Electrostatic MEMS Vibration Energy Harvesters inside of Tire Treads

Abstract

1. Introduction

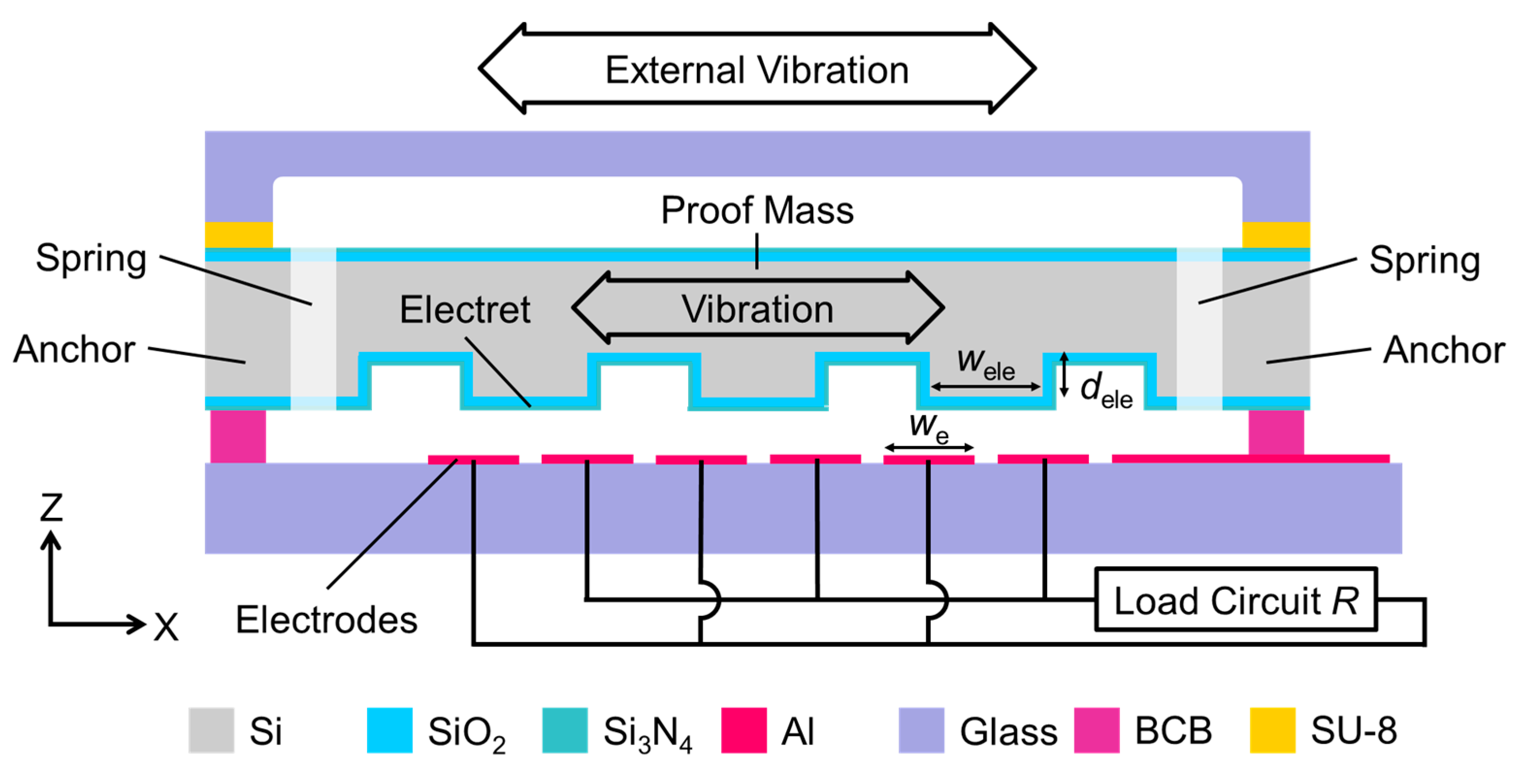

2. Design

2.1. Basic Concept of an Electrostatic MEMS Vibration Energy Harvester

2.2. Electrode Configuration for High Power Generation

2.3. Electret Structure for a High Charge Ratio on Output Electrodes

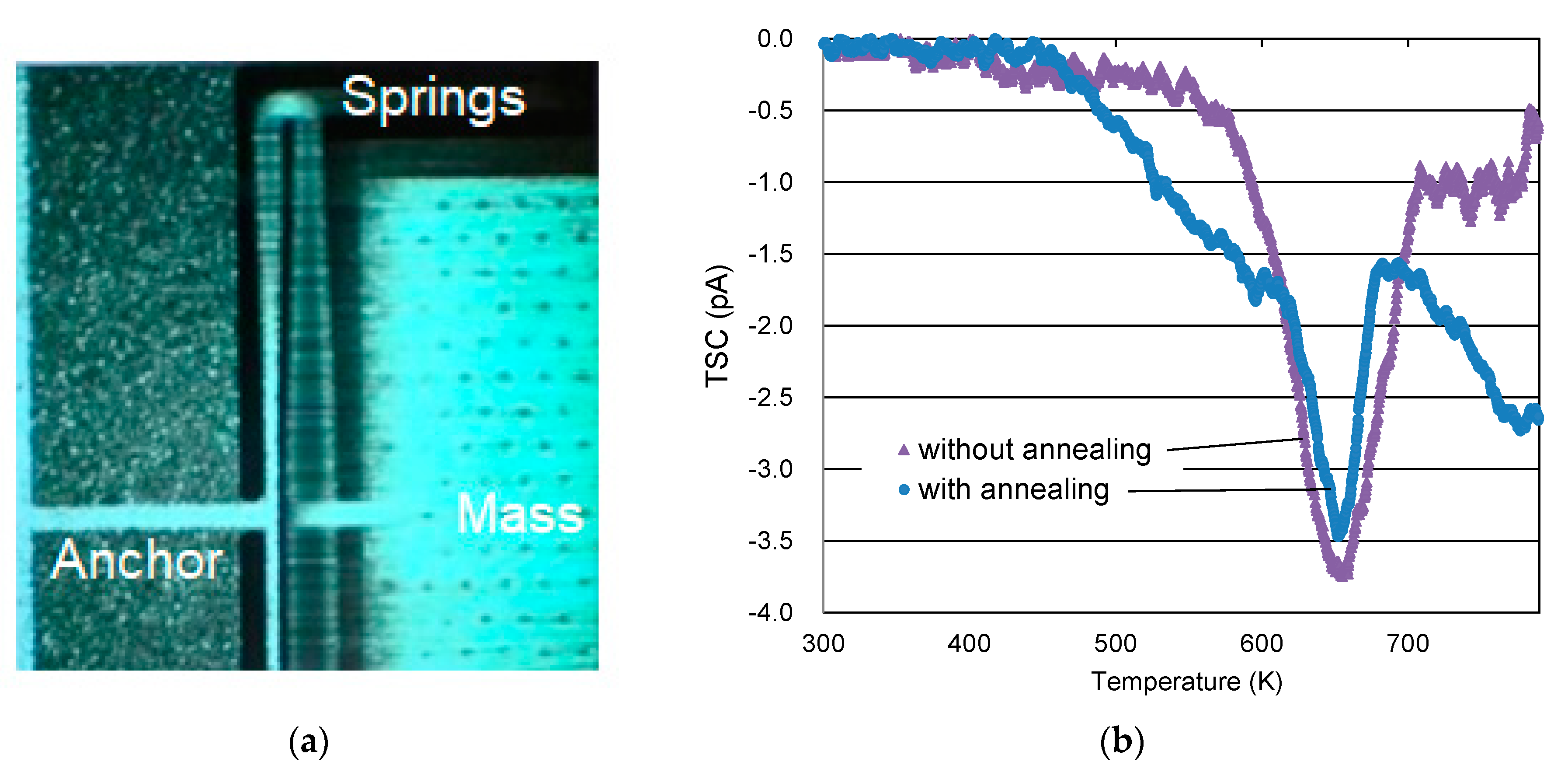

3. Fabrication

3.1. Process Flow

3.2. Annealing Process for a Highly-Stable Inorganic Electret

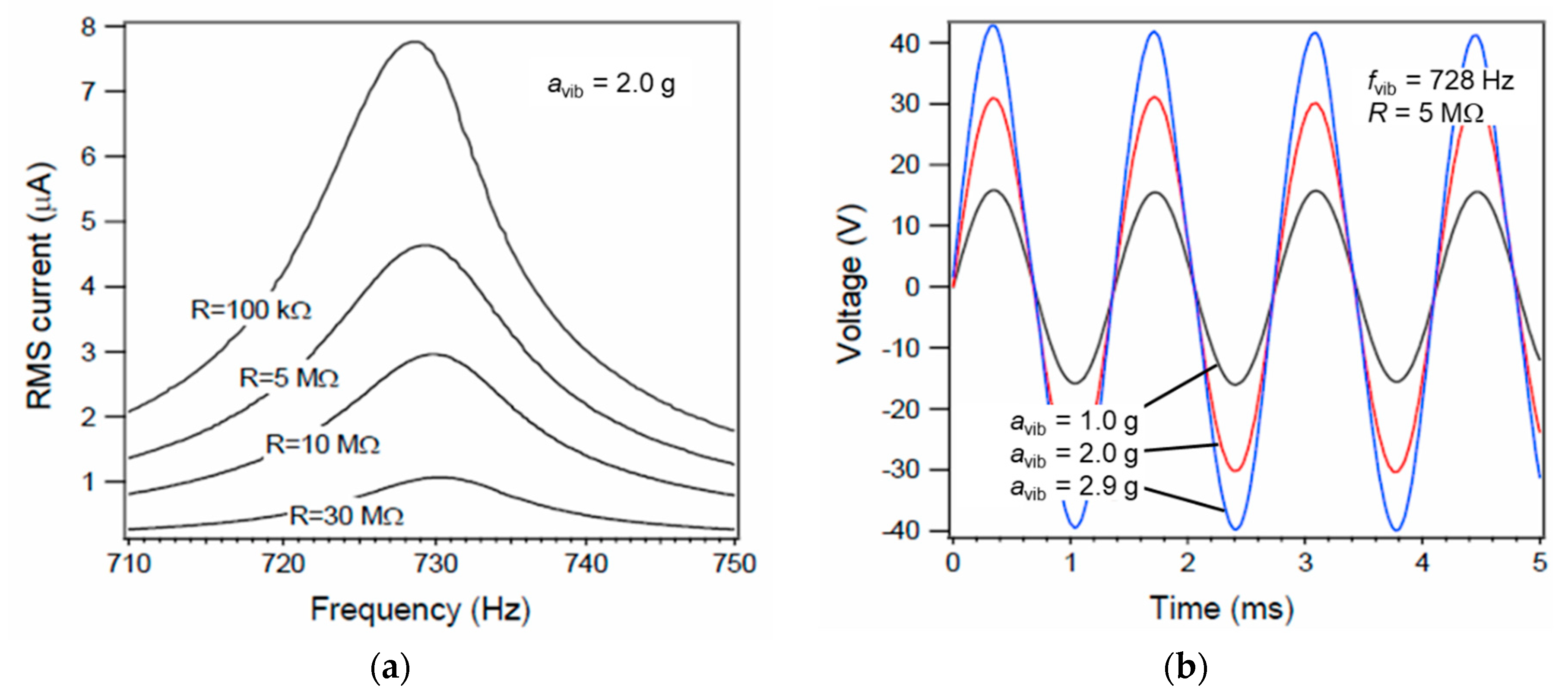

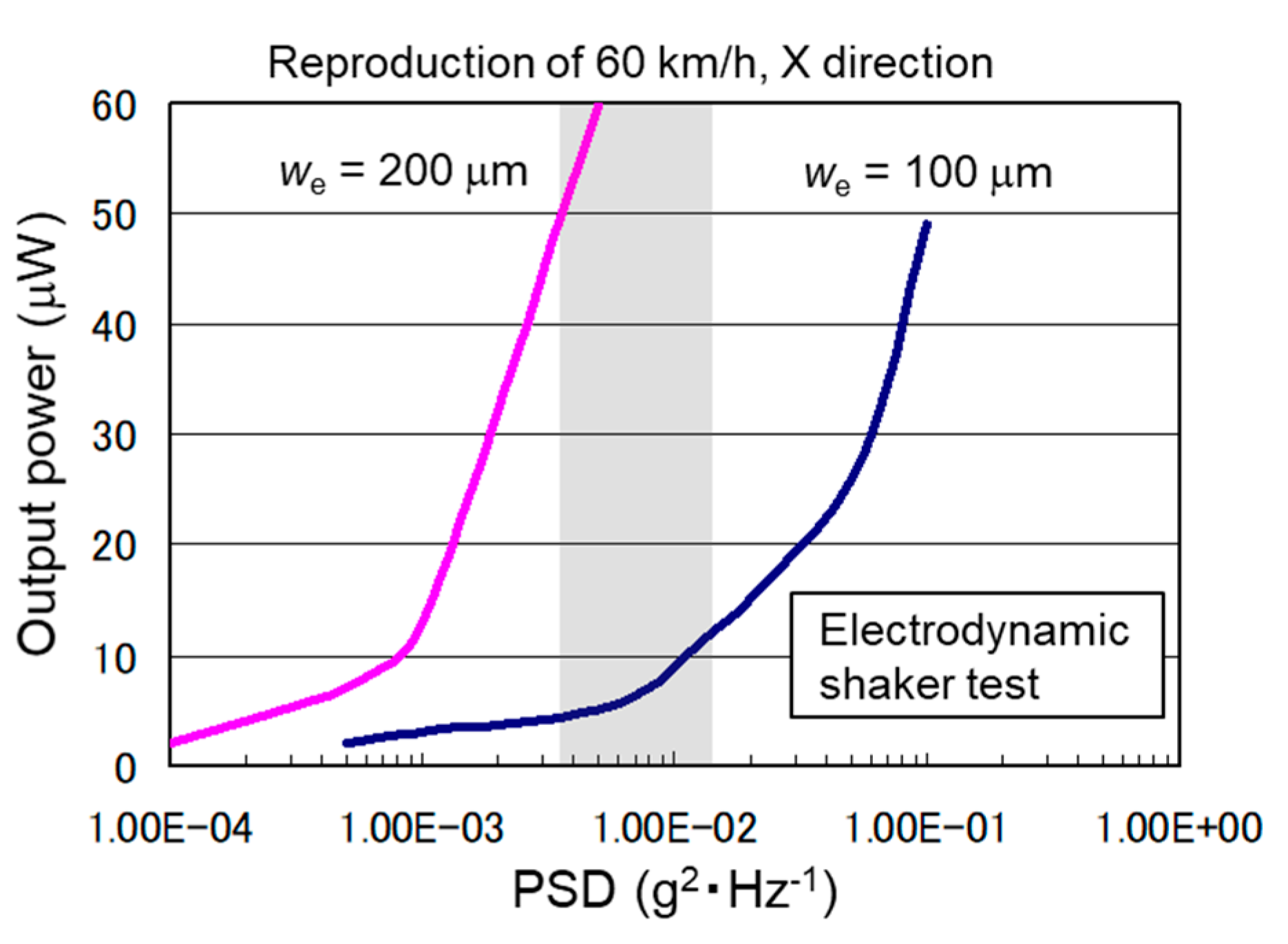

4. Measurement Result

4.1. Sign-Wave Vibration

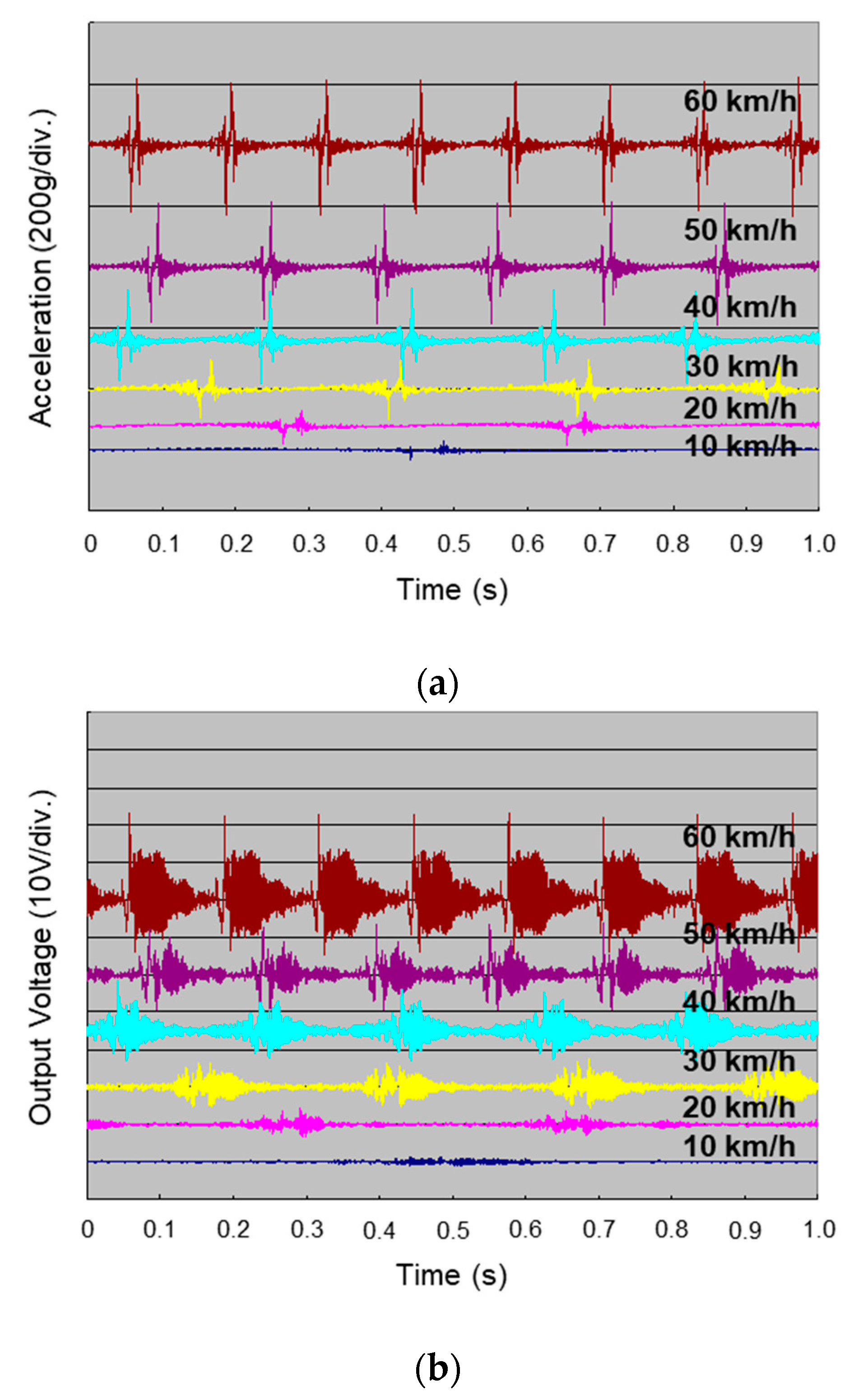

4.2. Impact Vibration in Tire Tread

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Löhndorf, M.; Kvisterøy, M.T.; Westby, E.; Halvorsen, E. Evaluation of energy harvesting concepts for tire pressure monitoring systems. In Proceedings of the PowerMEMS 2007, Freiburg, Germany, 28–29 November 2007; pp. 331–334. [Google Scholar]

- Westby, E.R.; Halvorsen, E. Design and modeling of a patterned-electret-based energy harvester for tire pressure monitoring systems. IEEE/ASME Trans. Mechatron. 2012, 17, 995–1005. [Google Scholar] [CrossRef]

- Jones, T.B. Lumped parameter electromechanics of electret transducers. IEEE Trans. Acoust. Speech Signal Process. 1974, 22, 141–145. [Google Scholar] [CrossRef]

- Suzuki, Y. Recent progress in MEMS electret generator for energy harvesting. IEEJ Trans. Electr. Electron. Eng. 2011, 6, 101–111. [Google Scholar] [CrossRef]

- Boisseau, S.; Despesse, G.; Seddik, B.A. Electrostatic conversion for vibration energy harvesting. In Small-Scale Energy Harvesting; Lallart, M., Ed.; IntechOpen: London, UK, 2012; pp. 91–134. ISBN 978-953-51-0826-9. [Google Scholar]

- Sakane, Y.; Suzuki, Y.; Kasagi, N. The development of a high-performance perfluorinated polymer electret and its application to micro power generation. J. Micromech. Microeng. 2008, 18, 104011. [Google Scholar] [CrossRef]

- Renaud, M.; Altena, G.; Goedbloed, M.; de Nooijer, C.; Matova, S.; Naito, Y.; Yamakawa, T.; Takeuchi, H.; Onishi, K.; van Schaijk, R. A high performance electrostatic MEMS vibration energy harvester with corrugated inorganic SiO2-Si3N4 electret. In Proceedings of the 17th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS & EUROSENSORS XXVII), Barcelona, Spain, 16–20 June 2013; pp. 693–696. [Google Scholar]

- Takahashi, T.; Suzuki, M.; Hirata, T.; Matsushita, N.; Yoneya, R.; Onishi, J.; Nishida, T.; Yoshikawa, Y.; Aoyagi, S. Electret energy harvesting based on fringe electrical field change inside trenched ferroelectric. In Proceedings of the 2011 IEEE 24th International Conference on Micro Electro Mechanical Systems, Cancun, Mexico, 23–27 January 2011; pp. 1305–1308. [Google Scholar]

- Kittipaisalsilpa, K.; Kato, T.; Suzuki, Y. Liquid-crystal-enhanced electrostatic vibration generator. In Proceedings of the 2016 IEEE 29th International Conference on Micro Electro Mechanical Systems (MEMS), Shanghai, China, 24–28 January2016; pp. 37–40. [Google Scholar]

- Tao, K.; Wu, J.; Tang, L.; Hu, L.; Lye, S.W.; Miao, J. Enhanced electrostatic vibrational energy harvesting using integrated opposite-charged electrets. J. Micromech. Microeng. 2017, 27, 044002. [Google Scholar] [CrossRef]

- Koga, H.; Mitsuya, H.; Toyama, Y.; Sugiyama, T.; Toshiyoshi, H.; Hashiguchi, G. Development of a metal-cantilever electrostatic vibration power generator combined with potassium ion electret technique. In Proceedings of the 2018 Joint International Conference on Information Storage and Processing Systems and Micromechatronics for Information and Precision Equipment, San Francisco, CA, USA, 29–30 August 2018; pp. 1–3. [Google Scholar]

- Asanuma, H.; Hara, M.; Oguchi, H.; Kuwano, H. Air gap optimization for output power and band width in out-of-plane vibration energy harvesters employing electrets. J. Micromech. Microeng. 2015, 25, 104013. [Google Scholar] [CrossRef]

- Tao, K.; Lye, S.W.; Miao, J.; Tang, L.; Hu, X. Out-of-plane electret-based MEMS energy harvester with the combined nonlinear effect from electrostatic force and a mechanical elastic stopper. J. Micromech. Microeng. 2015, 25, 104014. [Google Scholar] [CrossRef]

- Asanuma, H.; Hara, M.; Oguchi, H.; Kuwano, H. Nonlinear restoring force of spring with stopper for ferroelectric dipole electret-based electrostatic vibration energy harvesters. AIP Adv. 2016, 6, 075206. [Google Scholar] [CrossRef]

- Basset, P.; Galayko, D.; Cottone, F.; Guillemet, R.; Blokhina, E.; Marty, F.; Bourouina, T. Electrostatic vibration energy harvester with combined effect of electrical nonlinearities and mechanical impact. J. Micromech. Microeng. 2014, 24, 035001. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, A.; Xu, Y.; Wang, T.; Zhang, A.; Wang, F. Electret-based electrostatic energy harvesting device with the MEMS technology. In Proceedings of the 2016 12th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications (MESA), Auckland, New Zealand, 29–31 August 2016; pp. 1–6. [Google Scholar]

- Sterken, T.; Fiorini, P.; Baert, K.; Puers, R.; Borghs, G. An electret-based electrostatic /spl mu/-generator. In Proceedings of the 12th International Conference on Solid-State Sensors, Actuators and Microsystems, Boston, MA, USA, 8–12 June 2003; pp. 1291–1294. [Google Scholar]

- Jefimenko, O. Slot effect in electret devices. Proc. West Va. Acad. Sci. 1968, 40, 345–348. [Google Scholar]

- Gerhard-Multhaupt, R. Theoretical and experimental study of the electromechanical electret slit-effect transducer. J. Phys. D Appl. Phys. 1984, 17, 649–663. [Google Scholar] [CrossRef]

- Genda, T.; Tanaka, S.; Esashi, M. High power electret motor and generator on shrouded turbine. In Proceedings of the PowerMEMS 2004, Kyoto, Japan, 28–30 November 2004; pp. 183–186. [Google Scholar]

- Mitcheson, P.D.; Green, T.C.; Yeatman, E.M.; Holmes, A.S. Architectures for vibration-driven micropower generators. J. Microelectromech. Syst. 2004, 13, 429–440. [Google Scholar] [CrossRef]

- Stanzione, S.; van Liempd, C.; van Schaijk, R.; Naito, Y.; Yazicioglu, F.; Van Hoof, C. A high voltage self-biased integrated DC-DC buck converter with fully analog MPPT algorithm for electrostatic energy harvesters. IEEE J. Solid-State Circuits 2013, 48, 3002–3010. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naito, Y.; Uenishi, K. Electrostatic MEMS Vibration Energy Harvesters inside of Tire Treads. Sensors 2019, 19, 890. https://doi.org/10.3390/s19040890

Naito Y, Uenishi K. Electrostatic MEMS Vibration Energy Harvesters inside of Tire Treads. Sensors. 2019; 19(4):890. https://doi.org/10.3390/s19040890

Chicago/Turabian StyleNaito, Yasuyuki, and Keisuke Uenishi. 2019. "Electrostatic MEMS Vibration Energy Harvesters inside of Tire Treads" Sensors 19, no. 4: 890. https://doi.org/10.3390/s19040890

APA StyleNaito, Y., & Uenishi, K. (2019). Electrostatic MEMS Vibration Energy Harvesters inside of Tire Treads. Sensors, 19(4), 890. https://doi.org/10.3390/s19040890