1. Introduction

During the past few decades, deformation reconstruction has played an important role in real-time structural health monitoring (SHM) with the flourish of civil engineering, aerospace, and smart structure development. Shape sensing techniques can be employed to reconstruct the displacement field based on strain sensor values in a real-time manner [

1,

2]. The advantage of this method is that a priori knowledge, such as model shape, load form, and elastic-inertial material information, is not required in the process of reconstruction. This is particularly the case in scenarios where the applied loads are difficult to be accurately determined or measured. For example, the applied loads are the aerodynamic forces, temperatures, impact loads, or vibrating excitation [

3].

The key technology in shape sensing was to accurately establish the mathematical model between the discrete surface strain and the displacement field. Previous researchers proposed many modeling methods. The adaptive fuzzy net was employed to establish the transformation relationship between measured surface strain and displacement [

4]. Moreover, neural nets were also used to perform the strain–displacement relationship [

5,

6]. However, the shortcoming of these net approaches was that the reconstructed displacement accuracy was heavily dependent on the selection of the load cases used for the training process. Ko et al. performed the integration of discrete surface strain to handle the beam deformation problem [

7]. Later, the shape sensing technique was further developed based on Ko’s displacement theory. This theory was then extended to solve the deformation displacement of beam, plate, and wing [

8,

9]. This method has shown a higher reconstructed accuracy in the resultant one-dimension than in the multi-dimensional loading conditions. The global or piecewise continuous basis functions have been used to describe the strain field [

10,

11,

12,

13,

14,

15,

16]. In this paper, the authors have combined the spatial functions with the appropriate weight coefficient to fit the measured strains, where the unknown weights were determined by the discrete measurement of the strain. However, the required strain number was generally larger. When normal modes are employed as the basis functions, the deformation reconstructions are referred to as modal method (MM) [

10,

14]. Zhu et al discovered that the reconstruction accuracy of the modal method was higher than the neural net method, but the accuracy of the modal method relied on the number of modes used and it was hard to implement [

15]. The discrete surface strains obtained by the strain sensors were interpolated into a predefined shape function to calculate the deformation displacement of the whole wing [

16].

In the process of reconstructing the displacement field, the aforementioned approaches involved structural properties, load forms, and material parameters. However, in the case of application, it was difficult to determine the load information. In order to solve this problem, Tessler et al. proposed the inverse finite element method (iFEM), which employed the variational principle and performed the three-displacement field according to the strain–displacement relationship based on the Timoshenko beam theory [

17,

18]. Moreover, the first-order shear deformation theory (FSDT) was used to develop a three-node inverse shell element [

19]. Additionally, some experiments have already been performed for the validation of the inverse finite element method [

20,

21].

During the application of the inverse finite element method, people have found that the schemes of strain sensor distribution had a great influence on the displacement reconstruction accuracy. The information entropy was proposed as a performance parameter of the sensor distribution. Then, the optimal sensor distribution schemes could be formulated as a single-objective optimization problem involving discrete-valued variables based on efficient sequential sensor placement algorithms [

22]. Therefore, a single-objective optimal model for the scheme of sensor distribution could be presented to investigate how to maintain the stability of the section strain computing, where the optimal senor distribution scheme based on the particle swarm optimization could be obtained according to Reference [

23,

24]. For the aforementioned optimal methods, the single-objective optimal model was used to optimize the sensor distribution schemes to overcome the drawback of not fully considering reconstruction accuracy, which may degenerate other performances [

23].

In order to further improve the performance using iFEM in the engineering application scenarios, the authors of this paper employed multi-objective particle swarm optimization (MOPSO) to optimize both the robustness and the accuracy simultaneously to obtain the optimal strain sensor distribution scheme. The paper is organized as follows. In the first section, a brief review of the inverse finite element method is presented. Next, bi-objective optimization functions are proposed based on the well-separated eigenvalues and the relative root mean square (RRMS). In the meantime, an introduction to the MOPSO is presented and the adopted optimization strategies are illustrated. Then, the optimization model is established considering both robustness and accuracy. Two different optimal schemes of strain sensor distribution are presented correspondingly. Finally, the two schemes are applied to a hollow circle beam subjected to various free-end loads. Both the simulation calculations and experiment tests were carried out. The experimental results showed that the optimization model established in this paper can effectively improve the performance of the inverse finite element method.

2. Inverse Finite Element Problem Specification

The original inverse finite element method (iFEM) was proposed in Reference [

18], and developed continually by certain researchers. Academic achievements were obtained in Reference [

17,

18,

19,

20,

21,

22,

23,

24,

25,

26]. Therefore, in this section, the inverse finite element method for beam elements is briefly reviewed as follows.

Based on the small-strain hypothesis, the strains can be obtained from the deviation of displacement based on the Timoshenko theory along the x axes, as given by Equation (1):

where

describes the section strain of the theory, and it can be presented further in terms of nodal displacement as follows:

where

(

i = 1,…,6) is the deviation of the displacement shape function.

contains the nodal displacement and rotation angle.

The iFEM uses the weighted least square principle to minimize the difference between in situ section strain,

, and analytic section strains,

, which can be written as follows:

The relationship between in situ strain measurement and deformed beam displacement can be obtained by substituting Equation (2) into Equation (3), which can be expressed as follows:

The two terms

and

are defined as follows:

with

where

n denotes the section number,

is the section location along the x axis, and

is the in situ section strains.

L denotes the element length.

(

k = 1,2,…,6) are positive-valued constants for the axial stretching, bending, twisting, and transverse shearing, respectively, and their initial values have been set as 1 in this paper.

Once the scheme of strain sensor distribution has been determined, which means that the values of

(

i = 1,2,…,6) are determined, the section strains can be calculated from the measured surface strains using strain–tensor transformations as follows:

where

is the Poisson ratio.

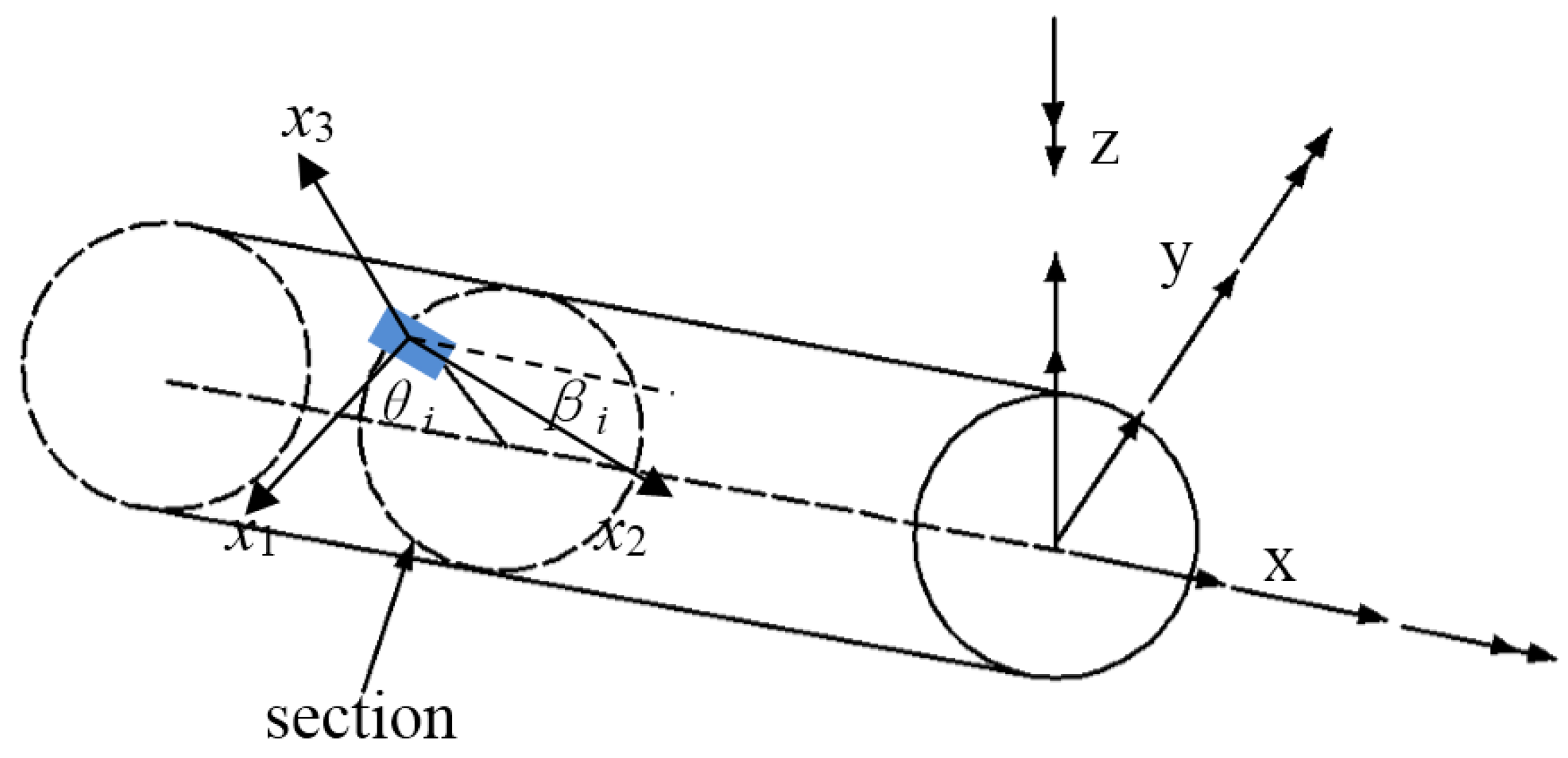

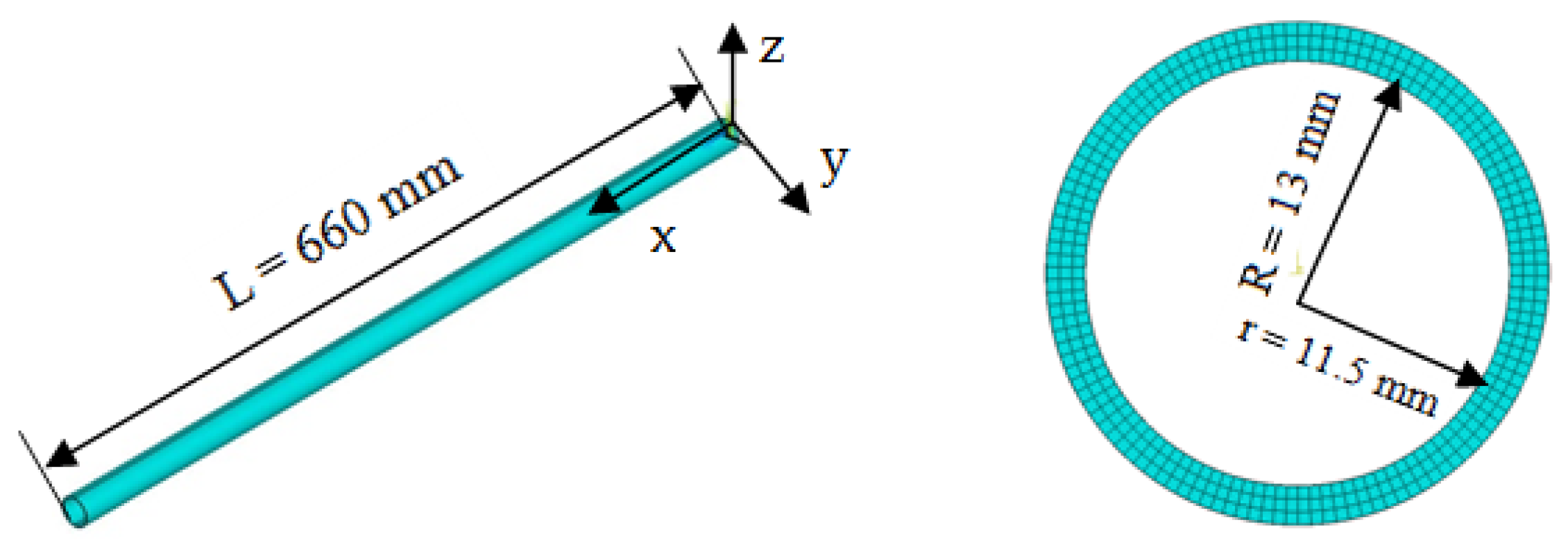

R is the external radius of the section as shown in

Figure 1.

Then, based on the analysis and calculation results of Equation (12) in Reference [

23], these unknown parameters (

a1, …,

a6), which are used to established the relationship between section strains and the position along the centroid axis, can be solved:

where

,

,

i = 1,2,…,6.

Therefore, for an arbitrary point on the centroid axis, the section strains (

e1,

e2,…

e6) can be determined by substituting Equation (8) into Equation (7):

where the

Q matrix can be obtained by replacing variable

xi by

yi in the

matrix, and

yi denotes an arbitrary point placement along the centroid axis direction.

The transfer relationship between deformation displacement and surface strain can be constructed by substituting Equation (9) into Equation (4). This relationship can be expressed as follows:

where

.

3. Establishing the Multi-Objective Particle Swarm Optimization Model

The section strains can be computed from the strain sensor values which can be measured by Fiber Bragg Grating (FBG) sensors. However, during the FBG sensor installation, installation errors occur between the installation position and the theoretical position of the sensor along the axial length

xi, angle parameter

θi, and

βi. Therefore, these position parameters with errors are substituted into Equation (7), which will affect the accuracy of the computed section strain. Moreover, in Equation (10), the transfer relationship (TR) is the matrix about the scheme of strain sensor distribution, and acts as a bridge between the surface strain and the deformation displacement. However, it was found that an inappropriate strain sensor distribution scheme could lead to a singular or ill-condition

TR matrix [

23]. For example, a tiny surface measured strain change might cause a significant reconstructed displacement change using the iFEM, which further deteriorates the accuracy or even leads to the process failure. Thus, the robustness of transfer relationship is one optimization objective (

), which can be constructed with well-separated eigenvalues [

27]:

where

represents the eigenvalues of transformation matrix

. Parameter

represents the sensor location along the centroid axis direction. It is difficult to determine the strain sensor locations on both end nodes in engineering applications. Therefore, the installed placements are selected in the range of

. In order to minimize the positioning errors for a strain sensor distribution scheme, one sensor is placed at

, whereas the other five sensors are located at

[

23].

The accuracy is the key reference to estimate the performance of deformation reconstruction using the iFEM. Generally, structural beam deformation is varied due to different load forms. In order to eliminate the effect of working conditions on deformation, the relative root mean square (RRMS) is proposed to act as another optimization objective function (

) for estimating reconstruction accuracy, which can be expressed as follows:

where

disp(

xi) is the deformation displacement along the centroid axis in one direction. The superscript

measurement denotes the actual deformation value from the simulation software or a measurement device. The

iFEM is the predicted value computed from the iFEM.

RMS indicates deformation reconstruction root-mean-square errors.

RRMS is the ratio of RMS and maximum deformation value from the actual deformation value.

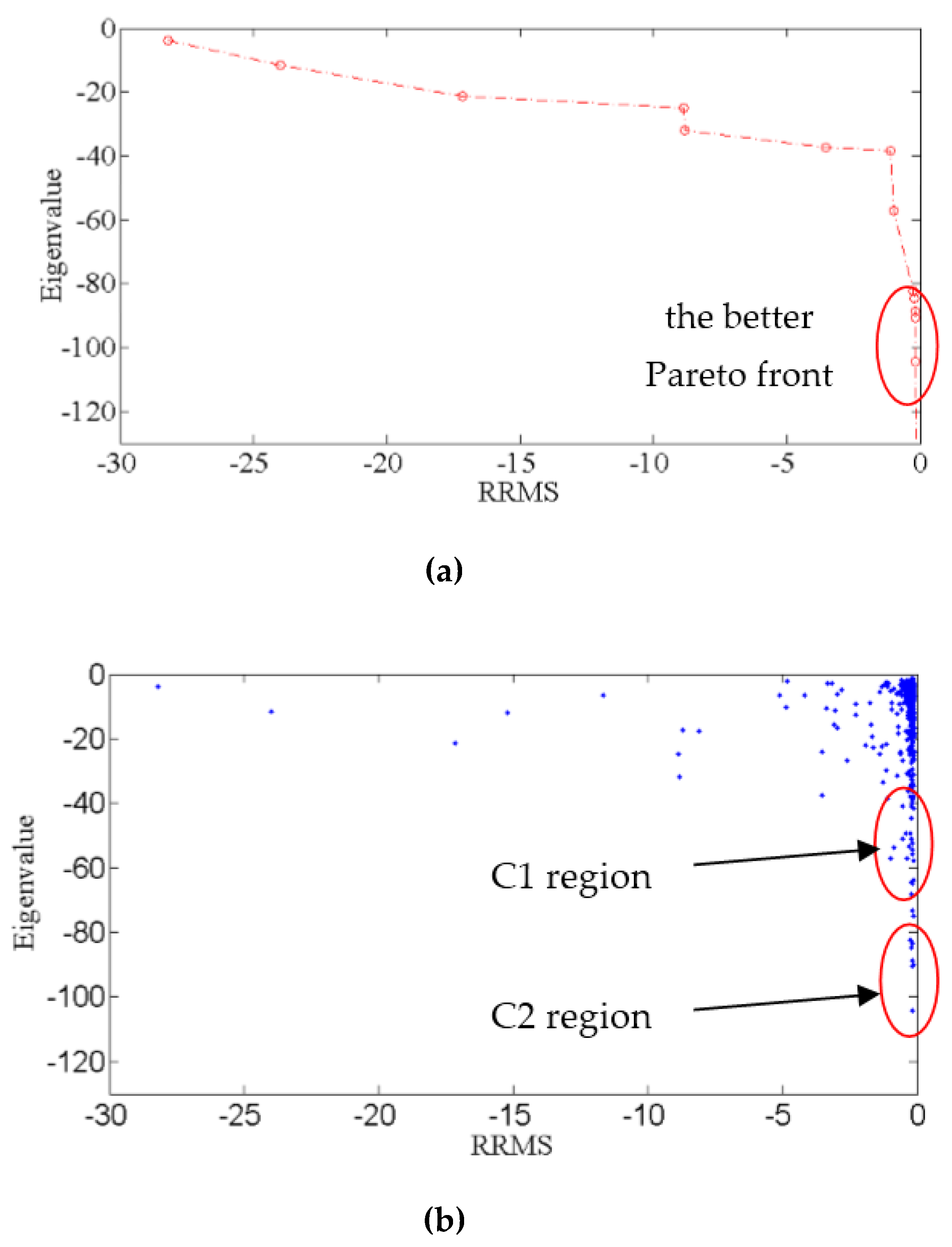

The purpose of strain sensor distribution scheme optimization is to find an optimal scheme, which can make the optimal balance between robustness and accuracy throughout a limited beam surface measurement. Thus, the optimization model can be described as follows:

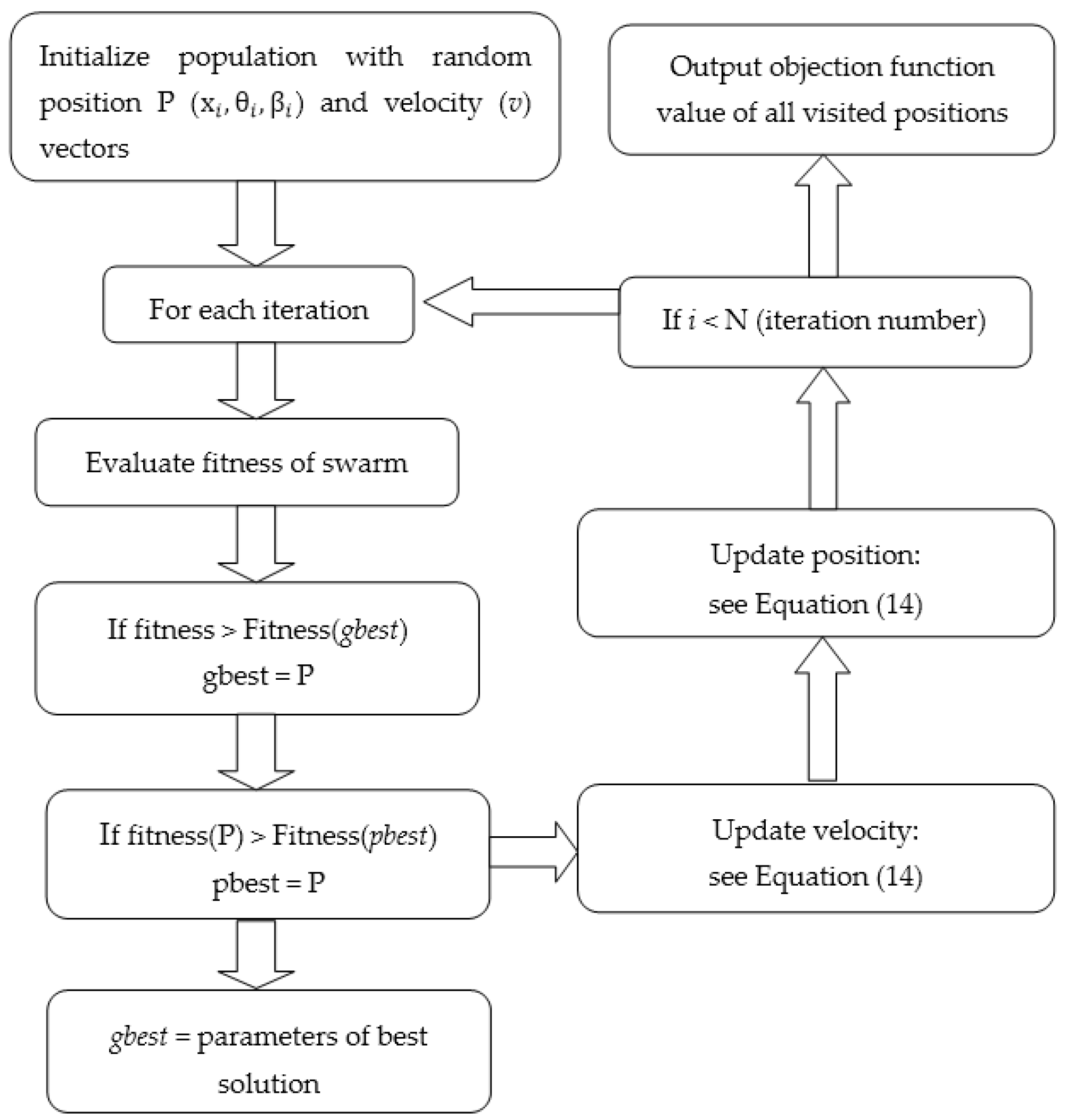

For multiple objective optimization problems, Coello et al. proposed an extending particle swarm optimization (PSO) approach to solve this problem, referred to as an MOPSO [

28]. Compared with other algorithms, the advantages of this method are a high convergence speed and a simple algorithm structure [

29].

According to the PSO algorithm theory [

30,

31,

32], a population size is 50 and randomly initialized in the limited beam surface. The maximum iteration number is 100. Each particle position can be expressed by a vector

pi = (

, …,

, …

, …,

,

…,

,

…,

)

1×36, which are random initialized in

xi ∈ [0,

L],

θi ∈ [−180°, 180°],

βi = 0° or 45°. Each particle has a corresponding velocity, represented by

vi = (

, …,

, …

, …,

,

…,

,

…,

)

1×36, which determines the direction that particle can move for the search of the optimal solutions. Then, each particle is introduced into an optimal model to calculate a potential solution (13). The optimal solutions are continuously searched by updating the velocity and position of particle according to Equation (14):

where

t indicates the

tth iteration in the PSO algorithms. Parameter

w denotes inertia weight, which is decreased from 0.9 to 0.4. Acceleration constant parameters are

=

= 2. Parameters

and

are random values uniformly distributed in [0,1]. Parameters

and

indicate the element of personal best solution (

pbest) and global best solution(

gbest). The maximum velocity (

) is equal to the dynamic range in each dimension of the particle, and

. PSO will be stopped if the

tth iteration satisfies the predefined maximum number of iterations. The concrete specifications of this optimization algorithm are explained in

Figure 2.

The

pbest is continuously updated in the following process: in the search space, if a particle searches a new solution that dominates its

pbest, the new solution can be selected as the new

pbest. Otherwise, the old solution has a probability of 0.5 to be replaced by a new solution. The criterion of crowding distance [

29], which is used to estimate the density of solutions surrounding a particular solution in the Pareto front, is proposed to select

gbest. For example, when the value of crowding distance is large, the solution in the Pareto front will be deviated from its surrounding solutions. Additionally, the reflecting wall proposed in Reference [

30] is used to improve the exploration of the particle.