Relative Humidity Sensors Based on Microfiber Knot Resonators—A Review

Abstract

1. Introduction

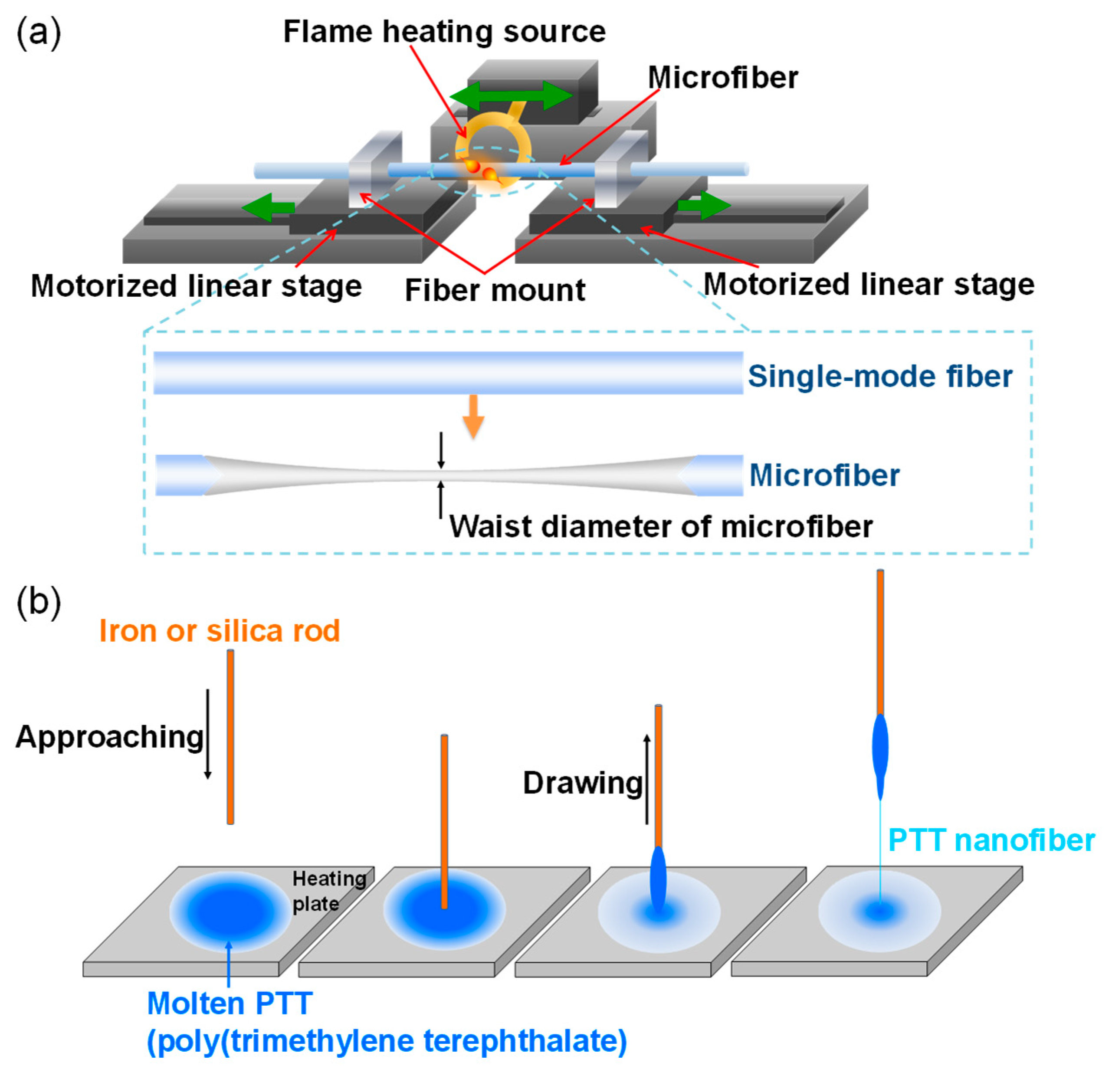

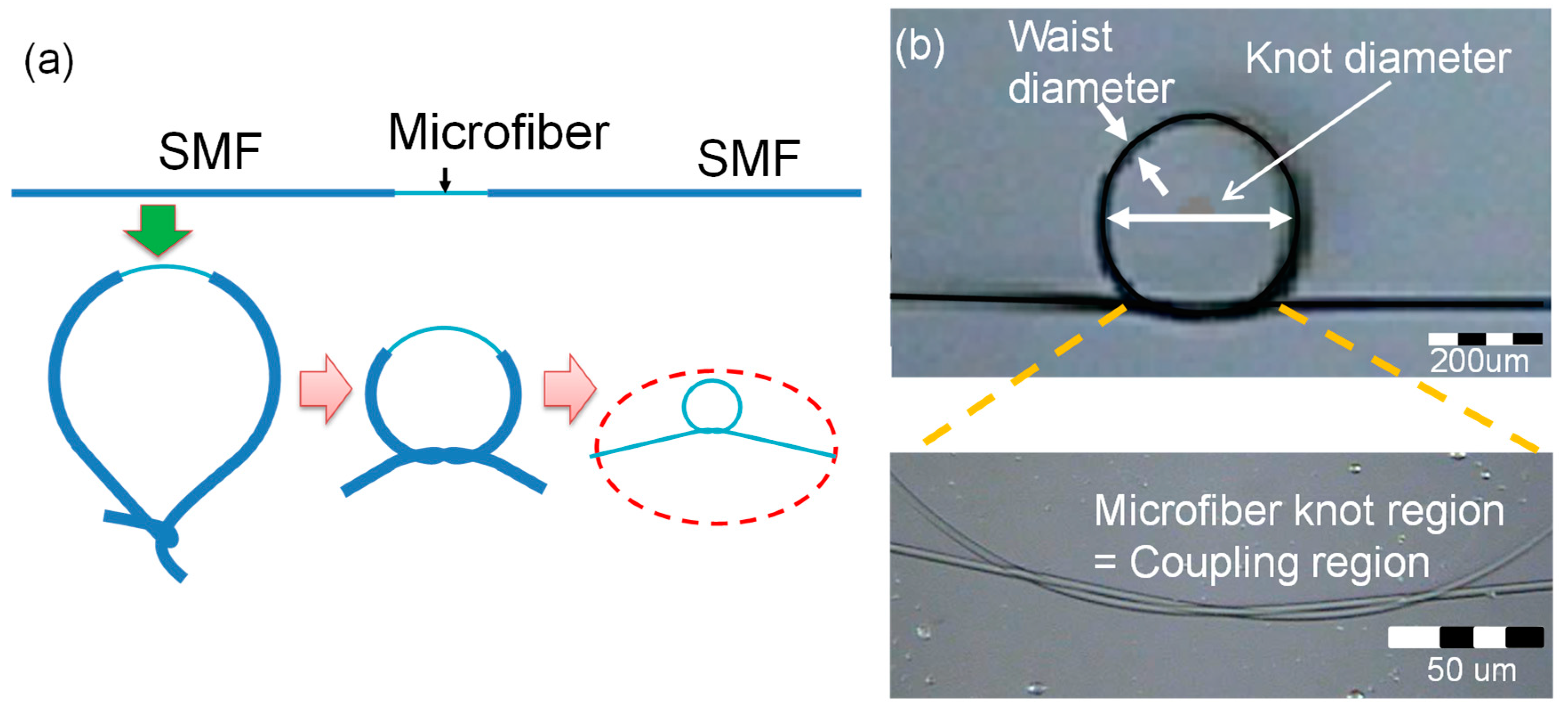

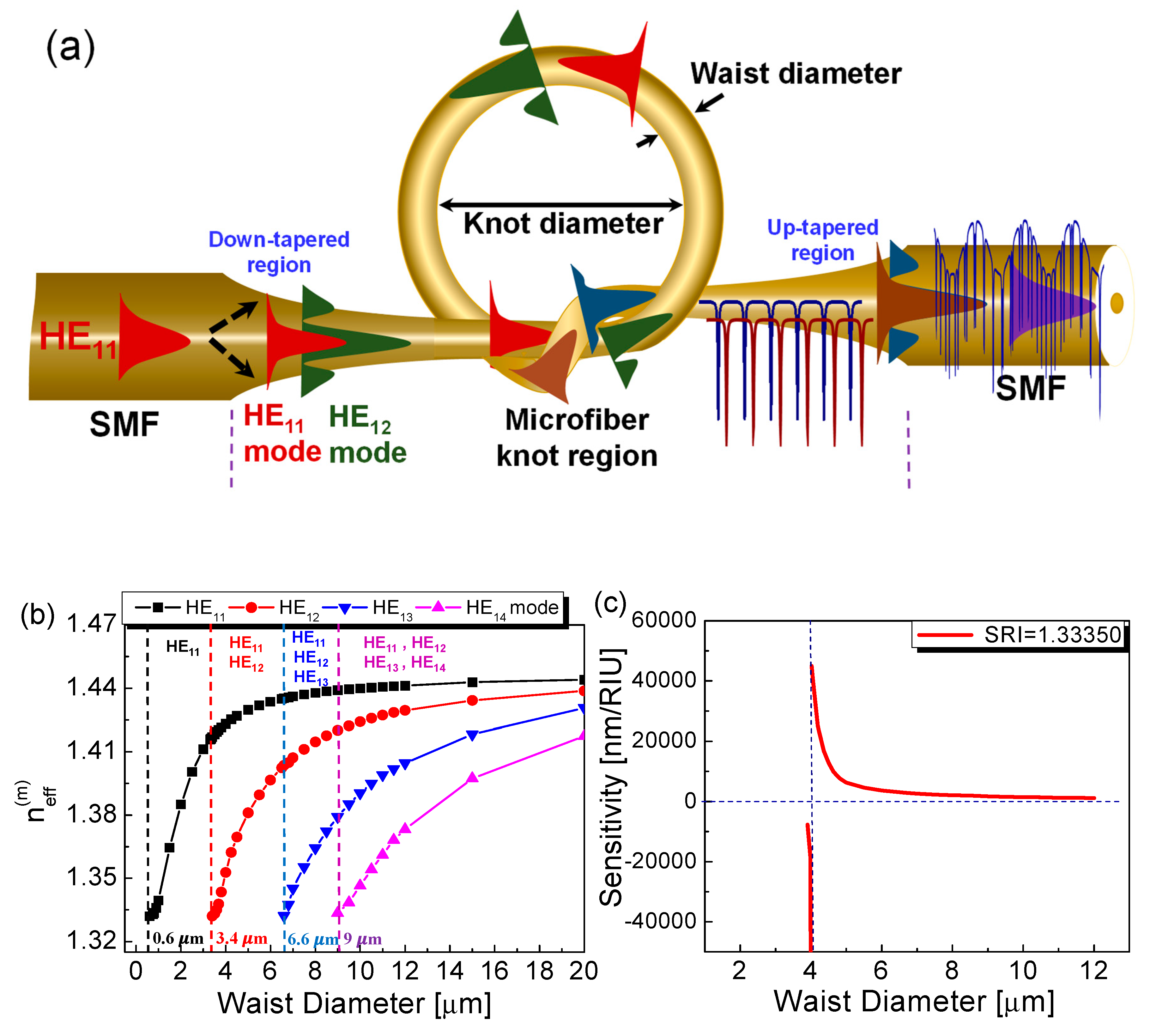

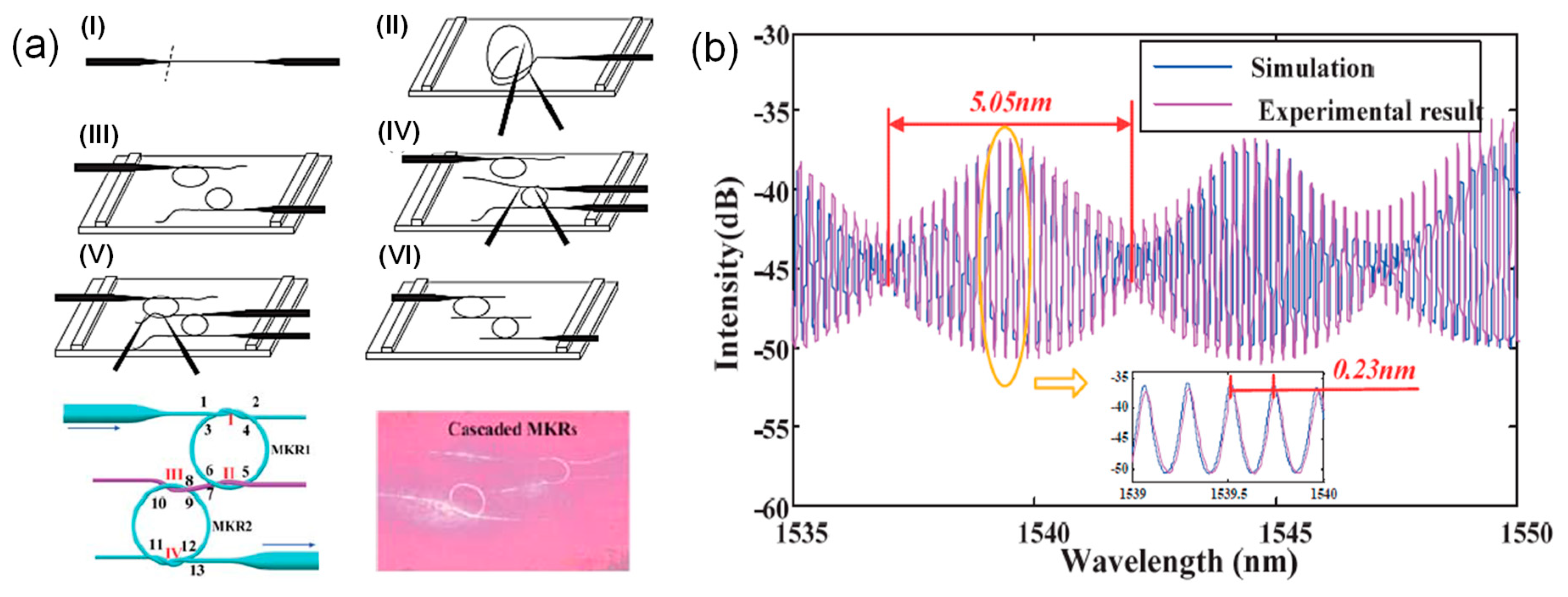

2. Fabrication, Operating Principle, and Supplementary Method for Improving the Ambient Index Sensitivity of the MKR

3. Relative Humidity Sensors Based on MKRs with Sensitive Materials

4. Conclusions

Funding

Conflicts of Interest

References

- Jiang, X.; Tong, L.; Vienne, G.; Guo, X.; Tsao, A.; Yang, Q.; Yang, D. Demonstration of optical microfiber knot resonators. Appl. Phys. Lett. 2006, 88, 223501. [Google Scholar] [CrossRef]

- Birks, T.A.; Li, Y.W. The shape of fiber tapers. J. Light. Technol. 1992, 10, 432–438. [Google Scholar] [CrossRef]

- Donlagic, D. In-line higher order mode filters based on long highly uniform fiber tapers. J. Light. Technol. 2006, 24, 3532–3539. [Google Scholar] [CrossRef]

- Brambilla, G. Optical fibre nanowires and microwires: A review. J. Opt. 2010, 12, 043001. [Google Scholar] [CrossRef]

- Sumetsky, M.; Dulashko, Y.; Hale, A. Fabrication and study of bent and coiled free silica nanowires: Self-coupling microloop optical interferometer. Opt. Express 2004, 12, 3521–3531. [Google Scholar] [CrossRef] [PubMed]

- Shi, L.; Chen, X.; Liu, H.; Chen, Y.; Ye, Z.; Liao, W.; Xia, Y. Fabrication of submicron-diameter silica fibers using electric strip heater. Opt. Express 2006, 14, 5055–5060. [Google Scholar] [CrossRef]

- Guo, X.; Ying, Y.; Tong, L. Photonic nanowires: From subwavelength waveguides to optical sensors. Acc. Chem. Res. 2014, 47, 656–666. [Google Scholar] [CrossRef]

- Li, J.H.; Chen, J.H.; Xu, F. Sensitive and wearable optical microfiber sensor for human health monitoring. Adv. Mater. Technol. 2018, 3, 1800296. [Google Scholar] [CrossRef]

- Lu, H.; Tao, J.; Chen, L.; Li, Y.; Liu, L.; Dong, H.; Dong, J.; Qiu, W.; Zhu, W.; Yu, J.; et al. All-optical tuning of micro-resonator overlaid with MoTe2 nanosheets. J. Light. Technol. 2019, 37, 3637–3646. [Google Scholar] [CrossRef]

- Meng, Y.; Deng, L.; Liu, Z.; Xiao, H.; Guo, X.; Liao, M.; Guo, A.; Ying, T.; Tian, Y. All-optical tunable microfiber knot resonator with graphene-assisted sandwich structure. Opt. Express 2017, 25, 18451–18461. [Google Scholar] [CrossRef]

- Wang, Y.; Gan, Z.; Zhao, C.; Fang, L.; Mao, D.; Zu, Y.; Zhang, F.; Zi, T.; Ren, L.; Zhao, J. All-optical control of microfiber resonator by graphene’s photothermal effect. Appl. Phys. Lett. 2016, 108, 171905. [Google Scholar] [CrossRef]

- Yi, Y.; Jiang, Y.; Lewis, E.; Brambilla, G.; Wang, P. Optical interleaver based on nested multiple knot microfiber resonators. Opt. Lett. 2019, 44, 1864–1867. [Google Scholar] [CrossRef]

- Tong, L.; Gattass, R.R.; Ashcom, J.B.; He, S.; Lou, J.; Shen, M.; Maxwell, I.; Mazur, E. Subwavelength-diameter silica wires for low-loss optical wave guiding. Nature 2003, 426, 816–819. [Google Scholar] [CrossRef] [PubMed]

- Lou, J.; Wang, Y.; Tong, L. Microfiber optical sensors: A Review. Sensors 2014, 14, 5852. [Google Scholar]

- Li, J.; Gai, L.; Li, H.; Hu, H. A high sensitivity temperature sensor based on packaged microfiber knot resonator. Sens. Actuators B Chem. 2017, 263, 369–372. [Google Scholar] [CrossRef]

- Fan, R.; Yang, J.; Li, J.; Meng, F. Temperature measurement using a microfiber knot ring encapsulated in PDMS. Phys. Scr. 2019, 94, 125706. [Google Scholar] [CrossRef]

- Li, J.; Yang, J.; Ma, J. Load sensing of a microfiber knot ring (MKR) encapsulated in polydimethylsiloxane (PDMS). Instrum. Sci. Technol. 2019, 47, 511–521. [Google Scholar] [CrossRef]

- Dass, S.; Jah, R. Square knot resonator-based compact bending sensor. IEEE Photon. Technol. Lett. 2018, 30, 1649–1652. [Google Scholar] [CrossRef]

- Ly, Y.; Pu, S.; Zhao, Y.; Yao, T. Fiber-optic magnetic field sensing based on microfiber knot resonator with magnetic fluid cladding. Sensors 2018, 18, 4358. [Google Scholar]

- Liao, Y.; Wang, J.; Yang, H.; Wang, X.; Wang, S. Salinity sensing based on microfiber knot resonator. Sens. Actuators A Phys. 2015, 233, 22–25. [Google Scholar] [CrossRef]

- Eryürek, M.; Karadag, Y.; Tasaltın, N.; Kilinc, N.; Kiraz, A. Optical sensor for hydrogen gas based on a palladium-coated polymer microresonator. Sens. Actuators B Chem. 2015, 212, 78–83. [Google Scholar] [CrossRef]

- Wu, X.; Gu, F.; Zeng, H. Palladium-coated silica microfiber knots for enhanced hydrogen sensing. IEEE Photon. Technol. Lett. 2015, 27, 1228–1231. [Google Scholar]

- Lim, K.S.; Harun, S.W.; Damanhuri, S.S.A.; Jasim, A.A.; Tio, C.K.; Ahmad, H. Current sensor based on microfiber knot resonator. Sens. Actuators A Phys. 2011, 167, 60–62. [Google Scholar] [CrossRef]

- Available online: https://www.mordorintelligence.com/industry-reports/global-automotive-temperature-and-humidity-sensors-market-industry (accessed on 27 November 2019).

- Leone, M.; Principe, S.; Consales, M.; Parente, R.; Laudati, A.; Caliro, S.; Cutolo, A.; Cusano, A. Fiber optic thermo-hygrometers for soil moisture monitoring. Sensors 2017, 17, 1451. [Google Scholar] [CrossRef] [PubMed]

- Chavanne, X.; Frangi, J.P. Autonomous sensors for measuring continuously the moisture and salinity of a porous medium. Sensors 2017, 17, 1094. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Wang, S.; Wang, X.; Wang, J.; Liap, Y. Temperature sensing in seawater based on microfiber knot resonator. Sensors 2014, 14, 18515. [Google Scholar] [CrossRef]

- Pang, Y.; Jian, J.; Tu, T.; Yang, Z.; Ling, J.; Li, Y.; Wang, X.; Qiao, Y.; Tian, H.; Yang, Y.; et al. Wearable humidity sensor based on porous graphene network for respiration monitoring. Biosens. Bioelectron. 2018, 116, 123–129. [Google Scholar] [CrossRef]

- Le, A.D.D.; Han, Y.G. Relative humidity sensor based on a few-mode microfiber knot resonator by mitigating the group index difference of a few-mode microfiber. J. Light. Technol. 2018, 36, 904–909. [Google Scholar] [CrossRef]

- Shin, J.C.; Yoon, M.S.; Han, Y.G. Relative humidity sensor based on an optical microfiber knot resonator with a polyvinyl alcohol overlay. J. Light. Technol. 2016, 34, 4511–4515. [Google Scholar] [CrossRef]

- Xing, X.; Wang, Y.; Li, B. Nanofiber drawing and nanodevice assembly in poly (trimethylene terephthalate). Opt. Express 2008, 16, 10815–10822. [Google Scholar] [CrossRef]

- Luo, H.; Sun, Q.; Li, X.; Yan, Z.; Li, Y.; Liu, D.; Zhang, Y. Refractive index sensitivity characteristics near the dispersion turning point of the multimode microfiber-based Mach-Zehnder interferometer. Opt. Lett. 2015, 40, 5042–5045. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Sun, Q.; Li, B.; Luo, Y.; Lu, W.; Liu, D.; Shum, P.P.; Zhang, L. Highly sensitive refractive index sensor based on cascaded microfiber knots with Vernier effect MKR humidity sensor. Opt. Express 2015, 23, 6662–6672. [Google Scholar] [CrossRef] [PubMed]

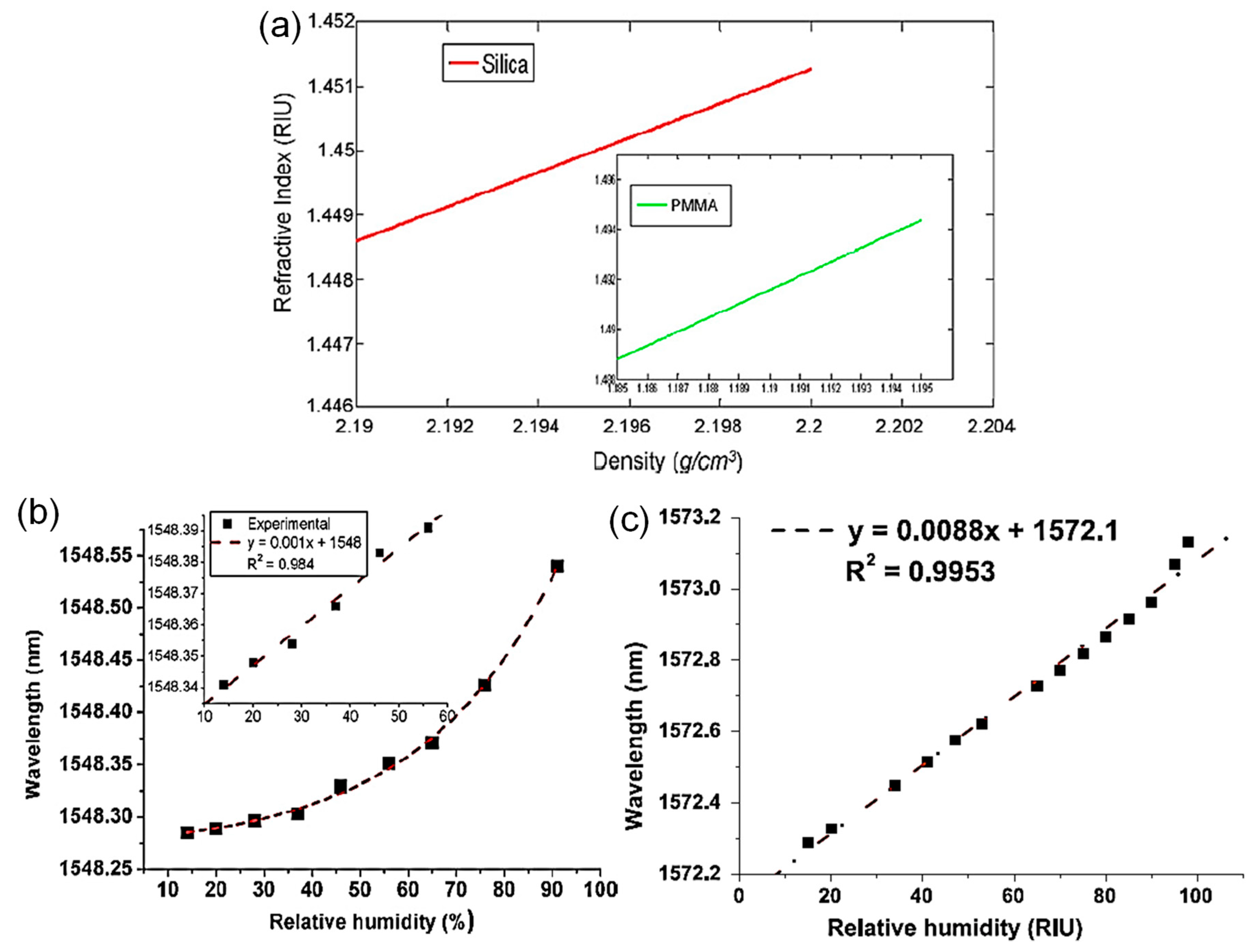

- Wu, Y.; Zhang, T.; Rao, Y.; Gong, Y. Miniature interferometric humidity sensors based on silica/polymer microfiber knot resonators. Sens. Actuators B Chem. 2011, 155, 258–263. [Google Scholar] [CrossRef]

- Xu, K.; Li, H.; Liu, Y.; Wang, Y.; Tian, J.; Wang, L.; Du, J.; He, Z.; Song, A. Optical fiber humidity sensor based on water absorption peak near 2-μm waveband. IEEE Photon. J. 2019, 11, 7101308. [Google Scholar] [CrossRef]

- Gouveia, M.A.; Pellegrini, P.E.S.; Santos, J.S.; Raimundo, I.M.; Cordeiro, C.M.B. Analysis of immersed silica optical microfiber knot resonator and its application as a moisture sensor. Appl. Opt. 2014, 53, 7454–7461. [Google Scholar] [CrossRef] [PubMed]

- Sasikumar, G.; Ihm, J.W.; Ryu, H. Optimum Nafion content in PEM fuel cell electrodes. Electrochim. Acta 2004, 50, 601–605. [Google Scholar] [CrossRef]

- Omosebi, A.; Besser, R.S. Electron beam assisted patterning and dry etching of Nafion membranes. J. Electrochem. Soc. 2011, 158, 603–610. [Google Scholar] [CrossRef]

- Liu, S.Q.; Ji, Y.K.; Yang, J.; Sun, W.M.; Li, H.Y. Nafion film temperature/humidity sensing based on optical fiber Fabry-Perot interference. Sens. Actuators A Phys. 2018, 269, 313–321. [Google Scholar] [CrossRef]

- Jin, X.L.; Li, W.; Sun, D.; Zhuang, Z.; Wang, X. Fabrication of relative humidity optical fiber sensor based on Nafion-crystal violet sensing film. Spectrosc. Spectr. Anal. 2005, 25, 1328–1331. [Google Scholar]

- Santos, J.S.; Raimundo, I.M., Jr.; Cordeiro, C.M.B.; Biazolib, C.R.; Gouveia, C.A.J.; Jorge, P.A.S. Characterization of a Nafion film by optical fiber Fabry–Perot interferometry for humidity sensing. Sens. Actuators B Chem. 2014, 196, 99–105. [Google Scholar] [CrossRef]

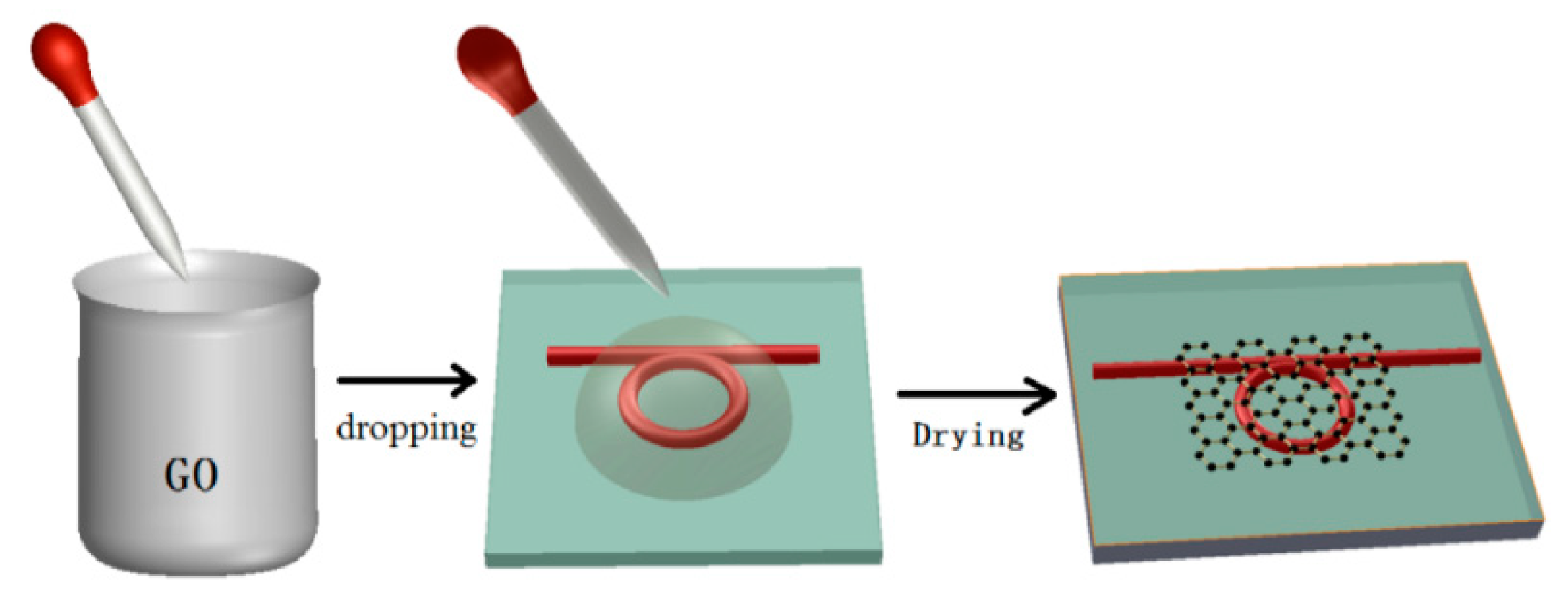

- Azzuhria, S.R.; Amiri, I.S.; Zulkhairi, A.S.; Salimd, M.A.M.; Razak, M.Z.A.; Khyasudeen, M.F.; Ahmad, H.; Zakariad, R.; Yupapin, P. Application of graphene oxide based microfiber-knot resonator for relative humidity sensing. Results Phys. 2018, 9, 1572–1577. [Google Scholar] [CrossRef]

- Yu, C.B.; Wu, Y.; Liu, X.L.; Yao, B.C.; Fu, F.; Gong, Y.; Rao, Y.J.; Chen, Y.F. Graphene oxide deposited microfiber knot resonator for gas sensing. Opt. Mater. Express. 2016, 6, 727–733. [Google Scholar] [CrossRef]

- Dash, J.N.; Hegi, N.; Jha, R. Graphene oxide coated PCF interferometer for enhanced strain sensitivity. J. Light. Technol. 2017, 35, 5385–5390. [Google Scholar] [CrossRef]

- Wang, M.; Li, D.; Wang, R.; Zhu, J.; Ren, Z. PDMS-assisted graphene microfiber ring resonator for temperature sensor. Opt. Quantum Electron. 2018, 50, 132. [Google Scholar] [CrossRef]

- Fu, H.; Jiang, Y.; Ding, J.; Zhang, J.; Zhang, M.; Zhu, Y.; Li, H. Zinc oxide nanoparticle incorporated graphene oxide as sensing coating for interferometric optical microfiber for ammonia gas detection. Sens. Actuators B Chem. 2018, 254, 239–247. [Google Scholar] [CrossRef]

- Xing, Z.; Zheng, Y.; Yan, Z.; Feng, Y.; Xiao, Y.; Yu, J.; Guan, H.; Luo, Y.; Wang, Z.; Zhong, Y.; et al. High-sensitivity humidity sensing of microfiber coated with three-dimensional graphene network. Sens. Actuators B Chem. 2019, 281, 953–959. [Google Scholar] [CrossRef]

- Gastón, A.; Pérez, F.; Sevilla, J. Optical fiber relative-humidity sensor with polyvinyl alcohol film. Appl Opt. 2004, 43, 4127–4132. [Google Scholar] [CrossRef]

- Wu, S.; Yan, G.; Lian, Z.; Chen, X.; Zhou, B.; He, S. An open-cavity Fabry-Perot interferometer with PVA coating for simultaneous measurement of relative humidity and temperature. Sens. Actuators B Chem. 2016, 225, 50–56. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Zou, F.; Jiang, C.; Mou, C.; Wang, T. Humidity sensor based on a long-period fiber grating coated with polymer composite film. Sensors 2019, 19, 2263. [Google Scholar] [CrossRef]

- Peng, Y.; Zhao, P.; Hu, X.G.; Chen, M.Q. Humidity sensor based on unsymmetrical U-shaped twisted microfiber coupler with wide detection range. Sens. Actuators B Chem. 2019, 290, 406–413. [Google Scholar] [CrossRef]

- Zhao, Y.; Peng, Y.; Chen, M.-Q.; Xia, F.; Tong, R.-J. U-shaped microfiber coupler coated with polyvinyl alcohol film for highly sensitive humidity detection. Sens. Actuators A Phys. 2019, 285, 628–636. [Google Scholar] [CrossRef]

- Liu, Y.; Deng, H.; Yuan, L. A novel polyvinyl alcohol and hypromellose gap-coated humidity sensor based on a Mach– Zehnder interferometer with off-axis spiral deformation. Sens. Actuators B Chem. 2019, 284, 323–329. [Google Scholar] [CrossRef]

- Zhao, Y.; Tong, R.J.; Chen, M.Q.; Xia, F. Relative humidity sensor based on hollow core fiber filled with GQDs-PVA. Sens. Actuators B Chem. 2019, 284, 96–102. [Google Scholar] [CrossRef]

- Faruki, M.J.; Ab Razak, M.Z.; Azzuhri, S.R.; Rahman, M.T.; Soltanian, M.R.K.; Brambilla, G.; Azizur Rahman, B.M.; Grattan, K.T.V.; Rue, R.D.L.; Ahmad, H. Effect of titanium dioxide (TiO2) nanoparticle coating on the detection performance of microfiber knot resonator sensors for relative humidity measurement. Mater. Express 2016, 6, 501–508. [Google Scholar] [CrossRef]

- Aneesh, R.; Khijwania, S.K. Titanium dioxide nanoparticle based optical fiber humidity sensor with linear response and enhanced sensitivity. Appl. Opt. 2012, 51, 2164–2171. [Google Scholar] [CrossRef] [PubMed]

- Peng, Y.; Zhao, Y.; Chen, M.Q.; Xia, F. Research advances in microfiber humidity sensors. Small 2018, 14, 1800524. [Google Scholar] [CrossRef]

- Yusoff, S.F.A.Z.; Lim, C.S.; Azzuhri, S.R.; Ahmad, H.; Zakaria, R. Studies of Ag/TiO2 plasmonics structures integrated in side polished optical fiber used as humidity sensor. Results Phys. 2018, 10, 308–316. [Google Scholar] [CrossRef]

- Chen, Z.; Lu, C. Humidity sensors: A review of materials and mechanisms. Sensor Lett. 2005, 3, 274–295. [Google Scholar] [CrossRef]

| Authors/Publication Year | Sensor Type | Waist Diameter of Microfiber | Knot Diameter of MKR | Sensitive Material | Sensitivity | Resolution/Accuracy | Response Time |

|---|---|---|---|---|---|---|---|

| Wavelength | |||||||

| J. Li et al./ 2017 [15] | Temperature | Not Available | 4.5 mm | Poly- Dimethylsiloxane (PDMS) | 1.408 nm/°C for 24–38 °C 0.973 nm/°C for 40–54 °C | 0.014 °C | Not Available |

| R. Fan et al./ 2019 [16] | Temperature | 8.6 μm | 4.5 mm | w/o Poly- Dimethylsiloxane (PDMS) | 183 pm/°C w/o PDMS | Not Available | Not Available |

| Poly- Dimethylsiloxane (PDMS) | 1.67 nm/°C w PDMS | 15 s | |||||

| J. Li et al./ 2018 [17] | Load | 6.92 μm | 6.0 mm | w/o Poly- Dimethylsiloxane (PDMS) | 6 pm/N w/o PDMS | Not Available | Not Available |

| 7.2 μm | 4.0 mm | Poly- Dimethylsiloxane (PDMS) | 90 pm/N w PDMS | 0.38 N | Not Available | ||

| S. Dass et al./ 2018 [18] | Bending | 16 μm | 885 μm | None | 3.04 nm/m−1 | 3.29 × 10−3 m−1 | Not Available |

| Y. Ly et al./ 2018 [19] | Magnetic Field | 4.0 μm | 155 μm | Water-Based Magnetic Fluid | 277 pm/mT | 0.07 mT (Accuracy) | Not Available |

| Y. Liao et al./ 2015 [20] | Salinity | 2.5 μm | 855 μm | None | 21.18 pm/%o | Not Available | Not Available |

| X. Wu et al./ 2015 [22] | Hydrogen | 2.98 μm | 7.25 mm | Palladium (Pd) | Not Available | Not Available | Not Available |

| K. S. Lim et al./ 2011 [23] | Current | 2.0 μm | 185 μm | None | 51.3 pm/A2 | Not Available | 3 s |

| Authors/Publication Year | MKR Material | Waist Diameter of Microfiber | Knot Diameter of MKR | Humidity-Sensitive Material | Sensitivity | Resolution (*RH: Relative Humidity) | Response Time | |

|---|---|---|---|---|---|---|---|---|

| Wavelength | Transmission Power | |||||||

| Y. Wu et al./2011 [34] | Silica MKR | 1.2 μm | 500 μm | Not Available | ~12 pm/10% RH | Not Available | 0.017% RH | Not Available |

| Polymer MKR | 2.1 μm | 500 μm | Not Available | ~88 pm/10% RH | Not Available | 0.0023% RH | ~0.5 s | |

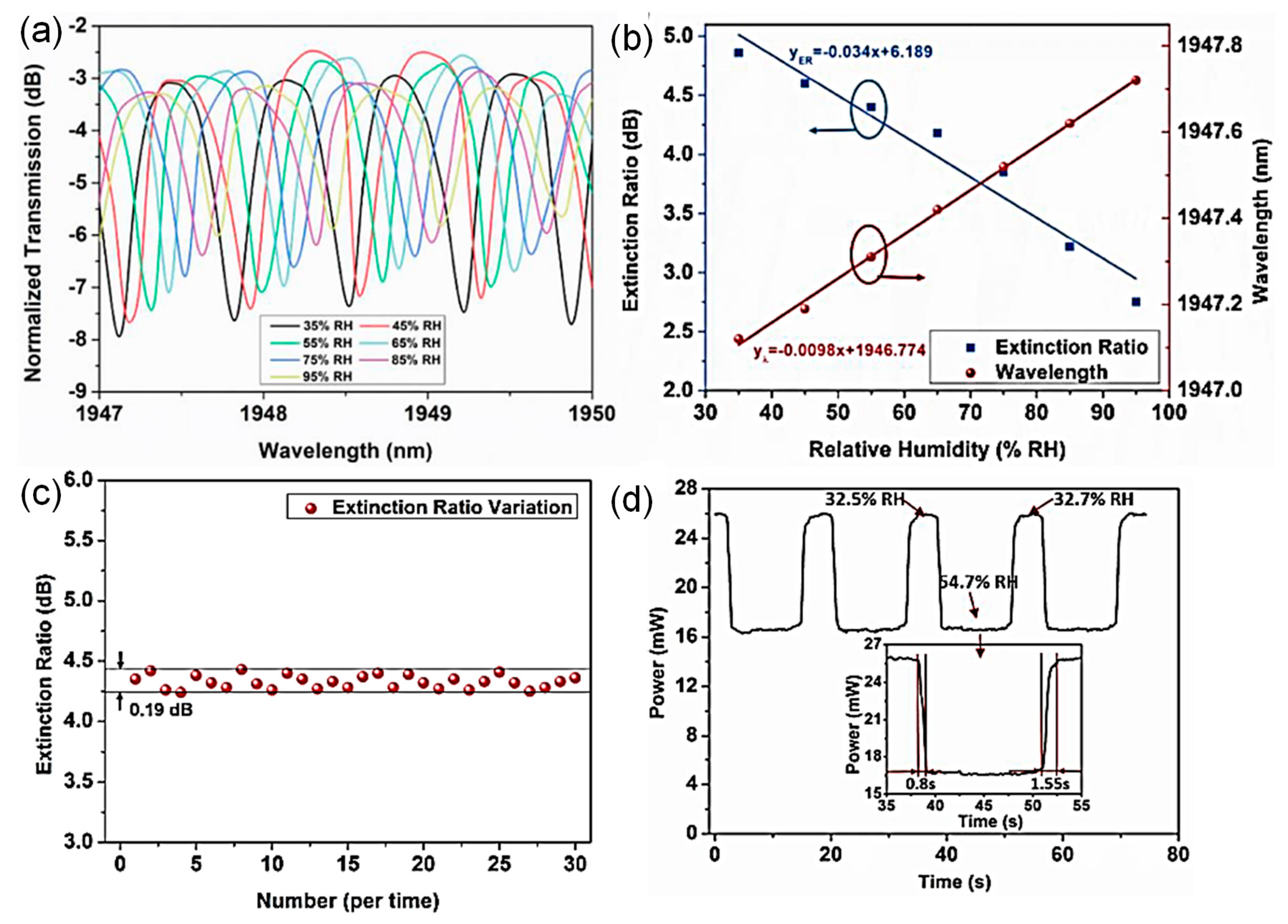

| K. Xu et al./2019 [35] | Silica MKR at 2-mm Waveband | 1 μm | 395 μm | Not Available | ~10 pm/% RH | 0.034 dB/% RH | Not Available | Rising: ~0.8 s Falling: ~1.55 s |

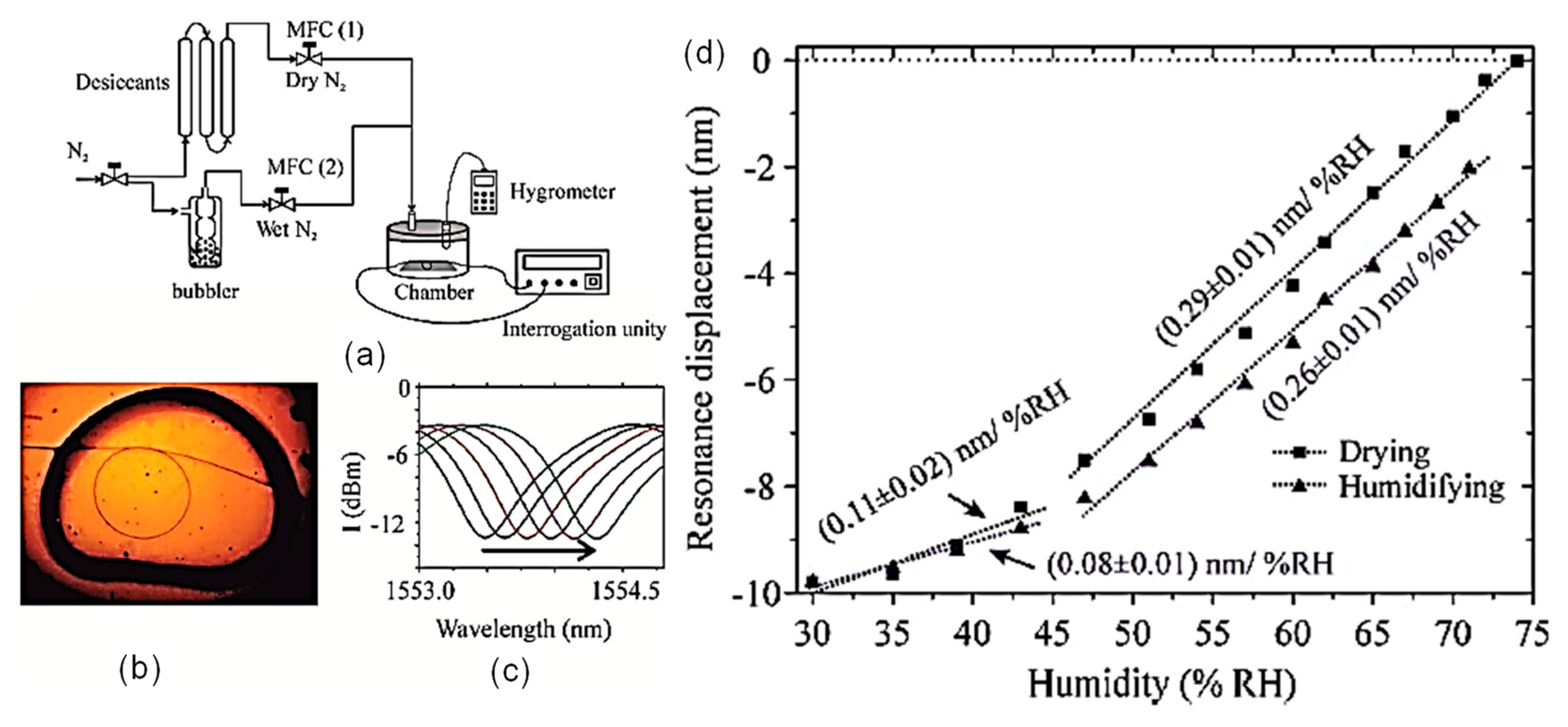

| M. Gouveia/2014 [36] | Silica MKR | 3 μm | 250 μm | Nafion | 0.11 nm/% RH for low RH 0.29 nm/% RH for High RH | Not Available | Not Available | Not Available |

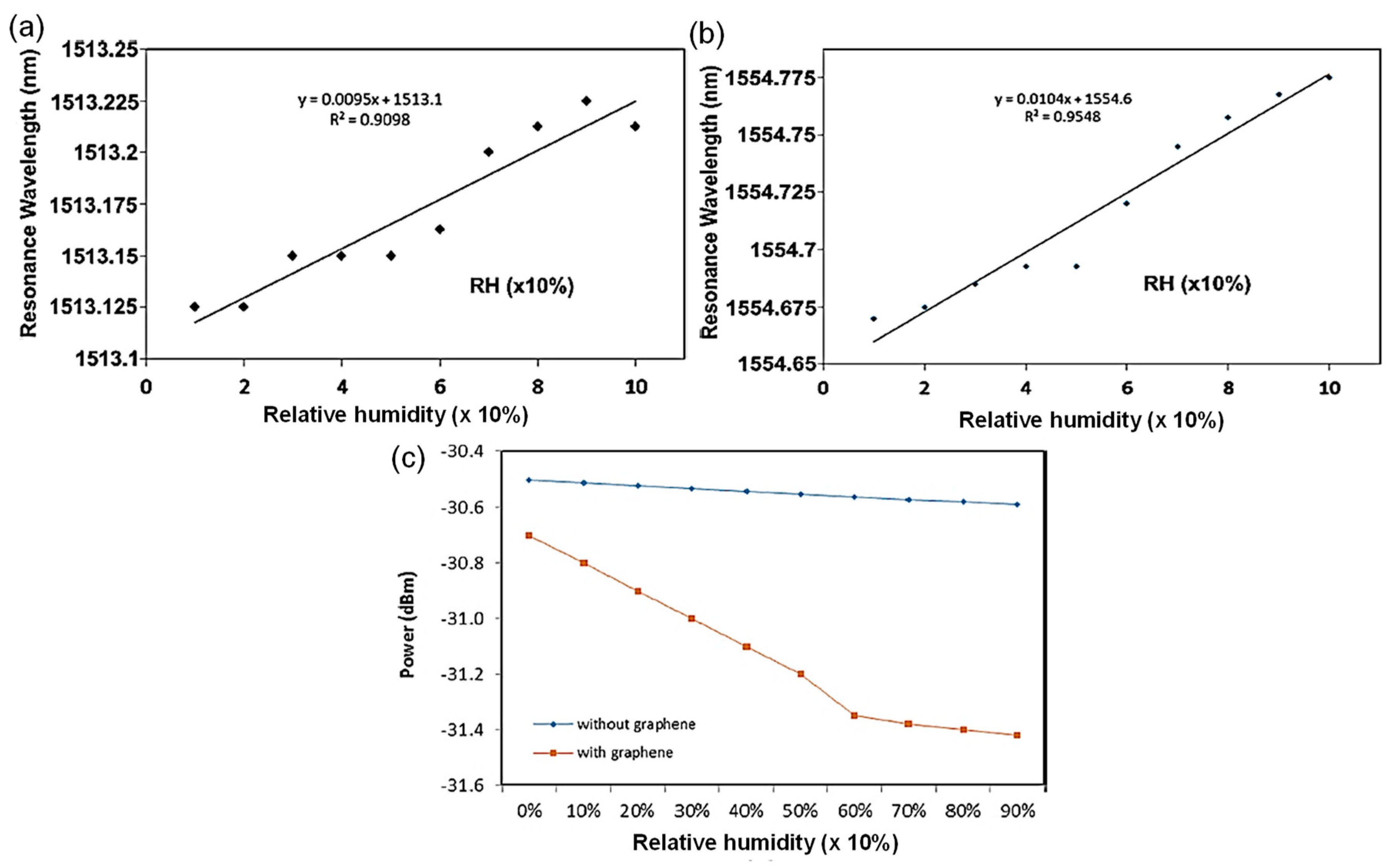

| S. Azzuhria et al./2018 [42] | Silica MKR | Not Available | 3.02 μm | Graphene Oxide | 0.0104 nm/% RH (0.0095 nm/% w/o Graphene Oxide) | Not Available | 0.096 % RH (0.1% RH w/o graphene oxide) | Not Available |

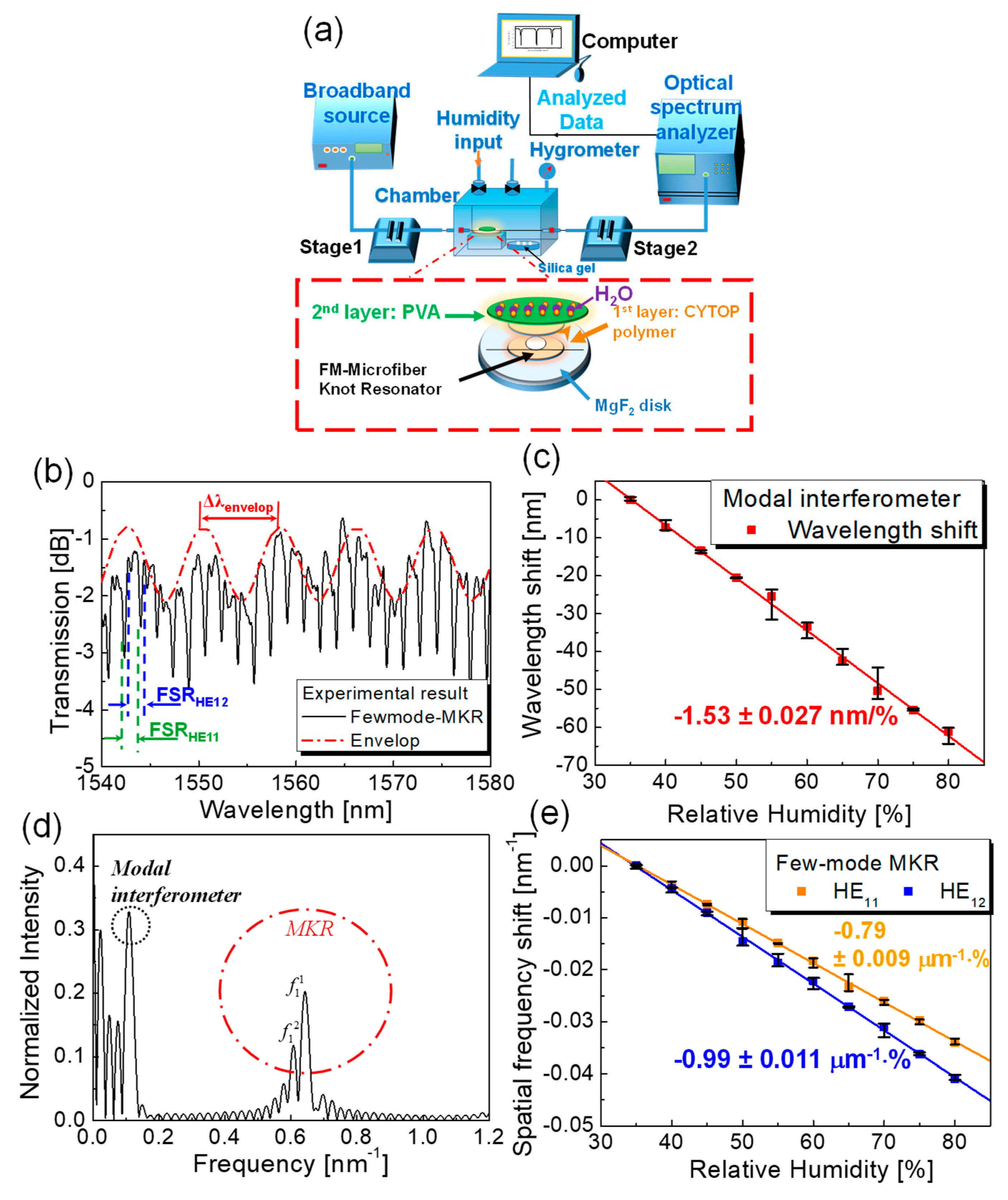

| A. D. D. Le et al./2018 [29] | Silica MKR | 4 μm | 380 μm | Polyvinyl Alcohol (PVA) | -1.53 nm/% RH | Not Available | Not Available | Not Available |

| M. Faruki et al./2016 [55] | Silica MKR | 2.1 μm | 2.5 mm | Titanium Dioxide (TiO2) | 2.5 pm/% RH (1.3 pm/%RH w/o TiO2) | 0.0836 dB/% RH (0.0626 dB/%RH w/o TiO2) | Not Available | Response: ~25 s Recovery: ~30 s |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, Y.-G. Relative Humidity Sensors Based on Microfiber Knot Resonators—A Review. Sensors 2019, 19, 5196. https://doi.org/10.3390/s19235196

Han Y-G. Relative Humidity Sensors Based on Microfiber Knot Resonators—A Review. Sensors. 2019; 19(23):5196. https://doi.org/10.3390/s19235196

Chicago/Turabian StyleHan, Young-Geun. 2019. "Relative Humidity Sensors Based on Microfiber Knot Resonators—A Review" Sensors 19, no. 23: 5196. https://doi.org/10.3390/s19235196

APA StyleHan, Y.-G. (2019). Relative Humidity Sensors Based on Microfiber Knot Resonators—A Review. Sensors, 19(23), 5196. https://doi.org/10.3390/s19235196