Intelligent Industrial Cleaning: A Multi-Sensor Approach Utilising Machine Learning-Based Regression

Abstract

1. Introduction

1.1. Sensor Research in Cleaning

1.2. Signal and Image Processing

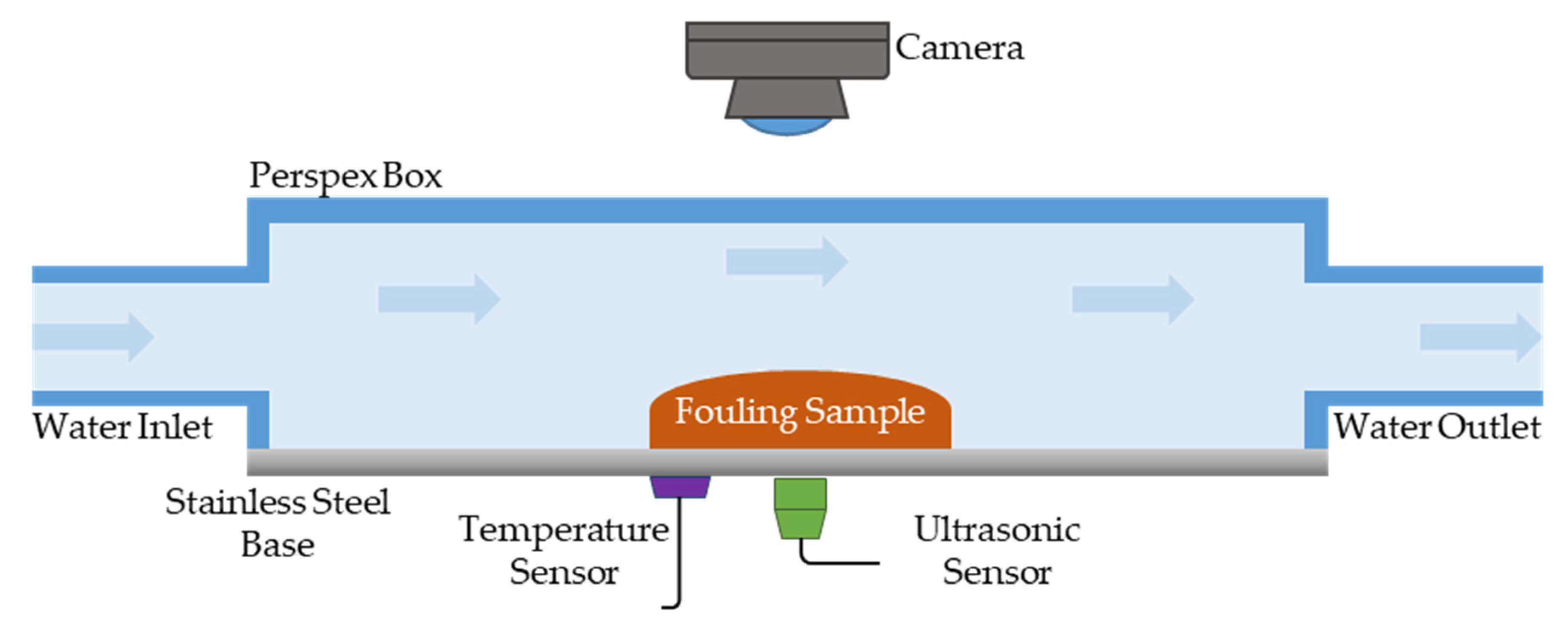

2. Materials and Methods

2.1. Experimental Tests

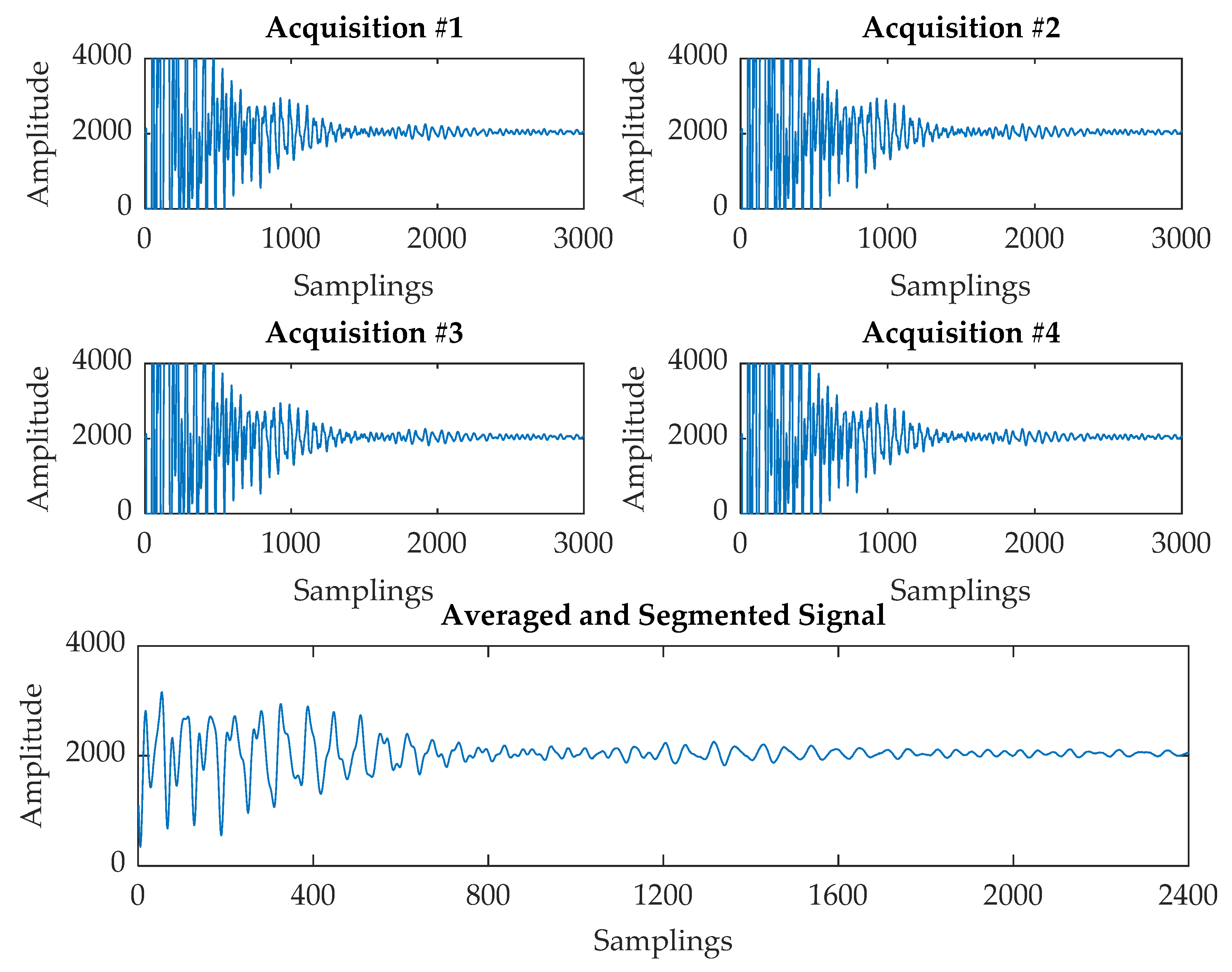

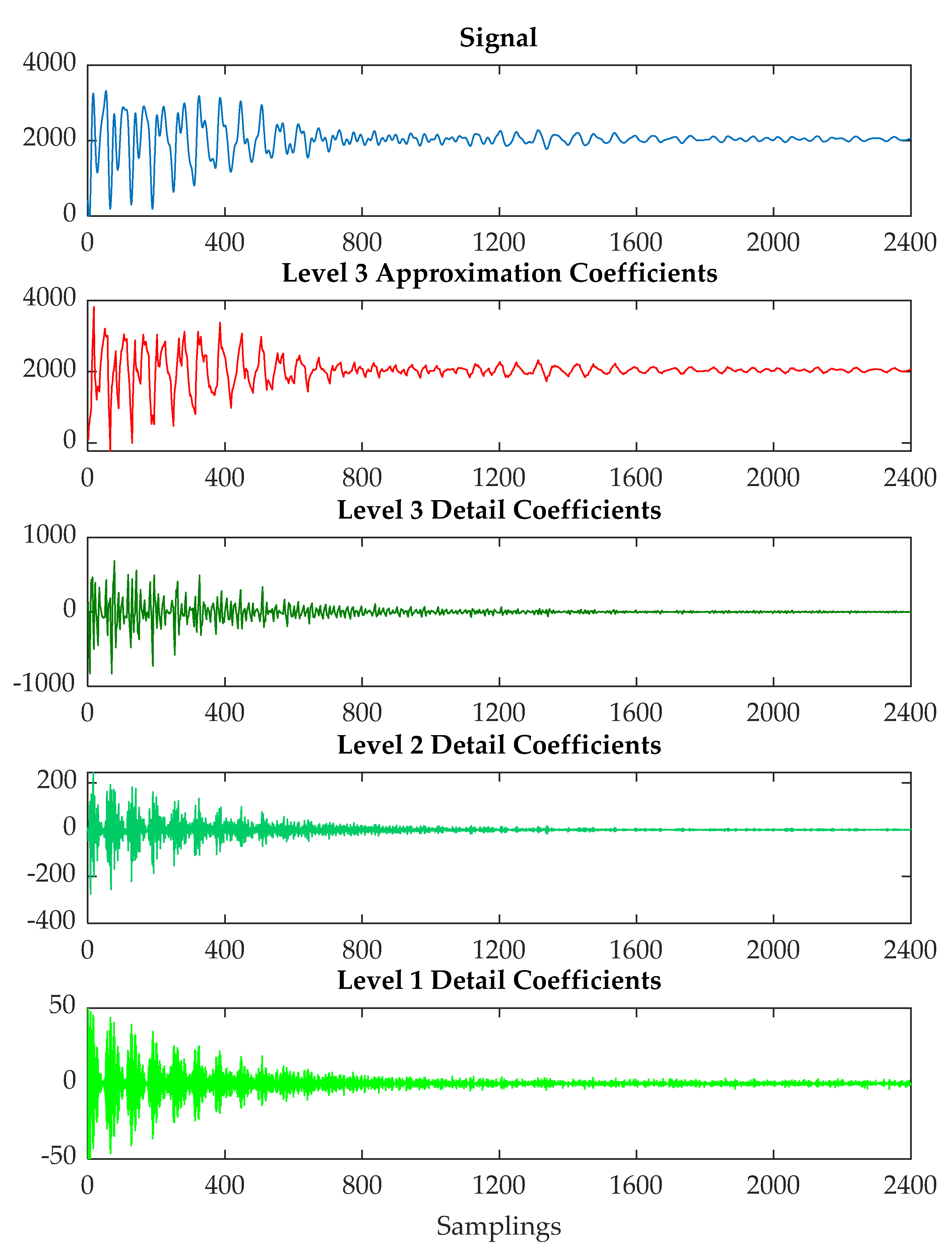

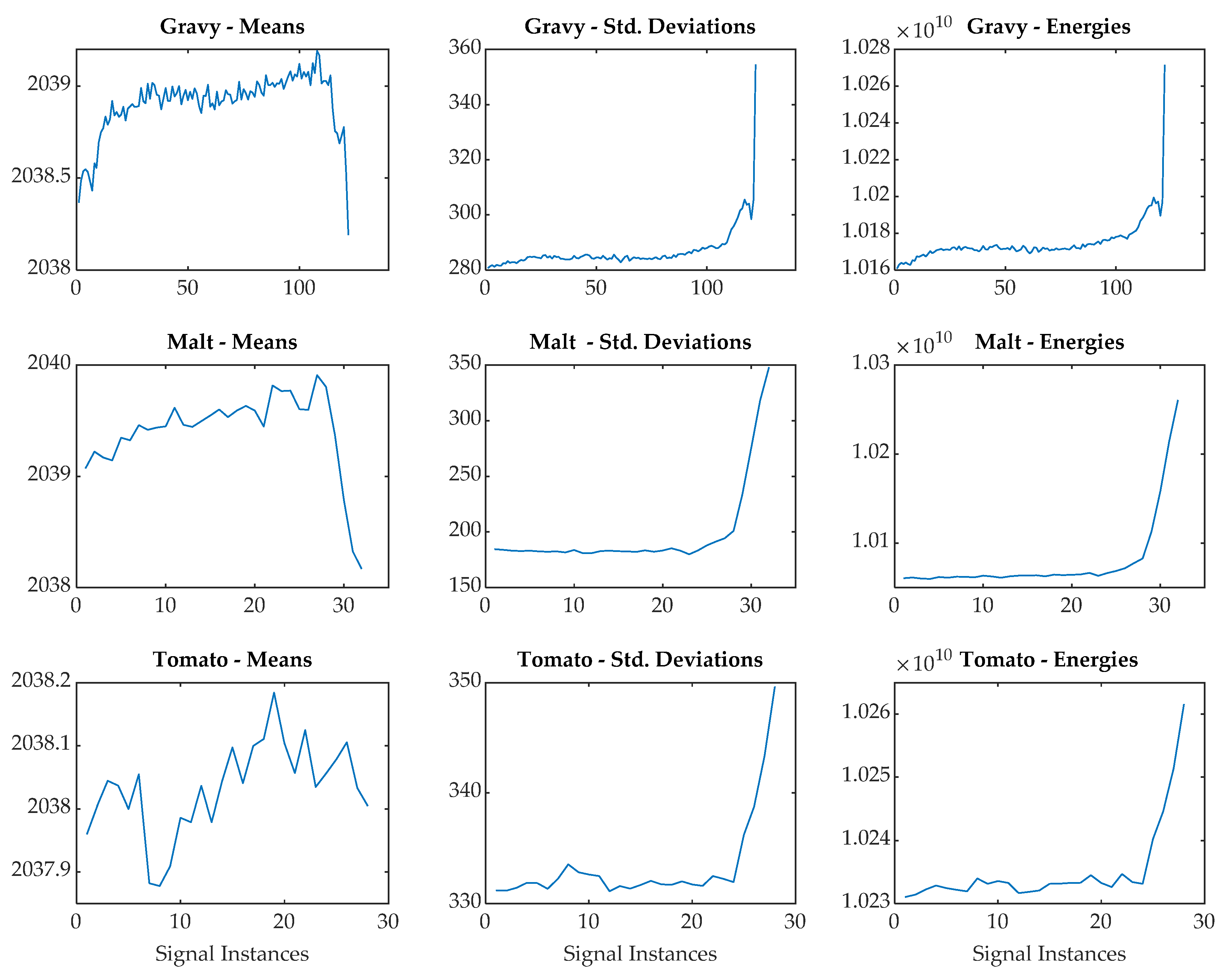

2.2. Data Processing and Features Extraction

2.2.1. Signal Processing

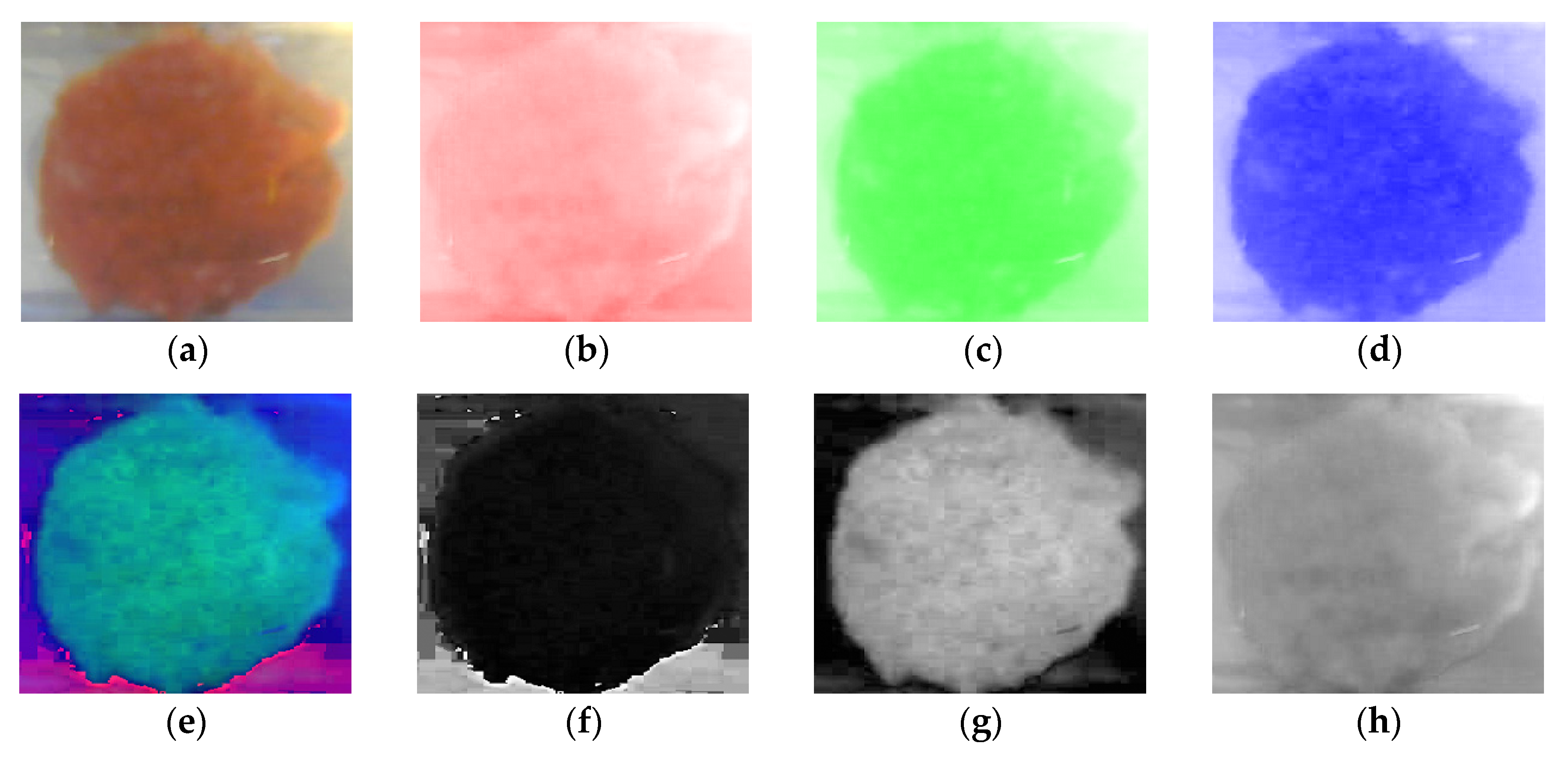

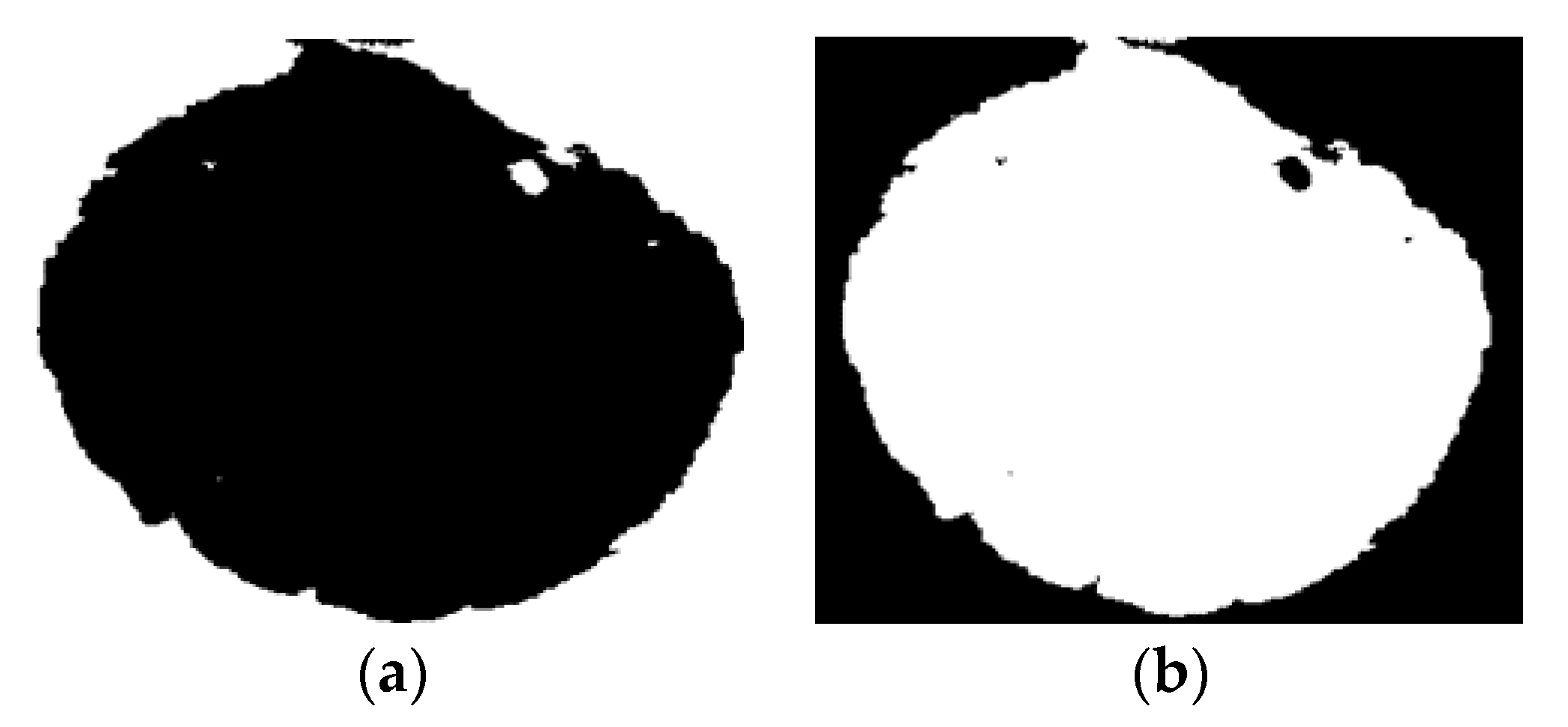

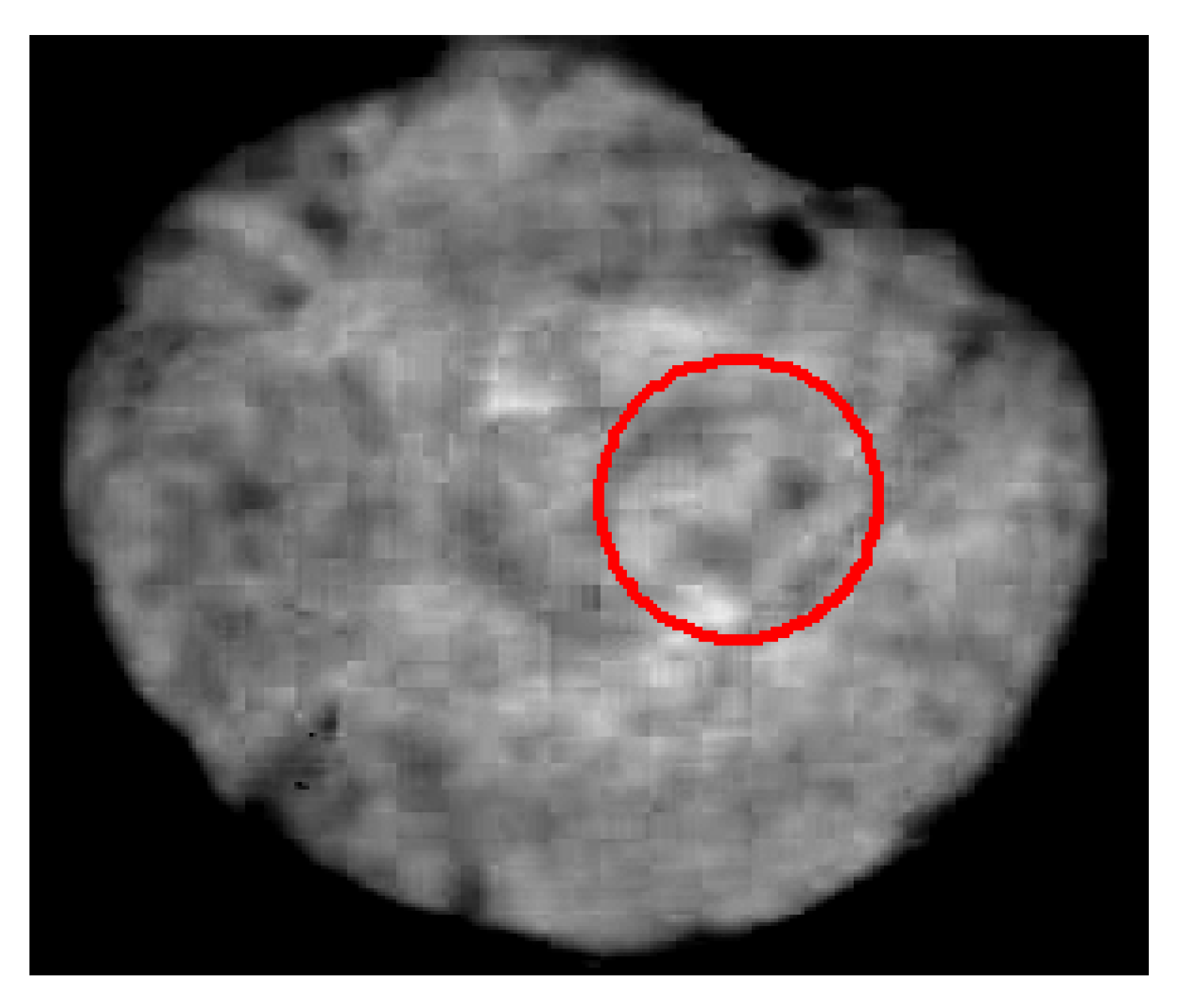

2.2.2. Image Processing

- Set the number of clusters , respectively “small”, “medium”, and “large” based on the pixel intensity value. The fuzzy matrix exponent was set to 2.

- Initialize the cluster membership with random values.

- Compute the cluster centers according to Equation (5):

- Update as per Equation (6):

- Compute the value of the objective function

- Recompute , , and until meeting a termination criterion, such as a minimum improvement or maximum number of iterations.

- Retrieve the final centroids coordinates and the final fuzzy membership degree of each piece of pixel data.

- Assign each pixel to one of the three clusters based on the maximum membership degree.

- Compute the maximum pixel intensity value for the cluster “small” and the minimum pixel intensity value for the cluster “medium” .

- Compute the threshold value as the average of the two values computed above, i.e.,

2.3. Machine Learning Regression for Surface Fouling and Fouling Volume Estimation

- Input layer nodes corresponding to the seven features extracted from the wavelet approximation coefficients

- Hidden layer nodes (HLN): 7

- Target layer: one node corresponding to the number of white pixels computed via image processing

- The training algorithm adopted in this research was the Bayesian Regularization (BR) [27].

- The dataset was partitioned into three sets using specified indices, specifically alternating one instance for training, one for validation, and one for testing [22].

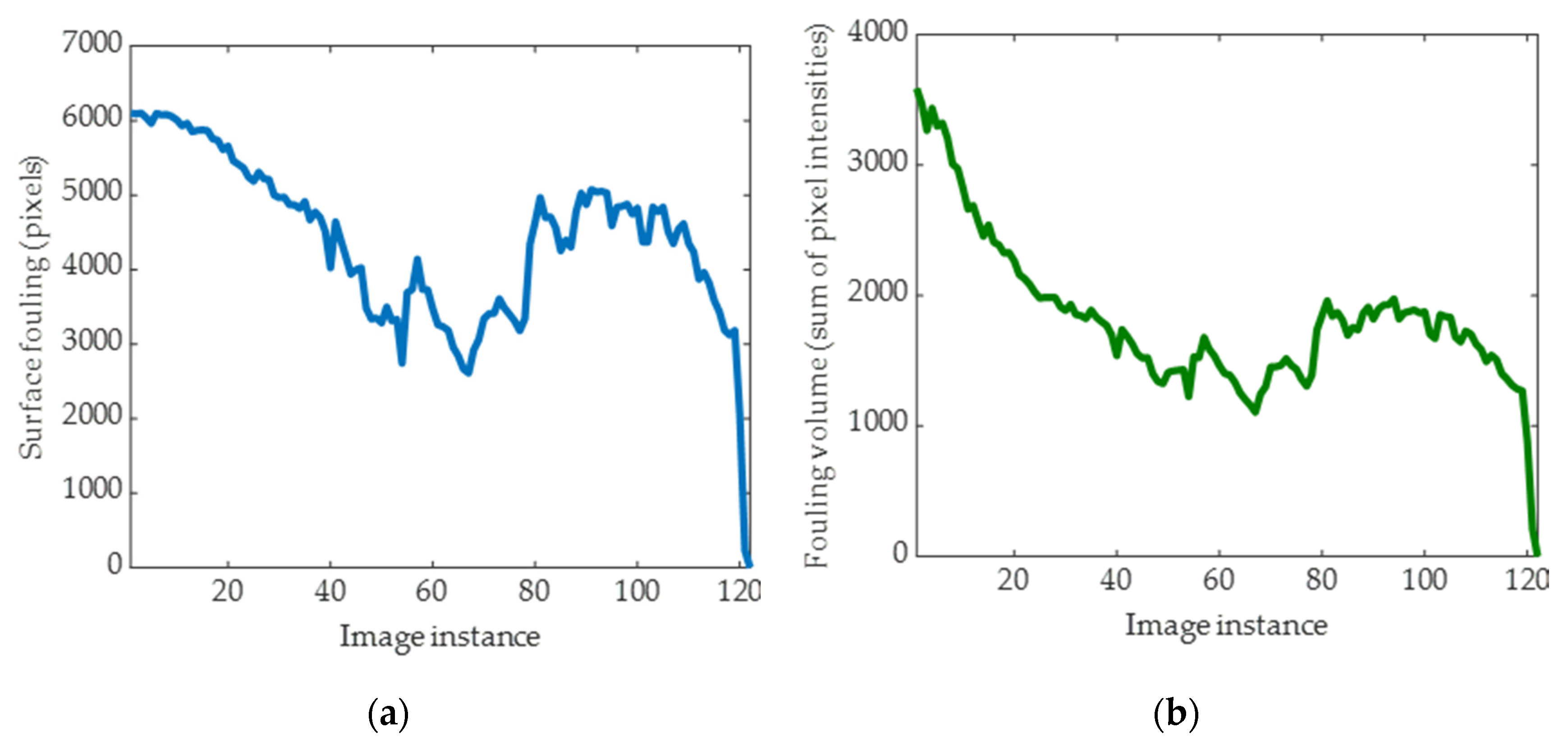

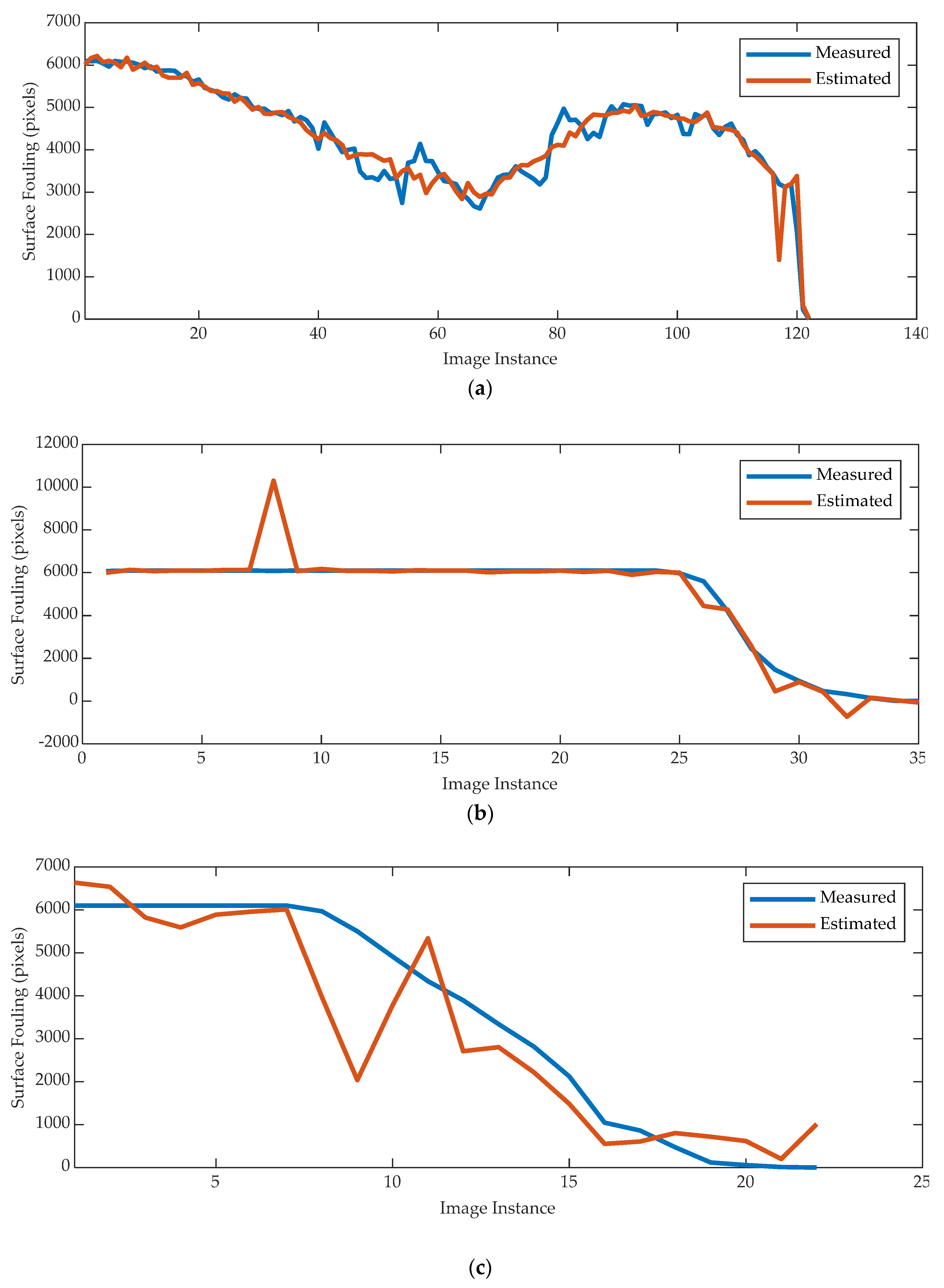

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fryer, P.; Christian, G.K.; Liu, W. How hygiene happens: Physics and chemistry of cleaning. Int. J. Dairy Technol. 2006, 59, 76–84. [Google Scholar] [CrossRef]

- Eide, M.; Homleid, J.; Mattsson, B. Life cycle assessment (LCA) of cleaning-in-place processes in dairies. LWT 2003, 36, 303–314. [Google Scholar] [CrossRef]

- Pettigrew, L.; Blomenhofer, V.; Hubert, S.; Groß, F.; Delgado, A. Optimisation of water usage in a brewery clean-in-place system using reference nets. J. Clean. Prod. 2015, 87, 583–593. [Google Scholar] [CrossRef]

- Fan, M.; Phinney, D.; Heldman, D.R. The impact of clean-in-place parameters on rinse water effectiveness and efficiency. J. Food Eng. 2018, 222, 276–283. [Google Scholar] [CrossRef]

- Fratamico, P.M.; Annous, B.A.; Iv, N.W.G. Biofilms in the Food and Beverage Industries; Woodhead: Cambridge, UK, 2009; pp. 1–580. [Google Scholar] [CrossRef]

- Lyndgaard, C.B.; Rasmussen, M.A.; Engelsen, S.B.; Thaysen, D.; Berg, F.V.D. Moving from recipe-driven to measurement-based cleaning procedures: Monitoring the Cleaning-In-Place process of whey filtration units by ultraviolet spectroscopy and chemometrics. J. Food Eng. 2014, 126, 82–88. [Google Scholar] [CrossRef]

- Berg, T.H.; Ottosen, N.; Berg, F.V.D.; Ipsen, R. Inline UV-Vis spectroscopy to monitor and optimize cleaning-in-place (CIP) of whey filtration plants. LWT 2017, 75, 164–170. [Google Scholar] [CrossRef]

- van Asselt, A.; van Houwelingen, G.; Giffel, M.T. Monitoring System for Improving Cleaning Efficiency of Cleaning-in-Place Processes in Dairy Environments. Food Bioprod. Process. 2002, 80, 276–280. [Google Scholar] [CrossRef]

- Wallhäußer, E.; Hussein, M.A.; Becker, T. Detection methods of fouling in heat exchangers in the food industry. Food Control. 2012, 27, 1–10. [Google Scholar] [CrossRef]

- Chen, X.D.; Li, D.X.Y.; Lin, S.X.Q.; Necati, O. On-line fouling/cleaning detection by measuring electric resistance–equipment development and application to milk fouling detection and chemical cleaning monitoring. Science 2003, 80, 8774. [Google Scholar] [CrossRef]

- Guerin, R.; Ronse, G.; Bouvier, L.; Debreyne, P.; Delaplace, G. Structure and rate of growth of whey protein deposit from in situ electrical conductivity during fouling in a plate heat exchanger. Chem. Eng. Sci. 2007, 62, 1948–1957. [Google Scholar] [CrossRef]

- Tlili, M.; Rousseau, P.; Ben Amor, M.; Gabrielli, C. An electrochemical method to study scaling by calcium sulphate of a heat transfer surface. Chem. Eng. Sci. 2008, 63, 559–566. [Google Scholar] [CrossRef]

- Withers, P.M. Ultrasonic, acoustic, and optical techniques for the non-invasive detection of fouling in food processing equipment. Trends Food Sci. Technol. 1996, 7, 293–298. [Google Scholar] [CrossRef]

- Simeone, A.; Deng, B.; Watson, N.; Woolley, E. Enhanced Clean-In-Place Monitoring Using Ultraviolet Induced Fluorescence and Neural Networks. Sensors 2018, 18, 3742. [Google Scholar] [CrossRef]

- Cheong, Y.-M.; Kim, K.-M.; Kim, D.-J. High-temperature ultrasonic thickness monitoring for pipe thinning in a flow-accelerated corrosion proof test facility. Nucl. Eng. Technol. 2017, 49, 1463–1471. [Google Scholar] [CrossRef]

- Simeone, A.; Watson, N.; Sterritt, I.; Woolley, E. A Multi-sensor Approach for Fouling Level Assessment in Clean-in-place Processes. Procedia CIRP 2016, 55, 134–139. [Google Scholar] [CrossRef]

- Tamachkiarow, A.; Flemming, H.-C. On-line monitoring of biofilm formation in a brewery water pipeline system with a fibre optical device. Water Sci. Technol. 2003, 47, 19–24. [Google Scholar] [CrossRef] [PubMed]

- Pereira, A.; Mendes, J.; Melo, L. Monitoring cleaning-in-place of shampoo films using nanovibration technology. Sensors Actuators B Chem. 2009, 136, 376–382. [Google Scholar] [CrossRef]

- Úbeda, M.A.; Hussein, W.B.; Hussein, M.A.; Hinrichs, J.; Becker, T.M. Acoustic sensing, and signal processing techniques for monitoring milk fouling cleaning operations. Eng. Life Sci. 2015, 16, 67–77. [Google Scholar] [CrossRef]

- Escrig, J.; Woolley, E.; Simeone, A.; Watson, N.J. Monitoring the cleaning of food fouling in pipes using ultrasonic measurements and machine learning. Food Control 2020. [Google Scholar] [CrossRef]

- Wallhäußer, E.; Hussein, W.B.; Hussein, M.A.; Hinrichs, J.; Becker, T. Detection of dairy fouling: Combining ultrasonic measurements and classification methods. Eng. Life Sci. 2013, 13, 292–301. [Google Scholar] [CrossRef]

- Wallhäußer, E.; Hussein, W.B.; Hussein, M.A.; Hinrichs, J.; Becker, T.M. On the usage of acoustic properties combined with an artificial neural network—A new approach of determining presence of dairy fouling. J. Food Eng. 2011, 103, 449–456. [Google Scholar] [CrossRef]

- Wallhäußer, E.; Sayed, A.; Nöbel, S.; Hussein, M.A.; Hinrichs, J.; Becker, T. Determination of cleaning end of dairy protein fouling using an online system combining ultrasonic and classification methods. Food Bioprocess Technol. 2013, 7, 506–515. [Google Scholar] [CrossRef]

- Pereira, A.; Rosmaninho, R.; Mendes, J.; Melo, L. Monitoring Deposit Build-up using a Novel Mechatronic Surface Sensor (MSS). Food Bioprod. Process. 2006, 84, 366–370. [Google Scholar] [CrossRef][Green Version]

- Wallhäußer, E.; Hussein, M.A.; Becker, T. Investigating and understanding fouling in a planar setup using ultrasonic methods. Rev. Sci. Instrum. 2012, 83, 94904. [Google Scholar] [CrossRef]

- Chen, B.; Callens, D.; Campistron, P.; Moulin, E.; Debreyne, P.; Delaplace, G. Monitoring cleaning cycles of fouled ducts using ultrasonic coda wave interferometry (CWI). Ultrasonics 2019, 96, 253–260. [Google Scholar] [CrossRef]

- Escrig, J.; Woolley, E.; Rangappa, S.; Simeone, A.; Watson, N.; Escrig, E.J. Clean-in-place monitoring of different food fouling materials using ultrasonic measurements. Food Control 2019, 104, 358–366. [Google Scholar] [CrossRef]

- Eckstein, M.; Vrabeľ, M.; Maňková, I. Application of Discrete Wavelet Decomposition in Monitoring of Hole-making Inconel 718. Procedia CIRP 2017, 62, 250–255. [Google Scholar] [CrossRef]

- Shao, H.; Shi, X.; Li, L. Power signal separation in milling process based on wavelet transform and independent component analysis. Int. J. Mach. Tools Manuf. 2011, 51, 701–710. [Google Scholar] [CrossRef]

- Segreto, T.; Karam, S.; Teti, R. Signal processing and pattern recognition for surface roughness assessment in multiple sensors monitoring of robot-assisted polishing. Int. J. Adv. Manuf. Technol. 2016, 90, 1023–1033. [Google Scholar] [CrossRef]

- Karam, S.; Teti, R. Wavelet Transform Feature Extraction for Chip form Recognition during Carbon Steel Turning. Procedia CIRP 2013, 12, 97–102. [Google Scholar] [CrossRef]

- Li, H.-Y.; Hwang, W.-J.; Chang, C.-Y. Efficient Fuzzy C-Means Architecture for Image Segmentation. Sensors 2011, 11, 6697–6718. [Google Scholar] [CrossRef]

- Ghosh, S.; Kumar, S.; Dubey, S.K. Comparative Analysis of K-Means and Fuzzy C-Means Algorithms. Int. J. Adv. Comput. Sci. Appl. 2013, 4, 4. [Google Scholar] [CrossRef]

- Xiong, G.; Zhou, X.; Ji, L. Automated Segmentation of Drosophila RNAi Fluorescence Cellular Images Using Deformable Models. IEEE Trans. Circuits Syst. I Regul. Pap. 2006, 53, 2415–2424. [Google Scholar] [CrossRef]

- Marwala, T. Multi-layer Perceptron. In Handbook of Machine Learning; World Scientific: 5 Toh Tuck Link, Singapore, 2018. [Google Scholar]

- Rajani, C.; Klami, A.; Salmi, A.; Rauhala, T.; Haggstrom, E.; Myllymaki, P. Detecting industrial fouling by monotonicity during ultrasonic cleaning. In Proceedings of the 2018 IEEE 28th International Workshop on Machine Learning for Signal Processing (MLSP), Aalborg, Denmark, 17–20 September 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Fryer, P.; Asteriadou, K. A prototype cleaning map: A classification of industrial cleaning processes. Trends Food Sci. Technol. 2009, 20, 255–262. [Google Scholar] [CrossRef]

- Cuckston, G.; Alam, Z.; Goodwin, J.; Ward, G.; Wilson, D. Quantifying the effect of solution formulation on the removal of soft solid food deposits from stainless steel substrates. J. Food Eng. 2019, 243, 22–32. [Google Scholar] [CrossRef]

- Wilson, D. Fouling during food Processing—Progress in tackling this inconvenient truth. Curr. Opin. Food Sci. 2018, 23, 105–112. [Google Scholar] [CrossRef]

- Malat, S.G. A theory for multiresolution signal decomposition: The wavelet representation. IEEE Trans. Pattern Anal. Mach. Intell. 1989, 11, 674–693. [Google Scholar] [CrossRef]

- Reyes-Archundia, E.; Antonio, J.; Rivas-Davalos, F. Discrete Wavelet Transform Application to the Protection of Electrical Power System: A Solution Approach for Detecting and Locating Faults in FACTS Environment. In Advances in Wavelet Theory and Their Applications in Engineering, Physics and Technology; IntechOpen: London, UK, 2012. [Google Scholar]

- Daubechies, I. The wavelet transform, time-frequency localization, and signal analysis. IEEE Trans. Inf. Theory 1990, 36, 961–1005. [Google Scholar] [CrossRef]

- Caggiano, A.; Angelone, R.; Napolitano, F.; Nele, L.; Teti, R. Dimensionality Reduction of Sensorial Features by Principal Component Analysis for ANN Machine Learning in Tool Condition Monitoring of CFRP Drilling. Procedia CIRP 2018, 78, 307–312. [Google Scholar] [CrossRef]

- Thompson, M.; Gonzalez, R.C.; Wintz, P. Digital Image Processing. Leon 1981, 14, 256. [Google Scholar] [CrossRef]

- Bowler, A.L.; Bakalis, S.; Watson, N. Monitoring Mixing Processes Using Ultrasonic Sensors and Machine Learning. Sensors 2020, 20, 1813. [Google Scholar] [CrossRef] [PubMed]

| Fouling Material | Temperature | Repetitions |

|---|---|---|

| Gravy | 12 °C | 2 |

| 45 °C | 7 | |

| Malt | 12 °C | 7 |

| 45 °C | 7 | |

| Tomato | 12 °C | 7 |

| 45 °C | 7 |

| Surface Fouling | ||||||

|---|---|---|---|---|---|---|

| Dataset | R | RMSE | ||||

| Training | Test | Overall | Training | Test | Overall | |

| Gravy Cold | 0.9210 | 0.8923 | 0.9175 | 360.4690 | 363.6912 | 361.6612 |

| Gravy Hot | 0.9275 | 0.9355 | 0.9285 | 723.6536 | 660.2220 | 700.1839 |

| Gravy Cold+Hot | 0.9271 | 0.8486 | 0.9149 | 544.6095 | 790.3567 | 635.5366 |

| Malt Cold | 0.9978 | 0.9132 | 0.9635 | 156.9672 | 1142.7719 | 521.7149 |

| Malt Hot | 0.9462 | 0.8524 | 0.9195 | 744.4553 | 1131.9732 | 887.8369 |

| Malt Cold+Hot | 0.9813 | 0.9595 | 0.9784 | 469.5991 | 656.6640 | 538.8131 |

| Tomato Cold | 0.9439 | 0.9056 | 0.9305 | 670.1577 | 914.743 | 760.6543 |

| Tomato Hot | 0.9359 | 0.9256 | 0.9324 | 832.4331 | 883.7525 | 851.4213 |

| Tomato Cold+Hot | 0.9104 | 0.9136 | 0.9075 | 912.20 | 1023.70 | 953.4550 |

| COLD | 0.9395 | 0.9310 | 0.9366 | 616.4055 | 659.4567 | 632.3344 |

| HOT | 0.9238 | 0.8576 | 0.9006 | 838.0589 | 1157.3449 | 956.1947 |

| ALL | 0.9173 | 0.8320 | 0.8877 | 783.6593 | 1120.2075 | 908.1821 |

| Fouling Volume | ||||||

|---|---|---|---|---|---|---|

| Dataset | R | RMSE | ||||

| Training | Test | Overall | Training | Test | Overall | |

| Gravy Cold | 0.9673 | 0.9307 | 0.9337 | 112.9609 | 130.3614 | 119.3991 |

| Gravy Hot | 0.8169 | 0.8025 | 0.8119 | 800.9874 | 857.0363 | 821.7255 |

| Gravy Cold+Hot | 0.9119 | 0.7079 | 0.8772 | 466.5958 | 869.9793 | 615.8477 |

| Malt Cold | 0.9728 | 0.7890 | 0.9027 | 453.6082 | 1374.5441 | 794.3545 |

| Malt Hot | 0.9461 | 0.8024 | 0.9016 | 669.7703 | 1174.9157 | 856.6741 |

| Malt Cold+Hot | 0.9336 | 0.9121 | 0.9301 | 734.3514 | 815.3636 | 764.3259 |

| Tomato Cold | 0.9498 | 0.8422 | 0.9116 | 413.8871 | 739.6857 | 534.4326 |

| Tomato Hot | 0.9833 | 0.9399 | 0.9690 | 289.2188 | 546.4321 | 384.3877 |

| Tomato Cold+Hot | 0.9232 | 0.9071 | 0.9176 | 573.7849 | 623.9646 | 592.3514 |

| COLD | 0.9387 | 0.9095 | 0.9287 | 493.7523 | 603.0507 | 534.1927 |

| HOT | 0.8584 | 0.8201 | 0.8453 | 789.2190 | 901.1648 | 830.6389 |

| ALL | 0.9243 | 0.8264 | 0.8897 | 571.2305 | 878.7315 | 685.0059 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simeone, A.; Woolley, E.; Escrig, J.; Watson, N.J. Intelligent Industrial Cleaning: A Multi-Sensor Approach Utilising Machine Learning-Based Regression. Sensors 2020, 20, 3642. https://doi.org/10.3390/s20133642

Simeone A, Woolley E, Escrig J, Watson NJ. Intelligent Industrial Cleaning: A Multi-Sensor Approach Utilising Machine Learning-Based Regression. Sensors. 2020; 20(13):3642. https://doi.org/10.3390/s20133642

Chicago/Turabian StyleSimeone, Alessandro, Elliot Woolley, Josep Escrig, and Nicholas James Watson. 2020. "Intelligent Industrial Cleaning: A Multi-Sensor Approach Utilising Machine Learning-Based Regression" Sensors 20, no. 13: 3642. https://doi.org/10.3390/s20133642

APA StyleSimeone, A., Woolley, E., Escrig, J., & Watson, N. J. (2020). Intelligent Industrial Cleaning: A Multi-Sensor Approach Utilising Machine Learning-Based Regression. Sensors, 20(13), 3642. https://doi.org/10.3390/s20133642