Novel Method for NTC Thermistor Production by Aerosol Co-Deposition and Combined Sintering

Abstract

1. Introduction

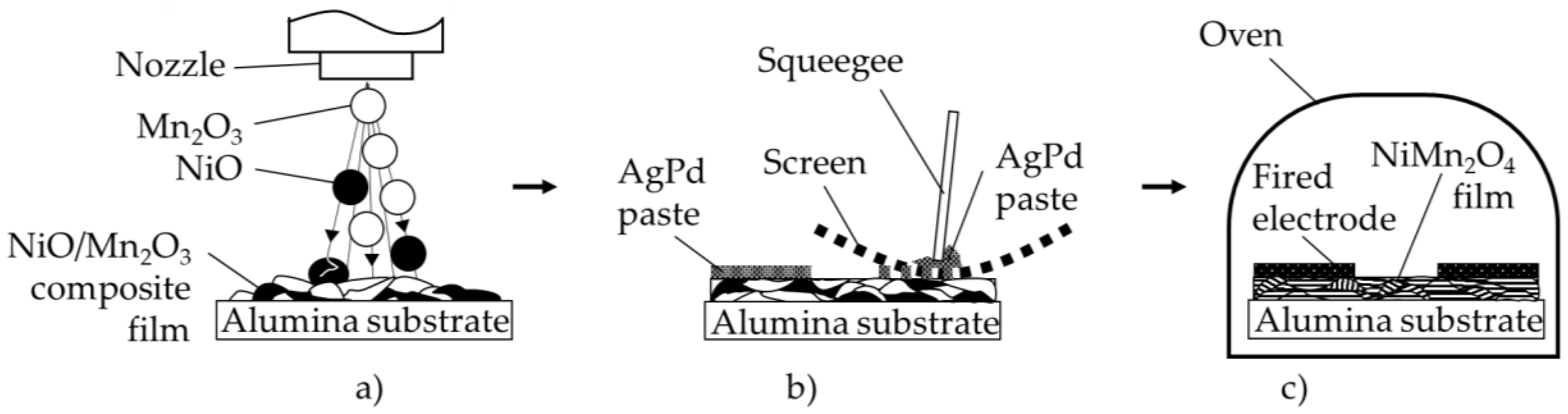

2. Materials and Methods

3. Results and Discussion

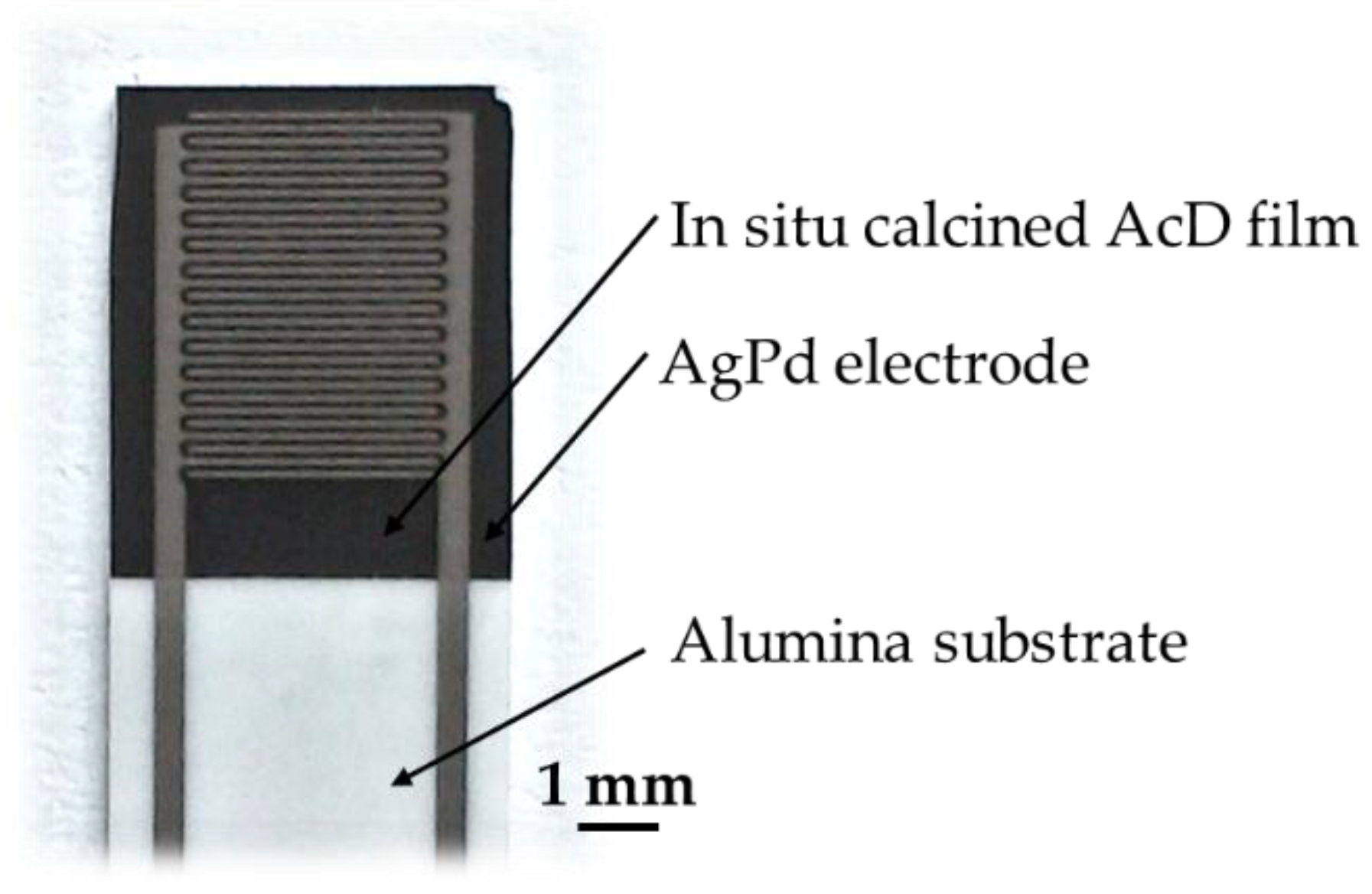

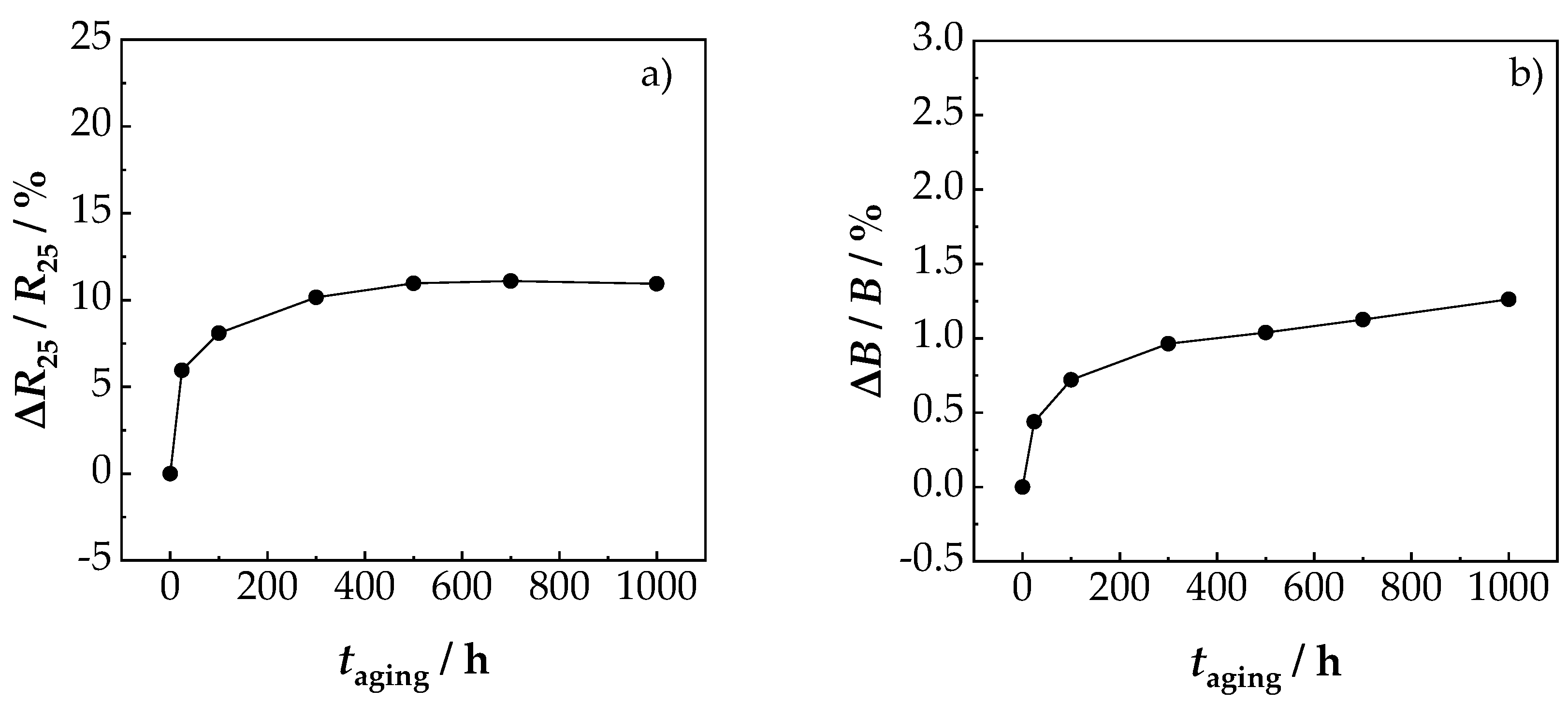

3.1. Characterization of the First Prototypes

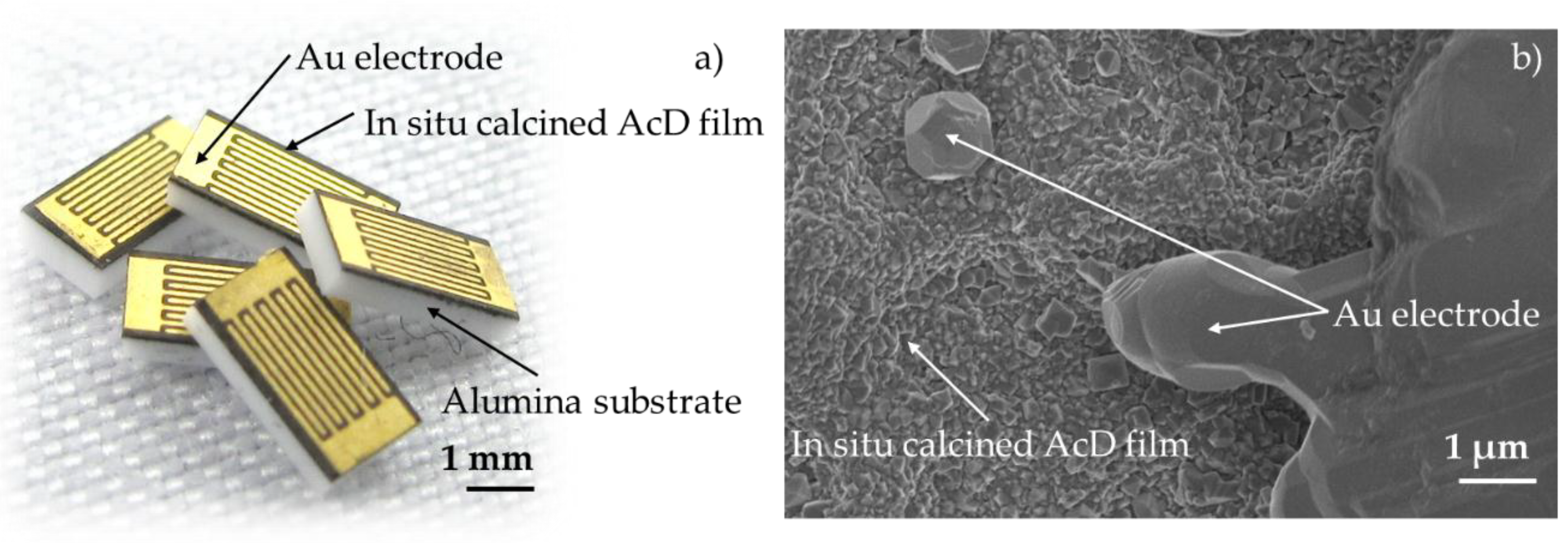

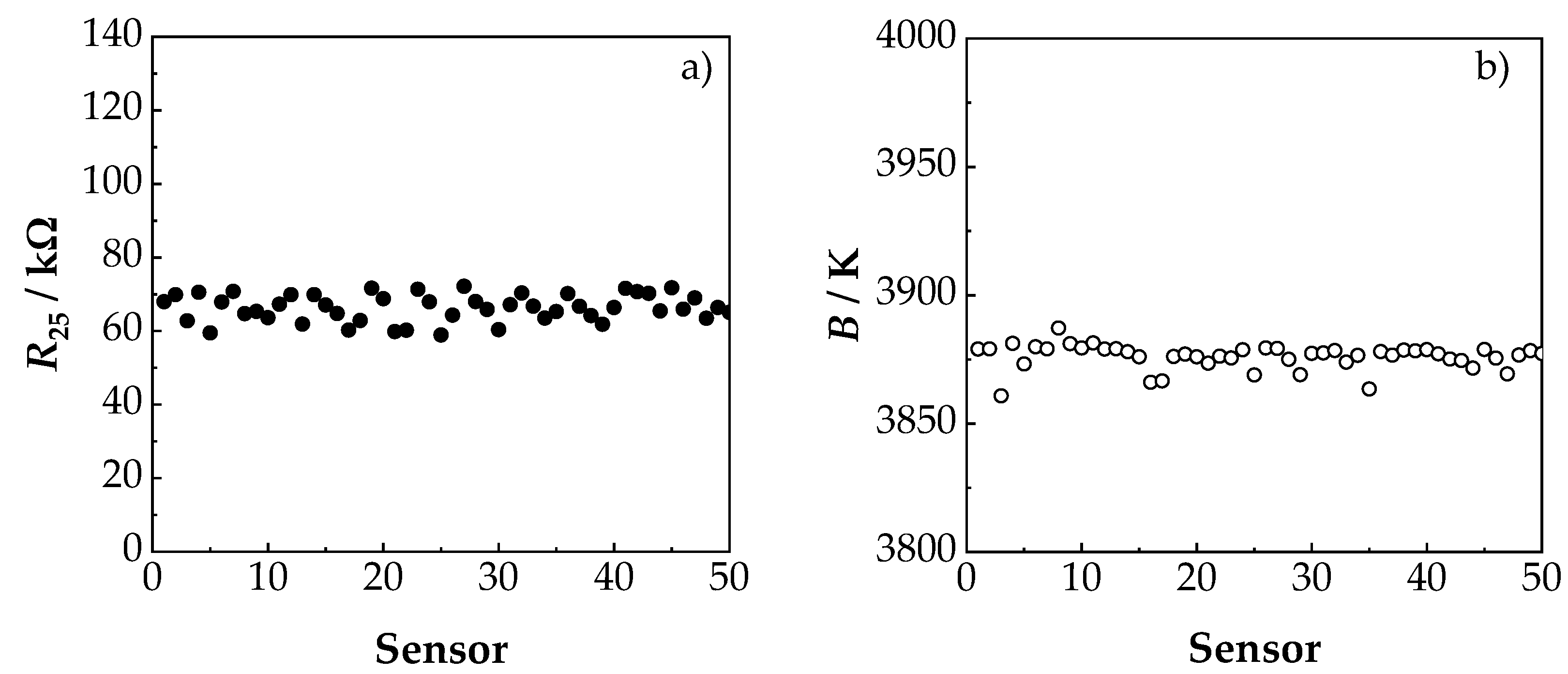

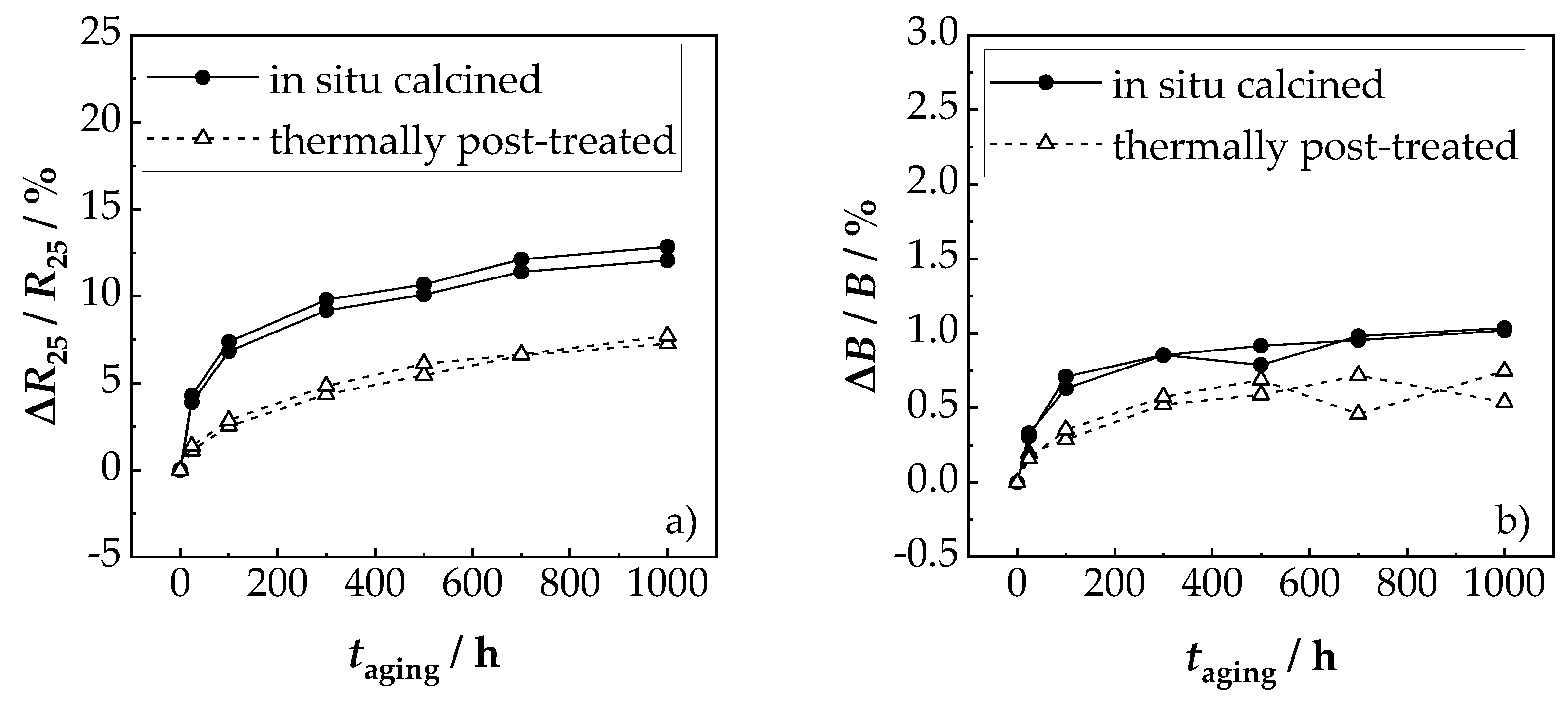

3.2. Chip-Based NTC Thermistor Components

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ma, C.; Gao, H. Preparation and characterization of single-phase NiMn2O4 NTC ceramics by two-step sintering method. J. Mater. Sci. Mater. Electron. 2017, 28, 6699–6703. [Google Scholar] [CrossRef]

- Feteira, A. Negative temperature coefficient resistance (NTCR) ceramic thermistors: An industrial perspective. J. Am. Ceram. Soc. 2009, 92, 967–983. [Google Scholar] [CrossRef]

- Csete de Györgyfalva, G.D.C.; Reaney, I.M. Decomposition of NiMn2O4 spinel: An NTC thermistor material. J. Eur. Ceram. Soc. 2001, 21, 2145–2148. [Google Scholar] [CrossRef]

- Gao, H.; Ma, C.; Sun, B. Preparation and characterization of NiMn2O4 negative temperature coefficient ceramics by solid-state coordination reaction. J. Mater. Sci. Mater. Electron. 2014, 25, 3990–3995. [Google Scholar] [CrossRef]

- Rousset, A.; Legros, R.; Lagrange, A. Recent progress in the fabrication of ceramic negative temperature coefficient thermistors. J. Eur. Ceram. Soc. 1994, 13, 185–195. [Google Scholar] [CrossRef]

- Gillot, B.; Baudour, J.L.; Bouree, F.; Metz, R.; Legros, R.; Rousset, A. Ionic configuration and cation distribution in cubic nickel manganite spinels NixMn3−xO4 (0.57 < x <1) in relation with thermal histories. Solid State Ion. 1992, 58, 155–161. [Google Scholar]

- Darmawansyah, A. NTC thermistors sensor thick film technology. In Proceedings of the SENTIA 2009, Malang, Indonesia, 12 March 2009. [Google Scholar]

- Schmidt, R.; Basu, A.; Brinkman, A.W. Small polaron hopping in spinel manganates. Phys. Rev. B 2005, 72, 115101. [Google Scholar] [CrossRef]

- Fau, P.; Bonino, J.P.; Demai, J.J.; Rousset, A. Thin films of nickel manganese oxide for NTC thermistor applications. Appl. Surf. Sci. 1993, 65/66, 319–324. [Google Scholar] [CrossRef]

- Savic, S.M.; Nikolic, M.V.; Aleksic, O.S.; Slankamenac, M.; Zivanov, M.; Nikolic, P.M. Intrinsic Resistivity of Sintered Nickel Manganite vs. Powder Activation Time and Density. Sci. Sinter. 2008, 40, 27–32. [Google Scholar] [CrossRef]

- Reimann, T.; Töpfer, J.; Barth, S.; Bartsch, H.; Müller, J. Low-Temperature Sintered NTC Thermistor Ceramics for Thick-Film Temperature Sensors. Int. J. Appl. Ceram. Technol. 2013, 10, 428–434. [Google Scholar] [CrossRef]

- Schaumburg, H. Keramik: Werkstoffe und Bauelemente der Elektrotechnik; B. G. Teubner: Stuttgart, Germany, 1994. [Google Scholar]

- Akedo, J. Room Temperature Impact Consolidation (RTIC) of Fine Ceramic Powder by Aerosol Deposition Method and Applications to Microdevices. J. Therm. Spray Technol. 2008, 17, 181–198. [Google Scholar] [CrossRef]

- Lee, D.-W.; Kim, H.-J.; Kim, Y.-H.; Yun, Y.-H.; Nam, S.-M. Growth Process of α-Al2O3 Ceramic Films on Metal Substrates Fabricated at Room Temperature by Aerosol Deposition. J. Am. Ceram. Soc. 2011, 94, 3131–3138. [Google Scholar] [CrossRef]

- Schubert, M.; Exner, J.; Moos, R. Influence of Carrier Gas Composition on the Stress of Al2O3 Coatings Prepared by the Aerosol Deposition Method. Materials 2014, 7, 5633–5642. [Google Scholar] [CrossRef]

- Johnson, S.D.; Glaser, E.R.; Cheng, S.-F.; Kub, F.J.; Eddy, C.R., Jr. Characterization of as-deposited and sintered yttrium iron garnet thick films formed by aerosol deposition. Appl. Phys. Express 2014, 7, 35501. [Google Scholar] [CrossRef]

- Ryu, J.; Kim, K.-Y.; Choi, J.-J.; Hahn, B.-D.; Yoon, W.-H.; Lee, B.-K.; Park, D.-S.; Park, C. Highly Dense and Nanograined NiMn2O4 Negative Temperature coefficient Thermistor Thick Films Fabricated by Aerosol-Deposition. J. Am. Ceram. Soc. 2009, 92, 3084–3087. [Google Scholar] [CrossRef]

- Schubert, M.; Münch, C.; Schuurman, S.; Poulain, V.; Kita, J.; Moos, R. Characterization of nickel manganite NTC thermistor films prepared by aerosol deposition at room temperature. J. Eur. Ceram. Soc. 2018, 38, 613–619. [Google Scholar] [CrossRef]

- Schubert, M.; Kita, J.; Münch, C.; Moos, R. Analysis of the characteristics of thick-film NTC thermistor devices manufactured by screen-printing and firing technique and by room temperature aerosol deposition method (ADM). Funct. Mater. Lett. 2017, 10, 1750073. [Google Scholar] [CrossRef]

- Baek, C.-W.; Han, G.; Hahn, B.-D.; Yoon, W.-H.; Choi, J.-J.; Park, D.-S.; Ryu, J.; Jeong, D.-Y. Fabrication and Characterization of NiMn2O4 NTC Thermistor Thick Films by Aerosol Deposition. Korean J. Mater. Res. 2011, 21, 42–47. [Google Scholar] [CrossRef]

- Ryu, J.; Park, D.-S.; Schmidt, R. In-plane impedance spectroscopy in aerosol deposited NiMn2O4 negative temperature coefficient thermistor films. J. Appl. Phys. 2011, 109, 113722. [Google Scholar] [CrossRef]

- Fang, D.-L.; Wang, Z.-B.; Yang, P.-h.; Liu, W.; Chen, C.-S.; Winnubst, A.J.A. Preparation of Ultra-Fine Nickel Manganite Powders and Ceramics by a Solid-State Coordination Reaction. J. Am. Ceram. Soc. 2006, 89, 230–235. [Google Scholar] [CrossRef]

- Feltz, A.; Töpfer, J.; Schirrmeister, F. Conductivity Data and Preparation Routes for NiMn2O4 Thermistor Ceramics. J. Eur. Ceram. Soc. 1992, 9, 187–191. [Google Scholar] [CrossRef]

- Schubert, M.; Münch, C.; Schuurman, S.; Poulain, V.; Kita, J.; Moos, R. Thermal Treatment of Aerosol Deposited NiMn2O4 NTC Thermistors for Improved Aging Stability. Sensors 2018, 18, 3982. [Google Scholar] [CrossRef]

- Exner, J.; Fuierer, P.; Moos, R. Aerosol Codeposition of Ceramics: Mixtures of Bi2O3-TiO2 and Bi2O3-V2O5. J. Am. Ceram. Soc. 2015, 98, 717–723. [Google Scholar] [CrossRef]

- Exner, J.; Schubert, M.; Hanft, D.; Stöcker, T.; Fuierer, P.; Moos, R. Tuning of the electrical conductivity of Sr(Ti,Fe)O3 oxygen sensing films by aerosol co-deposition with Al2O3. Sens. Actuators B Chem. 2016, 230, 427–433. [Google Scholar] [CrossRef]

- Schubert, M.; Kita, J.; Münch, C.; Moos, R. Investigation of the in situ calcination of aerosol co-deposited NiO-Mn2O3 films. Funct. Mater. Lett. 2019, 1950039. [Google Scholar] [CrossRef]

- Hanft, D.; Exner, J.; Schubert, M.; Stöcker, T.; Fuierer, P.; Moos, R. An Overview of the Aerosol Deposition Method: Process Fundamentals and New Trends in Materials Applications. J. Ceram. Sci. Technol. 2015, 6, 147–182. [Google Scholar]

- Jung, J.; Töpfer, J.; Feltz, A. Thermoanalytic characterization of NiMn2O4 formation. J. Therm. Anal. 1990, 36, 1505–1518. [Google Scholar] [CrossRef]

- Exner, J.; Fuierer, P.; Moos, R. Aerosol deposition of (Cu,Ti) substituted bismuth vanadate films. Thin Solid Films 2014, 573, 185–190. [Google Scholar] [CrossRef]

- Ryu, J.; Park, D.-S.; Hahn, B.-D.; Choi, J.-J.; Yoon, W.-H.; Kim, K.-Y.; Yun, H.-S. Photocatalytic TiO2 thin films by aerosol-deposition: From micron-sized particles to nano-grained thin film at room temperature. Appl. Catal. B 2008, 83, 1–7. [Google Scholar] [CrossRef]

- Kim, J.-H.; Kang, Y.-M.; Byun, M.-S.; Hwang, K.-T. Study on the chemical stability of Y-doped BaCeO3−δ and BaZrO3−δ films deposited by aerosol deposition. Thin Solid Films 2011, 520, 1015–1021. [Google Scholar] [CrossRef]

- Hoshina, T.; Furuta, T.; Kigoshi, Y.; Hatta, S.; Horiuchi, N.; Takeda, H.; Tsurumi, T. Size Effect of Nanograined BaTiO3 Ceramics Fabricated by Aerosol Deposition Method. Jpn. J. Appl. Phys. 2010, 49, 09MC02. [Google Scholar] [CrossRef]

- Akedo, J.; Lebedev, M. Microstructure and Electrical Properties of Lead Zirconate Titanate (Pb(Zr52/Ti48)O3) Thick Films Deposited by Aerosol Deposition Method. Jpn. J. Appl. Phys. 1999, 38, 5397–5401. [Google Scholar] [CrossRef]

- Akedo, J.; Lebedev, M. Powder Preparation in Aerosol Deposition Method for Lead Zirconate Titanate Thick Films. Jpn. J. Appl. Phys. 2002, 41, 6980–6984. [Google Scholar] [CrossRef]

- Ryu, J.; Priya, S.; Park, C.-S.; Kim, K.-Y.; Choi, J.-J.; Hahn, B.-D.; Yoon, W.-H.; Lee, B.-K.; Park, D.-S.; Park, C. Enhanced domain contribution to ferroelectric properties in freestanding thick films. J. Appl. Phys. 2009, 106, 24108. [Google Scholar] [CrossRef]

- Rousset, A.; Tenailleau, C.; Dufour, P.; Bordeneuve, H.; Pasquet, I.; Guillemet-Fritsch, S.; Poulain, V.; Schuurman, S. Electrical Properties of Mn3−x CoxO4 (0 ≤ x ≤ 3) Ceramics: An Interesting System for Negative Temperature Coefficient Thermistors. Int. J. Appl. Ceram. Technol. 2013, 10, 175–185. [Google Scholar] [CrossRef]

- Metz, R. Electrical properties of N.T.C. thermistors made of manganite ceramics of general spinel structure: Mn3−x−x′MxNx′O4 (0 ≤ x + x′ ≤ 1; M and N beeing Ni, Co or Cu). Aging phenomenon study. J. Mater. Sci. 2000, 35, 4705–4711. [Google Scholar] [CrossRef]

- Schmidt, R.; Basu, A.; Brinkman, A.W. Production of NTCR thermistor devices based on NiMn2O4+δ. J. Eur. Ceram. Soc. 2004, 24, 1233–1236. [Google Scholar] [CrossRef]

- Schmidt, R.; Stiegelschmitt, A.; Roosen, A.; Brinkman, A.W. Screen printing of co-precipitated NiMn2O4+δ for production of NTCR thermistors. J. Eur. Ceram. Soc. 2003, 23, 1549–1558. [Google Scholar] [CrossRef]

- Castelan, P.; Ai, B.; Loubiere, A.; Rousset, A.; Legros, R. Aging study of nickel-copper-manganite negative temperature coefficient thermistors by thermopower measurements. J. Appl. Phys. 1992, 72, 4705–4709. [Google Scholar] [CrossRef]

- Park, K. Improvement in electrical stability by addition of SiO2 in (Mn1.2Ni0.78Co0.87−xCu0.15Six)O4 negative temperature coefficient thermistors. Scr. Mater. 2004, 50, 551–554. [Google Scholar] [CrossRef]

- Cheng, F.; Wang, J.; Zhang, H.; Chang, A.; Kong, W.; Zhang, B.; Chen, L. Phase transition and electrical properties of Ni1−xZnxMn2O4 (0 ≤ x ≤ 1.0) NTC ceramics. J. Mater. Sci. Mater. Electron. 2015, 26, 1374–1380. [Google Scholar] [CrossRef]

- Tang, X.-X.; Manthiram, A.; Goodenough, J.B. NiMn2O4 revisited. J. Less Common Met. 1989, 156, 357–368. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schubert, M.; Münch, C.; Schuurman, S.; Poulain, V.; Kita, J.; Moos, R. Novel Method for NTC Thermistor Production by Aerosol Co-Deposition and Combined Sintering. Sensors 2019, 19, 1632. https://doi.org/10.3390/s19071632

Schubert M, Münch C, Schuurman S, Poulain V, Kita J, Moos R. Novel Method for NTC Thermistor Production by Aerosol Co-Deposition and Combined Sintering. Sensors. 2019; 19(7):1632. https://doi.org/10.3390/s19071632

Chicago/Turabian StyleSchubert, Michaela, Christian Münch, Sophie Schuurman, Véronique Poulain, Jaroslaw Kita, and Ralf Moos. 2019. "Novel Method for NTC Thermistor Production by Aerosol Co-Deposition and Combined Sintering" Sensors 19, no. 7: 1632. https://doi.org/10.3390/s19071632

APA StyleSchubert, M., Münch, C., Schuurman, S., Poulain, V., Kita, J., & Moos, R. (2019). Novel Method for NTC Thermistor Production by Aerosol Co-Deposition and Combined Sintering. Sensors, 19(7), 1632. https://doi.org/10.3390/s19071632