A Fault Diagnosis Method of Rotating Machinery Based on One-Dimensional, Self-Normalizing Convolutional Neural Networks

Abstract

1. Introduction

- A fault diagnosis model based on 1D-SCNN is presented, which has a simple and compact architecture configuration with only a convolutional layer and a pooling layer. Compared with the conventional techniques, it can achieve competitive performance in terms of fault diagnosis accuracy and generalization capability.

- The scaled exponential linear units (SeLU) are employed to strengthen the features of the fault signal. With the self-normalizing properties, activations can maintain normalization when propagating through layers of the network. Therefore, SeLU can maintain the stability and convergence of the network, and enhance the generalization capability of the model.

- The -dropout algorithm is introduced into the feature extractor and classifier simultaneously, which not only can restrain the overfitting at the initial stage of training, but also should be able to accelerate the speed of the network’s parameters updating and further boost the generalization capability of the model.

- A series of experiments utilizing the Case Western Reserve University bearing dataset are conducted. The results demonstrate that the proposed method possesses good fault diagnosis accuracy and generalization capability, and provides an excellent solution for enhancing the reliability and maintainability of mechanical equipment.

2. One-Dimensional Convolutional Neural Networks

2.1. Feature Extractor

2.2. Classifier

3. Methodology

3.1. Overview

3.2. SeLU-Based Enhancement of Convolutional Fault Feature Extraction

3.3. -Dropout-Based Improvement of Pooling Layer Generalization Capability

3.4. SeLU and -Dropout-Based Advancement of Full-Connection Layer Generalization Capability

3.5. Training of 1D-SCNN

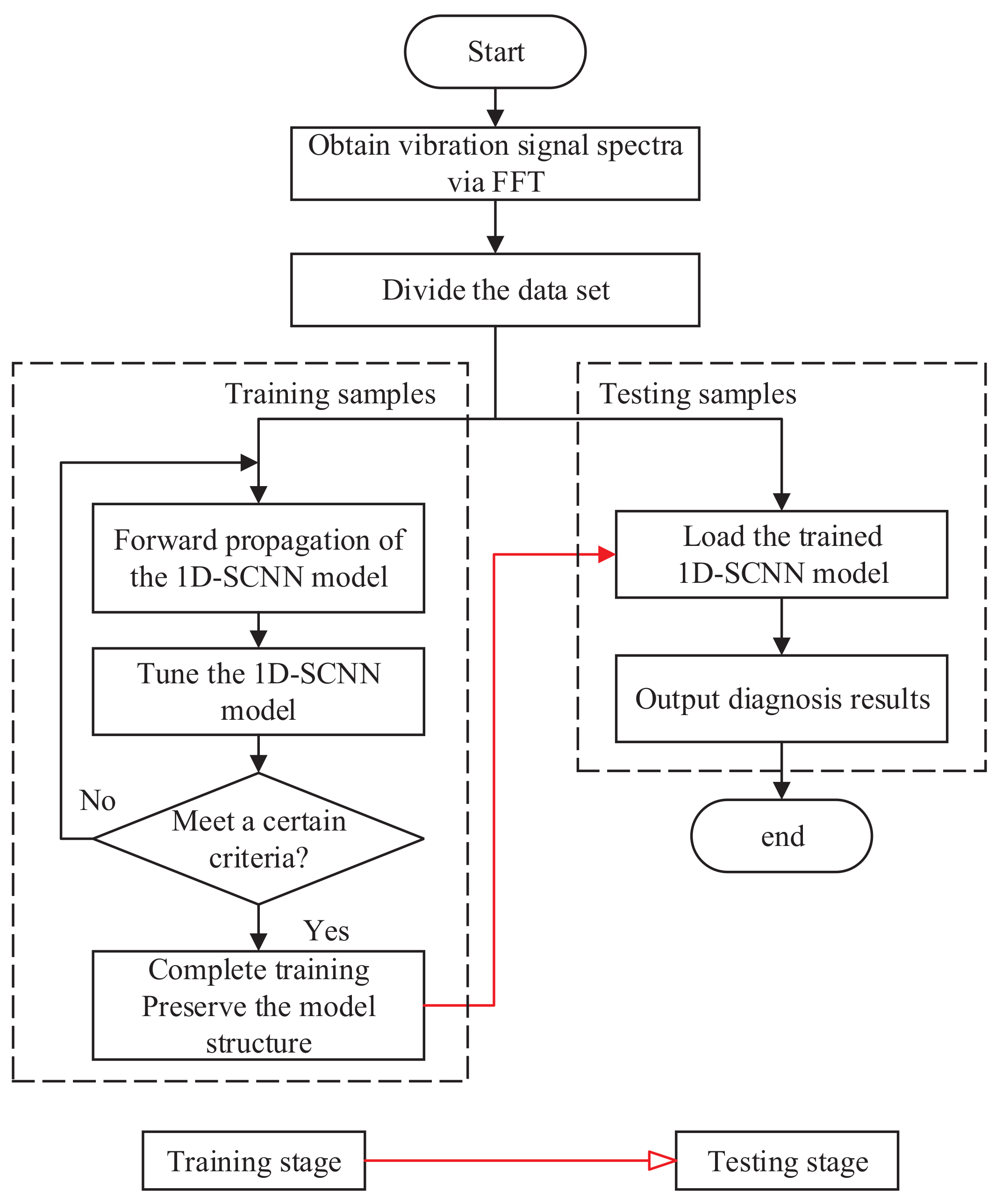

3.6. Fault Diagnosis Process

- The spectra of the vibration signals are obtained using the fast Fourier transform (FFT) at the raw signal length without the windowing function, and are used as input samples for the 1D-SCNN model.

- Randomly divide the input samples into a training sample set and a testing sample set with a ratio of 7:3. The training sample set serve as the input for the training stage of the model and the testing sample set is adopted for the testing stage.

- Train the 1D-SCNN model by the forward propagation and the backward propagation operations, and save the trained model after meeting a certain criterion.

- Load the trained fault diagnosis model and input the testing sample set into above diagnosis model to obtain the fault diagnosis results.

4. Experimental Results and Analysis

4.1. Dataset Description

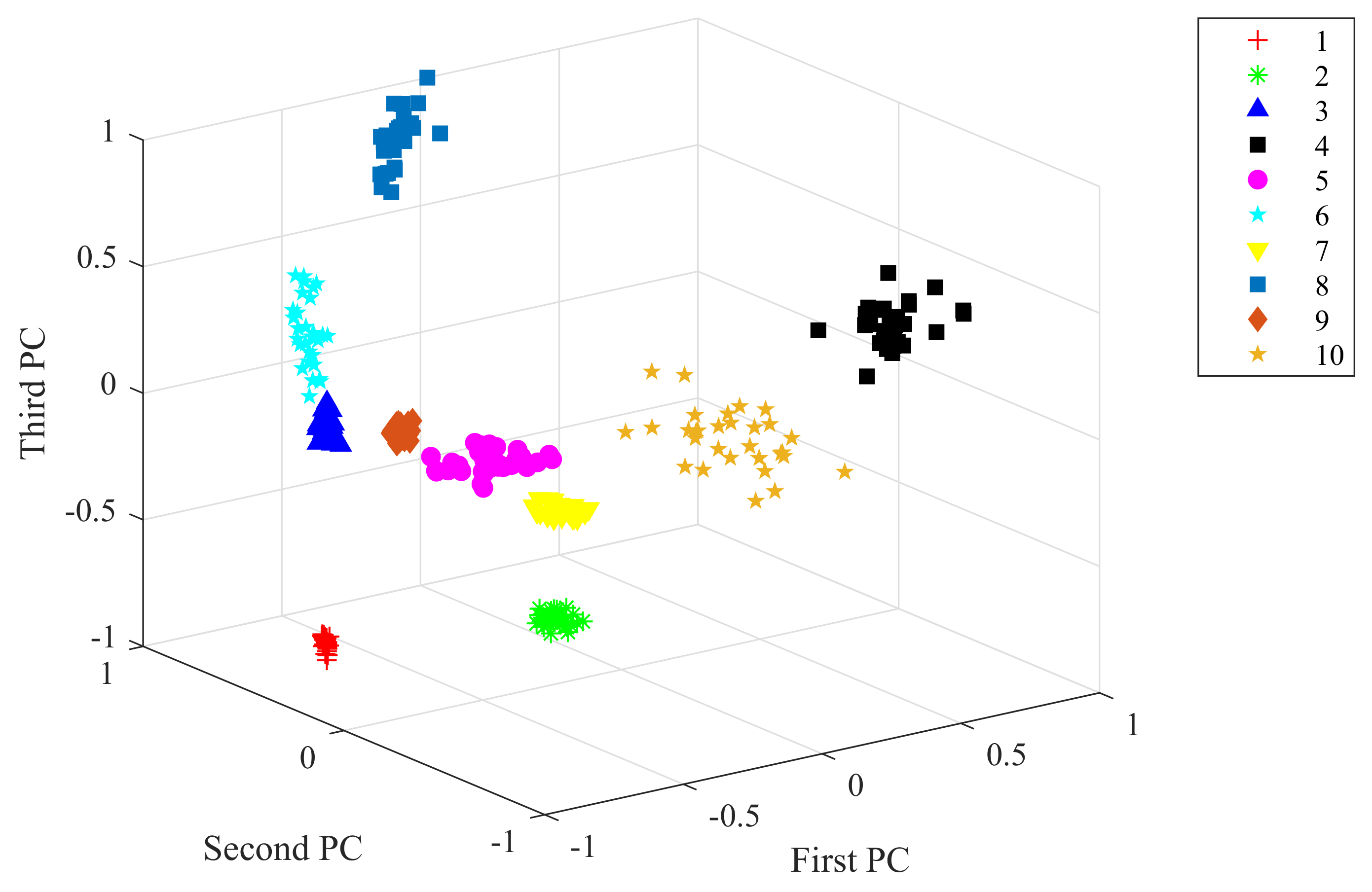

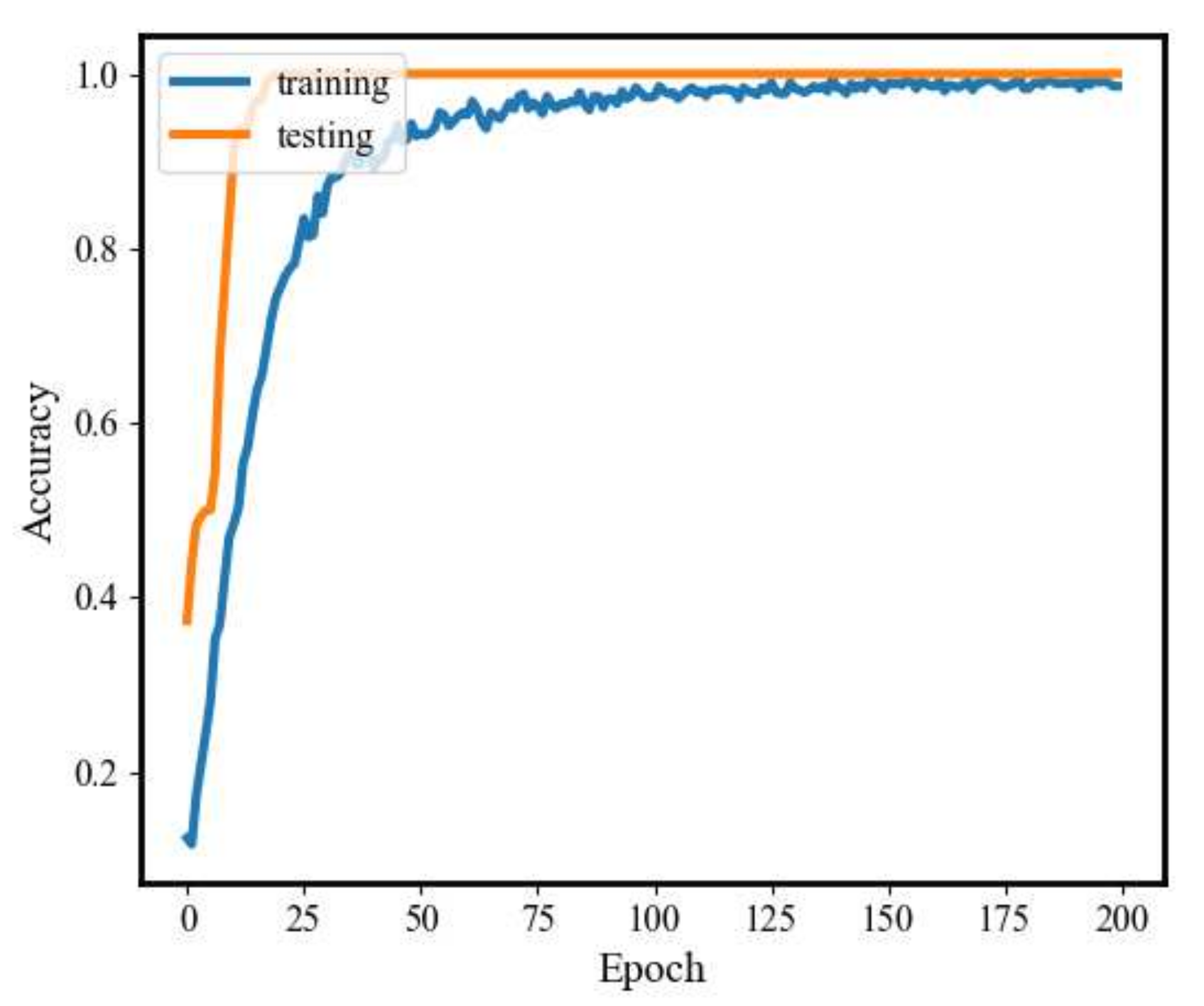

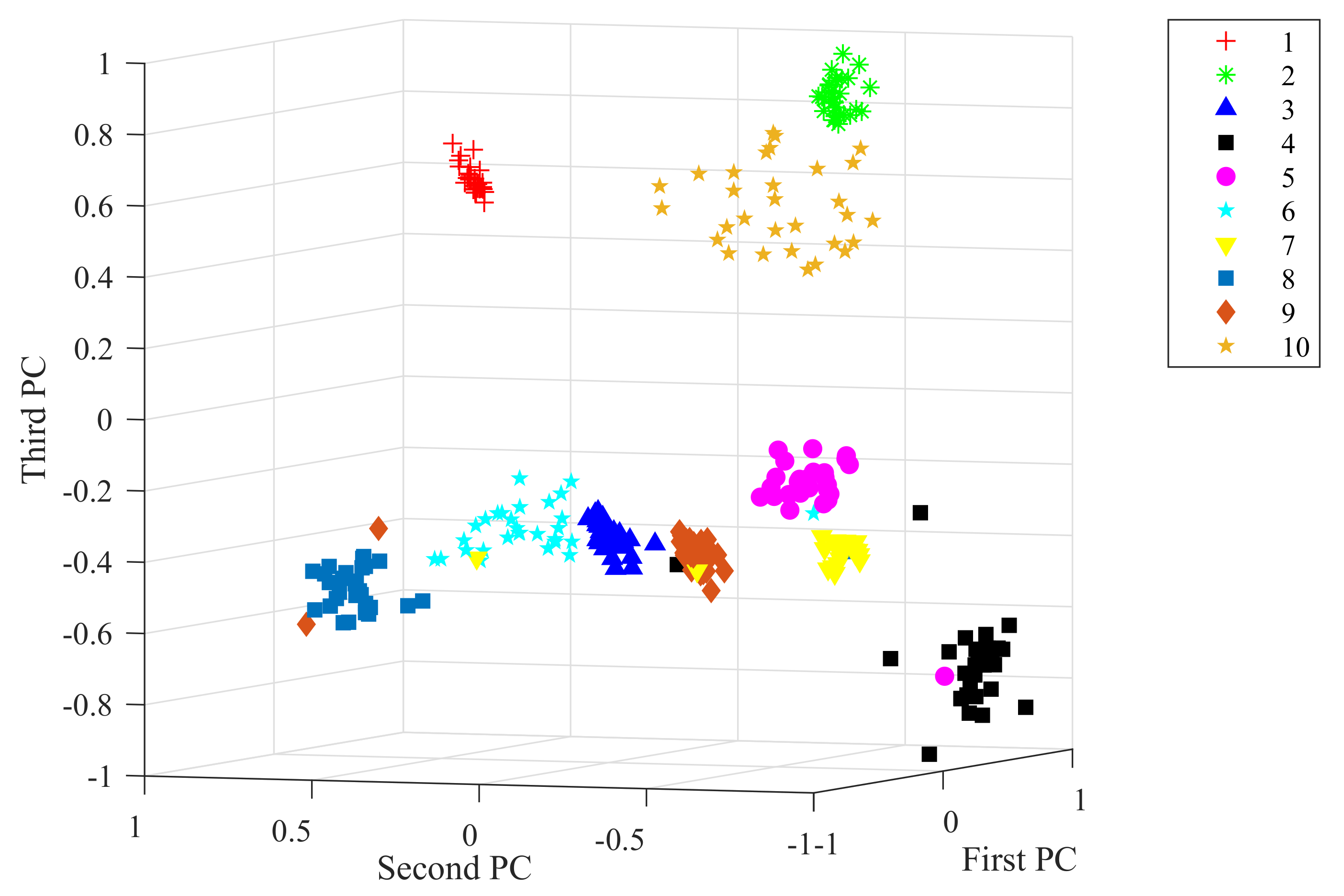

4.2. Results Analysis

4.2.1. Selection of Model Parameters

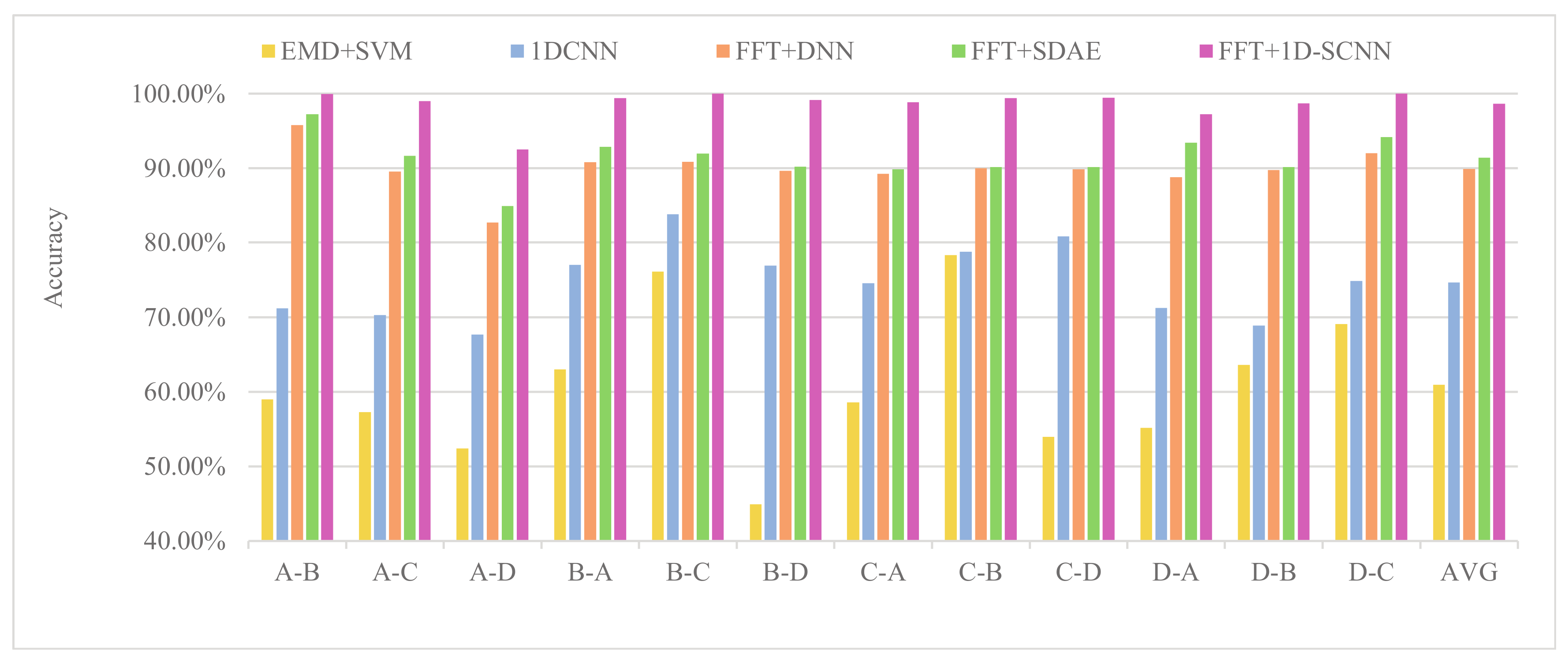

4.2.2. Fault Diagnosis Accuracy Assessment

4.2.3. Model Generalization Capability Assessment

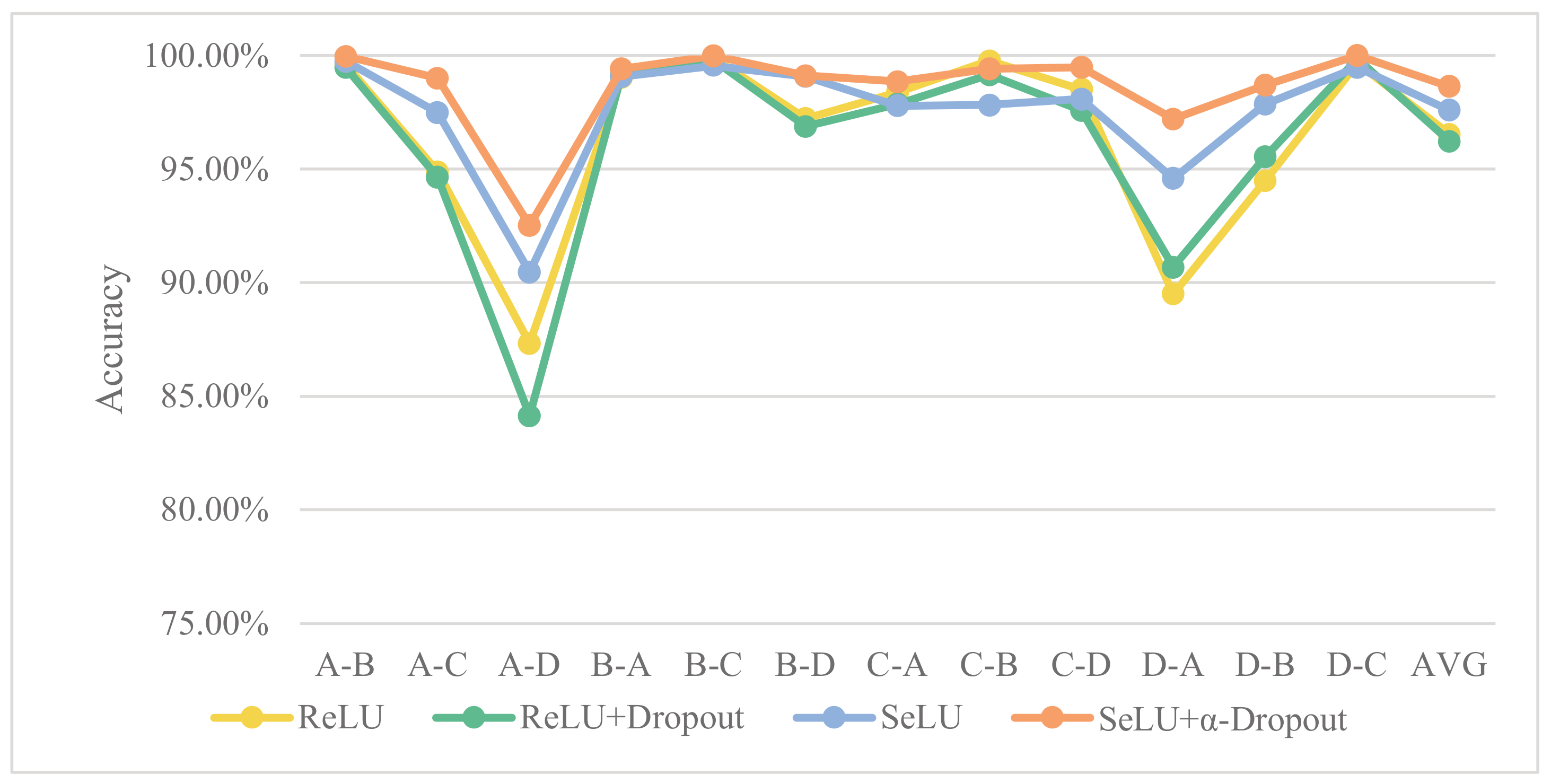

4.2.4. Influence of SeLU and -Dropout on Model Performance

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Frank, P.M. Analytical and Qualitative Model Based Fault Diagnosis-A survey and Some New Results. Eur. J. Control 1996, 2, 6–28. [Google Scholar] [CrossRef]

- Gao, Z.; Cecati, C.; Ding, S.X. A Survey of Fault Diagnosis and Fault-Tolerant Techniques—Part II: Fault Diagnosis With Knowledge-Based and Hybrid/Active Approaches. IEEE Trans. Ind. Electron. 2015, 62, 3768–3774. [Google Scholar] [CrossRef]

- Cheng, Z.; Hu, N. Quantitative damage detection for planetary gear sets based on physical models. Chin. J. Mech. Eng. 2012, 25, 1–7. [Google Scholar] [CrossRef]

- Park, J.; Ha, J.M.; Oh, H.; Youn, B.D.; Choi, J.; Kim, N.H. Model-Based Fault Diagnosis of a Planetary Gear: A Novel Approach Using Transmission Error. IEEE Trans. Reliab. 2016, 65, 1830–1841. [Google Scholar] [CrossRef]

- Kandukuri, S.T.; Klausen, A.; Karimi, H.R.; Robbersmyr, K.G. A review of diagnostics and prognostics of low-speed machinery towards wind turbine farm-level health management. Renew. Sustain. Energy Rev. 2016, 53, 697–708. [Google Scholar] [CrossRef]

- Gao, Z.; Cecati, C.; Ding, S.X. A survey of fault diagnosis and fault-tolerant techniques—Part I: Fault diagnosis with model-based and signal-based approaches. IEEE Trans. Ind. Electron. 2015, 62, 3757–3767. [Google Scholar] [CrossRef]

- Teng, W.; Ding, X.; Zhang, X.; Liu, Y.; Ma, Z. Multi-fault detection and failure analysis of wind turbine gearbox using complex wavelet transform. Renew. Energy 2016, 93, 591–598. [Google Scholar] [CrossRef]

- Feng, Z.; Qin, S.; Liang, M. Time–frequency analysis based on Vold-Kalman filter and higher order energy separation for fault diagnosis of wind turbine planetary gearbox under nonstationary conditions. Renew. Energy 2016, 85, 45–56. [Google Scholar] [CrossRef]

- Lei, Y.; Jia, F.; Kong, D.; Lin, J.; Xing, S. Opportunities and Challenges of Machinery Intelligent Fault Diagnosis in Big Data Era. J. Mech. Eng. 2018, 54, 94–104. [Google Scholar] [CrossRef]

- Knapp, G.M.; Wang, H.P. Machine fault classification: A neural network approach. Int. J. Prod. Res. 1992, 30, 811–823. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, Y.; Zhu, Y. Intelligent fault diagnosis of rolling bearing based on kernel neighborhood rough sets and statistical features. J. Mech. Sci. Technol. 2012, 30, 2649–2657. [Google Scholar] [CrossRef]

- Sun, R.; Yang, Z.; Luo, W.; Qiao, B.; Chen, X. Weighted sparse representation based on failure dynamics simulation for planetary gearbox fault diagnosis. Meas. Sci. Technol. 2012, 30, 1361–6501. [Google Scholar] [CrossRef]

- Wang, C.; Gan, M.; Zhu, C. Fault feature extraction of rolling element bearings based on wavelet packet transform and sparse representation theory. J. Intell. Manuf. 2015, 29, 937–951. [Google Scholar] [CrossRef]

- Deng, W.; Yao, R.; Sun, M.; Zhao, H.M.; Luo, Y.L.; Dong, C. Study on a novel fault diagnosis method based on integrating EMD, fuzzy entropy, improved PSO and SVM. J. Vibroeng. 2017, 19, 2562–2577. [Google Scholar]

- Wu, J.; Tang, T.; Chen, M.; Hu, T. Self-Adaptive Spectrum Analysis Based Bearing Fault Diagnosis. Sensors 2018, 18, 3312. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zhou, J.; Xiao, H.; Wang, E.; Xiao, J.; Zhang, H. Fault diagnosis based on comprehensive geometric characteristic and probability neural network. Appl. Math. Comput. 2014, 230, 542–554. [Google Scholar] [CrossRef]

- Pandya, D.H.; Upadhyay, S.H.; Harsha, S.P. Fault diagnosis of rolling element bearing with intrinsic mode function of acoustic emission data using APFKNN. Expert Syst. Appl. 2013, 40, 4137–4145. [Google Scholar] [CrossRef]

- Jia, F.; Lei, Y.; Lin, J.; Zhou, X.; Lu, N. Deep neural networks: A promising tool for fault characteristic mining and intelligent diagnosis of rotating machinery with massive data. Mech. Syst. Signal Process. 2016, 72, 303–315. [Google Scholar] [CrossRef]

- Wang, J.; Li, S.; Han, B.; An, Z.; Xin, Y.; Qian, W.; Wu, Q. Construction of a batch-normalized autoencoder network and its application in mechanical intelligent fault diagnosis. Meas. Sci. Technol. 2018, 30, 1361–6501. [Google Scholar] [CrossRef]

- Yang, Y.; Fu, P.; He, Y. Bearing fault automatic classification based on deep learning. IEEE Access 2018, 6, 71540–71554. [Google Scholar] [CrossRef]

- Shen, C.; Qi, Y.; Wang, J.; Cai, G.; Zhu, Z. An automatic and robust features learning method for rotating machinery fault diagnosis based on contractive autoencoder. Eng. Appl. Artif. Intell. 2018, 76, 170–184. [Google Scholar] [CrossRef]

- Yin, J.; Zhao, W. Fault diagnosis network design for vehicle on-board equipments of highspeed railway: A deep learning approach. Eng. Appl. Artif. Intell. 2016, 56, 250–259. [Google Scholar] [CrossRef]

- Gan, M.; Wang, C.; Zhu, C. Construction of hierarchical diagnosis network based on deep learning and its application in the fault pattern recognition of rolling element bearings. Mech. Syst. Signal Process. 2016, 72, 92–104. [Google Scholar] [CrossRef]

- Chen, Z.; Li, W. Multisensor Feature Fusion for Bearing Fault Diagnosis Using Sparse Autoencoder and Deep Belief Network. IEEE Trans. Instrum. Meas. 2016, 66, 1693–1702. [Google Scholar] [CrossRef]

- Shang, Z.; Liao, X.; Geng, R.; Gao, M.; Liu, X. Fault diagnosis method of rolling bearing based on deep belief network. J. Mech. Sci. Technol. 2018, 32, 5139–5145. [Google Scholar] [CrossRef]

- Lecun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef] [PubMed]

- Bengio, Y. Learning Deep Architectures for AI; Foundations and Trends in Machine Learning Series; Now Publishers Inc.: Hanover, MA, USA, 2009; Volume 2, pp. 1–127. [Google Scholar]

- Wen, L.; Li, X.; Gao, L.; Zhang, Y. A New Convolutional Neural Network Based Data-Driven Fault Diagnosis Method. IEEE Trans. Ind. Electron. 2017, 65, 5990–5998. [Google Scholar] [CrossRef]

- Guo, S.; Yang, T.; Gao, W.; Zhang, C. A Novel Fault Diagnosis Method for Rotating Machinery Based on a Convolutional Neural Network. Sensors 2018, 18, 1429. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, T.; Chu, F. Deep convolutional neural network based planet bearing fault classification. Comput. Ind. 2019, 107, 59–66. [Google Scholar] [CrossRef]

- Sun, Y.; Gao, H.; Guo, L.; Hong, X.; Song, X.; Zhang, J. A New Intelligent Fault Diagnosis Method and Its Application on Bearings. In Proceedings of the 13th International Conference on Damage Assessment of Structures, Porto, Portugal, 9–10 July 2019; pp. 618–628. [Google Scholar]

- Palaz, D.; Collobert, R.; Doss, M.M. Estimating phoneme class conditional probabilities from raw speech signal using convolutional neural networks. Comput. Sci. 2013, 1766–1770. [Google Scholar]

- Kim, Y. Convolutional neural networks for sentence classification. arXiv 2014, arXiv:1408.5882. [Google Scholar]

- Liu, X.; Zhou, Q.; Zhao, J.; Shen, H.; Xiong, X. Real-time and anti-noise fault diagnosis algorithm based on 1-D convolutional neural network. J. Harbin Inst. Technol. 2019, 51, 89–95. [Google Scholar]

- Levent, E.; Turker, I.; Serkan, K.A. Generic Intelligent Bearing Fault Diagnosis System Using Compact Adaptive 1D CNN Classifier. J. Signal Process. Syst. 2019, 91, 179–189. [Google Scholar]

- Zhang, W.; Peng, G.; Li, C.; Chen, Y. A new deep learning model for fault diagnosis with good anti-noise and domain adaptation ability on raw vibration signals. Sensors 2017, 17, 425. [Google Scholar] [CrossRef] [PubMed]

- An, J.; Ai, P.; Xu, S.; Liu, C.; Xia, J.; Liu, D. Intelligent fault diagnosis method for rotating machinery based on one dimensional convolution neural network. J. Nanjing Univ. Nat. Sci. 2019, 55, 133–142. [Google Scholar]

- Jing, L.; Zhao, M.; Li, P.; Li, X. A convolutional neural network based feature learning and fault diagnosis method for the condition monitoring of gearbox. Measurement 2017, 111, 1–10. [Google Scholar] [CrossRef]

- Liu, T.; Zhou, D.; Li, M.; Li, X. Multi-Resolution Fusion Convolutional Neural Network for Screw Locking Series. J. Xi’an Jiaotong Univ. 2020, 54, 161–178. [Google Scholar]

- Klambauer, G.; Unterthiner, T.; Mayr, A.; Hochreiter, S. Self-Normalizing Neural Networks. In Proceedings of the Advances in Neural Information Processing Systems, Long Beach, CA, USA, 4–9 December 2017; pp. 971–980. [Google Scholar]

- Srivastava, N.; Geoffrey, H.; Alex, K.; Ilya, S.; Ruslan, S. Dropout: A simple way to prevent neural networks from overfitting. J. Mach. Learn. Res. 2014, 15, 1929–1958. [Google Scholar]

- Zhang, W.; Li, C.; Peng, G.; Chen, Y.; Zhang, Z. A deep convolutional neural network with new training methods for bearing fault diagnosis under noisy environment and different working load. Mech. Syst. Signal Process. 2018, 100, 439–453. [Google Scholar] [CrossRef]

| Damaged Parts | None | Inner Race | Ball | Outer Race | Load | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Label | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| Damaged degree | 0 | 0.007 | 0.014 | 0.021 | 0.007 | 0.014 | 0.021 | 0.007 | 0.014 | 0.021 | ||

| A | train | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 0 |

| test | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | ||

| B | train | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 1 |

| test | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | ||

| C | train | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 2 |

| test | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | ||

| D | train | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 3 |

| test | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | ||

| Number of Convolutional Kernels | 8 | 16 | 32 | 64 |

|---|---|---|---|---|

| Accuracy | 98.51% | 98.64% | 98.54% | 98.44% |

| Network Structure | Monolayer | Bilayer | Trilayer | Four Layers | Five Layers |

|---|---|---|---|---|---|

| Accuracy | 98.64% | 97.6% | 96.37% | 93.62% | 91.84% |

| Number | Network Layer | Kernel Size/Step Length | Number of Kernels | Output Size |

|---|---|---|---|---|

| 1 | Convolution | 32 × 1/8 × 1 | 16 | 128 × 16 |

| 2 | Pooling | 2 × 1/2 × 1 | 16 | 64 × 16 |

| 3 | Full-connection | 64 | 1 | 64 × 1 |

| 4 | Softmax | 10 | 1 | 10 |

| Comparison Method | A | B | C | D | AVG |

|---|---|---|---|---|---|

| EMD+SVM | 80.90% | 84.77% | 93.27% | 96.57% | 88.88% |

| 1D-CNN | 92.59% | 85.22% | 91.29% | 92.82% | 90.48% |

| FFT+DNN | 100% | 100% | 100% | 100% | 100% |

| FFT+SDAE | 100% | 100% | 100% | 100% | 100% |

| FFT+1D-SCNN | 99.81% | 100% | 100% | 100% | 99.95% |

| Comparison Method | A | B | C | D | AVG |

|---|---|---|---|---|---|

| ReLU | 99.78% | 100% | 100% | 100% | 99.95% |

| ReLU + Dropout | 99.82% | 100% | 100% | 100% | 99.96% |

| SeLU | 99.90% | 100% | 100% | 100% | 99.95% |

| SeLU + -Dropout | 99.81% | 100% | 100% | 100% | 99.95% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Yin, S.; Chang, Y.; Gao, T. A Fault Diagnosis Method of Rotating Machinery Based on One-Dimensional, Self-Normalizing Convolutional Neural Networks. Sensors 2020, 20, 3837. https://doi.org/10.3390/s20143837

Yang J, Yin S, Chang Y, Gao T. A Fault Diagnosis Method of Rotating Machinery Based on One-Dimensional, Self-Normalizing Convolutional Neural Networks. Sensors. 2020; 20(14):3837. https://doi.org/10.3390/s20143837

Chicago/Turabian StyleYang, Jingli, Shuangyan Yin, Yongqi Chang, and Tianyu Gao. 2020. "A Fault Diagnosis Method of Rotating Machinery Based on One-Dimensional, Self-Normalizing Convolutional Neural Networks" Sensors 20, no. 14: 3837. https://doi.org/10.3390/s20143837

APA StyleYang, J., Yin, S., Chang, Y., & Gao, T. (2020). A Fault Diagnosis Method of Rotating Machinery Based on One-Dimensional, Self-Normalizing Convolutional Neural Networks. Sensors, 20(14), 3837. https://doi.org/10.3390/s20143837