Application of a Novel Long-Gauge Fiber Bragg Grating Sensor for Corrosion Detection via a Two-level Strategy

Abstract

:1. Introduction

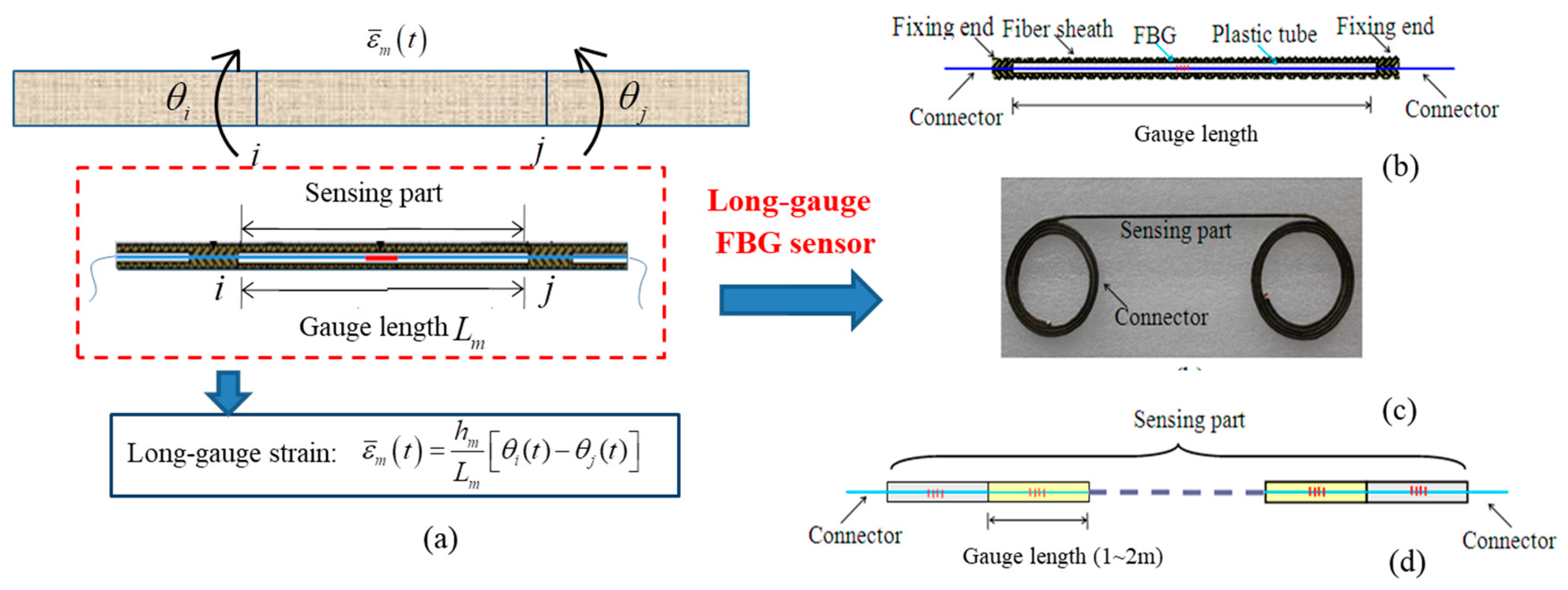

2. Long-Gauge Fiber Optic Sensor

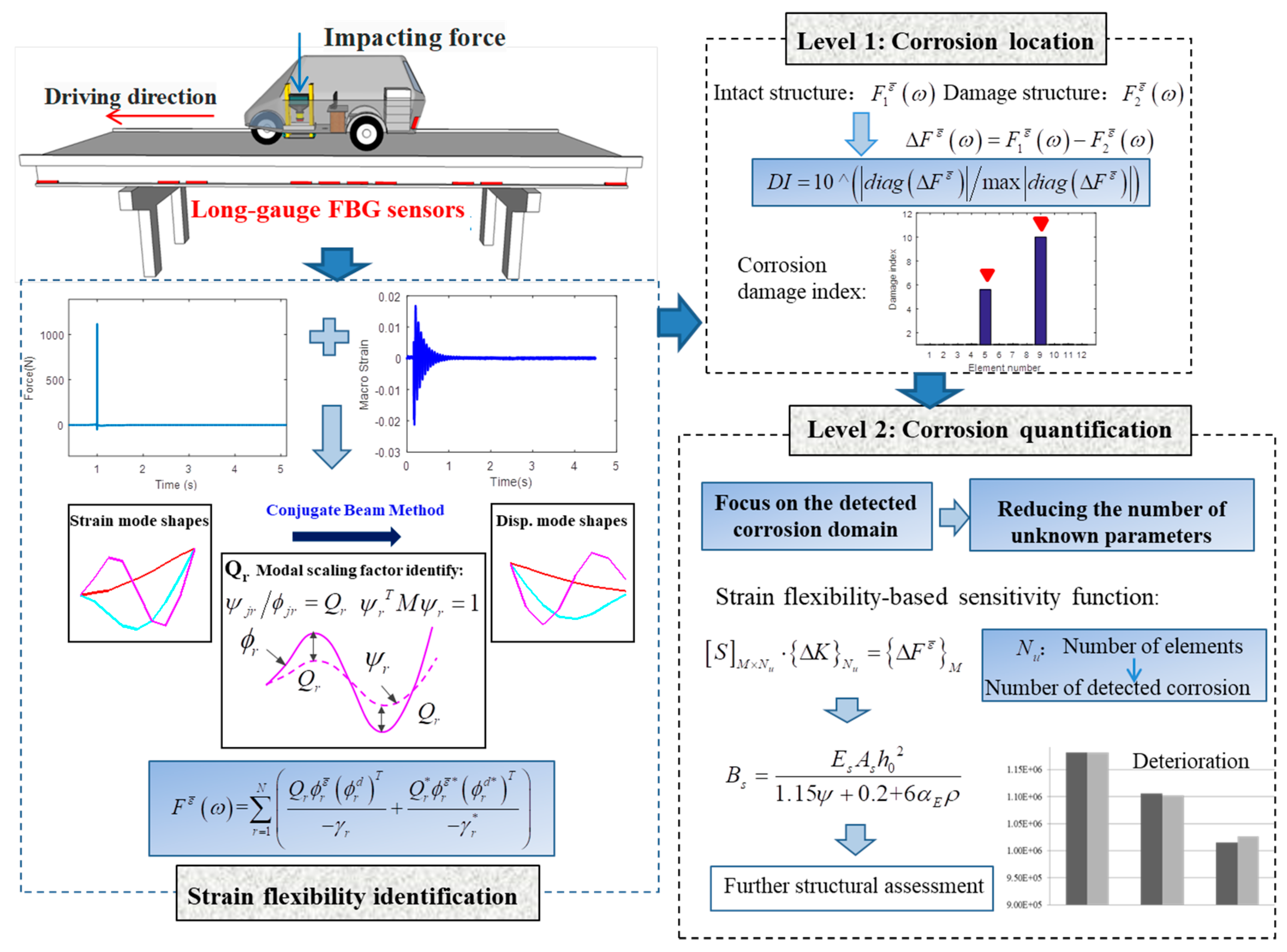

3. Two-Level Corrosion Detection Strategy Based on FBG Sensors

3.1. Framework of the Proposed Method

3.2. Theoretical Basis of the Proposed Method

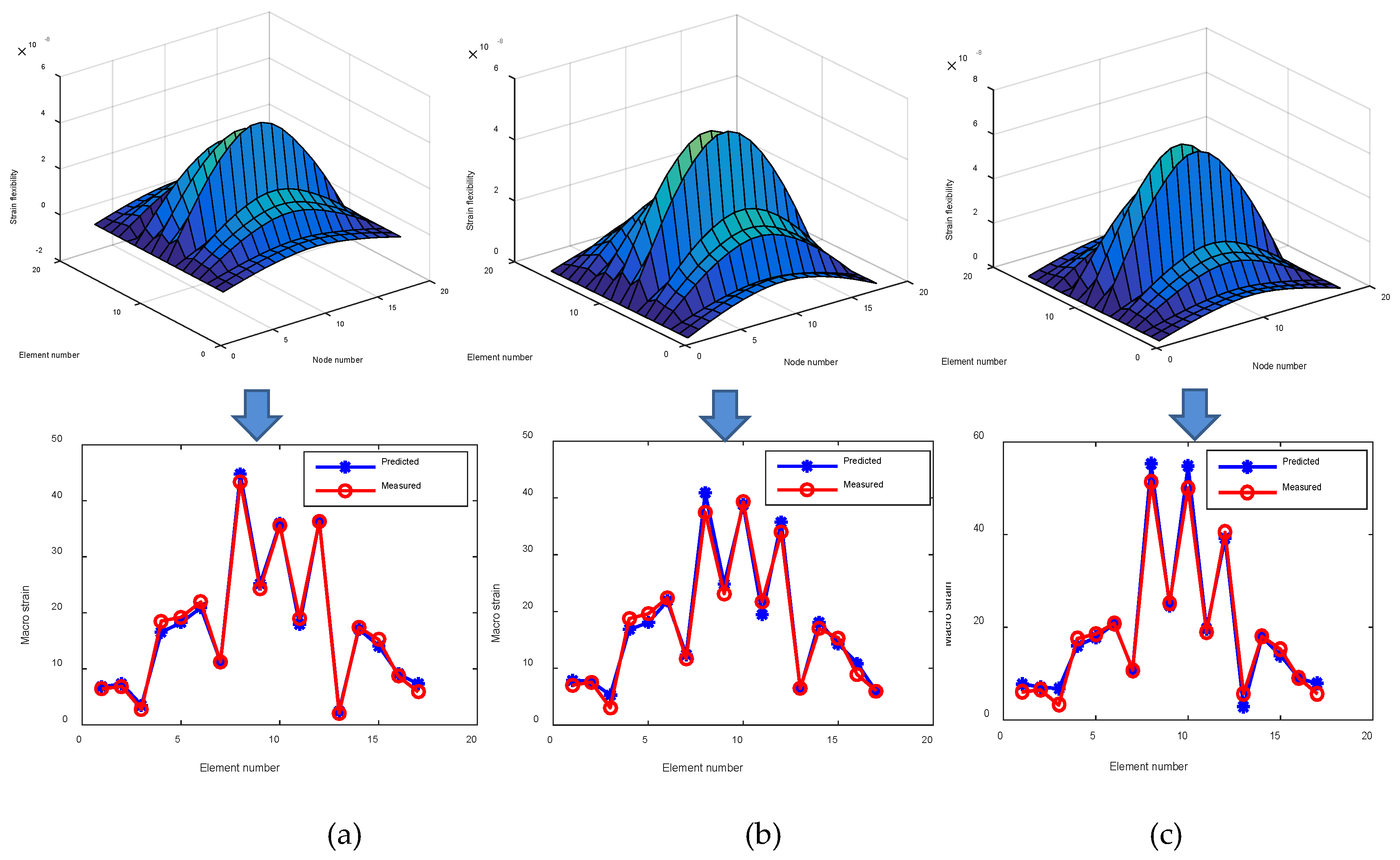

3.2.1. Strain Flexibility Identification

3.2.2. Two-Level Corrosion Detection

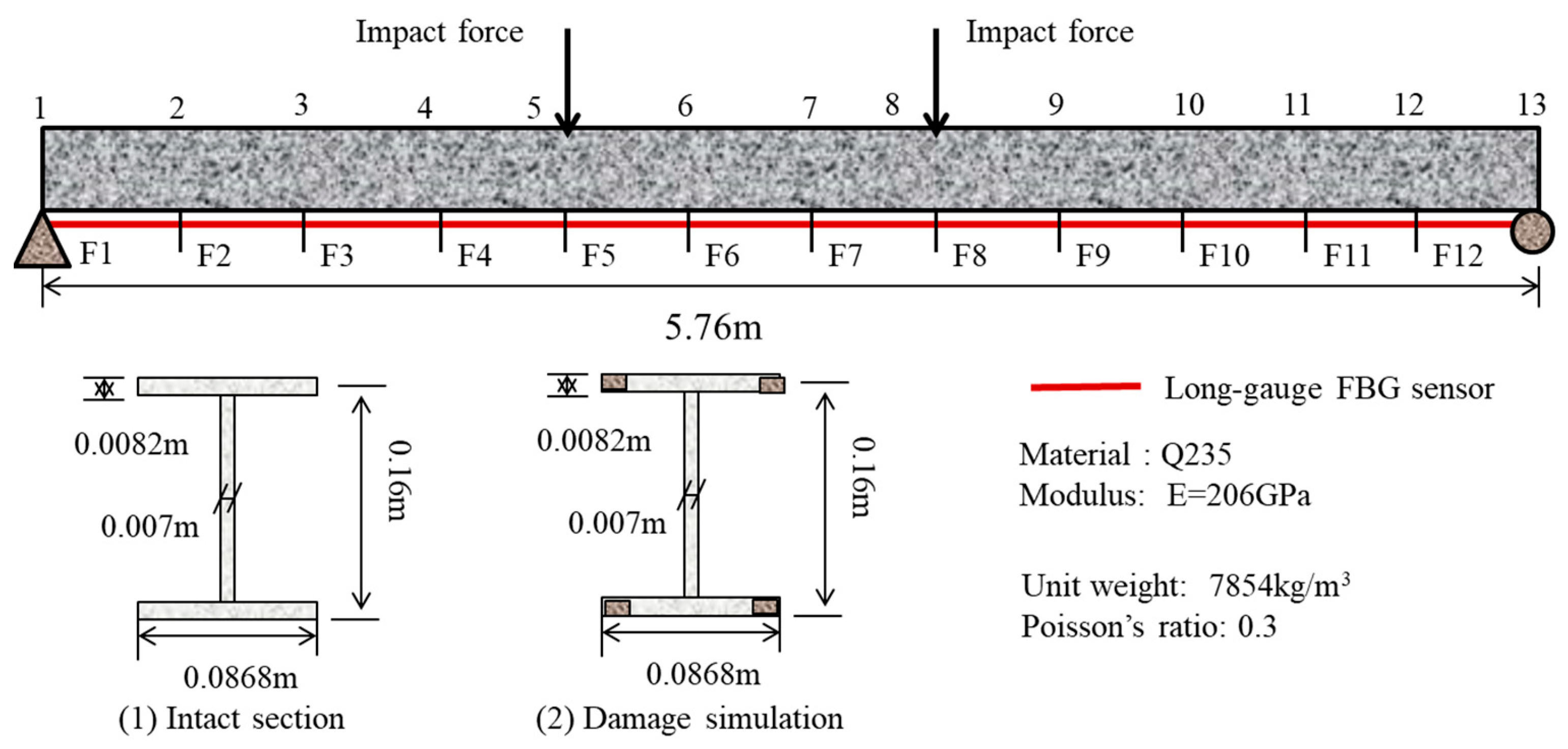

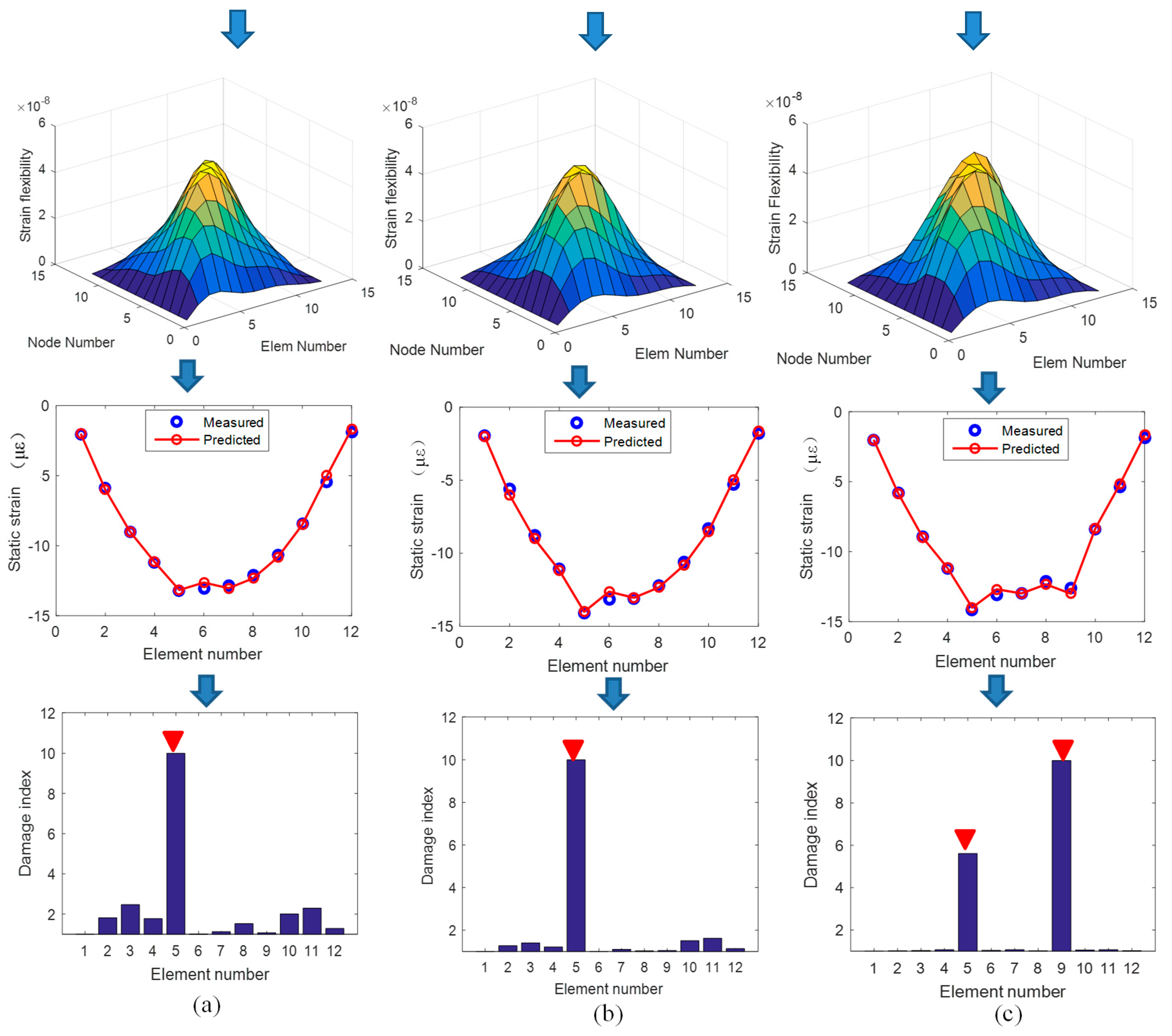

4. Numerical Example of a Steel Beam

5. Experimental Verification through a Reinforced Concrete (RC) Beam

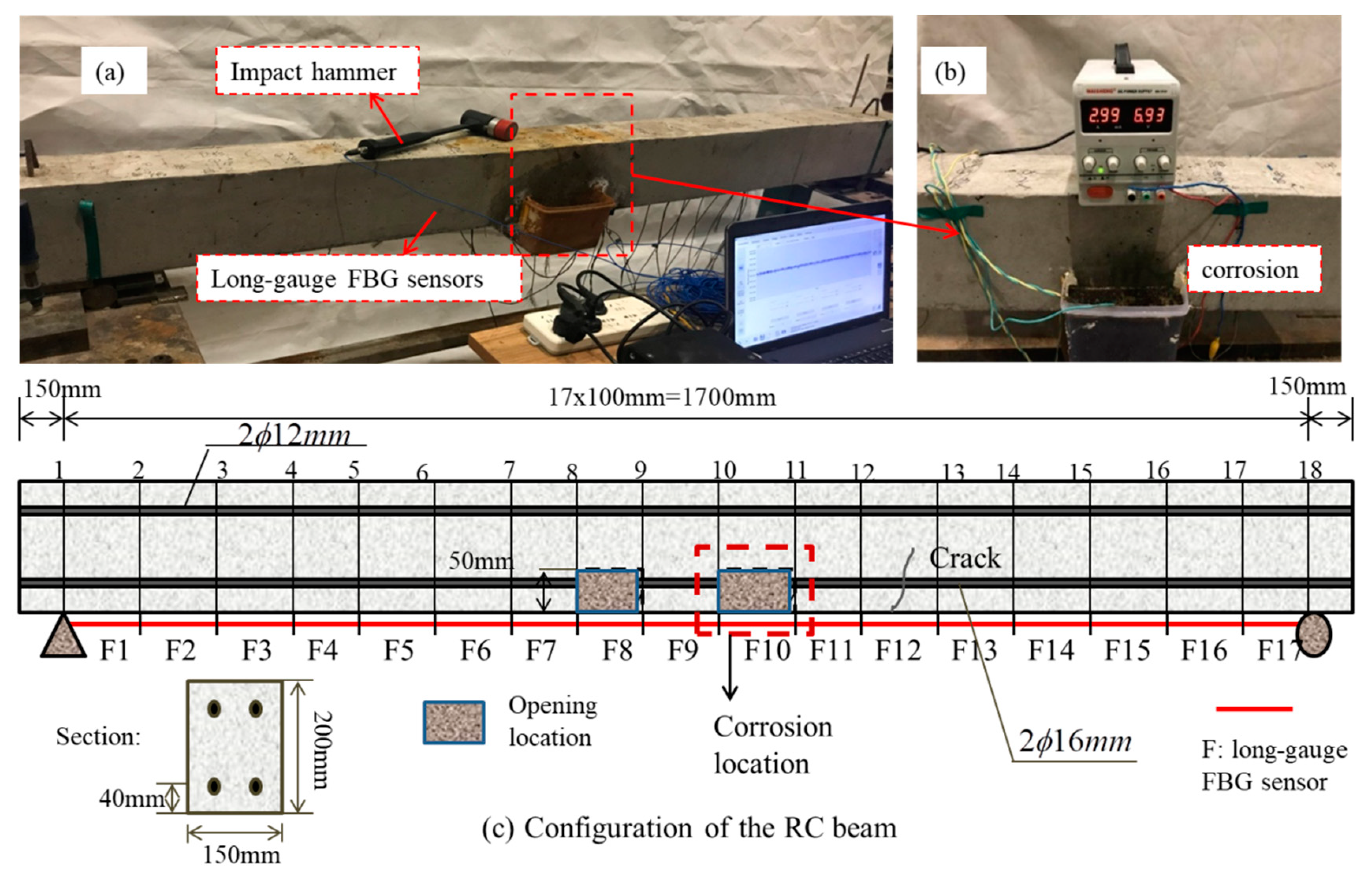

5.1. Description of the Experimental Setup

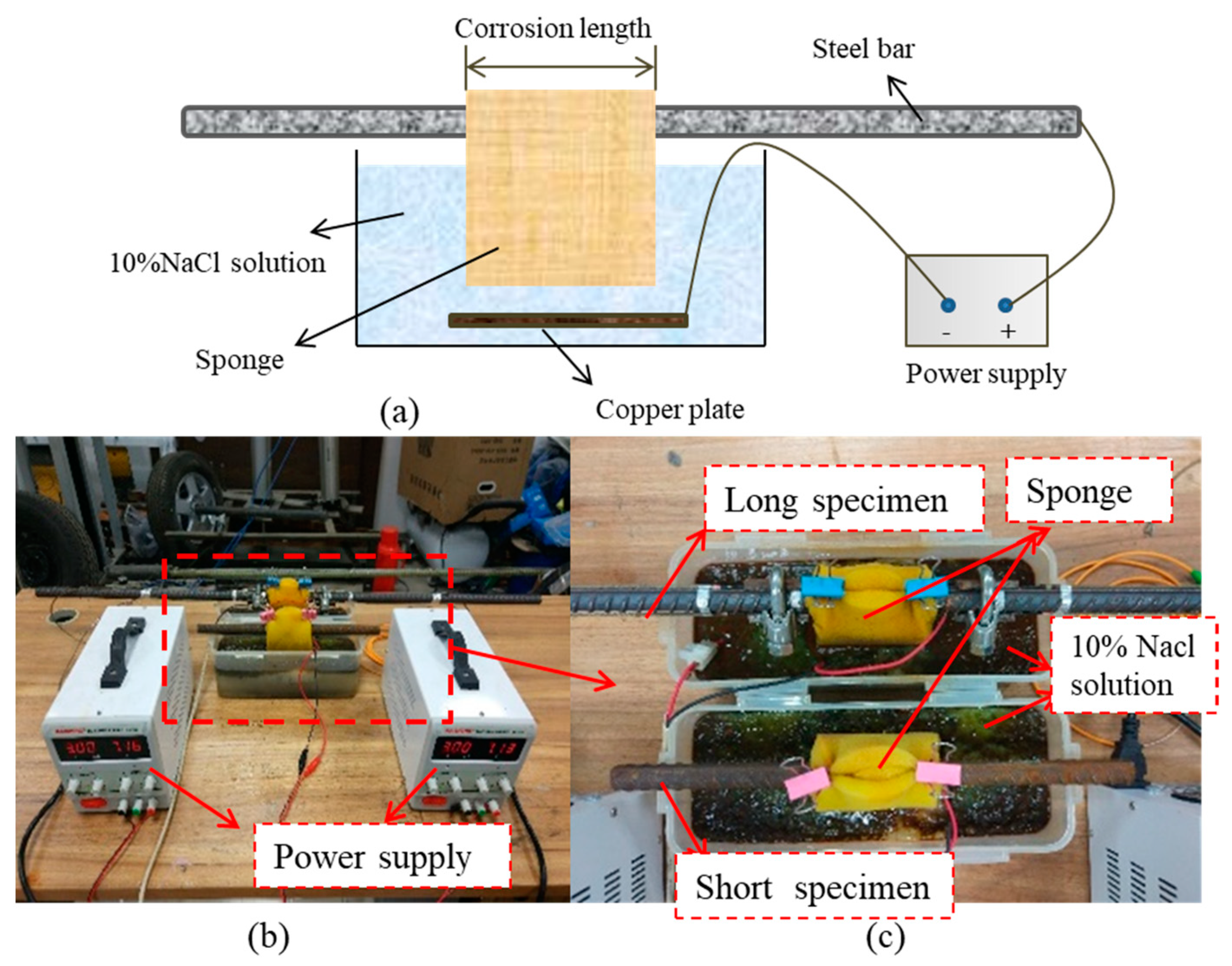

5.2. Accelerated Corrosion Procedure

5.2.1. Calibration Test

5.2.2. Corrosion Setup

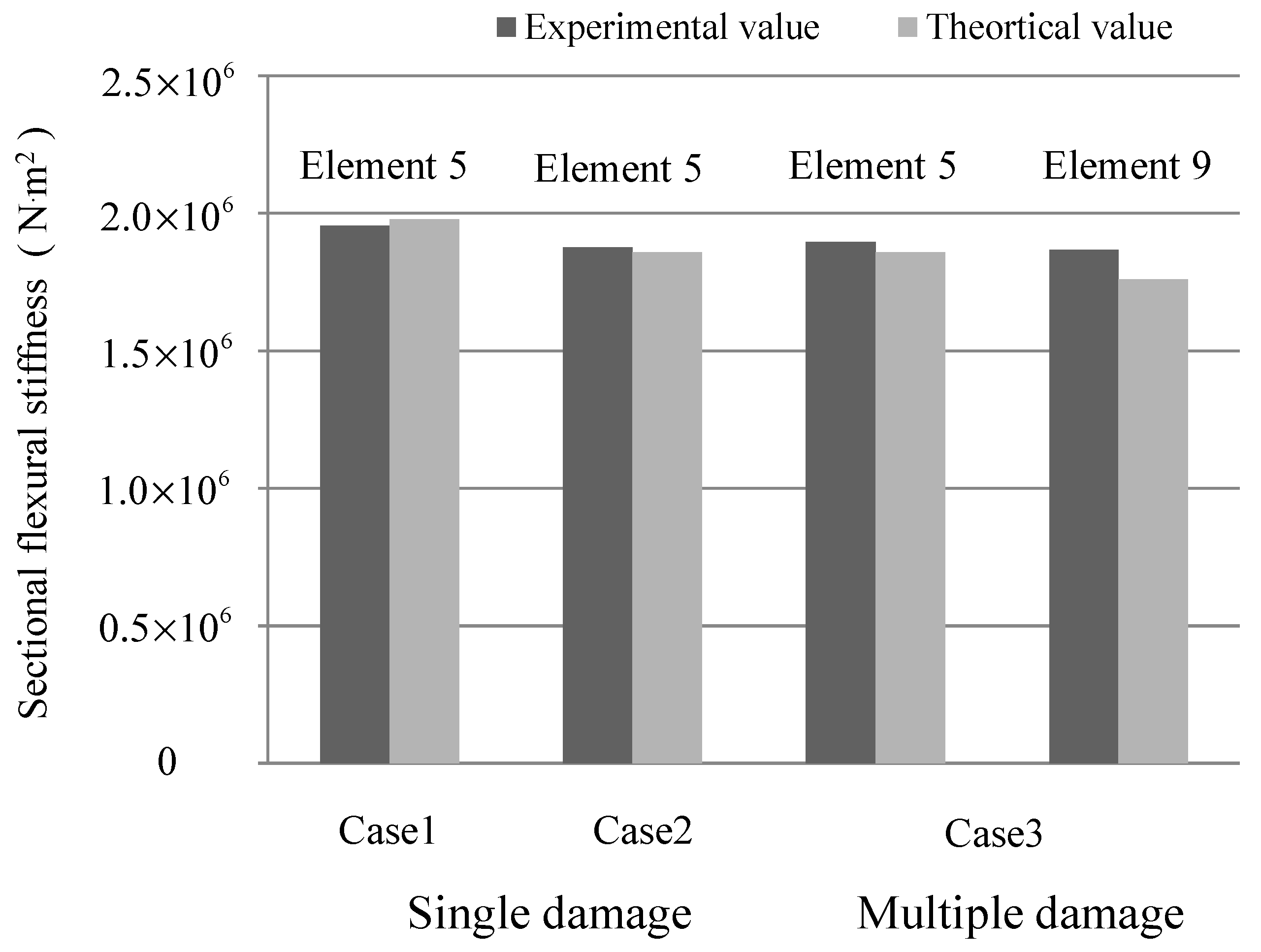

5.3. Two Level Strategy for Corrosion Damage Quantification

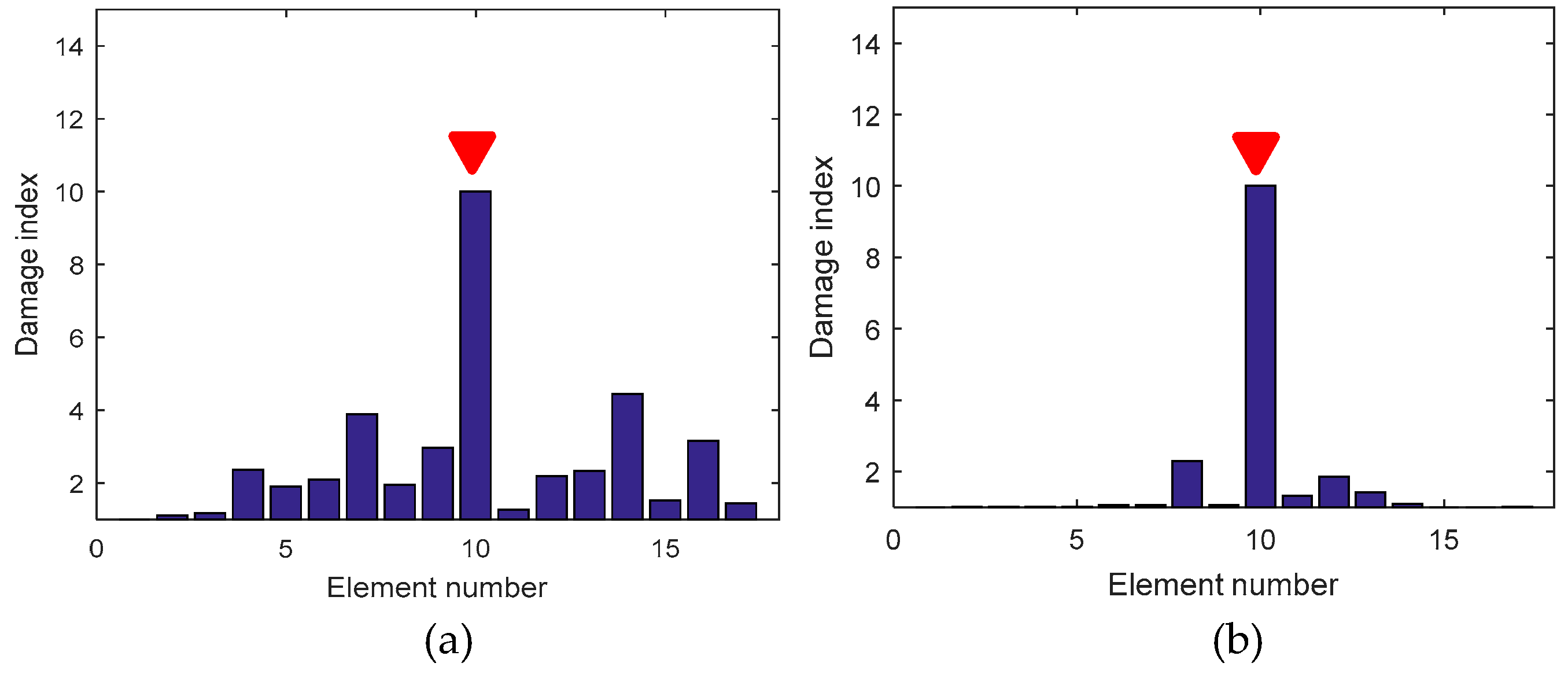

5.3.1. Level 1: Corrosion Damage Localization

5.3.2. Level 2: Corrosion Damage Quantification

6. Conclusions

- (1)

- Based on the long-gauge FBG strain sensors, a new kind of corrosion detection methodology via impact test is proposed and demonstrated.

- (2)

- The original contribution of this paper is the development of a step-by-step strategy that helps to locate and quantify corrosion damage by using a long-gauge FBG sensor; a solid theoretical basis has been developed to guarantee that this sensor will detect corrosion accurately.

- (3)

- The proposed two-level corrosion detection methodology presents a distinct advantage in that locating Level 1 damage significantly reduces the number of unknown parameters in the sensitivity equations and increases the success of Level 2 corrosion quantification.

7. Patents

Author Contributions

Funding

Conflicts of Interest

Appendix A. Relationship between Modal Mass and Modal Scaling Factor

References

- Li, Z.; Jin, Z.Q.; Zhao, T.J.; Wang, P.G.; Li, Z.J.; Xiong, C.S.; Zhang, K.L. Use of a novel electro-magnetic apparatus to monitor corrosion of reinforced bar in concrete. Sens. Actuators A 2019, 286, 14–27. [Google Scholar] [CrossRef]

- Hong, S.X.; Wiggenhauser, H.; Helmerich, R.; Dong, B.Q. Long-term monitoring of reinforcement corrosion in concrete using ground penetrating radar. Corros. Sci. 2017, 114, 123–132. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, L.J.; Xu, Y.Z.; Cao, Y.Z.; Song, S.D. A novel system for corrosion protection of reinforced steels in the underwater zone. Corros. Eng. Sci. Technol. 2016, 51, 566–572. [Google Scholar] [CrossRef]

- Lu, Y.Y.; Zhang, J.R.; Li, Z.J.; Dong, B.Q. Corrosion monitoring of reinforced concrete beam using embedded cement-based piezoelectric sensor. Mag. Concr. Res. 2013, 65, 1265–1276. [Google Scholar] [CrossRef]

- Zhang, J.R.; Liu, C.; Sun, M.; Li, Z.J. An innovative corrosion evaluation technique for reinforced concrete structures using magnetic sensors. Constr. Build. Mater. 2017, 135, 68–75. [Google Scholar] [CrossRef]

- Sunny, A.I.; Tian, G.Y.; Zhang, J.; Pal, M. Low frequency (LF) RFID sensors and selective transient feature extraction for corrosion characterization. Sens. Actuators A Phys. 2016, 241, 34–43. [Google Scholar] [CrossRef]

- Bertolini, L.; Elsener, B.; Pedeferri, P.; Redaelli, E.; Polder, R.B. Corrosion of Steel in Concrete—Prevention, Diagnosis and Repair, 2nd ed.; Wiley: Hoboken, NJ, USA, 2014. [Google Scholar]

- Li, W.J.; Xu, C.H.; Ho, S.C.M.; Wang, B.; Song, G.B. Monitoring concrete deterioration due to reinforcement corrosion by integrating acoustic emission and FBG strain measurements. Sensors 2017, 17, 657. [Google Scholar] [CrossRef] [PubMed]

- Mao, J.H.; Chen, J.Y.; Cui, L.; Jin, W.L.; Xu, C.; He, Y. Monitoring the corrosion process of reinforced concrete using BOTBA and FBG sensors. Sensors 2015, 15, 8866–8883. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Gong, P.; Qiao, G.; Lu, J.; Lv, X.; Ou, J. Brillouin corrosion expansion sensors for steel reinforced concrete structures using a fiber optic coil winding method. Sensors 2011, 11, 10798–10819. [Google Scholar] [CrossRef]

- Lee, J.R.; Yun, C.Y.; Yoon, D.J. A structural corrosion-monitoring sensor based on a pair of prestrained fiber Bragg gratings. Meas. Sci. Technol. 2009, 21, 017002. [Google Scholar] [CrossRef]

- Zheng, Z.; Sun, X.; Lei, Y. Monitoring corrosion of reinforcement concrete structures via FBG sensors. Front. Mech. Eng. China 2009, 4, 316–319. [Google Scholar]

- Tan, C.H.; Shee, Y.G.; Yap, B.K.; Adikan, F.M. Fiber Bragg grating based sensing system: Early corrosion detection for structural health monitoring. Sens. Actuators. A 2016, 246, 123–128. [Google Scholar] [CrossRef]

- Gurpreet, K.; Kaler, R.S.; Naveen, K. Experiment on a highly sensitive fiber Bragg grating sensor to monitor strain and corrosion in civil structures. J. Opt. Technol. 2018, 85, 36–41. [Google Scholar]

- Magne, S.; Alvarez, S.A.; Rougeault, S. Distributed corrosion detection using dedicated OFS-based steel rebar within reinforced concrete structures by OFDR. In Proceedings of the 9th European Workshop on Structural Health Monitoring (EWSHM), Manchester, UK, 10–13 July 2018. [Google Scholar]

- Zhang, J.; Cheng, Y.Y.; Xia, Q.; Wu, Z.S. Change localization of a steel-stringer bridge through long-gauge strain measurements. J. Bridge Eng. 2016, 21, 04015057. [Google Scholar] [CrossRef]

- Fouad, N.; Saifeldeen, M.A.; Huang, H.; Wu, Z.S. Corrosion monitoring of flexural reinforced concrete members under service loads using distributed long-gauge carbon fiber sensors. Struct. Health Monit. 2018, 17, 379–394. [Google Scholar] [CrossRef]

- Malumbela, G.; Moyo, P.; Alexander, M. Longitudinal strains and stiffness of RC beams under load as measures of corrosion levels. Eng. Struct. 2012, 35, 215–227. [Google Scholar] [CrossRef]

- Wu, Z.S.; Li, S.Z. Two-level damage detection strategy based on modal parameters from distributed dynamic macro-strain measurements. J. Intell. Mater. Syst. Struct. 2007, 18, 667–676. [Google Scholar] [CrossRef]

- Grande, E.; Imbimbo, M. A multi-stage approach for damage detection in structural systems based on flexibility. Mech. Syst. Signal Process. 2016, 76–77, 455–475. [Google Scholar] [CrossRef]

- Cao, M.S.; Radzienski, M.; Xu, W.; Ostachowicz, W. Identification of multiple damage in beams based on robust curvature mode shapes. Mech. Syst. Signal Process. 2014, 46, 468–480. [Google Scholar] [CrossRef]

- Zhao, J.; DeWolf, J.T. Sensitivity study for vibrational parameters used in damage detection. J. Struct. Eng. 1999, 125, 410–416. [Google Scholar] [CrossRef]

- Perera, R.; Ruiz, A.; Manzano, C. An evolutionary multiobjective framework for structural damage localization and quantification. Eng. Struct. 2007, 29, 2540–2550. [Google Scholar] [CrossRef]

- Zhang, J.; Xia, Q.; Cheng, Y.Y.; Wu, Z.S. Strain flexibility identification of bridges from long-gauge strain measurements. Mech. Syst. Signal Process. 2015, 62–63, 272–283. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Q.Q.; Guo, S.L.; Xu, D.W.; Wu, Z.S. Structural identification of short/middle span bridges by rapid impact testing: Theory and verification. Smart Mater. Struct. 2015, 24, 065020. [Google Scholar] [CrossRef]

- Cheng, W.R.; Wang, T.C.; Yan, D.H. Design Theory for Concrete Structure, 4th ed.; China Architecture & Building Press: Beijing, China, 2008. [Google Scholar]

| Damage Location | Element 5 | Element 9 | ||||

|---|---|---|---|---|---|---|

| Damage Quantification | Theoretical Value () | Experimental Value () | Error (%) | Theoretical Value () | Experimental Value () | Error (%) |

| Case 1 | 1.16 | - | - | - | ||

| Case 2 | 0.97 | - | - | - | ||

| Case 3 | 1.93 | 6.2 | ||||

| Short Specimen (325 mm) | Long Specimen (1000 mm) | ||||||

|---|---|---|---|---|---|---|---|

| Time (h) | Residual Mass (g) | Lost Mass (g) | Weight Loss Ratio (%) | Residual Mass (g) | Lost Mass (g) | Weight Loss Ratio (%) | Mean of the Ratio (%) |

| 0 | 454.5 | 0 | 0 | 1517.07 | 0 | 0 | 0 |

| 2 | 448 | 6.5 | 5.96 | 1510.65 | 6.42 | 5.44 | 5.7 |

| 4 | 441.5 | 13 | 11.92 | 1504.37 | 12.7 | 10.76 | 11.34 |

| 6 | 435 | 19.5 | 17.88 | 1497.89 | 19.18 | 16.25 | 17.1 |

| 8 | 429 | 25.5 | 23.38 | 1491.55 | 25.52 | 21.62 | 22.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Y.; Zhao, C.; Zhang, J.; Wu, Z. Application of a Novel Long-Gauge Fiber Bragg Grating Sensor for Corrosion Detection via a Two-level Strategy. Sensors 2019, 19, 954. https://doi.org/10.3390/s19040954

Cheng Y, Zhao C, Zhang J, Wu Z. Application of a Novel Long-Gauge Fiber Bragg Grating Sensor for Corrosion Detection via a Two-level Strategy. Sensors. 2019; 19(4):954. https://doi.org/10.3390/s19040954

Chicago/Turabian StyleCheng, Yuyao, Chenyang Zhao, Jian Zhang, and Zhishen Wu. 2019. "Application of a Novel Long-Gauge Fiber Bragg Grating Sensor for Corrosion Detection via a Two-level Strategy" Sensors 19, no. 4: 954. https://doi.org/10.3390/s19040954

APA StyleCheng, Y., Zhao, C., Zhang, J., & Wu, Z. (2019). Application of a Novel Long-Gauge Fiber Bragg Grating Sensor for Corrosion Detection via a Two-level Strategy. Sensors, 19(4), 954. https://doi.org/10.3390/s19040954