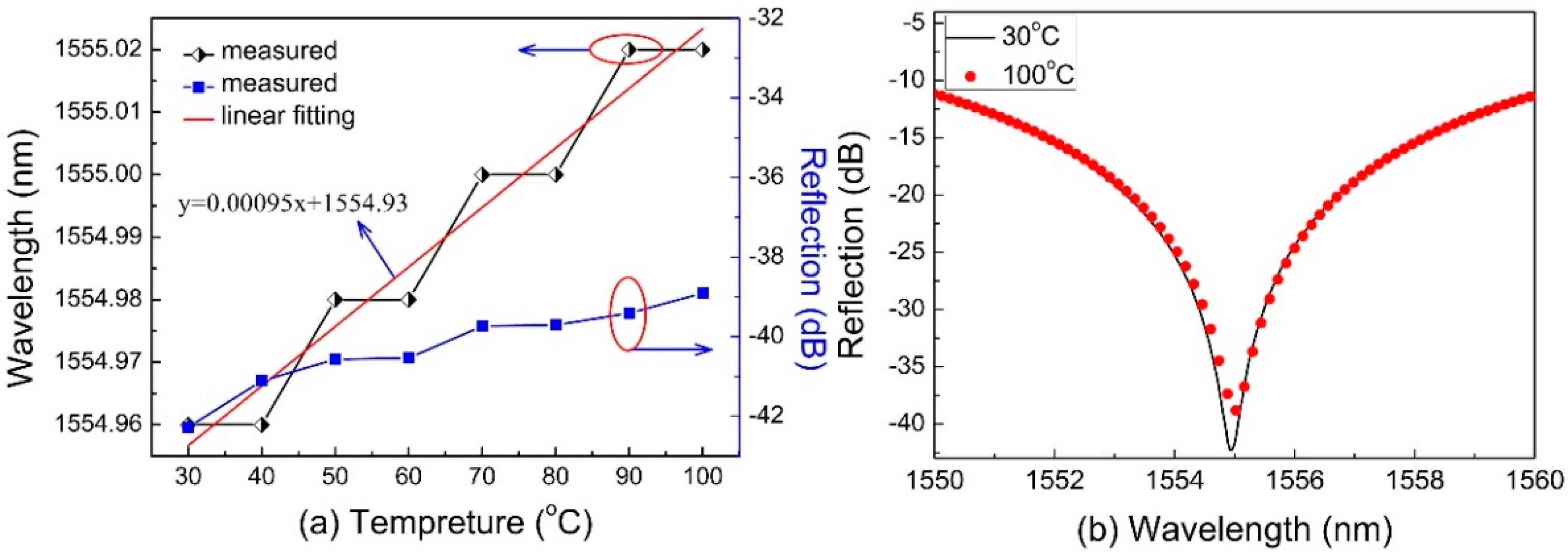

3. Strain Sensing and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yang, T.; Ran, Z.; He, X.; Li, Z.; Xie, Z.; Wang, Y.; Rao, Y.; Qiao, X.; He, Z.; He, P. Temperature-Compensated Multifunctional All-Fiber Sensors for Precise Strain/High-Pressure Measurement. J. Lightwave Technol. 2019, 37, 4634–4642. [Google Scholar] [CrossRef]

- Song, I.C.; Lee, S.K.; Jeong, S.H.; Lee, B.H. Absolute Strain Measurements Madewith Fiber Bragg Grating Sensors. Appl. Opt. 2004, 43, 1337–1341. [Google Scholar] [CrossRef] [PubMed]

- Rao, Y.; Ran, Z.; Liao, X.; Deng, H. Hybrid LPFG/MEFPI Sensor for Simultaneous Measurement of High-Temperature and Strain. Opt. Express 2007, 43, 14936–14941. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Zhang, Y.; Wu, J.; Yuan, P. Temperature-Insensitive Fiber Optic Fabry-Perot Interferometer Based on Special Air Cavity for Transverse Load and Strain Measurements. Opt. Express 2017, 25, 9443–9448. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Liao, C.; Wang, G.; Li, Z.; Wang, Q.; Zhou, J.; Yang, K.; Zhong, X.; Zhao, J. High-Sensitivity Strain Sensor Based on in-Fiber Improved Fabry-Perot Interferometer. Opt. Lett. 2014, 39, 2121–2124. [Google Scholar] [CrossRef]

- Liu, S.; Yang, K.; Wang, Y.; Qu, J.; Liao, C.; He, J.; Li, Z.; Yin, G.; Sun, B.; Zhou, J. High-Sensitivity Strain Sensor Based on in-Fiber Rectangular Air Bubble. Sci. Rep. 2015, 5, 7624. [Google Scholar] [CrossRef]

- Zhang, C.; Fu, S.; Tang, M.; Liu, D. Parallel Fabry-Perot Interferometers Fabricated on Multicore-Fiber for Temperature and Strain Discriminative Sensing. Opt. Express 2020, 28, 3190–3199. [Google Scholar] [CrossRef]

- Liao, C.; Wang, D.; Wang, Y. Microfiber in-Line Mach–Zehnder Interferometerfor Strain Sensing. Opt. Lett. 2013, 38, 757–7559. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, Z.; Shum, P.P.; Dinh, X.Q.; Low, C.W.; Xu, Z.; Wang, R.; Shao, X.; Fu, S.; Tong, W. Highly Sensitive Strain Sensor Based on Helical Structure Combined with Mach-Zehnder Interferometer in Multicore Fiber. Sci. Rep. 2017, 7, 46633. [Google Scholar] [CrossRef]

- Gan, L.; Wang, R.; Liu, D.; Duan, L.; Liu, S.; Fu, S.; Li, B.; Feng, Z.; Wei, H.; Tong, W. Spatial-Division Multiplexed Mach–Zehnder Interferometers in Heterogeneous Multicore Fiber for Multiparameter Measurement. IEEE Photonics J. 2016, 8, 1–8. [Google Scholar] [CrossRef]

- Zhou, A.; Qin, B.; Zhu, Z.; Zhang, Y.; Liu, Z.; Yang, J.; Yuan, L. Hybrid Structured Fiber-Optic Fabry-Perot Interferometer for Simultaneous Measurement of Strain and Temperature. Opt. Lett. 2014, 39, 5267–5270. [Google Scholar] [CrossRef] [PubMed]

- Kowal, D.; Urbanczyk, W.; Mergo, P. Twin-Core Fiber-Based Mach Zehnder Interferometer for Simultaneous Measurement of Strain and Temperature. Sensors 2018, 18, 915. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Peng, W.; Shao, L.; Pan, W.; Yan, L. Strain and Temperature Discrimination by Using Temperature-Independent Fpi and Fbg. Sens. Actuators A 2018, 272, 134–138. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Liao, C.; Wang, Y.; He, J.; Fu, C.; Yang, K.; Bai, Z.; Zhang, F. Nano Silica Diaphragm in-Fiber Cavity for Gas Pressure Measurement. Sci. Rep. 2017, 7, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Liao, C.; Liu, S.; Xu, L.; Wang, C.; Wang, Y.; Li, Z.; Wang, Q.; Wang, D.N. Sub-Micron Silica Diaphragm-Based Fiber-Tip Fabry-Perot Interferometer for Pressure Measurement. Opt. Lett. 2014, 39, 2827–2830. [Google Scholar] [CrossRef] [PubMed]

- Liao, C.; Xu, L.; Wang, C.; Wang, D.N.; Wang, Y.; Wang, Q.; Yang, K.; Li, Z.; Zhong, X.; Zhou, J. Tunable Phase-Shifted Fiber Bragg Grating Based on Femtosecond Laser Fabricated in-Grating Bubble. Opt. Lett. 2013, 38, 4473–4476. [Google Scholar] [CrossRef]

- Cibula, E.; Donlagic, D. In-Line Short Cavity Fabry-Perot Strain Sensor for Quasi Distributed Measurement Utilizing Standard OTDR. Opt. Express 2007, 15, 8719–8730. [Google Scholar] [CrossRef]

- Tian, J.; Jiao, Y.; Fu, Q.; Ji, S.; Li, Z.; Quan, M.; Yao, Y. A Fabry–Perot Interferometer Strain Sensor Based on Concave-Core Photonic Crystal Fiber. J. Lightwave Technol. 2018, 36, 1952–1958. [Google Scholar] [CrossRef]

- Deng, M.; Tang, C.; Zhu, T.; Rao, Y. Pcf-Based Fabry–Pérot Interferometric Sensor for Strain Measurement at High Temperatures. IEEE Photonics Technol. Lett. 2011, 23, 700–702. [Google Scholar] [CrossRef]

- Tang, Z.; Lou, S.; Wang, X.; Zhang, W.; Yan, S.; Xing, Z. Using Mode Coupling Mechanism in Symmetrical Triple-Core Photonic Crystal Fiber for High Performance Strain Sensing. IEEE J. Sel. Top. Quantum Electron. 2019, 26, 1–7. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, M.; Peng, Y. Tapered Hollow-Core Fiber Air-Microbubble Fabry-Perot Interferometer for High Sensitivity Strain Measurement. Adv. Mater. Interfaces 2018, 5, 1800886. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, D.N.; Wang, C.; Hu, T. Compressible Fiber Optic Micro-Fabry-Perot Cavity with Ultra-High Pressure Sensitivity. Opt. Express 2013, 21, 14084–14089. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Wei, T.; Zhou, Z.; Zhang, Y.; Chen, G.; Xiao, H. An Extrinsic Fabry–Perot Interferometer-Based Large Strain Sensor with High Resolution. Meas. Sci. Technol. 2010, 21, 105308. [Google Scholar] [CrossRef]

- Villatoro, J.; Arrizabalaga, O.; Durana, G.; Saez de Ocariz, I.; Antonio-Lopez, E.; Zubia, J.; Schulzgen, A.; Amezcua-Correa, R. Accurate Strain Sensing Based on Super-Mode Interference in Strongly Coupled Multi-Core Optical Fibres. Sci. Rep. 2017, 7, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Liu, S.; Zhao, Y.; Chen, Y.; Yang, K.; Guo, K.; He, J.; Liao, C.; Wang, Y. A phase-shifted FBG modulated by a hollow cavity for measuring gas pressure. Opt. Lett. 2019, 45, 507–510. [Google Scholar] [CrossRef]

- Villatoro, J.; Finazzi, V.; Coviello, G.; Pruneri, V. Photonic-crystal-fiber-enabled micro-FabryPerot interferometer. Opt. Lett. 2009, 34, 2441–2443. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Luo, J.; Liu, S.; Zou, M.; Lu, S.; Yang, Y.; Liao, C.; Wang, Y. A High-Strength Strain Sensor Based on a Reshaped Micro-Air-Cavity. Sensors 2020, 20, 4530. https://doi.org/10.3390/s20164530

Chen Y, Luo J, Liu S, Zou M, Lu S, Yang Y, Liao C, Wang Y. A High-Strength Strain Sensor Based on a Reshaped Micro-Air-Cavity. Sensors. 2020; 20(16):4530. https://doi.org/10.3390/s20164530

Chicago/Turabian StyleChen, Yanping, Junxian Luo, Shen Liu, Mengqiang Zou, Shengzhen Lu, Yong Yang, Changrui Liao, and Yiping Wang. 2020. "A High-Strength Strain Sensor Based on a Reshaped Micro-Air-Cavity" Sensors 20, no. 16: 4530. https://doi.org/10.3390/s20164530

APA StyleChen, Y., Luo, J., Liu, S., Zou, M., Lu, S., Yang, Y., Liao, C., & Wang, Y. (2020). A High-Strength Strain Sensor Based on a Reshaped Micro-Air-Cavity. Sensors, 20(16), 4530. https://doi.org/10.3390/s20164530