Piezoelectric Sensing Techniques in Structural Health Monitoring: A State-of-the-Art Review

Abstract

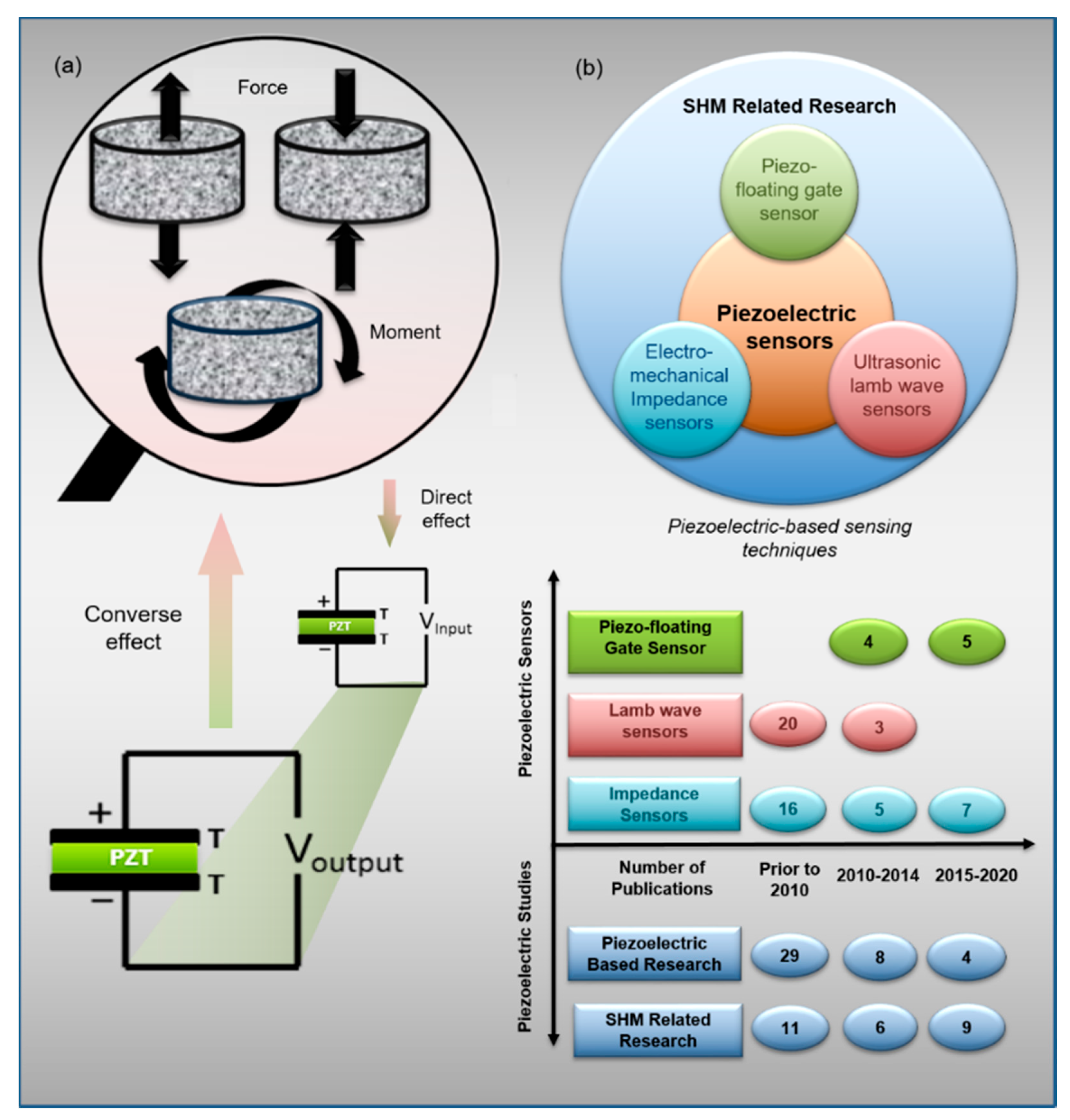

1. Introduction

2. Principle of Piezoelectric Sensing in SHM

- ∂: Deflection or displacement of the piezoelectric device;

- Q: Charge on the terminals of the piezoelectric device;

- F: Force exerted on the device;

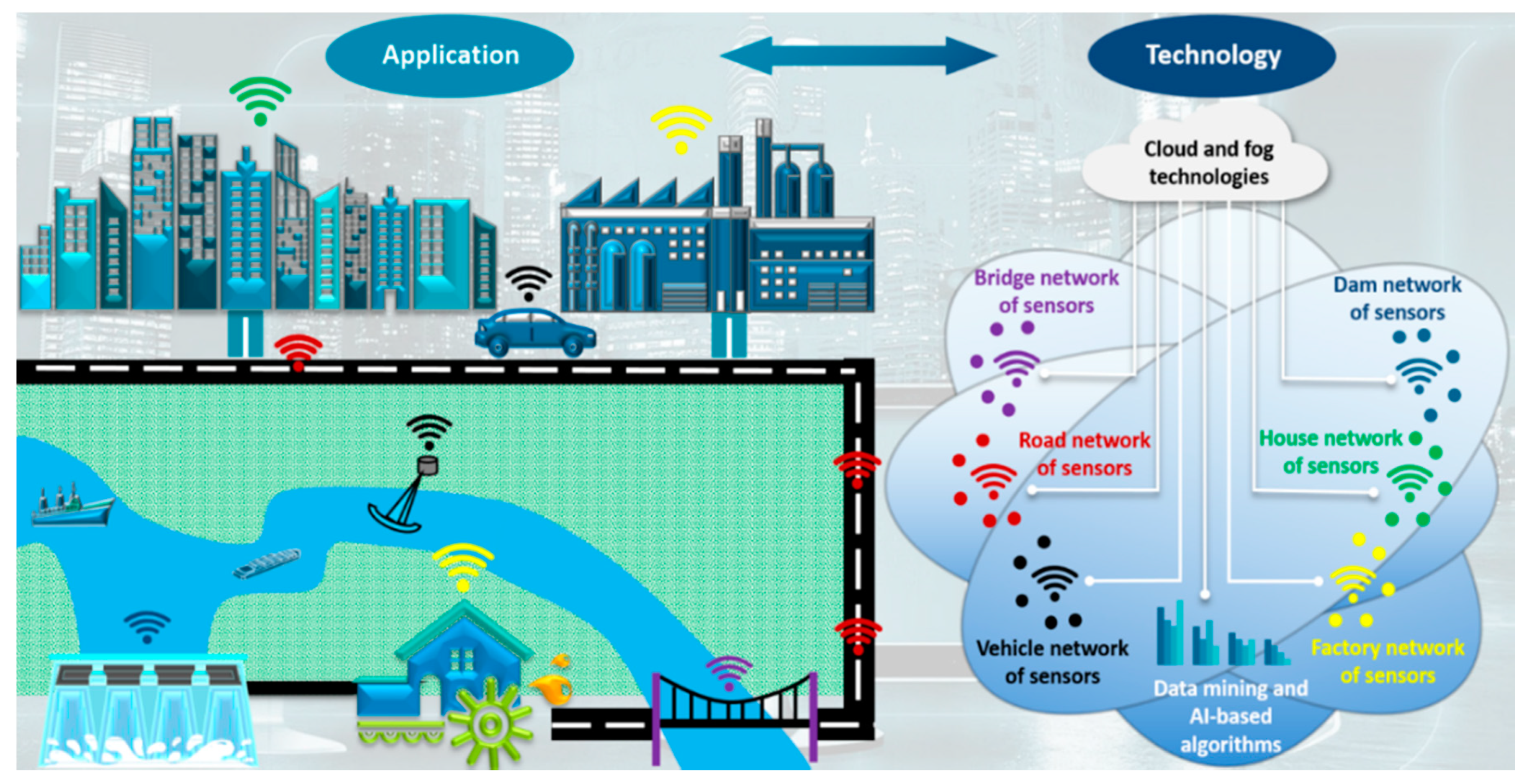

- V: Voltage across the electrodes;

- SV: Compliance under constant voltage;

- d: Piezoelectric coefficient;

- CF: Capacitance under constant force.

3. Piezoelectric Impedance Sensing Technique

3.1. Design Principle and Paradigms

3.2. Applications of the Piezoelectric Impedance Sensors in SHM

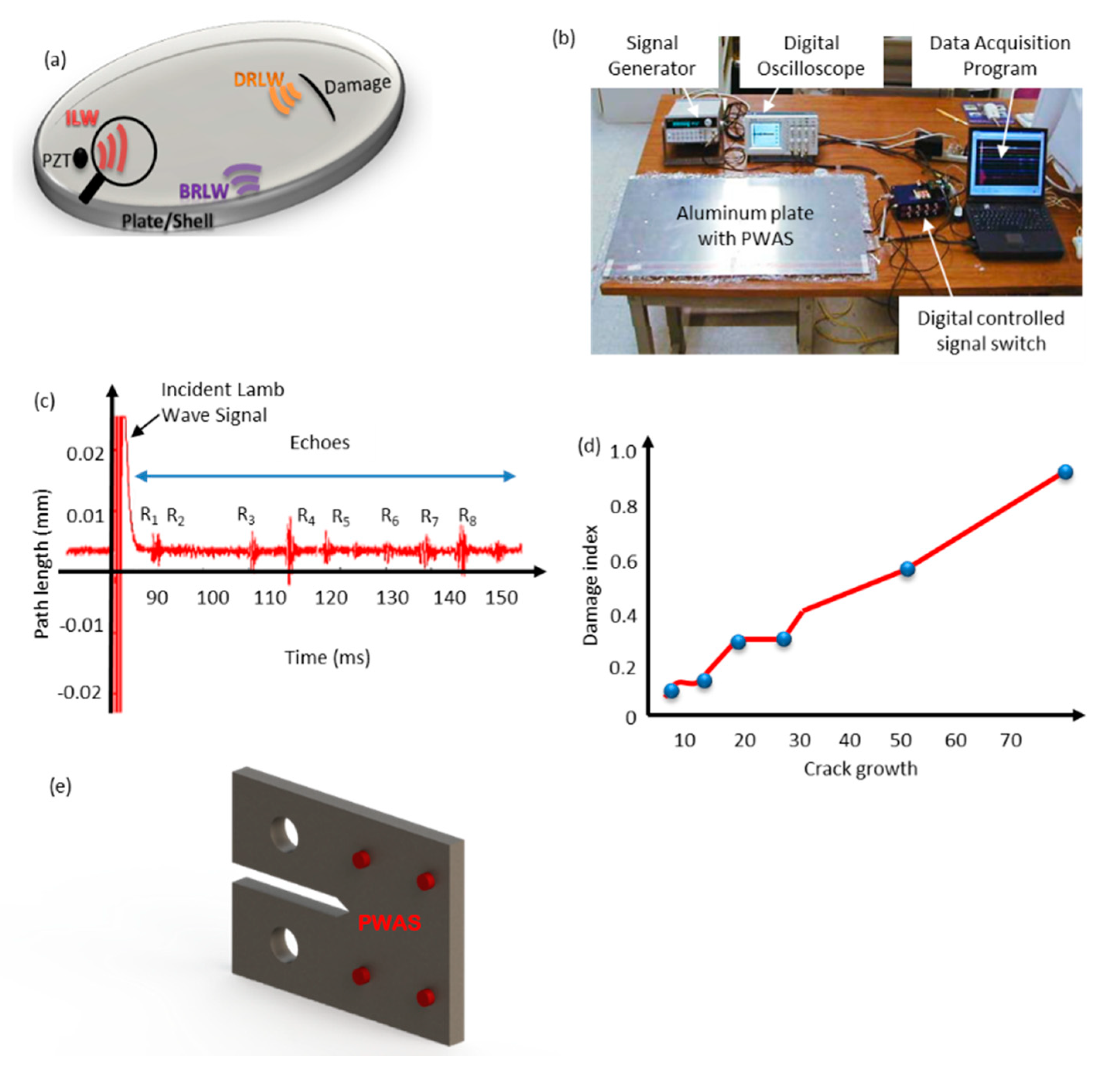

4. Piezoelectric Guided Wave Ultrasonic Technique

4.1. Design Principle and Paradigms

4.2. Applications of the Ultrasonic Lamb Wave Technique in SHM

4.2.1. PWAS Technology

4.2.2. SMART Technology

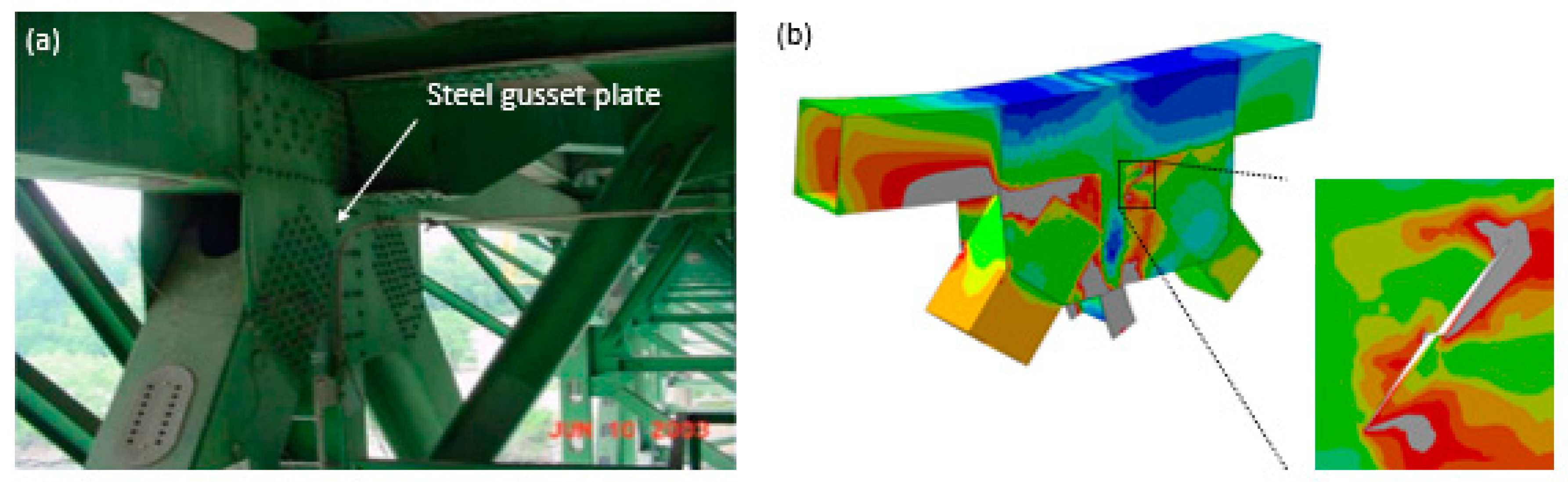

5. Piezoelectric-Floating-Gate Sensing Technology

5.1. Design Principles and Paradigms

- S: Strain;

- E: Piezoelectric material Young’s modulus;

- d31: Piezoelectric constant;

- t: Piezoelectric thickness;

- Piezoelectric electrical permittivity.

5.2. Applications of PFG in SHM

6. Methods of Power Delivery to SHM Sensor Nodes

7. Discussion: Piezoelectric Sensing Techniques for Smart and Connected Civil Infrastructure

- ▪

- The ability to perform spatial SHM over large structural areas without a need to deploy hundreds of sensing nodes;

- ▪

- Enhancing sensitivity to various damage types;

- ▪

- On-board computation algorithms;

- ▪

- Reliable wireless communication techniques;

- ▪

- Enhancing the power density of piezoelectric sensors for self-powering applications;

- ▪

- Integrating the sensor with different plug-in functionalities;

- ▪

- Reducing the deployment cost via material design, optimal sensor placement strategies, etc.

8. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Farrar, C.R.; Worden, K. An introduction to structural health monitoring. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 365, 303–315. [Google Scholar] [CrossRef] [PubMed]

- Brownjohn, J.M. Structural health monitoring of civil infrastructure. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 365, 589–622. [Google Scholar] [CrossRef]

- Sohn, H. Effects of environmental and operational variability on structural health monitoring. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 365, 539–560. [Google Scholar] [CrossRef]

- Park, G.; Rosing, T.; Todd, M.D.; Farrar, C.R.; Hodgkiss, W. Energy Harvesting for Structural Health Monitoring Sensor Networks. J. Infrastruct. Syst. 2007, 14, 64–79. [Google Scholar] [CrossRef]

- Nagayama, T.; Spencer, B. NSEL Report Series Structural Health Monitoring Using Smart Sensors Newmark Structural Engineering Laboratory. Available online: https://www.ideals.illinois.edu/bitstream/handle/2142/3521/NSEL.Report.001.pdf?sequence=4 (accessed on 10 March 2020).

- Egbe, K.I. Experimental Study of the Impact of Particle Packing Density Optimization on Strength and Water Absorption Properties of Concrete. Int. J. Eng. Res. Adv. Technol. 2019, 05, 67–79. [Google Scholar] [CrossRef]

- Lynch, J.P.; Wang, Y.; Loh, K.J.; Yi, J.-H.; Yun, C.-B. Performance monitoring of the Geumdang Bridge using a dense network of high-resolution wireless sensors. Smart Mater. Struct. 2006, 15, 1561–1575. [Google Scholar] [CrossRef]

- Raghavan, A. Guided-Wave Structural Health Monitoring. 2007. Available online: https://deepblue.lib.umich.edu/bitstream/handle/2027.42/77498/Raghavan_PhD_thesis_GWSHM.pdf?sequence=1 (accessed on 15 March 2020).

- Ko, J.M.; Ni, Y.Q. Technology developments in structural health monitoring of large-scale bridges. Eng. Struct. 2005, 27, 1715–1725. [Google Scholar] [CrossRef]

- ASCE: A Comprehensive Assessment of America’s Infrastructure; 2017 Report Card for America’s Infrastructure; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2017.

- Lynch, J.P.; Farrar, C.R.; Michaels, J.E. Structural health monitoring: Technological advances to practical implementations [scanning the issue]. Proc. IEEE 2016, 104, 1508–1512. [Google Scholar] [CrossRef]

- Paek, J.; Chintalapudi, K.; Caffrey, J.; Govindan, R.; Masri, S. A Wireless Sensor Network for Structural Health Monitoring: Performance and Experience. 2005. Escholarship.Org. Available online: https://escholarship.org/uc/item/7wz2×25d (accessed on 15 March 2020).

- Lynch, J.P.; Loh, K. A Summary Review of Wireless Sensors and Sensor Networks for Structural Health Monitoring. Shock Vib. Dig. 2006, 38, 91–128. [Google Scholar] [CrossRef]

- Chintalapudi, K.; Fu, T.; Paek, J.; Kothari, N.; Rangwala, S.; Caffrey, J.; Govindan, R.; Johnson, E.; Masri, S. Monitoring civil structures with a wireless sensor network. IEEE Internet Comput. 2006, 10, 26–34. [Google Scholar] [CrossRef]

- Alavi, A.H.; Hasni, H.; Lajnef, N.; Chatti, K.; Faridazar, F. An intelligent structural damage detection approach based on self-powered wireless sensor data. Autom. Constr. 2016, 62, 24–44. [Google Scholar] [CrossRef]

- Croxford, A.; Wilcox, P.; Drinkwater, B.; Konstantinidis, G. Strategies for guided-wave structural health monitoring. Proc. R. Soc. A Math. Phys. Eng. Sci. 2007, 463, 2961–2981. [Google Scholar] [CrossRef]

- Mascarenas, D.L.; Todd, M.D.; Park, G.; Farrar, C.R. Development of an impedance-based wireless sensor node for structural health monitoring. Smart Mater. Struct. 2007, 16, 2137–2145. [Google Scholar] [CrossRef]

- Na, W.; Baek, J. Impedance-Based Non-Destructive Testing Method Combined with Unmanned Aerial Vehicle for Structural Health Monitoring of Civil Infrastructures. Appl. Sci. 2016, 7, 15. [Google Scholar] [CrossRef]

- Yan, W.; Chen, W.Q. Structural Health Monitoring Using High-Frequency Electromechanical Impedance Signatures. Adv. Civ. Eng. 2010, 2010, 1–11. [Google Scholar] [CrossRef]

- Aono, K.; Lajnef, N.; Faridazar, F.; Chakrabartty, S. Infrastructural Health Monitoring Using Self-Powered Internet-of-Things. In Proceedings of the 2016 IEEE International Symposium on Circuits and Systems (ISCAS), Montreal, QC, Canada, 22–25 May 2016; pp. 2058–2061. [Google Scholar]

- Kondapalli, S.H.; Pochettino, O.; Aono, K.; Chakrabartty, S. Hybrid-Powered Internet-of-Things for Infrastructure-to-Vehicle Communication. In Proceedings of the 2018 IEEE 61st International Midwest Symposium on Circuits and Systems (MWSCAS), Windsor, ON, Canada, 5–8 August 2018. [Google Scholar]

- Qing, X.; Li, W.; Wang, Y.; Sun, H. Piezoelectric Transducer-Based Structural Health Monitoring for Aircraft Applications. Sensors 2019, 19, 545. [Google Scholar] [CrossRef]

- Liu, Y.; Tian, G.; Wang, Y.; Lin, J.; Zhang, Q.; Hofmann, H.F. Active Piezoelectric Energy Harvesting: General Principle and Experimental Demonstration. J. Intell. Mater. Syst. Struct. 2008, 20, 575–585. [Google Scholar] [CrossRef]

- Annamdas, V.G.; Radhika, M.A. Electromechanical impedance of piezoelectric transducers for monitoring metallic and non-metallic structures: A review of wired, wireless and energy-harvesting methods. J. Intell. Mater. Syst. Struct. 2013, 24, 1021–1042. [Google Scholar] [CrossRef]

- Baptista, F.; Budoya, D.; Almeida, V.; Ulson, J. An Experimental Study on the Effect of Temperature on Piezoelectric Sensors for Impedance-Based Structural Health Monitoring. Sensors 2014, 14, 1208–1227. [Google Scholar] [CrossRef]

- Shao, J.; Wang, T.; Yin, H.; Yang, D.; Li, Y. Bolt Looseness Detection Based on Piezoelectric Impedance Frequency Shift. Appl. Sci. 2016, 6, 298. [Google Scholar] [CrossRef]

- Xu, Y.G.; Liu, G.R. A Modified Electro-Mechanical Impedance Model of Piezoelectric Actuator-Sensors for Debonding Detection of Composite Patches. J. Intell. Mater. Syst. Struct. 2002, 13, 389–396. [Google Scholar] [CrossRef]

- Park, G.; Inman, D.J. Impedance-Based Structural Health Monitoring. In Damage Prognosis; Wiley: Hoboken, NJ, USA, 2005; pp. 275–292. [Google Scholar] [CrossRef]

- Rathod, V.T.; Mahapatra, D.R.; Jain, A.; Gayathri, A. Characterization of a large-area PVDF thin film for electro-mechanical and ultrasonic sensing applications. Sens. Actuators A Phys. 2010, 163, 164–171. [Google Scholar] [CrossRef]

- Ai, D.; Zhu, H.; Luo, H.; Wang, C. Mechanical impedance based embedded piezoelectric transducer for reinforced concrete structural impact damage detection: A comparative study. Constr. Build. Mater. 2018, 165, 472–483. [Google Scholar] [CrossRef]

- Park, G.; Cudney, H.H.; Inman, D.J. An Integrated Health Monitoring Technique Using Structural Impedance Sensors. J. Intell. Mater. Syst. Struct. 2000, 11, 448–455. [Google Scholar] [CrossRef]

- Overly, T.G.S.; Park, G.; Farinholt, K.M.; Farrar, C.R. Development of an extremely compact impedance-based wireless sensing device. Smart Mater. Struct. 2008, 17, 065011. [Google Scholar] [CrossRef]

- Park, S.; Ahmad, S.; Yun, C.-B.; Roh, Y. Multiple Crack Detection of Concrete Structures Using Impedance-based Structural Health Monitoring Techniques. Exp. Mech. 2006, 46, 609–618. [Google Scholar] [CrossRef]

- Lim, Y.Y.; Bhalla, S.; Soh, C.K. Structural identification and damage diagnosis using self-sensing piezo-impedance transducers. Smart Mater. Struct. 2006, 15, 987–995. [Google Scholar] [CrossRef]

- Na, W.; Baek, J. A Review of the Piezoelectric Electromechanical Impedance Based Structural Health Monitoring Technique for Engineering Structures. Sensors 2018, 18, 1307. [Google Scholar] [CrossRef]

- Liang, C.; Sun, F.; Rogers, C. An Impedance Method for Dynamic Analysis of Active Material Systems. In Proceedings of the 34th Structures, Structural Dynamics and Materials Conference, La Jolla, CA, USA, 19–22 April 1993; Volume 116, pp. 120–128. [Google Scholar] [CrossRef]

- Liang, C.; Sun, F.P.; Rogers, C.A. Coupled Electro-Mechanical Analysis of Adaptive Material Systems-Determination of the Actuator Power Consumption and System Energy Transfer. J. Intell. Mater. Syst. Struct. 1994, 5, 12–20. [Google Scholar] [CrossRef]

- Park, G.; Inman, D.J. Structural health monitoring using piezoelectric impedance measurements. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 365, 373–392. [Google Scholar] [CrossRef]

- Park, G.; Sohn, H.; Farrar, C.R.; Inman, D.J. Overview of Piezoelectric Impedance-Based Health Monitoring and Path Forward. Shock Vib. Dig. 2003, 35, 451–463. [Google Scholar] [CrossRef]

- Thien, A.; Chiamori, H.; Ching, J.; Wait, J.; Park, G. Piezoelectric Active Sensing for Damage Detection in Pipeline Structures. In Proceedings of the 23rd International Modal Analysis Conference, Orlando, FL, USA, 31 January–5 February 2005; pp. 323–636. [Google Scholar]

- Baptista, F.G.; Filho, J.V. A New Impedance Measurement System for PZT-Based Structural Health Monitoring. IEEE Trans. Instrum. Meas. 2009, 58, 3602–3608. [Google Scholar] [CrossRef]

- Park, S.; Park, G.; Yun, C.-B.; Farrar, C.R. Sensor Self-diagnosis Using a Modified Impedance Model for Active Sensing-based Structural Health Monitoring. Struct. Health Monit. 2008, 8, 71–82. [Google Scholar] [CrossRef]

- Park, S.; Yun, C.-B.; Roh, Y.; Lee, J.-J. PZT-based active damage detection techniques for steel bridge components. Smart Mater. Struct. 2006, 15, 957–966. [Google Scholar] [CrossRef]

- Na, W.; Baek, J. Adhesive Defect Monitoring of Glass Fiber Epoxy Plate Using an Impedance-Based Non-Destructive Testing Method for Multiple Structures. Sensors 2017, 17, 1439. [Google Scholar] [CrossRef]

- Giurgiutiu, V.; Zagrai, A.N. Characterization of Piezoelectric Wafer Active Sensors. J. Intell. Mater. Syst. Struct. 2000, 11, 959–976. [Google Scholar] [CrossRef]

- Giurgiutiu, V.; Zagrai, A.; Jing Bao, J. Piezoelectric Wafer Embedded Active Sensors for Aging Aircraft Structural Health Monitoring. Struct. Health Monit. 2002, 1, 41–61. [Google Scholar] [CrossRef]

- Cuc, A.; Giurgiutiu, V.; Joshi, S.; Tidwell, Z. Structural Health Monitoring with Piezoelectric Wafer Active Sensors for Space Applications. AIAA J. 2007, 45, 2838–2850. [Google Scholar] [CrossRef]

- Rathod, V.T.; Mahapatra, D.R.; Gopalakrishnan, S. Lamb wave based identification and parameter estimation of corrosion in metallic plate structure using a circular PWAS array. Health Monit. Struct. Biol. Syst. 2009, 2009, 7295–72951C. [Google Scholar] [CrossRef]

- Rathod, V.T.; Mahapatra, D.R. Lamb wave based monitoring of plate-stiffener deboding using a circular array of piezoelectric sensors. Int. J. Smart Sens. Intell. Syst. 2010, 3, 27–44. [Google Scholar] [CrossRef]

- Raghavan, A.; Cesnik, C.E.S. Modeling of piezoelectric-based Lamb wave generation and sensing for structural health monitoring. Smart Struct. Mater. 2004, 5391, 419–430. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Tuned Lamb Wave Excitation and Detection with Piezoelectric Wafer Active Sensors for Structural Health Monitoring. J. Intell. Mater. Syst. Struct. 2005, 16, 291–305. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Lamb wave generation with piezoelectric wafer active sensors for structural health monitoring. J. Opt. Microsys. 2003, 5056, 111–122. [Google Scholar] [CrossRef]

- Wait, J.R.; Park, G.; Worden, C.R. Integrated Structural Health Assessment Using Piezoelectric Active Sensors. Shock Vib. 2005, 12, 389–405. [Google Scholar] [CrossRef]

- Park, S.; Kim, J.-W.; Lee, C.; Park, S.-K. Impedance-based wireless debonding condition monitoring of CFRP laminated concrete structures. NDT E Int. 2011, 44, 232–238. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Structural Health Monitoring with Piezoelectric Wafer Active Sensors; Elsevier: Amsterdam, The Netherlands, 2014; Available online: https://www.elsevier.com/books/structural-health-monitoring-with-piezoelectric-wafer-active-sensor/giurgiutiu/978-0-12-418691-0 (accessed on 5 March 2020).

- Giurgiutiu, V. Structural Health Monitoring with Piezoelectric Wafer Active Sensors. In Proceedings of the 16th International Conference of Adaptive Structures and Technologies ICAST, Paris, France, 10–12 October 2005. [Google Scholar]

- Gresil, M.; Giurgiutiu, V. Guided wave propagation in composite laminates using piezoelectric wafer active sensors. Aeronaut. J. 2013, 117, 971–995. [Google Scholar] [CrossRef]

- Gresil, M.; Yu, L.; Giurgiutiu, V. Fatigue crack detection in thick steel structures with piezoelectric wafer active sensors. In Nondestructive Characterization for Composite Materials Aerospace Engineering, Civil Infrastructure, and Homeland Security 2011; SPIE: Bellingham, WA, USA, 2011; p. 79832Y. [Google Scholar] [CrossRef]

- Yu, L.; Giurgiutiu, V.; Pollock, P. A multi-mode sensing system for corrosion detection using piezoelectric wafer active sensors. In Sensors and Smart Structures Technologies for Civil 2008 Mechanical, and Aerospace Systems 2008; SPIE: Bellingham, WA, USA, 2008; p. 6932. [Google Scholar] [CrossRef]

- Yu, L.; Cheng, L.; Su, Z. Correlative sensor array and its applications to identification of damage in plate-like structures. Struct. Control Health Monit. 2011, 19, 650–671. [Google Scholar] [CrossRef]

- Giurgiutiu, V.; Bao, J.; Zhao, W. Piezoelectric wafer active sensor embedded ultrasonics in beams and plates. Exp. Mech. 2003, 43, 428–449. [Google Scholar] [CrossRef]

- Qing, X.P.; Beard, S.J.; Ikegami, R.; Chang, F.-K.; Boller, C. Aerospace Applications of SMART Layer Technology. In Encyclopedia of Structural Health Monitoring; Boller, C., Chang, F.-K., Fujino, Y., Eds.; Wiley: Chichester, UK, 2009. [Google Scholar]

- Lin, M.; Qing, X.; Kumar, A.; Beard, S.J. SMART Layer and SMART Suitcase for structural health monitoring applications. Int. Soc. Opt. Photonics 2001, 4332, 98–106. [Google Scholar] [CrossRef]

- Qing, X.P.; Beard, S.J.; Kumar, A.; Ooi, T.K.; Chang, F.-K. Built-in Sensor Network for Structural Health Monitoring of Composite Structure. J. Intell. Mater. Syst. Struct. 2006, 18, 39–49. [Google Scholar] [CrossRef]

- Qing, X.P.; Beard, S.J.; Kumar, A.; Li, I.; Lin, M.; Chang, F.-K. Stanford Multiactuator–Receiver Transduction (SMART) Layer Technology and Its Applications. In Encyclopedia of Structural Health Monitoring; Boller, C., Chang, F.-K., Fujino, Y., Eds.; Wiley: Chichester, UK, 2009. [Google Scholar]

- Haywood, J.; Coverley, P.T.; Staszewski, W.J.; Worden, K. An automatic impact monitor for a composite panel employing smart sensor technology. Smart Mater. Struct. 2004, 14, 265–271. [Google Scholar] [CrossRef]

- Qing, X.P.; Chan, H.-L.; Beard, S.J.; Ooi, T.K.; Marotta, S.A. Effect of adhesive on the performance of piezoelectric elements used to monitor structural health. Int. J. Adhes. Adhes. 2006, 26, 622–628. [Google Scholar] [CrossRef]

- Park, J.; Chang, F.-K. System identification method for monitoring impact events. Int. Soc. Opt. Photonics 2005, 5758, 189–200. [Google Scholar] [CrossRef]

- Kumar, A.; Wu, H.F.; Lin, M.; Beard, S.; Qing, X.; Zhang, C.; Hamilton, M.; Ikegami, R. Potential applications of SMART Layer technology for homeland security. Int. Soc. Opt. Photonics 2004, 5395, 61–69. [Google Scholar] [CrossRef]

- Qing, X.P.; Chan, H.-L.; Beard, S.J.; Kumar, A. An Active Diagnostic System for Structural Health Monitoring of Rocket Engines. J. Intell. Mater. Syst. Struct. 2006, 17, 619–628. [Google Scholar] [CrossRef]

- Lajnef, N.; Rhimi, M.; Chatti, K.; Mhamdi, L.; Faridazar, F. Toward an Integrated Smart Sensing System and Data Interpretation Techniques for Pavement Fatigue Monitoring. Comput. Aided Civ. Infrastruct. Eng. 2011, 26, 513–523. [Google Scholar] [CrossRef]

- Hasni, H.; Alavi, A.H.; Jiao, P.; Lajnef, N. Detection of fatigue cracking in steel bridge girders: A support vector machine approach. Arch. Civ. Mech. Eng. 2017, 17, 609–622. [Google Scholar] [CrossRef]

- Hasni, H.; Jiao, P.; Lajnef, N.; Alavi, A.H. Damage localization and quantification in gusset plates: A battery-free sensing approach. Struct. Control Health Monit. 2018, 25, e2158. [Google Scholar] [CrossRef]

- Alavi, A.H.; Hasni, H.; Lajnef, N.; Chatti, K.; Faridazar, F. Damage detection using self-powered wireless sensor data: An evolutionary approach. Measurement 2016, 82, 254–283. [Google Scholar] [CrossRef]

- Shin, S.W.; Oh, T.K. Application of electro-mechanical impedance sensing technique for online monitoring of strength development in concrete using smart PZT patches. Constr. Build. Mater. 2009, 23, 1185–1188. [Google Scholar] [CrossRef]

- Crawley, E.F.; Anderson, E.H. Detailed Models of Piezoceramic Actuation of Beams. J. Intell. Mater. Syst. Struct. 1990, 1, 4–25. [Google Scholar] [CrossRef]

- Liu, P.; Wang, W.; Chen, Y.; Feng, X.; Miao, L. Concrete damage diagnosis using electromechanical impedance technique. Constr. Build. Mater. 2017, 136, 450–455. [Google Scholar] [CrossRef]

- Talakokula, V.; Bhalla, S.; Gupta, A. Monitoring early hydration of reinforced concrete structures using structural parameters identified by piezo sensors via electromechanical impedance technique. Mech. Syst. Signal Process. 2018, 99, 129–141. [Google Scholar] [CrossRef]

- Vieira Filho, J.; Baptista, F.G.; Inman, D.J. Time-domain analysis of piezoelectric impedance-based structural health monitoring using multilevel wavelet decomposition. Mech. Syst. Signal Process. 2011, 25, 1550–1558. [Google Scholar] [CrossRef]

- Ghafari, E.; Yuan, Y.; Wu, C.; Nantung, T.; Lu, N. Evaluation the compressive strength of the cement paste blended with supplementary cementitious materials using a piezoelectric-based sensor. Constr. Build. Mater. 2018, 171, 504–510. [Google Scholar] [CrossRef]

- Min, J.; Park, S.; Yun, C.-B.; Lee, C.-G.; Lee, C. Impedance-based structural health monitoring incorporating neural network technique for identification of damage type and severity. Eng. Struct. 2012, 39, 210–220. [Google Scholar] [CrossRef]

- Lin, B.; Giurgiutiu, V. Modeling and testing of PZT and PVDF piezoelectric wafer active sensors. Smart Mater. Struct. 2006, 15, 1085–1093. [Google Scholar] [CrossRef]

- Park, G.; Farrar, C.R.; Scalea, F.L.; di Coccia, S. Performance assessment and validation of piezoelectric active-sensors in structural health monitoring. Smart Mater. Struct. 2006, 15, 1673–1683. [Google Scholar] [CrossRef]

- Park, S.; Shin, H.-H.; Yun, C.-B. Wireless impedance sensor nodes for functions of structural damage identification and sensor self-diagnosis. Smart Mater. Struct. 2009, 18, 055001. [Google Scholar] [CrossRef]

- Lamb, H. On the Vibrations of an Elastic Sphere. Proc. Lond. Math. Soc. 1881, 1, 189–212. [Google Scholar] [CrossRef]

- Degertakin, F.L.; Khuri-Yakub, B. Lamb wave excitation by Hertzian contacts with applications in NDE. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1997, 44, 769–779. [Google Scholar] [CrossRef]

- Gachagan, A.; Hayward, G.; Banks, R. A flexible piezoelectric transducer design for efficient generation and reception of ultrasonic Lamb waves. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 1175–1182. [Google Scholar] [CrossRef] [PubMed]

- Jia, X. Modal analysis of Lamb wave generation in elastic plates by liquid wedge transducers. J. Acoust. Soc. Am. 1997, 101, 834–842. [Google Scholar] [CrossRef]

- Greve, D.W.; Sohn, H.; Yue, C.P.; Oppenheim, I.J. An Inductively Coupled Lamb Wave Transducer. IEEE Sens. J. 2007, 7, 295–301. [Google Scholar] [CrossRef]

- Lanza di Scalea, F.; Matt, H.; Bartoli, I. The response of rectangular piezoelectric sensors to Rayleigh and Lamb ultrasonic waves. J. Acoust. Soc. Am. 2007, 121, 175–187. [Google Scholar] [CrossRef]

- Park, H.W.; Kim, S.B.; Sohn, H. Understanding a time reversal process in Lamb wave propagation. Wave Motion 2009, 46, 451–467. [Google Scholar] [CrossRef]

- Pei, J.; Yousuf, M.I.; Degertekin, F.L.; Honein, B.V.; Khuri-Yakub, B.T. Lamb Wave Tomography and Its Application in Pipe Erosion/Corrosion Monitoring. Res. Nondestruct. Eval. 1996, 8, 189–197. [Google Scholar] [CrossRef]

- Alleyne, D.N.; Cawley, P. The interaction of Lamb waves with defects. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1992, 39, 381–397. [Google Scholar] [CrossRef]

- Alleyne, D.N.; Cawley, P. The excitation of Lamb waves in pipes using dry-coupled piezoelectric transducers. J. Nondestruct. Eval. 1996, 15, 11–20. [Google Scholar] [CrossRef]

- Cawley, P.; Adams, R.D. The location of defects in structures from measurements of natural frequencies. J. Strain Anal. Eng. Des. 1979, 14, 49–57. [Google Scholar] [CrossRef]

- Giridhara, G.; Rathod, V.T.; Naik, S.; Roy Mahapatra, D.; Gopalakrishnan, S. Rapid localization of damage using a circular sensor array and Lamb wave based triangulation. Mech. Syst. Signal Process. 2010, 24, 2929–2946. [Google Scholar] [CrossRef]

- Leonard, K.R.; Malyarenko, E.V.; Hinders, M.K. Ultrasonic Lamb wave tomography. Inverse Probl. 2002, 18, 1795–1808. [Google Scholar] [CrossRef]

- Lowe, M.J.S.; Alleyne, D.N.; Cawley, P. Defect detection in pipes using guided waves. Ultrasonics 1998, 36, 147–154. [Google Scholar] [CrossRef]

- Monkhouse, R.S.C.; Wilcox, P.W.; Lowe, M.J.S.; Dalton, R.P.; Cawley, P. The rapid monitoring of structures using interdigital Lamb wave transducers. Smart Mater. Struct. 2000, 9, 304–309. [Google Scholar] [CrossRef]

- Rathod, V.T.; Roy Mahapatra, D. Ultrasonic Lamb wave based monitoring of corrosion type of damage in plate using a circular array of piezoelectric transducers. NDT E Int. 2011, 44, 628–636. [Google Scholar] [CrossRef]

- Koh, Y.; Chiu, W.; Rajic, N. Effects of local stiffness changes and delamination on Lamb wave transmission using surface-mounted piezoelectric transducers. Compos. Struct. 2002, 57, 437–443. [Google Scholar] [CrossRef]

- Lanza di Scalea, F.; Salamone, S. Temperature effects in ultrasonic Lamb wave structural health monitoring systems. J. Acoust. Soc. Am. 2008, 124, 161–174. [Google Scholar] [CrossRef]

- Lemistre, M.; Balageas, D. Structural health monitoring system based on diffracted Lamb wave analysis by multiresolution processing. Smart Mater. Struct. 2001, 10, 504–511. [Google Scholar] [CrossRef]

- Su, Z.; Ye, L.; Bu, X. A damage identification technique for CF/EP composite laminates using distributed piezoelectric transducers. Compos. Struct. 2002, 57, 465–471. [Google Scholar] [CrossRef]

- Rathod, V.T.; Roy Mahapatra, D.; Jain, A.; Gayathri, A. Ultrasonic performance of the PVDF thin film sensors under thermal fatigue. Behav. Mech. Multifunct. Mater. Compos. 2012, 8342, 83420E. [Google Scholar] [CrossRef]

- Rathod Vivek, T.; Jain, A. Ultrasonic guided wave sensitivity of piezopolymer films subjected to thermal exposure. ISSS J. Micro Smart Syst. 2018, 7, 15–24. [Google Scholar] [CrossRef]

- Kim, Y.; Ha, S.; Chang, F.-K. Time-Domain Spectral Element Method for Built-In Piezoelectric-Actuator-Induced Lamb Wave Propagation Analysis. AIAA J. 2008, 46, 591–600. [Google Scholar] [CrossRef]

- Kudela, P.; Radzienski, M.; Ostachowicz, W.; Yang, Z. Structural Health Monitoring system based on a concept of Lamb wave focusing by the piezoelectric array. Mech. Syst. Signal Process. 2018, 108, 21–32. [Google Scholar] [CrossRef]

- Aryan, P.; Kotousov, A.; Ng, C.T.; Cazzolato, B.S. Lamb wave characterisation and damage imaging for isotropic plate-like structures using 3D laser vibrometry. In Proceedings of the Recent Advances in Structural Integrity Analysis-Proceedings of the International Congress (APCF/SIF-2014), Sydney, Australia, 9–12 December 2014; pp. 585–589. [Google Scholar] [CrossRef]

- Wilcox, P.D.; Lowe, M.J.S.; Cawley, P. Mode and Transducer Selection for Long Range Lamb Wave Inspection. J. Intell. Mater. Syst. Struct. 2001, 12, 553–565. [Google Scholar] [CrossRef]

- Yeum, C.M.; Sohn, H.; Ihn, J.B. Lamb wave mode decomposition using concentric ring and circular piezoelectric transducers. Wave Motion 2011, 48, 358–370. [Google Scholar] [CrossRef]

- Sohn, H.; Lee, S.J. Lamb wave tuning curve calibration for surface-bonded piezoelectric transducers. Smart Mater. Struct. 2009, 19, 015007. [Google Scholar] [CrossRef]

- Choi, S.-W.; Farinholt, K.M.; Taylor, S.G.; Light-Marquez, A.; Park, G. Damage Identification of Wind Turbine Blades Using Piezoelectric Transducers. Shock Vib. 2014, 2014, 430854. [Google Scholar] [CrossRef]

- Lajnef, N.; Chatti, K.; Chakrabartty, S.; Rhimi, M.; Sarkar, P. Smart Pavement Monitoring System; Report: FHWA-HRT-12-072; Federal Highway Administration (FHWA): Washington, DC, USA, 2013.

- Chakrabartty, S.; Lajnef, N.; Elvin, N.; Elvin, A.; Gore, A. Self-Powered Sensor. U.S. Patent 8,056,420 B2, 15 November 2011. [Google Scholar]

- Chakrabartty, S. Self-Powered Strain-Rate Sensor. U.S. Patent 7757565, 20 July 2010. [Google Scholar]

- Alavi, A.H.; Hasni, H.; Lajnef, N.; Chatti, K. Damage growth detection in steel plates: Numerical and experimental studies. Eng. Struct. 2016, 128, 124–138. [Google Scholar] [CrossRef]

- Lynch, J.P. An overview of wireless structural health monitoring for civil structures. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 365, 345–372. [Google Scholar] [CrossRef]

- Etemadrezaei, M. Wireless Power Transfer. Power Electronics Handbook, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Tran, H.-V.; Kaddoum, G. RF Wireless Power Transfer: Regreening Future Networks. IEEE Potentials 2018, 37, 35–41. [Google Scholar] [CrossRef]

- Clerckx, B.; Zhang, R.; Schober, R.; Ng, D.W.K.; Kim, D.I.; Poor, H.V. Fundamentals of Wireless Information and Power Transfer: From RF Energy Harvester Models to Signal and System Designs. IEEE J. Sel. Areas Commun. 2019, 37, 4–33. [Google Scholar] [CrossRef]

- Rekhi, A.S.; Khuri-Yakub, B.T.; Arbabian, A. Wireless Power Transfer to Millimeter-Sized Nodes Using Airborne Ultrasound. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2017, 64, 1526–1541. [Google Scholar] [CrossRef] [PubMed]

- Mahmood, M.F.; Mohammed, S.L.; Gharghan, S.K. Ultrasound Sensor-Based Wireless Power Transfer for Low-Power Medical Devices. J. Low Power Electron. Appl. 2019, 9, 20. [Google Scholar] [CrossRef]

- Denisov, A.; Yeatman, E. Ultrasonic vs. Inductive Power Delivery for Miniature Biomedical Implants. In Proceedings of the 2010 International Conference on Body Sensor Networks, Singapore, 7–9 June 2010. [Google Scholar] [CrossRef]

- Lu, F.; Zhang, H.; Mi, C. A Review on the Recent Development of Capacitive Wireless Power Transfer Technology. Energies 2017, 10, 1752. [Google Scholar] [CrossRef]

- Baguley, C.A.; Jayasinghe, S.G.; Madawala, U.K. Theory and Control of Wireless Power Transfer Systems. In Control of Power Electronic Converters and Systems; Academic Press: Cambridge, MA, USA, 2018; pp. 291–307. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Alavi, A.H.; Asghari, A.; Niroomand, H.; Nazar, A.M. An innovative approach for modeling of hysteretic energy demand in steel moment resisting frames. Neural Comput. Appl. 2013, 24, 1285–1291. [Google Scholar] [CrossRef]

| Sensing Mode | Sensor Type | Principle | Existing Studies |

|---|---|---|---|

| Electromechanical impedance | Piezoelectric Impedance Transducers | Measuring effective resistance of structures and comparing to baseline data | [18,19], [24,25], [30,31,32,33,34,35,36,37,38,39,40,41,42,43,44] |

| Guided Lamb Wave | Piezoelectric wafer active sensor | Generating Lamb waves and detecting reflected Lamb wave using pulse-echo method | [45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61] |

| Stanford multi-actuator–receiver transduction technology layer | Generating ultrasonic signals from actuators and detect measurements from sensors | [62,63,64,65,66,67,68,69,70] | |

| Electrical signals | Piezo-floating-gate | Recording piezoelectric transducer electrical signals above predefined thresholds | [15,71,72,73,74] |

| Sensor Type | Suitability | Pros | Cons |

|---|---|---|---|

| Piezoelectric-Impedance Technique | • Suitable for a broad spectrum of civil infrastructure systems; • Applicable to concrete, metallic and other fiber composite structures. | • High sensitivity to inchoate damages as a result of the high-frequency detection mechanism; • Measures a broad spectrum of defects such as crack growth, deboning, corrosion, loosening bolts; • Data interpretation is relatively easy; • It is not very sensitive to structural boundaries. | • Wired; • Due to high-frequency detection, an effective range of detection is reduced; • The use of a network of sensors to adequately monitor a given area is required. • An external power source is required, e.g., a battery. |

| Piezoelectric Guided Wave Ultrasonic Technique | • Most suitable for metallic plates and shells. It can also be applied to thin fiber composites. | • Lamb wave modes vary in their sensitivity to damages, i.e., a given mode may be more sensitive to specific damage than others; • Lamb wave modes can be tuned at certain frequencies, which permits specific modes to be generated for the primary purpose of detecting a particular type of defect; • Can be used to monitor a large area. | • Wired; • Very sensitive to frequency and can be complicated to excite and interpret its data especially when a single mode is required for damage interrogation; • Mode conversion may occur as a result of lamb wave reflection from damage; • External power is required, e.g., a battery; • Very Sensitive to reflection from boundaries, which should be taken into account during damage detection. |

| PFG Technique | • Most suitable for steel and metallic structures but may also be used for concrete structures. | • Wireless; • Self-Powered; • Inexpensive; • Easy installation. | • Data interpretation is relatively complicated. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, P.; Egbe, K.-J.I.; Xie, Y.; Matin Nazar, A.; Alavi, A.H. Piezoelectric Sensing Techniques in Structural Health Monitoring: A State-of-the-Art Review. Sensors 2020, 20, 3730. https://doi.org/10.3390/s20133730

Jiao P, Egbe K-JI, Xie Y, Matin Nazar A, Alavi AH. Piezoelectric Sensing Techniques in Structural Health Monitoring: A State-of-the-Art Review. Sensors. 2020; 20(13):3730. https://doi.org/10.3390/s20133730

Chicago/Turabian StyleJiao, Pengcheng, King-James I. Egbe, Yiwei Xie, Ali Matin Nazar, and Amir H. Alavi. 2020. "Piezoelectric Sensing Techniques in Structural Health Monitoring: A State-of-the-Art Review" Sensors 20, no. 13: 3730. https://doi.org/10.3390/s20133730

APA StyleJiao, P., Egbe, K.-J. I., Xie, Y., Matin Nazar, A., & Alavi, A. H. (2020). Piezoelectric Sensing Techniques in Structural Health Monitoring: A State-of-the-Art Review. Sensors, 20(13), 3730. https://doi.org/10.3390/s20133730