Towards Highly Efficient Polymer Fiber Laser Sources for Integrated Photonic Sensors

Abstract

1. Introduction

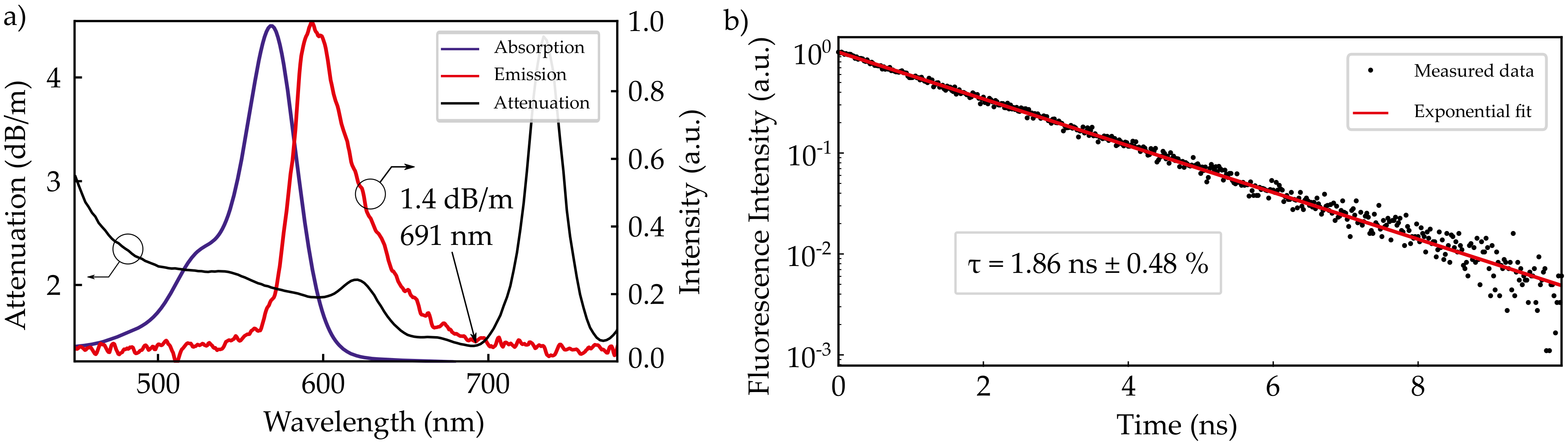

2. Manufacturing and Characteristics

3. Numerical Model

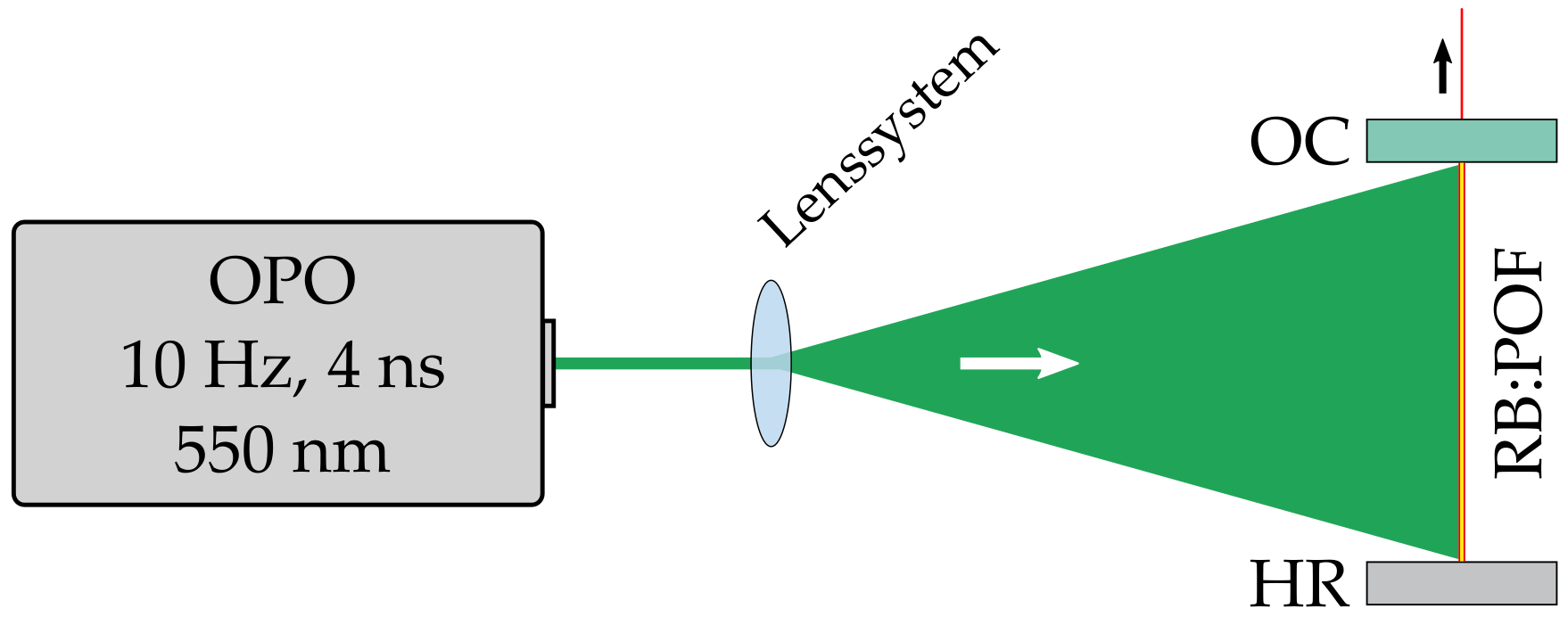

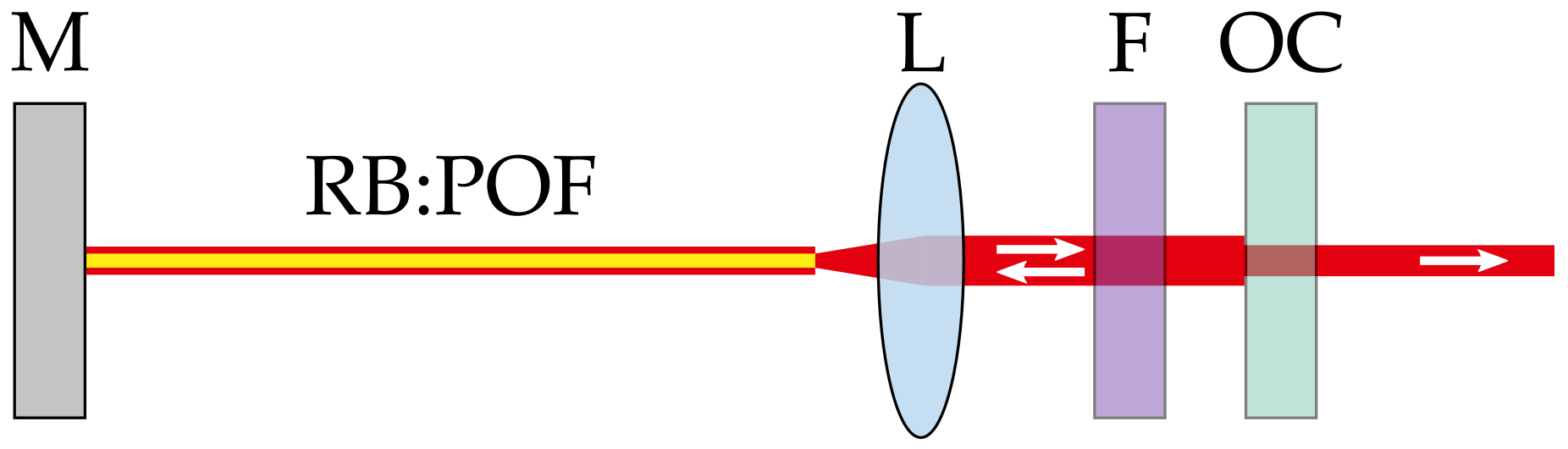

4. RB:POF Laser

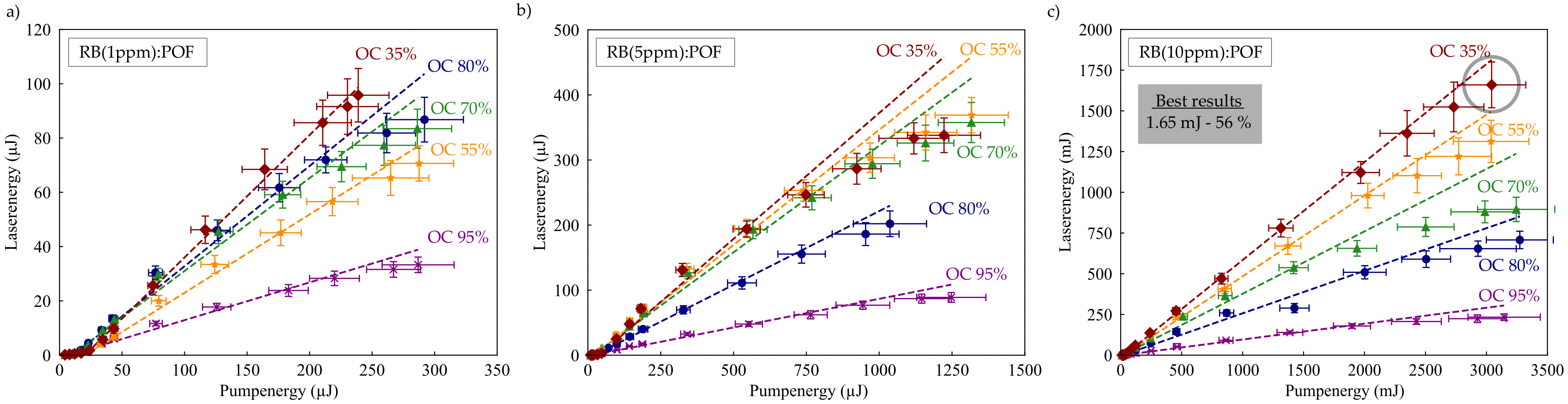

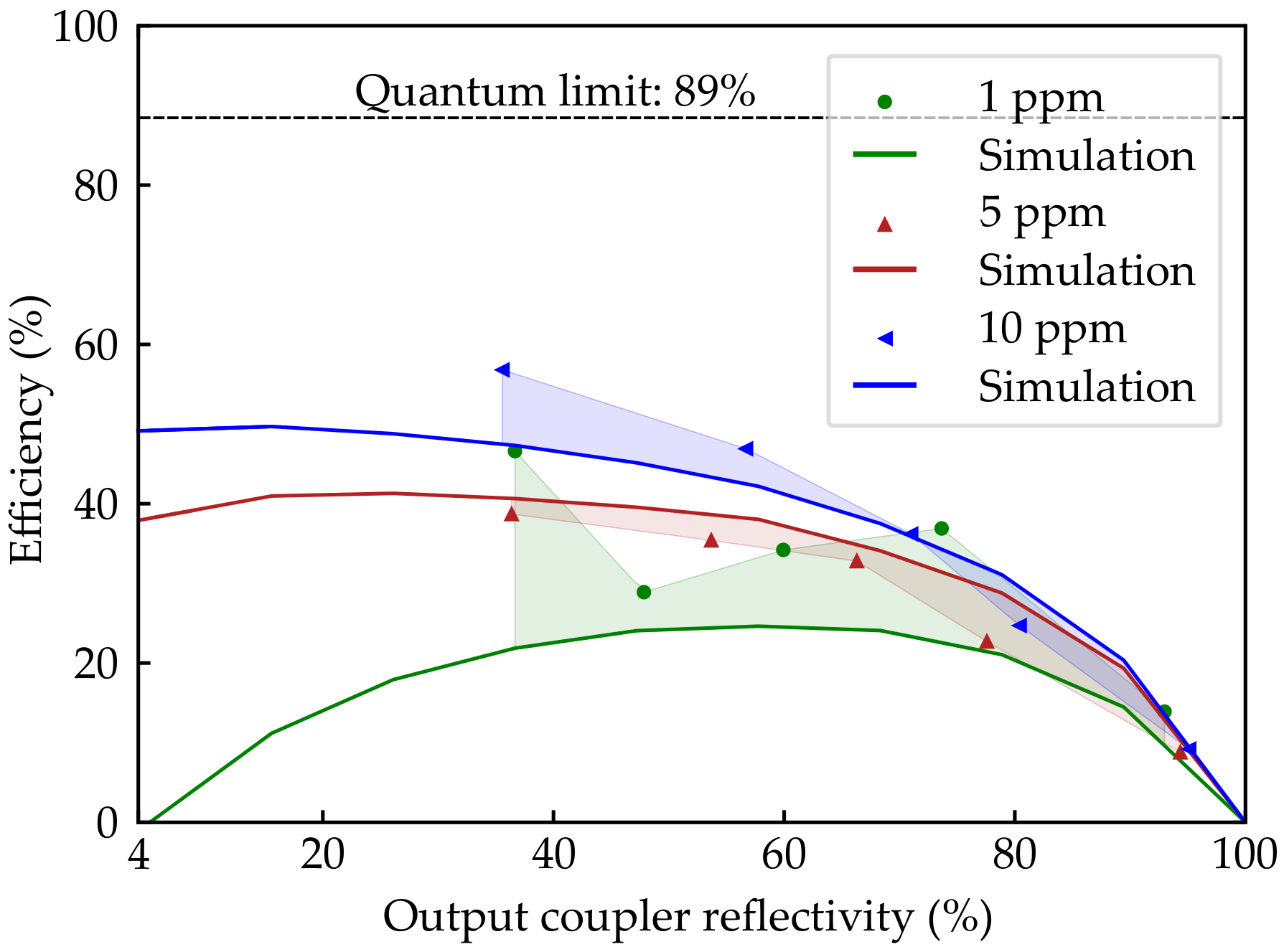

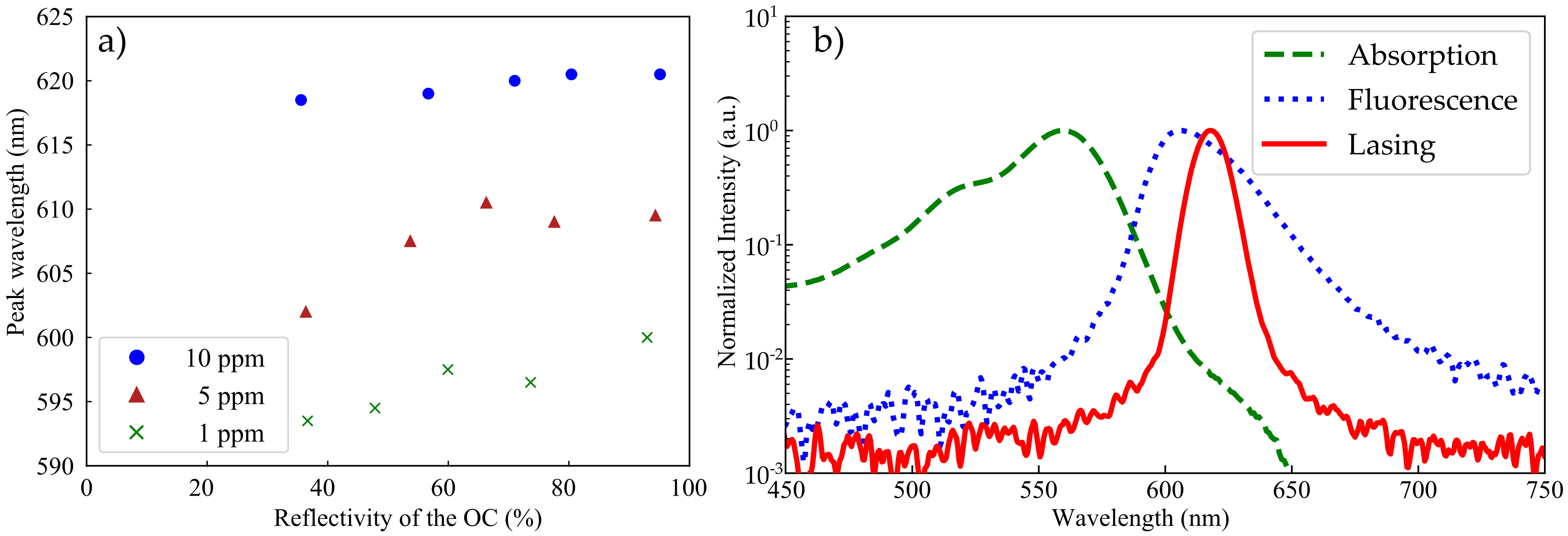

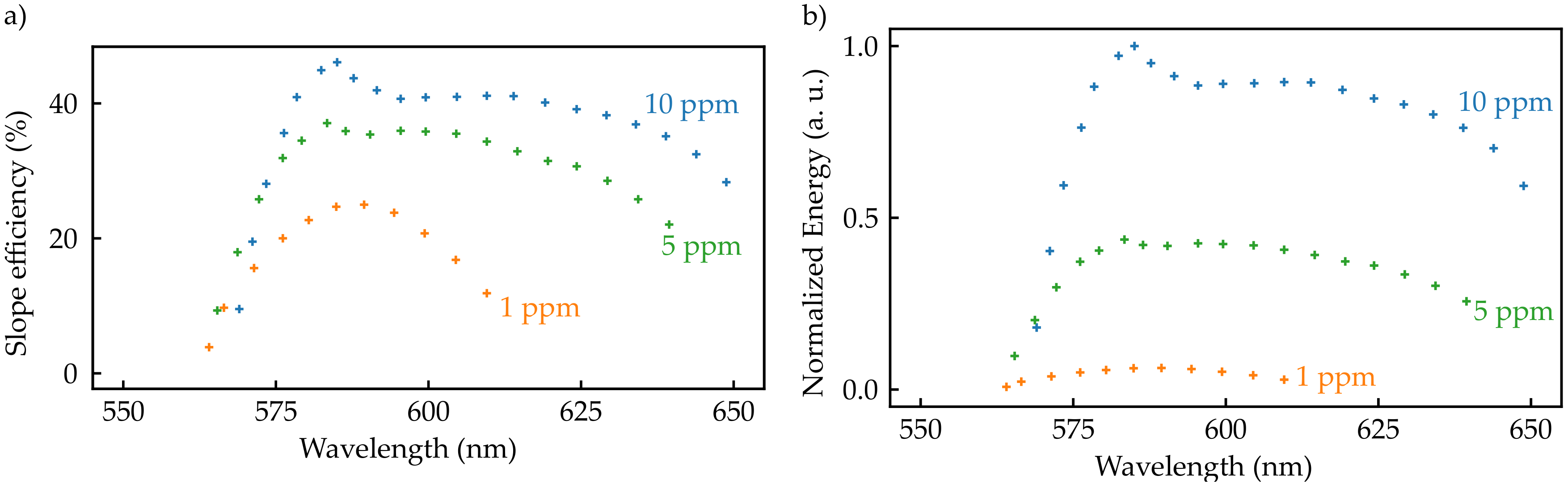

4.1. Optimization of the Laser Efficiency

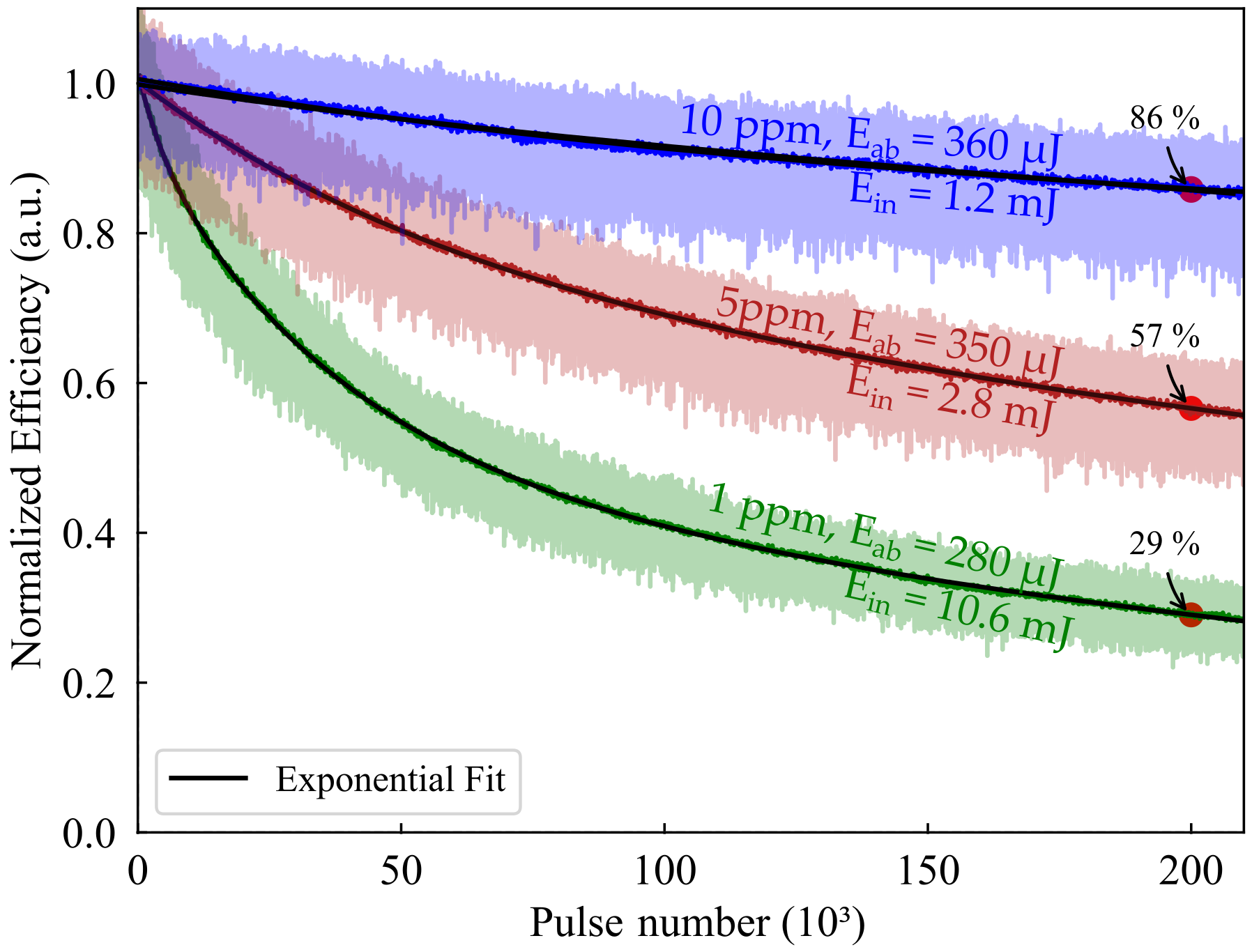

4.2. Long-Term Stability of the Laser Operation

4.3. Spectral Analysis

4.4. Numerical Results on the Wavelength Tunability

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Akbar, M.; Restaino, M.; Agah, M. Chip-scale gas Chromatography: From injection through detection. Microsyst. Nanoeng. 2015, 1, 15039. [Google Scholar] [CrossRef]

- Tao, J.; Zhang, Q.; Xiao, Y.; Li, X.; Yao, P.; Pang, W.; Zhang, H.; Duan, X.; Zhang, D.; Liu, J. A Microfluidic- Based Fabry-Pérot Gas Sensor. Micromachines 2016, 7, 36. [Google Scholar] [CrossRef] [PubMed]

- Paknahad, M.; Mcintosh, C.; Hoorfar, M. Selective detection of volatile organic compounds in microfluidic gas detectors based on “like dissolves like”. Sci. Rep. 2019, 9, 161. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Kim, T. Review of microfluidic approaches for surface-enhanced Raman scattering. Sens. Actuator B Chem. 2016, 227, 504–514. [Google Scholar] [CrossRef]

- Vaezi, M.; Seitz, H.; Yang, S. A review on 3D micro-additive manufacturing technologies. Int. J. Adv. Manuf. Technol. 2013, 67, 1721–1754. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Composites Part B 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Shu, Z.; Kemper, F.; Beckert, E.; Eberhardt, R.; Tünnermann, A. Highly sensitive on-chip fluorescence sensor with integrated fully solution processed organic light sources and detectors. RSC Adv. 2017, 7, 26384–26391. [Google Scholar] [CrossRef]

- Sandanayaka, A.; Matsushima, T.; Bencheikh, F.; Terakawa, S.; Potscavage, W.; Qin, C.; Fujihara, T.; Goushi, K.; Ribierre, J.-C.; Adachi, C. Indication of Current-Injection Lasing from an Organic Semiconductor. Appl. Phys. Express 2019, 12, 061010. [Google Scholar] [CrossRef]

- Kuriki, K.; Kobayashi, T.; Imai, N.; Tamura, T.; Nishihara, S.; Nishizawa, Y.; Tagaya, A.; Koike, Y.; Okamoto, Y. High-Efficiency Organic Dye-doped Polymer Optical Fiber Lasers. Appl. Phys. Lett. 2000, 77, 331–333. [Google Scholar] [CrossRef]

- Tagaya, A.; Koike, Y.; Kinoshita, T.; Nihei, E.; Yamamoto, T.; Sasaki, K. Polymer Optical Fiber Amplifier. Appl. Phys. Lett. 1993, 63, 883–884. [Google Scholar] [CrossRef]

- Kuriki, K.; Kobayashi, T.; Imai, N.; Tamura, T.; Koike, Y.; Okamoto, Y. Organic Dye-doped Polymer Optical Fiber Lasers. Polym. Adv. Technol. 2000, 11, 612–616. [Google Scholar] [CrossRef]

- Caspary, R.; Jakobs, F.; Kielhorn, J.; Ang, P.Y.; Cehovski, M.; Beck, M.; Johannes, H.-H.; Balendat, S.; Neumann, J.; Unland, S.; et al. Polymer Fiber Lasers. ICTON Proc. 2019, 1–4. [Google Scholar] [CrossRef]

- Zaremba, D.; Evert, R.; Kielhorn, J.; Jakobs, F.; Caspary, R.; Kowalsky, W.; Johannes, H.-H. Molecular weight variations in perylene-doped poly(methyl methacrylate) for luminescent solar concentrators. Polym. Int. 2018, 67, 1179–1185. [Google Scholar] [CrossRef]

- Ahmed, R.; Saif, M. Optical Properties of Rhodamine B Dye Doped in Transparent Polymers for Sensor Application. Chin. J. Phys. 2000, 11, 570–580. [Google Scholar]

- Bavali, A.; Parvin, P.; Mortazavi, S.Z.; Mohammadian, M.; Mousavi Pour, M.R. Red/blue spectral shifts of laser-induced fluorescence emission due to different nanoparticle suspensions in various dye solutions. Appl. Opt. 2014, 53, 5398–5409. [Google Scholar] [CrossRef]

- Kristoffersen, A.S.; Erga, S.R.; Hamre, B.; Frette, Ø. Testing Fluorescence Lifetime Standards using Two-Photon Excitation and Time-Domain Instrumentation: Rhodamine B, Coumarin 6 and Lucifer Yellow. J. Fluoresc. 2014, 24, 1015–1024. [Google Scholar] [CrossRef]

- Arrue, J.; Illarramendi, M.; Ayesta, I.; Jimenez, F.; Zubia, J.; Tagaya, A.; Koike, Y. Laser-Like Performance of Side-Pumped Dye-Doped Polymer Optical Fibers. IEEE Photonics J. 2015, 7, 7100611. [Google Scholar] [CrossRef]

- Sujecki, S. Photonics Modelling and Design; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2015. [Google Scholar]

- George, N.A.; Aneeshkumar, B.; Radhakrishnan, P.; Vallabhan, C.P.G. Photoacoustic study on photobleaching of rhodamine 6g doped in poly(methyl methacrylate). J. Phys. D Appl. Phys. 1999, 32, 1745–1749. [Google Scholar] [CrossRef]

- Kurian, A.; George, N.A.; Paul, B.; Nampoori, V.P.N.; Vallabhan, C.P.G. Studies on fluorescence efficiency and photodegradation of rhodamine 6G doped PMMA using a dual beam thermal lens technique. Laser Chem. 2002, 20, 99–110. [Google Scholar] [CrossRef]

- Arrue, J.; Jiménez, F.; Illarramendi, M.A.; Zubia, J.; Ayesta, I.; Bikandi, I.; Berganza, A. Computational Analysis of the Power Spectral Shifts and Widths Along Dye-Doped Polymer Optical Fibers. Photonics J. 2010, 2, 521–531. [Google Scholar] [CrossRef]

- Mhibik, O.; Leang, T.; Siove, A.; Forget, S.; Chenais, S. Broadly tunable (440–670 nm) solid-state organic laser with disposable capsules. Appl. Phy. Lett. 2013, 102, 041112. [Google Scholar] [CrossRef]

- Sinha, S. High power tunable dye lasers for photo-ionization applications. BARC Newsl. 2008, 297, 1–8. [Google Scholar]

- Peng, G.D.; Chu, P.L.; Xiong, Z.; Whitbread, T.W.; Chaplin, R.P. Dye-Doped Step-Index Polymer Optical Fiber for Broadband Optical Amplification. J. Lightwace Tech. 1996, 10, 2215–2223. [Google Scholar] [CrossRef]

- Al-Shamiri, H.A.S.; Abou Kana, M.T.H. Laser performance and photostability of Rhodamin B in solid host matrices. Appl. Phys. B 2010, 101, 129–135. [Google Scholar] [CrossRef]

- Arrue, J.; Jimenez, F.; Ayesta, I.; Illarramendi, M.A.; Zubia, J. Polymer-Optical-Fiber Lasers and Amplifiers Doped with Organic Dyes. Polymers 2011, 3, 1162–1180. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spelthann, S.; Unland, S.; Thiem, J.; Jakobs, F.; Kielhorn, J.; Ang, P.Y.; Johannes, H.-H.; Kracht, D.; Neumann, J.; Ruehl, A.; et al. Towards Highly Efficient Polymer Fiber Laser Sources for Integrated Photonic Sensors. Sensors 2020, 20, 4086. https://doi.org/10.3390/s20154086

Spelthann S, Unland S, Thiem J, Jakobs F, Kielhorn J, Ang PY, Johannes H-H, Kracht D, Neumann J, Ruehl A, et al. Towards Highly Efficient Polymer Fiber Laser Sources for Integrated Photonic Sensors. Sensors. 2020; 20(15):4086. https://doi.org/10.3390/s20154086

Chicago/Turabian StyleSpelthann, Simon, Stefanie Unland, Jonas Thiem, Florian Jakobs, Jana Kielhorn, Pen Yiao Ang, Hans-Hermann Johannes, Dietmar Kracht, Joerg Neumann, Axel Ruehl, and et al. 2020. "Towards Highly Efficient Polymer Fiber Laser Sources for Integrated Photonic Sensors" Sensors 20, no. 15: 4086. https://doi.org/10.3390/s20154086

APA StyleSpelthann, S., Unland, S., Thiem, J., Jakobs, F., Kielhorn, J., Ang, P. Y., Johannes, H.-H., Kracht, D., Neumann, J., Ruehl, A., Kowalsky, W., & Ristau, D. (2020). Towards Highly Efficient Polymer Fiber Laser Sources for Integrated Photonic Sensors. Sensors, 20(15), 4086. https://doi.org/10.3390/s20154086