Multifunctional Smart Ball Sensor for Wireless Structural Health Monitoring in a Fire Situation

Abstract

1. Introduction

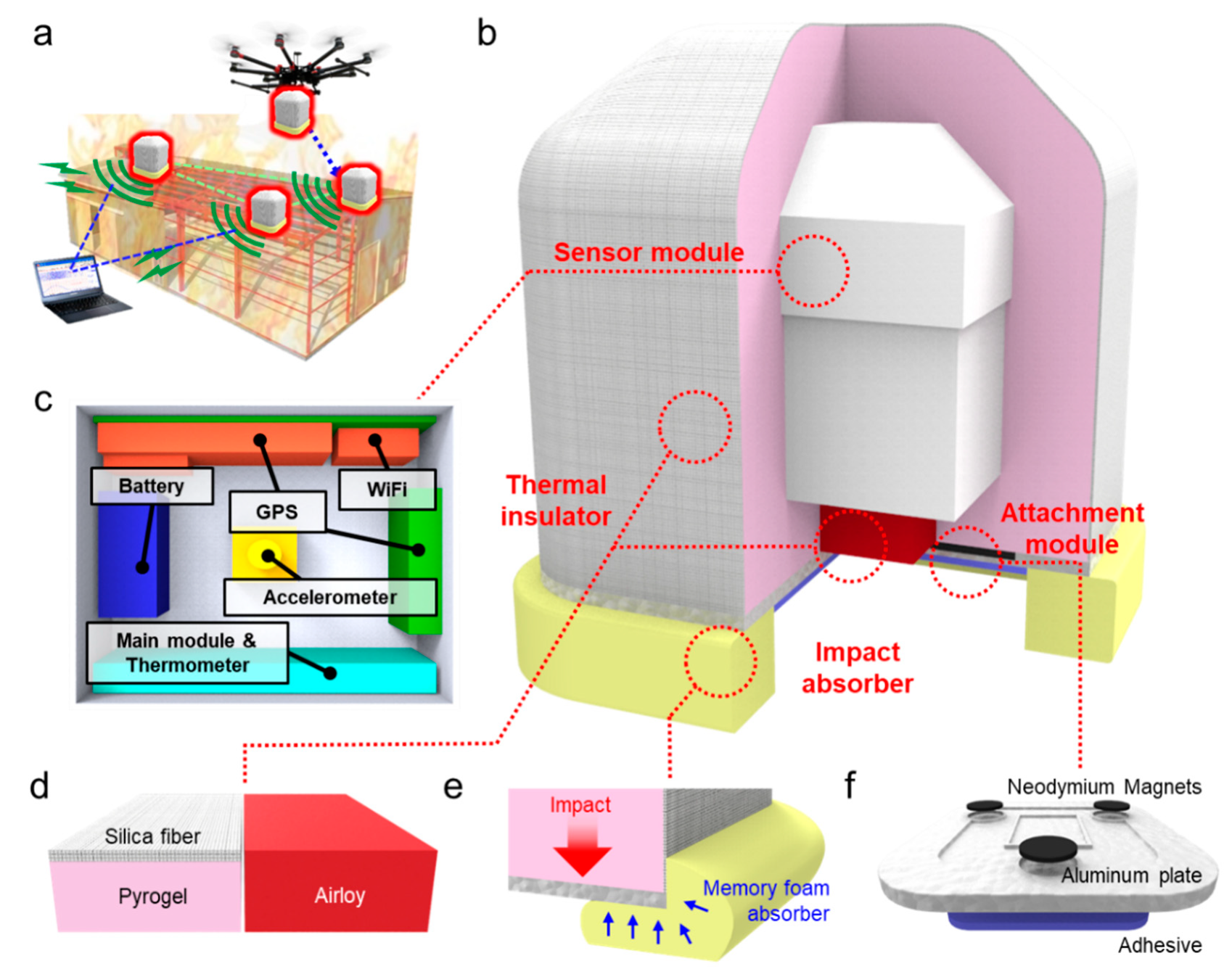

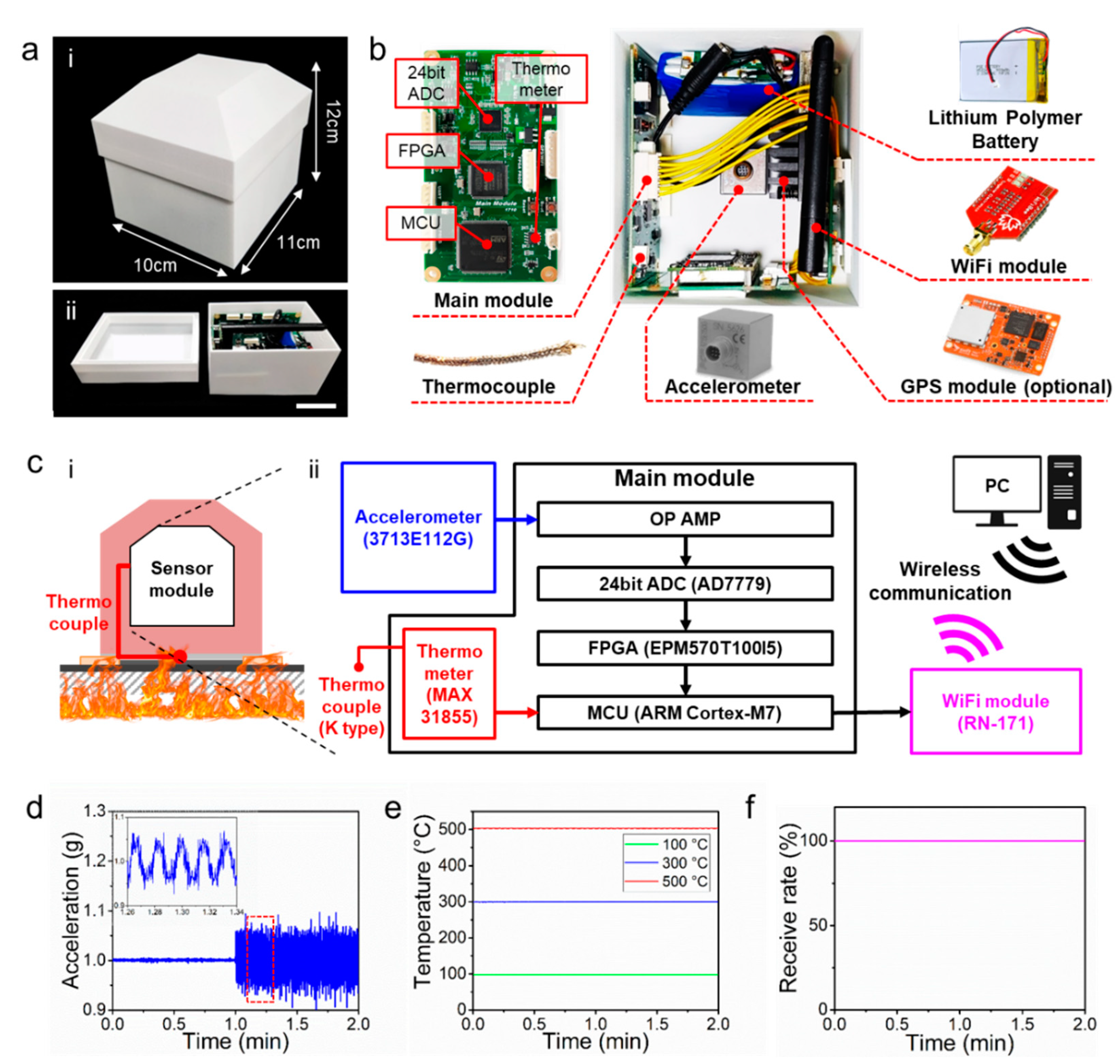

2. Overall, Design and Working Principle of the Smart Ball Sensor

3. Structure and Performance of the Sensor Module

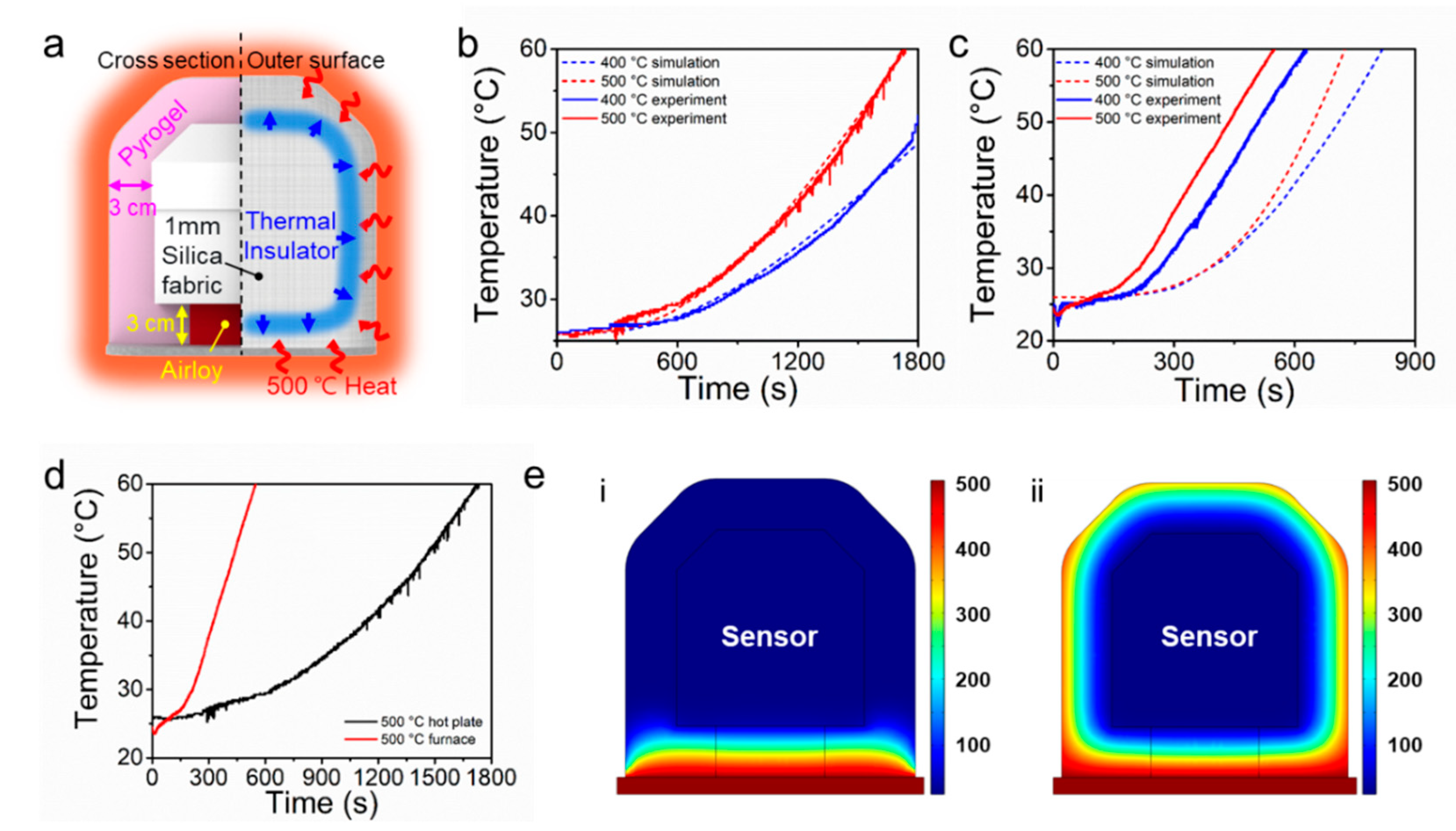

4. Structure and Performance of the Thermal Insulator

5. Structure and Performance of the Adhesive and Impact Absorber Modules

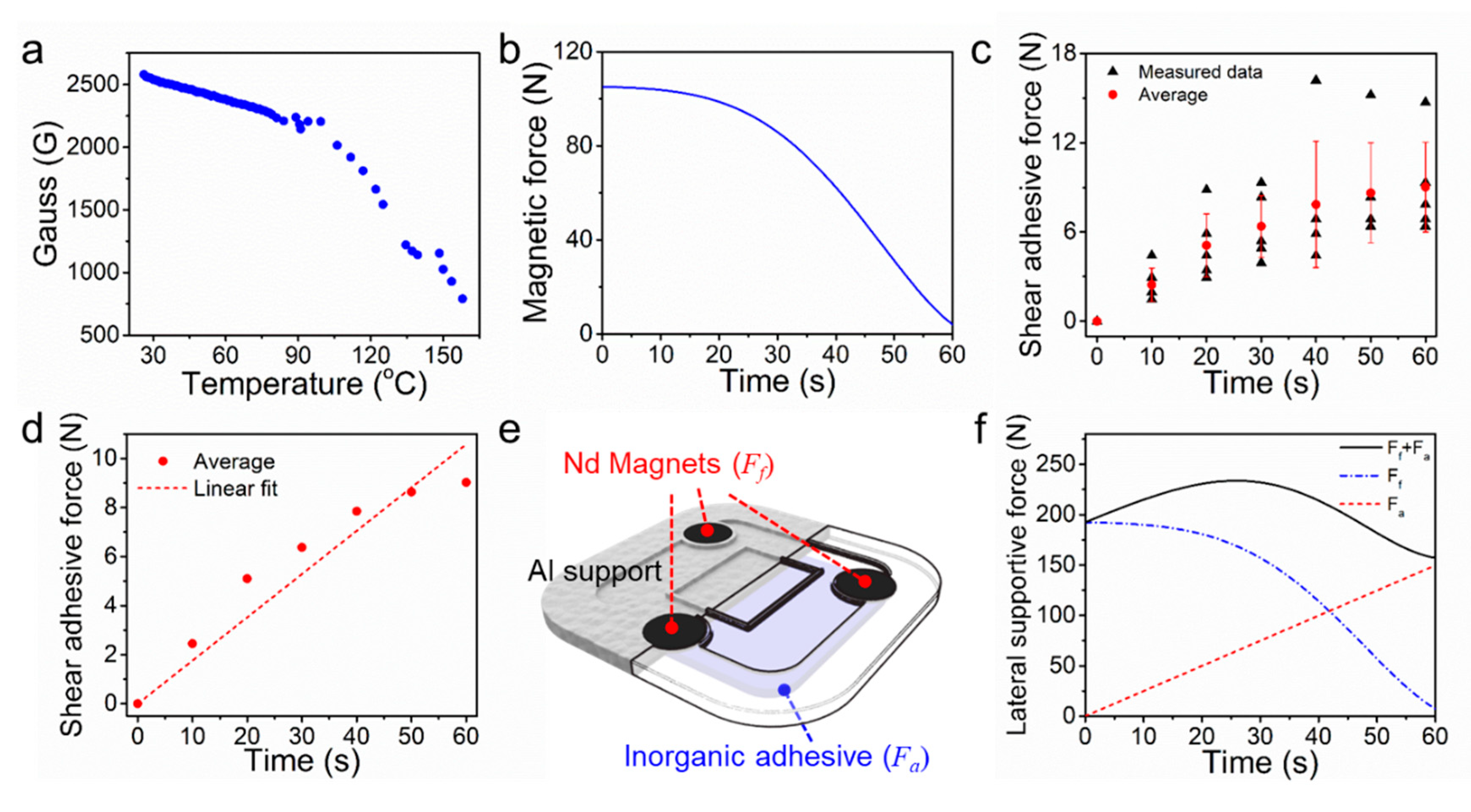

5.1. Attachment Module

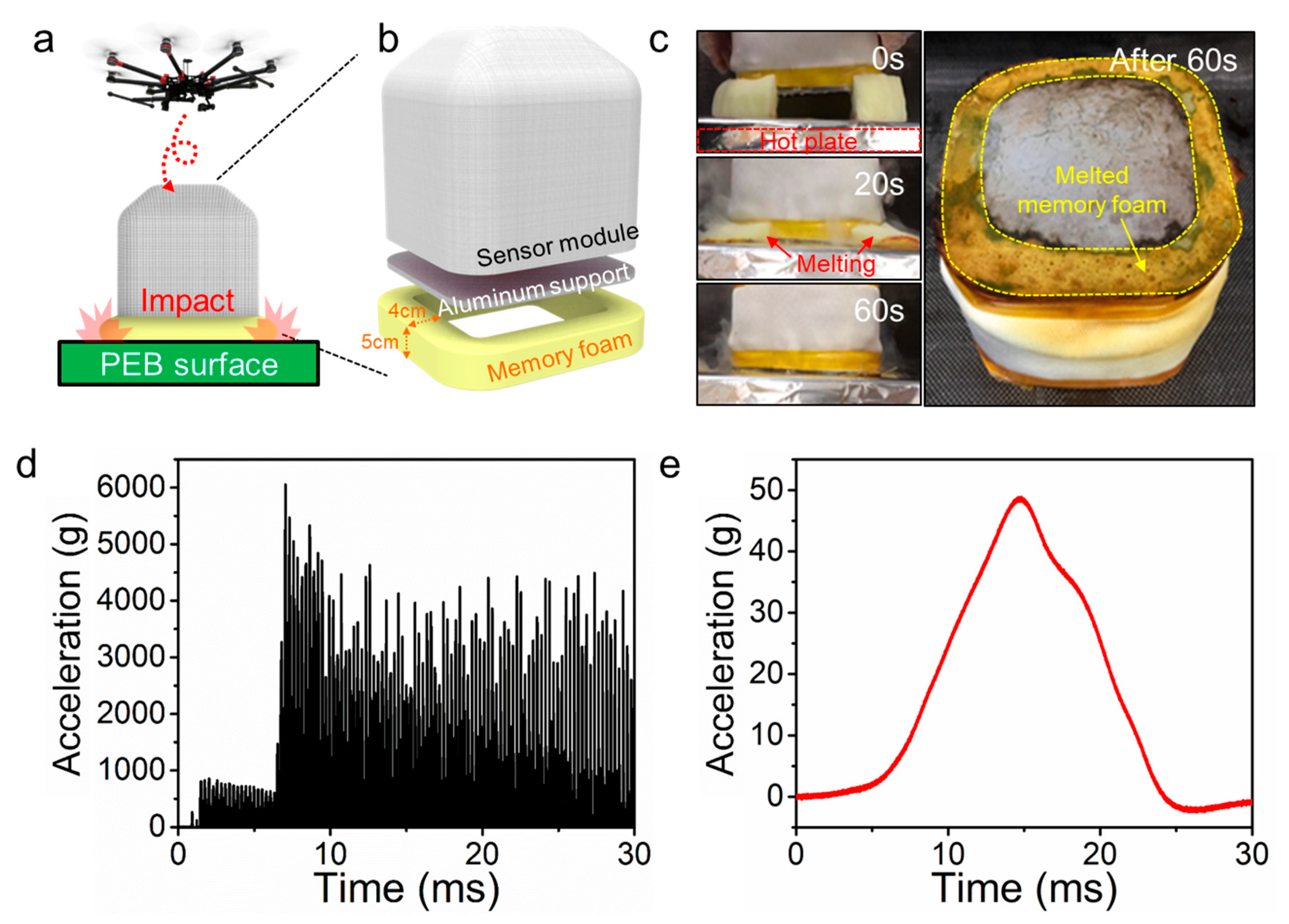

5.2. Impact Absorber

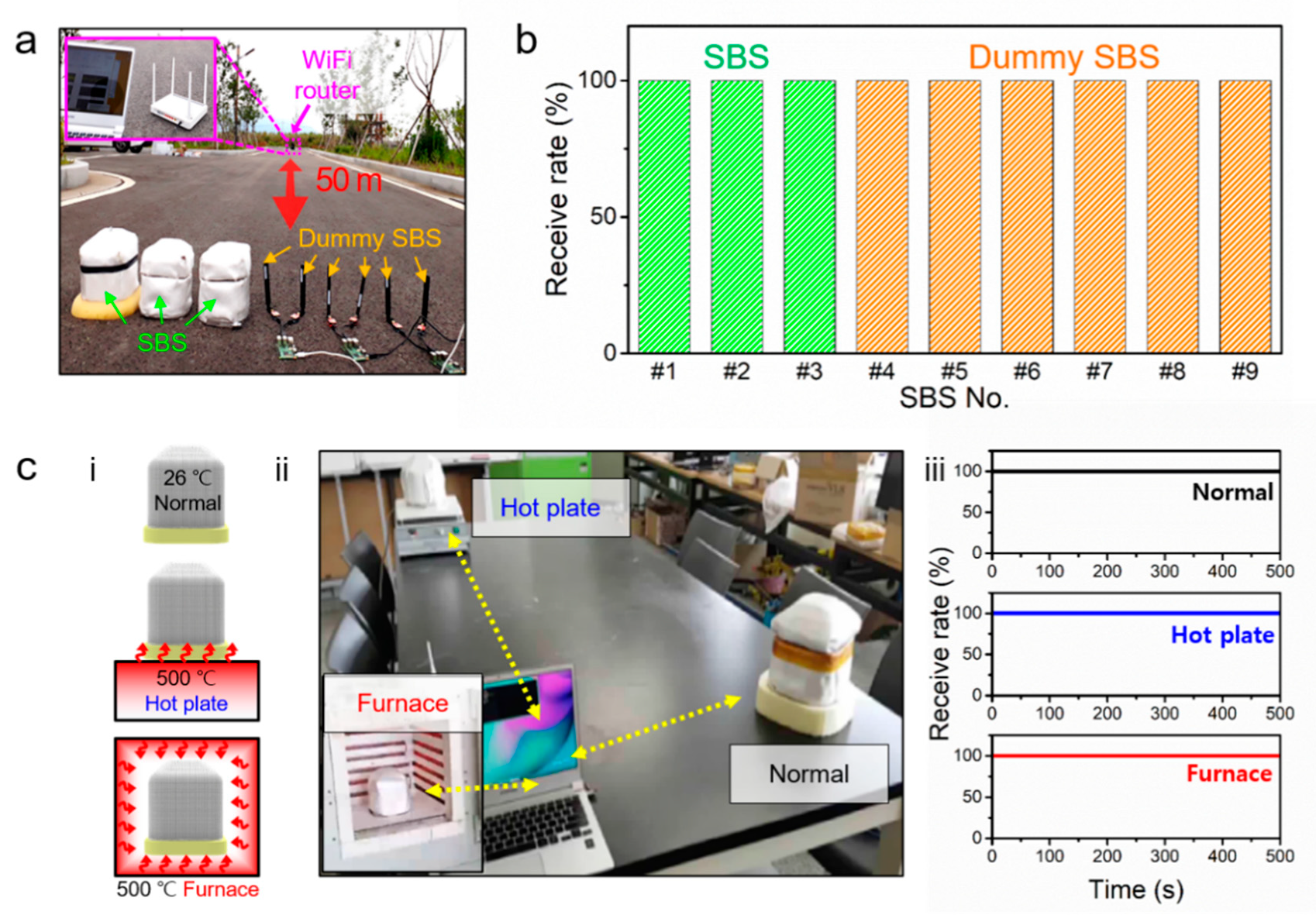

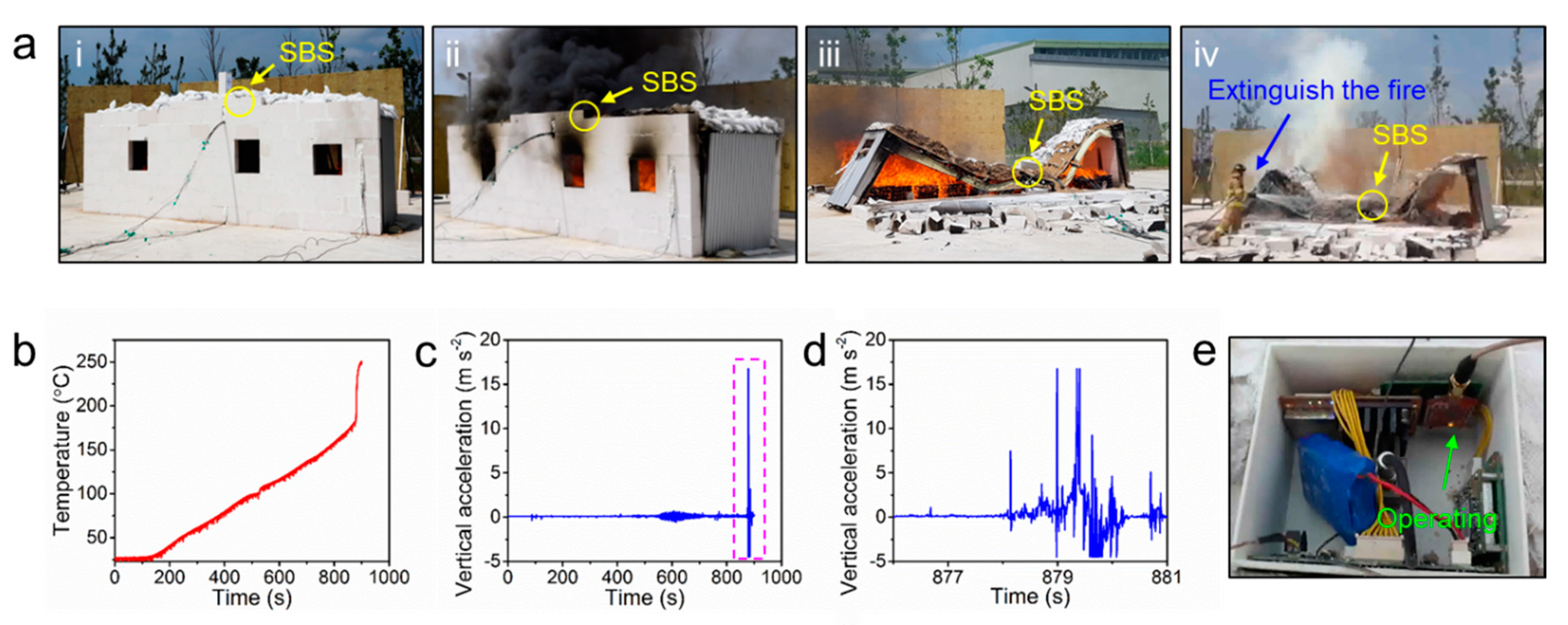

6. Testbed Experiments

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Firoz, S.; Ch, S.; Kumar, R.; Rao, S.K. Design concept of pre-engineered building. Int. J. Eng. Res. Appl. 2012, 2, 267–272. [Google Scholar]

- Meera, C.M. Pre-engineered building design of an industrial warehouse. Int. J. Eng. Sci. Emerg. Technol. 2013, 5, 75–82. [Google Scholar]

- Rita, F.; Paul, R.; Joseph, L. Firefighter Fatalities in the United States-2012; National Fire Protection Association: Quincy, MA, USA, 2013. [Google Scholar]

- Fahy, R.F. US Fire Service Fatalities in Structure Fires, 1977–2009; National Fire Protection Association: Quincy, MA, USA, 2010. [Google Scholar]

- Merzbacher, C.I.; Kersey, A.D.; Friebele, E.J. Fiber optic sensors in concrete structures: A review. Smart Mater. Struct. 1996, 5, 196. [Google Scholar] [CrossRef]

- López-Higuera, J.M.; Cobo, L.R.; Incera, A.Q.; Cobo, A. Fiber optic sensors in structural health monitoring. J. Lightwave Technol. 2011, 29, 587–608. [Google Scholar] [CrossRef]

- Joe, H.E.; Yun, H.; Jo, S.H.; Jun, M.B.; Min, B.K. A review on optical fiber sensors for environmental monitoring. Int. J. Pr. Eng. Man-GT 2018, 5, 173–191. [Google Scholar] [CrossRef]

- Lee, D.; Chung, J.; Yong, H.; Lee, S.; Shin, D. A deformable foam-layered triboelectric tactile sensor with adjustable dynamic range. Int. J. Pr. Eng. Man-GT 2019, 6, 43–51. [Google Scholar] [CrossRef]

- Bang, H.J.; Kim, H.I.; Lee, K.S. Measurement of strain and bending deflection of a wind turbine tower using arrayed FBG sensors. Int. J. Pr. Eng. Man-GT 2012, 13, 2121–2126. [Google Scholar] [CrossRef]

- Wilson, W.C.; Malocha, D.C.; Kozlovski, N.; Gallagher, D.R.; Fisher, B.; Pavlina, J.; Atkinson, G.M. Orthogonal frequency coded SAW sensors for aerospace SHM applications. IEEE Sens. J. 2009, 9, 1546–1556. [Google Scholar] [CrossRef]

- Roh, H.D.; Lee, H.; Park, Y.B. Structural health monitoring of carbon-material-reinforced polymers using electrical resistance measurement. Int. J. Pr. Eng. Man-GT 2016, 3, 311–321. [Google Scholar] [CrossRef]

- Azhari, F.; Banthia, N. Cement-based sensors with carbon fibers and carbon nanotubes for piezoresistive sensing. Cement Concrete Comp. 2012, 34, 866–873. [Google Scholar] [CrossRef]

- Li, Y.; Lu, X.; Guan, H.; Ying, M.; Yan, W. A case study on a fire-induced collapse accident of a reinforced concrete frame-supported masonry structure. Fire Technol. 2016, 52, 707–729. [Google Scholar] [CrossRef]

- Mahmoud, H.; Ellingwood, B.; Turbert, C.; Memari, M. Response of steel reduced beam section connections exposed to fire. J. Struct. Eng. 2016, 142, 04015076. [Google Scholar] [CrossRef]

- Agarwal, A.; Varma, A.H. Fire induced progressive collapse of steel building structures: The role of interior gravity columns. Eng. Struct. 2014, 58, 129–140. [Google Scholar] [CrossRef]

- Duron, Z.H.; Yoder, N.; Kelcher, R.; Hutchings, A.; Markwardt, S.; Panish, R. Fire Induced Vibration Monitoring for Building Collapse. Final Report; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2005; pp. 6–885.

- Stroup, D.W.; Bryner, N.P.; Lee, J.; McElroy, J.; Roadarmel, G.; Twilley, W.H. Structural Collapse Fire Tests: Single Story, Wood Frame Structures; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2004.

- Dorcheh, A.S.; Abbasi, M.H. Silica aerogel; synthesis, properties and characterization. J. Mater. Process. Technol. 2008, 199, 10–26. [Google Scholar] [CrossRef]

- Goranson, P.; Freudenberg, K.; McGinnis, G.; Dudek, L.; Zarnstorff, M. Application of high-performance aerogel insulating materials (analysis & test results). In Proceedings of the 2009 23rd IEEE/NPSS Symposium on Fusion Engineering, San Diego, CA, USA, 1–5 June 2009; IEEE: New York, NY, USA, 2009. [Google Scholar]

- Rubert, A.; Schaumann, P. Structural steel and plane frame assemblies under fire action. Fire Safety J. 1986, 10, 173–184. [Google Scholar] [CrossRef]

- Sun, R.; Huang, Z.; Burgess, I.W. Progressive collapse analysis of steel structures under fire conditions. Eng. Struct. 2012, 34, 400–413. [Google Scholar] [CrossRef]

- Sagawa, M.; Fujimura, S.; Togawa, N.; Yamamoto, H.; Matsuura, Y. New material for permanent magnets on a base of Nd and Fe. J. Appl. Phys. 1984, 55, 2083–2087. [Google Scholar] [CrossRef]

- Ma, B.M.; Narasimhan, K.S.V.L. Temperature dependence of magnetic properties of Nd-Fe-B magnets. J. Magn. Magn. Mater. 1986, 54, 559–562. [Google Scholar] [CrossRef]

- Mochigase, H.; Suzuki, Y.; Miki, E.; Mitsumune, S.; Ohba, Y.; Inoue, Y. Development of Lightweight Fire-resistant Putty. Furukawa Rev. 2014, 45, 2–7. [Google Scholar]

- Tobushi, H.; Okumura, K.; Endo, M.; Hayashi, S. Thermomechanical properties of polyurethane-shape memory polymer foam. J. Intel. Mat. Syst. Struct. 2001, 12, 283–287. [Google Scholar] [CrossRef]

- Di Prima, M.A.; Lesniewski, M.; Gall, K.; McDowell, D.L.; Sanderson, T.; Campbell, D. Thermo-mechanical behavior of epoxy shape memory polymer foams. Smart Mater. Struct. 2007, 16, 2330. [Google Scholar] [CrossRef]

| SBS Module | Manufacturer | Sensing Range | Overload Limit (Shock) | Max. Operating Temperature |

|---|---|---|---|---|

| Accelerometer | PCB piezotronics, 3713E112G | ±2 g pk (0.1 mg rms) | ±2000 g pk | 121 °C |

| Wi-Fi module | Roving networks, RN-171 | 1 to 11Mbps | – | 85 °C |

| Power supply | Z-SUN Technology Co., H503450 (3.7 V 900 mA) | – | ±150 g pk | 60 °C |

| Thermometer & Thermocouple | Maxim integrated, MAX31855 Sparkfun, Thermocouple K type | −270 to 1372 °C | – | 125 °C (Thermometer) |

| GPS | Swift navigation, Piksi multi | 0.01 m +1 ppm | ±75 g pk | 85 °C |

| Main module | STMicroelectronics, STM32F767ZIT6 ALTERA, EPM570T100I5 Analog Devices, Inc., AD7779 | – | – | 85 °C |

| Material | Airloy | Pyrogel | Silicate Fabric |

|---|---|---|---|

| Manufacturer | Aerogel Technologies, LLC. | Aspen Aerogels, Inc. | HITCO Carbon Composites, Inc. |

| Density (g/cm3) | 0.4 | 0.2 | 2.1 |

| Thermal conductivity (W/mK) | 0.032 | 0.025 | 0.033 |

| Max. operating temperature (°C) | 650 | 300 | 1593 |

| Compressive modulus (MPa) | 113 | – | – |

| Mechanical characteristic | Strong solid | Flexible blanket | Thin fabric |

| Usage | Insulating support | Insulating filler | Outer cover |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, M.; Hwang, I.; Seong, M.; Choi, J.; Kim, M.; Lee, H.-D.; Shin, K.-J.; Son, H.; Sohn, H.; Choi, J.; et al. Multifunctional Smart Ball Sensor for Wireless Structural Health Monitoring in a Fire Situation. Sensors 2020, 20, 4328. https://doi.org/10.3390/s20154328

Kim M, Hwang I, Seong M, Choi J, Kim M, Lee H-D, Shin K-J, Son H, Sohn H, Choi J, et al. Multifunctional Smart Ball Sensor for Wireless Structural Health Monitoring in a Fire Situation. Sensors. 2020; 20(15):4328. https://doi.org/10.3390/s20154328

Chicago/Turabian StyleKim, Minsu, Insol Hwang, Minho Seong, Jaemook Choi, Myunggun Kim, Hee-Du Lee, Kyung-Jae Shin, Hungsun Son, Hoon Sohn, Junho Choi, and et al. 2020. "Multifunctional Smart Ball Sensor for Wireless Structural Health Monitoring in a Fire Situation" Sensors 20, no. 15: 4328. https://doi.org/10.3390/s20154328

APA StyleKim, M., Hwang, I., Seong, M., Choi, J., Kim, M., Lee, H.-D., Shin, K.-J., Son, H., Sohn, H., Choi, J., Jeong, H. E., & Kwak, M. K. (2020). Multifunctional Smart Ball Sensor for Wireless Structural Health Monitoring in a Fire Situation. Sensors, 20(15), 4328. https://doi.org/10.3390/s20154328