1. Introduction

Gears are crucial components in the power transmission of automatic robotics and transportation vehicles. With the increasing demand for high-precision gears for speed reducers used in industrial robots and electric vehicles, high efficiency, as well as accurate in-situ inspection of the gear profile and quality grade, are essential in the gear production process. Moreover, the resolution required for high-quality gear profile inspection is in the range of a few micrometers.

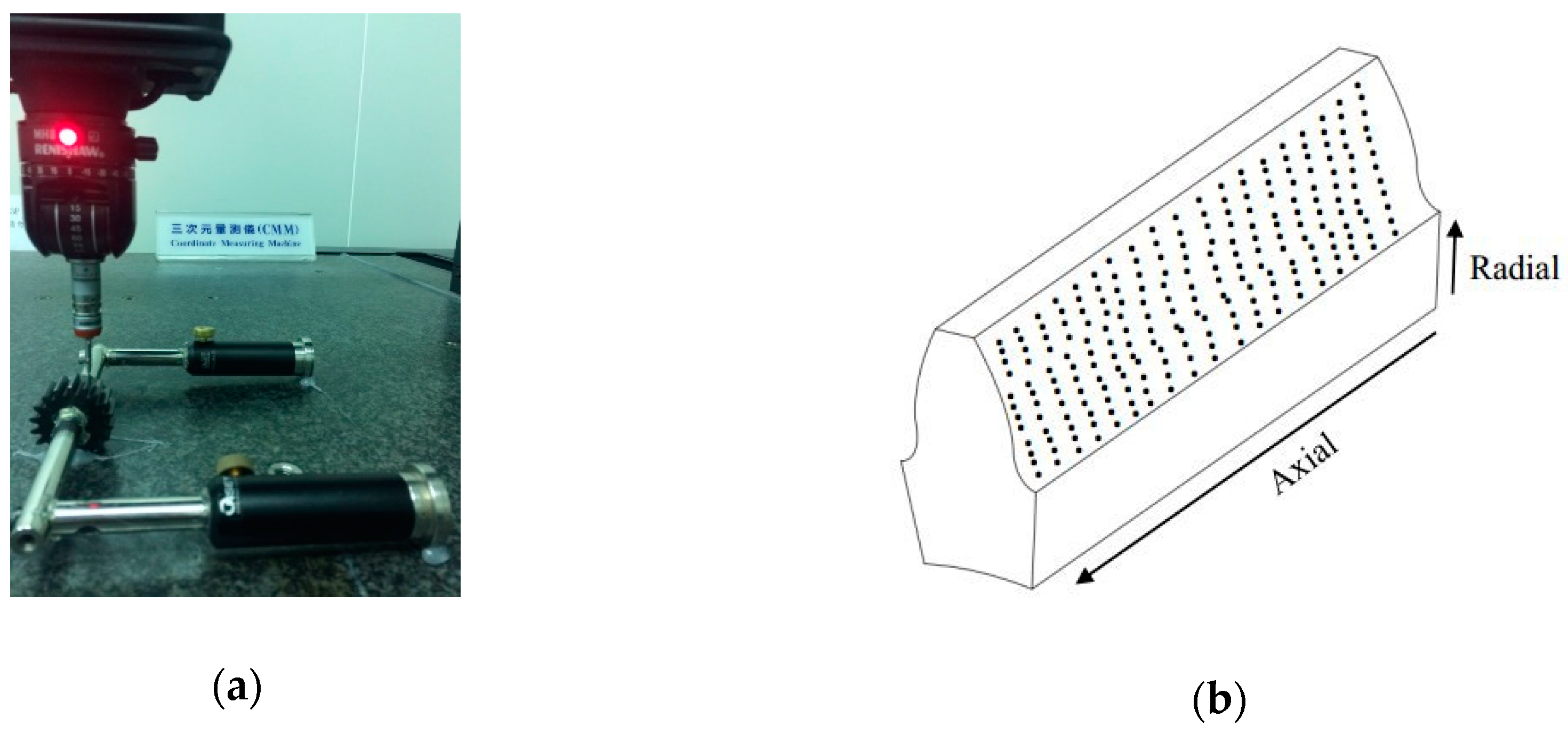

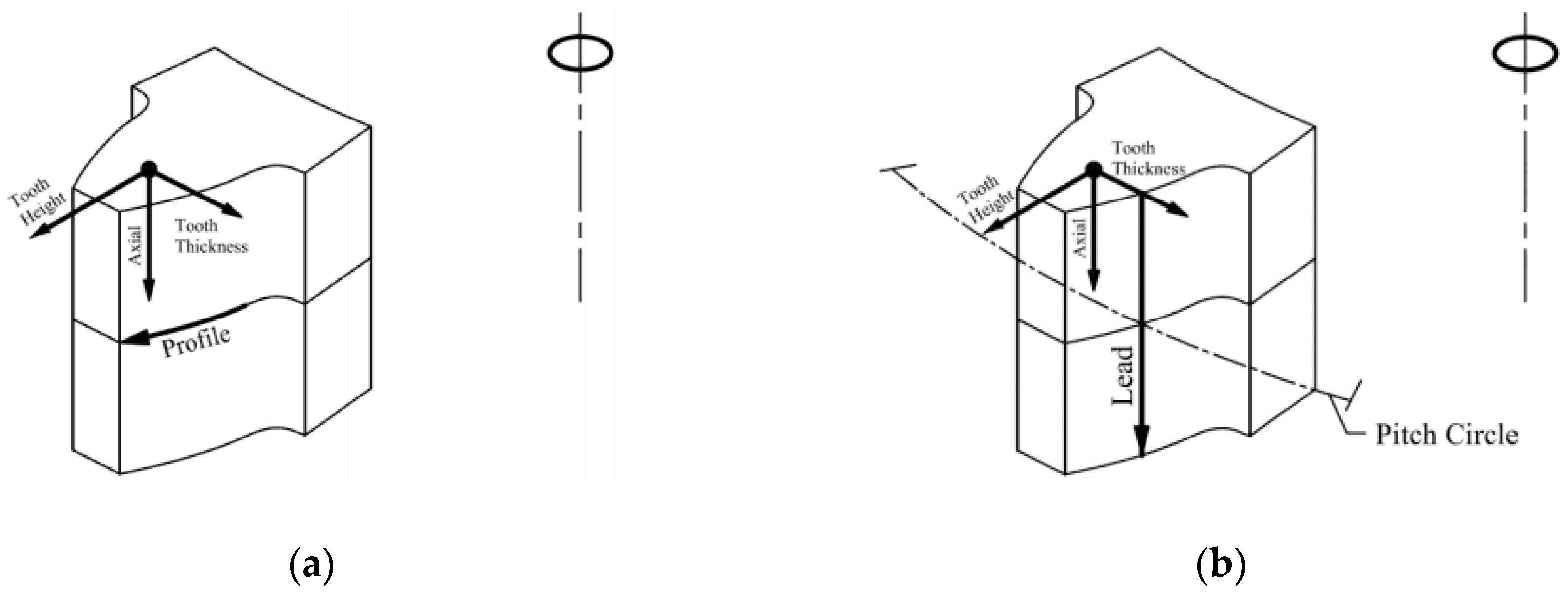

Conventionally, the gears are measured by contacting probes on the tooth surface with multiple points or by scanning several traces on the tooth surface. The industrial measurement facility for gear tooth surfaces is usually a coordinate measuring machine (CMM) with contact probing. The resolution increases with the increase of contact points on the tooth surface. However, the overall measuring time for a gear workpiece also increases with an increase in the number of measuring points. Therefore, the common practice is to measure only a few teeth, typically four teeth oriented 90 degrees apart. Moreover, only a few traces on one tooth surface are measured, including the involute profile and axial-direction traces. Consequently, these measurements present only partial information of all the gear teeth.

Recently, optical metrology has been applied in measuring 3-D surfaces, including gear tooth surfaces. Optical metrology possesses the advantages of being a non-contact method and having high resolution and efficiency for workpiece contour measurement and surface quality inspection. Several methods exist for measuring optical topography, including the stereoscopic method, structured light, laser triangulation, conoscopic holography, the moiré method, and heterodyne interferometry [

1,

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13].

The structured light method is becoming popular for handheld scanning devices that have relatively low precision but are more convenient. Peters et al. [

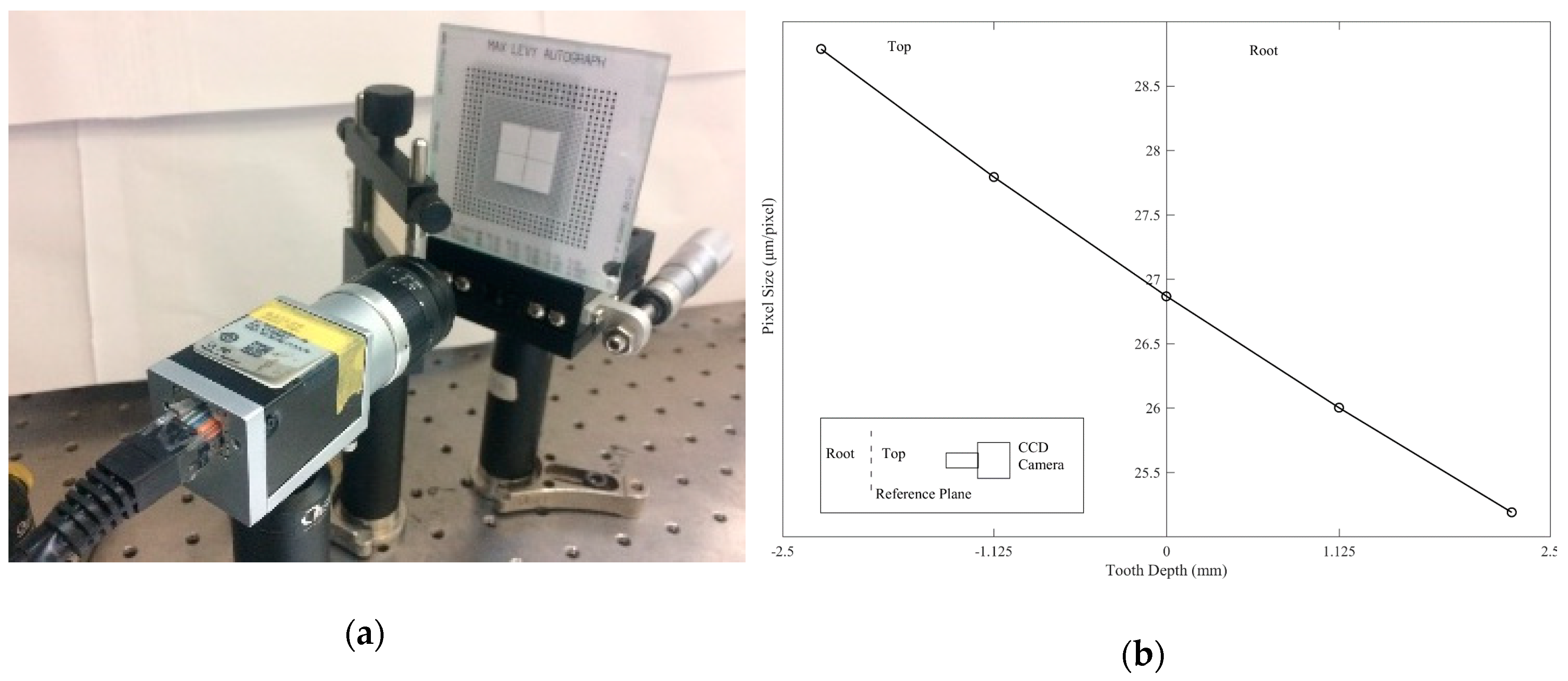

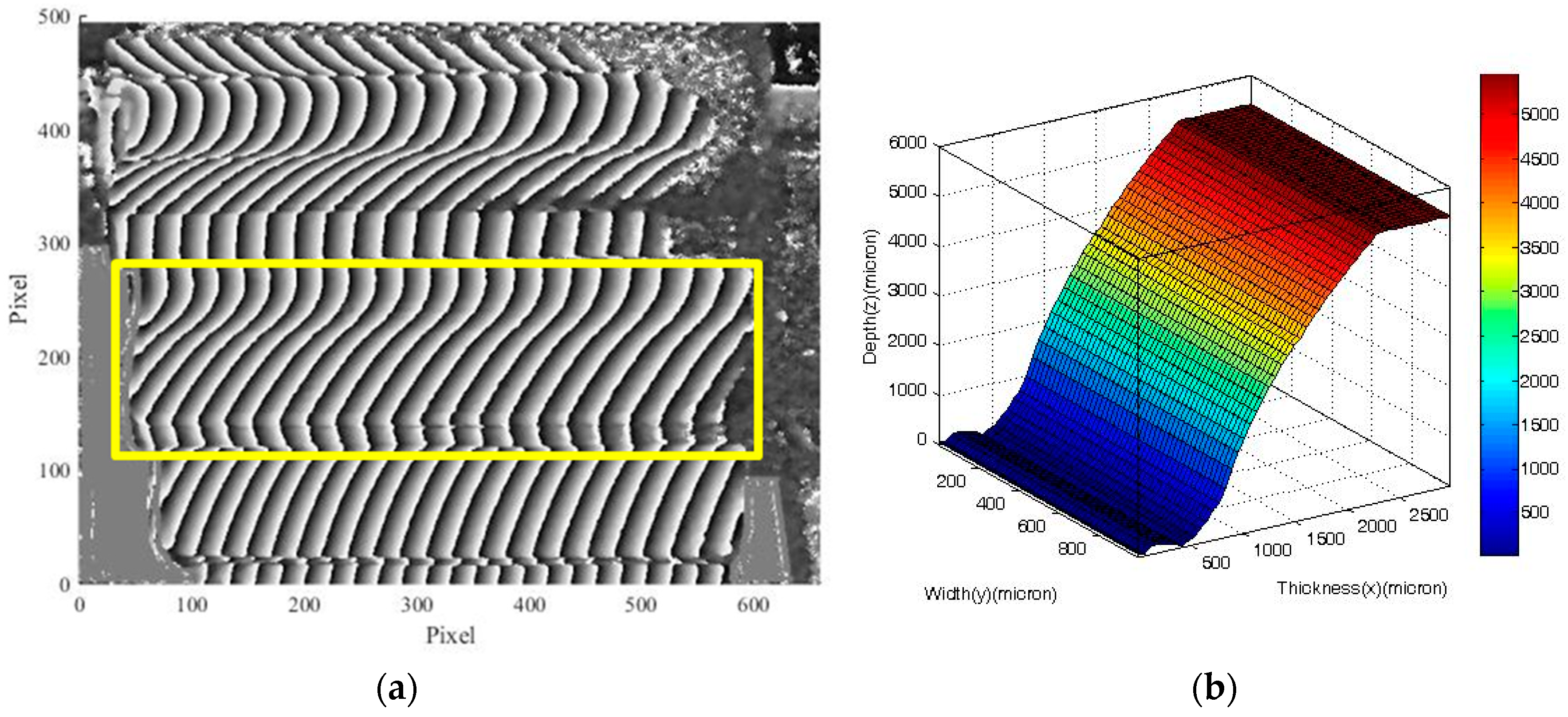

1] applied structured light patterns for the high-efficiency measurement of gear tooth surfaces. A charge-coupled device (CCD) camera was used to capture the deformed stripes produced by the interaction between the light pattern and the tooth surface. Their measuring area was a few square centimeters, and the resolution was approximately 1 μm.

Several different interferometric methods have been applied for 3-D contouring. Laser interferometry has high resolution but is sensitive to vibration and air turbulence during the phase-shifting process. Fang et al. [

2] used laser interferometry to compensate for the inevitable installation errors that occur when measuring the gear tooth surface. Their experimental results demonstrated the feasibility of their compensation method.

The laser triangulation technique is the most common method for online non-contact inspection; however, it has fundamental limitations of limited precision and short standoffs. In addition, laser triangulation is used to measure 3-D contours, especially for large workpieces that conventional CMM cannot measure. Smith et al. [

3] used point laser triangulation for the inspection of helical gear. They studied an optimal path plan for helical gear profile inspection with a point laser triangulation probe to avoid collision and create a complex sensor-to-surface orientation. Recently, Auerswald et al. [

4] proposed a laser line triangulation sensor for a large cylindrical involute gear with a pitch diameter of 922 mm and a face width of 246 mm. They developed a laser line triangulation sensor that can provide 1280 points at a 25-mm line width, and the speed can reach 200 lines/s. Their measurement deviation is ±8.2 μm due to random and systematic errors. The measuring speed is fast, but the accuracy can be improved.

Conoscopic holography has the advantages of a high viewing angle, robustness, and a high point sampling rate. It has also been used for 3-D profile measurement with CMM [

5] and in adverse environments [

6]. Fernández et al. [

5] integrated a conoscopic holography sensor onto a CMM and obtained an accuracy similar to that of laser triangular sensors. The errors of the conoscopic holography sensor compared with the CMM results range from 4 μm to 18 μm. Enguita et al. [

6] developed an optical profilometer for distance calculation based on conoscopic holography and used it in a harsh steelmaking environment. The resolution was 0.2 mm with a long working distance of 1200 mm when they used conoscopic holography to inspect hot (over 800 °C) steel slabs. Álvarez et al. [

7] reviewed the application of conoscopic holography techniques for submicron roughness measurement and high-temperature surface detection. They reported that multiple wavelength conoscopic holography can correctly resolve 3-μm steeps, extending the measurement range of the conoscopic holography to online roughness measurement and microdefect detection. Moreover, an online inspection system using conoscopic holography integrated with a robot was implemented for inspecting automobile synchronizer hubs. The 3-D data were acquired and measured automatically for every workpiece, and the precision was reported to nearly ±1 μm.

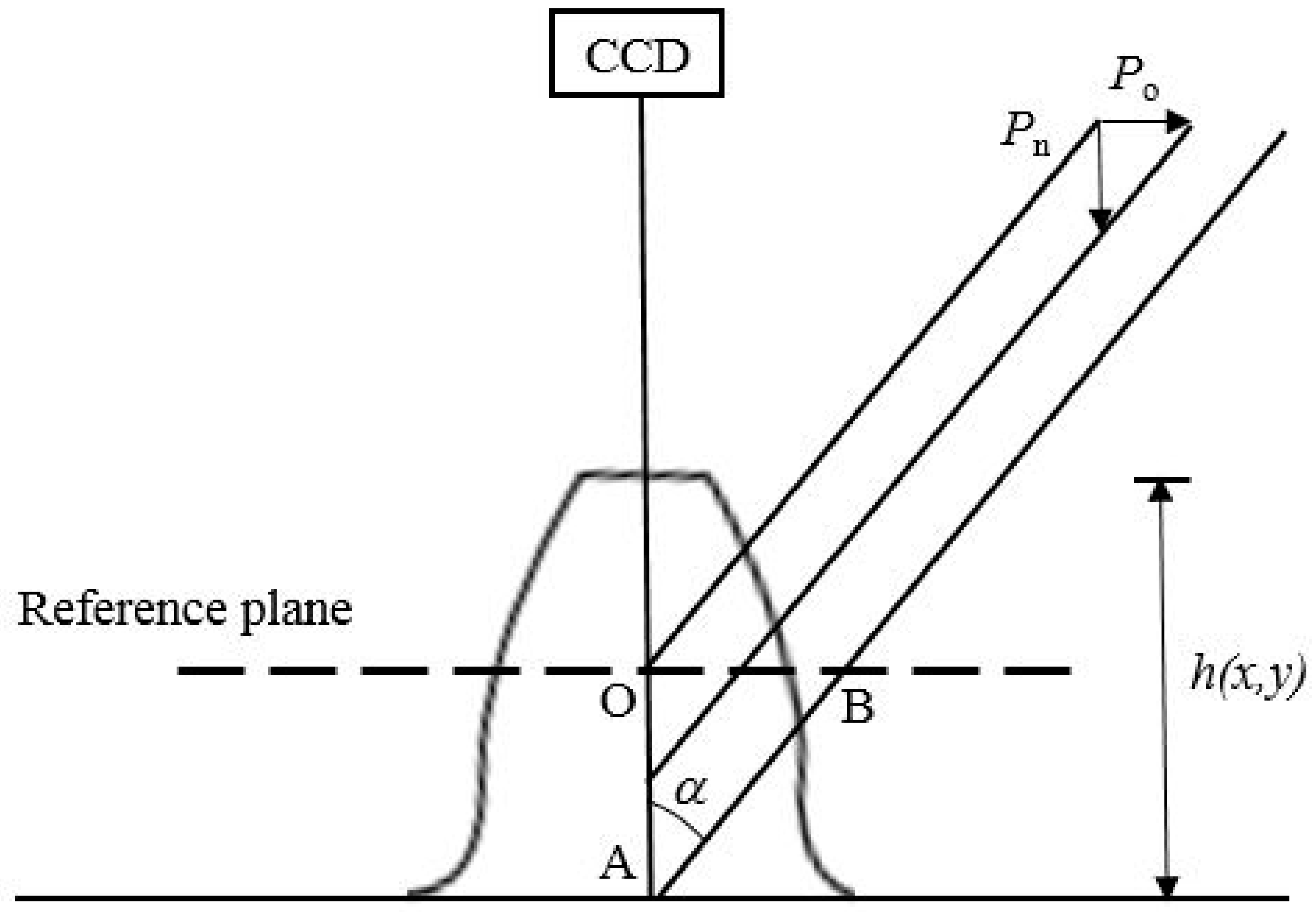

The moiré technique, which is similar to interferometry, has been applied in several moiré methods in 3-D surface contouring, including projection moiré, shadow moiré, and moiré with heterodyne interferometry [

8,

9]. Chang et al. [

10] proposed a method for reconstructing surface profiles based on projection moiré and heterodyne interferometry. The projection grating moves at a constant velocity along the grating plane to produce a series of sinusoidal waves, similar to heterodyne interferometric signals. The resolution of this system is improved to approximately 1.9 μm by combining the projection moiré and heterodyne interferometry.

Jeong and Kim [

11] presented a high-speed moiré method by performing 3-D contouring with one fringe captured on the basis of the color grating projection. Practically, the accuracy of the moiré method can be affected by errors induced during phase-shifting. Mu et al. [

12] investigated the error analysis of the phase-shifting in shadow moiré by changing the incidence angle of the collimating beams. Experiments were performed to verify the proposed technique, and the results were found to be 5% better than those of the conventional phase-shifting technique.

Sciammarella et al. [

13] applied projection moiré in evaluating gear contours and reported the feasibility of using the projection moiré method. They produced the topographic information on a gear surface and compared it with that provided by a mechanical tactile device. The involute profiles of the gear measured by the optical method and by the mechanical method were examined and compared. However, the lead profile and 3-D topology errors, which are frequently presented in gear inspection report sheets, were not studied in their research.

In addition to the academic research on the optical metrology of gears, the industry has focused on developing commercial machines for the optical measurement of gear surfaces. Nikon announced the launch of HN-C3030 for 3-D gear surface measurement [

14]. Laser structured patterns are projected on the gear tooth surface, and the computer numerical control (CNC) measurement machine has a five-axis movement. The resolution for this non-contact gear surface-measuring machine is reported to be 5 μm. Recently, Gleason announced the development of a gear rolling tester with laser inspection on a single machine [

15]. The optical method for the profile inspection of cylindrical gears is reported to be ten times faster than the conventional probing method.

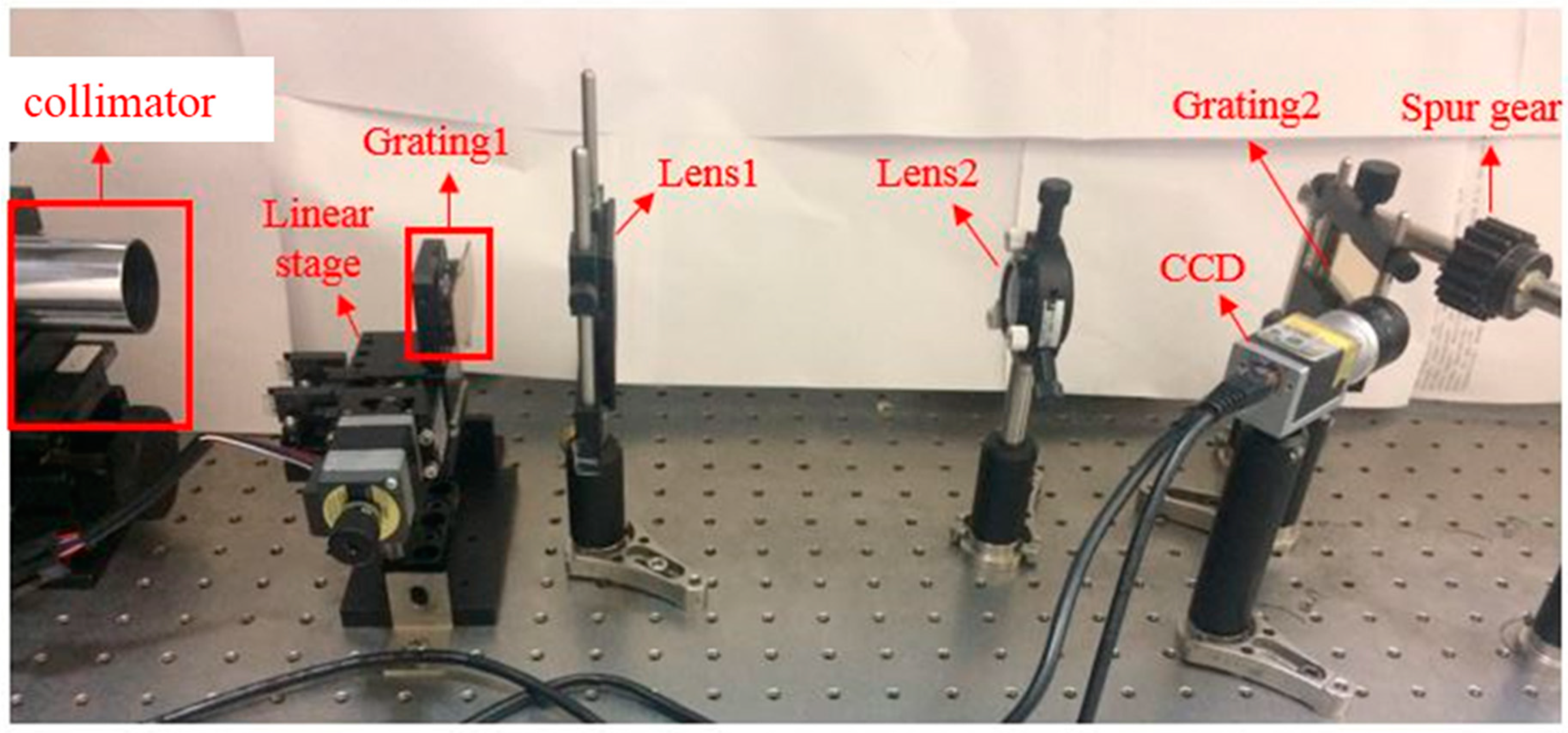

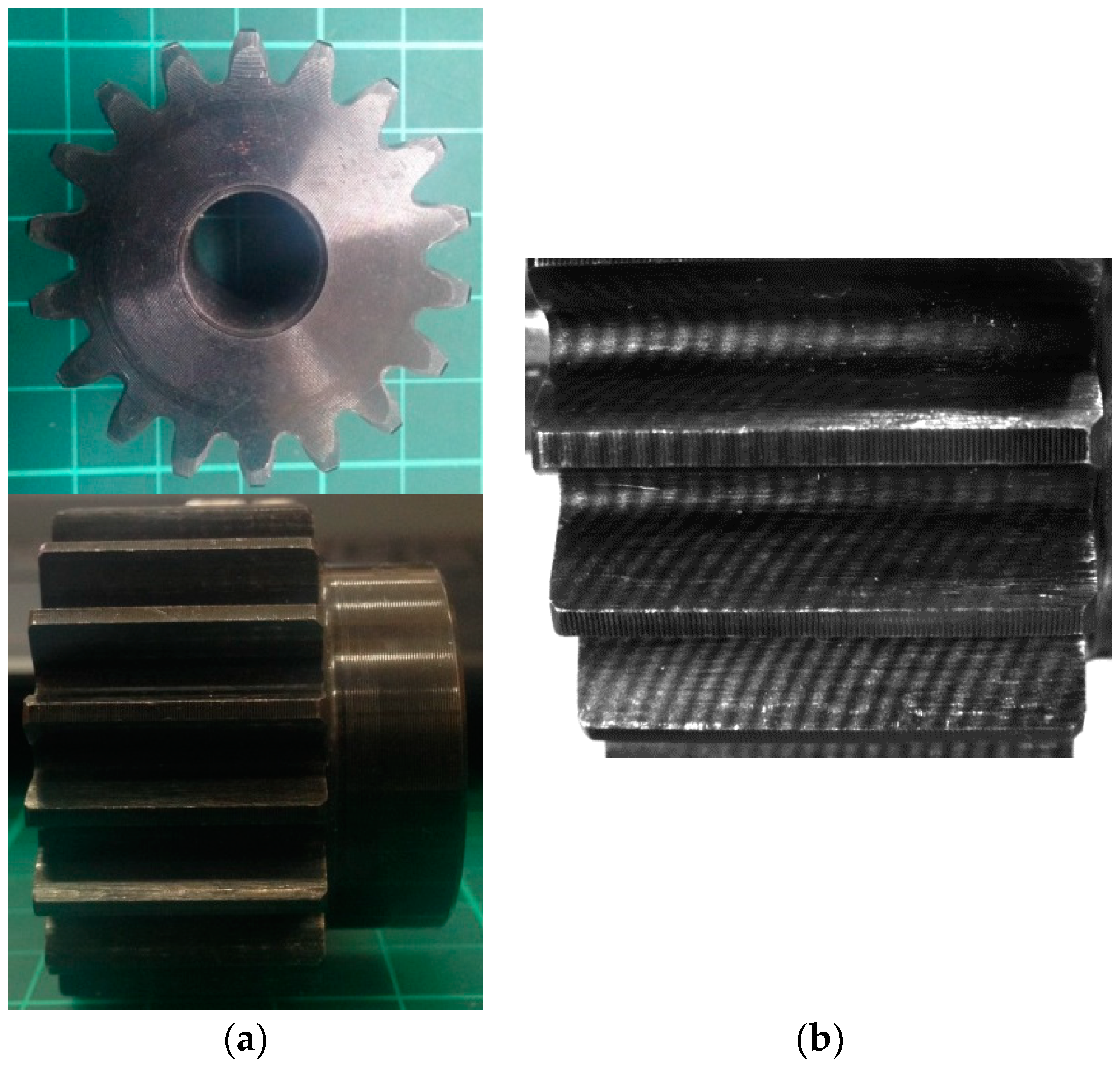

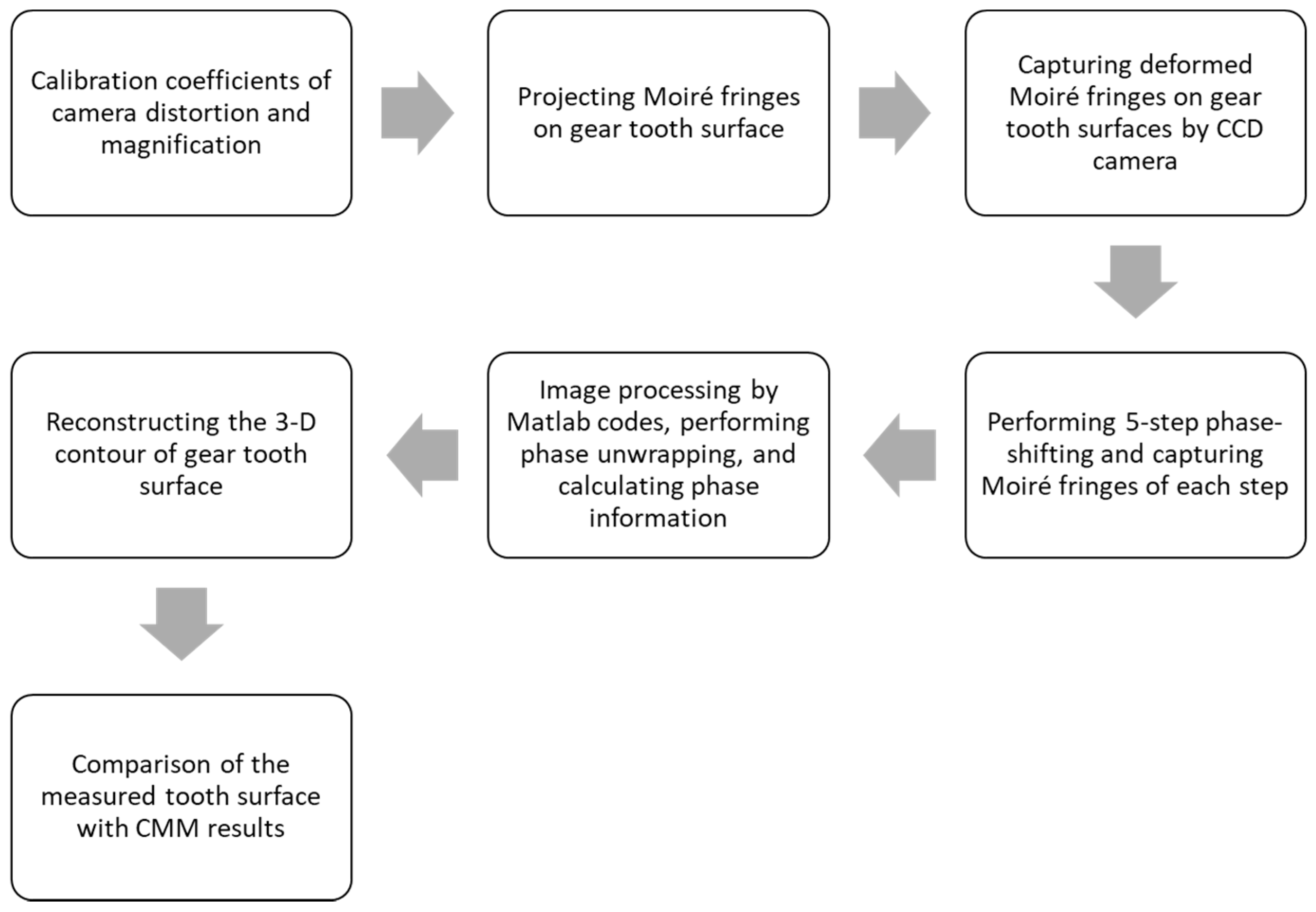

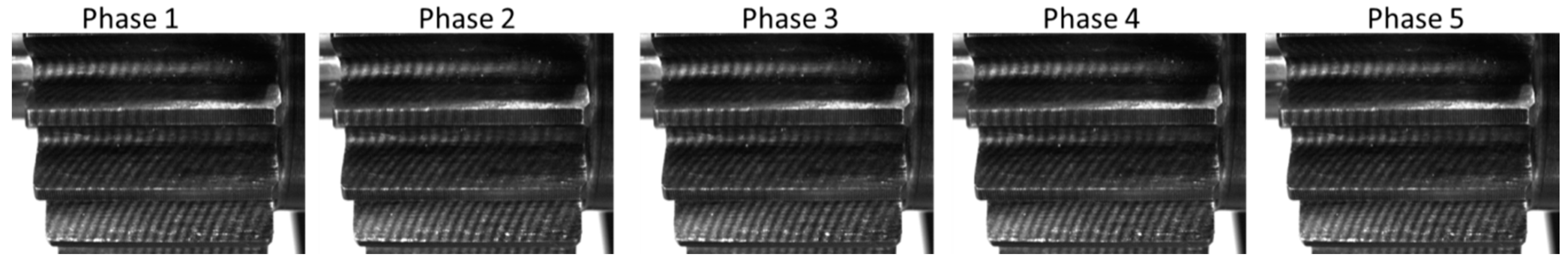

This study proposed an optical measurement method for the inspection of gear tooth surfaces. First, projection moiré fringes were formed on the gear tooth surface. Subsequently, the moiré fringe information produced by the five-step phase-shifting was used to determine the phase information to reconstruct the surface topography, and the contour of the gear tooth was estimated using our developed computer codes. To verify the accuracy of the inspection system, a spur gear tooth surface measured by a commercial CMM was defined as the reference tooth profile. The 3-D tooth topography, involute profile deviation, and lead deviation were successfully calculated by comparing the deviation of the optically measured surface and the reference gear tooth profiles using the CMM. Moreover, a gauge block was measured using our optical method to confirm measurement accuracy.

4. Discussion

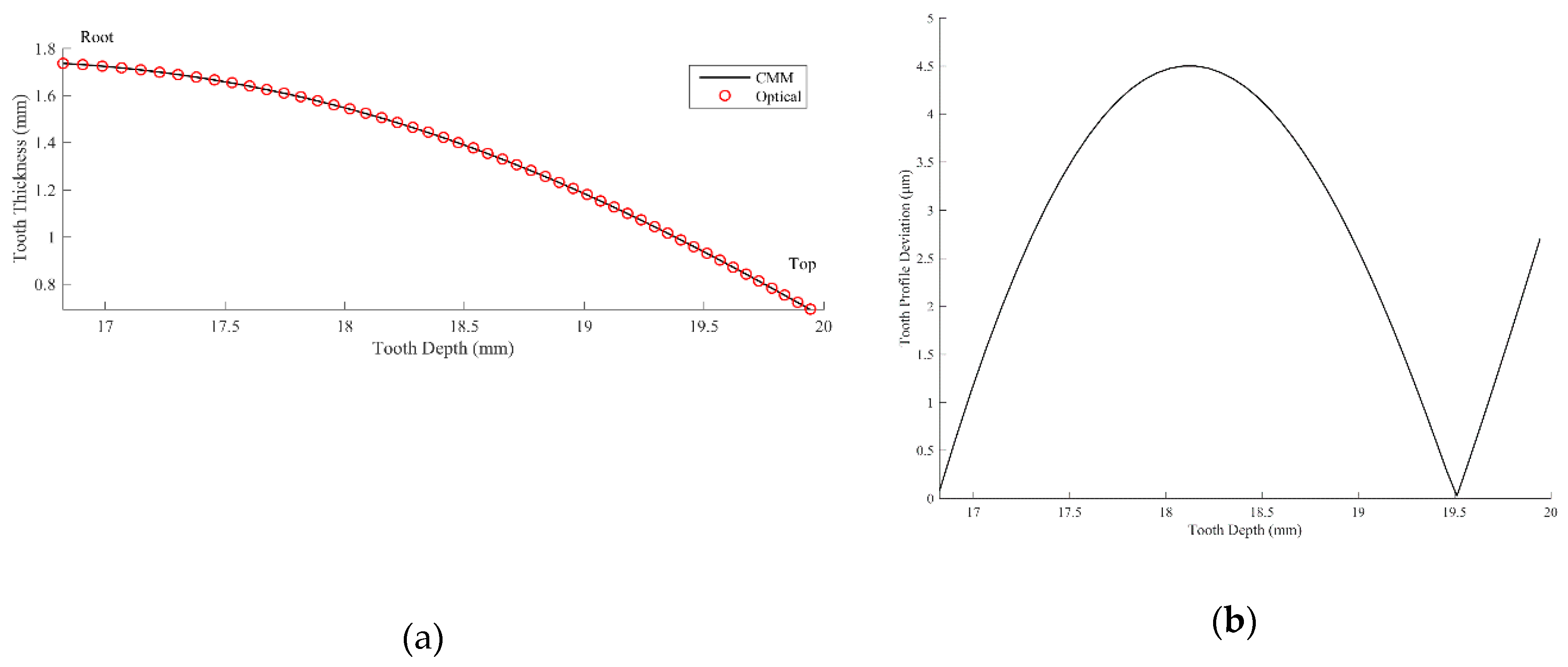

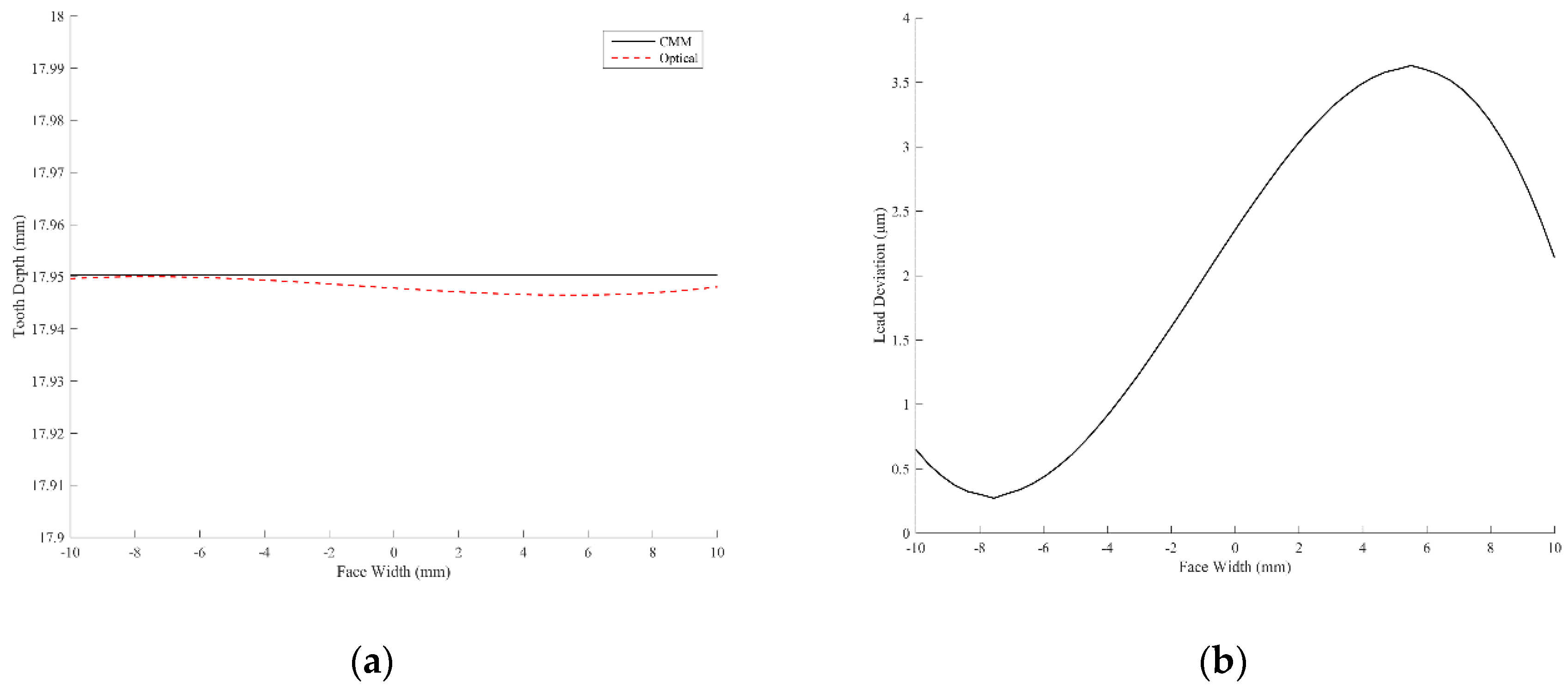

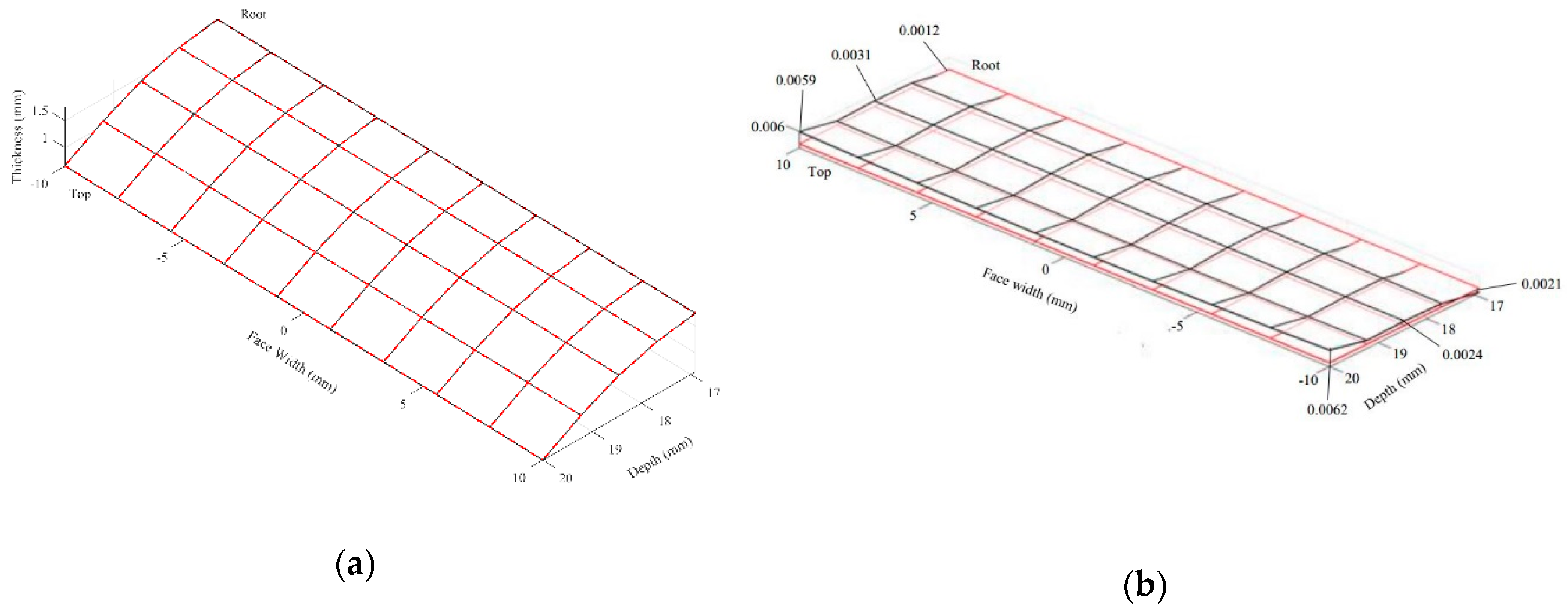

The proposed optical method can inspect the whole tooth surface of the spur gear, and the three types of deviations commonly used in the gear inspection reports are calculated and presented. Three forms of deviations of the gear tooth surface measured by the projection moiré method from the CMM results are illustrated in

Figure 11,

Figure 12 and

Figure 13.

Table 3 summarizes the maximum, minimum, mean value, and standard deviation of the three tooth surface deviations. The mean values of the tooth surface deviation of the three forms are all smaller than 3 μm, which is the accuracy range of the CMM used in this study. In addition, the standard deviations of the three types of deviations are all in the range of 1–2 μm.

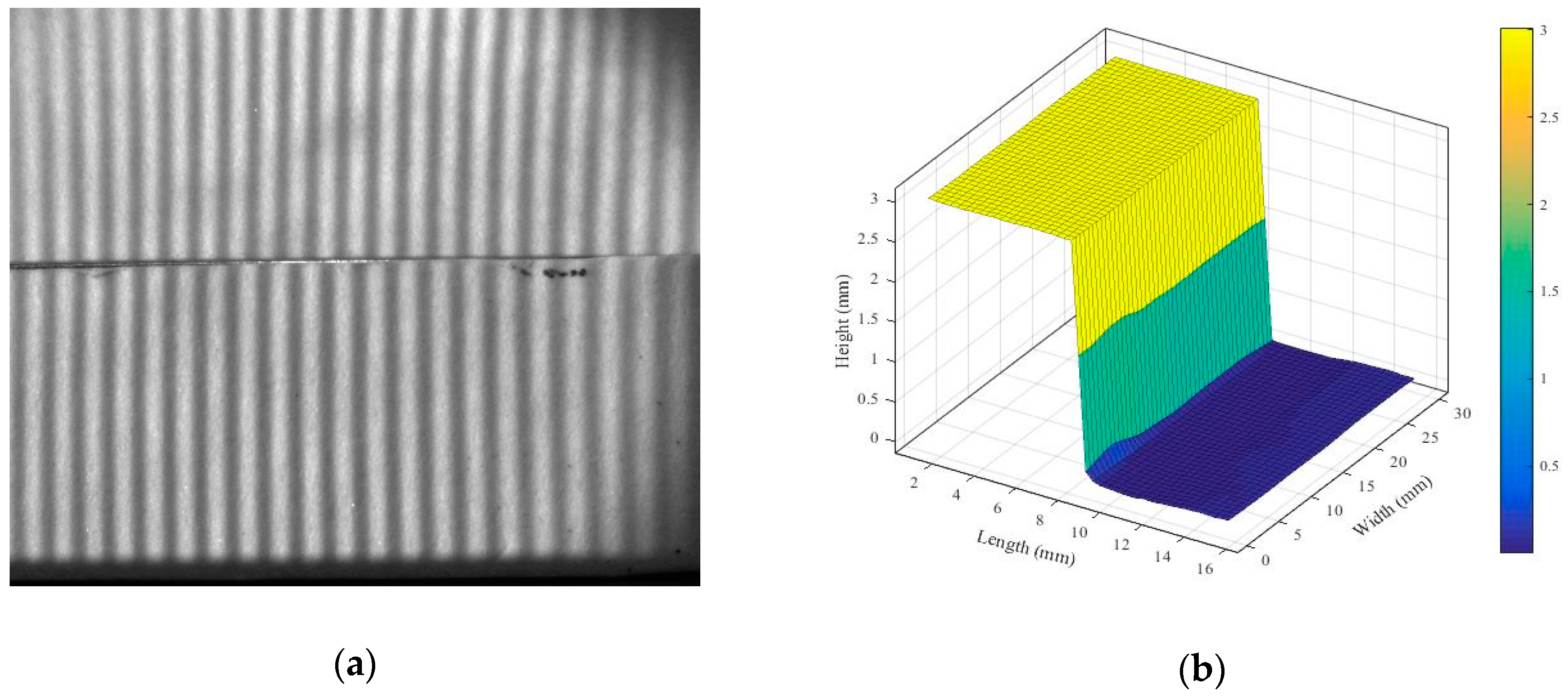

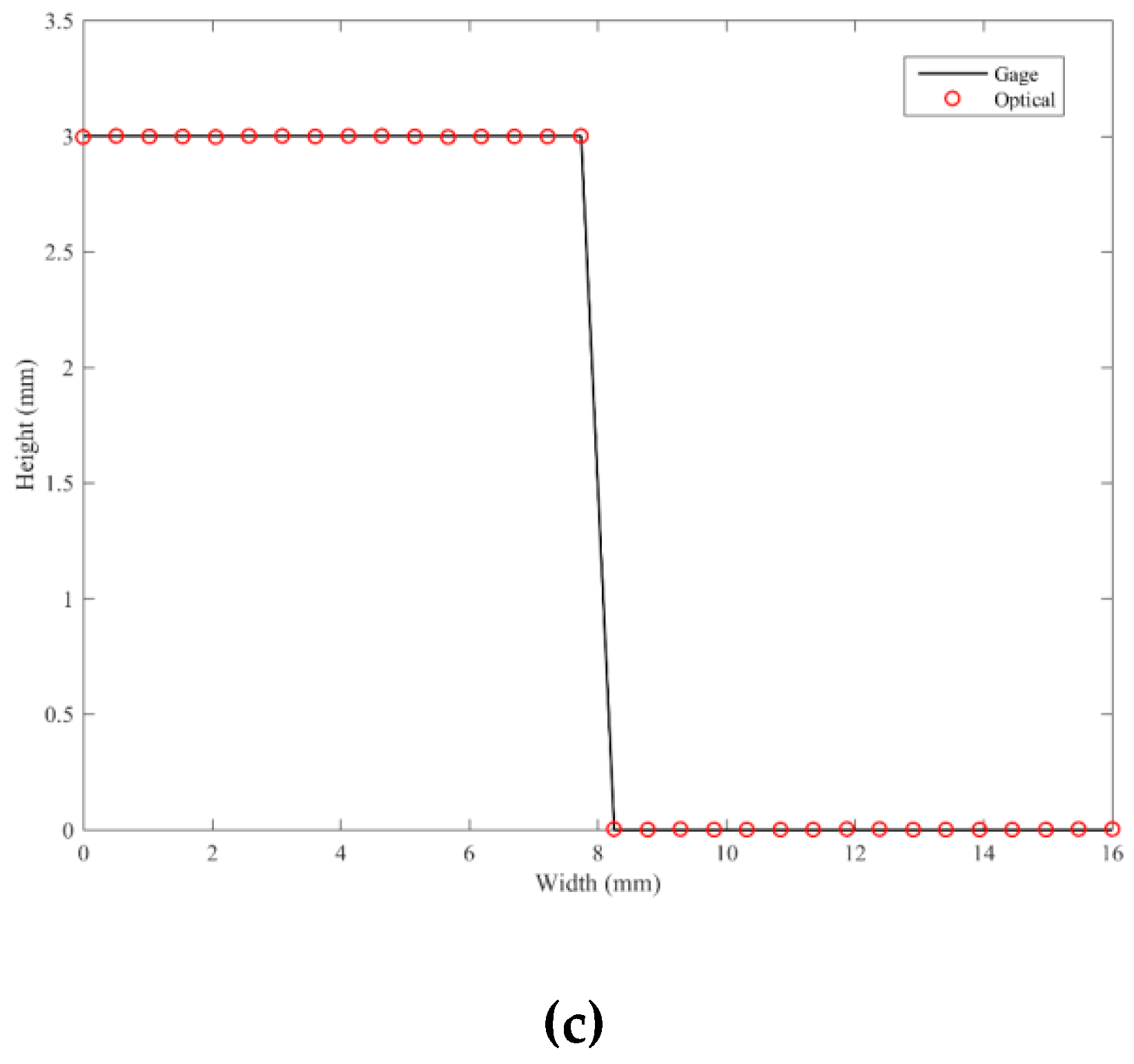

According to the experimental results presented in

Table 3, the deviations of the three forms are all smaller than 3 μm, which is the accuracy range of the CMM. To determine the accuracy of our proposed method, a Mitutoyo grade K gauge block of dimension 30(L) × 8(W) × 3(H) mm

3 was measured, and the deviation was calculated.

Figure 14a,b depicts the moiré fringes on the gage block and the reconstructed 3-D profile by our optical method, respectively. In addition,

Figure 14c illustrates the height reconstructed by our method and the nominal height of the gage block. The average value of the height deviation is 2.76 μm.

Therefore, the accuracy of our optical measurement method is 2.76 μm, which is justified by the gauge block measurement and is also consistent with comparisons of the CMM and optical results in the preceding section. The accuracy of our system is comparable with the reported accuracy of 0.6–2.6 μm, and the average difference of 1.6 μm was confirmed by using a Zeiss CMM and following the method in [

7]. The sources of errors in our system are discussed in the next paragraph. Moreover, the accuracy of our system can be further improved by modifying our projection moiré system.

The errors during the phase-shifting measurement may come from the following sources: (1) The data acquisition system; (2) environmental disturbance; (3) the nonlinearity of the sensors; (4) quantizing the signal from analog to digital; (5) source instability; (6) stray reflection. The data acquisition system includes the camera and the phase-shifting mechanism. A five-step phase-shifting algorithm was used in this study to minimize the effect of phase-shifting errors. Moreover, dial indicators and laser displacement sensors were applied to improve the accuracy of each phase-shifting step. The accuracy can be further enhanced by using a more accurate phase-shifting motorized stage, such as a piezoelectric actuator.

Although the magnification calibration along the depth, as well as the distortion calibration of the camera, were performed for the system, the accuracy can be further improved if a telecentric camera lens system is used for image capturing. In addition, the vibration and air disturbance were kept to a minimum because the experiments were performed on a vibration-isolated optical bench in a laboratory with shielding curtains. Surface reflection and shadows should be avoided; otherwise, these may result in the saturation of sensor pixels and missing data on the corresponding measured area.

In summary, the proposed projection moiré method is considered a trustworthy and accurate non-contact method for gear tooth surface inspection. Moreover, the precision is related to the number of fringes used in the measurement; it can be further improved by applying different gratings to the projection moiré system. It will also be interesting and challenging to inspect two tooth surfaces simultaneously in the future, which may be affected by the shadowed area, reflection, and the steep slope of the tooth surface. The advantages of the projection moiré method are that it is contact-free, accurate, allows time savings, and that the tooth surface can be measured in one measurement. The optical method is expected to be applied to other 3-D surfaces as well, such as ball-screws, cams, screw compressors, and turbine blades.

5. Conclusions

An optical inspection method for gear tooth surfaces using the projection moiré is proposed and studied in this paper. The tooth surface of a spur gear was measured using the projection moiré method, and the measured results were compared with those from a commercial CMM. In addition, three forms of tooth surface deviations, namely involute profile, lead profile, and 3-D topology, measured by the optical method from the reference surface (CMM results) and presented in gear inspection sheets, were calculated and illustrated. The results revealed that the mean values of the profile deviations of the tooth surface measured by the proposed projection moiré method were within 3 μm, which was the accuracy range of the CMM used in this study. The accuracy of our optical measurement method is 2.76 μm, which was justified using the gauge block measurement.

The results imply that the projection moiré method is an alternative, trustworthy, rapid, and non-contact method for measuring gear tooth surfaces. Furthermore, the precision grades of the measured gear, such as DIN (Deutsches Institut für Normung), ISO (International Organization for Standardization), and AGMA (American Gear Manufacturers Association) grades, can be determined and classified using a theoretical tooth surface geometry as the reference surface when calculating the involute, lead, and topology deviations.