A Multi-Sensor Based Roadheader Positioning Model and Arbitrary Tunnel Cross Section Automatic Cutting

Abstract

1. Introduction

2. Methods

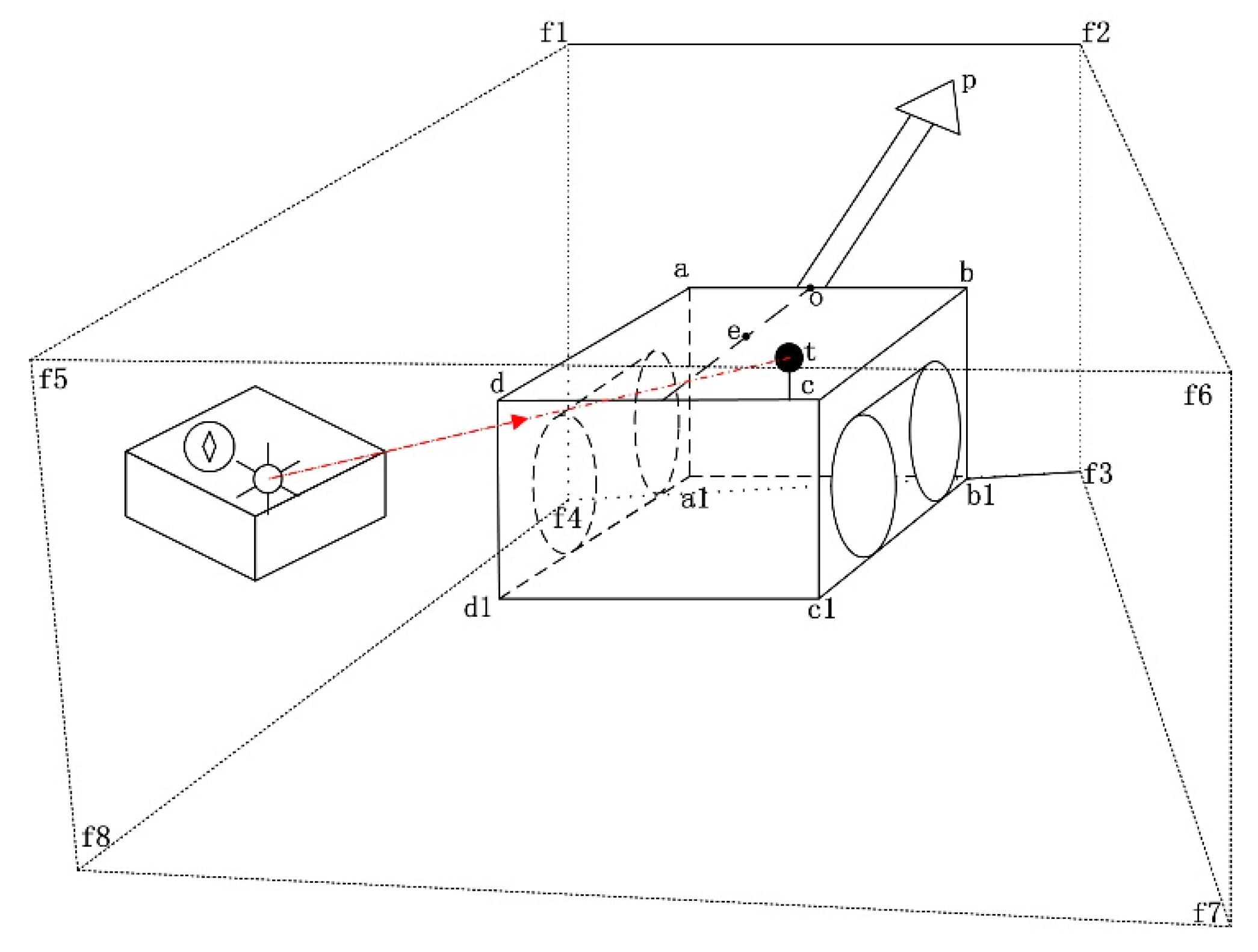

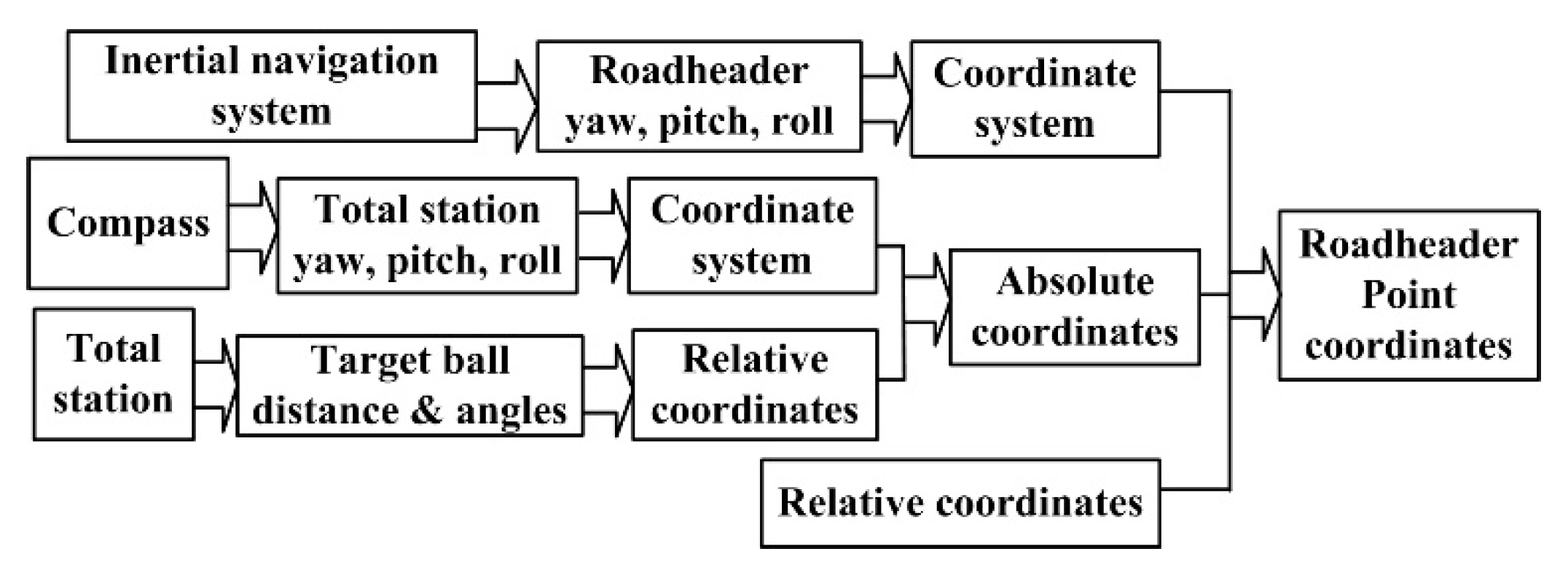

2.1. Principle of Positioning and Cutter Control

2.1.1. Positioning Workflow

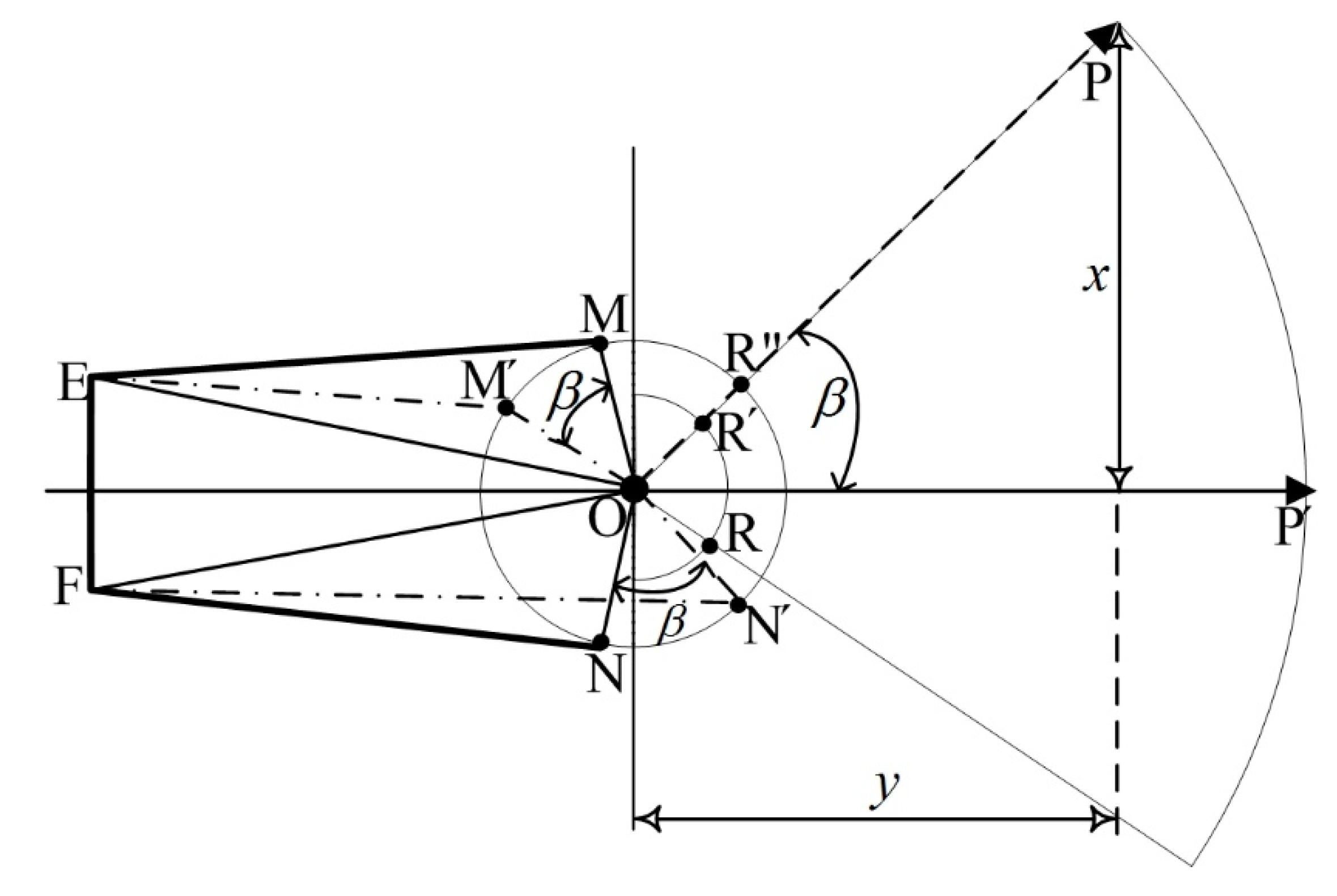

2.1.2. Cutter Control Model

2.1.3. Moving the Explosion Proof Positioning Box

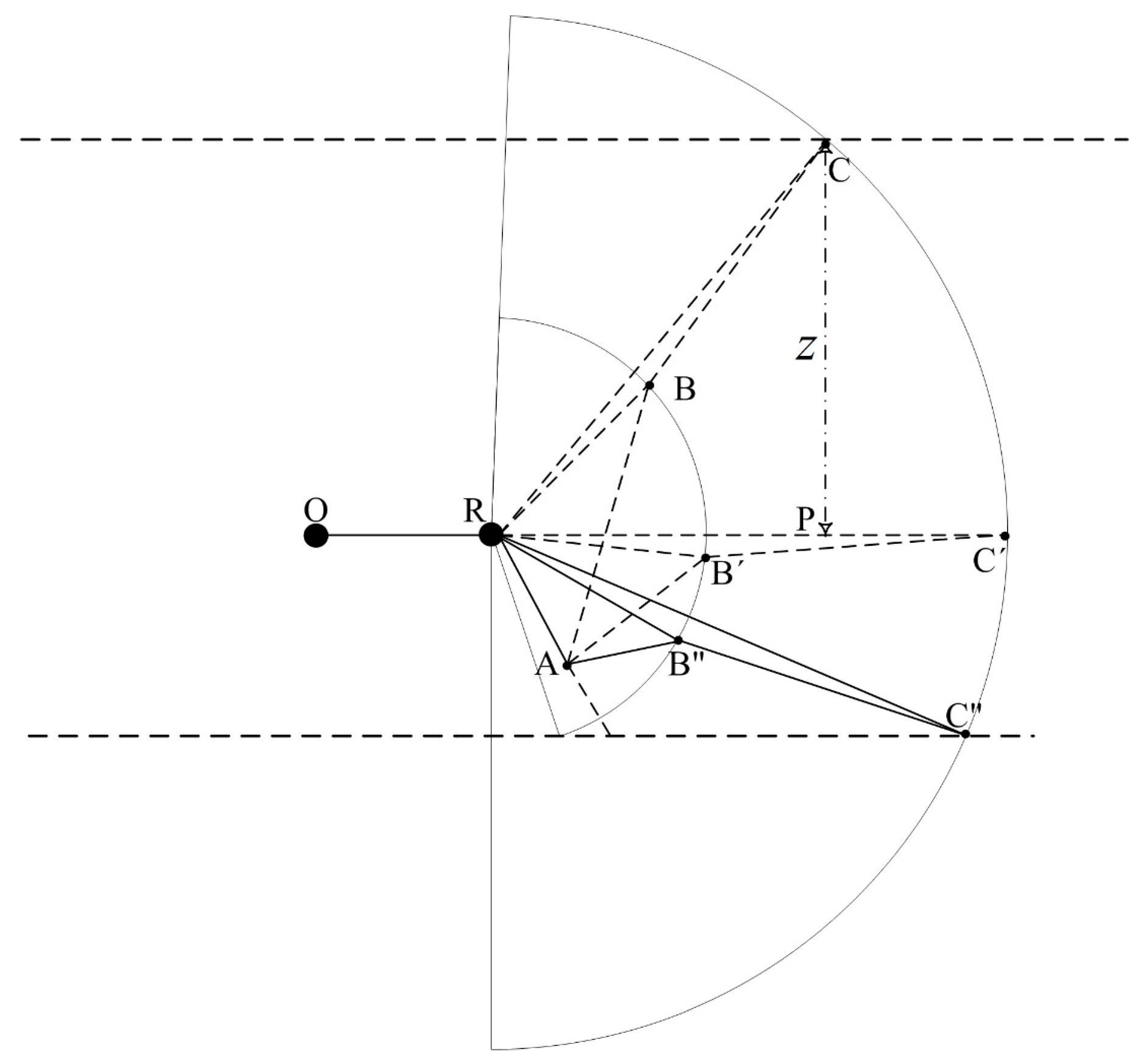

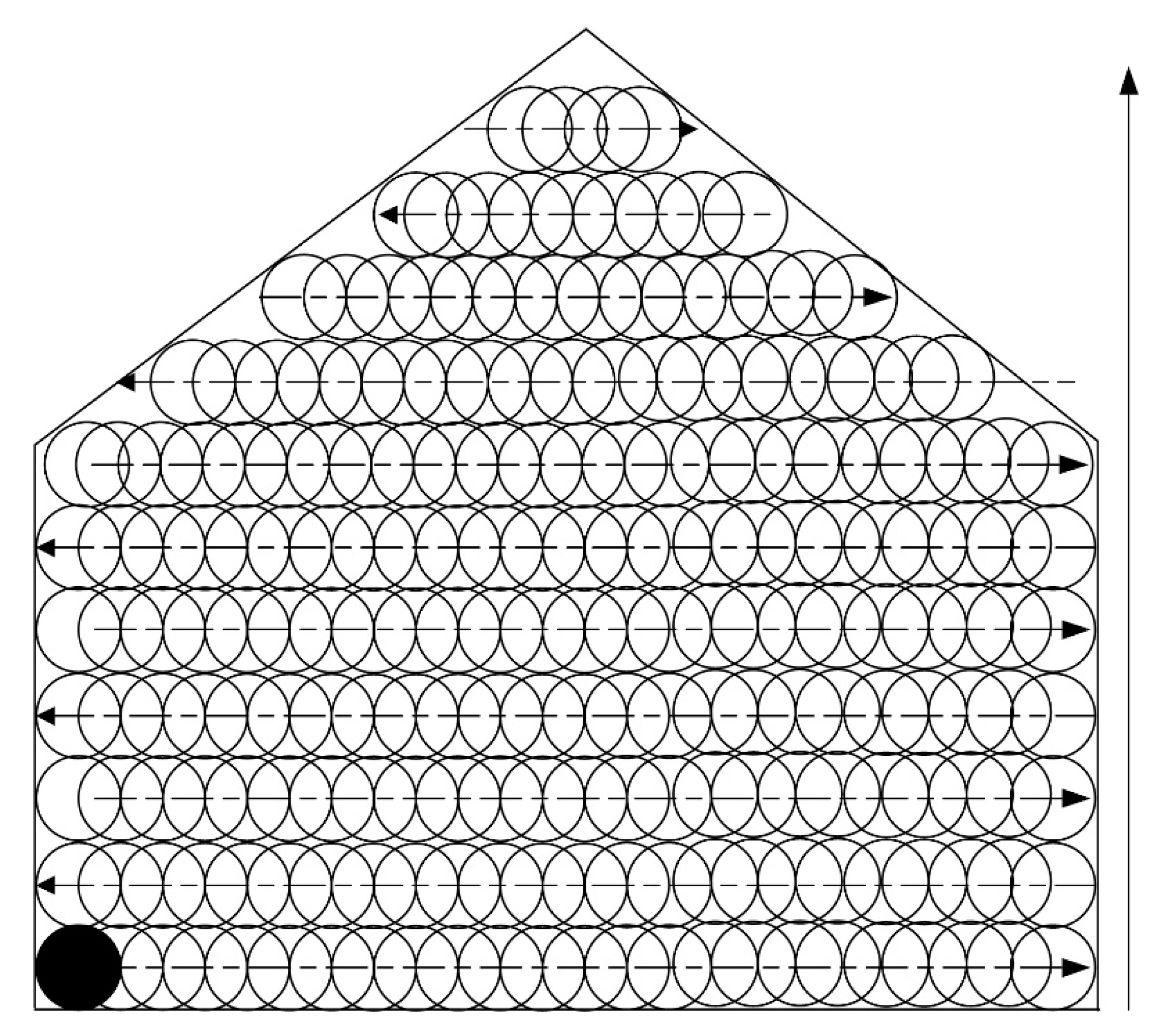

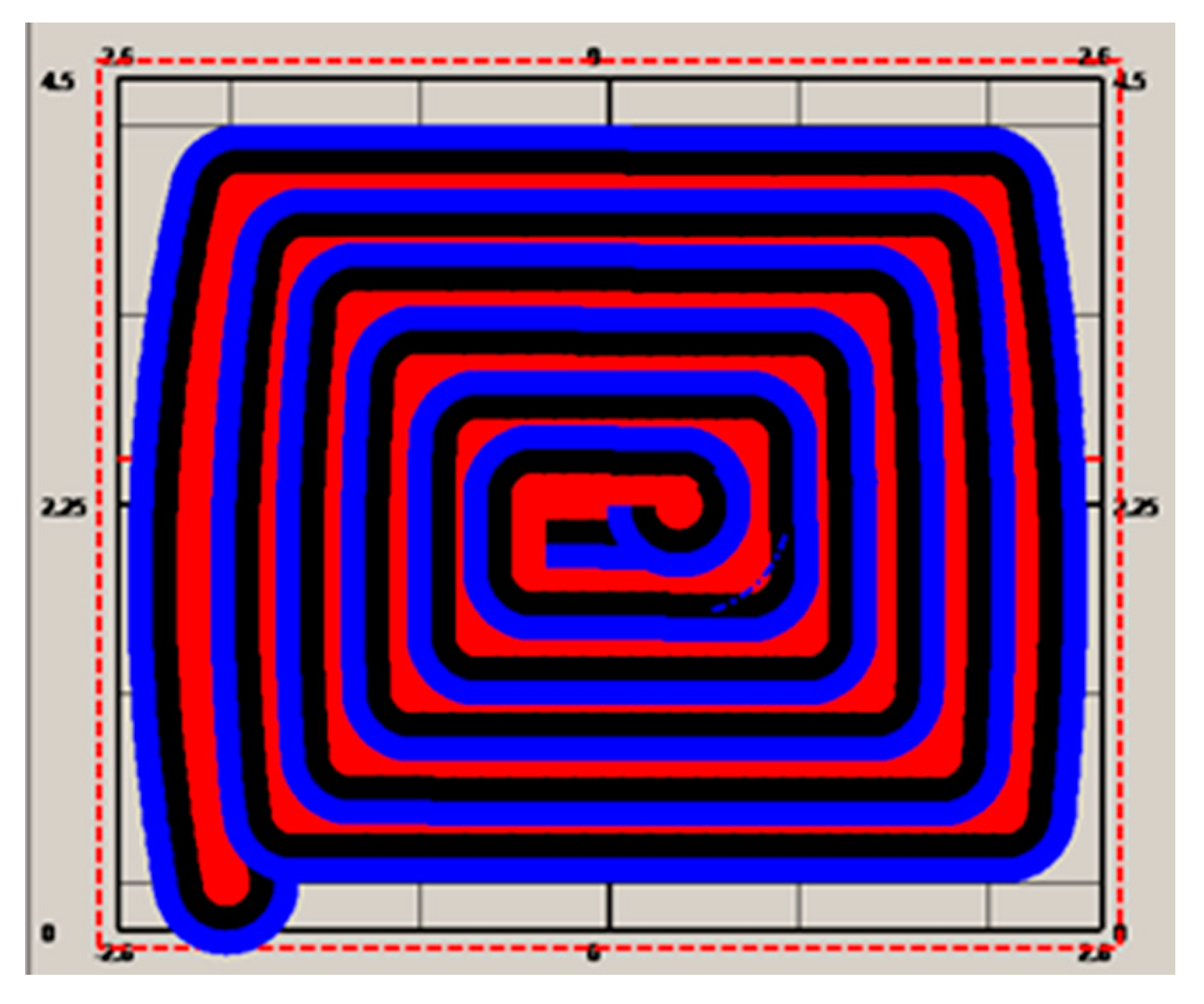

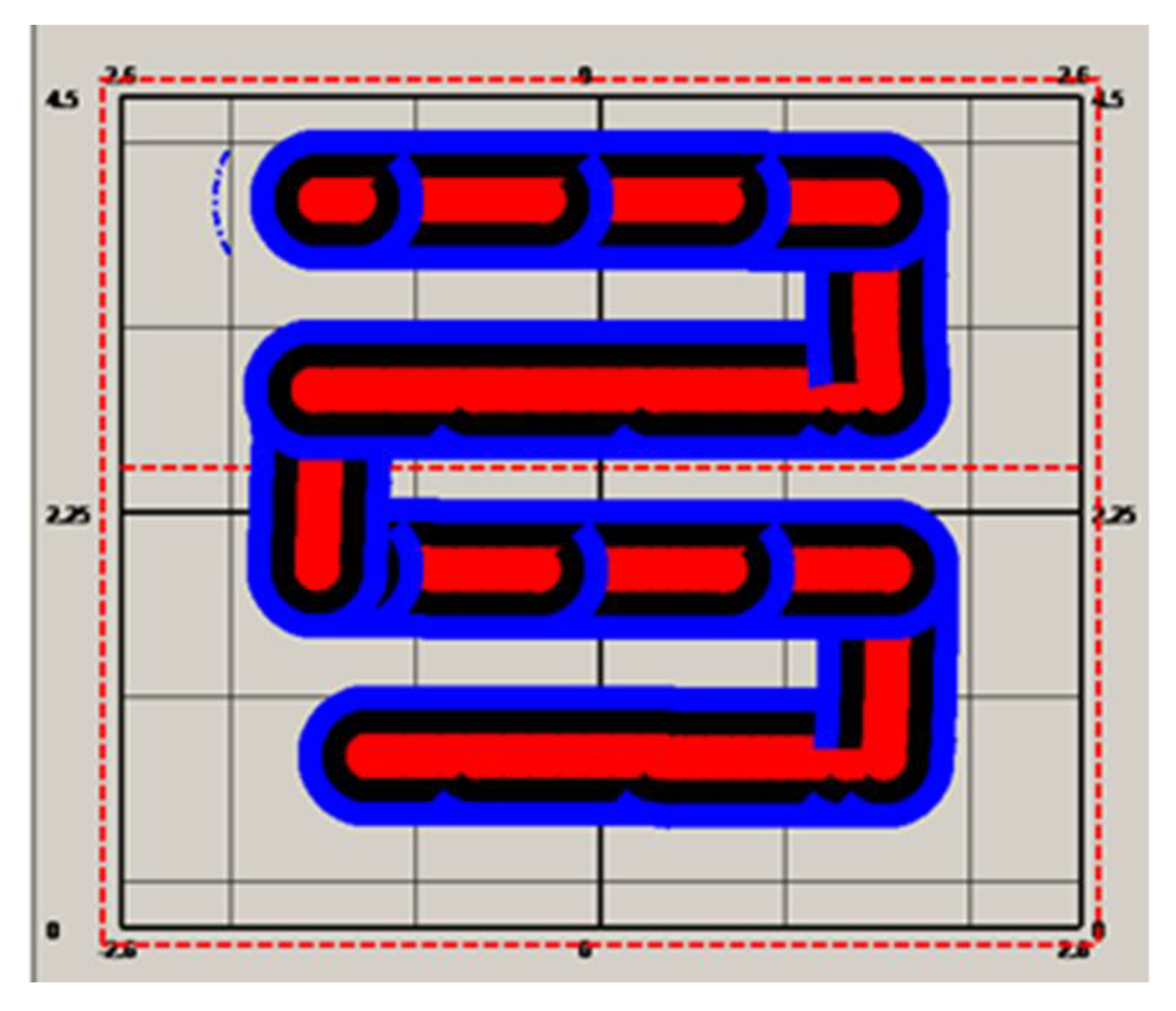

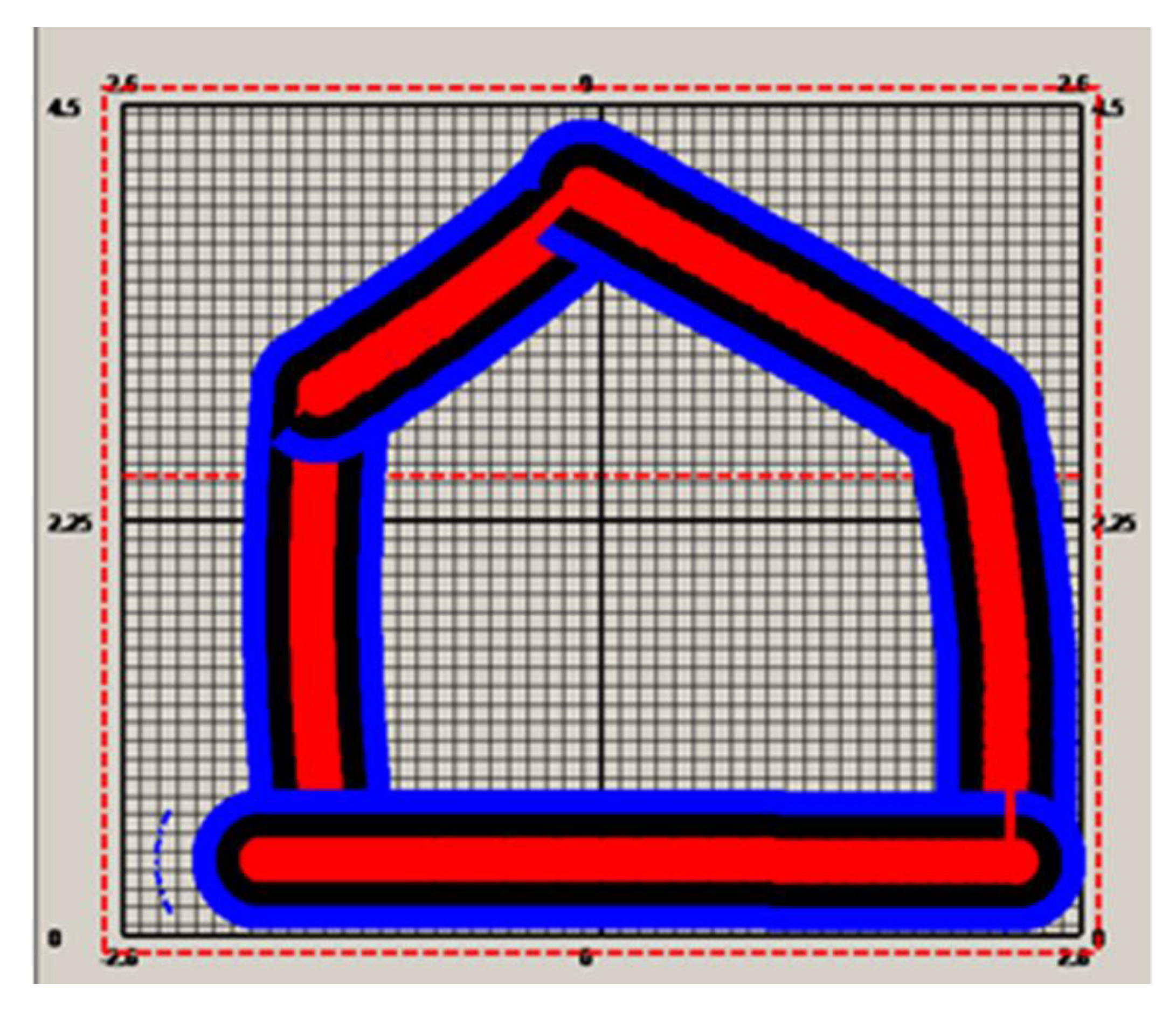

2.2. Arbitrary Cross Section Trajectory Planning and Automatic Cutting

2.2.1. Trajectory Planning

| Algorithm 1 Trajectory planning |

|

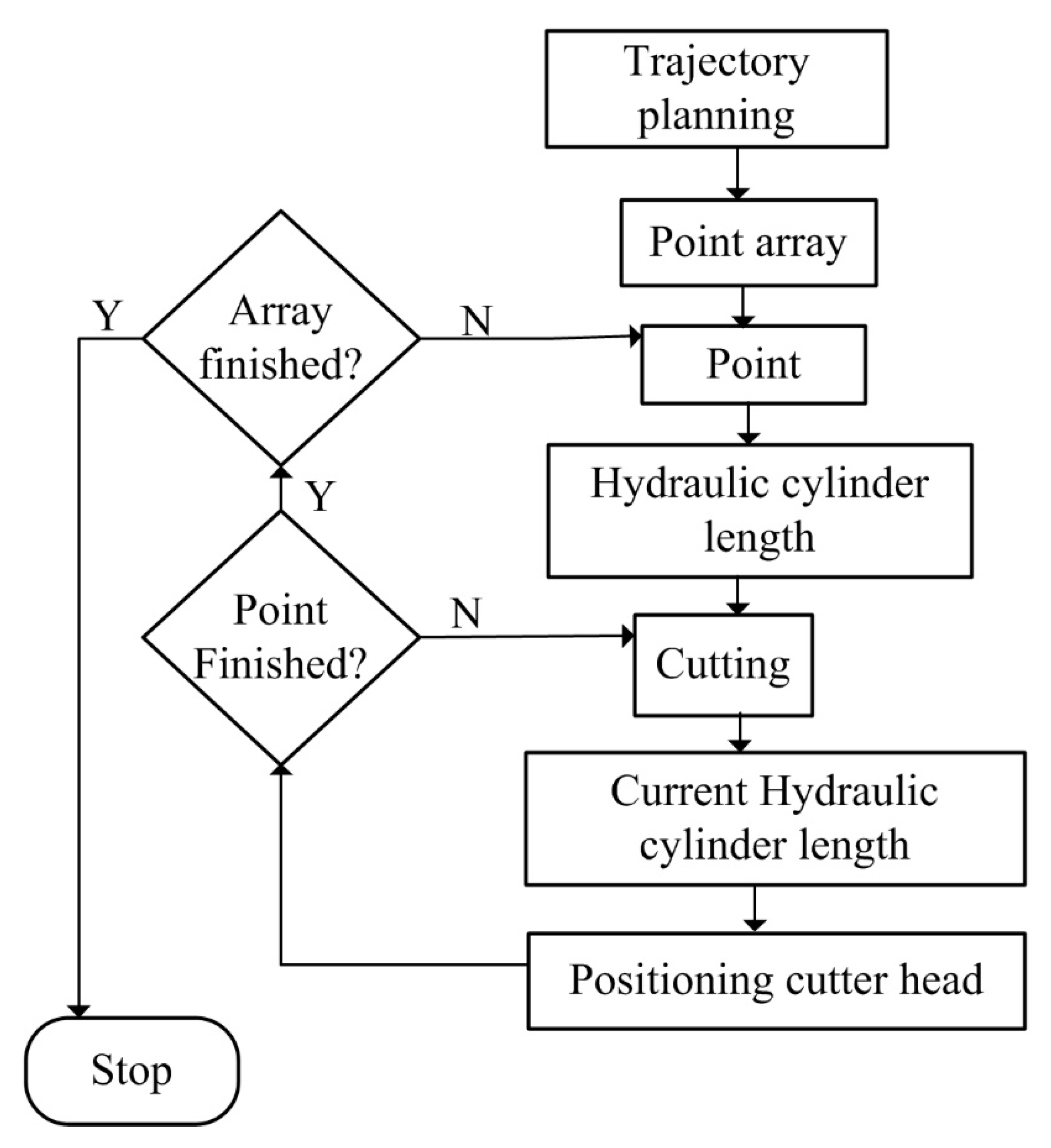

2.2.2. Cutting Process

3. Experiments and Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, L.; Yang, X.; Gong, G.; Du, J. Pose and trajectory control of shield tunneling machine in complicated stratum. Autom. Constr. 2018, 93, 192–199. [Google Scholar] [CrossRef]

- Fu, S.; Li, Y.; Zong, K.; Liu, C.; Liu, D.; Wu, M. Ultra-wideband pose detection method based on TDOA positioning model for boom-type roadheader. AEU Int. J. Electron. Commun. 2019, 99, 70–80. [Google Scholar] [CrossRef]

- Vahdatikhaki, F.; Hammad, A.; Siddiqui, H. Optimization-based excavator pose estimation using real-time location systems. Autom. Constr. 2015, 56, 76–92. [Google Scholar] [CrossRef]

- Du, Y.; Tong, M.; Liu, T.; Dong, H. Visual measurement system for roadheaders pose detection in mines. Opt. Eng. 2016, 55, 104–107. [Google Scholar] [CrossRef]

- Tian, J.; Wang, S.; Wu, M. Kinematic models and simulations for trajectory planning in the cutting of Spatially-Arbitrary crosssections by a robotic roadheader. Tunn. Undergr. Sp. Tech. 2018, 78, 115–123. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, G.; Huang, Z.; Ye, Y.; Ma, B.; Wang, Y. Research on position and orientation measurement method for roadheader based on vision/INS. In Proceedings of the 2017 International Conference on Optical Instruments and Technology: Optoelectronic Measurement Technology and Systems, International Society for Optics and Photonics, Beijing, China, 12 January 2018; p. 1062105. [Google Scholar]

- Zong, K.; Jia, W.; Wu, M. Position and Attitude Measurement System Design of Boom-type Roadheader. DEStech Trans. Mater. Sci. Eng. 2016, 167–173. [Google Scholar] [CrossRef]

- Barrett, J.M.; Gennert, M.A.; Michalson, W.R.; Audi, M.D.; Center, J.L.; Kirk, J.F.; Welch, B.W. Development of a low-cost, self-contained, combined vision and inertial navigation system. In Proceedings of the 2013 IEEE Conference on Technologies for Practical Robot Applications (TePRA), Woburn, MA, USA, 22–23 April 2013; pp. 1–6. [Google Scholar]

- Yang, W.J.; Zhang, X.H.; Ma, H.W.; Zhang, G.M. Infrared LEDs-Based Pose Estimation with Underground Camera Model for Boom-Type Roadheader in Coal Mining. IEEE Access 2019, 7, 33698–33712. [Google Scholar] [CrossRef]

- Galceran, E.; Carreras, M. A survey on coverage path planning for robotics. Robot. Auton. Syst. 2013, 61, 1258–1276. [Google Scholar] [CrossRef]

| Tball_mx | Tball_my | Tball_mz | Tball_x | Tball_y | Tball_z |

|---|---|---|---|---|---|

| 2.551 | −6.025 | 3.796 | 2.473 | −6.02 | 3.80201 |

| 7.261 | −3.657 | 3.759 | 7.22 | −3.678 | 3.75789 |

| −2.549 | 6.059 | 3.513 | −2.627627 | 5.301803 | 3.49537 |

| −2.958 | 6.864 | 6.143 | −3.01761 | 6.247142 | 6.168197 |

| −2.679 | 6.248 | 1.945 | −2.724617 | 5.516208 | 1.926952 |

| −5.566 | 5.526 | 2.959 | −5.802043 | 4.944234 | 2.934521 |

| −2.639 | 6.146 | 3.44 | −2.713292 | 5.431437 | 3.5042 |

| −5.627 | 5.637 | 3.99 | −5.81226 | 4.942852 | 3.99768 |

| Error_x | Error_y | Error_z |

|---|---|---|

| 0.07174 | −0.00259 | −0.00601 |

| 0.03161 | 0.020911 | 0.00111 |

| 0.078627 | 0.004197 | 0.01763 |

| 0.05961 | 0.016858 | −0.0252 |

| 0.045617 | 0.011792 | 0.018048 |

| 0.036043 | −0.01823 | 0.024479 |

| 0.014292 | 0.014563 | −0.0642 |

| −0.01474 | 0.044148 | −0.00768 |

| Cutter_mx | Cutter_my | Cutter_mz | Cutter_x | Cutter_y | Cutter_z |

|---|---|---|---|---|---|

| 2.117 | 8.186 | 4.597 | 2.145352 | 8.158442 | 4.571989 |

| 2.117 | 8.129 | 2.423 | 2.166604 | 8.106151 | 2.392711 |

| 1.929 | 8.468 | 5.442 | 1.99126 | 8.485817 | 5.47986 |

| −0.232 | 7.545 | 3.521 | −0.16831 | 7.49267 | 3.503577 |

| 3.383 | 8.803 | 3.547 | 3.386812 | 8.792561 | 3.496827 |

| Error_x | Error_y | Error_z |

|---|---|---|

| 0.07174 | −0.00259 | −0.00601 |

| 0.03161 | 0.020911 | 0.00111 |

| 0.078627 | 0.004197 | 0.01763 |

| 0.05961 | 0.016858 | −0.0252 |

| 0.045617 | 0.011792 | 0.018048 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, C.; Zhao, W.; Lu, X. A Multi-Sensor Based Roadheader Positioning Model and Arbitrary Tunnel Cross Section Automatic Cutting. Sensors 2019, 19, 4955. https://doi.org/10.3390/s19224955

Yan C, Zhao W, Lu X. A Multi-Sensor Based Roadheader Positioning Model and Arbitrary Tunnel Cross Section Automatic Cutting. Sensors. 2019; 19(22):4955. https://doi.org/10.3390/s19224955

Chicago/Turabian StyleYan, Changqing, Wenxiao Zhao, and Xinming Lu. 2019. "A Multi-Sensor Based Roadheader Positioning Model and Arbitrary Tunnel Cross Section Automatic Cutting" Sensors 19, no. 22: 4955. https://doi.org/10.3390/s19224955

APA StyleYan, C., Zhao, W., & Lu, X. (2019). A Multi-Sensor Based Roadheader Positioning Model and Arbitrary Tunnel Cross Section Automatic Cutting. Sensors, 19(22), 4955. https://doi.org/10.3390/s19224955