Local Seeing Measurement for Increasing Astrophysical Observatory Quality Images Using an Autonomous Wireless Sensor Network

Abstract

1. Introduction

- Indoor’s dome seeing: It arises from the differences in temperature between the interior face of the dome, the different elements and the temperature of the air inside it. It is calculated following Equation (1) based on the development of the work in [5]:where is the difference in temperature between the interior surface of the dome and the temperature of the indoor ambient air.

- Outdoor’s dome seeing: Here, the turbulence is originated due to the temperature differences between the outer surface of the dome and the local temperature of the air that surrounds it. It is calculated following Equation (2) based on the analysis performed by the authors of [6,7]:where is the difference in temperature between the outer surface of the dome and the temperature of the ambient air that surrounds it.

- A comparison of thermistor devices to increase temperature reading accuracy and reducing the node power consumption.

- A construction of sensor nodes with data transfer capabilities using the Zigbee technology.

- A deployment of a wireless sensor network to acquire temperature data along the dome.

- A graphical user interface environment to receive in real time the measured temperature.

2. Materials and Methods

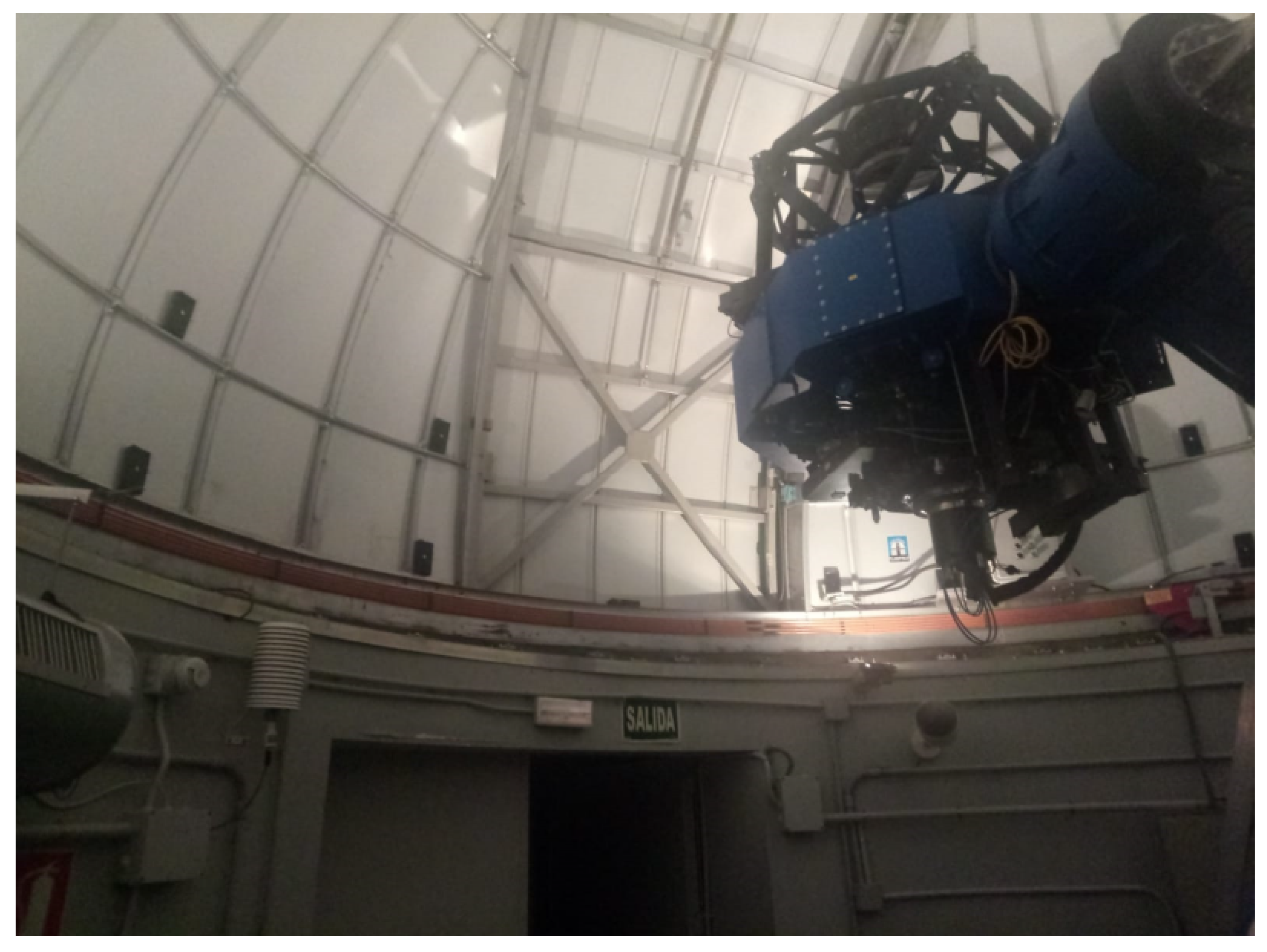

2.1. Experimental Facilities

2.2. Communication Module

- Reliability: The sensors can fail due to blockages, energy losses, environmental damage, interference, etc. The failure of any sensor node should not affect the overall operation of the network. Therefore, the network should continue operating in the event of operational losses of one of its nodes.

- Simplicity: Wired sensors increase both the deployment and the maintenance complexity and, limiting their mobility along the space. Wireless sensors are suitable to simplify the network design by solving the above-wired issues.

- Scalability: The number of sensors deployed in the environment to study can range from a few nodes to thousands of them. Sensor networks should allow adding and eliminating nodes according to the needs of the task to be performed.

- Topology: The working configuration mode of a network is key to assure a communication flow between all nodes.

- Size: The nodes should adapt to any environment for a fast and simple deployment, and thus, the smaller the hardware component, the better.

- Consumption: As the nodes in the sensor networks can only be equipped with a limited power source, the maximum time of use of it is essential.

2.3. Temperature Sensors

2.3.1. Preliminary Requirements

2.3.2. TMP36 Sensor

2.3.3. LMT84 Sensor

2.3.4. PR103J2 Sensor

2.3.5. Sensor Election

- The highest resolution precision results are achieved with the NTC thermistor.

- The price of the NTC thermistor (including the resistances) is almost ten times higher than the LMT84.

- The consumption is of 50 A and 5.4 A for the LMT84 sensor when it is measuring and on standby, respectively. While in the worst-case scenario using the NTC thermistor continuously (with the voltage divider) it is about 15.3 A (see Equation (8)).

2.3.6. Sensor Calibration

- Linearize the behavior with a circuit in a trade-off of the required precision measurements.

- Use the parameter B0/50 from the manufacturer and the Steinhart-Hart equation [28] to convert the values of resistance in temperature. However, the table resistance/temperature from the manufacturer and the results do not match due to the lack of second order parameters.

- Perform a quadratic regression from the values by the manufacturer to find the most fitting curve. For this purpose, it has been used Matlab, specifically the curve fitting tool, obtaining the equation that fits the data provided and whose root-mean-square error (RMSE) is of the order of the hundredth of degrees Celsius:

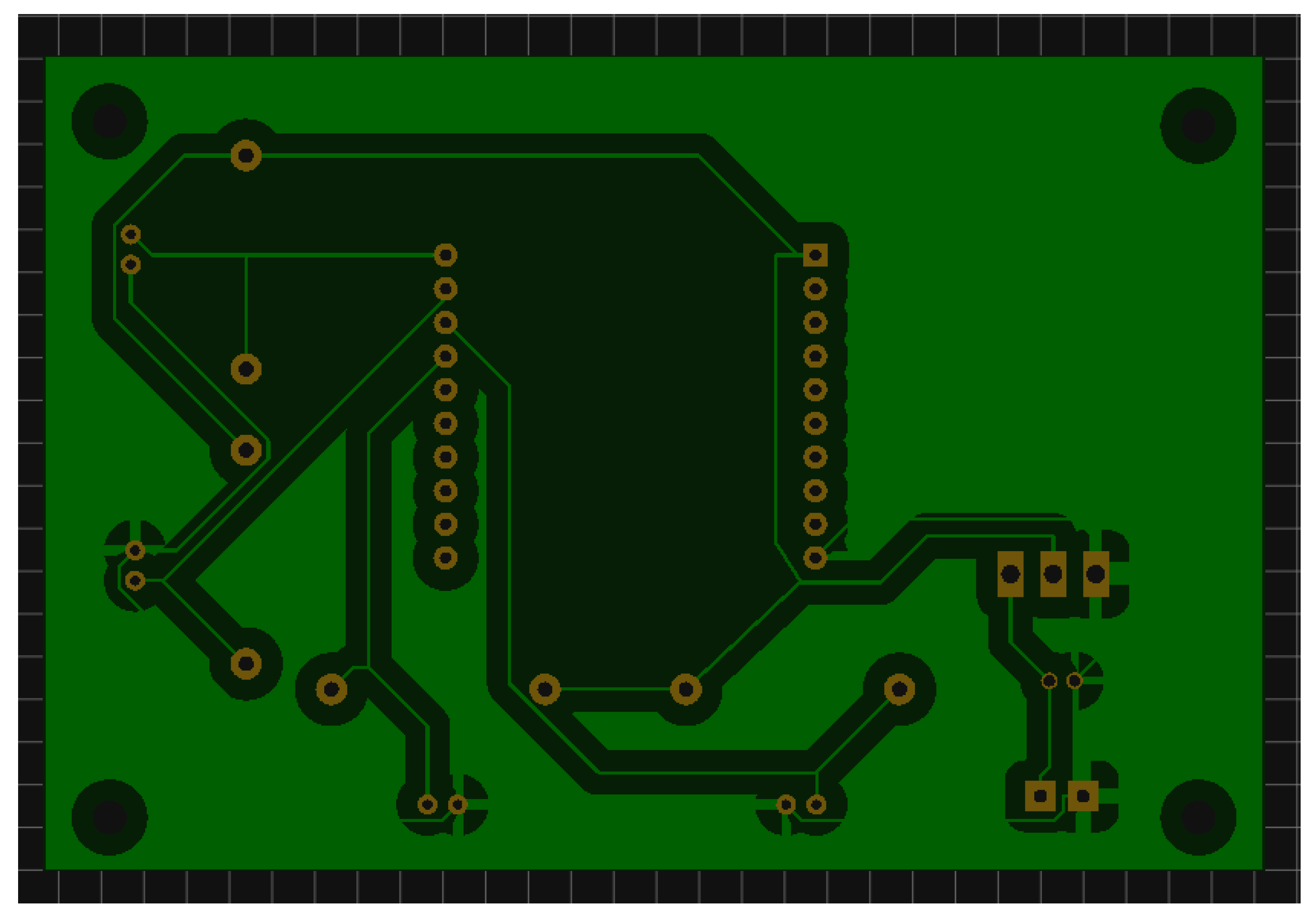

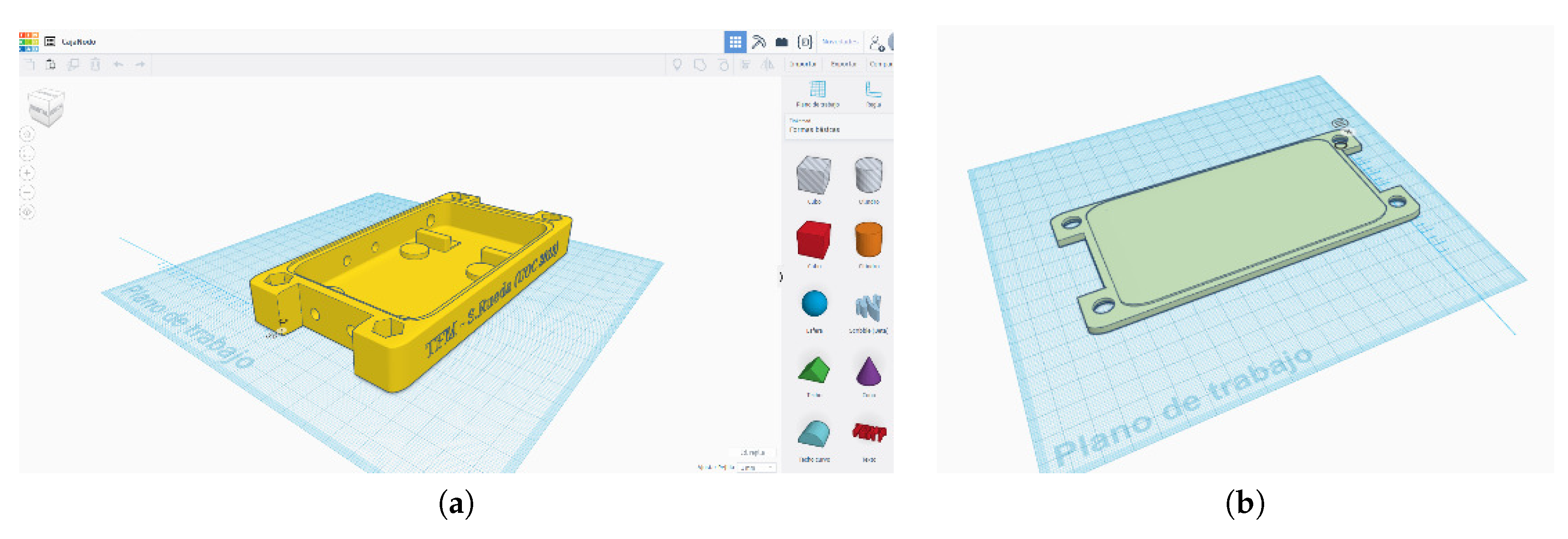

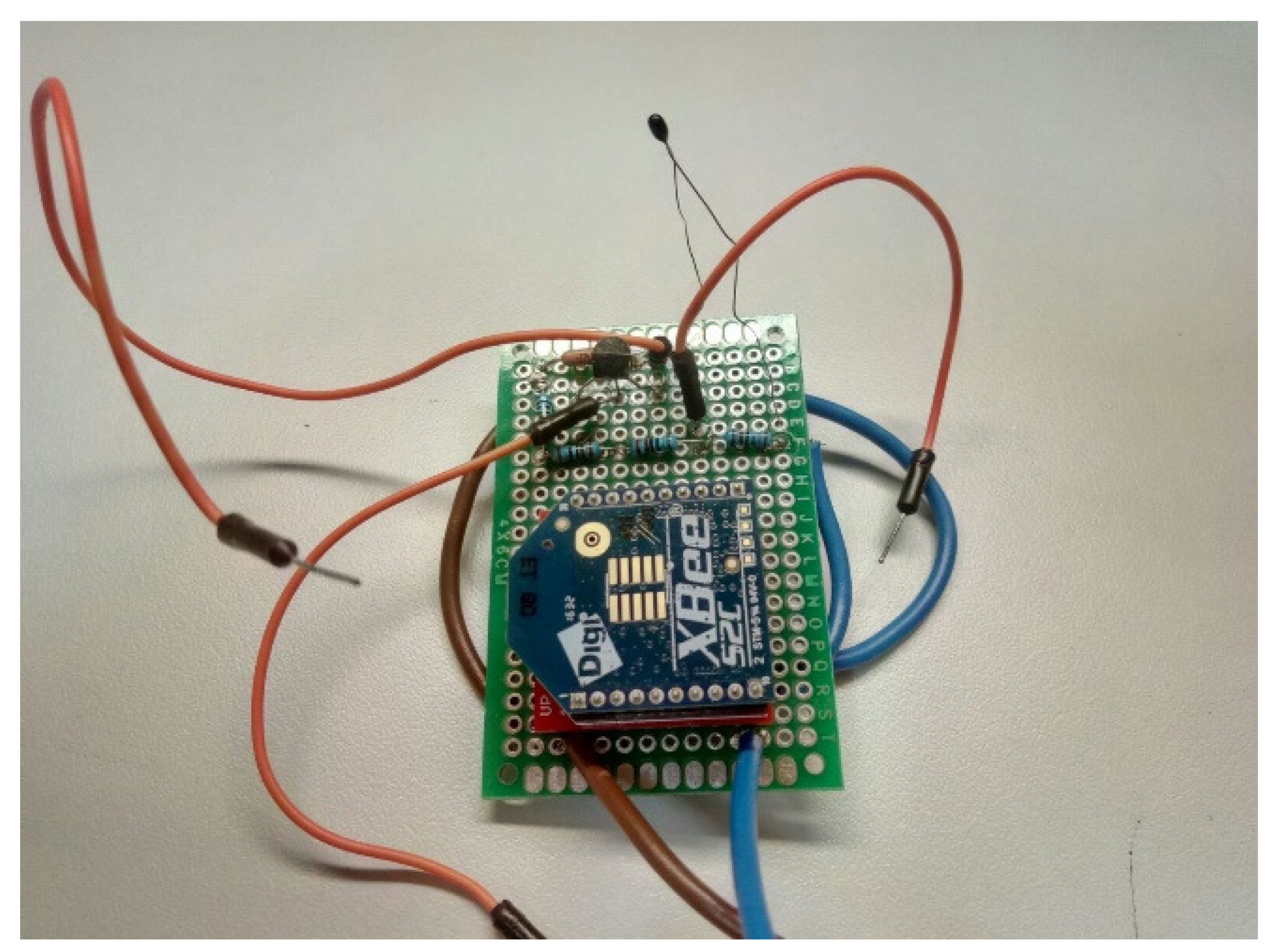

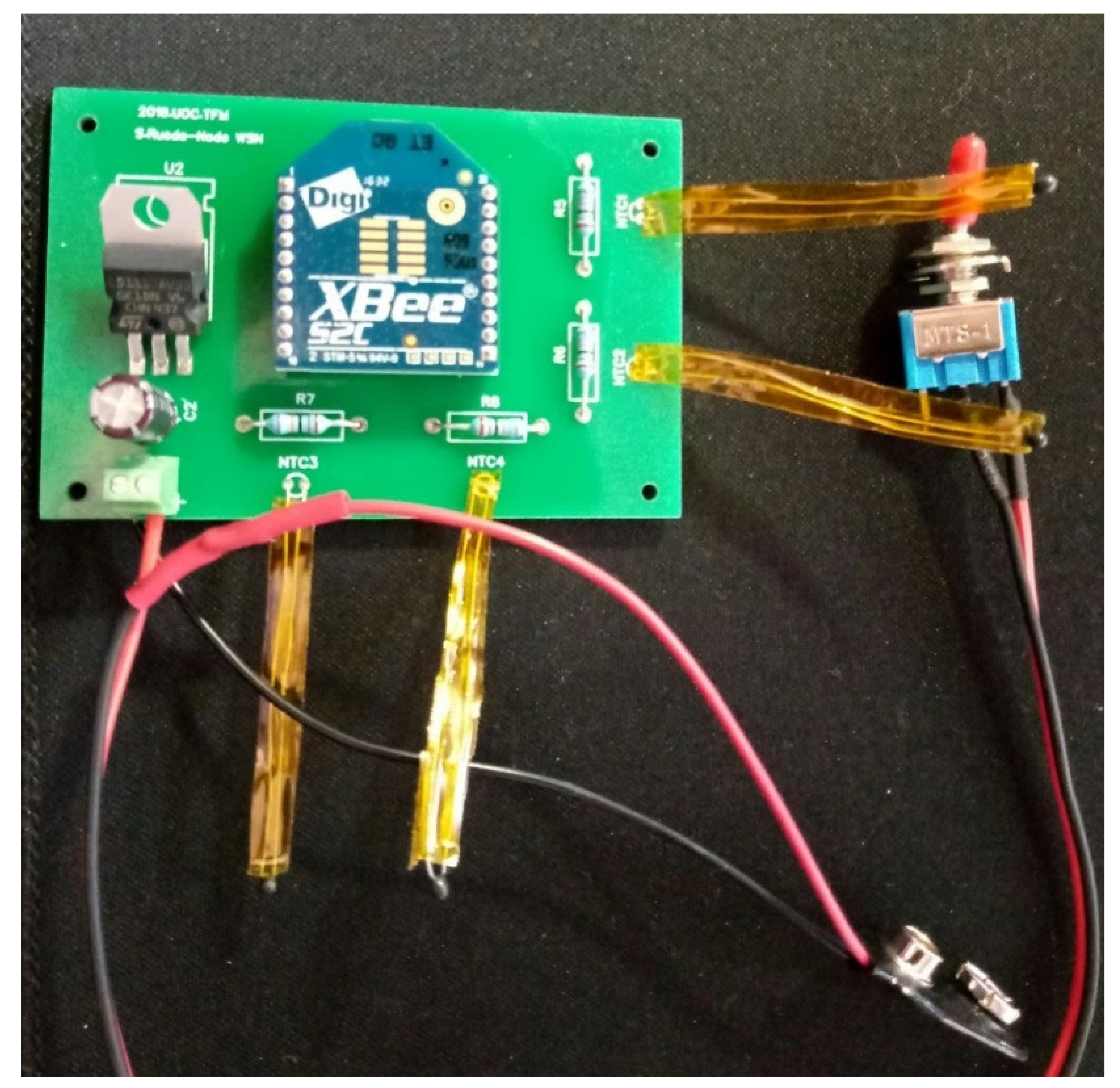

2.4. PCB Fabrication

- Energy source (battery) system:

- -

- Two pole terminal block, 2.54 mm for PCB

- -

- 9 V battery connector (4)

- -

- Micro switch (on/off)

- -

- Battery element (c.f. Section 2.5)

- Tension conditioner system:

- -

- Electrolytic capacitor 16V 100 F

- -

- Tension regulator LDO 3.3 1 A

- Node and conditioning system for PCB:

- -

- Digi XBee S2C node

- -

- 10 pins socket

- Measurement elements:

- -

- Thermistors PR103J2 10K 0.05 °C

- -

- Low tolerance resistance 201 K

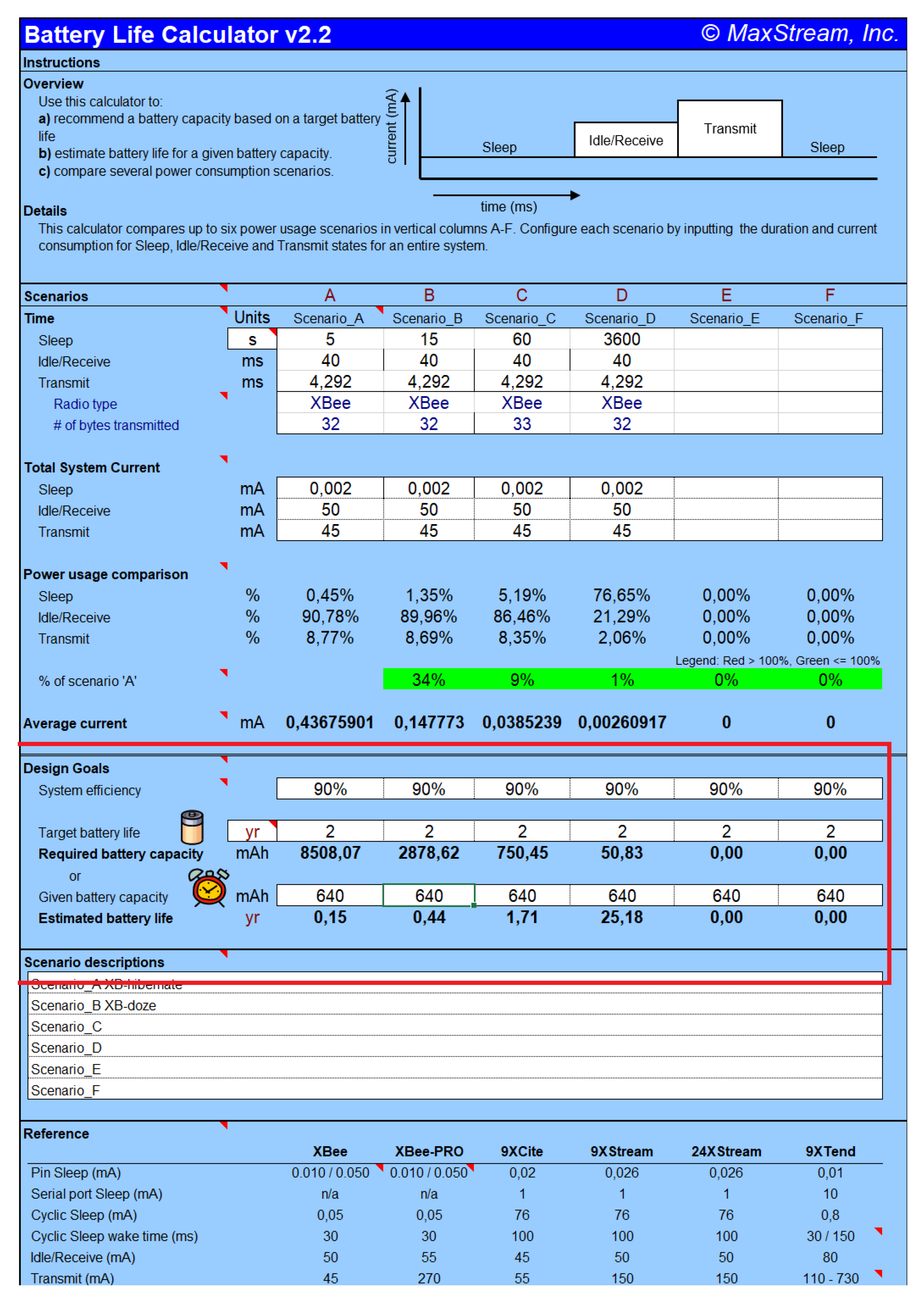

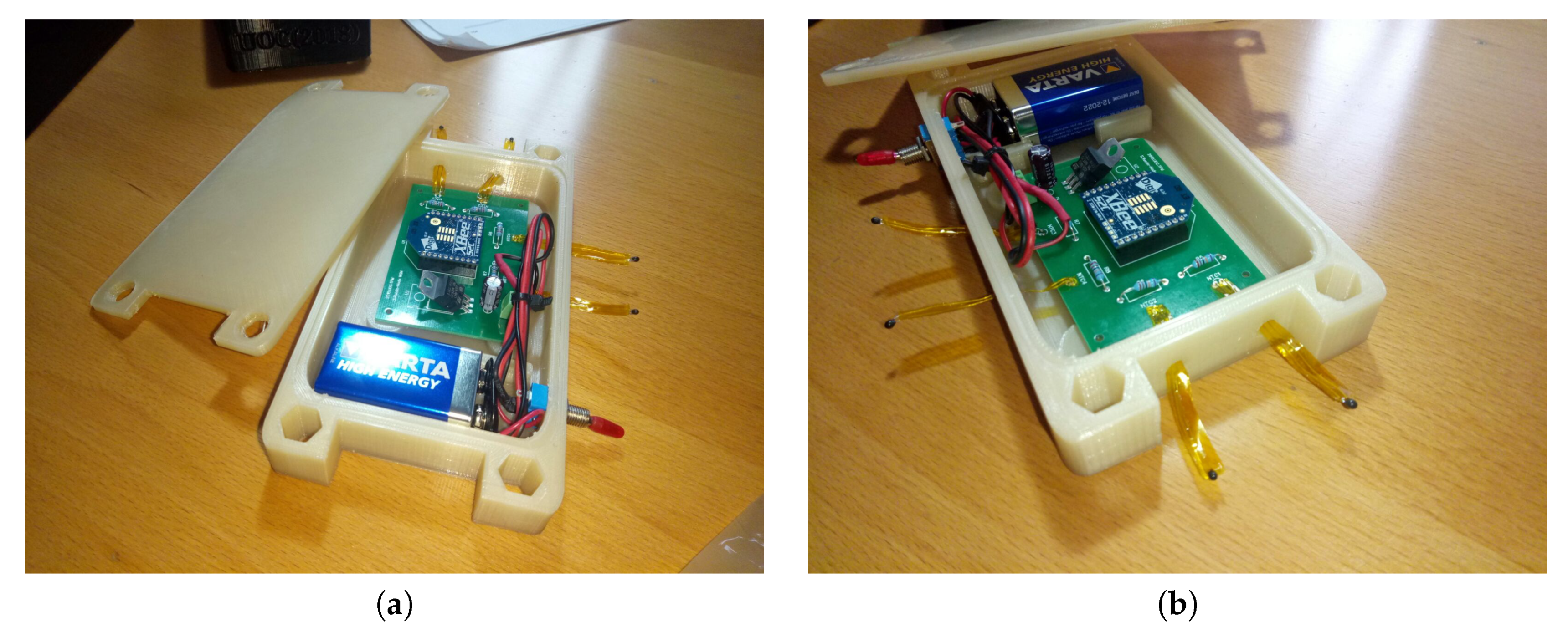

2.5. Battery System

- The temperature conditions can affect the performance of the batteries. Thus, in environments with non-extreme temperature conditions, the batteries are well preserved. On the contrary, in both very hot and cold environments, batteries may lose effectiveness and not be able to provide the expected performance. The OAJ is a center where temperatures tend to be very mild in summer, so this point would not affect the battery. However, the environment turns extremely cold in winter, and therefore, we should take this point into account. Moreover, future tasks may include carrying out measurements in warmer environments (generator room, electrical panels, etc.), then, the battery performance could also be affected.

- The actual capacity of the batteries is not linear and depends on supplied current. Even though the manufacturer provides us with a nominal load, it is worth bearing in mind that the real one will depend on supplied current.

- 45 mA (maximum) in transmission mode,

- 50 mA (maximum) in reception mode, and

- <10 A in sleep mode.

- Alkaline: It is the most common type of battery for domestic use, its main advantages are its low cost, the fact that they can be easily acquired, and that they are ideal for applications with low current demand at ambient temperature. However, they have two drawbacks: the first is that their performance declines a lot for high current consumption and second and more important in our case, that their performance gets much worse at very cold temperatures, which occurs in winter at OAJ.

- Lithium: There is a wide variety of lithium batteries on the market, however, they all have a common behavior, and they work better at low temperatures than alkaline batteries, however, their price is multiplied by a factor of three or four if we compare with these alkaline batteries.

- Nickel–metal hydride: It is high quality rechargeable batteries, one of its advantages is that they do not lose performance after many recharge, something that happens with the nickel-cadmium battery. This kind of battery can be considered as an improvement of the alkaline since they behave better at low temperatures and with high current demand. As regards its price, it can be found, approximately, at double the price of alkaline batteries.

2.6. Waterproof Case

2.7. Data Collector System

3. Results

3.1. Prototype Implementation

3.2. Laboratory Tests

- Validation of the radio signal range: The nodes were separated more than 20 m from the collector node without loss of data, which is totally satisfactory as no separation between end nodes and the collector node greater than 10 m is expected within the dome

- Validation of the system of fixation by magnets: The nodes were attached to metal surfaces and subjected to vibrations and traction without any node being detached. As indicated, each node is equipped with four neodymium magnets that support more than 2 kg each.

- Precision in the measurement: The values captured by the nodes were contrasted with a meteorological station and with an infrared thermometer. Although there were no large discrepancies in the measurements, the differences in the measurements varied, according to the acquisition system used, between 0.5 and 1 °C. This makes this test simply give us a guiding idea of the validity of the developed system. Finally, as has been said, we chose, on the one hand, to measure the input voltage, which was done with a good quality multimeter (Fluke FLUKE-87-V/EUR) in all entries comparing their value with that shown by the software developed, and on the other hand, repeating the measurements placing different sensors at the exact same point without, in any case, appreciating significant differences (at some time, at most of the order of hundredths of a degree). As has been said, in the long term it would be interesting to perform a more exhaustive calibration of the sensors; however, this point is validated, especially if even in the case that the error may exist, it is an error of the same order in all the nodes and in all the sensors and therefore it is not significant if we work with differences between them. Moreover, indicate that the nodes have been subjected to temperatures ranging from 3 °C (inside a refrigerator) to 37 °C with a correct response in the measurement.

- Robustness of the software: Software uses a multithreaded implementation, one thread for each node and one for failure events detection. In addition, Zigbee WSN-based networks are resilient to nodes’ failures. The proposed system has been left running with all nodes for periods of time ranging from a couple of hours to three days, and in its final version, the software is considered fully stable and ready for production.

- Battery life with different node parameters: The Digi XBee nodes provide few parameters to adapt their communication behavior according to the goal. Depending on those communication parameters, the battery life varies. One of the most important parameters affecting the battery life is the sleep mode. The sleep mode is used to reduce energy consumption and therefore increase the life of the batteries. They are based on the use of what is known as indirect messages, these types of messages occur when, during one of those “dream” cycles, the coordinator or router must store the message to be sent to the node when it wakes up, this is possible because when this awakening of a node occurs, it sends a message to its parent device to know if there is any data or request pending. The coordinator node is only able to save an indirect message for each node, that is, it cannot save a message queue per node. In addition, the coordinator stores the message during a period of 2.5 times the time marked in the time before sleep (ST) parameter. A remote device is activated once per period and sends a request to the coordinator to know if there is an indirect message for him. If it does not exist, the node will return to sleep mode during another new cycle, this process consumes approximately 30 ms per cycle. On the other hand, if there is a pending message for the remote node, the coordinator will transmit this direct message, and the remote node will remain awake according to the ST parameter, during which time the entire message must be received. We have performed six tests (see Table 2) modifying the following parameters to study how long the battery life stays.

- -

- Sleep period (SP): period of time that a final device is in sleep mode (valid values from 320 ms to 28,000 ms).

- -

- Number of cyclic sleep periods (SN): Indicates the number of cycles that the device will consider for the rest periods and therefore for the timeouts, this is done by setting the sleep options (SO) parameter that will be seen later and allows the extension of the resting periods of the nodes (valid values from 0x1-0xFFFF).

- -

- Time before sleep (ST): Defines the period for the reception of the indirect message before entering sleep mode (valid values from 0x1-0xFFFE).

- -

- Sleep options (SO): This parameter admits to values: 2-always awake during the whole ST period and 4-Enables extended sleep mode (sleeps during SP×SN milliseconds).

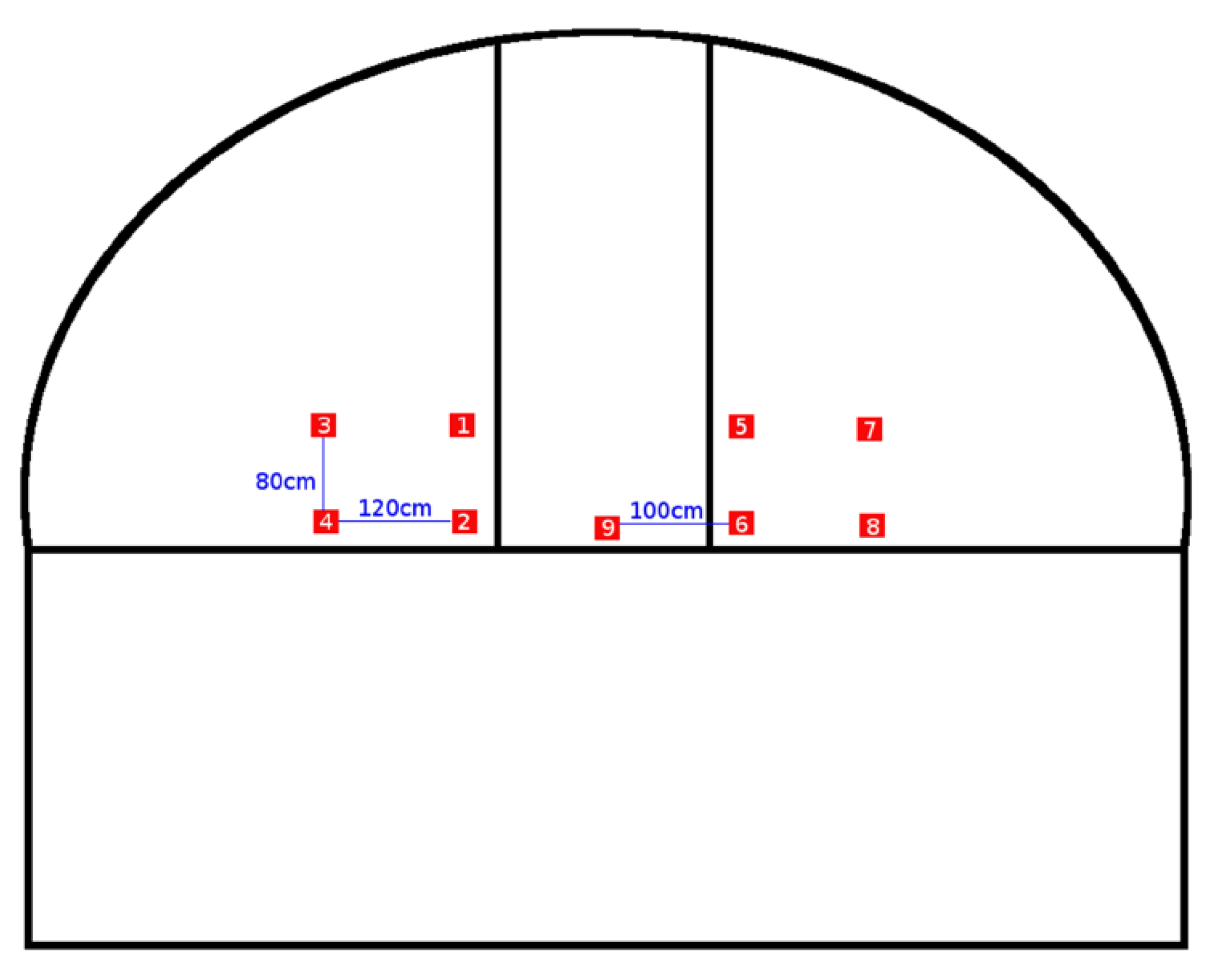

3.3. Real Location Experiment Design

3.4. Software Monitoring System

- Drop-down menu that allows you to select a specific node, from REMOTE_1 to REMOTE_9.

- This panel shows the temperature difference in °C between pairs of sensors of each node, that is, sensor1-sensor2 and sensor3-sensor4. On the right side, the current, maximum, and minimum values.

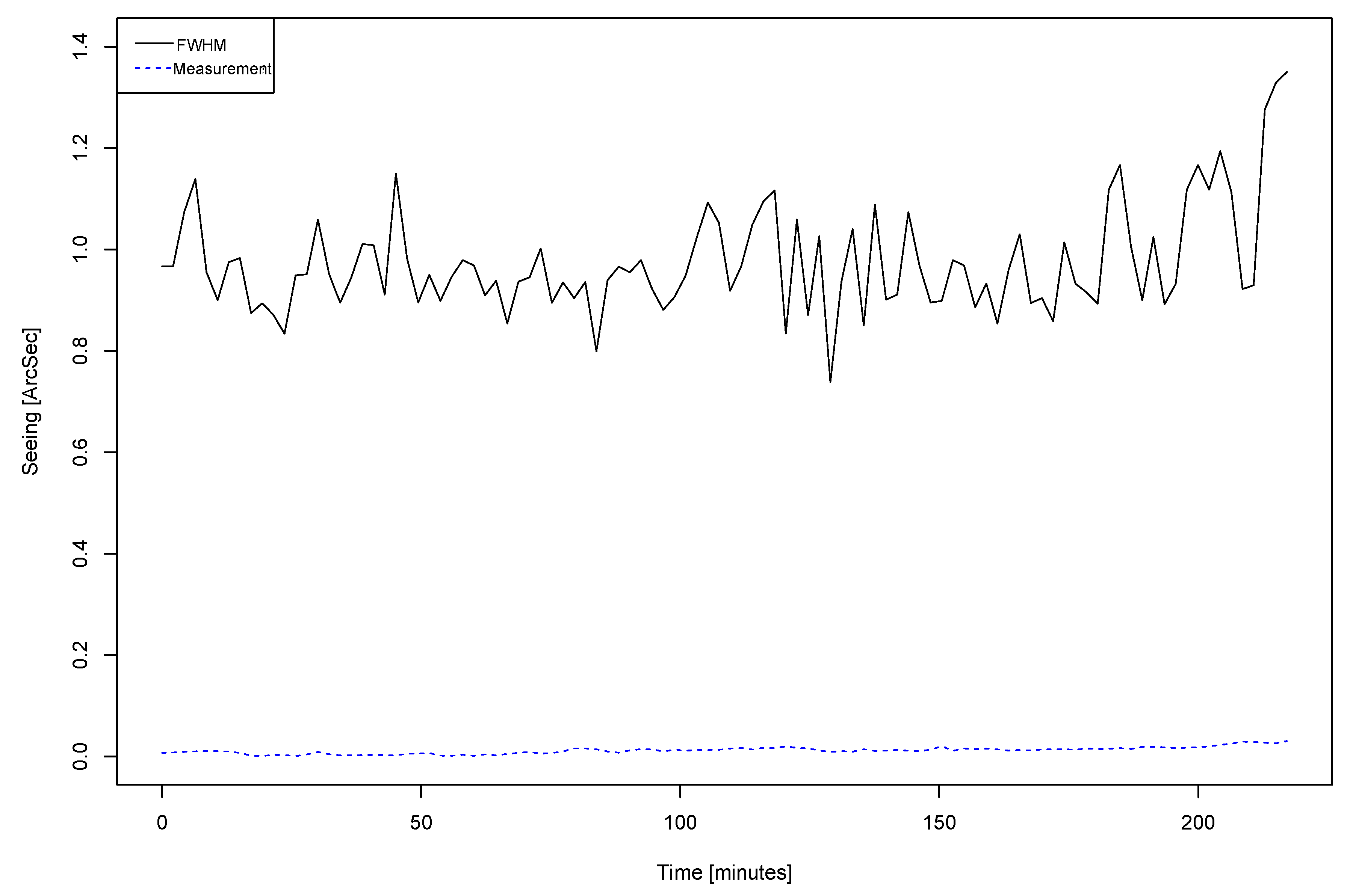

- Here the FWHM values are shown in arc seconds of each image acquired by the T080 telescope, on the right, the maximum, minimum and current values are also shown. The intuition behind the FWHM measurement can be explained in the following example. Assuming an observed star through a telescope, the star can be represented by its brightness vs the pixel position. If you represent those parameters in a plot, you will get a Gaussian like curves that come up and drop back down to the background value. Statistically there are no zero values on both sides of the curve, therefore it is almost impossible to measure the true diameter of a star; therefore, what astronomers do is they look at the height of the Gaussian representation, they divide it in half and then they measured the width of the star at that 1/2 point, this line is a measure of the full-width at half of the maximum height of the star’s profile. To determine the contribution in seconds of arc that the differences in temperature in C have on the FWHM, it will be necessary to carry out statistical studies that allow us to obtain correlation values between both physical parameters; however, we expect to reach some simple relationships such as those obtained by the works of D. Blanco [4].

- In this section there are four graphs, one for each thermistor of the selected node, showing the temperature history in C, the maximum, minimum, and current value.

- An image of the selected node with the current temperature value (C) calculated for each sensor is displayed.

- Current value of the node’s power supply voltage.

- From here you can choose the viewing period, allowing us to choose a specific date, or periods of time so wide ranging from the last seconds to the last years.

3.5. Local Seeing Calculation

4. Discussion

- We had to test our circuit using a pre-drilled board since the breadboard returned unstable results.

- We obtained consistent temperature measurements using our system. In addition, we contrasted the results with a meteorological station and an infrared thermometer.

- We find out that both the protocol and the XBee devices chosen lack an internal and synchronized management of the sleep mode. In our configuration, each node goes into sleep mode and does not wake up until its own internal clock indicates that it should do so. Since these clocks work autonomously, there is no way within the protocol to synchronize the equipment to take data in unison. This is a problem for long periods of sleep where data can be requested from a node and it does not respond until it wakes up, while another node can be awake and respond with your data at that moment. Although these modules support activation from sleep mode by using an external pin, this would require the use of another micro-controller to perform this management, increasing complexity and consumption.

- Configuring sleep mode periods of five seconds, the shifting is not higher than three seconds, not critical in our application.

- Redirect the air conditioning to an inconsistent area of the dome for homogeneity.

- Rotate the dome according to the season and hours of sun to keep a constant temperature along the dome.

- Study the thermal conductivity of the dome. In case of differences between the inside and outside of the dome, isolating material may be implied.

- Study if the entrance window of the dome gap creates turbulence phenomena. In this case, we can install a fabric with 50% permeability to reduce the air intake (also known as a windshield).

- Study the thermal evolution of the dome and propose ventilation routines. Therefore, create ventilation models adapted to the climatic conditions.

- Study of the vertical temperature gradient: Locate sensors every meter in height to study if there is an important thermal gradient that produces convection movements in the air. If this is the case, we would seek to homogenize the temperatures, such as, for example, installing fans that mix the air during the day (obviously, it should allow time for the atmosphere to be stable at night) or use the air conditioning of the dome (it has addressable gratings) in order to create an environment as homogeneous as possible.

- Study of the temperature gradient in the horizontal plane of the dome: Locate sensors by the perimeter of the surface of the dome, ideally at the height of the instrument, to see if any part of the dome heats up much more than the other. The idea here would be to study whether heating by solar radiation or the orientation of the dome produces any considerable effect (the north side is noticeably colder than the south side). With the data obtained, we can make an estimate of whether it is necessary to move the dome during the day in order to get more homogeneous temperatures or some other action.

- Study of point heat sources: As mentioned, inside the dome there are different points that generate heat, such as electrical panels, motors and lighting systems. The idea would be to place sensors in the vicinity and in the elements themselves and thus study if there is any temperature gradient, if this is so, and it is considered important, there are solutions such as cooling those systems (i.e., in the observatory there are cooling systems based on glycol water that are used to cool important heat sources).

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Redd, N.T. Hubble Space Telescope: Pictures, Facts & History. Available online: https://www.space.com/15892-hubble-space-telescope.html (accessed on 21 May 2020).

- NASA. Available online: https://commons.wikimedia.org/wiki/File:NGC_3370HSTGround.jpg (accessed on 21 May 2020).

- Bustos, E.; Tokovinin, A. Dome seeing monitor and its results for the 4 m Blanco telescope. Proc. SPIE 2018, 10700, 107000Q. [Google Scholar] [CrossRef]

- Blanco, D. Estimating local seeing at the DCT facility. In Proceedings of the Ground-based and Airborne Telescopes II, Marseille, France, 23–28 June 2008; p. 70123V. [Google Scholar] [CrossRef]

- Racine, R.; Salmon, D.; Cowley, D.; Sovka, J. Mirror, Dome, and Natural Seeing at CFHT. Publ. Astron. Soc. Pac. 1991, 103, 1020. [Google Scholar] [CrossRef]

- Ford, R. Seeing Control Strategy for the 8m Enclosure; GEMINI Project Rep. RPT-TE-G0039; GEMINI PROJECT OFFICE: Tucson, AZ, USA, 1993. [Google Scholar]

- Nathan, E.D.; Jacobus, M.O.J.; Robert, P.H. ATST enclosure: Seeing performance, thermal modeling, and error budgets. In Proceedings of the SPIE-The International Society for Optical Engineering, Glasgow, UK, 21–25 June 2004; pp. 497–507. [Google Scholar]

- Zago, L. The Effect of the Local Atmospheric Environment on Astronomical Observations Thèse No 1394; Lausanne, EPFL: Lausanne, Switzerland, 1995. [Google Scholar]

- Instituto Astrofísico de Canarias. William Herschel Telescope. 2020. Available online: http://www.ing.iac.es/astronomy/telescopes/wht/ (accessed on 21 May 2020).

- Buffa, F.; Cocco, G.; Porceddu, I.; Serrau, M. Dome seeing and temperature forecasting: A feasibility study for the Galileo Telescope. New Astron. Rev. 1998, 42, 447–449. [Google Scholar] [CrossRef]

- Bridgeland, M.T.; Jenkins, C.R. Measurements of mirror seeing in the laboratory and at the telescope. Mon. Not. R. Astron. Soc. 1997, 287, 87–109. [Google Scholar] [CrossRef][Green Version]

- Wilson, R.W.; O’Mahony, N.; Packham, C.; Azzaro, M. The seeing at the William Herschel Telescope. Mon. Not. R. Astron. Soc. 1999, 309, 379–387. [Google Scholar] [CrossRef][Green Version]

- Sánchez, L.J.; Avila, R.; Agabi, A.; Azouit, M.; Cuevas, S.; Cruz, D.X.; Cruz-González, I.; Garfias, F.; González, S.I.; Harris, O.; et al. Surface layer seeing at San Pedro Mártir revisited. Rev. Mex. Astron. Astrofis. 2007, 31, 93–100. [Google Scholar]

- Fuensalida, J.J.; García-Lorenzo, B.; Hoegemann, C. Correction of the dome seeing contribution from generalized-SCIDAR data using evenness properties with Fourier analysis. Mon. Not. R. Astron. Soc. 2008, 389, 731–740. [Google Scholar] [CrossRef]

- Masciadri, E.; Stoesz, J.; Hagelin, S.; Lascaux, F. Optical turbulence vertical distribution with standard and high resolution at Mt Graham. Mon. Not. R. Astron. Soc. 2010, 404, 144–158. [Google Scholar]

- Potanin, S.A. Shack-Hartmann wavefront sensor for testing the quality of the optics of the 2.5-m SAI telescope. Astron. Rep. 2009, 53, 703–709. [Google Scholar] [CrossRef]

- Potanin, S.A. Estimation of the dome seeing from results of the optics quality tests with Shack-Hartman wavefront sensor. arXiv 2011, arXiv:1101.3882. [Google Scholar]

- Mackay, C.D. Charge-Coupled Devices in Astronomy. Ann. Rev. Astron. Astrophys. 1986, 24, 255–283. [Google Scholar] [CrossRef]

- Okita, H.; Ichikawa, T.; Ashley, M.C.B.; Takato, N.; Motoyama, H. Excellent daytime seeing at Dome Fuji on the Antarctic plateau. Astron. Astrophys. 2013, 554, L5. [Google Scholar] [CrossRef]

- Guesalaga, A.; Neichel, B.; Cortes, A.; Béchet, C.; Guzmán, D. Cn2 and wind profiler method to quantify the frozen flow decay using wide-field laser guide stars adaptive optics. arXiv 2014, arXiv:1402.6934. [Google Scholar]

- Li, T.; Zhang, Z. Data collection based on mobile agent in wireless sensor networks. In Proceedings of the 10th World Congress on Intelligent Control and Automation, Beijing, China, 6–8 July 2012; pp. 392–396. [Google Scholar]

- Bertin, E.; Arnouts, S. SExtractor: Software for source extraction. Astron. Astrophys. Suppl. Ser. 1996, 117, 393–404. [Google Scholar] [CrossRef]

- Rueda, S. Diseño de una WSN para la estimación del seeing de la cúpula D080, en el Observatorio Astrofísico de Javalambre. 2018. Available online: http://hdl.handle.net/10609/81426 (accessed on 21 May 2020).

- XBee Zigbee Mesh Kit User Guide. 2020. Available online: https://www.digi.com/resources/documentation/Digidocs/90001942-13/ (accessed on 21 May 2020).

- Low Voltage Temperature Sensors: TMP35/TMP36/TMP37. 1996–2015. Available online: http://www.analog.com/media/en/technical-documentation/data-sheets/TMP35_36_37.pdf (accessed on 21 May 2020).

- LMT84 1.5-V, SC70/TO-92/TO-92S, Analog Temperature Sensors. 2020. Available online: http://www.ti.com/lit/ds/symlink/lmt84.pdf (accessed on 21 May 2020).

- PR Series Ultra Precision Interchangeable Thermistors. 2020. Available online: https://www.littelfuse.com/products/temperature-sensors/leaded-thermistors/interchangeable-thermistors/ultra-precision-pr.aspx (accessed on 21 May 2020).

- NTC Thermistors Steinhart and Hart Equation. 1998–2013. Available online: https://www.ametherm.com/thermistor/ntc-thermistors-steinhart-and-hart-equation (accessed on 21 May 2020).

- Custom PCBs Made Simple. 2020. Available online: https://jlcpcb.com/ (accessed on 21 May 2020).

- Joel, K.Y. A Practical Guide to Battery Technologies for Wireless Sensor Networking. 2008. Available online: https://www.sensorsmag.com/components/a-practical-guide-to-battery-technologies-for-wireless-sensor-networking (accessed on 21 May 2020).

- XBee/XBee-PRO S2C Zigbee: RF Module. 2020. Available online: https://www.digi.com/resources/documentation/digidocs/pdfs/90002002.pdf (accessed on 21 May 2020).

- Battery Life Calculator v2.2. 2020. Available online: http://ftp1.digi.com/support/utilities/batterylifecalculator.xls (accessed on 21 May 2020).

- Rueda, S. TFM UOC 2018 XBEE ZigBEE. 2020. Available online: https://github.com/sruedat/TFM_Srueda.git (accessed on 21 May 2020).

Sample Availability: Samples of the plots are available from the authors in the GitHub link https://github.com/sruedat/TFM_Srueda.git. |

| Characteristic | TMP36 | LMT84 | PR103J2 |

|---|---|---|---|

| Operative Voltage (V) | 2.7–5.5 1.5 | No limit (1) | |

| Calibration unit | C | C | C |

| Scale factor (mV/C) | 10 −5.5 | 16 (2) | |

| Precision | ±2 C | ±0.4 C | 0.05 C (±0.1%, 10 K at 25 C) |

| Linearity | ±0.5 C | High linearity | No lineal (3) |

| Operative Temperature | −40 C to 125 C | −50 C to 150 C | −55 C to 80 C |

| Power consumption | 50 A (0.5 A stand-by) | ±50 A (5.4 A stand-by) | Power input dependent (4) |

| Configuration | ST (sec) | SO | SN | SP (sec) | Duration (h) |

|---|---|---|---|---|---|

| 1 | 8 | 0 | 1 | 5 | 12.83 |

| 2 | 8 | 0 | 1 | 10 | 13.80 |

| 3 | 1 | 0 | 2 | 10 | 25.61 |

| 4 | 8 | 0 | 1 | 60 | 75.63 |

| 5 | 1 | 0 | 6 | 10 | 97.90 |

| 6 | 1 | 4 | 2 | 30 | 100.31 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parada, R.; Rueda-Teruel, S.; Monzo, C. Local Seeing Measurement for Increasing Astrophysical Observatory Quality Images Using an Autonomous Wireless Sensor Network. Sensors 2020, 20, 3792. https://doi.org/10.3390/s20133792

Parada R, Rueda-Teruel S, Monzo C. Local Seeing Measurement for Increasing Astrophysical Observatory Quality Images Using an Autonomous Wireless Sensor Network. Sensors. 2020; 20(13):3792. https://doi.org/10.3390/s20133792

Chicago/Turabian StyleParada, Raúl, Sergio Rueda-Teruel, and Carlos Monzo. 2020. "Local Seeing Measurement for Increasing Astrophysical Observatory Quality Images Using an Autonomous Wireless Sensor Network" Sensors 20, no. 13: 3792. https://doi.org/10.3390/s20133792

APA StyleParada, R., Rueda-Teruel, S., & Monzo, C. (2020). Local Seeing Measurement for Increasing Astrophysical Observatory Quality Images Using an Autonomous Wireless Sensor Network. Sensors, 20(13), 3792. https://doi.org/10.3390/s20133792