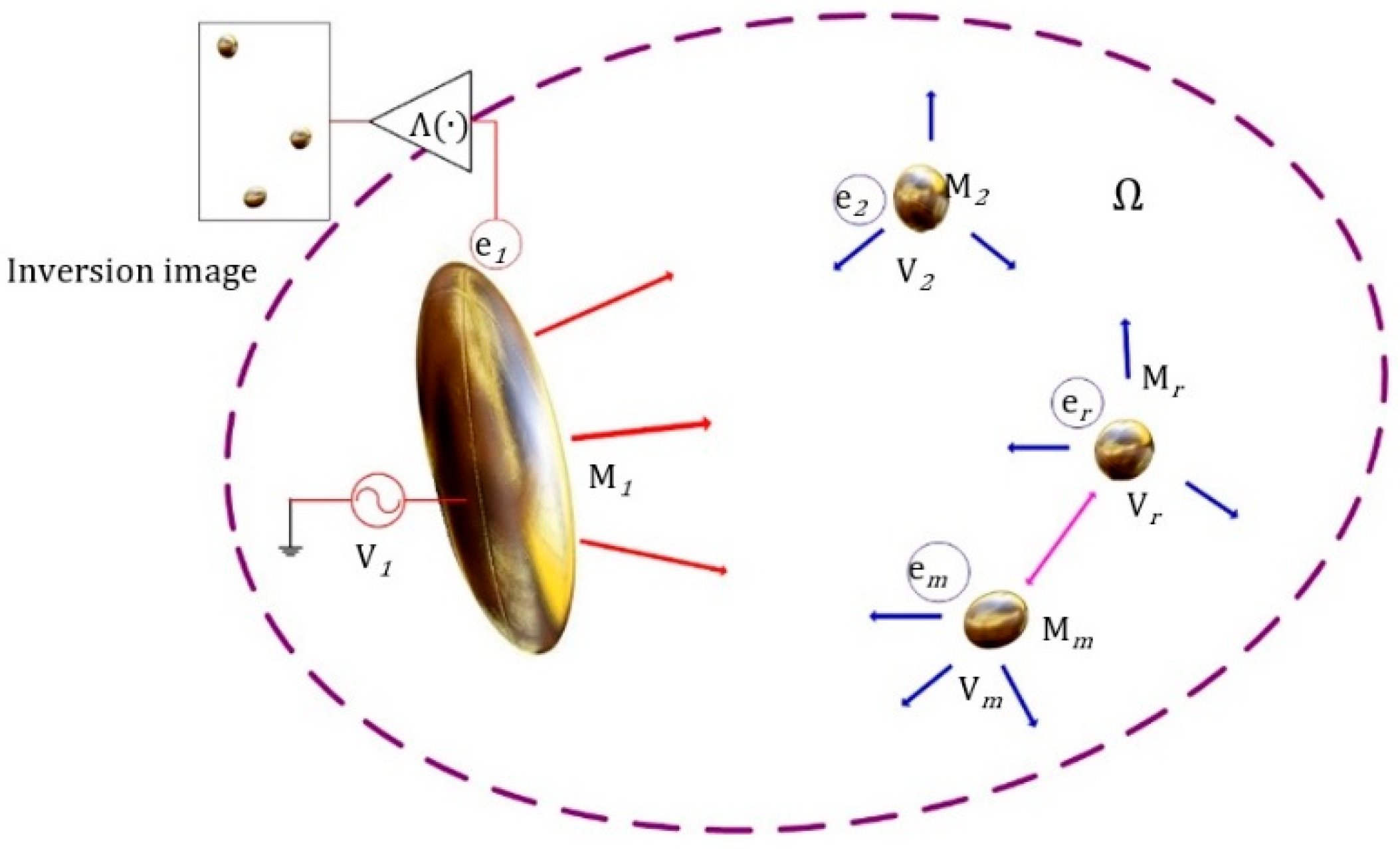

4.1. SA-CGA Inversion

Inversion of the capacitance array of wear debris in lubricating oils is a non-convex problem in the non-monotonic solution space of multi-induction Dirac poles. The distributions of oil in continuous and abrasive discrete phases are random, and the smoothness of the problem is unknown. The genetic algorithm (GA) optimization process does not depend on gradient information [

21], and is suitable for dealing with complex non-linear problems. Cellular automata (CA) is an emergent computing method [

22]. Combining the genetic algorithm of CA, it can better simulate the non-linear dynamic state of individual interactions of genetic algorithm populations, and it can also use the algorithm to introduce prior knowledge to achieve adaptive heuristic algorithms.

The calculation steps of the SA-CGA algorithm for inverse solutions of capacitance array imaging of wear debris in lubricating oil abrasive arrays are as follows:

(1) Population initialization

To a genetic algorithm cell individual , each individual has a chromosome , where i, j represent individual coordinates, .

(2) Coding

According to the accuracy of the calculation, the mesh of variables x is partitioned, which belongs to a region of . The minimum integer of is expressed by m, then can be expressed with a binary string, and the dielectric constant of the corresponding parameter space is expressed by a genetic algorithm gene.

(3) Computational fitness

The gene expression of the individual in the cell space population is calculated, that is, the fitness eval () of dielectric constant value. The mathematical model of imaging detection of capacitance arrays of wear debris in lubricating oil is the change of the capacitance array calculated using a forward 3D finite element method and the coincidence of the measured value.

(4) Learning select operations

Each individual

in the cell space evaluates the fitness of its neighbors (including itself) whose fitness is greater than or equal to its own cell (denoted as

) according to the difference between the neighbor form and radius in two-dimensional space.

where,

is the probability that the neighbor

of individual

is selected (if

). Unlike traditional genetic algorithms, the individuals involved in the selection are limited to the individual and the set of neighbors

, which is the process that the central cell learns from the neighbor.

(5) Heuristic crossover

When the individual

of the neighboring cell is selected by the individual

of the central cell, and the crossover probability is defined as

, the individual

updates the chromosome in the following way.

The cross probability

of the cellular genetic algorithm is different from the cross probability of traditional genetic algorithms. This can be regarded as the “confidence” or “learning tendency” of individual

. When

= 1, individual

learns aggressively from the better individuals in the neighborhood, while when

= 0, individual

is completely confident and has no confidence in its neighbors. The interest interaction in Equation (19) represents the crossover probability at a fixed value. All individuals adopt the same crossover probability, which results in the same crossover learning probability regardless of the “excellence” of their neighbors. Using this heuristic strategy, the crossover probability has a self-adaptability based on heuristic learning, which is similar to the effect of “learning intensity”.

where,

and

are adaptive heuristic coefficients of learning intensity, which can realize the adaptability of heuristic learning intensity [

23]. Without sacrificing the convergence speed, the solution quality is improved.

(6) Adaptive heuristic mutation

Here we define the mutation probability

. For individual

in cell space, the random number

is selected from [0,1]. If

, the chromosome of the individual is updated as follows.

Among them, is constant, .

Traditional genetic algorithms define the mutation probability

as a constant, and its selection often depends on empirical values. The mutation probability is large, and the global search ability is strong, but the search speed is slow. The probability of mutation is small, the convergence rate is fast, the diversity of the population is poor, and meaningless local solutions are obtained. The selection of actual constants is a compromise of the empirical value at the expense of adaptability. The mutation probability is adjusted adaptively.

where,

is the mutation probability of the previous population generation,

is the new mutation probability when the local population undergoes mutation operations, and

is the population of the superposition of the optimal elite under the strategy of retaining the elite, that is, the local optimal continuous reproduction algebra.

The initial value of mutation probability is a very small original mutation probability . When the optimal elite passes through the iteration, new locally optimum points with higher adaptability are found, and the mutation rate is restored to the initial value . Through adaptive variation of the mutation probability, the mutation rate is related to the number that fall into local optima. The longer the time of iteration, the greater the mutation probability, thus it accelerates exponentially. The convergence of the algorithm is good in most cases, and the search for all optimum points can be accelerated when the iteration falls into a local optimum.

(7) Determination of whether criteria for evaluating biological groups are met; if not, return to step 3.

Generally, the fitness of selected populations is larger than a certain value, and the increasing rate of the population fitness does not increase with the number of evolutions or reach a certain number of evolutions. Rudolph proves that the elite-preserving genetic algorithms converge to the global optimal solution with probability 1, based on Markov chain theory. The strategy of retaining the elite refers to the strategy of retaining the best individuals in the population to the next generation in the selection operator. This strategy does not participate in crossover and mutation operations, so as to prevent the excellent individuals in each generation from losing due to crossover and mutation operations, thus falling into local extrema. This strategy is introduced into the cellular genetic algorithm. In the crossover operation, the individual cell not only learns from the excellent neighbors, but is also influenced by the contemporary global optimum. A new crossover operation model is proposed.

where

indicates that the maximum fitness of the contemporary population corresponds to the chromosome of the individual. Cellular individuals are affected not only by the excellent neighbors around them, but also by the best individuals in the contemporary population.

The fitness of each individual in the population is calculated using 3D-FEM. To ensure the accuracy of the inversion solution of the capacitance array of lubricating wear debris, a non-linear calculation model is adopted, and the calculation time cost is the highest. Therefore, before evaluating the fitness of biological groups, the heuristic algorithm [

24,

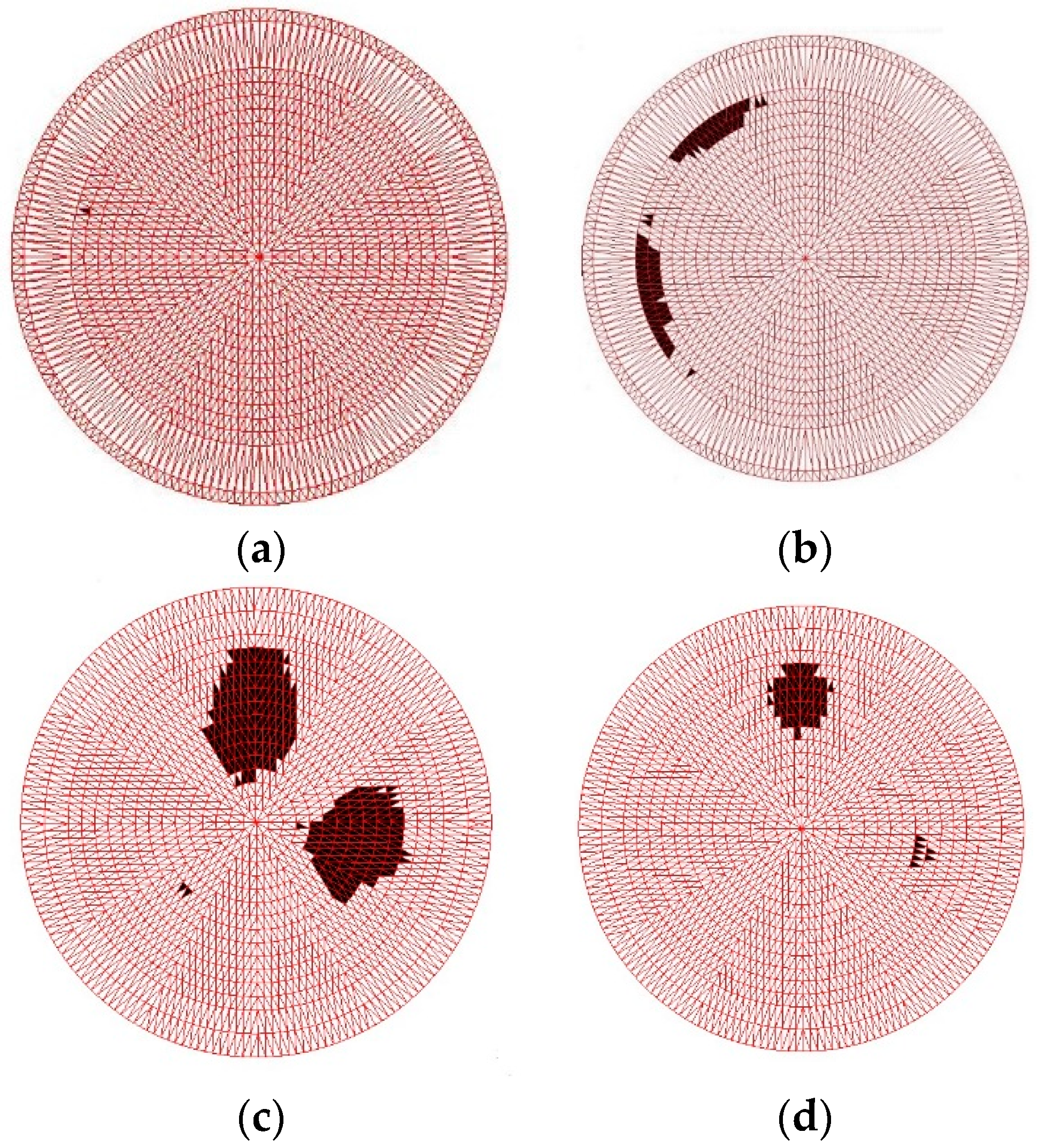

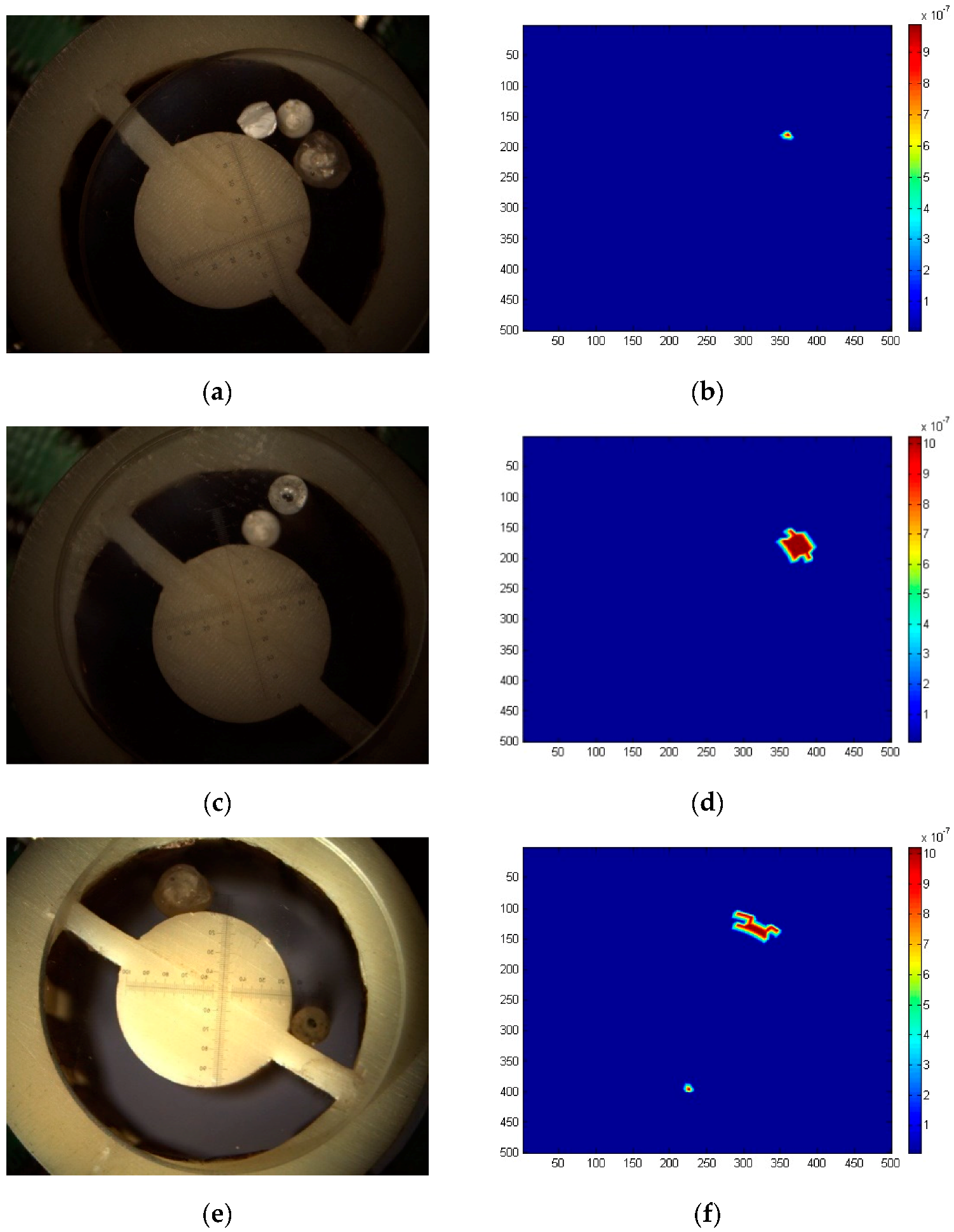

25] is implemented by introducing the prior knowledge of tribological statistics (such as the number and size range of wear debris) to improve the results of obvious non-conformity with a small computational cost. Using the SA-CGA algorithm, the inversion results of measured signals are shown in

Figure 5.

Figure 5b shows two 900 μm wear debris and one 200 μm wear debris separated by a plate. The inversion calculation has artifacts but can distinguish them. For two particles with similar size at different times on a plate (for instance, in

Figure 5d where two 200 μm particles and one 900 μm particle are separated by one plate), only two particles are displayed after inversion. This is because the size of the particle is large, although the other is far away from the three particles, which affects the threshold decision of the debris judgment strategy. In the next section, a High-Level Strategy (HLS) heuristic algorithm will be used to optimize the detection effects by utilizing the prior statistical knowledge of local morphology of wear debris.

4.2. Morphological Hyper-Heuristic

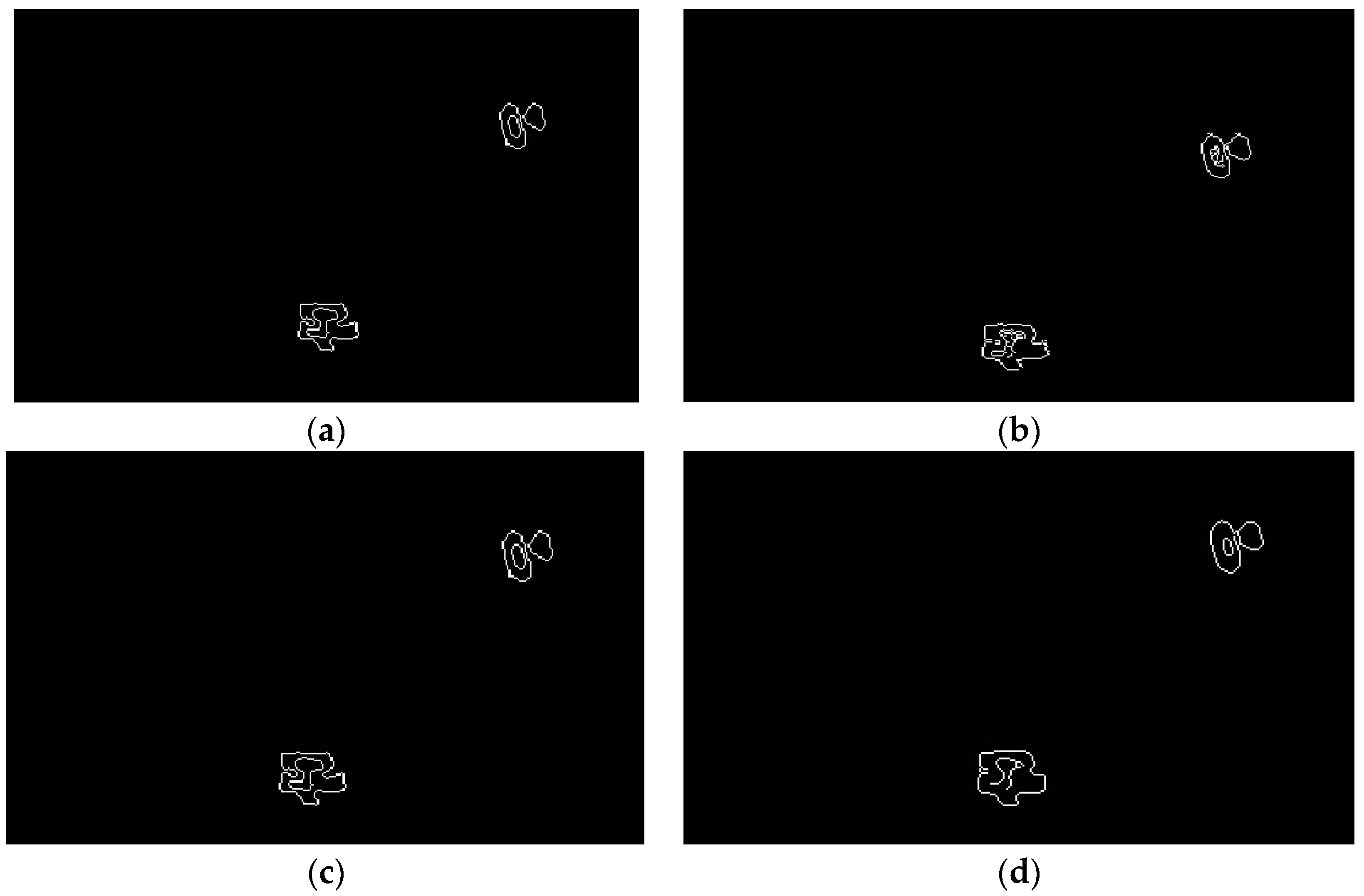

Combining the prior knowledge of piecewise constants of wear debris distributions and effective pixel-sparse statistical features, while using the local or global differential or gray distribution information, the features of the boundary between the debris object and the oil background can be identified. The key point is to identify the boundary in the case of low signal-to-noise ratios and avoid the artifacts of the multilateral boundary as far as possible. The heuristic intelligent-image edge-detection algorithm, using the local second derivative information of the image, combined with intelligent filtering, has better adaptability for gray image processing with noise, such as in the case of the Laplacian-Gauss (LOG) operator. The effect of different edge extraction operators is verified by the 3-debris image of

Figure 5d, which is the most difficult to distinguish, as shown in

Figure 6.

The Sobel and Prewitt operators only segmented two non-connected regions of the actual distribution of the gray image where the number of wear debris was 3. The number of image segmentations is obviously not consistent with the number of wear debris. In the edge-recognition and segmentation algorithms for the three non-connected regions, the LOG operator uses a two-pixel boundary. The Canny algorithm uses a double-threshold operator to overcome this problem. After edge recognition and segmentation with a Canny operator, the number of oil and wear debris detection and size target features can be extracted. The number of wear debris is the number of non-connected segmentation areas in image morphology, and the size of abrasive particles is the fitted line length of image using a mathematical morphology skeleton.

For the image with a recognized boundary, the wear debris region is obtained with a filling operation. Let the set

A of region boundaries be complemented by

. The region can be filled by expanding, complementing, and exchanging the structure element

B (morphological mapping of abrasive particle inversion image). Firstly, a point in the boundary is assigned a value of 1, according to the iteration formula.

We fill in these values, where the last iteration result of the image set is , and the solution result is . When , the iteration stops; is an expansion mapping operation, and is an intersection mapping operation. According to the minimum size of wear debris judged by the target of lubricating oil, the size of the wear particles is 250 μm. The corresponding image is a pixel spatial area. According to the prior knowledge of the shape of the wear particles, the structural element is defined as a circle.

According to the typical hyper-heuristic knowledge of aero-engine fatigue wear debris, the shape boundary of wear debris satisfies Lipschitz smoothness, so the image of wear debris is de-sharpened. Using a closed mapping of the set algebra, the image expands and corrodes again. On the premise of maintaining the area and shape characteristics of the wear debris image, the wear debris boundary is de-sharpened and defined as:

where

is the expansion operator of image mathematical morphology and

is the image mathematical morphology corrosion operator.

The actual size of the wear debris corresponds to the characteristics of the length of the central axis in the non-connected areas of the image:

where

is the actual size of the abrasive particles, L is the length feature, and

is the skeleton of the non-connected area of the image after deburring by the operations of Equation (26).

Here,

is the skeleton subset,

B is the structural element,

represents the continuous

k-times

B-to-

D corrosion operation, and

K is the last iteration number before

D is corroded into an empty set.

According to Equation (28), the main factor affecting the conversion relationship between the actual size of wear debris and image features is the selection of structural element B. B is too small to cause connectivity damage, but B is too large to easily lose skeleton branch details of the skeleton. The details of skeleton branches do not affect the calculation of skeleton length, but the failure of skeleton connectivity affects the calculation of skeleton length. Therefore, the B selection strategy should be the maximum structural element with the resolution allowed. According to the minimum target resolution pixel of for abrasive particles, structural elements are selected.

After wear debris edge recognition, it is necessary to fill in the internal pixels according to the outermost layer recognized as the edge of the wear debris. This kind of wear debris recognition filling can use mathematical morphology algorithms and basic operations combining processing with set theory to extract the corresponding morphological structure characteristics of wear debris. For images with recognized boundaries, the debris region is obtained by a filling operation. The number of wear debris can be determined by checking the connectivity between each pixel and adjacent pixels. The number of pixels in the image itself is small, and the number of abrasive particles can be measured using the pixel marking algorithm. When labeling in detail, the binary image after edge recognition and boundary determination is scanned from left to right and from top to bottom.

The image processing recognition and length measurement are carried out using the central axis of different wear debris in the image, and the debris size measurement is achieved using morphological skeleton extraction algorithms. Due to the edge recognition and image filling of wear debris, the shapes of debris edges are irregular, and there are protrusions and concave angles on the edges of wear debris.

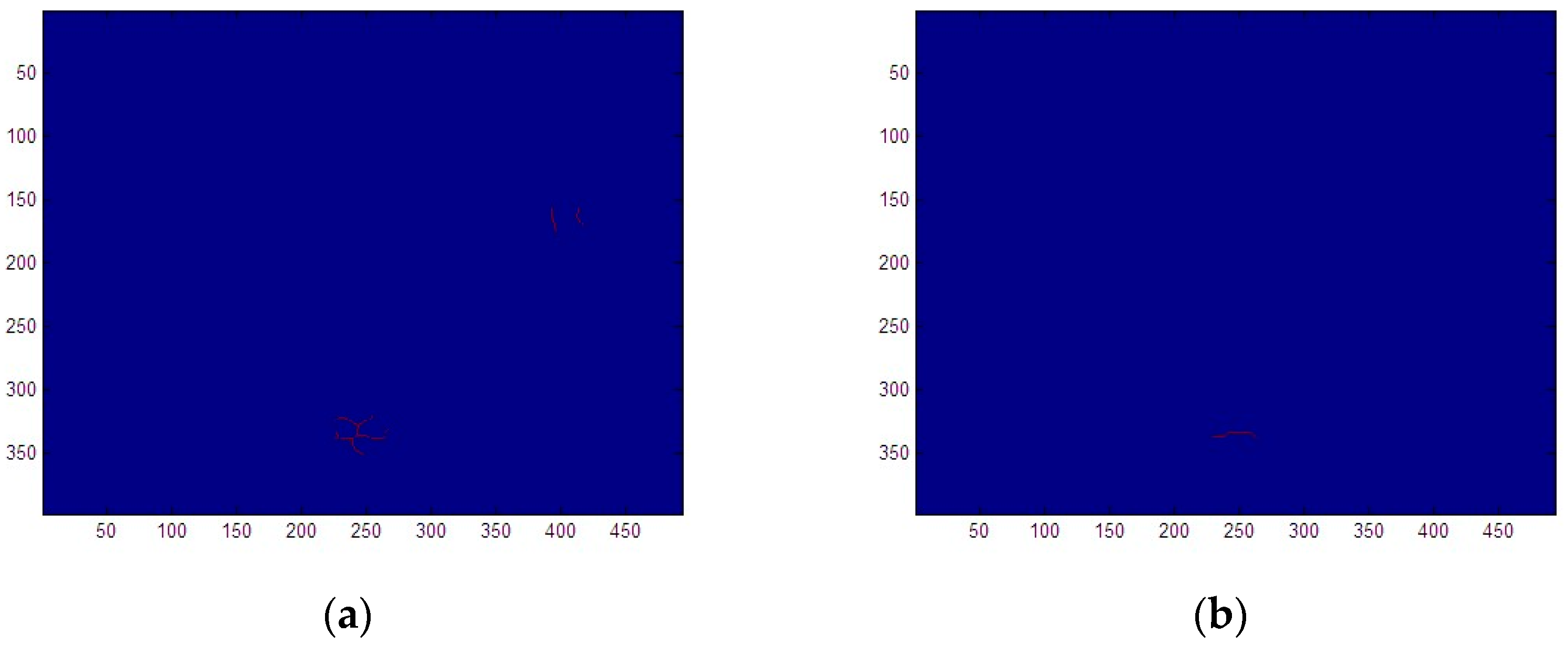

Figure 7a demonstrates how the mathematical morphological skeleton is obtained, where the edge is very irregular, resulting in skeleton bifurcation, which cannot effectively measure the size of wear debris. The typical shape boundary of aero-engine fatigue wear debris is used to satisfy the Lipschitz-smooth a priori hyper-heuristic criterion, and the image of wear debris is de-sharpened. Set algebraic closed mapping is used to corrode the image after expansion, and the wear debris is de-sharpened, while the area and shape features of the debris image are preserved. Through mathematical morphological closure of the debris image, the debris edge of the original irregular edge is smooth enough, considering the premise that the shape of the debris area is basically unchanged, and then a satisfactory single debris skeleton line can be obtained by calculating the skeleton of the wear debris image, as shown in

Figure 7b. For the extracted debris skeleton, diagonal fitting is used to measure the wear debris size.

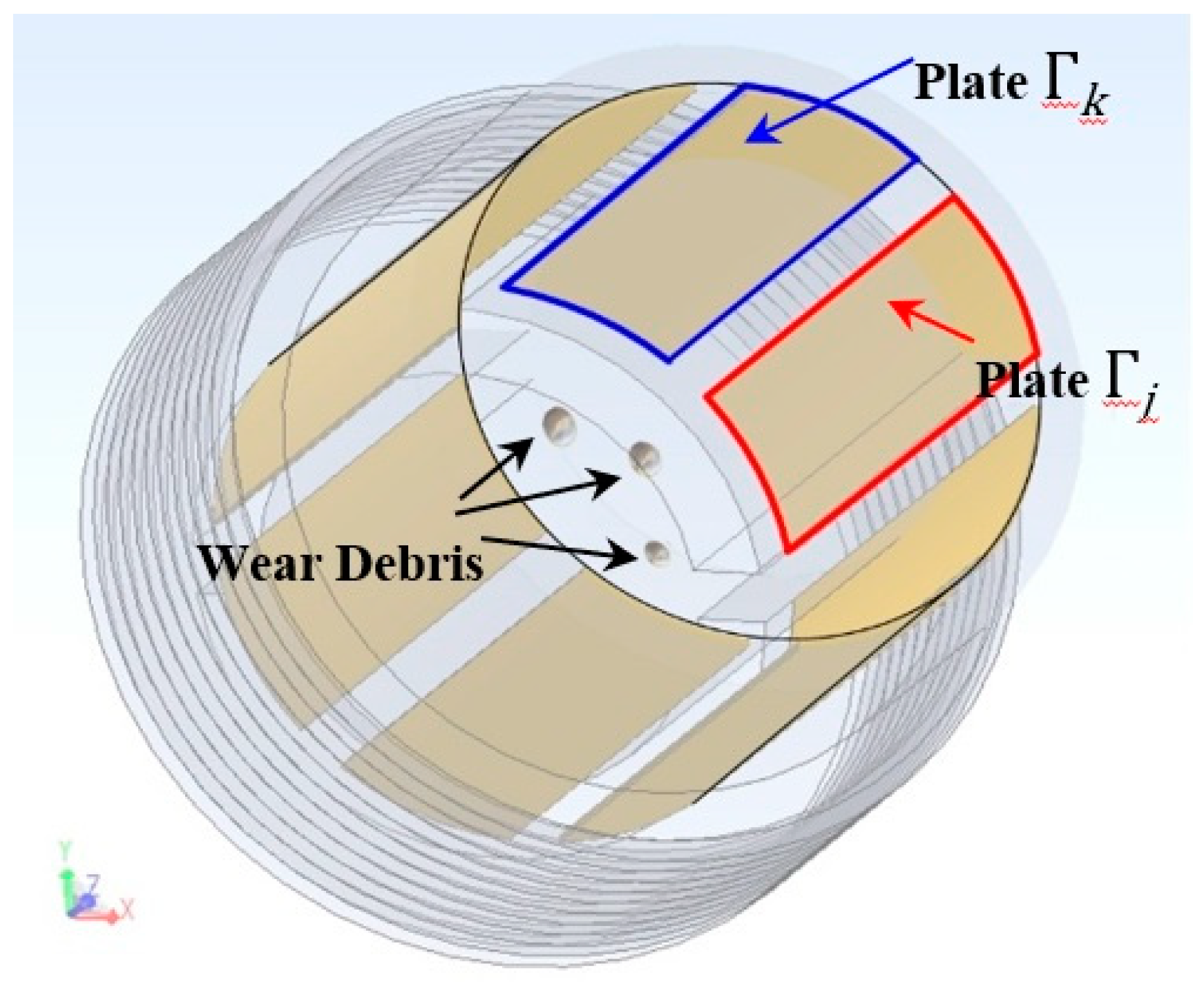

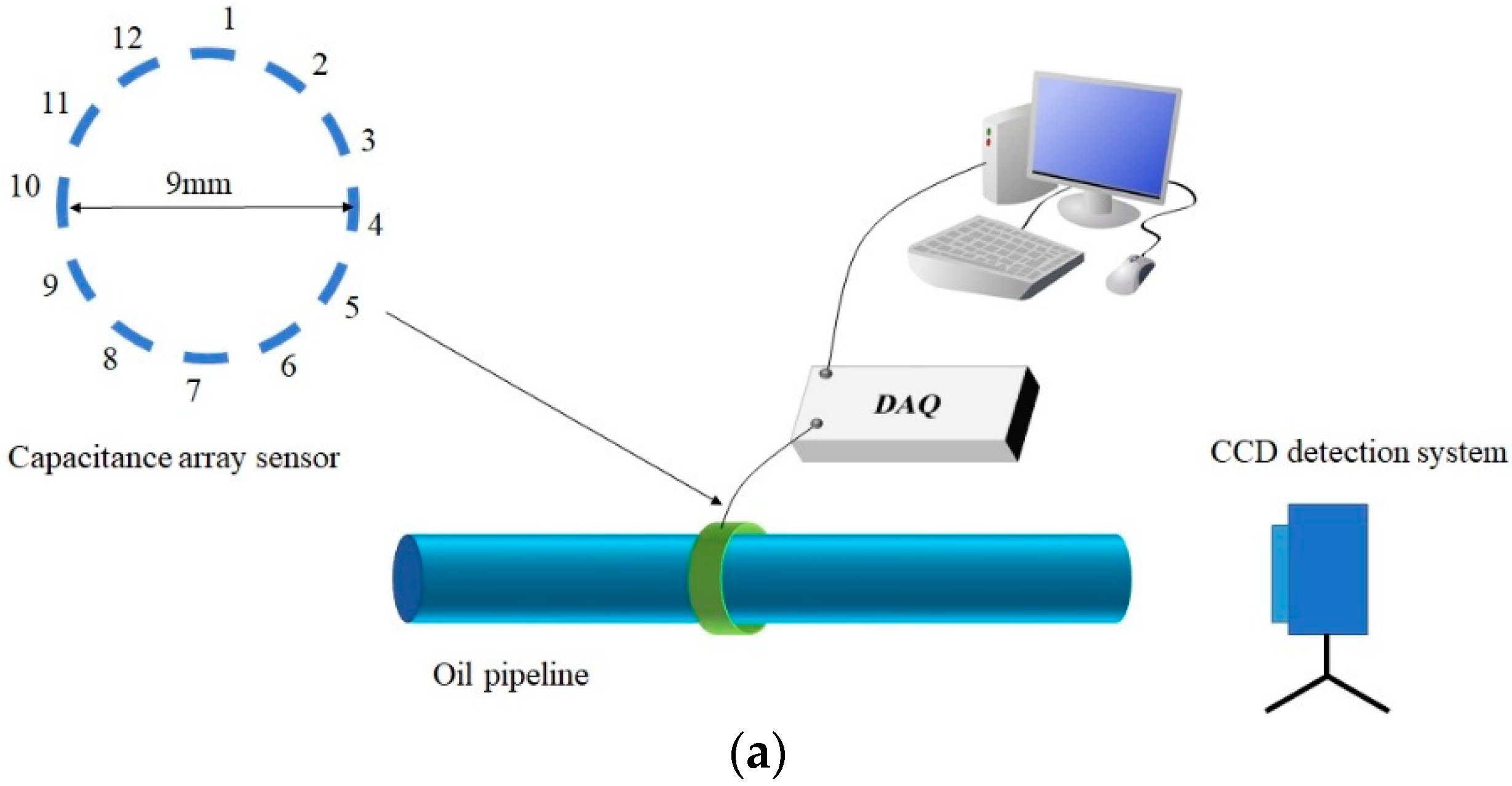

4.3. Experimental Set-Up

The detection system consists of hardware and software. The hardware consists of sensors on an oil pipeline, data acquisition (DAQ) circuits, cables, connectors and interface circuit boards, as shown in

Figure 8a. A CCD detection system is used for comparison.

The sensor adopts 12 annular channel capacitance arrays. The diameter of a typical aero-engine oil pipeline is 8 mm. The outer diameter of the capacitance sensor is

R. To ensure that the minimum cross-sectional area of differential pressure fluid flow is 70%, the allowable area is 150 mm

2. Based on the area,

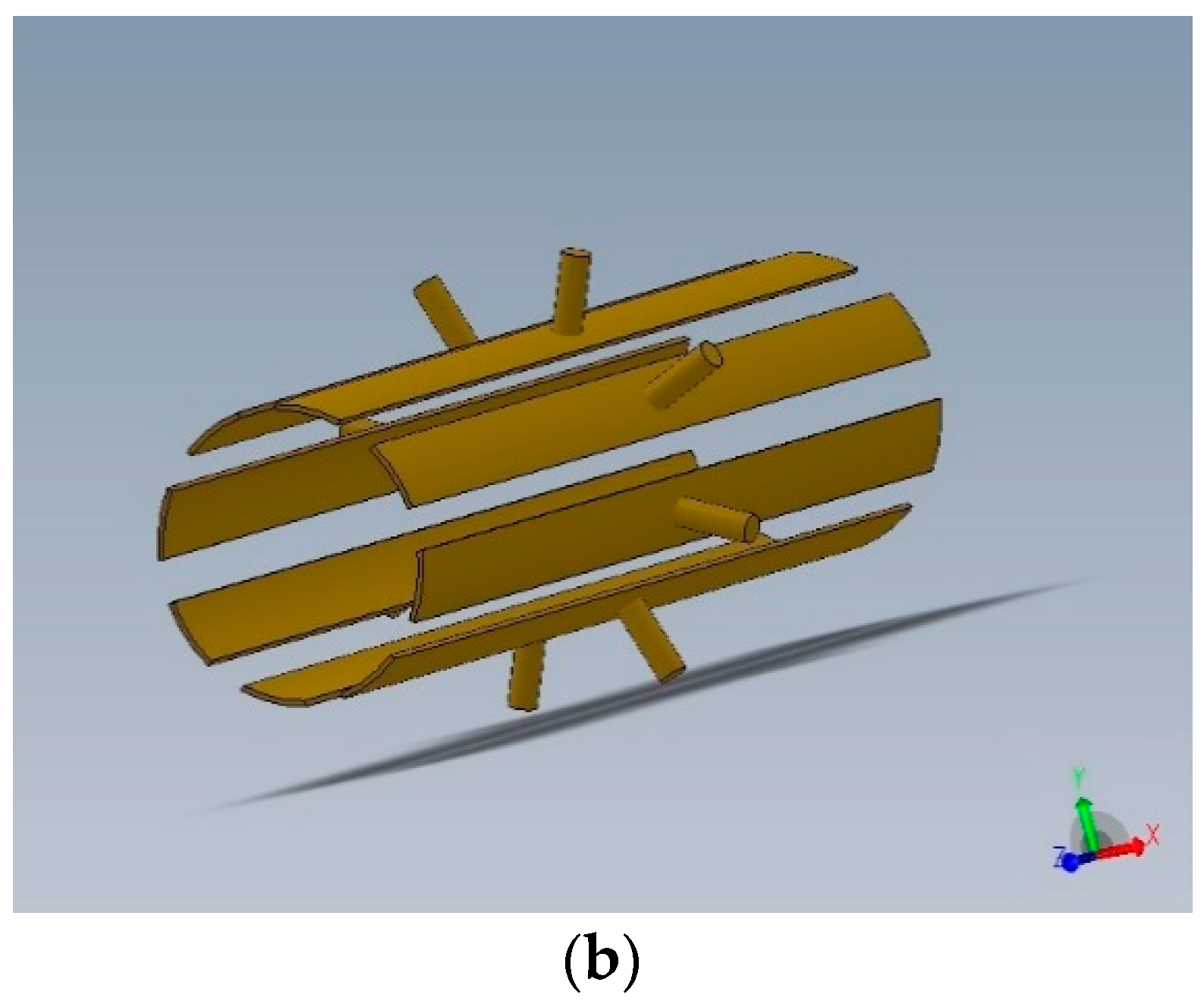

R = 8.24 mm and the diameter of the capacitance sensor is 9 mm. The theoretical value of the capacitance between adjacent plates is about 2 pF. The interval between the plates is 2.3 mm. The 3-D model of the capacitance array sensor is shown in

Figure 8b. The diameter is 9 mm and the length is 50 mm. When the size of the wear debris is 250 μm, the detection distance of the plate with the corresponding resolution

= 0.061 fF is 5 mm.

The data acquisition (DAQ) adopts digital switched capacity technology. It is realized by ADI AD7746 chip circuit module EVAL-AD7745/46EBZ. The highest resolution is 4 aF (21 bits), and the calibration accuracy is 4 fF. The capacitance measurement range is +4 pF. To minimize the background stray capacitance of cables, joints and interface circuit boards, tetrafluoroethylene (PTFE) materials are used for sensor interface boards and joints and cables. The detection software is based on LabVIEW.

The simulated wear debris are made of standard metal particles from the CONSTANT Company, USA. The sizes of the debris are calibrated by electron microscopy and molecular sieving after calibration. Large wear debris (≥400 μm) are purchased as standard spherical abrasives. The background scale is set by a microscopic cross-shaped eyepiece micrometer (model CAT907). Small-size wear debris (<400 μm) measure the longest side according to the calibrated microscope image and determine the length-to-diameter ratio. The experimental parameters are shown in

Table 2.

A CCD image (with model MV1300UC-1 of Microvision Co., Ltd., San Diego, CA, USA) of an electronic magnifier is used for comparison with the image of the capacitance array sensor. The CCD detection system is equipped with a 0.7–4.5 industrial variable lens, an 8-million-pixel CCD, and supporting software. The wear debris are calibrated with a standard micrometer. The rigid PU rod was fixed with a transparent liquid adhesive.

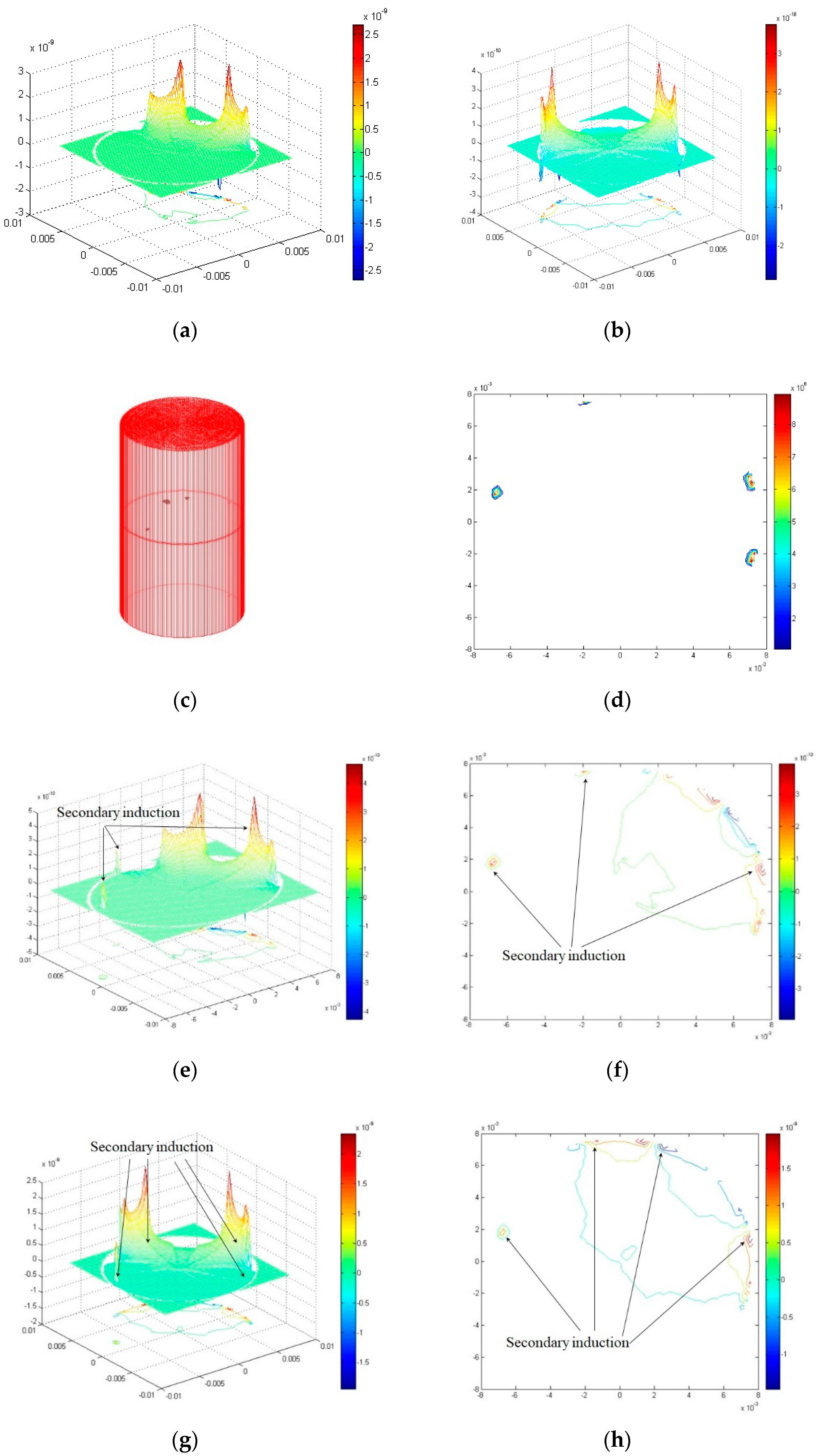

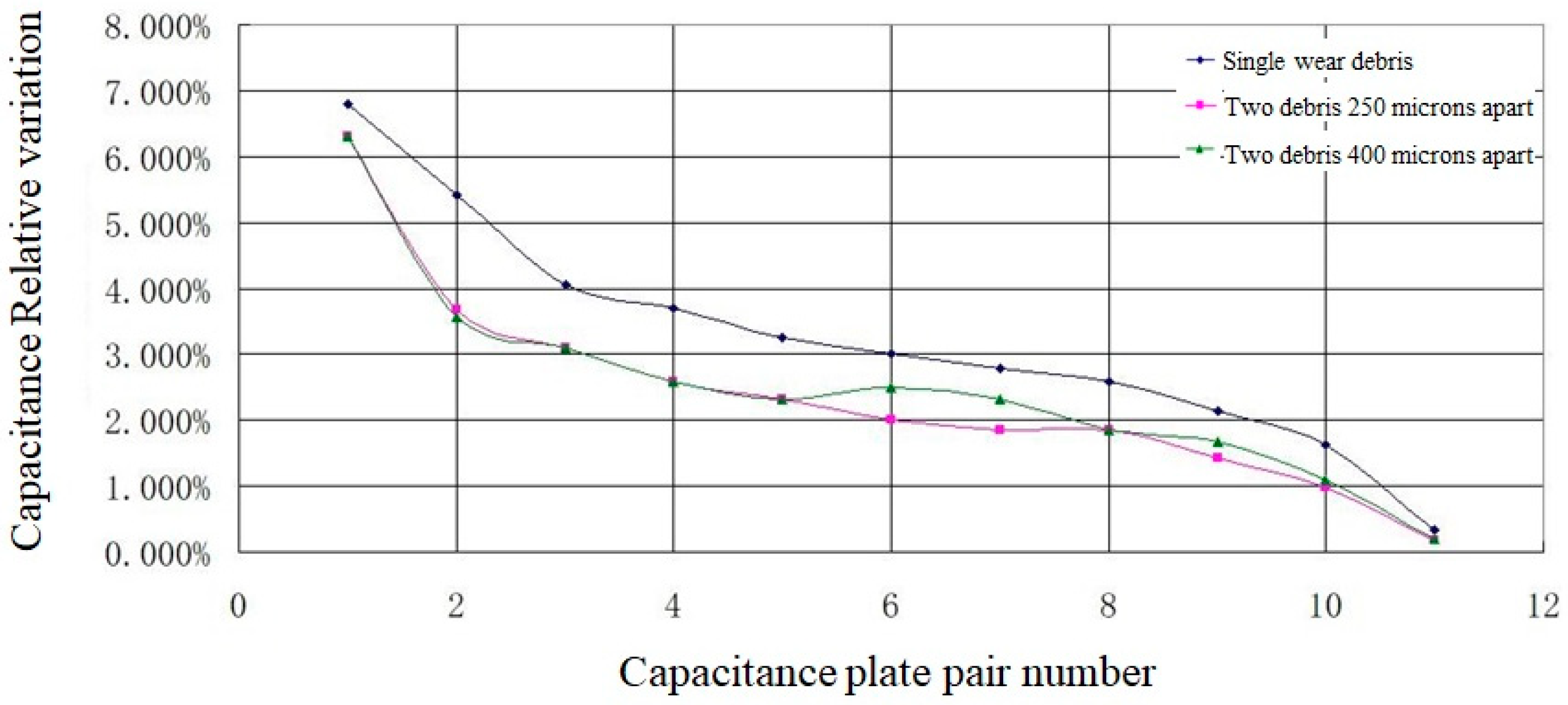

4.4. Results and Discussions

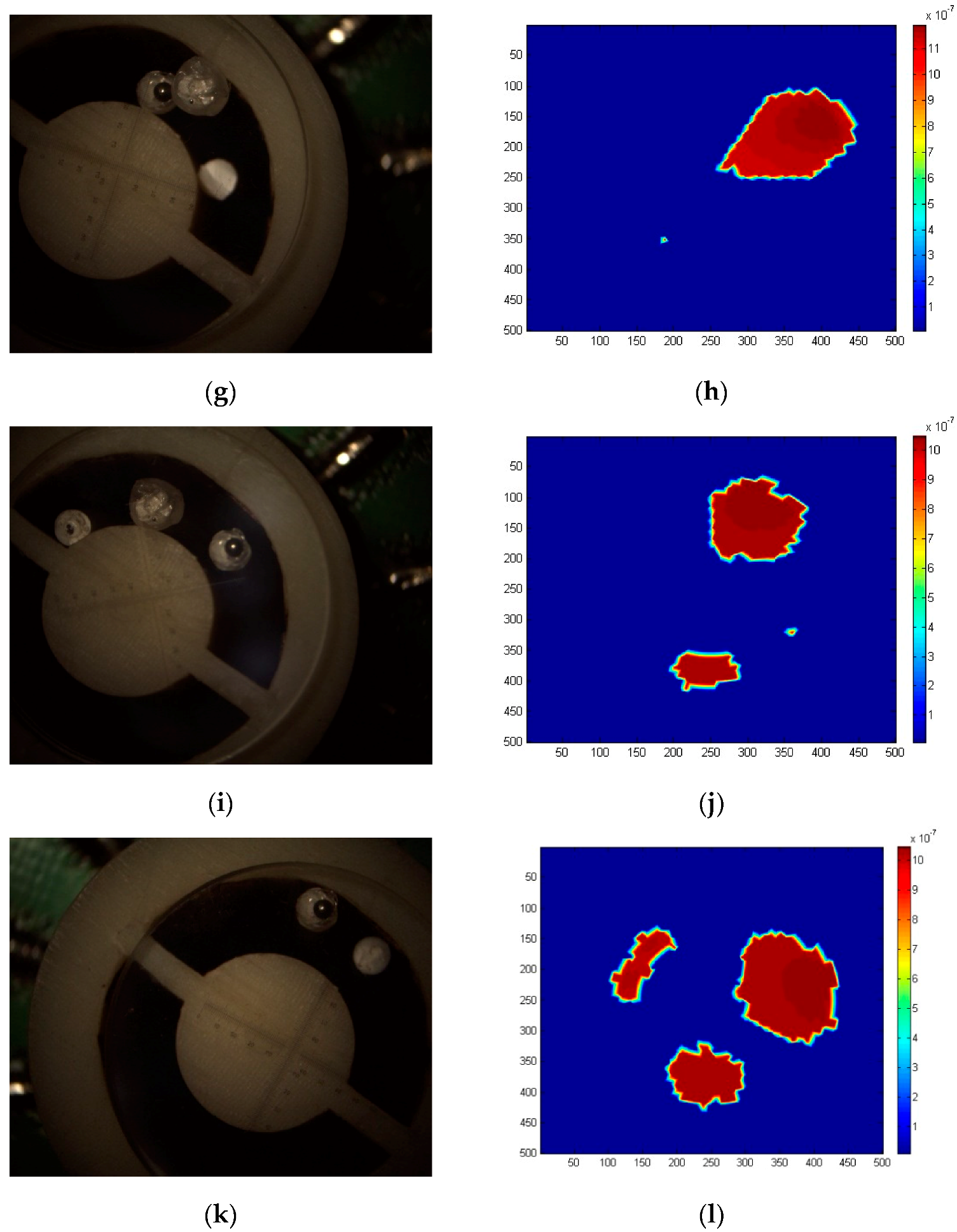

By changing the size of wear debris that have been calibrated over 200, 900 and 500 μm, the experiments are carried out at different positions of the sensor, and the CCD image and capacitance array inversion image are measured simultaneously. The images and feature recognition outputs are compared. The image comparison results of wear debris are shown in

Figure 9. In the sensor, the dielectric constant of the sensor and the plastic rod are close to that of the oil without wear debris, so the capacitance array inversion results in fluctuations lower than 2.

The results of single wear debris detection are as follows. In

Figure 9a–d, the CCD image is calibrated with a stand micrometer, and the wear debris size of corresponding inversion image is monotonous. Due to the iterative synthesis calculation of array inversion, the debris edge is not smooth, and the image morphology processing does not affect the wear debris size detection.

Figure 9e–h shows that when two wear debris are present at the same time, the inversion effect is obviously affected by the secondary induction field effect. The size of small wear debris near each other will increase due to the induction field, as shown in

Figure 9h. The secondary induction field will distort the shape of the inverted debris, resulting in low recognition accuracy of the size of wear debris. The shape distortion effect of wear debris in the secondary induction field exists in the detection and inversion of multi-wear debris, as shown in

Figure 9i–l. The array inversion calculation does not consider the distance information between wear debris. Therefore, the number and size information of wear debris in the inversion results are better, and the corresponding accuracy of the distance and relative position relationship between single wear debris and the CCD image is low. For one, two, and three pieces of debris, the error of the size inversion is lower than 9%, 15% and 17%, respectively, and for the number of abrasives, the error of the size inversion is less than 18%.

As seen in

Table 3, compared with gradient or convexity optimization algorithms, the minimum relative capacitance residual of LBP or TSVD algorithm is about 1.12%. The minimum relative capacitance residual of the convexity regularization LANDWEB algorithm is about 2.01%. Continuous iteration of the LANDWEB algorithm will lead to the increase of the relative capacitance residual. SA-CGA and LFLCS hyper-heuristic algorithms are useful for improving the detection accuracy, especially when the recognition error of the number of multi-wear debris is reduced by half.

Linear gradient methods can only obtain one pole point; other secondary induction pole point information is all missing. Furthermore, when linear gradient methods are used to detect multiple pieces of wear debris, their being mistaken for single particles leads to a serious reduction in accuracy. The nonlinear gradient method falls into local solutions and produces a large number of artifacts satisfying pseudo-convergence in the sense of the least squares norm. There is little difference between heuristic algorithms and non-heuristic algorithms in terms of size accuracy for single abrasive particle detection. Simple heuristic algorithms have insufficient prior knowledge, and obvious superfluous artifacts appear in the calculation of the sensor inner core and connecting rib. The HLS knowledge of image morphology related to debris and sensors introduced in the hyper-heuristic algorithm greatly improves of number error.

The SA-CGA+LFLCS cyclic iteration hyper-heuristic strategy introduces a genetic algorithm for excellent population DNA and feeds it back into the inversion algorithm. This is better than the strategy of SA-CGA image inversion combined once, using SA-CGA+LFLCS as hyper-heuristic knowledge. Cyclic iterative processes are equivalent to the eugenic and eugenic reproductive hyper-heuristic strategies. The test results show that the accuracy of size recognition was further improved by 5%. The iterative hyper-heuristic algorithm significantly improves size accuracy. The calculation times of each algorithm are compared, as shown in

Table 3. The algorithm is implemented by the software of MATLAB version 7.0.0.19920 (R14). The total code file is 49.5 MB. The running platform is a Pentium dual-core CUP E5800@3.20GHz computer, with 1.96 GB memory.

The LBP algorithm mainly calculates matrix multiplication. The TSVD algorithm mainly calculates matrix singular value decomposition. The linear gradient algorithm is a non-iterative solution, so the calculation time is short. The main computational tasks of Land-Weber are numerical integration and generalized inverse matrix. Pre-iteration of the generalized inverse matrix by off-line calculation can save computational time, and the computational time of the non-linear gradient algorithm based on this strategy is about 250 milliseconds. The calculation time of the meta-heuristic algorithm increases greatly, which is mainly because the fitness value of each iteration needs to be calculated, and the search space is greatly enlarged. In the hyper-heuristic algorithm, ONE HLS and Iteration HLS strategies have little difference in computing time. Although they increase the computational complexity of image morphological processing, the overall computing time is slightly shorter than the meta-heuristic algorithm because of the introduction of a large amount of high-level heuristic a priori knowledge, which greatly reduces the search space.

To ensure the resolution of micro-scale wear debris, the total number of three-dimensional finite element elements used in the calculation model of all algorithm is 9216. According to the characteristics of the inversion problem, the sparse matrix processing method is adopted. The peak memory usage by the algorithm is no more than 1 GB. The calculation time of each algorithm is independent of the number and size of the wear debris.

The 32-cell hyper-heuristic algorithm was run in parallel with EPM570T100C5N (Altera) CPU (8 MHz main frequency). The computing time was about 340 milliseconds, meeting the requirement for on-line detection.