Measurement of the Geometric Center of a Turnout for the Safety of Railway Infrastructure Using MMS and Total Station

Abstract

1. Introduction

- Single point (single turnout, point);

- Slip turnout;

- Curved slip (Y-points);

- Three-way turnout.

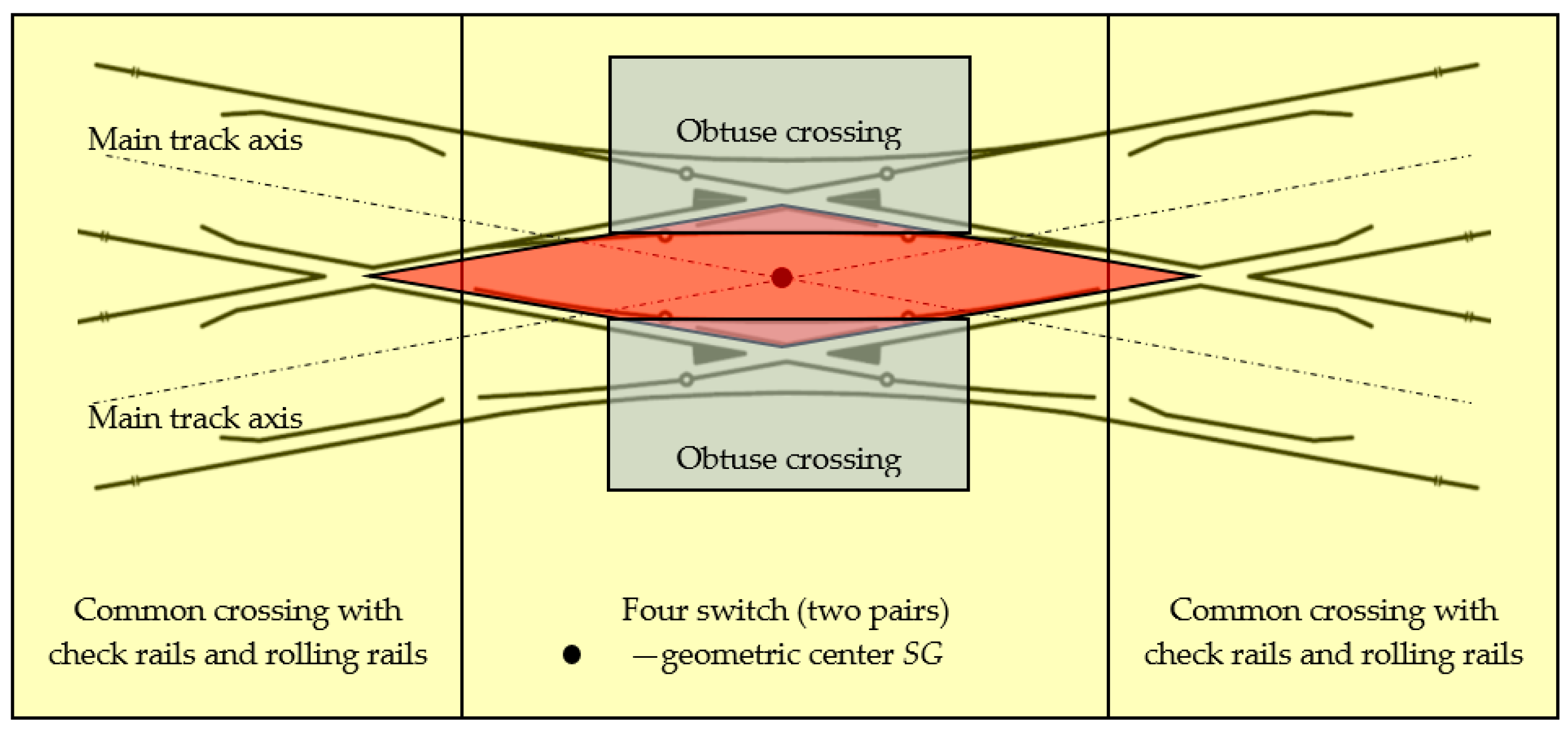

- Four switches (two pairs);

- Two obtuse crossings; and,

- Two common crossings (single crossing) with check rails and rolling rails.

- 205 m at a tangent of crossing angle of 1:9 and an S42 turnout type; and,

- 190 m at a tangent of crossing angle of 1:9 and 49E1 and 60E1 turnout types.

- The position of the point condition geometric center SG of the double slip turnout.

- The geometric condition of the curves of circular diverted tracks by measuring the horizontal versines.

- The geometric irregularity condition of turnouts.

2. Related Work

- Having a decisive influence on the operational parameters of railway lines;

- Having a significant impact on the construction costs of new lines; and,

- Being marked by a low susceptibility to change.

3. Methodology

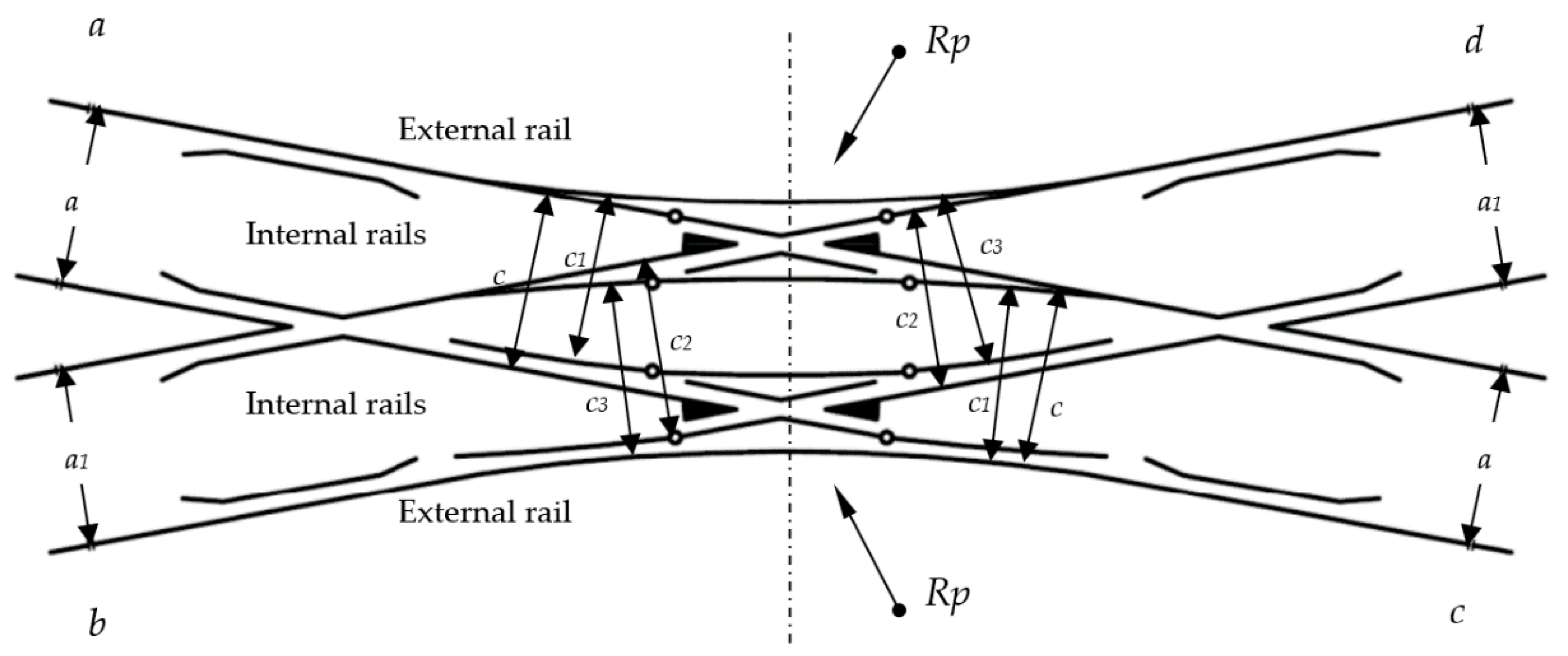

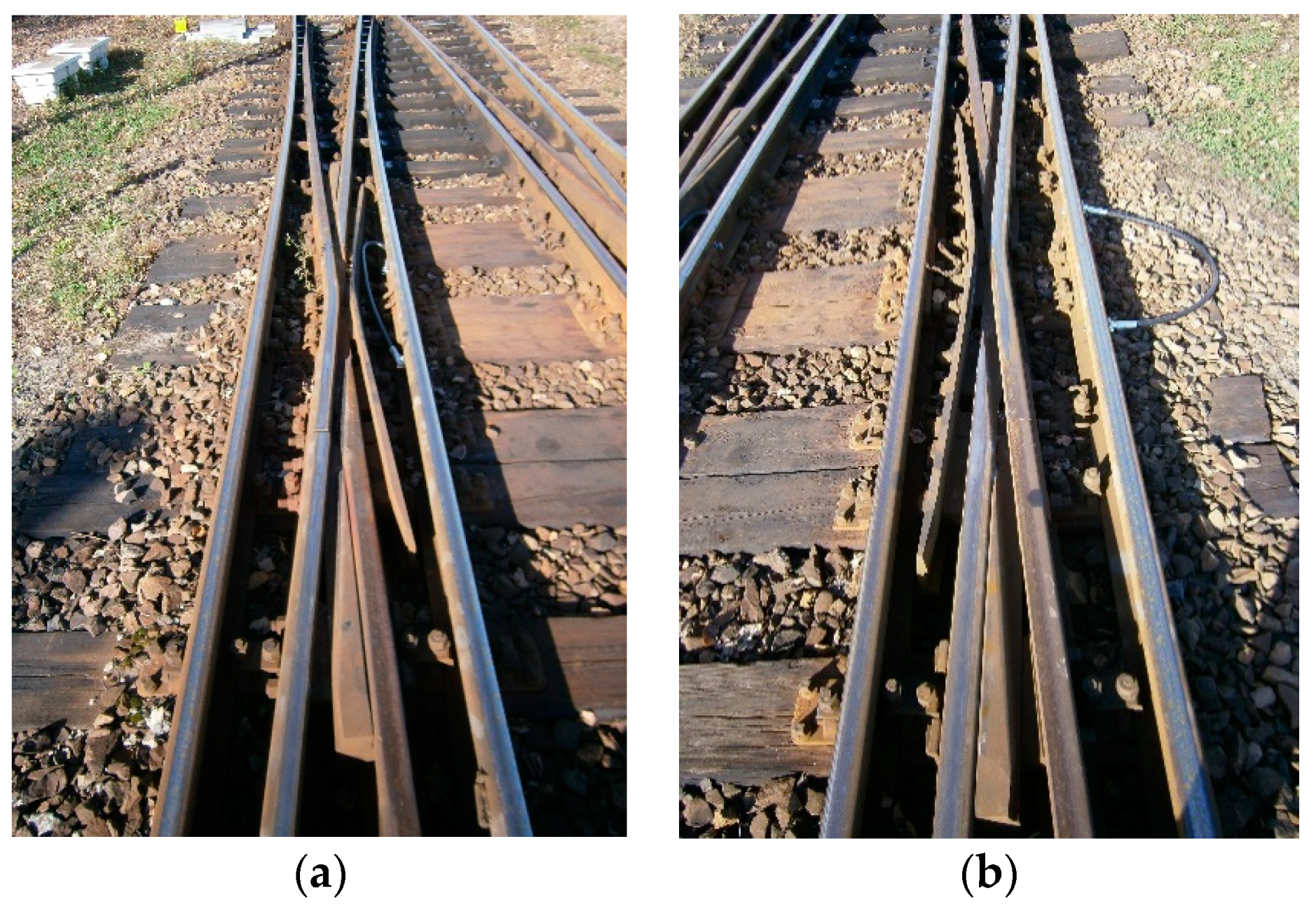

3.1. Surveying the Geometric Center Double Slip Turnout—Rkpdiwew—With Blades Inside the Quadrilateral

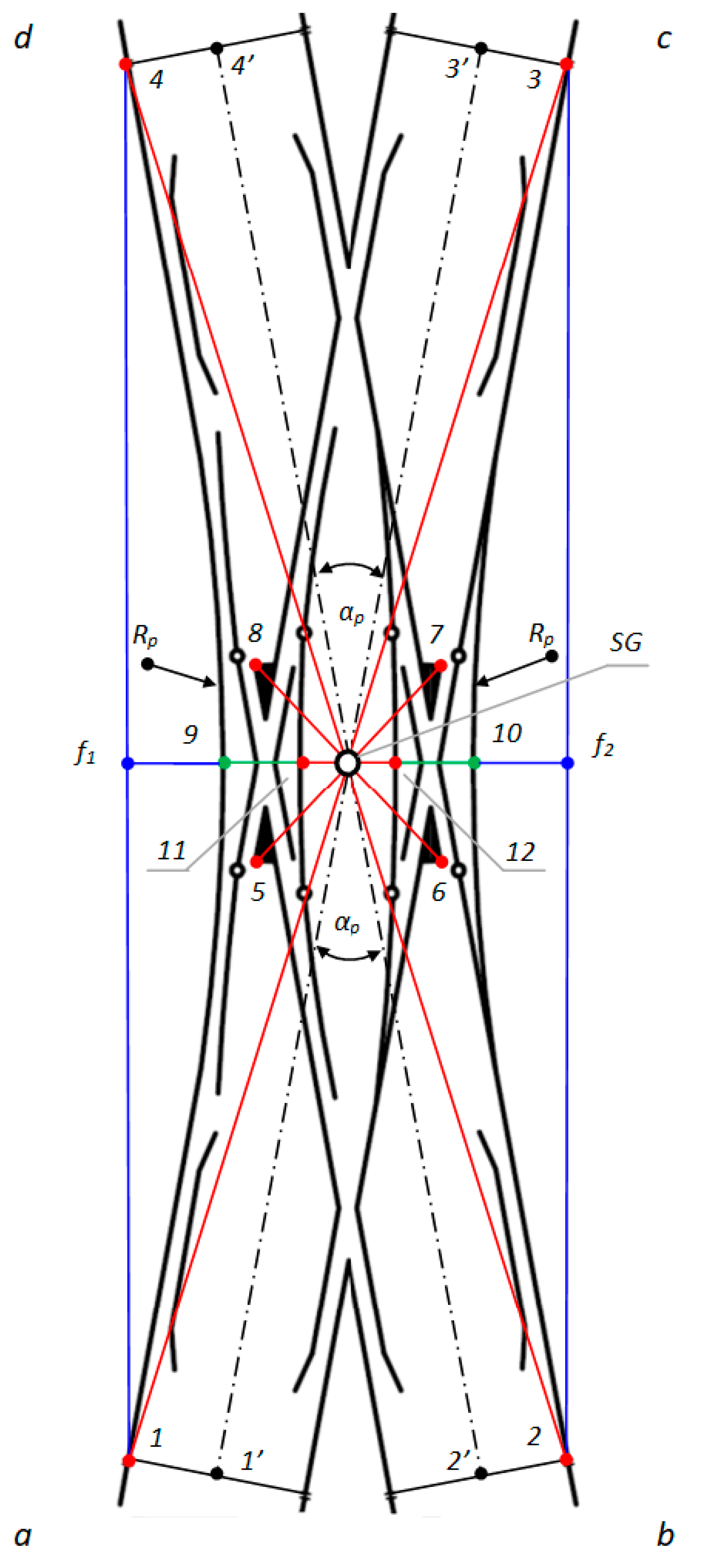

- SG = the geometric center of Rkpdiwew;

- 1, 2, 3, 4 = endpoints of Rkpdiwew (from sides “a”, “b”, “c”, and “d”, respectively);

- 5, 6, 7, 8 = the external endpoints of the obtuse crossing of Rkpdiwew;

- 9, 10 = the points of contact connecting the stock rail in a straight line, defining the geometric center of Rkpdiwew;

- 11, 12 = the points of contact connecting the blades on the fixed plates in a straight line, determining the geometric center of Rkpdiwew;

- 1′, 2′, 3′, 4′ = endpoints of Rkpdiwew on the axis of the main track (from sides “a”, “b”, “c”, and “d”, respectively);

- f1 = measuring the versine on chords 1–4;

- f2 = measuring the versine on chords 2 and 3;

- αp = main turnout angle—project (between the main track axles); and,

- Rp = project radius.

- The external endpoints of the obtuse crossings of Rkpdiwew;

- The points of contact connecting the stock rail in a straight line, defining the geometric center of Rkpdiwew;

- The points of contact connecting the blades on the fixed plates in a straight line, determining the geometric center of Rkpdiwew; and,

- The endpoints of Rkpdiwew.

- External points of Obtuse Crossings 5–8 and the following:

- The points of contact—No. 9 and 10—connecting the stock rail in a straight line, defining the geometric center of Rkpdiwew; and,

- The points of contact—No. 11 and 12—connecting the blades on the fixed plates in a straight line, determining the geometric center of Rkpdiwew;

- Turnout Endpoints 1–4.

- Zipper closures—locking points in the turnout railway;

- Blade resilience;

- Electrical adjustability;

- Crossings with a forge-welded nose;

- Railway fish plate variety;

- No electric heaters;

- Wooden switch sleepers; and,

- Ballast—natural broken stone.

- The points of intersection (cuts) using the measuring lines (cord measuring) as diagonals. However, the components of the steel sections as a turnout structure run at different heights, thereby causing the measuring line to cut incorrectly on the horizontal plane (e.g., rails and check rails). In addition, weather conditions influence the measurement results (wind) and string that is too long can cause sagging and suspension from the turnout’s structural elements. The manoeuvring of the measuring line on a specific turnout reflects the accuracy and safety of the work (the measuring line can fall and hook between the blade or stock rail). This makes it impossible to quickly remove this line from the exploited turnout;

- The point of intersection of straight lines using ranging poles (survey poles) located at the axis of the turnout endpoints and delimiting the points of intersection acting as the designated centers of the turnout. This method required setting a minimum of five surveying poles directly at the Rkpd, which is a reference for the accuracy of the point to be determined. In the situation of an incoming train, the surveying poles had to be removed quickly, and after the train had left, the measurement process had to be repeated;

- Using a traditional surveying prism or a mini-prism with a survey pole and the surveying pole tip as a standard surveying solution and applying both to the steel elements of the turnout structure for which traditional survey poles and surveying pole tips do not provide correct point of destination signaling. The traditional solutions used so far resulted in signalling errors depending on the non-verticality of the survey pole and the surveying pole tips with the surveying prism; not locating the prism at a height of 14 mm below the top rolling surface of the rail head (crown of the rail) induced a signalling error for the destination point on the steel turnout sections; and,

- Measurements of the main length elements via surveying tape. The operation of the developed length of the surveying tape with a minimum length of 33.230 m (turnout length) reflected the measurement accuracy and safety of the works.

- The external endpoints of the obtuse crossing (which have not yet been defined);

- Extra points such as the points of contact connecting the stock rail and the points of contact connecting the blades; and,

- The turnout endpoints.

- The location of an electronic total station in the coordinate system. The measurements were carried out using a single setup (station, location) in the so-called local coordinate system defined by the instrument, thereby ensuring a common coordinate system and the uniform accuracy of measurements for the whole turnout. The measuring station’s (measuring setup) electronic total station was located in the middle of the total length of the double slip turnout outside the infrastructure gauge (structure gauge) in the intertrack space. Because the measurements carried out in the coordinate system were defined by the instrument itself and not by the state coordinate system, the effect of the electronic total station’s location was delimited;

- State of instrumental errors. Errors were eliminated by calibrating the instrument and using the measurement methods;

- The influence of atmospheric conditions, which were limited by the application of so-called atmospheric corrections (e.g., air temperature and pressure during the measurements);

- Signalling the measuring point at the turnout. The turnout is characterized by a large number of steel elements with characteristic profile shapes. As a result of the integration of the geodetic mini prism with the MMS (equipped with neodymium magnets), the turnout was stabilized directly above the measuring points, followed by the verticality and correct signalling of points at a height of 14 mm below the top of the rolling rail head or the lower edge of the steel elements of the turnout (e.g., wedges on the obtuse crossing) together with the provision of an aiming direction (pointing line, sight line). The height of the Leica GMP111 geodetic mini prism integrated into the MMS was 10 cm; and,

- The accuracy of the distance and angle measurement is a characteristic feature of a stationary electronic total station, as defined by ISO 17123: accuracy standard deviation Hsd—horizontal direction, Vsd—vertical angle/zenith angle (acc. to ISO 17123-3) is 7″ (20cc); electronic Distance Measurement—EDM measuring program IR_Dokł/IR_Fine (standard deviation acc. to ISO 17123-4) is 2 mm + 2 ppm [78].

3.2. Surveying the Geometric Center Outside the Slip Turnout—Rkpdizew—With Blades Outside the Quadrilateral

- The external endpoints of the obtuse crossings of Rkpdizew;

- The points of contact connecting the stock rail in a straight line, thereby defining the geometric center of Rkpdizew; and,

- The endpoints of Rkpdizew.

- SG = geometric center of Rkpdizew;

- 1, 2, 3, 4 = endpoints of Rkpdizew (from the sides “a”, “b”, “c”, and “d”, respectively);

- 5, 6, 7, 8 = external endpoints of the obtuse crossing of Rkpdizew;

- 9, 10 = the points of contact connecting the stock rail in a straight line, thereby defining the geometric center of Rkpdizew;

- 1′, 2′, 3′, 4′ = endpoints of Rkpdizew in the axis of the main track (from the sides “a”, “b”, “c”, and “d”, respectively);

- f1 = measuring the versine on chords 1–4;

- f2 = measuring the versine on chords 2 and 3;

- αp = main turnout angle—project (between the main track axles); and,

- Rp = project radius.

- The external points of Obtuse Crossings 5–8 and the points of contact connecting the stock rail in a straight line (No. 9 and 10), defining the geometric center of Rkpdizew; and,

- The turnout Endpoints 1–4.

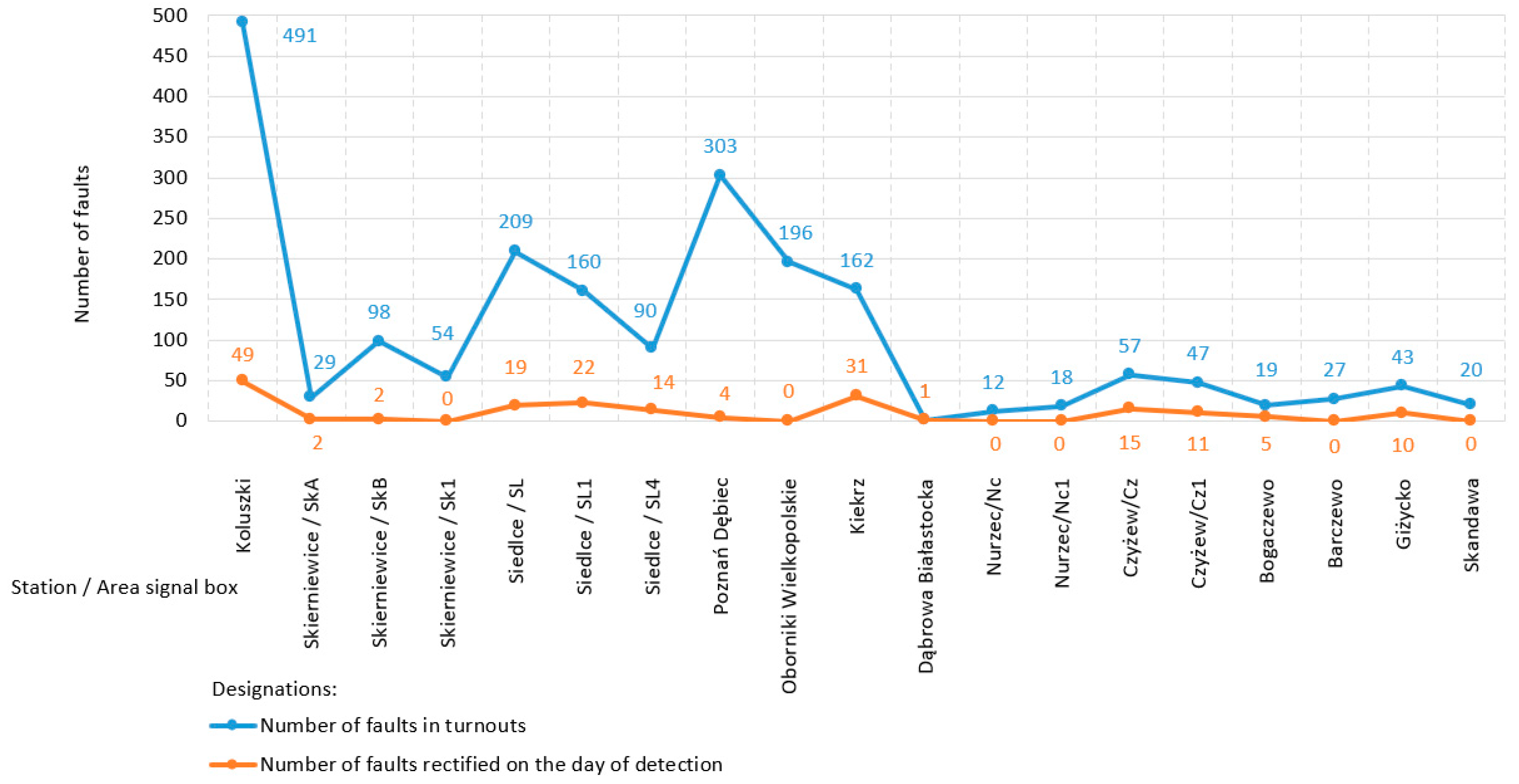

4. Results and Discussion

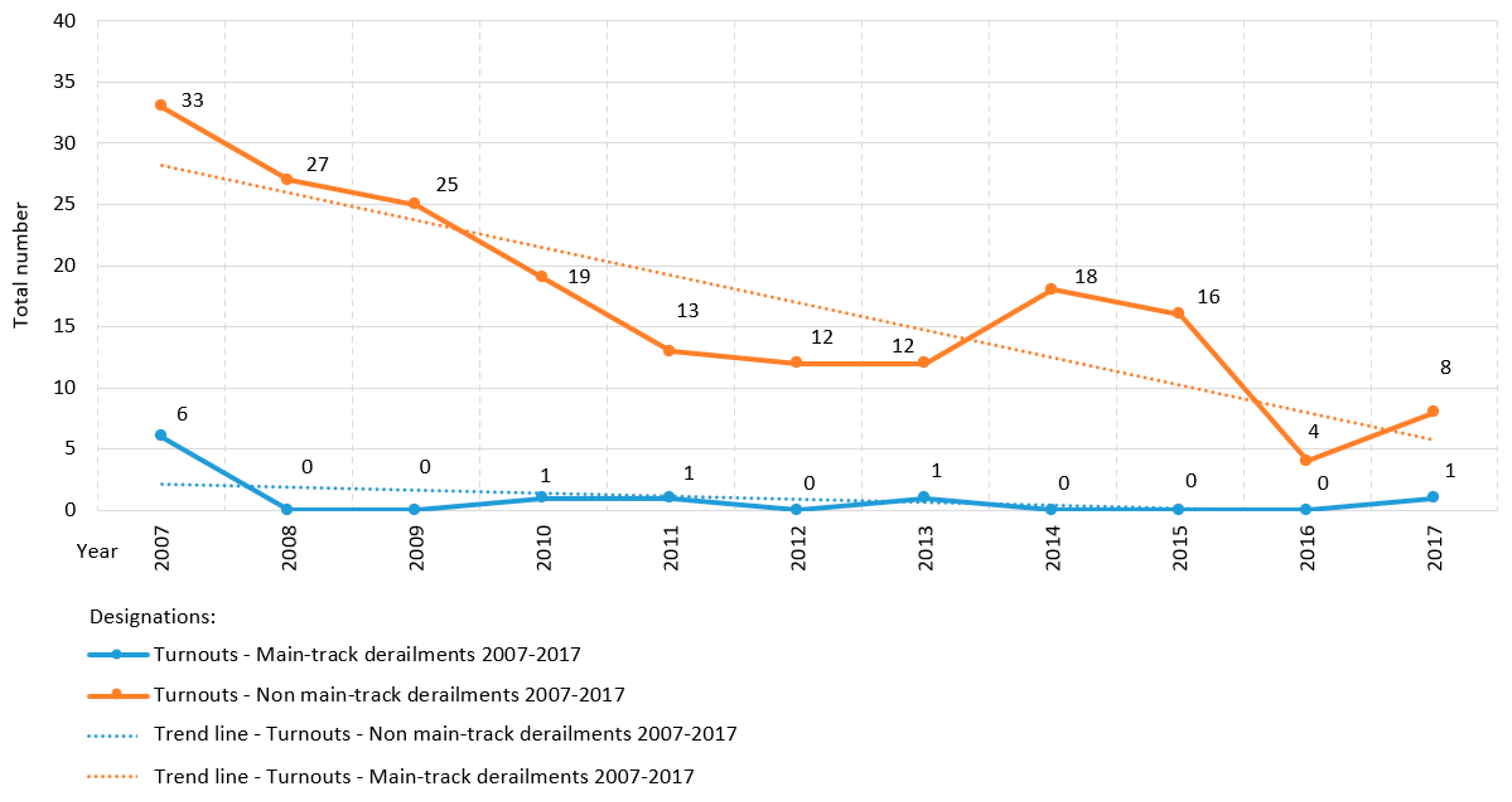

4.1. Structure of the Number of Derailments and Safety Status

- collisions;

- derailments;

- accidents at level crossings and pedestrian crossings;

- accidents including persons outside level crossings and pedestrian crossings (excluding suicides);

- rolling stock fires; and,

- other accidents.

- Main-track derailments; and,

- Non main-track derailments.

4.2. Case study and Field Measurements

- a track gauge and cant–turnout pre-blade contact for turnout side “a” and “c”;

- a1 track gauge and cant–turnout pre-blade contact for turnout side “b” and “d”;

- c track gauge and cant of the switch (on the first fixed plate) of the internal rails—the “a” and “c” sides of the turnout on the main track;

- c1 track gauge and cant of the switch (on the first fixed plate) of the external rails—the “a” and “c” sides of the turnout on the diverted track;

- c2 track gauge and cant of the switch (on the first fixed plate) of the internal rails—the “b” and “d” sides of the switch on the main track;

- c3 track gauge and cant of the switch (on the first fixed plate) of the external rails—the “b” and “d” sides of the switch on the diverted track;

- a, b, c, d turnout sides; and,

- Rp project radius.

- a Track gauge and cant–turnout pre-blade contact on turnout side “a” and “c”; and,

- a1 Track gauge and cant–turnout pre-blade contact on turnout side “b” and “d”.

- c The track gauge and cant for the switch (on the first fixed plate) of the internal rails—the “a” and “c” sides of the turnout on the main track;

- c1 the track gauge and cant for the switch (on the first fixed plate) of the external rails—the “a” and “c” sides of the turnout on the diverted track;

- c2 the track gauge and cant for the switch (on the first fixed plate) of the internal rails—the “b” and “d” sides of the switch on the main track; and,

- c3 the track gauge and cant for the switch (on the first fixed plate) of the external rails—the “b” and “d” sides of the switch on the diverted track.

- The incorrect shape of the curvature of the turnout-diverted track and a change in its radius (these anomalies are reflected in the rate of wear of the turnout structural elements, especially the rails, changes in the state of the track gauge, and the cant parameters of the turnout track, switch sleeper wear, and peace-of-mind of driving);

- Incorrect maintenance of the track gauge and cant values, especially within a switch, with special attention given to the diverted tracks for running on a curve;

- The incorrect determination of the exploitation speed on the diverted and main tracks;

- The impact of centrifugal forces;

- The deregulation of spacing track axis values (including the intertrack space);

- The condition of the blades;

- An inadequately compacted ballast underneath the switch sleepers;

- The lack of straightness of the main tracks, under-tightened screws, and a bad state of fixings;

- The wear of the nose or wing rails and obtuse crossings;

- Irregularities in the track rails on the vertical and horizontal planes;

- Incorrectly conducted repair work during current maintenance, e.g., improving the track gauge parameters and replacing the switch sleepers;

- Incorrect assessment of the position of the geometric center of the turnout;

- Incorrect surveying of the turnout’s location;

- Incorrectly assembled turnout; and,

- The creep (rail movement) of rails before and after the turnout.

5. Conclusions

6. Patents

Funding

Acknowledgments

Conflicts of Interest

References

- Law on Rail Transport of 28 March 2003. Available online: http://prawo.sejm.gov.pl/isap.nsf/download.xsp/WDU20190000710/U/D20190710Lj.pdf (accessed on 8 March 2020).

- Kampczyk, A. Technische Spezifikationen für die Interoperabilität und die polnischen Vorschriften in der Projektierung von der Geometrie der Eisenbahnstrecken. Bauingenieur 2015, 90, 229–234. [Google Scholar]

- Korab, D. Nowe rozwiązania konstrukcyjne rozjazdu krzyżowego podwójnego na podrozjazdnicach strunobetonowych. Przegląd Komun. 2016, 5, 4–8. [Google Scholar]

- Paś, J.; Dyduch, J. Metody pomiaru sił przestawiania ruchomych części rozjazdów dużych prędkości. Logistyka 2015, 3, 3758–3766. [Google Scholar]

- Márquez, F.P.G.; Lewis, R.W.; Tobias, A.M.; Roberts, C. Life Cycle Costs for Railway Condition Monitoring. Transp. Res. Part E Logist. Transp. Rev. 2008, 44, 1175–1187. [Google Scholar] [CrossRef]

- Hegedűs, C.; Ciancarini, P.; Frankó, A.; Kancilija, A.; Moldován, I.; Papa, G.; Poklukar, Š.; Riccardi, M.; Sillitti, A.; Varga, P. Proactive Maintenance of Railway Switches. In Proceedings of the 2018 5th International Conference on Control, Decision and Information Technologies (CoDIT), Thessaloniki, Greece, 10–13 April 2018; pp. 725–730. [Google Scholar] [CrossRef]

- Aniołek, K.; Herian, J. Obciążenie i zużycie rozjazdów kolejowych w warunkach eksploatacyjnych oraz materiały stosowane do ich budowy. TTS Tech. Transp. Szyn. 2013, 20, 85–89, 96. [Google Scholar]

- Bałuch, H.; Bałuch, M. Eksploatacyjne Metody Zwiększenia Trwałości Rozjazdów Kolejowych; Wydawnictwo Centrum Naukowo-Techniczne Kolejnictwa: Warszawa, Poland, 2009. [Google Scholar]

- Rosiński, P.; Michowski, P. Linia CMK a tunel Gottharda na przykładzie techniki rozjazdowej. TTS Tech. Transp. Szyn. 2011, 10, 37–40. [Google Scholar]

- Jönsson, J.; Khouy, I.A.; Lundberg, J.; Rantatalo, M.; Nissen, A. Measurement of vertical geometry variations in railway turnouts exposed to different operating conditions. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2014, 230, 486–501. [Google Scholar] [CrossRef]

- Sae Siew, J.; Mirza, O.; Kaewunruen, S. Torsional effect on track-support structures of railway turnouts crossing impact. J. Transp. Eng. Part A Syst. 2017, 143, 06016001. [Google Scholar] [CrossRef]

- Khouy, I.A.; Larsson-Kråik, P.O.; Nissen, A.; Lundberg, J.; Kumar, U. Geometrical degradation of railway turnouts: A case study from a Swedish heavy haul railroad. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2013, 228, 611–619. [Google Scholar] [CrossRef]

- Xu, J.; Wang, P.; Wang, L.; Chen, R. Effects of profile wear on wheel-rail contact conditions and dynamic interaction of vehicle and turnout. Adv. Mech. Eng. 2016, 8, 1–14. [Google Scholar] [CrossRef]

- Pletz, M.; Daves, W.; Ossberger, H. A wheel passing a crossing nose: Dynamic analysis under high axle loads using finite element modelling. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2012, 226, 603–611. [Google Scholar] [CrossRef]

- Ahlbeck, D.R. A study of dynamic impact load effects due to railroad wheel profile roughness. Veh. Syst. Dyn. Int. J. Veh. Mech. Mobil. 2007, 17 (Suppl. 1), 13–16. [Google Scholar] [CrossRef]

- Pletz, M.; Daves, W.; Ossberger, H. A wheel set/crossing model regarding impact, sliding and deformation-Explicit finite element approach. Wear 2012, 294–295, 446–456. [Google Scholar] [CrossRef]

- Pålsson, B.A.; Nielsen, J.C.O. Wheel–Rail interaction and damage in switches and crossings. J. Veh. Syst. Dyn. Int. J. Veh. Mech. Mobil. 2011, 50, 43–58. [Google Scholar] [CrossRef]

- Johansson, A.; Pålsson, B.; Ekh, M.; Nielsen, J.C.O.; Ander, M.K.A.; Brouzoulis, J.; Kassa, E. Simulation of wheel–rail contact and damage in switches & crossings. Wear 2011, 271, 472–481. [Google Scholar] [CrossRef]

- Wan, C.; Markine, V.L.; Shevtsov, I.Y.; Dollevoet, R.P. Improvement of Train-Track Interaction in Turnouts by Optimising the Shape of Crossing Nose. In Proceedings of the IAVSD 2013 23rd International Symposium on Dynamics of Vehicles on Roads and Tracks, Qingdao, China, 19–23 August 2013. [Google Scholar]

- Markine, V.L.; Steenbergen, M.J.; Shevtsov, I.Y. Combatting RCF on switch points by tuning elastic track properties. Wear 2011, 271, 158–167. [Google Scholar] [CrossRef]

- Andersson, C.; Dahlberg, T. Wheel/rail impacts at a railway turnout crossing. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 1998, 212, 123–134. [Google Scholar] [CrossRef]

- Rama, D.; Andrews, J.D. A reliability analysis of railway switches. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2013, 227, 344–363. [Google Scholar] [CrossRef]

- Instruction for Visual Inspection, Technical Examination and Maintenance of Turnouts Id-4. 2015. Available online: https://www.plk-sa.pl/files/public/user_upload/pdf/Akty_prawne_i_przepisy/Instrukcje/Podglad/Id-4_.pdf (accessed on 16 February 2020).

- Instruction for Measuring, Researching and Assessing Track Condition Id-14 (D-75). 2010. Available online: https://www.plk-sa.pl/files/public/user_upload/pdf/Akty_prawne_i_przepisy/Instrukcje/Podglad/Id-14.pdf (accessed on 12 March 2020).

- Technical Conditions for Maintaining Track Surface on Railway Lines Id-1 (D-1). Warsaw. 2015. Available online: https://www.plk-sa.pl/files/public/user_upload/pdf/Akty_prawne_i_przepisy/Instrukcje/Wydruk/Warunki_techniczne_Id-1_ujednolic.pdf (accessed on 20 April 2020).

- Regulation of the Minister of Transport and Maritime Economy of 10 September 1998 on Technical Conditions to Be Met by Railway Structures and Their Location. Available online: http://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU19981510987 (accessed on 23 July 2020).

- Technical Standard “About Organization and Execution of Measurements in Railway Surveying” GK-1, Warsaw. 2015. Available online: https://www.pkp.pl/images/geodezja/dokumenty/Standard%20techniczny%20%E2%80%9EO%20organizacji%20i%20wykonywaniu%20pomiar%C3%B3w%20w%20geodezji%20kolejowej%E2%80%9D%20GK-1.pdf (accessed on 21 July 2020).

- En 13232 Railway Applications-Track-Switches and Crossings. Available online: https://www.pkn.pl/en (accessed on 24 May 2020).

- Grulkowski, S.; Kędra, Z.; Koc, W.; Nowakowski, M.J. Drogi Szynowe; Wydawnictwo Politechniki Gdańskiej: Gdańsk, Poland, 2013. [Google Scholar]

- Łączyński, J. Rozjazdy Kolejowe; Wydawnictwo Komunikacyjne: Warszawa, Poland, 1958. [Google Scholar]

- Lichtberger, B. Handbuch Gleis; DVV Media Group GmbH Eurailpress: Hamburg, Germany, 2010. [Google Scholar]

- Marx, L.; Moβmann, D.; Kullmann, H. Arbeitsverfahren für die Instandhaltung des Oberbaus; Eisenbahn-Fachverlag: Heidelberg, Germany, 2003. [Google Scholar]

- Kampczyk, A. Punkty charakterystyczne rozjazdów i skrzyżowań kolejowych. TTS Tech. Transp. Szyn. 2013, 20, 33–40. [Google Scholar]

- Kampczyk, A. Pomiar strzałek montażowych toru zwrotnego w rozjeździe. Przegląd Geod. 2017, 89, 4–9. [Google Scholar] [CrossRef]

- Kampczyk, A. Pomiar strzałek w torze zwrotnym rozjazdu przykładnicą magnetyczno-pomiarową. Czas. Inżynierii Lądowej Środowiska Archit. 2017, 34, 91–105. [Google Scholar] [CrossRef]

- Kampczyk, A. Przykładnica magnetyczno-pomiarowa w pomiarach strzałek eksploatacyjnych rozjazdu zwyczajnego. Czas. Inżynierii Lądowej Środowiska Archit. 2017, 34, 439–452. [Google Scholar] [CrossRef]

- Kampczyk, A. Magnetic-Measuring Square in the Measurement of the Circular Curve of Rail Transport Tracks. Sensors 2020, 20, 560. [Google Scholar] [CrossRef] [PubMed]

- Kampczyk, A. Digital Track Gauge. Utility Model PL 067852 Y1, 25 February 2013. [Google Scholar]

- Kampczyk, A. Magnetic-Measuring Parallel Motion Protractor and Its Application. Patent PL 235051 B1, 16 January 2017. [Google Scholar]

- Bemment, S.D.; Ebinger, E.; Goodall, R.M.; Ward, C.P.; Dixon, R. Rethinking rail track switches for fault tolerance and enhanced performance. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2017, 231, 1048–1065. [Google Scholar] [CrossRef]

- Harrison, T.; Bemment, S.D.; Ebinger, E.; Goodall, R.M.; Ward, C.P.; Dixon, R. Rethinking rail track switches for fault tolerance and enhanced performance. IFAC-PapersOnLine 2016, 49, 260–266. [Google Scholar] [CrossRef][Green Version]

- Abril, M.; Salido, M.A.; Barber, F.; Ingolotti, L.P.; Lova, A.L.; Tormos, M.P. A Heuristic Technique for the Capacity Assessment of Periodic Trains. In Proceedings of the 8th International Conference of the ACIA, CCIA 2005, Alguer, Italy, 26–28 October 2005. [Google Scholar]

- Ingolotti, L.P.; Lova, A.L.; Barber, F.; Tormos, M.P.; Salido, M.A.; Abril, M. New heuristics to solve the “CSOP” railway timetabling problem. In Proceedings of the 19th International Conference on Industrial, Engineering and Other Applications of Applied Intelligent Systems, IEA/AIE 2006, Annecy, France, 27–30 June 2006; pp. 400–409. [Google Scholar] [CrossRef]

- Abril, M.; Barber, F.; Ingolotti, L.P.; Salido, M.A.; Tormos, P.; Lova, A. An assessment of railway capacity. Transp. Res. Part E Logist. Transp. Rev. 2008, 44, 774–806. [Google Scholar] [CrossRef]

- Bemment, S.; Dixon, R.; Goodall, R.; Brown, S. Redundantly engineered track switching for enhanced railway nodal capacity. IFAC Proc. 2013, 46, 25–30. [Google Scholar] [CrossRef]

- Bemment, S.D.; Goodall, R.M.; Dixon, R.; Ward, C.P. Improving the reliability and availability of railway track switching by analysing historical failure data and introducing functionally redundant subsystems. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2017, 232, 1407–1424. [Google Scholar] [CrossRef]

- Kisilowski, J.; Kowalik, R. The vision system for diagnostics of railway turnout elements. In Proceedings of the 18th International Conference on Transport System Telematics (TST 2018), Krakow, Poland, 20–23 March 2018; pp. 221–233. [Google Scholar] [CrossRef]

- Hamarat, M.; Kaewunruen, S.; Papaelias, M.; Silvast, M. New Insights from Multibody Dynamic Analyses of a Turnout System under Impact Loads. Appl. Sci. 2019, 9, 4080. [Google Scholar] [CrossRef]

- Hamadache, M.; Dutta, S.; Olaby, O.; Ambur, R.; Stewart, E.; Dixon, R. On the Fault Detection and Diagnosis of Railway Switch and Crossing Systems: An Overview. Appl. Sci. 2019, 9, 5129. [Google Scholar] [CrossRef]

- Malekjafarian, A.; OBrien, E.; Quirke, P.; Bowe, C. Railway Track Monitoring Using Train Measurements: An Experimental Case Study. Appl. Sci. 2019, 9, 4859. [Google Scholar] [CrossRef]

- Mańka, A. Analiza Ryzyka w Transporcie Szynowym—Metoda FMEA i Dobre Praktyki jej Stosowania. Logistyka. 2014. Available online: https://www.czasopismologistyka.pl/artykuly-naukowe/send/318-artykuly-na-plycie-cd-3/6724-artykul (accessed on 16 February 2020).

- Salvador, P.; Naranjo, V.; Insa, R.; Teixeira, P. Axlebox accelerations: Their acquisition and time–frequency characterisation for railway track monitoring purposes. Measurement 2016, 82, 301–312. [Google Scholar] [CrossRef]

- Gamon, W.; Gómez, J.M.N. Main Problems of Railway Cross-Border Transport Between Poland, Germany and Czech Republic. Sustainability 2019, 11, 4900. [Google Scholar] [CrossRef]

- Bałuch, H.; Bałuch, M. Kształtowanie układów geometrycznych toru z uwzględnieniem trwałości nawierzchni. TTS Tech. Transp. Szyn. 2009, 15, 39–42. [Google Scholar]

- Bałuch, H.; Bałuch, M. Ocena zagrożeń w eksploatacji nawierzchni kolejowej. Estimation of the threats in railway track operations. Przegląd Komun. 2011, 9/10, 14–16. [Google Scholar]

- Kwiatkowska, E. Innowacyjne metody diagnostyki rozjazdów kolejowych. Przegląd Komun. 2018, 8, 22–26. [Google Scholar]

- Minbashi, N.; Bagheri, M.; Golroo, A.; Khouy, I.A. Use of power spectral density for effective turnout geometry maintenance. Transp. Res. Rec. J. Transp. Res. Board 2016, 2545, 79–88. [Google Scholar] [CrossRef]

- Minbashi, N.; Bagheri, M.; Golroo, A.; Khouy, I.A. Geometrical degradation analysis of railway turnouts using power spectral density. J. Transp. Eng. Part A Syst. 2017, 143, 8. [Google Scholar] [CrossRef]

- Sysyn, M.P.; Kovalchuk, V.V.; Jiang, D. Performance study of the inertial monitoring method for railway turnouts. Int. J. Rail Transp. 2018, 7, 103–116. [Google Scholar] [CrossRef]

- Liu, X.; Markine, V.L.; Shevtsov, I.Y. Performance Study of a Double Crossover for Facing and Trailing Directions. In Proceedings of the IAVSD 2015: 24th International Symposium on Dynamics of Vehicles on Roads and Tracks, Graz, Austria, 17–21 August 2015. [Google Scholar]

- Kovalchuk, V.; Sysyn, M.; Hnativ, Y.; Bal, O.; Parneta, B.; Pentsak, A. Development of a promising system for diagnosing the frogs of railroad switches using the transverse profile measurement metod. Eastern Eur. J. Enterp. Technol. 2018, 2, 33–42. [Google Scholar] [CrossRef]

- Ma, X.; Wang, P.; Xu, J.; Chen, R. Parameters Studies on Surface Initiated Rolling Contact Fatigue of Turnout Rails by Three-Level Unreplicated Saturated Factorial Design. Appl. Sci. 2018, 8, 461. [Google Scholar] [CrossRef]

- Wei, Z.; Núñez, A.; Li, Z.; Dollevoet, R. Evaluating Degradation at Railway Crossings Using Axle Box Acceleration Measurements. Sensors 2017, 17, 2236. [Google Scholar] [CrossRef]

- Pålsson, B.A. Optimisation of railway crossing geometry considering a representative set of wheel profiles. Journal Vehicle System Dynamics. Int. J. Veh. Mech. Mobil. 2015, 53, 274–301. [Google Scholar] [CrossRef]

- Kaewunruen, S.; You, R.; Ishida, M. Composites for Timber-Replacement Bearers in Railway Switches and Crossings. Infrastructures 2017, 2, 13. [Google Scholar] [CrossRef]

- Gamage, E.K.; Kaewunruen, S.; Remennikov, A.M.; Ishida, T. Toughness of Railroad Concrete Crossties with Holes and Web Openings. Infrastructures 2017, 2, 3. [Google Scholar] [CrossRef]

- An, B.; Wang, P.; Xu, J.; Chen, R.; Cui, D. Observation and Simulation of Axle Box Acceleration in the Presence of Rail Weld in High-Speed Railway. Appl. Sci. 2017, 7, 1259. [Google Scholar] [CrossRef]

- Li, S.; Li, Z.; Núñez, A.; Dollevoet, R. New Insights into the Short Pitch Corrugation Enigma Based on 3D-FE Coupled Dynamic Vehicle-Track Modeling of Frictional Rolling Contact. Appl. Sci. 2017, 7, 807. [Google Scholar] [CrossRef]

- Zou, R.; Fan, X.; Qian, C.; Ye, W.; Zhao, P.; Tang, J.; Liu, H. An Efficient and Accurate Method for Different Configurations Railway Extraction Based on Mobile Laser Scanning. Remote Sens. 2019, 11, 2929. [Google Scholar] [CrossRef]

- Arastounia, M.; Elberink, S.O. Application of Template Matching for Improving Classification of Urban Railroad Point Clouds. Sensors 2016, 16, 2112. [Google Scholar] [CrossRef]

- Shin, M.H.; Lee, H.K.; Kim, H.Y. Benefit–Cost Analysis of Building Information Modeling (BIM) in a Railway Site. Sustainability 2018, 10, 4303. [Google Scholar] [CrossRef]

- Maciuk, K. Advantages of combined GNSS processing involving a limited number of visible satellites. Sci. J. Silesian Univ. Technol. Ser. Transp. 2018, 98, 89–100. [Google Scholar] [CrossRef]

- Maciuk, K. Monitoring of Galileo on-board oscillators variations, disturbances & noises. Measurement 2019, 147, 1–7. [Google Scholar] [CrossRef]

- Maciuk, K. GPS-only, GLONASS-only and combined GPS+GLONASS absolute positioning under different sky view conditions. Teh. Vjesn. 2018, 25, 933–939. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, Q.; Niu, X.; Shi, C. Requirement Assessment of the Relative Spatial Accuracy of a Motion-Constrained GNSS/INS in Shortwave Track Irregularity Measurement. Sensors 2019, 19, 5296. [Google Scholar] [CrossRef] [PubMed]

- Kaewunruen, S.; Lian, Q. Digital Twin Aided Sustainability-based Lifecycle Management for Railway Turnout Systems. J. Clean. Prod. 2019, 228, 1537–1551. [Google Scholar] [CrossRef]

- Oberbauvorschriften DV 820 1939. Available online: https://epoche2.modellbahnfrokler.de/dv/e2d_3308.html (accessed on 7 March 2020).

- Leica TPS400 Series. User Manual. Leica Geosystems. Version 4.0. Available online: http://webarchiv.ethz.ch/geometh-data/student/anleitungen/leicaman/tps400/TPS400User_en.pdf (accessed on 29 July 2020).

- Raporty Roczne PKP Polskie Linie Kolejowe, S.A. Available online: https://www.plk-sa.pl/biuro-prasowe/raport-roczny/ (accessed on 24 July 2020).

- Bezpieczeństwo Ruchu Kolejowego w Polsce. Najwyższa Izba Kontroli-NIK. Available online: https://www.nik.gov.pl/plik/id,5682,vp,7354.pdf (accessed on 23 July 2020).

- Transportation Safety Board of Canada (TSB). Statistical Summary. Available online: https://www.bst-tsb.gc.ca/eng/stats/rail/2017/sser-ssro-2017.html (accessed on 24 July 2020).

- Batarlienė, N. Improving Safety of Transportation of Dangerous Goods by Railway Transport. Infrastructures 2020, 5, 54. [Google Scholar] [CrossRef]

- Dindar, S.; Kaewunruen, S.; An, M. Identification of Appropriate Risk Analysis Techniques for Railway Turnout Systems. J. Risk Res. 2016, 21, 974–995. [Google Scholar] [CrossRef]

- Mistry, P.; Lane, P.; Allen, P. Railway Point-Operating Machine Fault Detection Using Unlabeled Signaling Sensor Data. Sensors 2020, 20, 2692. [Google Scholar] [CrossRef]

- Dindar, S.; Kaewunruen, S.; An, M. Rail Accident Analysis using Large-scale Investigations of Train Derailments on Switches and Crossings: Comparing the Performances of a Novel Stochastic Mathematical Prediction and Various Assumptions. Eng. Fail. Anal. 2019, 103, 203–216. [Google Scholar] [CrossRef]

- Marx, A. Spezialität: Weichen, Kreuzungen und Kreuzungsweichen. 2019. Available online: https://rsv.gmbh/spezialitaet-weichen-kreuzungen-und-kreuzungsweichen/ (accessed on 11 June 2020).

- Kaewunruen, S.; Osman, M.H.; Eric, W.H.C. Risk-Based Maintenance Planning for Rail Fastening Systems. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2019, 5, 04019007. [Google Scholar] [CrossRef]

- Kuźmiński, Ł.; Maśloch, P.; Bazan, M.; Janiczek, T.; Halawa, K.; Wojtaszek, H.; Miciuła, I.; Chajduga, T.; Kawecki, A.; Czwartosz, R.; et al. Management of Delay Optimization at Intersections. Energies 2020, 13, 3087. [Google Scholar] [CrossRef]

| Name | Proper Condition | Existing Condition | Difference |

|---|---|---|---|

| Diverted track radius | Rp = 190 m | Ri ≈ 225 m | 35 m |

| Horizontal versine of the diverted track ad | fp = 0.726 | f1 = fiad = 0.612 m | 0.114 m |

| Horizontal versine of the diverted track bc | fp = 0.726 | f2 = fibc = 0.612 m | 0.114 m |

| Main angle of the turnout (between the main tracks axles 1′–SG–2′) | αp = 7g04c466cc | αiab = 7g02c408cc | 0g02c058cc |

| Main angle of the turnout (between the main tracks axles 3′–SG–4′) | αp = 7g04c466cc | αicd = 7g06c190cc | 0g01c724cc |

| Main track length 1′–3′ in the axis (in full) | |1′–3′|p axis = 33.230 m | |1′–3′|i axis = 33.249 m | 0.019 m |

| Main track length 2′–4′ in the axis (in full) | |2′–4′|p axis = 33.230 m | |2′–4′|i axis = 33.226 m | 0.004 m |

| Length of main track 1′–SG in axis | |1′–SG|p axis = 16.615 m | |1′–SG|i axis = 16.618 m | 0.003 m |

| Length of main track SG–3′ in axis | |SG–3′|p axis = 16.615 m | |SG–3′|i axis = 16.631 m | 0.016 m |

| Length of main track 2′–SG in axis | |2′–SG|p axis = 16.615 m | |2′–SG|i axis = 16.604 m | 0.011 m |

| Length of main track SG–4′ in axis | |SG–4′|p axis = 16.615 m | |SG–4′|i axis = 16.622 m | 0.007 m |

| Turnout Number and Type Date of Measurement | Name of the Parameter | Turnout Side | Proper Condition and Permissible Deviation of the Parameter Track Gauge and Cant [mm] | |

|---|---|---|---|---|

| Main Track | Main Track | |||

| a | a1 | |||

| Track Gauge | ||||

| Track Cant | ||||

| 9 ab/cd S49/1:9/190 7 May 2018 | Track gauge | ab | 43 | 34 |

| Track gauge | cd | 41 | 33 | |

| Track cant | ab | −3 | 6 | |

| Track cant | cd | 0 | −3 | |

| 9 ab/cd S49/1:9/190 5 February 2019 | Track gauge | ab | 42 | 35 |

| Track gauge | cd | 40 | 35 | |

| Track cant | ab | −4 | 5 | |

| Track cant | cd | 1 | −1 | |

| 9 ab/cd S49/1:9/190 5 August 2019 | Track gauge | ab | 43 | 35 |

| Track gauge | cd | 40 | 35 | |

| Track cant | ab | 2 | −2 | |

| Track cant | cd | 0 | −1 | |

| 9 ab/cd S49/1:9/190 2 November 2019 | Track gauge | ab | 45 | 35 |

| Track gauge | cd | 40 | 35 | |

| Track cant | ab | −3 | 8 | |

| Track cant | cd | 1 | 2 | |

| Turnout Number and Type Date of Measurement | Name of the Parameter | Turnout Side | Proper Conditions and Permissible Deviation of the Parameter Track Gauge and Cant [mm] | |||

|---|---|---|---|---|---|---|

| Main Track | Diverted Track | Main Track | Diverted Track | |||

| c | c1 | c2 | c3 | |||

| Track Gauge | ||||||

| Track Cant | ||||||

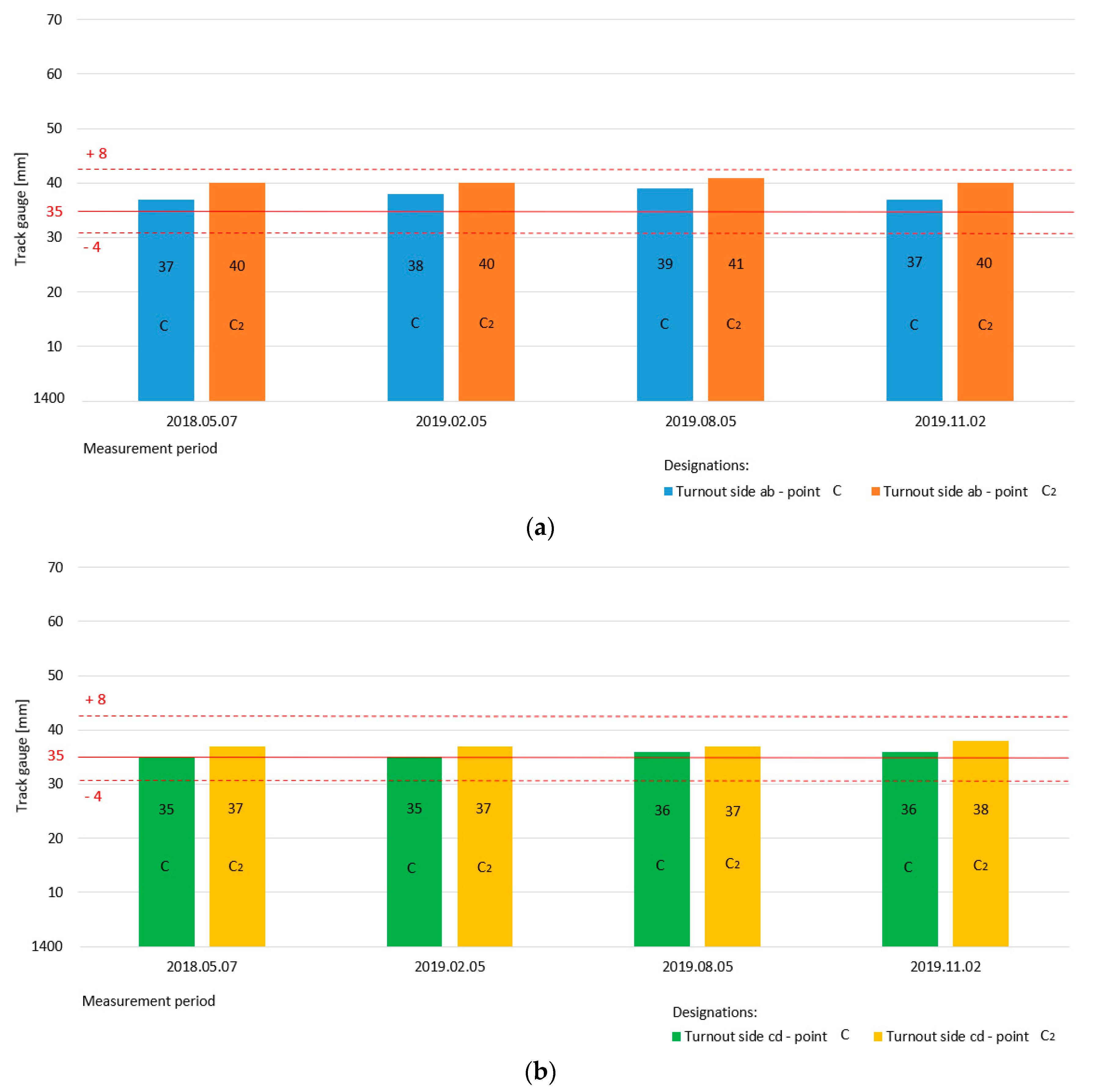

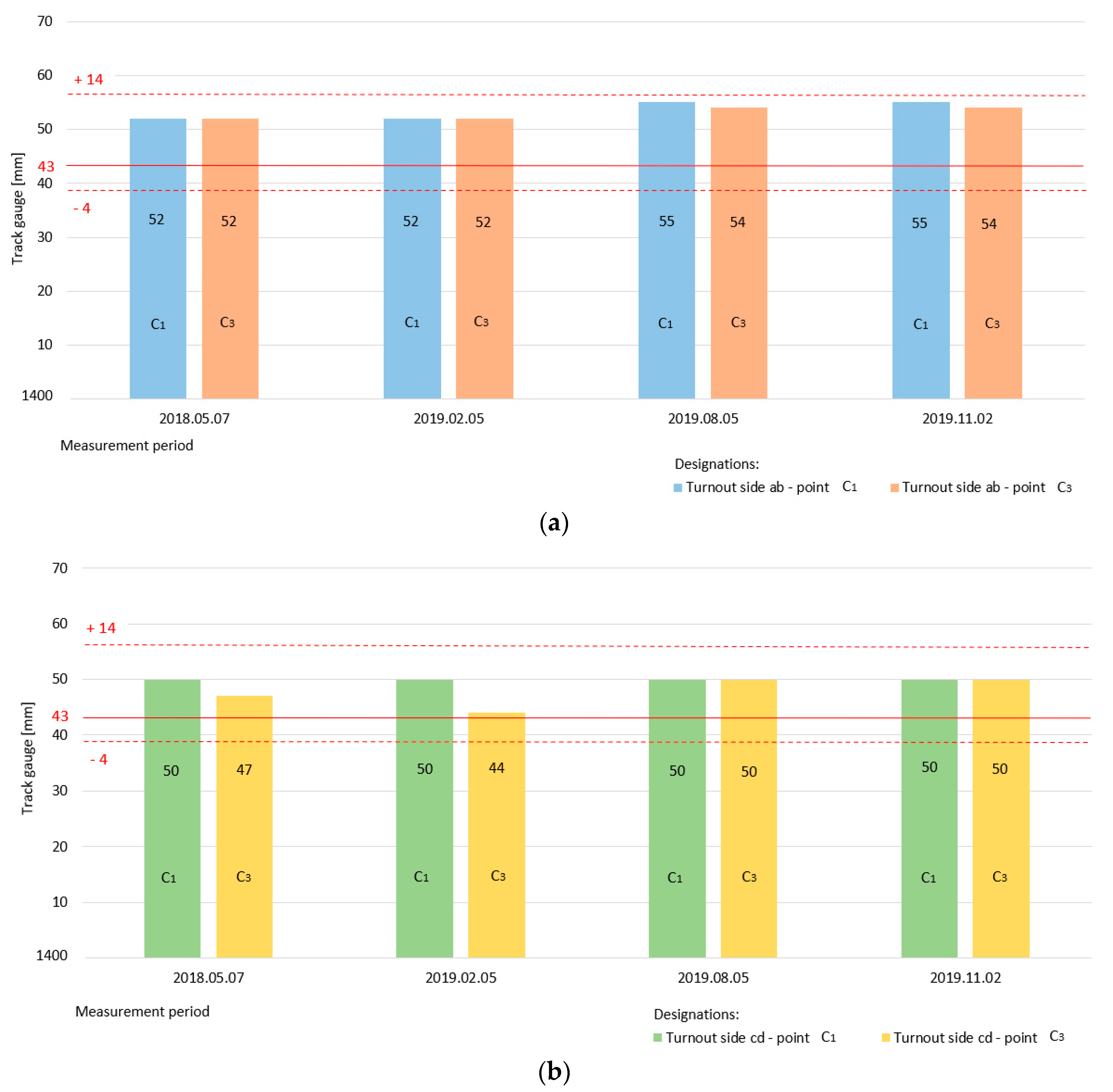

| 9 ab/cd S49/1:9/190 7 May 2018 | Track gauge | ab | 37 | 52 | 40 | 52 |

| Track gauge | cd | 35 | 50 | 37 | 47 | |

| Track cant | ab | −1 | −1 | −2 | −3 | |

| Track cant | cd | 0 | −1 | 0 | 0 | |

| 9 ab/cd S49/1:9/190 5 February 2019 | Track gauge | ab | 38 | 52 | 40 | 52 |

| Track gauge | cd | 35 | 50 | 37 | 44 | |

| Track cant | ab | −1 | −1 | −3 | −4 | |

| Track cant | cd | −1 | −1 | −3 | 0 | |

| 9 ab/cd S49/1:9/190 5 August 2019 | Track gauge | ab | 39 | 55 | 41 | 54 |

| Track gauge | cd | 36 | 50 | 37 | 50 | |

| Track cant | ab | 0 | 0 | 0 | 1 | |

| Track cant | cd | 2 | −3 | 2 | −3 | |

| 9 ab/cd S49/1:9/190 2 November 2019 | Track gauge | ab | 37 | 55 | 40 | 54 |

| Track gauge | cd | 36 | 50 | 38 | 50 | |

| Track cant | ab | 0 | 1 | −3 | −3 | |

| Track cant | cd | 0 | −1 | 0 | 0 | |

| Turnout Number and Type Date of Measurement | Name of the Parameter | Turnout Side | Proper Conditions and Permissible Deviation of the Parameter Track Gauge and Cant [mm] | |||

|---|---|---|---|---|---|---|

| Main Track | Diverted Track | Main Track | Diverted Track | |||

| c | c1 | c2 | c3 | |||

| Track Gauge | ||||||

| Track Cant | ||||||

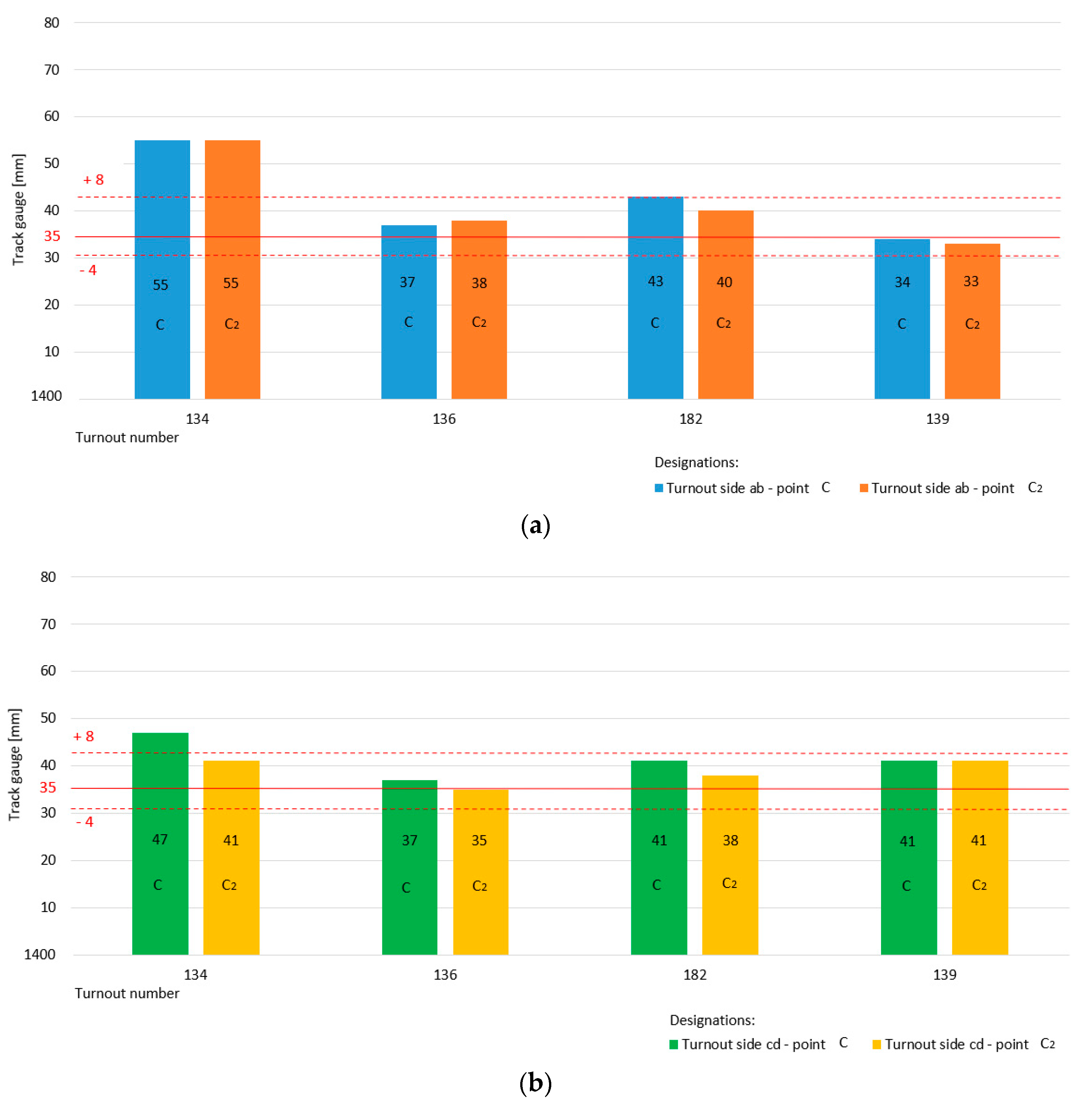

| 134 ab/cd S49/1:9/190 4 November 2019 | Track gauge | ab | 55 | 78 | 55 | 70 |

| Track gauge | cd | 47 | 62 | 41 | 58 | |

| Track cant | ab | 1 | 4 | 4 | 8 | |

| Track cant | cd | 0 | 4 | 1 | 1 | |

| 136 ab/cd S49/1:9/190 4 November 2019 | Track gauge | ab | 37 | 49 | 38 | 57 |

| Track gauge | cd | 37 | 58 | 35 | 52 | |

| Track cant | ab | −1 | −2 | 0 | 1 | |

| Track cant | cd | 3 | 3 | 4 | 8 | |

| 182 ab/cd S49/1:9/190 5 November 2019 | Track gauge | ab | 43 | 55 | 40 | 60 |

| Track gauge | cd | 41 | 60 | 38 | 49 | |

| Track cant | ab | 15 | 12 | 11 | 15 | |

| Track cant | cd | 11 | 15 | 13 | 10 | |

| 139 ab/cd S49/1:9/190 5 November 2019 | Track gauge | ab | 34 | 52 | 33 | 54 |

| Track gauge | cd | 41 | 61 | 41 | 68 | |

| Track cant | ab | 0 | 0 | 0 | 0 | |

| Track cant | cd | 0 | 0 | 0 | 0 | |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kampczyk, A. Measurement of the Geometric Center of a Turnout for the Safety of Railway Infrastructure Using MMS and Total Station. Sensors 2020, 20, 4467. https://doi.org/10.3390/s20164467

Kampczyk A. Measurement of the Geometric Center of a Turnout for the Safety of Railway Infrastructure Using MMS and Total Station. Sensors. 2020; 20(16):4467. https://doi.org/10.3390/s20164467

Chicago/Turabian StyleKampczyk, Arkadiusz. 2020. "Measurement of the Geometric Center of a Turnout for the Safety of Railway Infrastructure Using MMS and Total Station" Sensors 20, no. 16: 4467. https://doi.org/10.3390/s20164467

APA StyleKampczyk, A. (2020). Measurement of the Geometric Center of a Turnout for the Safety of Railway Infrastructure Using MMS and Total Station. Sensors, 20(16), 4467. https://doi.org/10.3390/s20164467