Selective Ultrasonic Gravimetric Sensors Based on Capacitive Micromachined Ultrasound Transducer Structure—A Review

Abstract

1. Introduction

2. Electromechanical Part

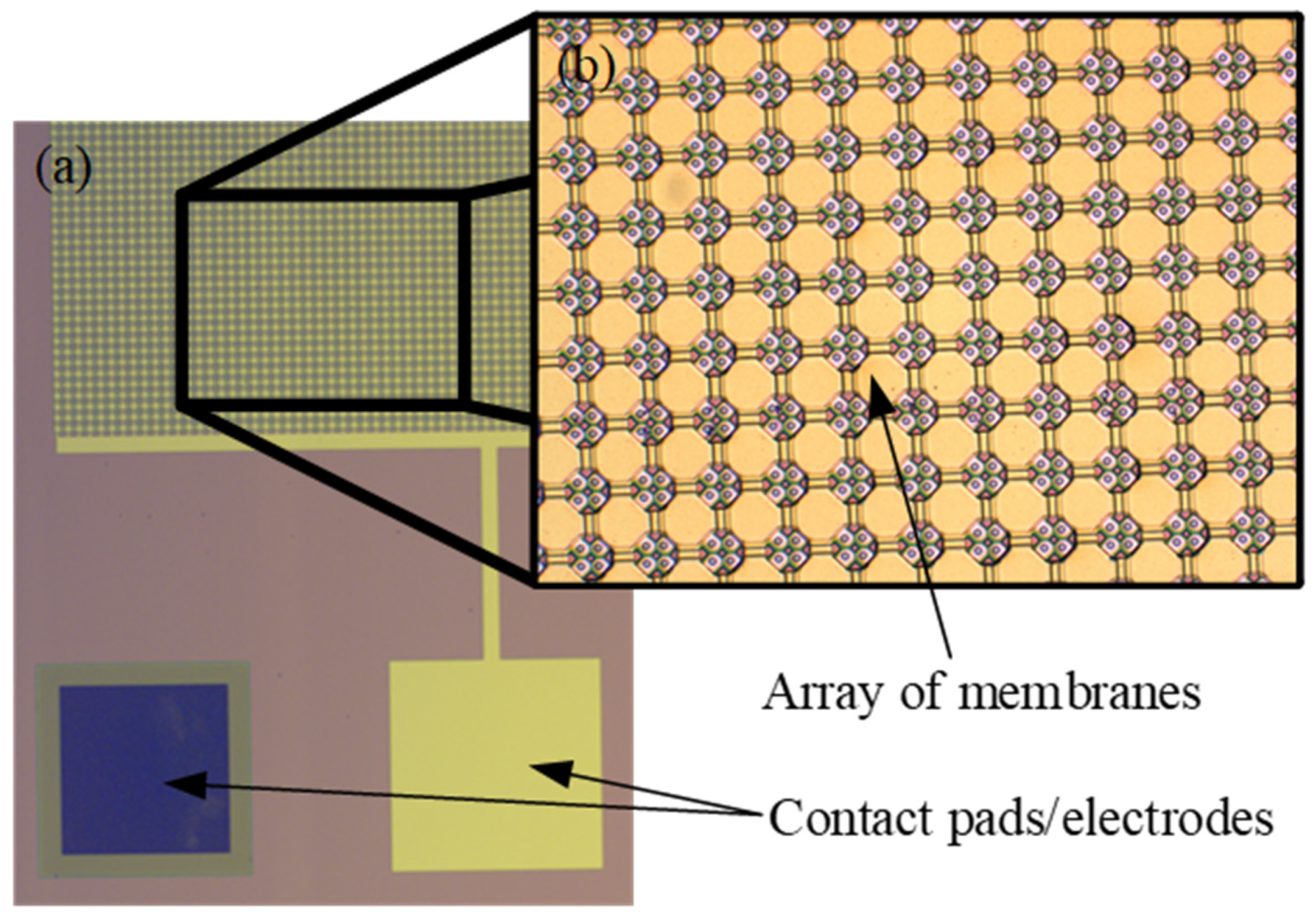

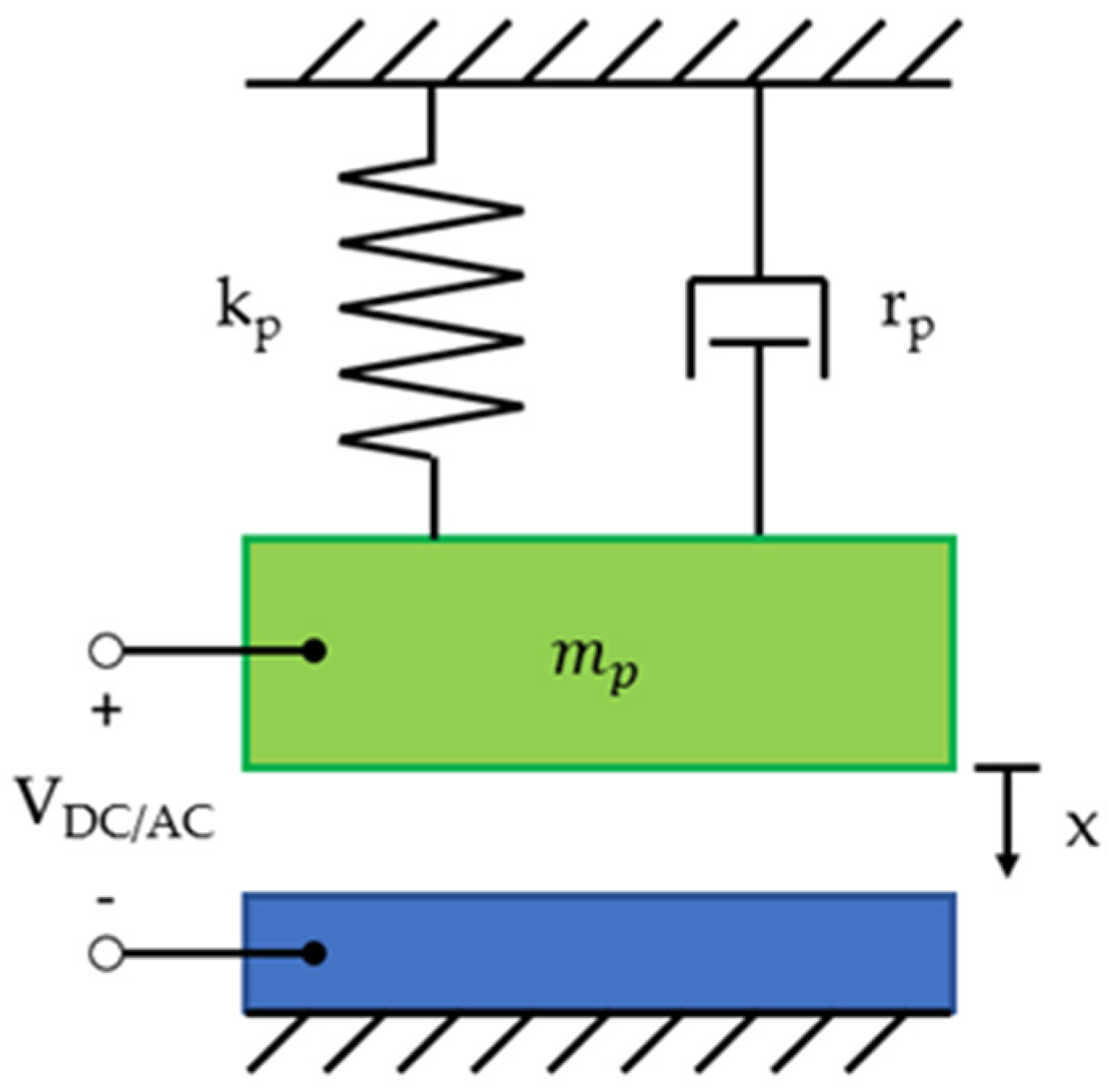

2.1. CMUT Structure and Working Principle

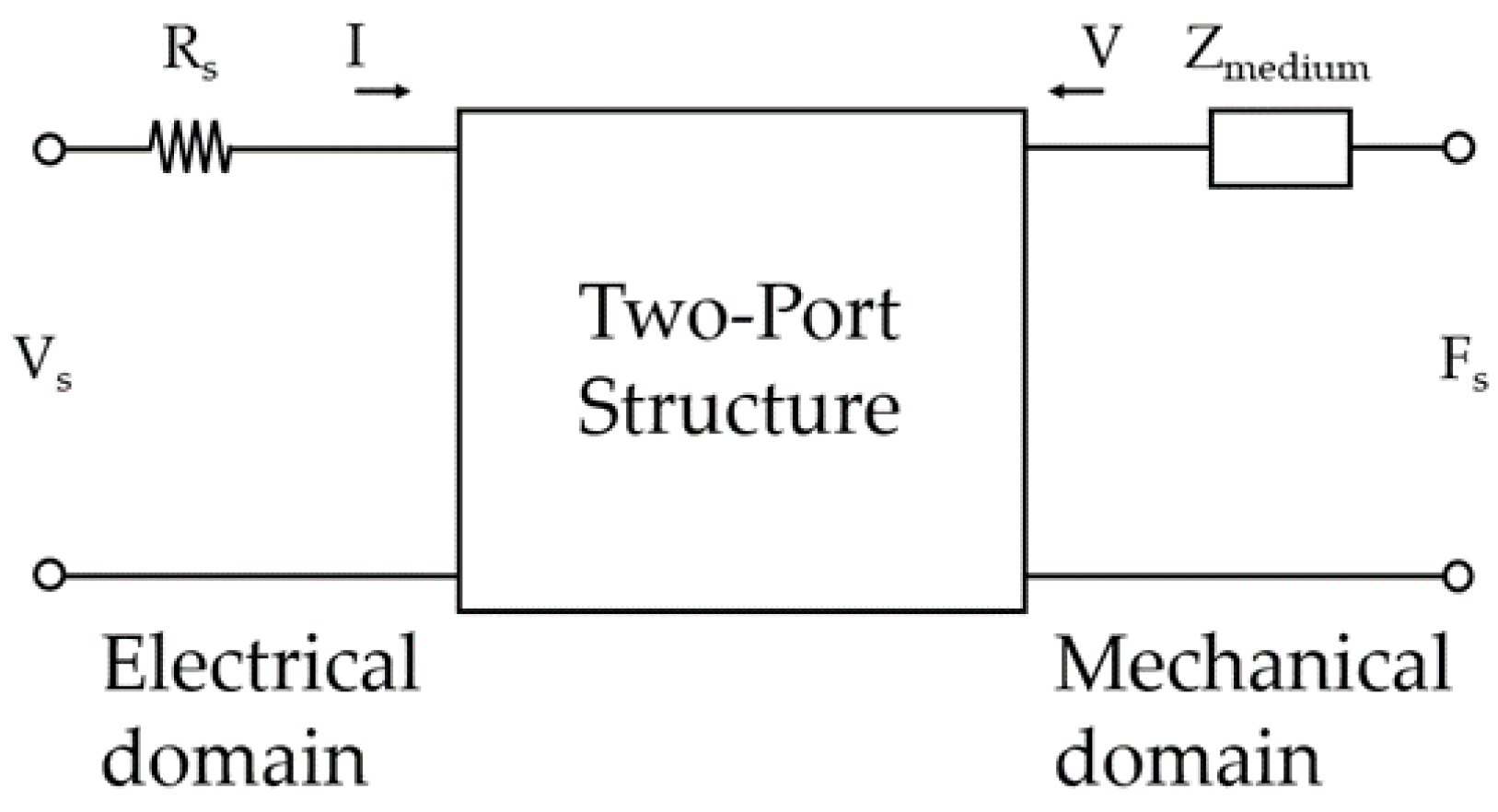

2.2. Theoretical Background for the CMUT-Based SUGS

2.3. CMUT Fabrication Methods

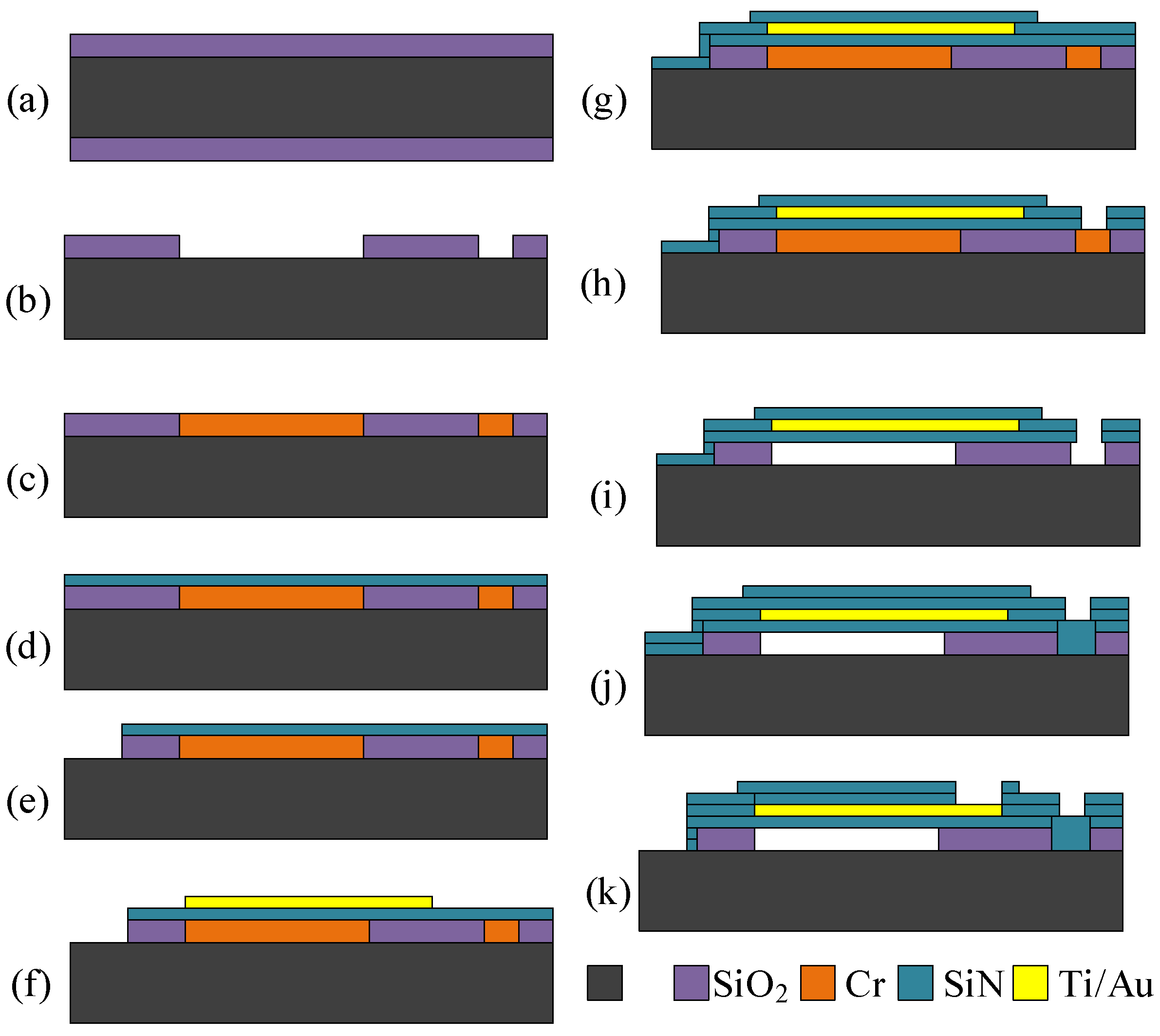

2.3.1. Sacrificial Release CMUT Fabrication Method

2.3.2. The Basic Wafer Bonding Method

2.3.3. Advanced Wafer Bonding Methods

2.3.4. Commonly Used Materials for CMUT Fabrication

3. Functional Materials

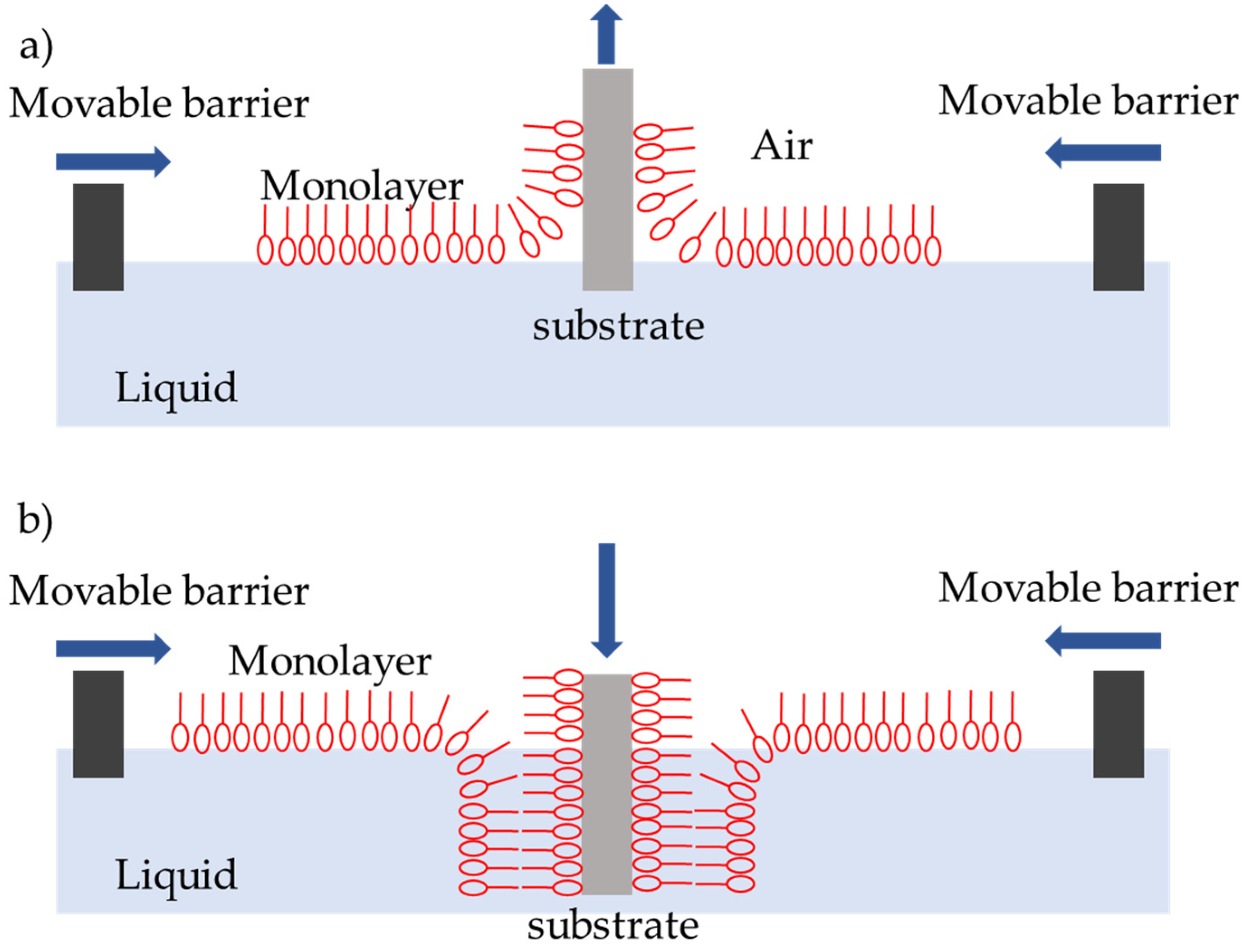

3.1. Surface Functionalization Methods

3.2. Materials for Surface Functionalization and Gas Sensing Applications

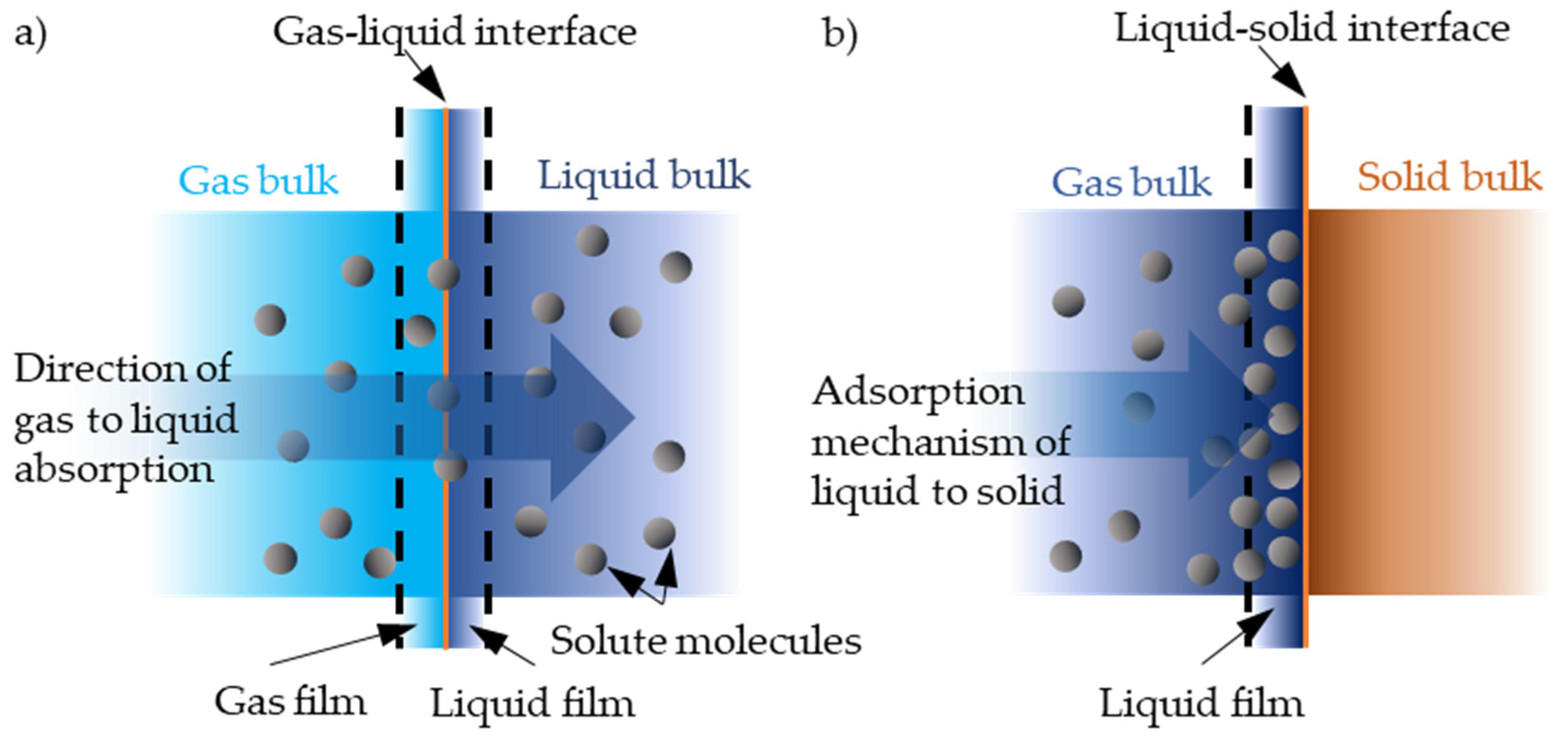

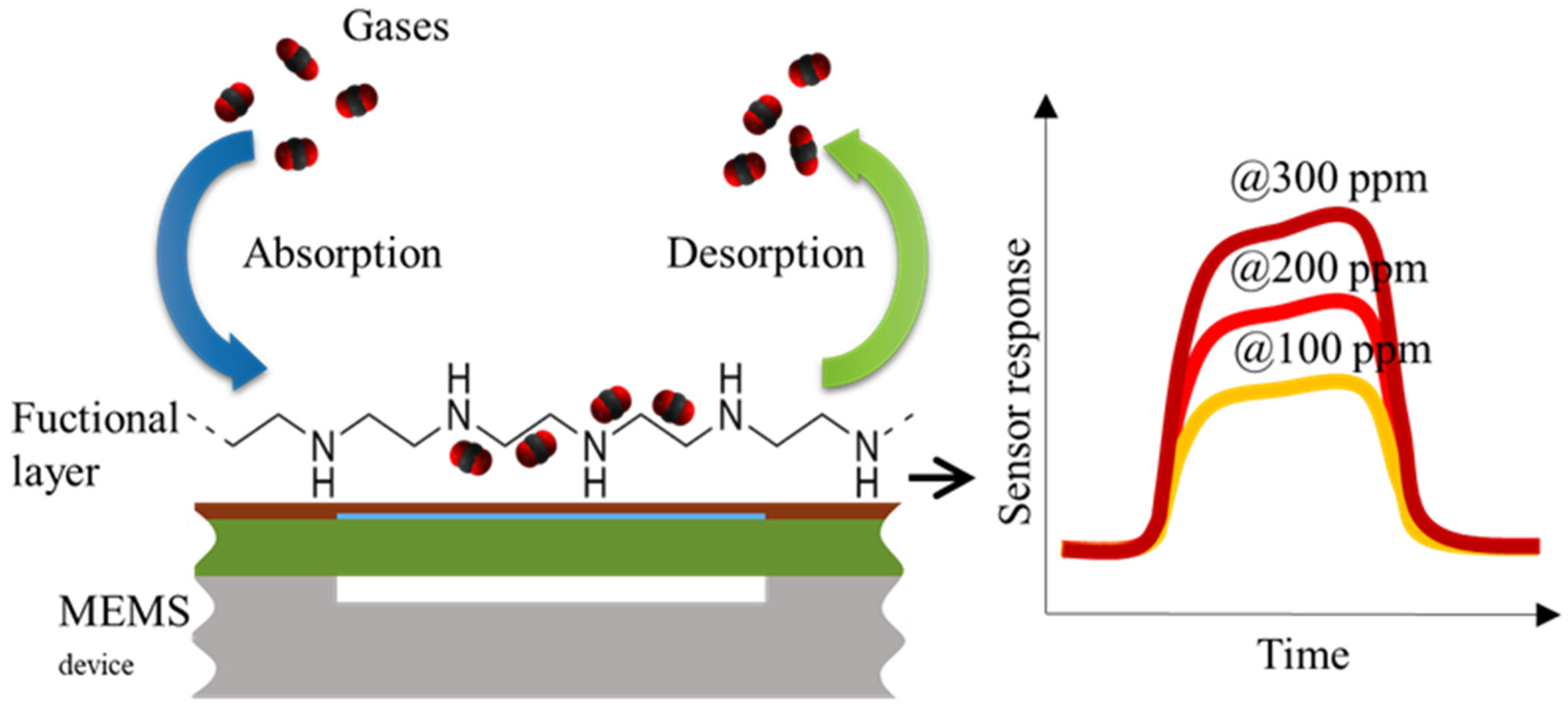

3.3. Absorption Mechanisms of Functional Materials

3.4. Gas and Biomolecule Sensing with SUGS Featuring CMUT Structure

3.5. Measurement of the CMUT Gravimetric Sensor

4. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Virzonis, D.; Vanagas, G.; Ramanaviciene, A.; Makaraviciute, A.; Barauskas, D.; Ramanavicius, A.; Wen, W.; Kodzius, R. Resonant gravimetric immunosensing based on capacitive micromachined ultrasound transducers. Microchim. Acta 2014, 181, 1749–1757. [Google Scholar] [CrossRef]

- Molgaard, M.J.G.; Hansen, J.M.F.; Jakobsen, M.H.; Thomsen, E.V. Sensitivity Optimization of Wafer Bonded Gravimetric CMUT Sensors. J. Microelectromech. Syst. 2018, 27, 1089–1096. [Google Scholar] [CrossRef]

- Molgaard, M.J.G.; Laustsen, M.; Thygesen, I.L.; Jakobsen, M.H.; Andresen, T.L.; Thomsen, E.V. Combined colorimetric and gravimetric CMUT sensor for detection of phenylacetone. In Proceedings of the IEEE International Ultrasonics Symposium, Washington, DC, USA, 6–9 September 2017. [Google Scholar]

- Park, K.K.; Lee, H.; Kupnik, M.; Oralkan, Ö.; Ramseyer, J.-P.; Lang, H.P.; Hegner, M.; Gerber, C.; Khuri-Yakub, B.T. Capacitive micromachined ultrasonic transducer (CMUT) as a chemical sensor for DMMP detection. Sens. Actuators B Chem. 2011, 160, 1120–1127. [Google Scholar] [CrossRef]

- Lee, H.J.; Park, K.K.; Kupnik, M.; Oralkan, O.; Khuri-Yakub, B.T. Highly sensitive detection of DMMP using a CMUT-based chemical sensor. In Proceedings of the 2010 IEEE Sensors, Kona, HI, USA, 1–4 November 2010; pp. 2122–2126. [Google Scholar]

- Lee, H.J.; Park, K.K.; Kupnik, M.; Oralkan, Ö.; Khuri-Yakub, B.T.; Oralkan, O.; Khuri-Yakub, B.T.; Oralkan, Ö.; Khuri-Yakub, B.T. Chemical Vapor Detection Using a Capacitive Micromachined Ultrasonic Transducer. Anal. Chem. 2011, 83, 9314–9320. [Google Scholar] [CrossRef] [PubMed]

- Barauskas, D.; Park, S.J.; Pelenis, D.; Vanagas, G.; Lee, J.J.; Virzonis, D.; Jones, C.W.; Baltrusaitis, J.; Viržonis, D.; Jones, C.W.; et al. CO2 and SO2 interactions with methylated poly(ethyleneimine) functionalized Capacitive Micromachined Ultrasonic Transducers (CMUTs): Gas sensing and degradation mechanism. ACS Appl. Electron. Mater. 2019, acsaelm.9b00151. [Google Scholar]

- Lee, H.J.; Park, K.K.; Oralkan, O.; Kupnik, M.; Khuri-Yakub, B.T. CMUT as a chemical sensor for DMMP detection. In Proceedings of the 2008 IEEE International Frequency Control Symposium, Honolulu, HI, USA, 16–21 May 2008; pp. 434–439. [Google Scholar]

- Barauskas, D.; Pelenis, D.; Virzonis, D.; Baltrus, J.P.; Baltrusaitis, J. Greenhouse Gas Molecule CO2 Detection Using a Capacitive Micromachined Ultrasound Transducer. Anal. Chem. 2016, 88, 6662–6665. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.J.; Park, K.K.; Kupnik, M.; Khuri-Yakub, B.T. Functionalization layers for CO2 sensing using capacitive micromachined ultrasonic transducers. Sens. Actuators B Chem. 2012, 174, 87–93. [Google Scholar] [CrossRef]

- Eaimkhong, S. Label-Free Biodetection Using Capacitive Micromachined Ultrasonic Transducers (CMUTs) and Its Application for Cardiovascular Disease Diagnostics. J. Nanomed. Nanotechnol. 2012, 3. [Google Scholar] [CrossRef]

- Barauskas, D.; Pelenis, D.; Sergalis, G.; Vanagas, G.; Mikolajunas, M.; Virzonis, D.; Baltrusaitis, J. CMUT for high sensitivity greenhouse gas sensing. In Proceedings of the 2015 IEEE International Ultrasonics Symposium (IUS), Taipei, Taiwan, 21–24 October 2015; pp. 1–4. [Google Scholar]

- Patil, S.J.; Patil, A.V.; Dighavkar, C.G.; Thakare, K.S.; Borase, R.Y.; Nandre, S.J.; Deshpande, N.G.; Ahire, R.R. Semiconductor metal oxide compounds based gas sensors: A literature review. Front. Mater. Sci. 2015, 9, 14–37. [Google Scholar] [CrossRef]

- Mondal, B.; Maity, S.; Das, S.; Panda, D.; Saha, H.; Kundu, A. Fabrication and packaging of MEMS based platform for hydrogen sensor using ZnO–SnO2 composites. Microsyst. Technol. 2016, 22, 2757–2764. [Google Scholar] [CrossRef]

- Mirzaei, A.; Janghorban, K.; Hashemi, B.; Neri, G. Metal-core@metal oxide-shell nanomaterials for gas-sensing applications: A review. J. Nanoparticle Res. 2015, 17, 371. [Google Scholar] [CrossRef]

- Long, H.; Zeng, W.; Zhang, H. Synthesis of WO3 and its gas sensing: A review. J. Mater. Sci. Mater. Electron. 2015, 26, 4698–4707. [Google Scholar] [CrossRef]

- Ulasevich, A.L.; Gorelik, A.V.; Kouzmouk, A.A.; Starovoitov, V.S. A compact resonant Π-shaped photoacoustic cell with low window background for gas sensing. Appl. Phys. B 2014, 117, 549–561. [Google Scholar] [CrossRef]

- Şennik, E.; Soysal, U.; Öztürk, Z.Z. Pd loaded spider-web TiO2 nanowires: Fabrication, characterization and gas sensing properties. Sens. Actuators B Chem. 2014, 199, 424–432. [Google Scholar] [CrossRef]

- Guerrero, R.S.; Nguyen, F.; Yoshikawa, G.; Guerrero, R.J.S.; Nguyen, F.; Yoshikawa, G. Real-time gas identification on mobile platforms using a nanomechanical membrane-type surface stress sensor. EPJ Tech. Instrum. 2014, 1, 9. [Google Scholar] [CrossRef]

- Lai, Y.-T.; Kuo, J.-C.; Yang, Y.-J. A novel gas sensor using polymer-dispersed liquid crystal doped with carbon nanotubes. Sens. Actuators A Phys. 2014, 215, 83–88. [Google Scholar] [CrossRef]

- Khine, L.; Tsai, J.M.; Heidari, A.; Yoon, Y.-J. Piezoelectric MEMS resonant gas sensor for defence applications. In Proceedings of the 2011 Defense Science Research Conference and Expo (DSR), Singapore, 3–5 August 2011; pp. 1–3. [Google Scholar]

- Fraiwan, A.; Lee, H.; Choi, S. A paper-based cantilever array sensor: Monitoring volatile organic compounds with naked eye. Talanta 2016, 158, 57–62. [Google Scholar] [CrossRef]

- Moon, S.E. Semiconductor-Type MEMS Gas Sensor for Real-Time Environmental Monitoring Applications. ETRI J. 2013, 35, 617–624. [Google Scholar] [CrossRef]

- Hynes, S.; Morrissey, K.; O’Donoghue, C. Modelling Greenhouse Gas Emissions from Agriculture; Springer: Berlin/Heidelberg, Germany, 2013; pp. 143–157. ISBN 1430-9602. [Google Scholar]

- Harkiolakis, N. Greenhouse Gases. In Encyclopedia of Corporate Social Responsibility; Springer: Berlin/Heidelberg, Germany, 2013; pp. 1309–1314. [Google Scholar]

- Galashev, A.E.; Rakhmanova, O.R. Emissivity of the main greenhouse gases. Russ. J. Phys. Chem. B 2013, 7, 346–353. [Google Scholar] [CrossRef]

- Wasisto, H.S.; Uhde, E.; Peiner, E. Enhanced performance of pocket-sized nanoparticle exposure monitor for healthy indoor environment. Build. Environ. 2016, 95, 13–20. [Google Scholar] [CrossRef]

- Bogue, R. Recent developments in MEMS sensors: A review of applications, markets and technologies. Sens. Rev. 2013, 33, 300–304. [Google Scholar] [CrossRef]

- Mohapatra, P.; Panigrahi, S.; Amamcharla, J. Evaluation of a commercial electronic nose system coupled with universal gas sensing chamber for sensing indicator compounds associated with meat safety. J. Food Meas. Charact. 2015, 9, 121–129. [Google Scholar] [CrossRef]

- Kweku, D.; Bismark, O.; Maxwell, A.; Desmond, K.; Danso, K.; Oti-Mensah, E.; Quachie, A.; Adormaa, B. Greenhouse Effect: Greenhouse Gases and Their Impact on Global Warming. J. Sci. Res. Rep. 2018. [Google Scholar] [CrossRef]

- Edenhofer, R.; Pichs-Madruga, Y.; Sokona, E.; Farahani, S.; Kadner, K.; Seyboth, A.; Adler, I.; Baum, S.; Brunner, P.; Eickemeier, B.; et al. (Eds.) IPCC, 2014: Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2015; ISBN 9781107058217. [Google Scholar]

- Gusakova, M.A.; Karlin, L.N. Assessment of contribution of greenhouse gases, water vapor, and cloudiness to the variations of global surface air temperature. Russ. Meteorol. Hydrol. 2014, 39, 146–151. [Google Scholar] [CrossRef]

- Stavi, I.; Lal, R. Agriculture and greenhouse gases, a common tragedy. A review. Agron. Sustain. Dev. 2013, 33, 275–289. [Google Scholar] [CrossRef]

- Le Quéré, C.; Peters, G.P.; Andres, R.J.; Andrew, R.M.; Boden, T.A.; Ciais, P.; Friedlingstein, P.; Houghton, R.A.; Marland, G.; Moriarty, R.; et al. Global carbon budget 2013. Earth Syst. Sci. Data 2014, 6, 235–263. [Google Scholar] [CrossRef]

- Delorme, N.; Blanc, C.; Dezzani, A.; Bély, M.; Ferret, A.; Laminette, S.; Roudier, J.; Colinet, E. A NEMS-Array Control IC for Subattogram Mass Sensing Applications in 28 nm CMOS Technology. IEEE J. Solid-State Circuits 2016, 51, 249–258. [Google Scholar]

- Lussac, E.; Barattin, R.; Cardinael, P.; Agasse, V. Review on Micro-Gas Analyzer Systems: Feasibility, Separations and Applications. Crit. Rev. Anal. Chem. 2016, 46, 455–468. [Google Scholar] [CrossRef] [PubMed]

- Fanget, S.; Hentz, S.; Puget, P.; Arcamone, J.; Matheron, M.; Colinet, E.; Andreucci, P.; Duraffourg, L.; Meyers, E.; Roukes, M.L.L.; et al. Gas sensors based on gravimetric detection—A review. Sens. Actuators B Chem. 2011, 160, 804–821. [Google Scholar] [CrossRef]

- Wetchakun, K.; Samerjai, T.; Tamaekong, N.; Liewhiran, C.; Siriwong, C.; Kruefu, V.; Wisitsoraat, A.; Tuantranont, A.; Phanichphant, S. Semiconducting metal oxides as sensors for environmentally hazardous gases. Sens. Actuators B Chem. 2011, 160, 580–591. [Google Scholar] [CrossRef]

- Bhattacharyya, P.; Basu, P.K.; Mondal, B.; Saha, H. A low power MEMS gas sensor based on nanocrystalline ZnO thin films for sensing methane. Microelectron. Reliab. 2008, 48, 1772–1779. [Google Scholar] [CrossRef]

- Yoon, J.-H.; Kim, J.-S. Study on the MEMS-type gas sensor for detecting a nitrogen oxide gas. Solid State Ionics 2011, 192, 668–671. [Google Scholar] [CrossRef]

- Liu, C.C. Electrochemical sensors. In Medical Devices and Systems; CRC Press: Boca Raton, FL, USA, 2006; ISBN 9781420003864. [Google Scholar]

- Barauskas, D.; Pelenis, D.; Vanagas, G.; Viržonis, D.; Baltrušaitis, J. Methylated Poly(ethylene)imine Modified Capacitive Micromachined Ultrasonic Transducer for Measurements of CO2 and SO2 in Their Mixtures. Sensors 2019, 19, 3236. [Google Scholar] [CrossRef] [PubMed]

- Zahorian, J.; Hochman, M.; Xu, T.; Satir, S.; Gurun, G.; Karaman, M.; Degertekin, F.L. Monolithic CMUT-on-CMOS integration for intravascular ultrasound applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2011, 58, 2659–2667. [Google Scholar] [CrossRef] [PubMed]

- Caronti, A.; Caliano, G.; Carotenuto, R.; Savoia, A.; Pappalardo, M.; Cianci, E.; Foglietti, V. Capacitive micromachined ultrasonic transducer (CMUT) arrays for medical imaging. Microelectron. J. 2006, 37, 770–777. [Google Scholar] [CrossRef]

- Savoia, A.S.; Caliano, G.; Pappalardo, M. A CMUT probe for medical ultrasonography: From microfabrication to system integration. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 1127–1138. [Google Scholar] [CrossRef]

- Caliano, G.; Carotenuto, R.; Cianci, E.; Foglietti, V.; Caronti, A.; Iula, A.; Pappalardo, M. Design, fabrication and characterization of a capacitive micromachined ultrasonic probe for medical imaging. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 2256–2269. [Google Scholar] [CrossRef]

- Cristman, P.; Oralkan, O.; Zhuang, X.; Ma, T.J.; Vaithilingam, S.; Carver, T.; Wygant, I.; Khuri-Yakub, B.T. A 2D CMUT hydrophone array: Characterization results. In Proceedings of the IEEE Ultrasonics Symposium, Rome, Italy, 20–23 September 2009. [Google Scholar]

- Guler, U.; Bozkurt, A. A low-noise front-end circuit for 2D cMUT arrays. In Proceedings of the IEEE Ultrasonics Symposium, Vancouver, BC, Canada, 2–6 October 2006. [Google Scholar]

- Brenner, K.; Ergun, A.; Firouzi, K.; Rasmussen, M.; Stedman, Q.; Khuri–Yakub, B. Advances in Capacitive Micromachined Ultrasonic Transducers. Micromachines 2019, 10, 152. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, H.; Jin, S.; Zeng, Z. An analytical model for CMUTs with square multilayer membranes using the Ritz method. Micromachines 2016, 7, 55. [Google Scholar] [CrossRef]

- Nikoozadeh, A.; Bayram, B.; Yaralioglu, G.G.; Khuri-Yakub, B.T. Analytical calculation of collapse voltage of CMUT membrane. In Proceedings of the IEEE Ultrasonics Symposium, Montreal, QC, Canada, 23–27 August 2004; Volume 1, pp. 256–259. [Google Scholar]

- Yaralioglu, G.G.; Ergun, A.S.; Khuri-yakub, B.T. Finite-Element Analysis of Capacitive Micromachined Ultrasonic Transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 2185–2198. [Google Scholar] [CrossRef]

- Kupnik, M.; Wygant, I.O.; Khuri-Yakub, B.T. Finite element analysis of stress stiffening effects in CMUTs. In Proceedings of the IEEE Ultrasonics Symposium, Beijing, China, 2–5 November 2008; pp. 487–490. [Google Scholar]

- Park, K.K.; Oralkan, O.; Khuri-Yakub, B. A comparison between conventional and collapse-mode capacitive micromachined ultrasonic transducers in 10-MHz 1-D arrays. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2013, 60, 1245–1255. [Google Scholar] [CrossRef] [PubMed]

- Ladabaum, I.; Jin, X.; Soh, H.T.; Atalar, A.; Khuri-Yakub, B.T. Surface micromachined capacitive ultrasonic transducers. IEEE Trans Ultrason. Ferroelectr Freq Control 1998, 45, 678–690. [Google Scholar] [CrossRef] [PubMed]

- Khuri-Yakub, B.T.; Degertekin, F.L.; Jin, X.C.; Calmes, S.; Ladabaum, I.; Hansen, S.; Zhang, X.J. Silicon micromachined ultrasonic transducers. In Proceedings of the IEEE Ultrasonics Symposium, Sendai, Japan, 5–8 October 1998; Volume 2, pp. 985–991. [Google Scholar]

- Kirchmayer, B.J.; Moussa, W.A.; Checkel, M.D. Finite element modeling of a capacitive micromachined ultrasonic transducer. In Proceedings of the International Conference on MEMS, NANO and Smart Systems, ICMENS 2003, Banff, ALT, Canada, 23 July 2003. [Google Scholar]

- Yaralioglu, G.G.; Bayram, B.; Khuri-Yakub, B.T. Finite element analysis of cmuts: Conventional vs. collapse operation modes. In Proceedings of the IEEE Ultrasonics Symposium, Vancouver, BC, Canada, 2–6 October 2006; Volume 1, pp. 586–589. [Google Scholar]

- Bayram, B.; Yaralioglu, G.G.; Kupnik, M.; Ergm, A.S.; Oralkan, O.; Nikoozadeh, A.; Khuri-Yakub, B.T. Dynamic Analysis of Capacitive Micromachined Ultrasonic Transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 2270–2275. [Google Scholar] [CrossRef] [PubMed]

- Caliano, G.; Caronti, A.; Savoia, A.; Longo, C.; Pappalardo, M.; Cianci, E.; Foglietti, V. Capacitive micromachined ultrasonic transducer (cMUT) made by a novel “reverse fabrication process”. In Proceedings of the IEEE Ultrasonics Symposium, Rotterdam, The Netherlands, 18–21 September 2005; Volume 1, pp. 479–482. [Google Scholar]

- Liu, L.L.; Mukdadi, O.M.; Herrmann, C.F.; Saravanan, R.A.; Hertzberg, J.R.; George, S.M.; Bright, V.M.; Shandas, R. A novel method for fabricating capacitive micromachined ultrasonic transducers with ultra-thin membranes. In Proceedings of the IEEE Ultrasonics Symposium, Montreal, QC, Canada, 23–27 August 2004; Volume 1, pp. 497–500. [Google Scholar]

- Barauskas, D.; Vanagas, G.; Virzonis, D.; Ramanaviciene, A.; Makaraviciute, A.; Ramanavicius, A. Application of CMUT as immunosensor. In Proceedings of the 2013 IEEE International Ultrasonics Symposium (IUS), Prague, Czech Republic, 21–25 July 2013; pp. 1708–1711. [Google Scholar]

- Barauskas, D.; Vanagas, G.; Virzonis, D.; Makaraviciute, A.; Ramanaviciene, A. Capacitive micromachined ultrasound transducers (CMUT) for resonant gravimetric immunosensing. In Proceedings of the 2014 IEEE International Ultrasonics Symposium, Chicago, IL, USA, 3–6 September 2014; pp. 2588–2590. [Google Scholar]

- Pelenis, D.; Barauskas, D.; Sapeliauskas, E.; Vanagas, G.; Mikolajunas, M.; Virzonis, D. Acoustical Streaming in Microfluidic CMUT Integrated Chip Controls the Biochemical Interaction Rate. J. Microelectromech. Syst. 2017, 26, 1012–1017. [Google Scholar] [CrossRef]

- Williams, K.R.; Gupta, K.; Wasilik, M. Etch rates for micromachining processing-part II. J. Microelectromech. Syst. 2003, 12, 761–778. [Google Scholar] [CrossRef]

- Somashekhar, A. Etching SiO2 Films in Aqueous 0.49% HF. J. Electrochem. Soc. 1996, 143, 2885. [Google Scholar] [CrossRef]

- Vanheusden, K.; Stesmans, A. Chemical etch rates in HF solutions as a function of thickness of thermal SiO2 and buried SiO2 formed by oxygen implantation. J. Appl. Phys. 1991, 69, 6656–6664. [Google Scholar] [CrossRef]

- Mikolajūnas, M.; Baltrušaitis, J.; Kopustinskas, V.; Vanagas, G.; Grigaliūnas, V.; Viržonis, D. Plasma etching of virtually stress-free stacked silicon nitride films. Thin Solid Films 2009, 517, 5769–5772. [Google Scholar] [CrossRef]

- Miyawaki, Y.; Kondo, Y.; Sekine, M.; Ishikawa, K.; Hayashi, T.; Takeda, K.; Kondo, H.; Yamazaki, A.; Ito, A.; Matsumoto, H.; et al. Highly Selective Etching of SiO2 over Si3N4 and Si in Capacitively Coupled Plasma Employing C5HF7 Gas. Jpn. J. Appl. Phys. 2013, 52, 16201. [Google Scholar] [CrossRef]

- Kastenmeier, B.E.E.; Matsuo, P.J.; Beulens, J.J.; Oehrlein, G.S. Chemical dry etching of silicon nitride and silicon dioxide using CF4/O2/N2 gas mixtures. J. Vac. Sci. Technol. A Vacuum Surf. Film. 1996, 14, 2802–2813. [Google Scholar] [CrossRef]

- Mikolajūnas, M.; Kaliasas, R.; Andrulevičius, M.; Grigaliūnas, V.; Baltrušaitis, J.; Viržonis, D. A study of stacked PECVD silicon nitride films used for surface micromachined membranes. Thin Solid Films 2008, 516, 8788–8792. [Google Scholar] [CrossRef]

- Virzonis, D.; Sinkevicius, V.; Grigaliunas, V.; Tamulevicius, S.; Kaliasas, R. Advanced process equipment for PECVD silicon nitride deposition—An experimental study. Mater. Sci. 2006, 12, 4–37. [Google Scholar]

- Joshi, B.C.; Eranna, G.; Runthala, D.P.; Dixit, B.B.; Wadhawan, O.P.; Vyas, P.D. LPCVD and PECVD silicon nitride for microelectronics technology. Indian J. Eng. Mater. Sci. 2000, 7, 5–6. [Google Scholar]

- Jin, X.C.; Ladabaum, I.; Degertekin, F.L.; Calmes, S.; Khuri-Yakub, B.T. Fabrication and characterization of surface micromachined capacitive ultrasonic immersion transducers. J. Microelectromech. Syst. 1999, 8, 100–114. [Google Scholar]

- Piccirillo, A. Physical-Electrical Properties of Silicon Nitride Deposited by PECVD on III–V Semiconductors. J. Electrochem. Soc. 1990, 137, 3910. [Google Scholar] [CrossRef]

- Dixit, P.; Vehmas, T.; Vähänen, S.; Monnoyer, P.; Henttinen, K. Fabrication and electrical characterization of high aspect ratio poly-silicon filled through-silicon vias. J. Micromech. Microeng. 2012, 22, 55021. [Google Scholar] [CrossRef]

- Mølgaard, M.J.G.; Laustsen, M.; Jakobsen, M.H.; Andresen, T.L.; Thomsen, E.V. Combined colorimetric and gravimetric CMUT sensor for detection of benzyl methyl ketone. Sens. Actuators B Chem. 2018, 275, 483–489. [Google Scholar] [CrossRef]

- Laermer, F.; Franssila, S.; Sainiemi, L.; Kolari, K. Deep Reactive Ion Etching. In Handbook of Silicon Based MEMS Materials and Technologies, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2015; ISBN 9780323312233. [Google Scholar]

- Park, K.K.; Lee, H.J.; Kupnik, M.; Oralkan, Ö.; Khuri-Yakub, B.T.; Oralkan, O.; Khuri-Yakub, B.T. Fabricating capacitive micromachined ultrasonic transducers with direct wafer-bonding and LOCOS technology. In Proceedings of the 2008 IEEE 21st International Conference on Micro Electro Mechanical Systems, Wuhan, China, 13–17 January 2008; pp. 339–342. [Google Scholar]

- Park, K.K.; Lee, H.; Kupnik, M.; Khuri-Yakub, B.T. Fabrication of Capacitive Micromachined Ultrasonic Transducers via Local Oxidation and Direct Wafer Bonding. J. Microelectromech. Syst. 2011, 20, 95–103. [Google Scholar] [CrossRef]

- Gunn, R.; Stephens, D.; Welch, C. Comparison of Etch Processes for Patterning High Aspect Ratio and Nanoscale Features in Silicon; Oxford Instruments Plasma Technology: Bristol, UK, 2009. [Google Scholar]

- Ergun, A.S.; Huang, Y.; Zhuang, X.; Oralkan, Ö.; Yaralıoglu, G.G.; Khuri-Yakub, B.T. Capacitive Micromachined Ultrasonic Transducers: Fabrication Technology. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 2242–2258. [Google Scholar]

- Liao, W.-S.; Cheunkar, S.; Cao, H.H.; Bednar, H.R.; Weiss, P.S.; Andrews, A.M. Subtractive Patterning via Chemical Lift-Off Lithography. Science (80-. ) 2012, 337, 1517–1521. [Google Scholar] [CrossRef]

- Cianci, E.; Schina, A.; Minotti, A.; Quaresima, S.; Foglietti, V. Dual frequency PECVD silicon nitride for fabrication of CMUTs’ membranes. Sens. Actuators A Phys. 2006, 127, 80–87. [Google Scholar] [CrossRef]

- Yongli, H.; Ergun, A.S.; Haggstrom, E.; Badi, M.H.; Khuri-Yakub, B.T. Fabricating capacitive micromachined ultrasonic transducers with wafer-bonding technology. J. Microelectromech. Syst. 2003, 12, 128–137. [Google Scholar] [CrossRef]

- Makaraviciute, A.; Virzonis, D.; Ramanaviciene, A.; Vanagas, G.; Barauskas, D.; Ramanavicius, A. An immunosensing system for antibody detection based on capacitive micromachined ultrasound transducer resonance sensors. Sens. Lett. 2014, 12. [Google Scholar] [CrossRef]

- Reck, K.; Stergaard, C.; Thomsen, E.V.; Hansen, O. Fusion bonding of silicon nitride surfaces. J. Micromech. Microeng. 2011, 21, 125015. [Google Scholar] [CrossRef]

- Logan, A.; Yeow, J.T.W. Fabricating capacitive micromachined ultrasonic transducers with a novel silicon-nitride-Based wafer bonding process. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2009, 56, 1074–1084. [Google Scholar] [CrossRef]

- Chen, A.I.H.; Wong, L.L.P.; Li, Z.; Na, S.; Yeow, J.T.W. Practical CMUT Fabrication with a Nitride-to-Oxide-Based Wafer Bonding Process. J. Microelectromech. Syst. 2017, 26, 829–836. [Google Scholar] [CrossRef]

- Cianci, E.; Visigalli, L.; Foglietti, V.; Caliano, G.; Pappalardo, M. Improvements towards a reliable fabrication process for cMUT. Microelectron. Eng. 2003, 67–68, 602–608. [Google Scholar] [CrossRef]

- Huang, Y.; Zhuang, X.; Haeggstrom, E.O.; Ergun, A.S.; Cheng, C.-H.; Khuri-Yakub, B.T. Capacitive micromachined ultrasonic transducers (CMUTs) with isolation posts. Ultrasonics 2008, 48, 74–81. [Google Scholar] [CrossRef]

- Liu, J.; Oakley, C.; Shandas, R. Capacitive micromachined ultrasonic transducers using commercial multi-user MUMPs process: Capability and limitations. Ultrasonics 2009, 49, 765–773. [Google Scholar] [CrossRef]

- Bayram, B. Diamond-based capacitive micromachined ultrasonic transducers. Diam. Relat. Mater. 2012, 22, 6–11. [Google Scholar] [CrossRef]

- Yamaner, F.Y.; Zhang, X.; Oralkan, Ö. Fabrication of anodically bonded capacitive micromachined ultrasonic transducers with vacuum-sealed cavities. In Proceedings of the IEEE International Ultrasonics Symposium, Chicago, IL, USA, 3–6 September 2014. [Google Scholar]

- Mukhiya, R.; Aditi; Prabakar, K.; Raghuramaiah, M.; Jayapandian, J.; Gopal, R.; Khanna, V.K.; Shekhar, C. Fabrication of Capacitive Micromachined Ultrasonic Transducer Arrays with Isolation Trenches Using Anodic Wafer Bonding. IEEE Sens. J. 2015, 15, 5177–5184. [Google Scholar] [CrossRef]

- Ge, C.; Cretu, E. A sacrificial-layer-free fabrication technology for MEMS transducer on flexible substrate. Sens. Actuators A Phys. 2019, 286, 202–210. [Google Scholar] [CrossRef]

- Gerardo, C.D.; Cretu, E.; Rohling, R. Fabrication and testing of polymer-based capacitive micromachined ultrasound transducers for medical imaging. Microsystems Nanoeng. 2018, 4, 19. [Google Scholar] [CrossRef] [PubMed]

- Buzanovskii, V.A. Gas nanosensors based on polymers. Rev. J. Chem. 2014, 4, 33–51. [Google Scholar] [CrossRef]

- Bai, H.; Shi, G.Q. Gas Sensors Based on Conducting Polymers. Sensors 2007, 7, 267–307. [Google Scholar] [CrossRef]

- Liu, X.; Cheng, S.; Liu, H.; Hu, S.; Zhang, D.; Ning, H. A Survey on Gas Sensing Technology. Sensors 2012, 12, 9635–9665. [Google Scholar] [CrossRef] [PubMed]

- Ramanaviciene, A.; Virzonis, D.; Vanagas, G.; Ramanavicius, A.A. Capacitive micromachined ultrasound transducer (cMUT) for immunosensor design. Analyst 2010, 135, 1531. [Google Scholar] [CrossRef]

- Mahmud, M.M.; Li, J.; Lunsford, J.E.; Zhang, X.; Yamaner, F.Y.; Nagle, H.T.; Oralkan, O. A low-power gas sensor for environmental monitoring using a capacitive micromachined ultrasonic transducer. In Proceedings of the IEEE SENSORS, Valencia, Spain, 2–5 November 2014; pp. 677–680. [Google Scholar]

- Richardson, J.J.; Bjornmalm, M.; Caruso, F. Technology-driven layer-by-layer assembly of nanofilms. Science (80-.) 2015, 348, aaa2491. [Google Scholar] [CrossRef]

- Wu, Y.; Long, Y.; Li, Q.-L.L.; Han, S.; Ma, J.; Yang, Y.-W.W.; Gao, H. Layer-by-Layer (LBL) Self-Assembled Biohybrid Nanomaterials for Efficient Antibacterial Applications. ACS Appl. Mater. Interfaces 2015, 7, 17255–17263. [Google Scholar] [CrossRef]

- Chen, Z.; Mucha, J.A.; Donnelly, V.M.; Economou, D.J. Plasma enhanced layer-by-layer deposition and nanocrystallization of hydrogenated amorphous silicon films. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2013, 31, 061209. [Google Scholar] [CrossRef]

- Krogman, K.C.; Lowery, J.L.; Zacharia, N.S.; Rutledge, G.C.; Hammond, P.T. Spraying asymmetry into functional membranes layer-by-layer. Nat. Mater. 2009, 8, 512–518. [Google Scholar] [CrossRef] [PubMed]

- Lee, T.; Min, S.H.; Gu, M.; Jung, Y.K.; Lee, W.; Lee, J.U.; Seong, D.G.; Kim, B.-S. Layer-by-Layer Assembly for Graphene-Based Multilayer Nanocomposites: Synthesis and Applications. Chem. Mater. 2015, 27, 3785–3796. [Google Scholar] [CrossRef]

- Michel, M.; Toniazzo, V.; Ruch, D.; Ball, V. Deposition Mechanisms in Layer-by-Layer or Step-by-Step Deposition Methods: From Elastic and Impermeable Films to Soft Membranes with Ion Exchange Properties. ISRN Mater. Sci. 2012, 2012, 1–13. [Google Scholar] [CrossRef]

- Talusan, T.J.E.; Baltazar, M.C.P.; Usman, K.A.S.; Payawan, L.M., Jr. Synthesis of Glucose-Sensitive Microcapsules via Layer-by-Layer Assembly for Controlled Insulin Release Applications. Appl. Mech. Mater. 2017, 863, 84–88. [Google Scholar] [CrossRef]

- Franz, G.; Schamberger, F. Evaporation and thermal cracking of dimeric parylenes. J. Vac. Sci. Technol. A Vacuum Surf. Film. 2013, 31, 61602. [Google Scholar] [CrossRef]

- Lee, K.I.; Choi, Y.S.; Park, H.J. Development of plasma assisted thermal vapor deposition technique for high-quality thin film. Rev. Sci. Instrum. 2016, 87, 123501. [Google Scholar] [CrossRef]

- Malik, S.; Tripathi, C.C. Thin Film Deposition by Langmuir Blodgett Technique for Gas Sensing Applications. J. Surf. Eng. Mater. Adv. Technol. 2013, 3, 235–241. [Google Scholar] [CrossRef][Green Version]

- Paul, S.; Pearson, C.; Molloy, A.; Cousins, M.A.; Green, M.; Kolliopoulou, S.; Dimitrakis, P.; Normand, P.; Tsoukalas, D.; Petty, M.C. Langmuir−Blodgett Film Deposition of Metallic Nanoparticles and Their Application to Electronic Memory Structures. Nano Lett. 2003, 3, 533–536. [Google Scholar] [CrossRef]

- Roberts, G.G. Langmuir-Blodgett films. Contemp. Phys. 1984, 25, 109–128. [Google Scholar] [CrossRef]

- Sorokin, A.V.; Bai, M.; Ducharme, S.; Poulsen, M. Langmuir–Blodgett films of polyethylene. J. Appl. Phys. 2002, 92, 5977–5981. [Google Scholar] [CrossRef]

- Agarwal, V.K. Langmuir-Blodgett Films. Phys. Today 1988, 41, 40–46. [Google Scholar] [CrossRef]

- Hu, D.; Peng, C.; Chen, G.Z. Electrodeposition of Nonconducting Polymers: Roles of Carbon Nanotubes in the Process and Products. ACS Nano 2010, 4, 4274–4282. [Google Scholar] [CrossRef] [PubMed]

- Li, F.B.; Albery, W.J. Electrochemical deposition of a conducting polymer, poly(thiophene-3-acetic acid): The first observation of individual events of polymer nucleation and two-dimensional layer-by-layer growth. Langmuir 1992, 8, 1645–1653. [Google Scholar] [CrossRef]

- Usmani, A.M. Electrodeposition of Polymers and Coatings. Polym. Plast. Technol. Eng. 1980, 15, 115–135. [Google Scholar] [CrossRef]

- Venstra, W.J.; Capener, M.J.; Elliott, S.R. Nanomechanical gas sensing with nonlinear resonant cantilevers. Nanotechnology 2014, 25, 425501. [Google Scholar] [CrossRef] [PubMed]

- Hall, D.B.; Underhill, P.; Torkelson, J.M. Spin coating of thin and ultrathin polymer films. Polym. Eng. Sci. 1998, 38, 2039–2045. [Google Scholar] [CrossRef]

- Extrand, C.W. Spin coating of very thin polymer films. Polym. Eng. Sci. 1994, 34, 390–394. [Google Scholar] [CrossRef]

- Lawrence, C.J. The mechanics of spin coating of polymer films. Phys. Fluids 1988, 31, 2786. [Google Scholar] [CrossRef]

- Park, K.K.; Lee, H.J.; Yaralioglu, G.G.; Ergun, A.S.; Oralkan, Ö.; Kupnik, M.; Quate, C.F.; Khuri-Yakub, B.T.; Braun, T.; Ramseyer, J.-P.; et al. Capacitive micromachined ultrasonic transducers for chemical detection in nitrogen. Appl. Phys. Lett. 2007, 91, 94102. [Google Scholar] [CrossRef]

- Adhikari, B.; Majumdar, S. Polymers in sensor applications. Prog. Polym. Sci. 2004, 29, 699–766. [Google Scholar] [CrossRef]

- Sahner, K.; Hagen, G.; Schonauer, D.; Reis, S.; Moos, R.; Schönauer, D.; Reiß, S.; Moos, R. Zeolites—Versatile materials for gas sensors. Solid State Ionics 2008, 179, 2416–2423. [Google Scholar] [CrossRef]

- Mahmud, M.M.; Kumar, M.; Zhang, X.; Yamaner, F.Y.; Nagle, H.T.; Oralkan, O. A capacitive micromachined ultrasonic transducer (CMUT) array as a low-power multi-channel volatile organic compound (VOC) sensor. In Proceedings of the 2015 IEEE SENSORS, Busan, Korea, 1–4 November 2015; pp. 1–4. [Google Scholar]

- Stedman, Q.; Park, K.K.; Khuri-Yakub, B.T. An 8-channel CMUT chemical sensor array on a single chip. In Proceedings of the 2017 IEEE International Ultrasonics Symposium (IUS), Washington, DC, USA, 6–9 September 2017; pp. 1–4. [Google Scholar]

- Mir, M.A.; Bhat, M.A.; Naikoo, R.A.; Bhat, R.A.; khan, M.; Shaik, M.; Kumar, P.; Sharma, P.K.K.; Tomar, R. Utilization of zeolite/polymer composites for gas sensing: A review. Sens. Actuators B Chem. 2017, 242, 1007–1020. [Google Scholar] [CrossRef]

- Fu, D.; Chung, J.; Liu, Q.; Raziq, R.; Kee, J.S.; Park, M.K.; Valiyaveettil, S.; Lee, P. Polymer coated silicon microring device for the detection of sub-ppm volatile organic compounds. Sens. Actuators B Chem. 2018, 257, 136–142. [Google Scholar] [CrossRef]

- Nguyen Minh, Q.; Kuijk, A.; Pujari, S.P.; van de Bent, F.; Baggerman, J.; Tong, H.D.; Zuilhof, H.; van Rijn, C.J.M. Preparation and gas sensing properties of nanocomposite polymers on micro-Interdigitated electrodes for detection of volatile organic compounds at room temperature. Sens. Actuators B Chem. 2017, 252, 1098–1104. [Google Scholar] [CrossRef]

- Lee, S.-P.; Mellon, N.; Shariff, A.M.; Leveque, J.-M. High-pressure CO2-CH4 selective adsorption on covalent organic polymer. J. Nat. Gas Sci. Eng. 2018, 50, 139–146. [Google Scholar] [CrossRef]

- Seok, C.; Mahmud, M.M.; Kumar, M.; Adelegan, O.J.; Yamaner, F.Y.; Oralkan, O. A Low-Power Wireless Multichannel Gas Sensing System Based on a Capacitive Micromachined Ultrasonic Transducer (CMUT) Array. IEEE Internet Things J. 2018, 6, 831–843. [Google Scholar] [CrossRef]

- Seok, C.; Mahmud, M.M.; Adelegan, O.; Zhang, X.; Oralkan, O. A battery-operated wireless multichannel gas sensor system based on a capacitive micromachined ultrasonic transducer (CMUT) array. In Proceedings of the 2016 IEEE SENSORS, Orlando, FL, USA, 30 October–3 November 2016; pp. 1–3. [Google Scholar]

- Crini, G.; Badot, P.-M. Sorption Processes and Pollution: Conventional and Non-Conventional Sorbents for Pollutant Removal from Wastewaters; Presses Universitaires de Franche-Comté: Besançon, France, 2010; ISBN 9782848673042 2848673044. [Google Scholar]

- Bolis, V. Fundamentals in Adsorption at the Solid-Gas Interface. Concepts Thermodyn. 2013, 154, 3–50. [Google Scholar]

- Culp, J.T.; Goodman, A.L.; Chirdon, D.; Sankar, S.G.; Matranga, C. Mechanism for the Dynamic Adsorption of CO2 and CH4 in a Flexible Linear Chain Coordination Polymer as Determined from In Situ Infrared Spectroscopy. J. Phys. Chem. C 2010, 114, 2184–2191. [Google Scholar] [CrossRef]

- Jackson, P.; Robinson, K.; Puxty, G.; Attalla, M. In situ Fourier Transform-Infrared (FT-IR) analysis of carbon dioxide absorption and desorption in amine solutions. Energy Procedia 2009, 1, 985–994. [Google Scholar] [CrossRef]

- Lee, S.; Eom, G.; Yoon, I.; Park, S.; Kook, G.; Kim, M.K.; Kim, H.; Seo, J.-W.; Lee, H.J. Capacitive Micromachined Ultrasonic Transducer (CMUT)-based Biosensor for Detection of Low Concentration Neuropeptide. In Proceedings of the 2018 40th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Honolulu, Hawaii, 17–21 July 2018; pp. 2897–2900. [Google Scholar]

- Pelenis, D.; Barauskas, D.; Vanagas, G.; Dzikaras, M.; Viržonis, D. CMUT-based biosensor with convolutional neural network signal processing. Ultrasonics 2019, 99, 105956. [Google Scholar] [CrossRef]

- Arcamone, J.; van den Boogaart, M.A.F.; Serra-Graells, F.; Fraxedas, J.; Brugger, J.; Pérez-Murano, F. Full-wafer fabrication by nanostencil lithography of micro/nanomechanical mass sensors monolithically integrated with CMOS. Nanotechnology 2008, 19, 305302. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Tang, H.X.; Roukes, M.L. Ultra-sensitive NEMS-based cantilevers for sensing, scanned probe and very high-frequency applications. Nat. Nanotechnol. 2007, 2, 114–120. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, X.; Lin, D.S.; Oralkan, Ö.; Khuri-Yakub, B.T. Fabrication of flexible transducer arrays with through-wafer electrical interconnects based on trench refilling with PDMS. J. Microelectromech. Syst. 2008, 17, 446–452. [Google Scholar] [CrossRef]

- Pang, D.C.; Chang, C.M. Development of a novel transparent flexible capacitive micromachined ultrasonic transducer. Sensors 2017, 17, 1443. [Google Scholar] [CrossRef] [PubMed]

- Cheng, C.H.; Chao, C.; Shi, X.; Leung, W.W.F. A flexible capacitive micromachined ultrasonic transducer (CMUT) array with increased effective capacitance from concave bottom electrodes for ultrasonic imaging applications. In Proceedings of the IEEE Ultrasonics Symposium, Rome, Italy, 20–23 September 2009. [Google Scholar]

- He, K.; Jin, Z.; Chu, X.; Bi, W.; Wang, W.; Wang, C.; Liu, S. Fast response–recovery time toward acetone by a sensor prepared with Pd doped WO 3 nanosheets. RSC Adv. 2019, 9, 28439–28450. [Google Scholar] [CrossRef]

- Dhall, S.; Jaggi, N.; Nathawat, R. Functionalized multiwalled carbon nanotubes based hydrogen gas sensor. Sens. Actuators A Phys. 2013, 201, 321–327. [Google Scholar] [CrossRef]

- Liu, B.; Chen, X.; Cai, H.; Mohammad Ali, M.; Tian, X.; Tao, L.; Yang, Y.; Ren, T. Surface acoustic wave devices for sensor applications. J. Semicond. 2016, 37, 21001. [Google Scholar] [CrossRef]

- Shu, L.; Jiang, T.; Xia, Y.; Wang, X.; Yan, D.; Wu, W. The Investigation of a SAW Oxygen Gas Sensor Operated at Room Temperature, Based on Nanostructured ZnxFeyO Films. Sensors 2019, 19, 3025. [Google Scholar] [CrossRef]

- Avetisov, V.; Bjoroey, O.; Wang, J.; Geiser, P.; Paulsen, K.G. Hydrogen Sensor Based on Tunable Diode Laser Absorption Spectroscopy. Sensors 2019, 19, 5313. [Google Scholar] [CrossRef]

- Tobias, P.; Hui, H.; Koochesfahani, M.; Ghosh, A.N. Millisecond response time measurements of high temperature gas sensors. In Proceedings of the IEEE Sensors, Vienna, Austria, 24–27 October 2004; pp. 770–771. [Google Scholar]

- Arafat, M.M.; Dinan, B.; Akbar, S.A.; Haseeb, A.S.M.A. Gas Sensors Based on One Dimensional Nanostructured Metal-Oxides: A Review. Sensors 2012, 12, 7207–7258. [Google Scholar] [CrossRef]

- Basu, S.; Wang, Y.-H.; Ghanshyam, C.; Kapur, P. Fast response time alcohol gas sensor using nanocrystalline F-doped SnO2 films derived via sol–gel method. Bull. Mater. Sci. 2013, 36, 521–533. [Google Scholar] [CrossRef]

| Molecule | Molecule Formula | Global Warming Potential (GWP) | Lifetime in Atmosphere |

|---|---|---|---|

| Carbon Dioxide | CO2 | 1 | Various years |

| Methane | CH4 | 25 | 12 years |

| Nitrous Oxide | N2O | 298 | 114 years |

| Fluorinated Gases | HFCs, PFCs, SF6, NF3 | HFCs: 12–14,800 PFCs: 7390–12,200 NF3: 17,200 SF6: 22,800 | HFCs: 1–270 years PFCs: 2600–50,000 years NF3: 740 years SF6: 3200 years |

| Membrane Material | Dielectric Constant, ε |

|---|---|

| Silicon | 11.68 |

| SiC | 6.5–10 |

| Silicon nitride | 7–8 |

| Polysilicon | 29.5 |

| Technique | Active Surface | Mass Resolution |

|---|---|---|

| CMUT [5,8] | 0.25–0.09 mm2 | 0.01–3×10−3 ng/cm2 |

| MEMS [141] | 7.3×10−6 mm2 | 0.1 ng/cm2 |

| NEMS [142] | 8.5×10−8 mm2 | 0.1 ng/cm2 |

| Other (BAW, SAW) [37] | 0.25–4 mm2 | 0.03–1 ng/cm2 |

| Sensing Method/Material | Response Time | Source |

|---|---|---|

| Electrochemical | 1–2 s | [146] |

| QCM | 7–118 s | [147] |

| CMUT | 20–200 s | [5] |

| BAW | <1 s | [148] |

| SAW | 150–250 s | [149] |

| TDLAS | 1 s | [150] |

| SiC-based sensors | 0.005 s | [151] |

| One dimensional nanostructured metal-oxides | 30–40 s | [152] |

| Nanocrystalline f-doped SnO2 films | 32–65 s | [153] |

| Electrocatalytic | <15 s |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barauskas, D.; Dzikaras, M.; Bieliauskas, D.; Pelenis, D.; Vanagas, G.; Viržonis, D. Selective Ultrasonic Gravimetric Sensors Based on Capacitive Micromachined Ultrasound Transducer Structure—A Review. Sensors 2020, 20, 3554. https://doi.org/10.3390/s20123554

Barauskas D, Dzikaras M, Bieliauskas D, Pelenis D, Vanagas G, Viržonis D. Selective Ultrasonic Gravimetric Sensors Based on Capacitive Micromachined Ultrasound Transducer Structure—A Review. Sensors. 2020; 20(12):3554. https://doi.org/10.3390/s20123554

Chicago/Turabian StyleBarauskas, Dovydas, Mindaugas Dzikaras, Dovydas Bieliauskas, Donatas Pelenis, Gailius Vanagas, and Darius Viržonis. 2020. "Selective Ultrasonic Gravimetric Sensors Based on Capacitive Micromachined Ultrasound Transducer Structure—A Review" Sensors 20, no. 12: 3554. https://doi.org/10.3390/s20123554

APA StyleBarauskas, D., Dzikaras, M., Bieliauskas, D., Pelenis, D., Vanagas, G., & Viržonis, D. (2020). Selective Ultrasonic Gravimetric Sensors Based on Capacitive Micromachined Ultrasound Transducer Structure—A Review. Sensors, 20(12), 3554. https://doi.org/10.3390/s20123554