Heat Source Forecast of Ball Screw Drive System Under Actual Working Conditions Based on On-Line Measurement of Temperature Sensors

Abstract

1. Introduction

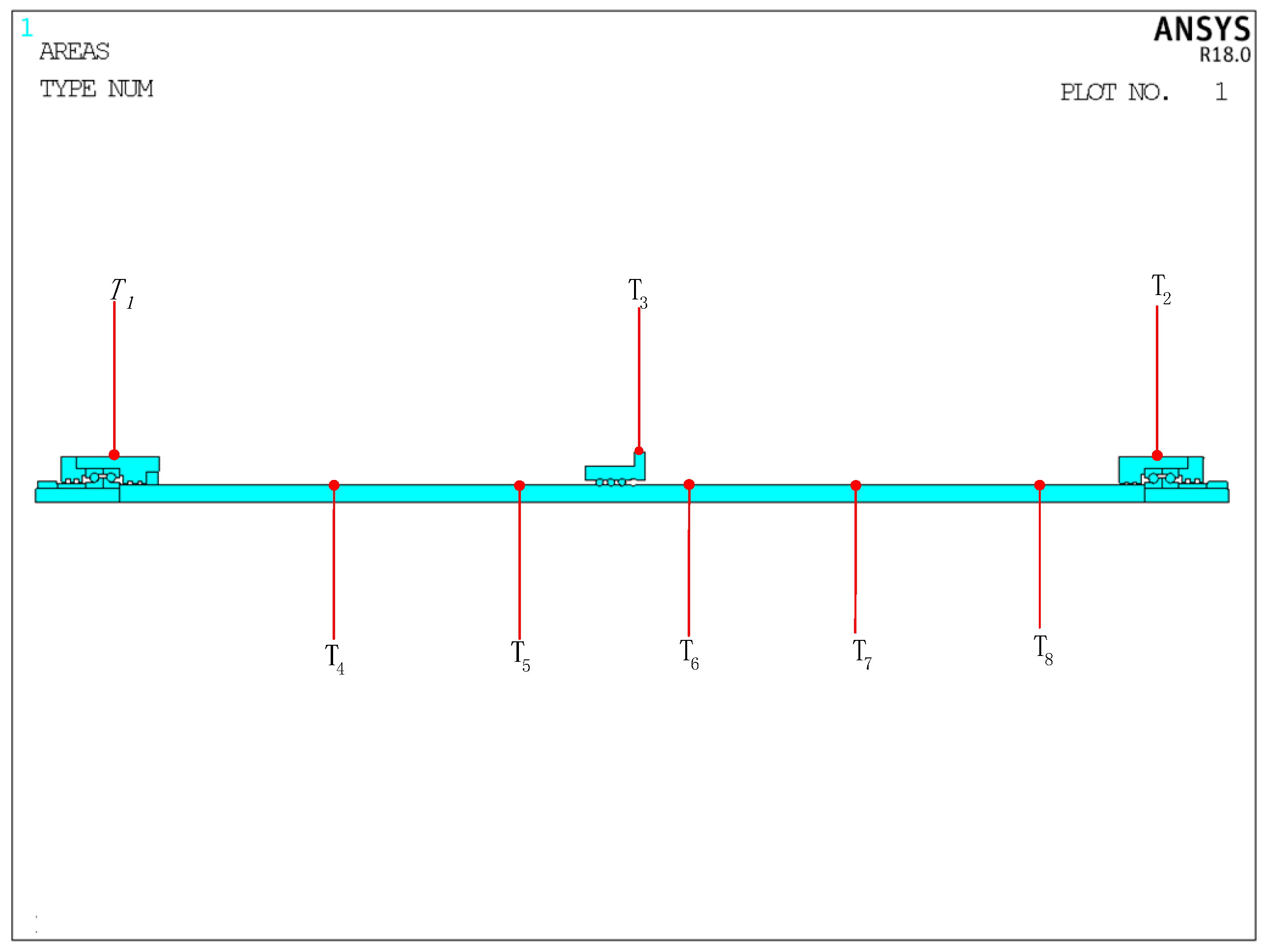

2. Experimental Process

3. Dynamic Thermal Network Modeling

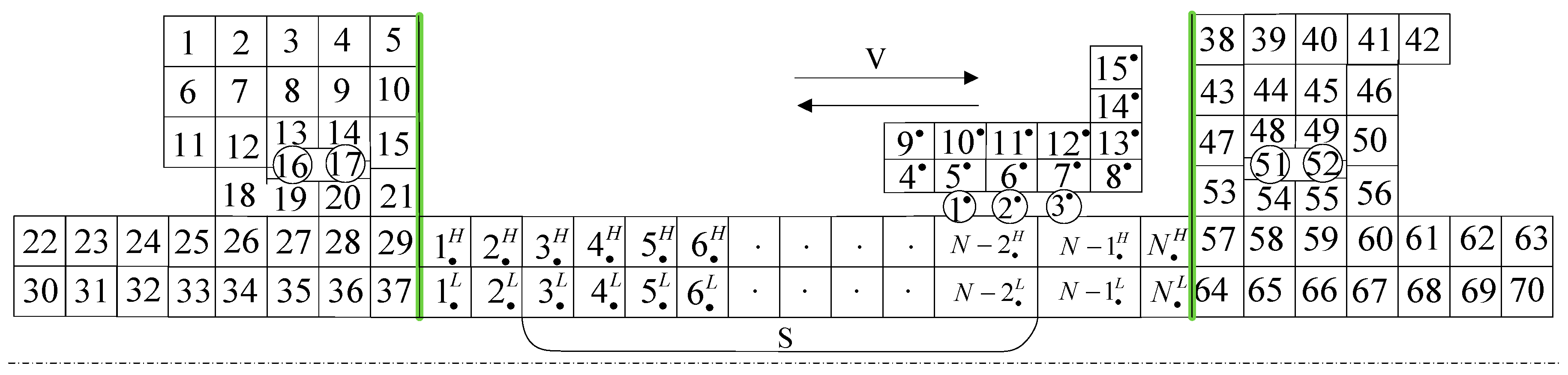

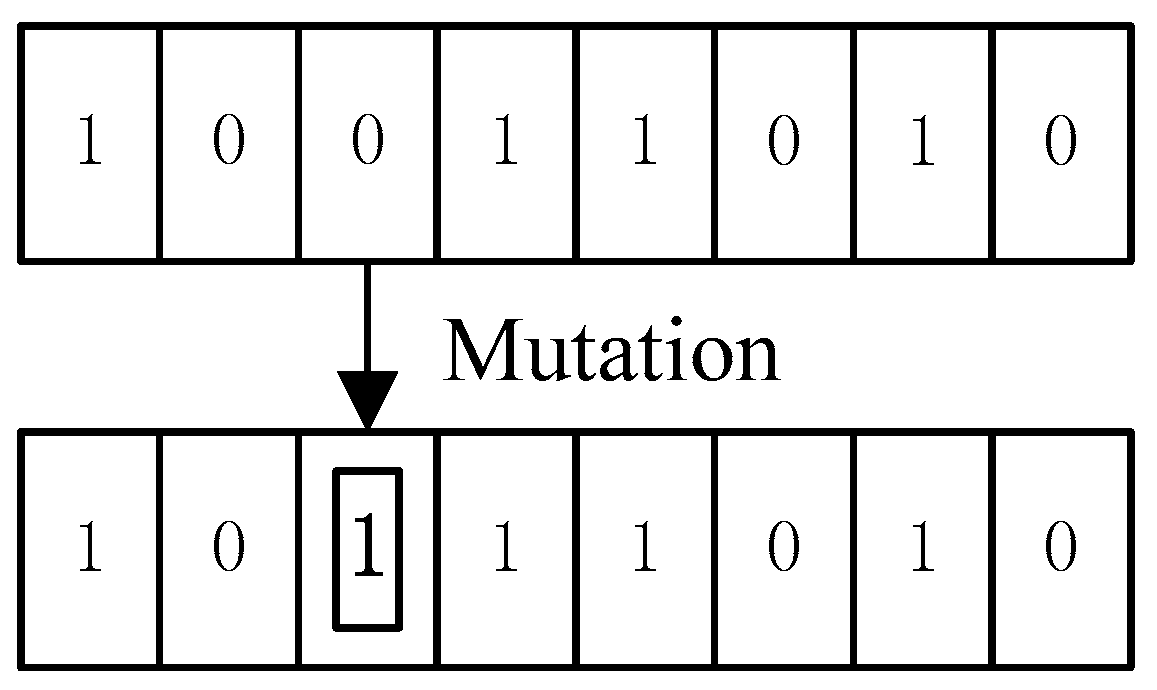

3.1. Arrangement and Modeling of Thermal Nodes

3.2. Heat Transfer Model

- The thermal resistance of the bearing outer ring, inner ring, and bearing housing of the bearing installed on the feed shaft is calculated as follows:in which , are inner radius and external radius of cylindrical body, is the thermal conductivity and L is the natural length. and stand the length of heat exchange and surface area.

- The thermal contact resistance is related to the ball parameters and preload and working temperature. Thermal contact resistance between the balls and outer/inner ring can be defined [37]. At the same time, the thermal resistance between the ball and raceway of screw nut is also calculated as follows:where , are the thermal conductivity of ball and ring, , are the long/short axis of contact ellipse formed.

- The assembly relationship between the shaft and bearing bore is interference fit, and the thermal resistance of the contact between the inner ring and shaft isHere, is the apparent contact area, is the real contact between two contact surfaces. is the void thickness of two contact surfaces. and are the thermal conductivities of the materials of the inner ring and the shaft.

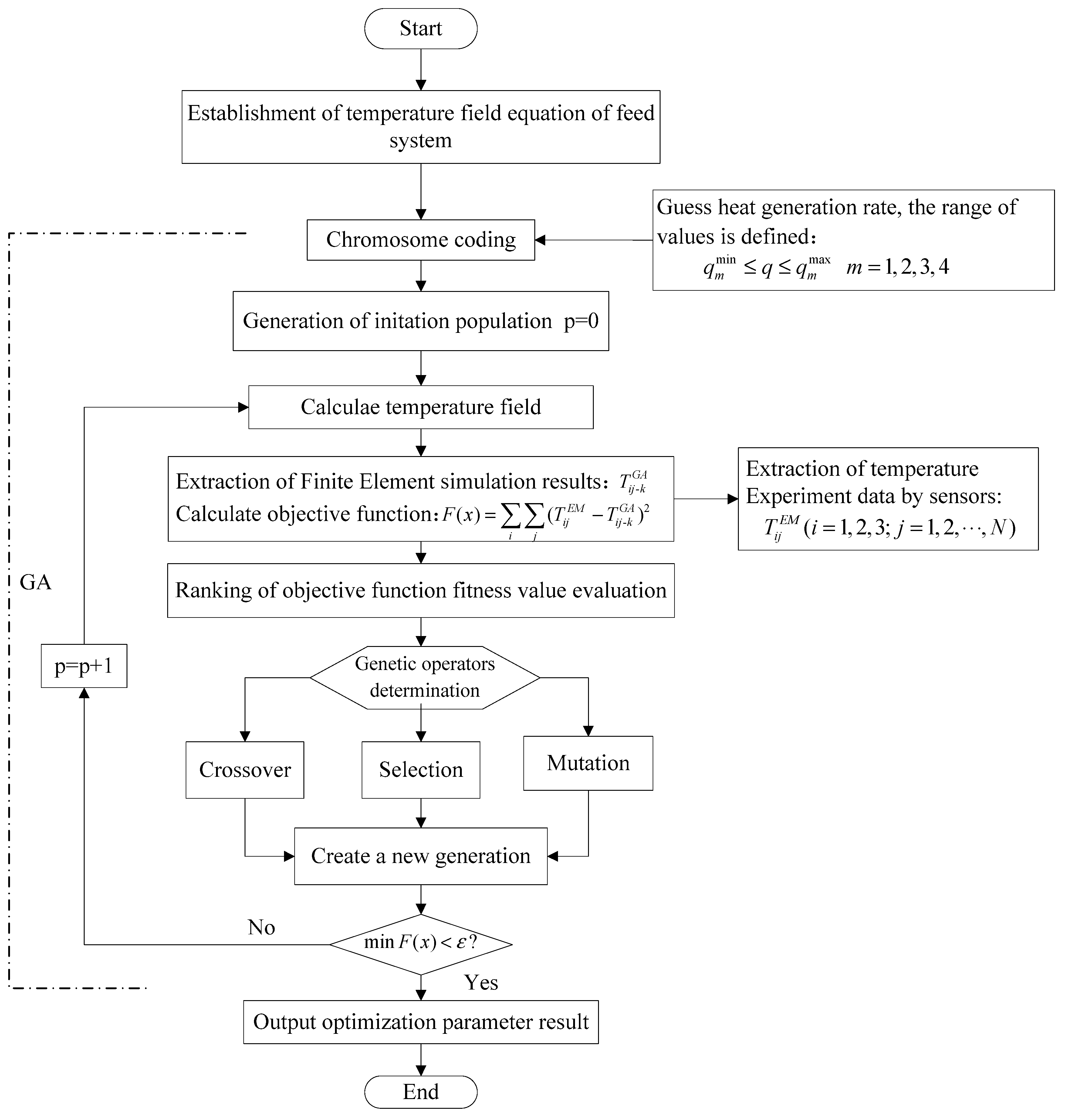

4. Inverse Method Solution of Heat Source by Genetic Optimization (GA)

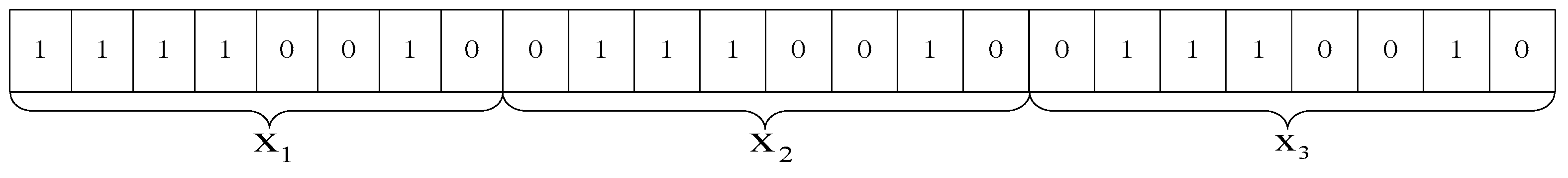

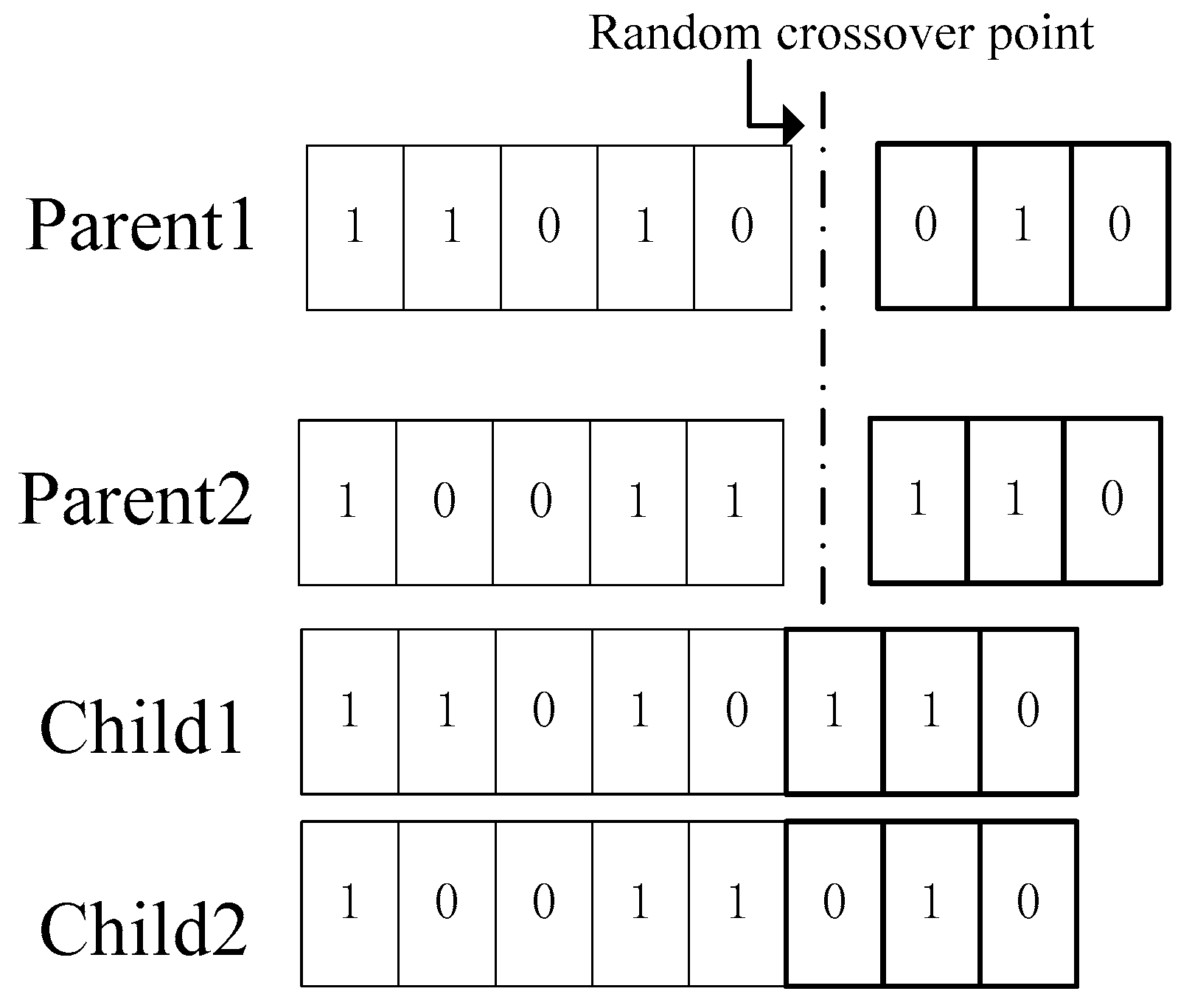

- Binary coding: The design variables defined by optimization problems are coded as the values of the design variables. In this paper, a finite length binary string is used to represent the parameters of each solution. So a sufficiently long chromosome can outline all the features of the design variable as shown in Figure 5.From the binary string to the real number mapping, the binary string number must be calculated first. To achieve the desired accuracy, the binary strings can be determined by the following formula:Binary string to real number can be decoded according to Formula (12):where .

- Generate initial population: In order to satisfy the constraints and the diversity of the population, the initial solution of K groups is randomly generated as the size parameter of the population. These K individuals are the initial points of iteration, and the results satisfy the precision to terminate the iteration evolution process.

- Fitness Arrangement: The objective function to be solved is directly transformed into fitness function correlation method. According to the size of K group objective function, the individual objective function is sorted from small to large.

5. Simulation Results and Verification

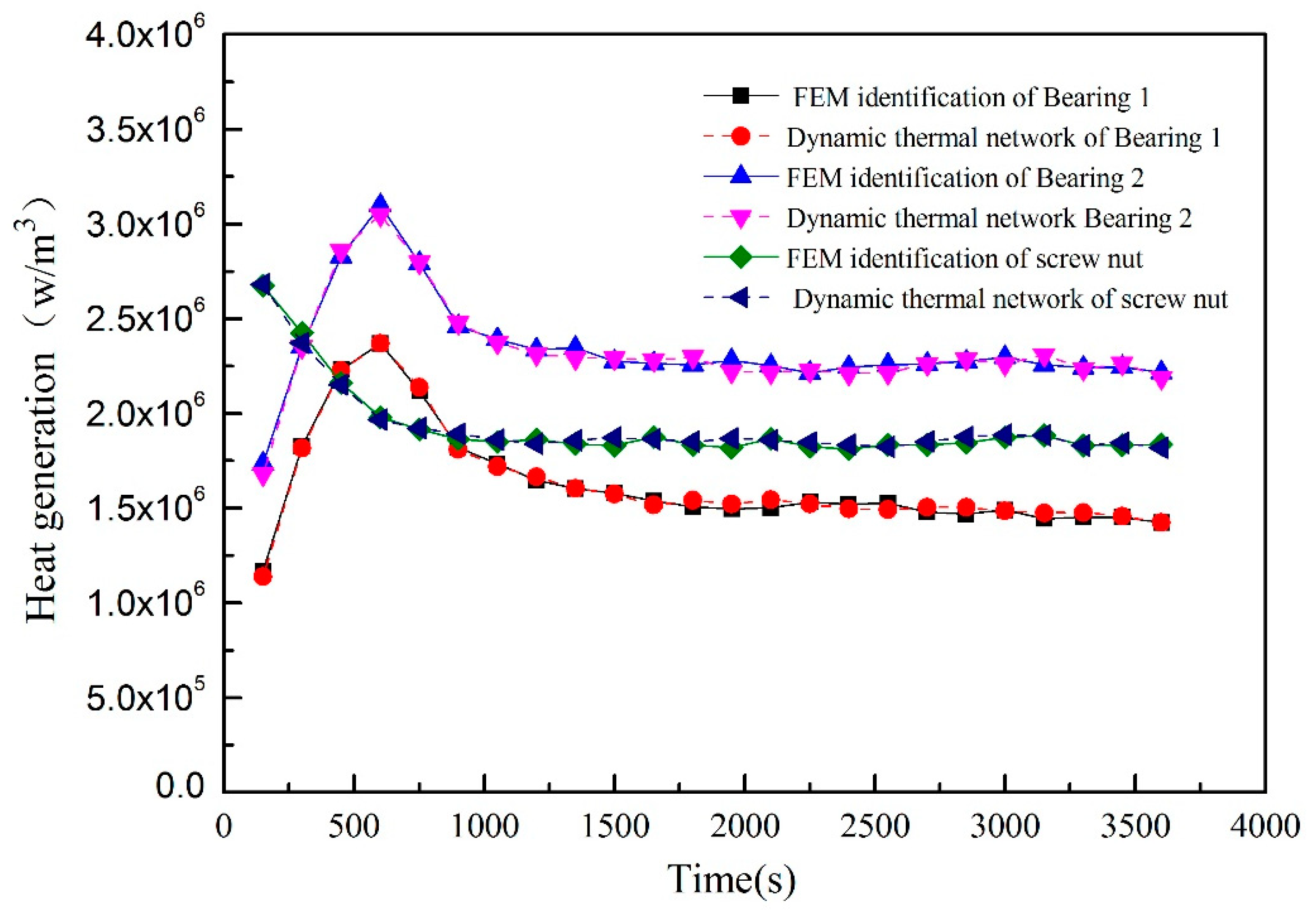

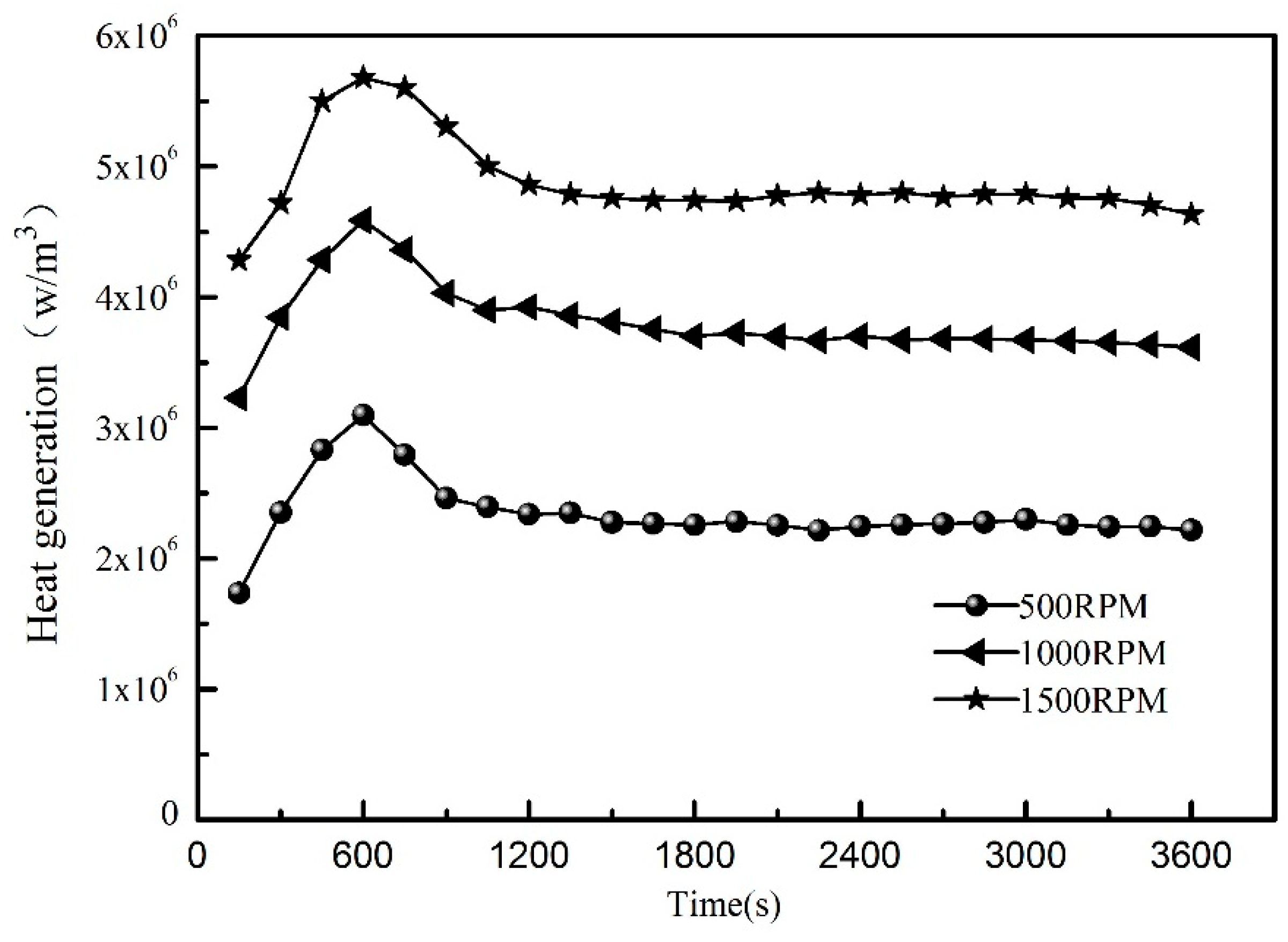

5.1. Simulated Identification by FEM Combined with Genetic Algorithms (GA)

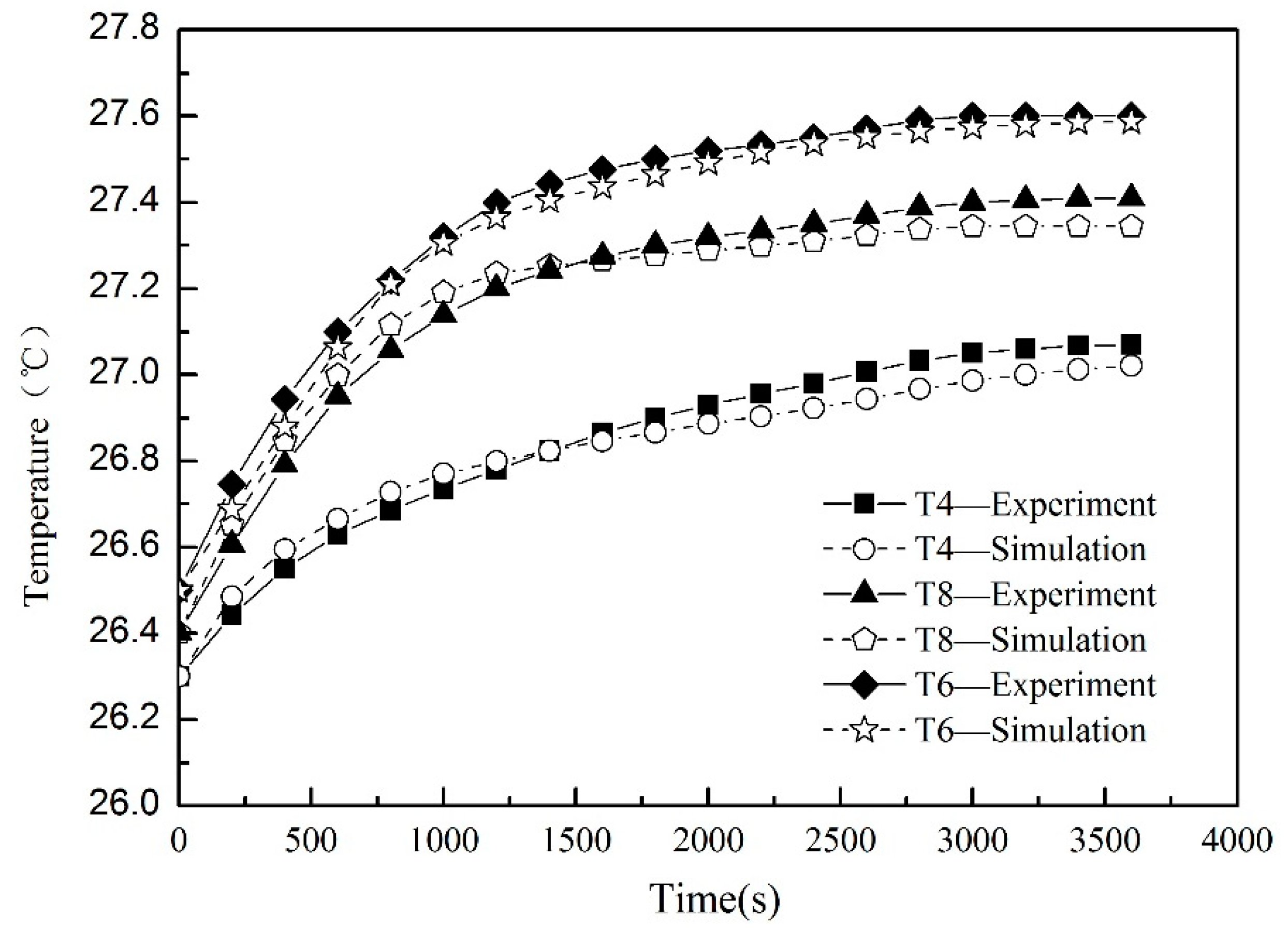

5.2. Identification and Verification of Inverse Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yau, H.T.; Yan, J.J. Adaptive sliding mode control of a high-precision ball-screw-driven stage. Nonlinear Anal. Real World Appl. 2009, 10, 1480–1489. [Google Scholar] [CrossRef]

- Bryan, J.B. International status of thermal error research. CIRP Ann. Manuf. Technol. 1990, 39, 645–656. [Google Scholar] [CrossRef]

- Liang, R.; Ye, W.; Zhang, H.; Yang, Q. The thermal error optimization models for CNC machine tools. Int. J. Adv. Manuf. Tech. 2012, 63, 1167–1176. [Google Scholar]

- Bossmanns, B.; Tu, J.F. Thermal model for high speed motorized spindles. Int. J. Mach. Tools Manuf. 1999, 39, 1345–1366. [Google Scholar] [CrossRef]

- Xu, T.; Xu, G.; Zhang, Q.; Hua, C.; Tan, H.; Zhang, S. A preload analytical method for ball bearings utilising bearing skidding criterion. Tribol. Int. 2013, 67, 44–50. [Google Scholar] [CrossRef]

- Huang, J.; Than, V.; Ngo, T.T. An inverse method for estimating heat sources in a high speed spindle. Appl. Eng. 2016, 105, 65–76. [Google Scholar] [CrossRef]

- Kim, S.; Lee, S. Prediction of thermoplastic behavior in a spindle-bearing system considering bearing surroundings. Int. J. Mach. Tools Manuf. 2001, 41, 809–831. [Google Scholar] [CrossRef]

- Cristea, A.; Pascovici, M.; Fillon, M. Clearance and lubricant selection for avoiding seizure in a circumferential groove journal bearing based on a lumped model analysis. Mech. Ind. 2011, 12, 399–408. [Google Scholar] [CrossRef]

- Yan, K.; Wang, Y.; Zhu, Y. Investigation on heat dissipation characteristic of ball bearing cage and inside cavity at ultra high rotation speed. Tribol. Int. 2016, 93, 470–481. [Google Scholar] [CrossRef]

- Lee, D.; Sun, K.; Kim, B. Thermal behavior of a worn tilting pad journal bearing: Thermohydrodynamic analysis and pad temperature measurement. Tribol. Trans. 2018, 61, 1074–1083. [Google Scholar] [CrossRef]

- Palmgren, A. Ball and Roller Bearing Engineering, 3rd ed.; SKF Industries Inc.: Philadelphia, PA, USA, 1959. [Google Scholar]

- Hernot, X.; Sartor, M.; Guillot, J. Calculation of the stiffness matrix of angular contact ball bearings by using the analytical approach. J. Mech. Des. 2000, 122, 83–90. [Google Scholar] [CrossRef]

- Harris, T.; Kotzalas, M. Advanced Concepts of Bearing Technology, 5th ed.; CRC Press, Taylor & Francis Group: New York, NY, USA, 2006. [Google Scholar]

- Jin, C.; Wu, B.; Hu, Y. Heat generation modeling of ball bearing based on internal load distribution. Tribol. Int. 2012, 45, 8–50. [Google Scholar] [CrossRef]

- Zhu, X.; Yang, J. Modeling for spindle thermal error in machine tools based on mechanism analysis and thermal basic characteristics tests. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 228, 3381–3394. [Google Scholar]

- Zivkovic, A.; Zeljkovic, M.; Tabakovic, S. Mathematical modeling and experimental testing of high-speed spindle behavior. Int. J. Adv. Manuf. Technol. 2015, 77, 1071–1086. [Google Scholar] [CrossRef]

- Xu, M.; Jiang, S.; Cai, Y. An improved thermal model for machine tool bearings. Int. J. Mach. Tools Manuf. 2007, 47, 53–62. [Google Scholar]

- Takabi, J.; Khonsari, M.M. Experimental testing and thermal analysis of ball bearings. Tribol. Int. 2013, 60, 93–103. [Google Scholar] [CrossRef]

- Mayr, J.; Ess, M.; Weikert, S.; Wegener, K. Compensation of thermal effects on machine tools using a FDEM simulation approach. In Proceedings of the 9th International Conference and Exhibition on Laser Metrology, Machine Tool, CMM & Robotic Performance (Lamdamap 2009), Uxbridge, UK, 30 June–2 July 2009; pp. 38–47. [Google Scholar]

- Chang, C.; Liu, C.; Wang, C. A Modified Polynomial Expansion Algorithm for Solving the Steady-state Allen-Cahn Equation for Heat Transfer in Thin Films. Appl. Sci. 2018, 8, 983. [Google Scholar] [CrossRef]

- Uhlmann, E.; Hu, J. Thermal modelling of an HSC machining centre to predict thermal error of the feed system. Prod. Eng. Res. Dev. 2012, 6, 603–610. [Google Scholar] [CrossRef]

- Zheng, D.-X.; Chen, W.F.; Li, M.M. An optimized thermal network model to estimate thermal performances on a pair of angular contact ball bearings under oil-air lubrication. Appl. Eng. 2018, 131, 328–339. [Google Scholar]

- Liu, J.; Chen, X. Dynamic design for motorized spindles based on an integrated model. Int. J. Adv. Manuf. Technol. 2014, 71, 1961–1974. [Google Scholar] [CrossRef]

- Lin, D.; Wang, C.C.; Yang, C.Y.; Li, J.C. Inverse estimation of temperature boundary conditions with irregular shape of gas tank. Int. J. Heat Mass Transf. 2010, 53, 4651–4662. [Google Scholar] [CrossRef]

- Lin, D.; Yang, C.Y.; Li, J.C.; Wang, C.C. Inverse estimation of the unknown heat flux boundary with irregular shape fins. Int. J. Heat Mass Transf. 2011, 54, 5275–5285. [Google Scholar] [CrossRef]

- Yu, Y.; Xu, D. On the inverse problem of thermal conductivity determination in nonlinear heat and moisture transfer model within textiles. Elsevier Sci. Inc. 2015, 264, 284–299. [Google Scholar] [CrossRef]

- Huang, C.; Jan, L.; Li, R. A three-dimensional inverse problem in estimating the applied heat flux of a titanium drilling—Theoretical and experimental studies. Int. J. Heat Mass Transf. 2007, 50, 3265–3277. [Google Scholar] [CrossRef]

- Duda, P. A general method for solving transient multidimensional inverse heat transfer problems. Int. J. Heat Mass Transf. 2016, 93, 665–673. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, L.; Wang, X.; Tai, B.L. An inverse method to reconstruct the heat flux produced by bone grinding tools. Int. J. Sci. 2016, 101, 85–92. [Google Scholar] [CrossRef]

- Lin, C.J.; Chu, W.; Wang, C.; Chen, C.; Chen, I. The Diagnosis of Ball Bearing Faults using SVM Based on the Artificial Fish Swarm Algorithm. J. Low Freq. Noise Vib. Act. Control 2019. [Google Scholar] [CrossRef]

- Wang, C.; Lee, R.; Yau, H.; Lee, T. Nonlinear analysis and simulation of active hybrid aerodynamic and aerostatic bearing system. J. Low Freq. Noise Vib. Act. Control 2018, 38, 1404–1421. [Google Scholar] [CrossRef]

- Irfan, M. A Novel Non-intrusive Method to Diagnose Bearings Surface Roughness Faults in Induction Motors. J. Fail. Anal. Prev. 2018, 18, 145–152. [Google Scholar] [CrossRef]

- Burrielvalencia, J.; Puchepanadero, R.; Martinezroman, J. Fault Diagnosis of Induction Machines in a Transient Regime Using Current Sensors with an Optimized Slepian Window. Sensors 2018, 18, 146. [Google Scholar] [CrossRef]

- Huang, Y.; Kao, C.; Chen, S. Diagnosis of the Hollow Ball Screw Preload Classification Using Machine Learning. Appl. Sci. 2018, 8, 1072. [Google Scholar] [CrossRef]

- Tao, W.Q. Numerical Heat Transfer; Xi’an Jiao Tong Univ. Press: Xi’an, China, 2001; pp. 86–98. (In Chinese) [Google Scholar]

- Burton, R.A.; Staph, H.E. Thermally activated seizure of angular contact bearings. Trib. Trans. 1967, 10, 408–417. [Google Scholar] [CrossRef]

- Muzychka, Y.; Yovanovitch, M. Modeling thermal resistance of non-circular moving heat sources on a half space. Heat Transf. Trans. ASME 2001, 123, 624–632. [Google Scholar] [CrossRef]

- Harris, T. Rolling Bearing Analysis; John Wiley & Sons, Inc.: New York, NY, USA, 2007. [Google Scholar]

- Churchill, S.W.; Chu, H.H.S. Correlation equations for laminar and turbulent free convection from a vertical plate. Int. J. Heat Mass Transf. 1975, 18, 1323–1329. [Google Scholar] [CrossRef]

- Churchill, S.W.; Chu, H.H.S. Correlation equations for laminar and turbulent free convection from a horizontal cylinder. Int. J. Heat Mass Transf. 1975, 18, 1049–1053. [Google Scholar] [CrossRef]

- Kendoush, A.A. An approximate solution of the convective heat transfer from an isothermal rotating cylinder. Int. J. Heat Fluid Flow 1996, 17, 439–441. [Google Scholar] [CrossRef]

- Wang, C.; Cui, D.; Qu, R. Finite Element Method for Heat Transfer and Structure Analysis and Its Application; China Science Press: Beijing, China, 2012; pp. 5–26. [Google Scholar]

| Part | Density | Elastic Modulu | Poisson’s Ratio v | Heat Capacity | Thermal Conductivity |

|---|---|---|---|---|---|

| Screw nut | 7810 | 2.07 | 0.3 | 553 | 50 |

| Housing | 7810 | 2.20 | 0.3 | 494 | 40 |

| Ball | 3200 | 3.20 | 0.26 | 800 | 11.63 |

| Outer/inner ring | 7810 | 2.07 | 0.3 | 450 | 40.1 |

| Shaft | 7860 | 2.12 | 0.298 | 485 | 42.3 |

| Cage | 7830 | 2.06 | 0.254 | 460 | 44 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Lu, Z.; Zhao, C.; Liu, F.; Chen, Y. Heat Source Forecast of Ball Screw Drive System Under Actual Working Conditions Based on On-Line Measurement of Temperature Sensors. Sensors 2019, 19, 4694. https://doi.org/10.3390/s19214694

Li Z, Lu Z, Zhao C, Liu F, Chen Y. Heat Source Forecast of Ball Screw Drive System Under Actual Working Conditions Based on On-Line Measurement of Temperature Sensors. Sensors. 2019; 19(21):4694. https://doi.org/10.3390/s19214694

Chicago/Turabian StyleLi, Zhenjun, Zechen Lu, Chunyu Zhao, Fangchen Liu, and Ye Chen. 2019. "Heat Source Forecast of Ball Screw Drive System Under Actual Working Conditions Based on On-Line Measurement of Temperature Sensors" Sensors 19, no. 21: 4694. https://doi.org/10.3390/s19214694

APA StyleLi, Z., Lu, Z., Zhao, C., Liu, F., & Chen, Y. (2019). Heat Source Forecast of Ball Screw Drive System Under Actual Working Conditions Based on On-Line Measurement of Temperature Sensors. Sensors, 19(21), 4694. https://doi.org/10.3390/s19214694