Magnetic Condition-Independent 3D Joint Angle Estimation Using Inertial Sensors and Kinematic Constraints

Abstract

1. Introduction

2. Method and Validation

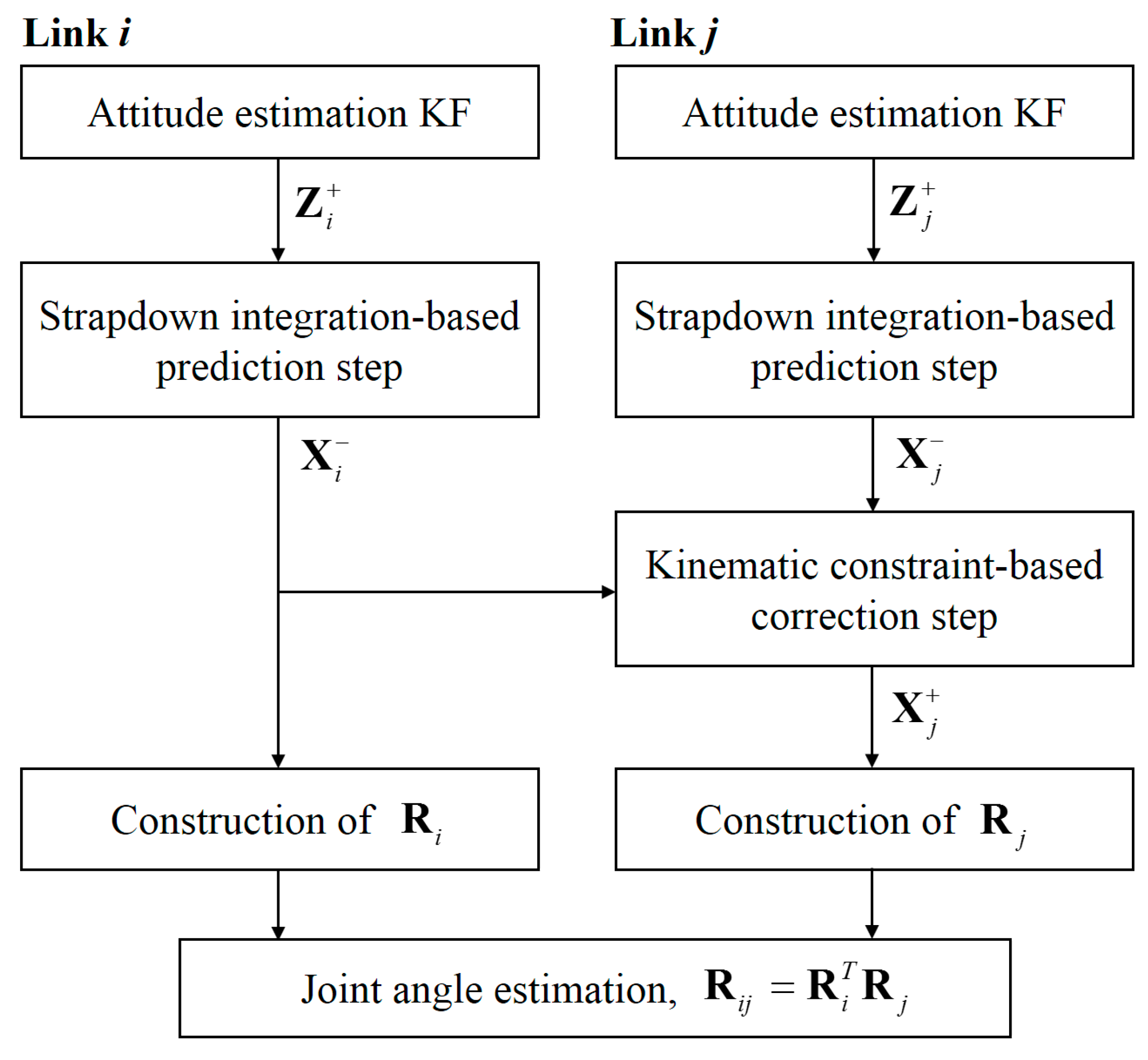

2.1. Joint Angle Estimation Kalman Filter

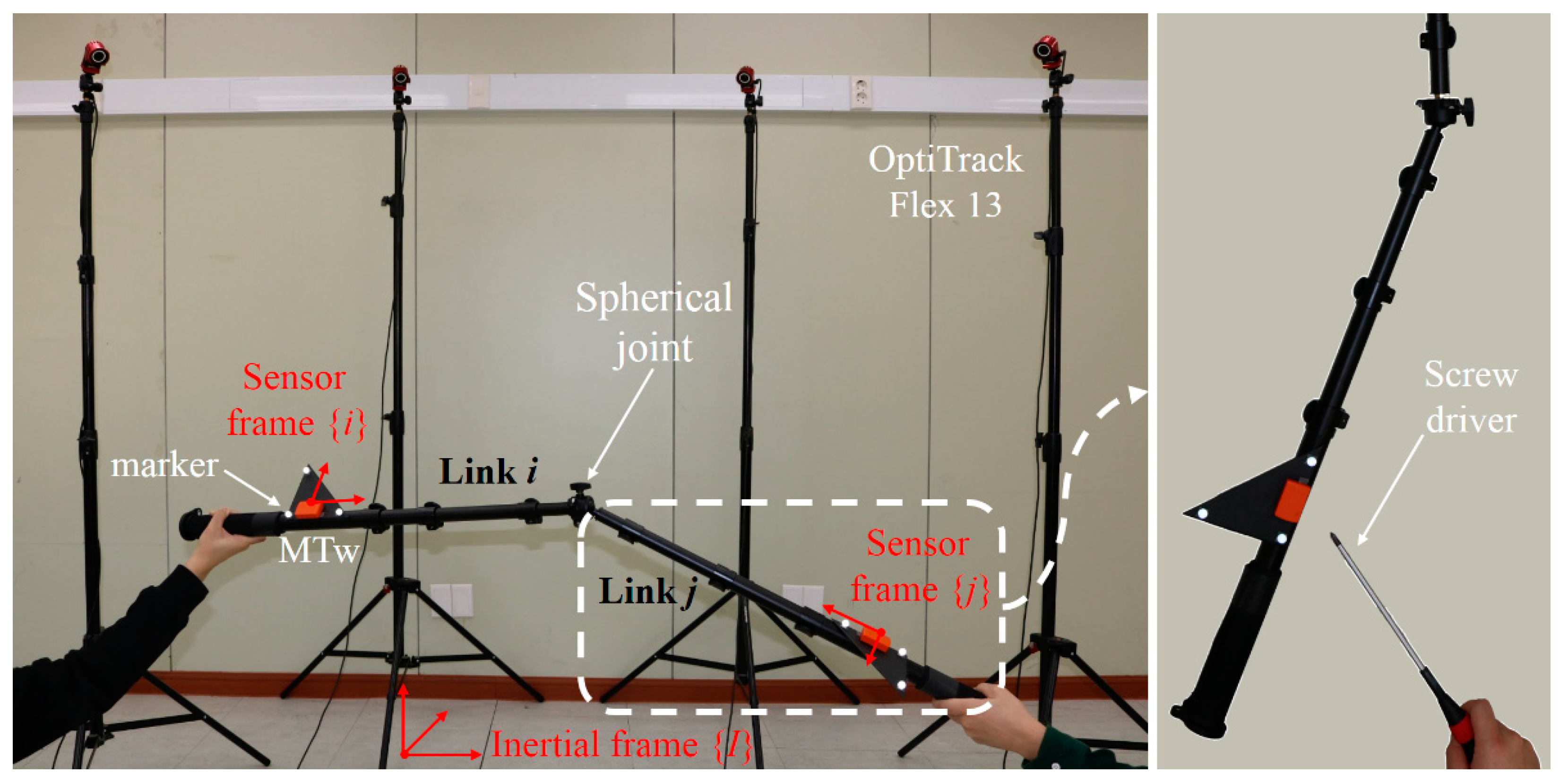

2.2. Validation

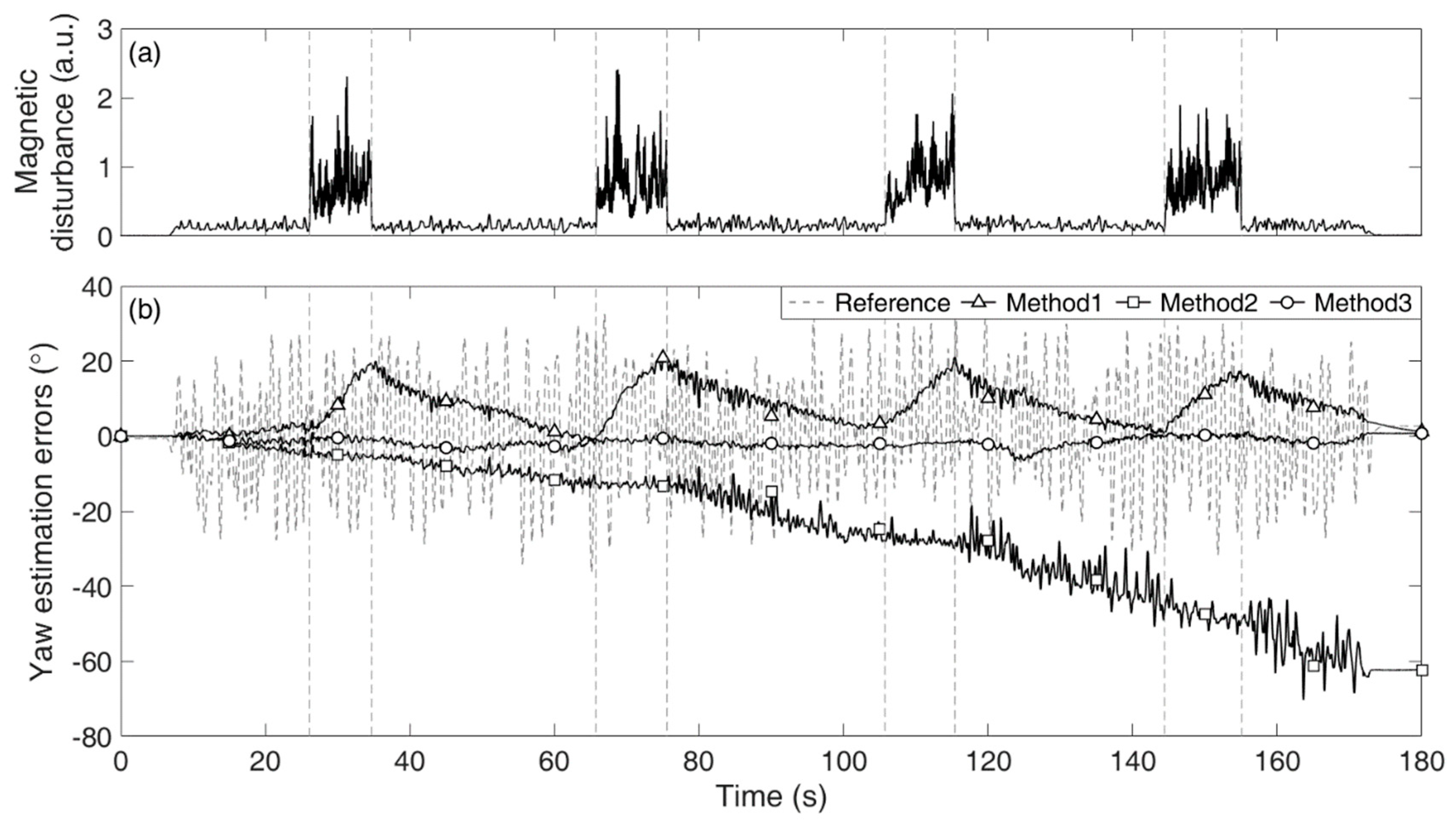

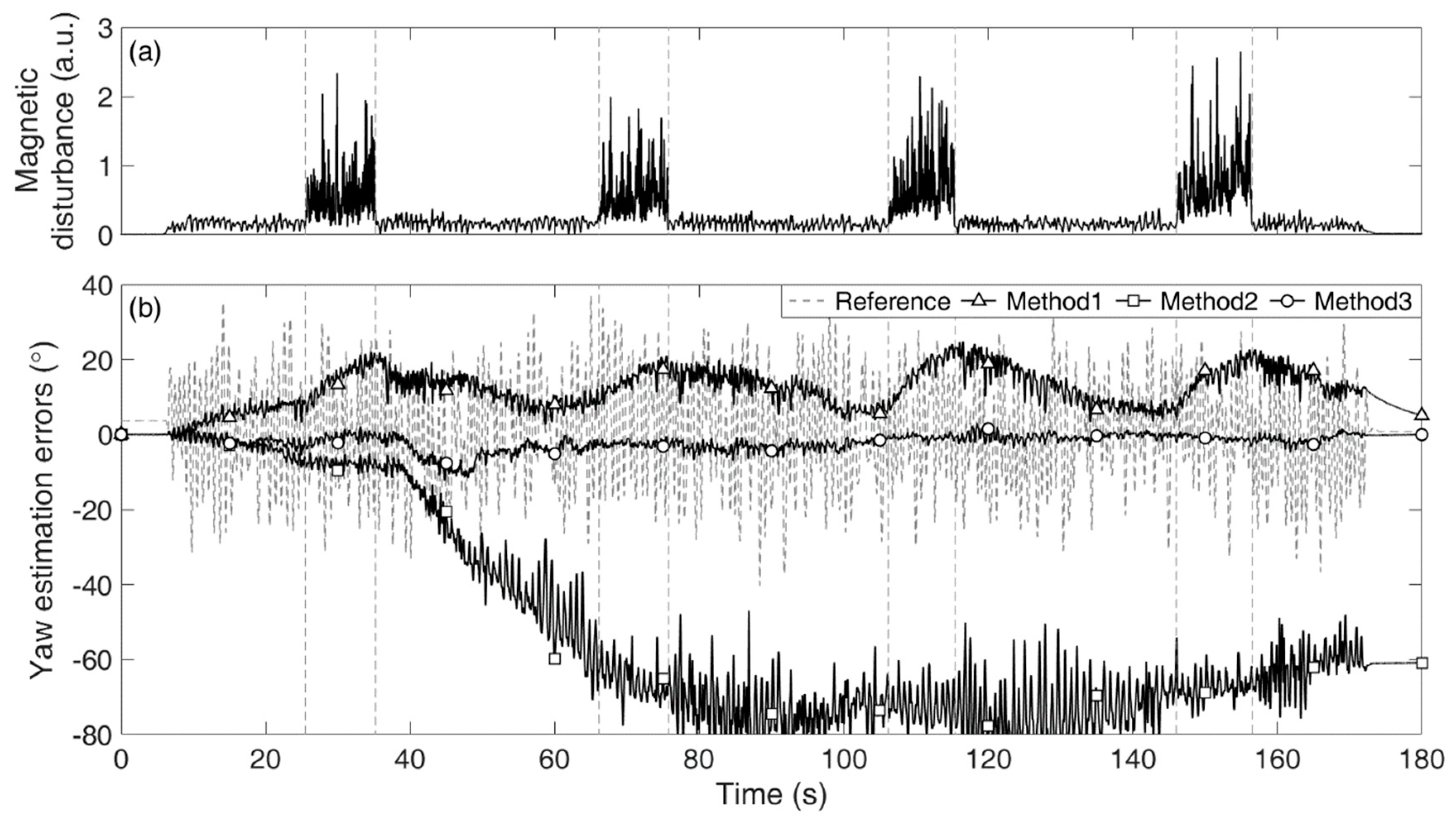

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Favre, J.; Jolles, B.M.; Aissaoui, R.; Aminian, K. Ambulatory measurement of 3D knee joint angle. J. Biomech. 2008, 41, 1029–1035. [Google Scholar] [CrossRef] [PubMed]

- Teufl, W.; Miezal, M.; Taetz, B.; Fröhlich, M.; Bleser, G. Validity, test-retest reliability and long-term stability of magnetometer free inertial sensor based 3D joint kinematics. Sensors 2018, 18, 1980. [Google Scholar] [CrossRef] [PubMed]

- Faisal, A.I.; Majumder, S.; Mondal, T.; Cowan, D.; Naseh, S.; Deen, M.J. Monitoring methods of human body joints: State-of-the-art and research challenges. Sensors 2019, 19, 2629. [Google Scholar] [CrossRef] [PubMed]

- Wolfgang, T.; Michael, L.; Markus, M.; Bertram, T.; Michael, F.; Gabriele, B. Towards Inertial Sensor Based Mobile Gait Analysis: Event-Detection and Spatio-Temporal Parameter. Sensors 2019, 19, 38. [Google Scholar]

- Kirking, B.; El-Gohary, M.; Kwon, Y. The feasibility of shoulder motion tracking during activities of daily living using inertial measurement units. Gait Posture 2016, 49, 47–53. [Google Scholar] [CrossRef] [PubMed]

- Bonato, P. Wearable sensors/systems and their impact on biomedical engineering. IEEE Eng. Med. Biol. Mag. 2003, 22, 18–20. [Google Scholar] [CrossRef]

- Seel, T.; Raisch, J.; Schauer, T. IMU-based joint angle measurement for gait analysis. Sensors 2014, 14, 6891–6909. [Google Scholar] [CrossRef]

- El-Gohary, M.; McNames, J. Shoulder and elbow joint angle tracking with inertial sensors. IEEE Trans. Biomed. Eng. 2012, 59, 2635–2641. [Google Scholar] [CrossRef]

- El-Gohary, M.; McNames, J. Human joint angle estimation with inertial sensors and validation with a robot arm. IEEE Trans. Biomed. Eng. 2015, 62, 1759–1767. [Google Scholar] [CrossRef]

- Vikas, V.; Crane, C.D. Joint angle measurement using strategically placed accelerometers and gyroscope. J. Mech. Robot. 2015, 8, 1–7. [Google Scholar] [CrossRef]

- Fasel, B.; Spörri, J.; Schütz, P.; Lorenzetti, S.; Aminian, K. Validation of functional calibration and strap-down joint drift correction for computing 3D joint angles of knee, hip, and trunk in alpine skiing. PLoS ONE 2017, 12, e0181446. [Google Scholar] [CrossRef] [PubMed]

- Laidig, D.; Schauer, T.; Seel, T. Exploiting Kinematic Constraints to Compensate Magnetic Disturbances When Calculating Joint Angles of Approximate Hinge Joints from Orientation Estimates of Inertial Sensors. In Proceedings of the 2017 IEEE International Conference on Rehabilitation Robotics (ICORR), London, UK, 17–20 July 2017; pp. 971–976. [Google Scholar]

- Muller, P.; Begin, M.; Schauer, T.; Seel, T. Alignment-free, self-calibrating elbow angles measurement using inertial sensors. IEEE J. Biomed. Health Inform. 2017, 21, 312–319. [Google Scholar] [CrossRef] [PubMed]

- O’Donovan, K.J.; Kamnik, R.; O’Keeffe, D.T.; Lyons, G.M. An inertial and magnetic sensor based technique for joint angle measurement. J. Biomech. 2007, 40, 2604–2611. [Google Scholar] [CrossRef] [PubMed]

- Picerno, P.; Cereatti, A.; Cappozzo, A. Joint kinematics estimate using wearable inertial and magnetic sensing modules. Gait Posture 2008, 28, 588–595. [Google Scholar] [CrossRef]

- Luinge, H.J.; Veltink, P.H.; Baten, C.T.M. Ambulatory measurement of arm orientation. J. Biomech. 2007, 40, 78–85. [Google Scholar] [CrossRef]

- Atrsaei, A.; Salarieh, H.; Alasty, A.; Abediny, M. Human arm motion tracking by inertial/magnetic sensors using unscented Kalman filter and relative motion constraint. J. Intell. Robot. Syst. 2017, 90, 161–170. [Google Scholar] [CrossRef]

- Fasel, B.; Sporri, J.; Chardonnens, J.; Kroll, J.; Muller, E.; Aminian, K. Joint inertial sensor orientation drift reduction for highly dynamic movements. IEEE J. Biomed. Health Inform. 2018, 22, 77–86. [Google Scholar] [CrossRef]

- Alonge, F.; Cucco, E.; D’Ippolito, F.; Pulizzotto, A. The use of accelerometers and gyroscopes to estimate hip and knee angles on gait analysis. Sensors 2014, 14, 8430–8446. [Google Scholar] [CrossRef]

- Saito, H.; Watanabe, T. Kalman-filtering-based joint angle measurement with wireless wearable sensor system for simplified gait analysis. IEICE Trans. Inf. Syst. 2011, 94, 1716–1720. [Google Scholar] [CrossRef]

- Brennan, A.; Zhang, J.; Deluzio, K.; Li, Q. Quantification of inertial sensor-based 3D joint angle measurement accuracy using an instrumented gimbal. Gait Posture 2011, 34, 320–323. [Google Scholar] [CrossRef]

- Nowka, D.; Kok, M.; Seel, T. On Motions that Allow for Identification of Hinge Joint Axes from Kinematic Constraints and 6D IMU Data. In Proceedings of the European Control Conference (ECC), Nice, France, 25–28 June 2019; p. 7. [Google Scholar]

- Filippeschi, A.; Schmitz, N.; Miezal, M.; Bleser, G.; Ruffaldi, E.; Stricker, D. Survey of motion tracking methods based on inertial sensors: A focus on upper limb human motion. Sensors 2017, 17, 1257. [Google Scholar] [CrossRef] [PubMed]

- Cheng, P.; Oelmann, B. Joint-angle measurement using accelerometers and gyroscopes—A survey. IEEE Trans. Instrum. Meas. 2010, 59, 404–414. [Google Scholar] [CrossRef]

- Cordillet, S.; Bideau, N.; Bideau, B.; Nicolas, G. Estimation of 3D knee joint angles during cycling using inertial sensors: Accuracy of a novel sensor-to-segment calibration procedure based on pedaling motion. Sensors 2019, 19, 2474. [Google Scholar] [CrossRef] [PubMed]

- Bachmann, E.R.; Yun, X.; Brumfield, A. Limitations of attitude estimation algorithms for inertial/magnetic sensor modules. IEEE Robot. Autom. Mag. 2007, 14, 76–87. [Google Scholar] [CrossRef]

- Slajpah, S.; Kamnik, R.; Munih, M. Compensation for magnetic disturbances in motion estimation to provide feedback to wearable robotic systems. IEEE Trans. Neural Syst. Rehabil. Eng. 2017, 25, 2398–2406. [Google Scholar] [CrossRef] [PubMed]

- Fan, B.; Li, Q.; Liu, T. How magnetic disturbance influences the attitude and heading in magnetic and inertial sensor-based orientation estimation. Sensors 2017, 18, 76. [Google Scholar] [CrossRef]

- Ligorio, G.; Sabatini, A. Dealing with magnetic disturbances in human motion capture: A survey of techniques. Micromachines 2016, 7, 43. [Google Scholar] [CrossRef]

- Sabatini, A.M. Quaternion-based extended Kalman filter for determining orientation by inertial and magnetic sensing. IEEE Trans. Biomed. Eng. 2006, 53, 1346–1356. [Google Scholar] [CrossRef]

- Lee, J.K.; Park, E.J. Minimum-order Kalman filter with vector selector for accurate estimation of human body orientation. IEEE Trans. Robot. 2009, 25, 1196–1201. [Google Scholar]

- Roetenberg, D.; Luinge, H.J.; Baten, C.T.M.; Veltink, P.H. Compensation of magnetic disturbances improves inertial and magnetic sensing of human body segment orientation. IEEE Trans. Neural Syst. Rehabil. Eng. 2005, 13, 395–405. [Google Scholar] [CrossRef]

- Sabatini, A.M. Variable-state-dimension Kalman-based filter for orientation determination using inertial and magnetic sensors. Sensors 2012, 12, 8491–8506. [Google Scholar] [CrossRef] [PubMed]

- Ligorio, G.; Sabatini, A.M. A Linear Kalman Filtering-Based Approach for 3D Orientation Estimation from Magnetic/Inertial Sensors. In Proceedings of the 2015 IEEE International Conference on Multisensor Fusion and Integration for Intelligent Systems (MFI), San Diego, CA, USA, 14–16 September 2015; pp. 77–82. [Google Scholar]

- Hu, J.S.; Sun, K.C. A robust orientation estimation algorithm using MARG sensors. IEEE Trans. Instrum. Meas. 2015, 64, 815–822. [Google Scholar]

- Miezal, M.; Taetz, B.; Bleser, G. On inertial body tracking in the presence of model calibration errors. Sensors 2016, 16, 1132. [Google Scholar] [CrossRef] [PubMed]

- Kok, M.; Hol, J.D.; Schoen, T.B. An Optimization-Based Approach to Human Body Motion Capture Using Inertial Sensors. In Proceedings of the 19th International Federation of Automatic Control World Congress, Cape Town, South Africa, 24–29 August 2014; pp. 79–85. [Google Scholar]

- Lee, J.K.; Choi, M.J. Robust inertial measurement unit-based attitude determination Kalman filter for kinematically constrained links. Sensors 2019, 19, 768. [Google Scholar] [CrossRef] [PubMed]

- Seel, T.; Schauer, T.; Raisch, J. Joint Axis and Position Estimation from Inertial Measurement Data by Exploiting Kinematic Constraints. In Proceedings of the 2012 IEEE International Conference on Control Applications, Dubrovnik, Croatia, 3–5 October 2012; pp. 45–49. [Google Scholar]

- Ligorio, G.; Sabatini, A.M. A novel Kalman filter for human motion tracking with an inertial-based dynamic inclinometer. IEEE Trans. Biomed. Eng. 2015, 62, 2033–2043. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.K.; Park, E.J.; Robinovitch, S.N. Estimation of attitude and external acceleration using inertial sensor measurement during various dynamic conditions. IEEE Trans. Instrum. Meas. 2012, 61, 2262–2273. [Google Scholar] [CrossRef]

- Park, S.K.; Suh, Y.S. A zero velocity detection algorithm using inertial sensors for pedestrian navigation systems. Sensors 2010, 10, 9163–9178. [Google Scholar] [CrossRef]

- Xu, Z.; Wei, J.; Zhang, B.; Yang, W. A robust method to detect zero velocity for improved 3D personal navigation using inertial sensors. Sensors 2015, 15, 7708–7727. [Google Scholar] [CrossRef]

| Acceleration of the Link i (m/s2) | Acceleration of the Link j (m/s2) | Disturbance of the Link j (a.u.) | ||||

|---|---|---|---|---|---|---|

| Mean | Max | Mean | Max | Mean | Max | |

| Test 1 | 1.28 | 8.22 | 1.30 | 6.11 | 0.23 | 2.60 |

| Test 2 | 2.14 | 14.05 | 1.87 | 11.50 | 0.27 | 2.41 |

| Test 3 | 5.56 | 37.09 | 4.69 | 18.54 | 0.25 | 2.65 |

| Roll | Pitch | Yaw | Average | ||

|---|---|---|---|---|---|

| Test 1 | Method 1 | 1.52 | 2.23 | 7.87 | 3.87 |

| Method 2 | 0.93 | 0.69 | 1.86 | 1.16 | |

| Method 3 | 1.16 | 0.56 | 1.10 | 0.94 | |

| Method 4 | 0.14 | 0.21 | 0.84 | 0.40 | |

| Test 2 | Method 1 | 1.48 | 3.81 | 9.16 | 4.82 |

| Method 2 | 6.19 | 9.76 | 31.56 | 15.84 | |

| Method 3 | 1.53 | 0.86 | 1.99 | 1.46 | |

| Method 4 | 0.35 | 0.75 | 1.87 | 0.99 | |

| Test 3 | Method 1 | 3.51 | 6.06 | 12.77 | 7.45 |

| Method 2 | 14.68 | 19.83 | 58.03 | 30.84 | |

| Method 3 | 2.65 | 1.49 | 2.86 | 2.33 | |

| Method 4 | 0.47 | 0.96 | 2.23 | 1.22 |

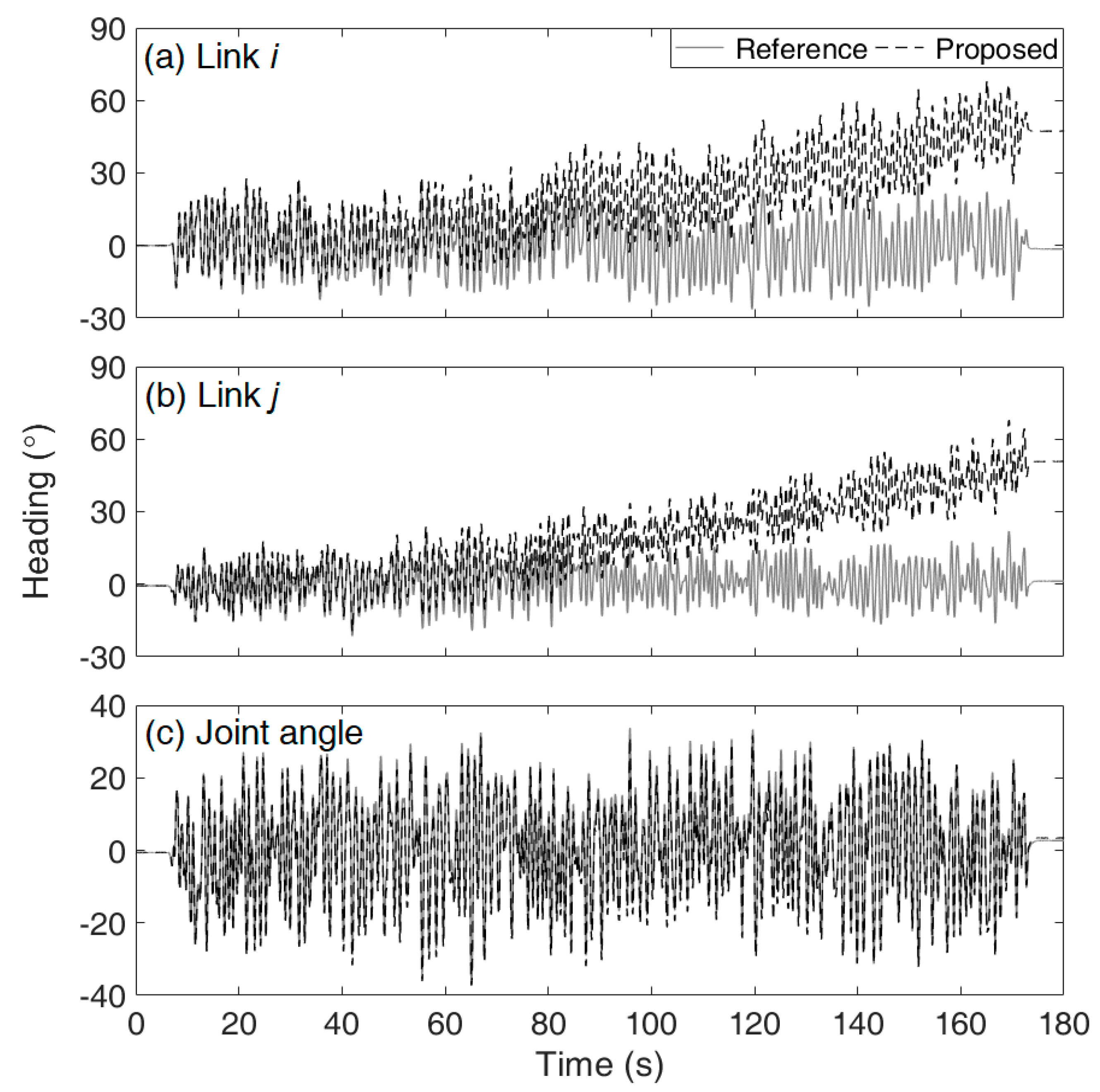

| Link i | Link j | Joint Angle | |

|---|---|---|---|

| Test 1 | 0.59 | 1.53 | 1.10 |

| Test 2 | 26.01 | 25.09 | 1.99 |

| Test 3 | 65.54 | 64.29 | 2.86 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.K.; Jeon, T.H. Magnetic Condition-Independent 3D Joint Angle Estimation Using Inertial Sensors and Kinematic Constraints. Sensors 2019, 19, 5522. https://doi.org/10.3390/s19245522

Lee JK, Jeon TH. Magnetic Condition-Independent 3D Joint Angle Estimation Using Inertial Sensors and Kinematic Constraints. Sensors. 2019; 19(24):5522. https://doi.org/10.3390/s19245522

Chicago/Turabian StyleLee, Jung Keun, and Tae Hyeong Jeon. 2019. "Magnetic Condition-Independent 3D Joint Angle Estimation Using Inertial Sensors and Kinematic Constraints" Sensors 19, no. 24: 5522. https://doi.org/10.3390/s19245522

APA StyleLee, J. K., & Jeon, T. H. (2019). Magnetic Condition-Independent 3D Joint Angle Estimation Using Inertial Sensors and Kinematic Constraints. Sensors, 19(24), 5522. https://doi.org/10.3390/s19245522