A Review of Force Myography Research and Development

Abstract

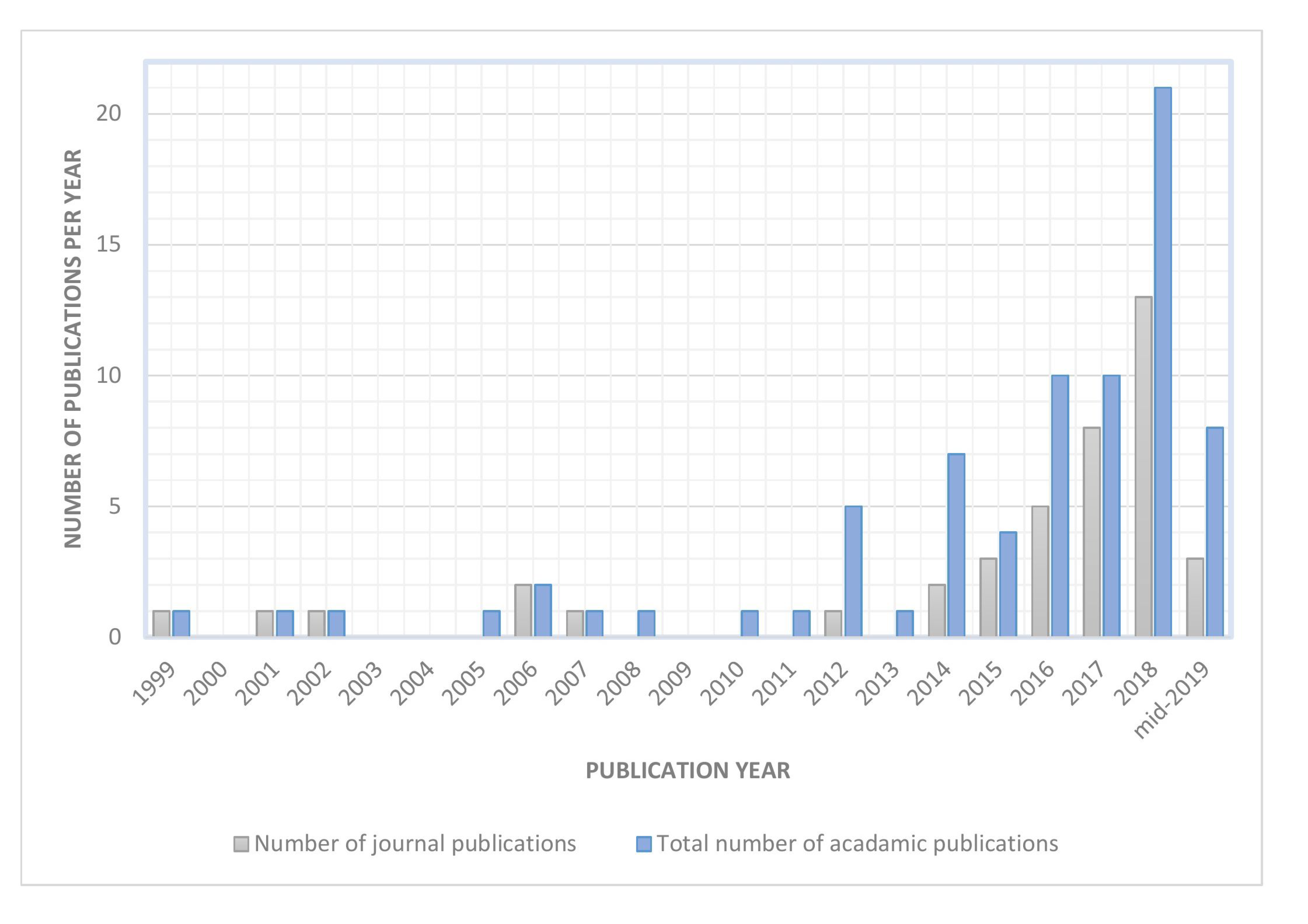

1. Introduction

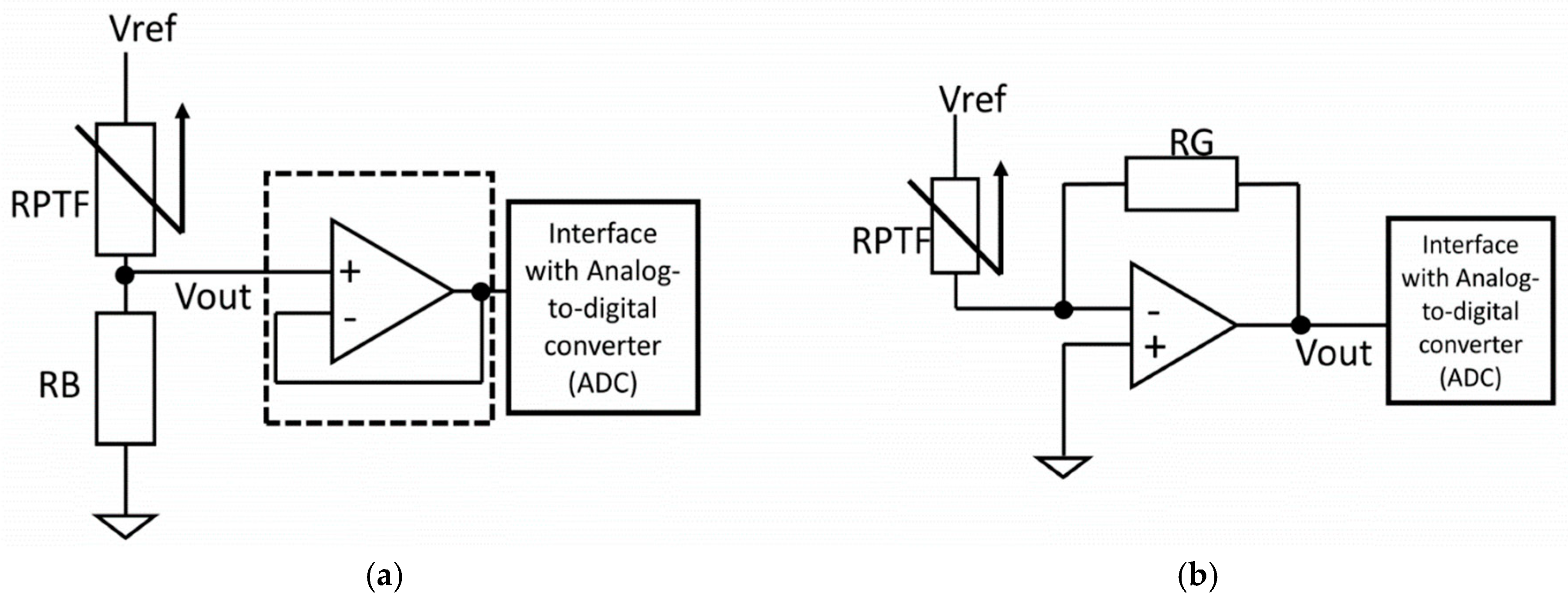

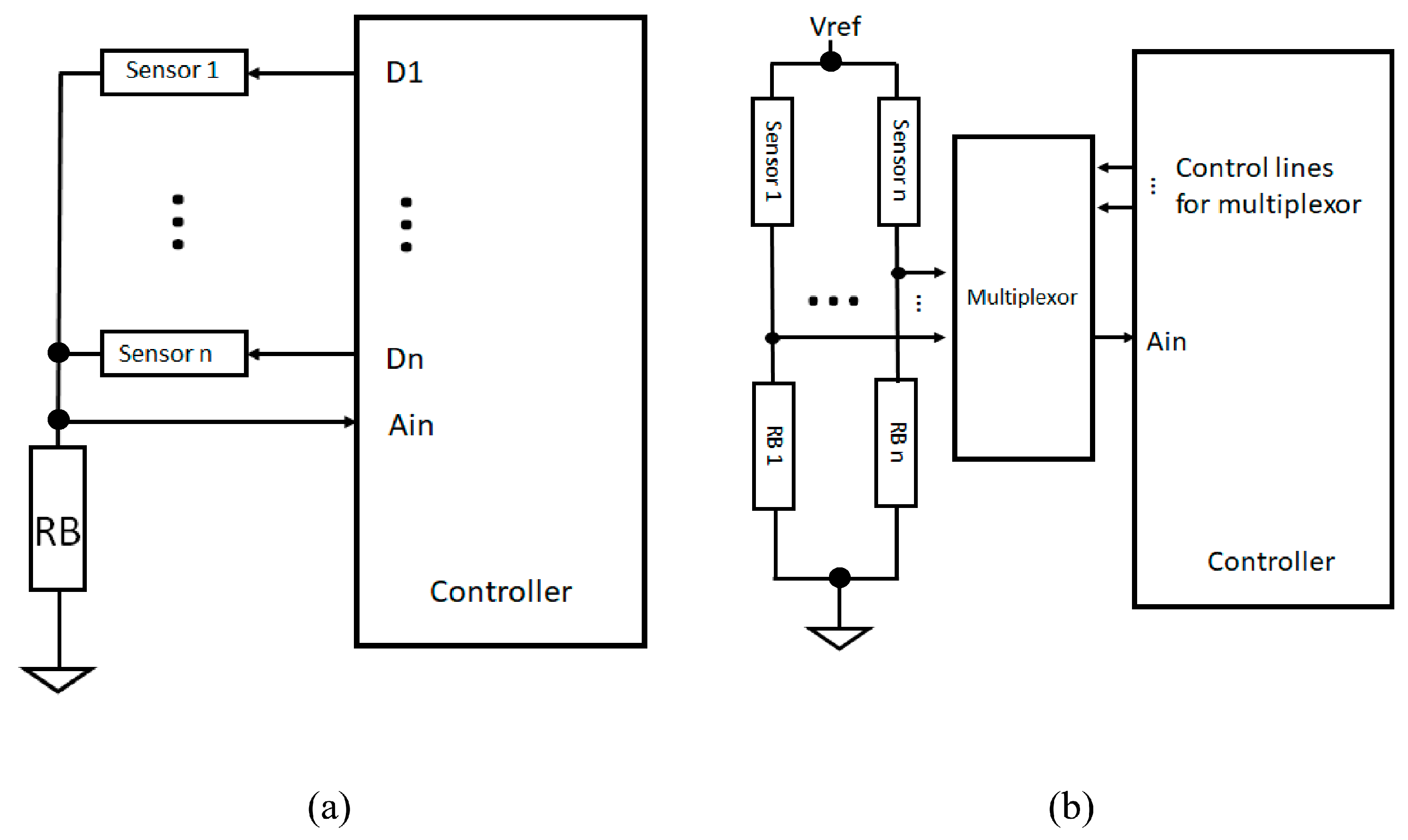

2. FMG Signal Acquisition

2.1. Resistive Polymer Thick Film Sensor (RPTF) for FMG Application

2.1.1. Element-Wise RPTF Sensor

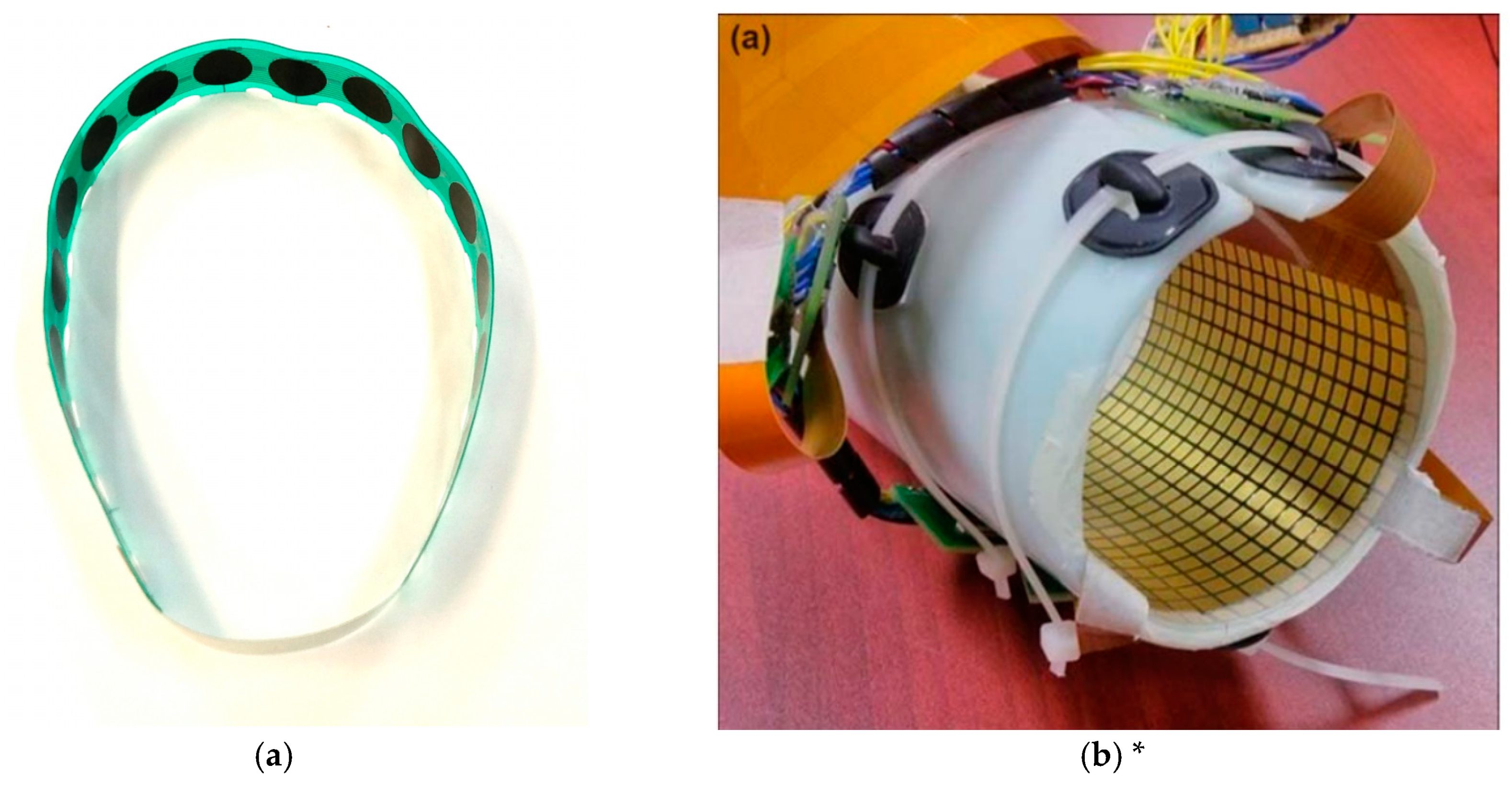

2.1.2. High-Density Polymer Thick Film Sensor Array and Matrix

2.1.3. Sampling Rate

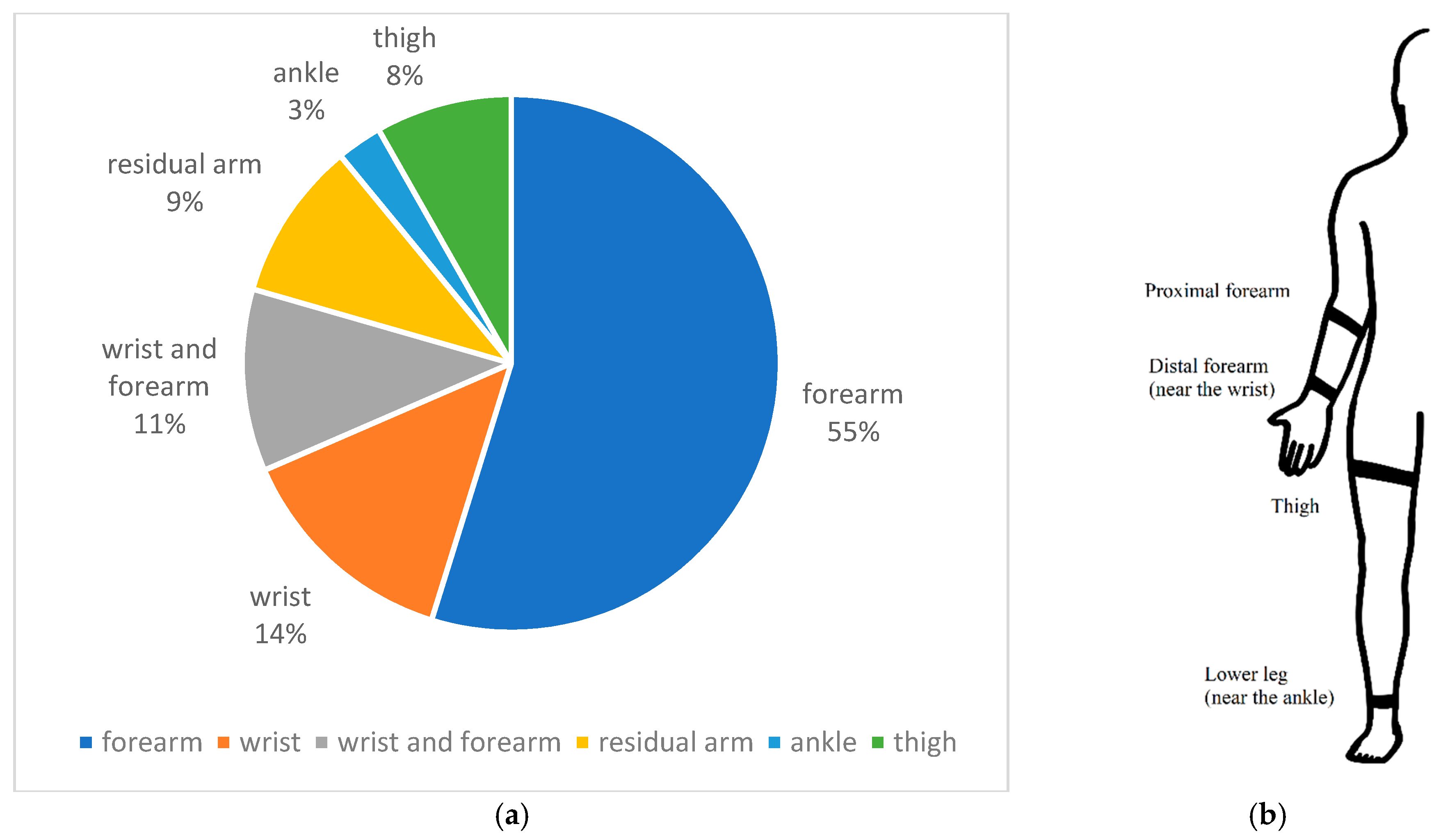

2.1.4. Sensor Placement and Applications

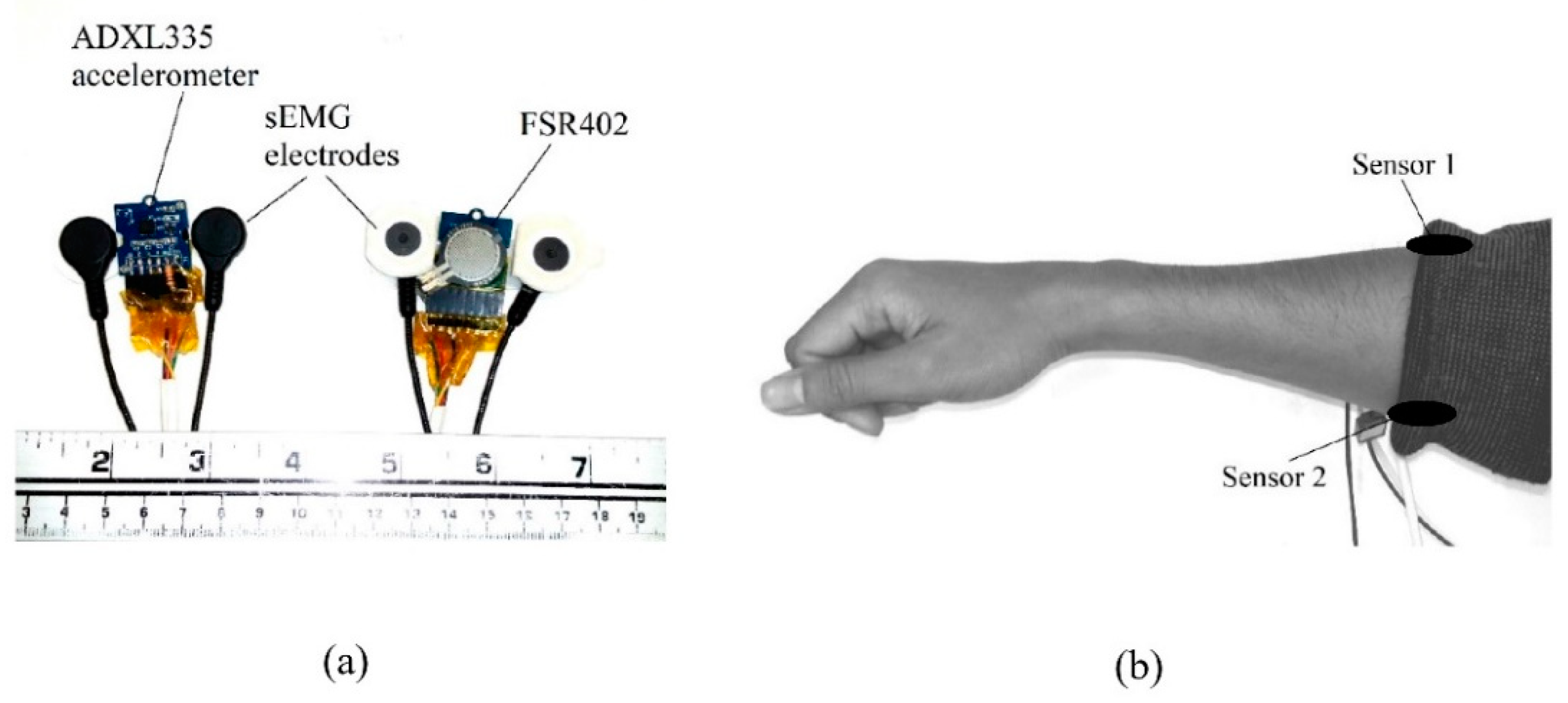

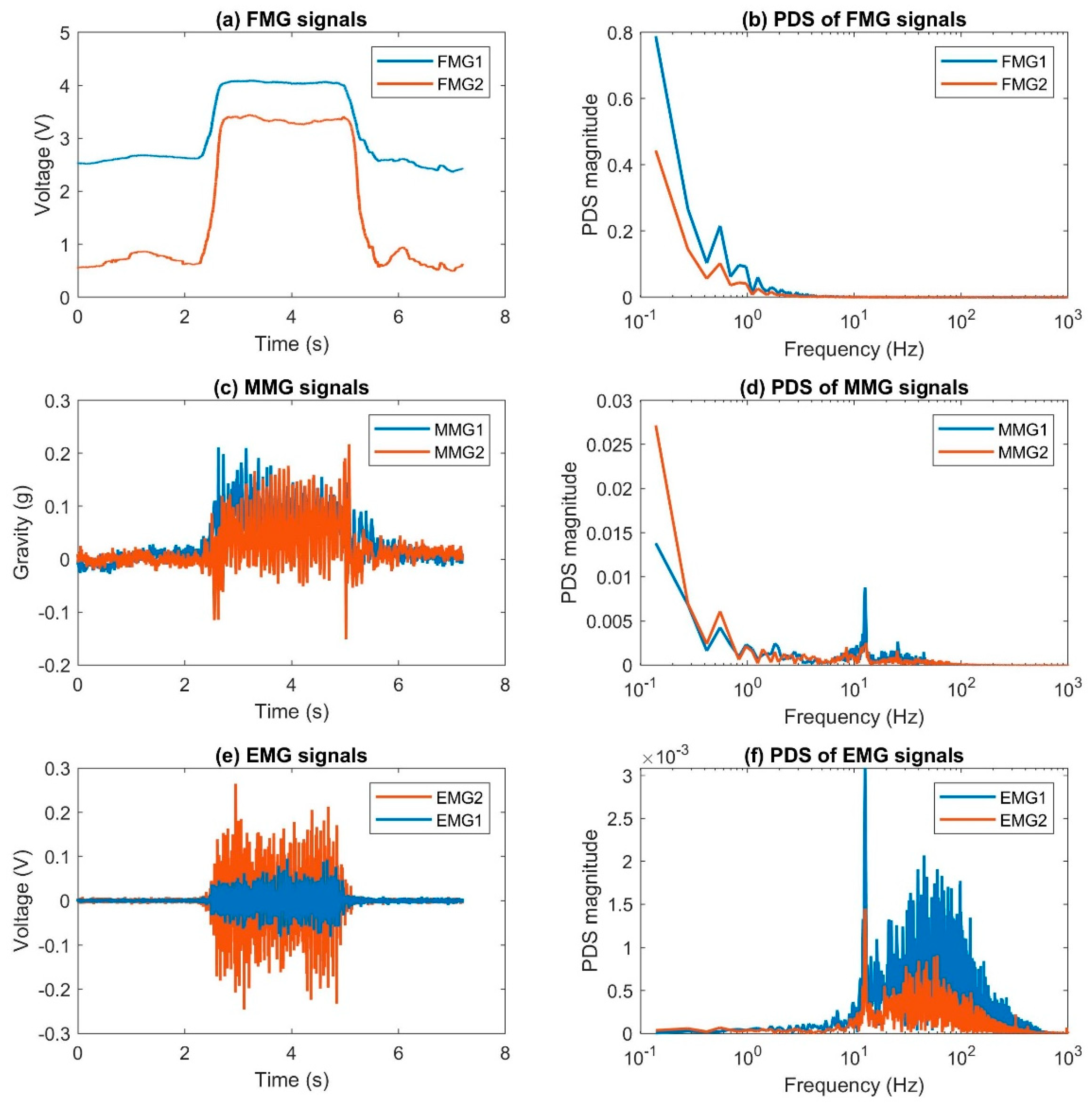

2.2. Example of FMG, MMG, and sEMG Signals from the Forearm for Squeezing Action

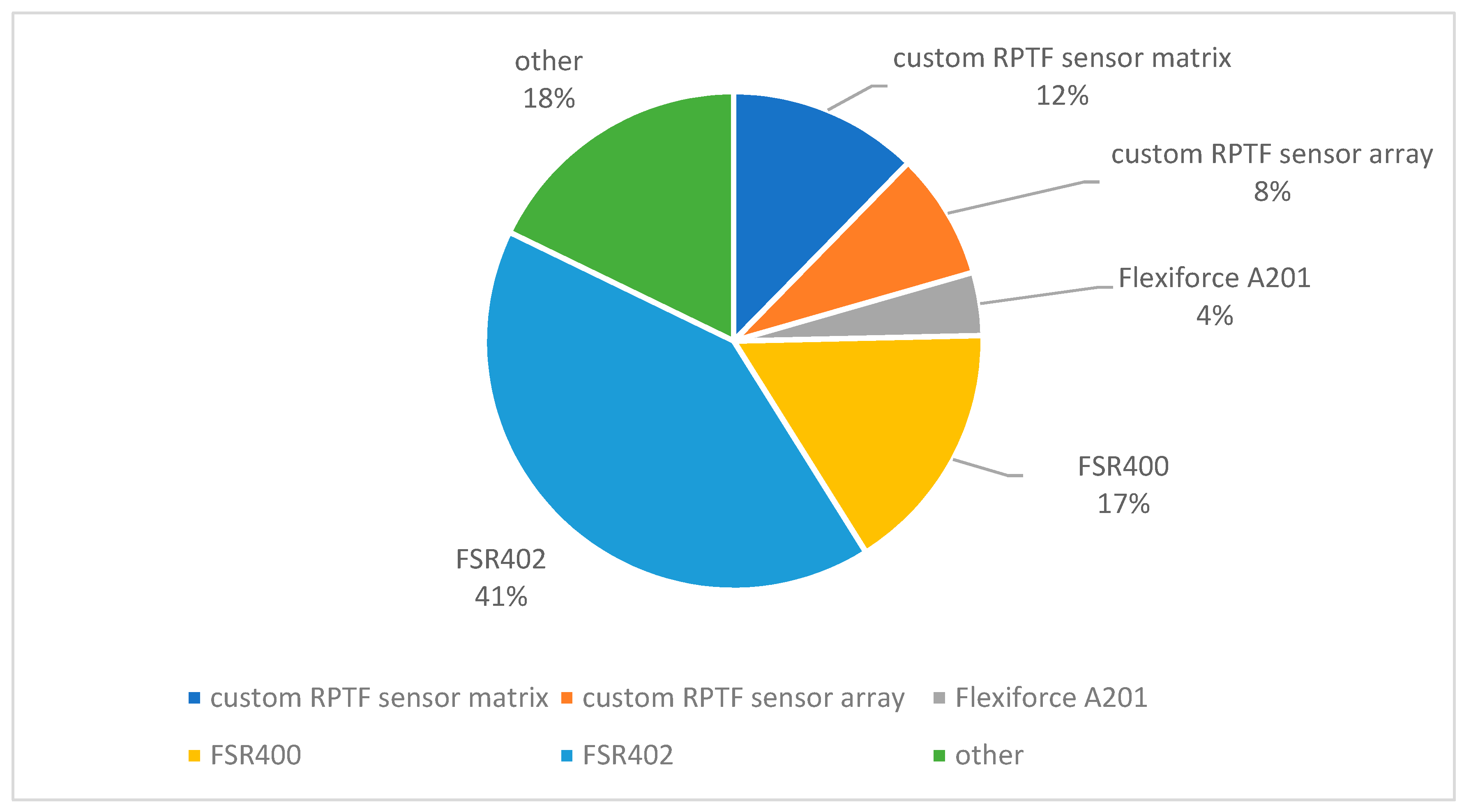

Other Force Sensors

3. FMG Processing Methods

3.1. FMG Signal Conditioning and Feature Extraction

3.2. Predict Limb Action Using Machine Learning Techniques

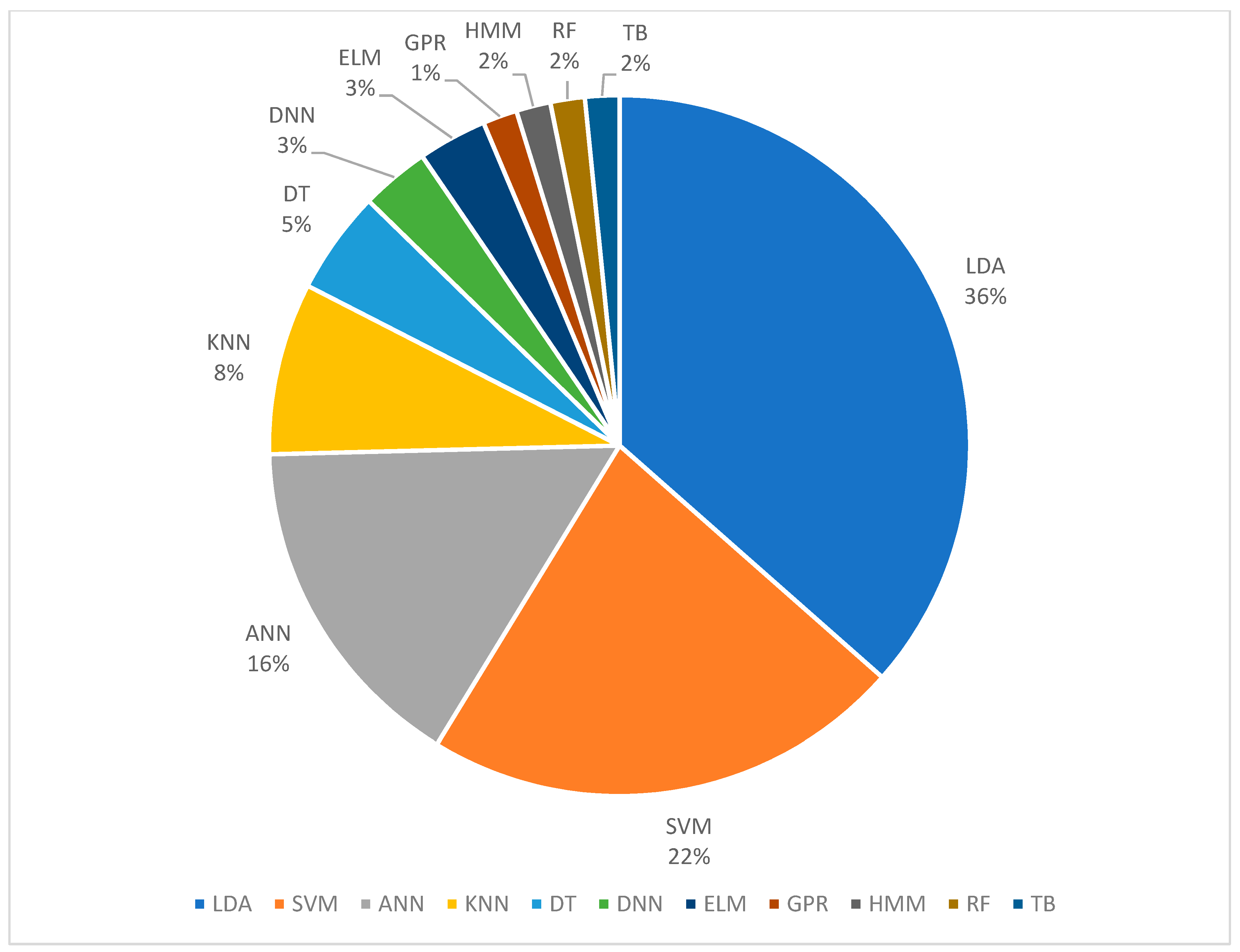

3.2.1. Classification

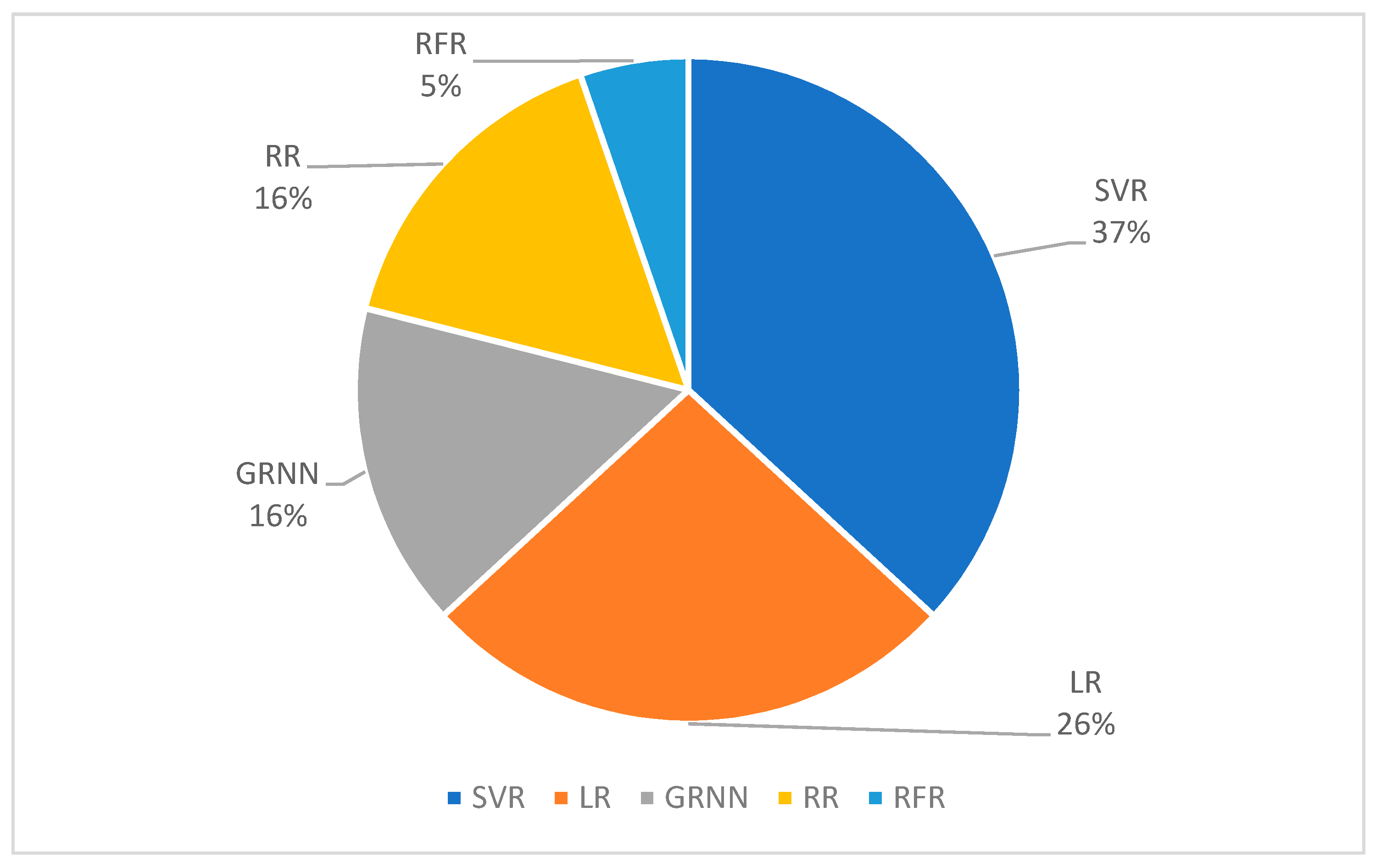

3.2.2. Regression

4. Discussion

4.1. Challenges in FMG Hardware Development

4.2. Challenges in FMG Software Development

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Reference | Title | Publication Type |

|---|---|---|

| Abboudi et al., 1999 [3] | A biomimetic controller for a multi-finger prosthesis | Journal |

| Curcie et al., 2001 [6] | Biomimetic finger control by filtering of distributed forelimb pressures | Journal |

| Craelius et al., 2002 [5] | The bionic man: restoring mobility | Journal |

| Phillips et al., 2005 [4] | Residual kinetic imaging: a versatile interface for prosthetic control | Journal |

| Amft et al., 2006 [8] | Sensing Muscle Activities with Body-Worn Sensors | Proceeding |

| Lukowicz et al., 2006 [7] | Detecting and Interpreting Muscle Activity with Wearable Force Sensors | Proceeding |

| Ogris et al., 2007 [9] | Using FSR-based muscule activity monitoring to recognize manipulative arm gestures | Proceeding |

| Wininger et al., 2008 [1] | Pressure signature of forearm as predictor of grip force | Journal |

| Wang et al., 2010 [37] | Biomechatronic approach to a multi-fingered hand prosthesis | Proceeding |

| Yungher et al., 2011 [47] | Surface muscle pressure as a measure of active and passive behavior of muscles during gait | Journal |

| Li et al., 2012 [13] | Combined Use of FSR Sensor Array and SVM Classifier for Finger Motion Recognition Based on Pressure Distribution Map | Journal |

| Bin et al., 2012 [73] | Multi-sensor arm rehabilitation monitoring device | Proceeding |

| Morganti et al., 2012 [24] | A Smart Watch with Embedded Sensors to Recognize Objects, Grasps and Forearm Gestures | Proceeding |

| Yungher et al., 2012 [34] | Improving fine motor function after brain injury using gesture recognition biofeedback | Journal |

| Castellini et al., 2012 [74] | Intention Gathering from Muscle Residual Activity for the Severely Disabled | Proceeding |

| Dementyev et al., 2014 [30] | WristFlex | Proceeding |

| Radmand et al., 2014 [12] | High-resolution muscle pressure mapping for upper-limb prosthetic control | Proceeding |

| Castellini et al., 2013 [75] | Using a high spatial resolution tactile sensor for intention detection | Proceeding |

| Xiao et al., 2014 [28] | Towards the development of a wearable feedback system for monitoring the activities of the upper-extremities | Journal |

| Carbonaro et al., 2014 [76] | An Innovative Multisensor Controlled Prosthetic Hand | Proceeding |

| Castellini et al., 2014 [10] | Proceedings of the first workshop on Peripheral Machine Interfaces: going beyond traditional surface electromyography | Journal |

| Castellini et al., 2014 [68] | A wearable low-cost device based upon Force-Sensing Resistors to detect single-finger forces | Proceeding |

| Ravindra et al., 2014 [35] | A Comparative Analysis of Three Non-Invasive Human-Machine Interfaces for the Disabled | Journal |

| Rasouli et al., 2015 [55] | Stable force-myographic control of a prosthetic hand using incremental learning | Proceeding |

| Sadarangani et al., 2015 [27] | A wearable sensor system for rehabilitation applications | Proceeding |

| Koiva et al., 2015 [77] | Shape conformable high spatial resolution tactile bracelet for detecting hand and wrist activity | Proceeding |

| Sanford et al., 2015 [78] | Surface EMG and intra-socket force measurement to control a prosthetic device | Proceeding |

| Chengani et al., 2016 [79] | Pilot study on strategies in sensor placement for robust hand/wrist gesture classification based on movement related changes in forearm volume | Proceeding |

| Cho et al., 2016 [41] | Force Myography to Control Robotic Upper Extremity Prostheses: A Feasibility Study | Journal |

| Connan et al., 2016 [23] | Assessment of a Wearable Force- and Electromyography Device and Comparison of the Related Signals for Myocontrol | Journal |

| Jiang et al., 2016 [50] | Ankle positions classification using force myography: An exploratory investigation | Proceeding |

| Jiang et al., 2016 [32] | Exploration of Force Myography and surface Electro Myography in Hand Gesture classification | Journal |

| Li et al., 2016 [56] | FMG-based body motion registration using piezoelectric sensors | Proceeding |

| Radmand et al., 2016 [46] | High-density force myography: A possible alternative for upper-limb prosthetic control | Journal |

| Yap et al., 2016 [38] | Design of a wearable FMG sensing system for user intent detection during hand rehabilitation with a soft robotic glove | Proceeding |

| Kadkhodayan et al., 2016 [70] | Continuous Prediction of Finger Movements Using Force Myography | Journal |

| Sakr et al., 2016 [69] | On the estimation of isometric wrist/forearm torque about three axes using Force Myography | Proceeding |

| Ahmadizadeh et al., 2017 [31] | Toward Intuitive Prosthetic Control: Solving Common Issues Using Force Myography, Surface Electromyography, and Pattern Recognition in a Pilot Case Study | Journal |

| Ferigo et al., 2017 [42] | A Case Study of a Force-myography Controlled Bionic Hand Mitigating Limb Position Effect | Journal |

| Ghataurah et al., 2017 [43] | A Multi-sensor Approach for Biomimetic Control of a Robotic Prosthetic Hand | Proceeding |

| Jaquier et al., 2017 [65] | Combining Electromyography and Tactile Myography to Improve Hand and Wrist Activity Detection in Prostheses | Journal |

| Nowak et al., 2017 [66] | Multi-modal myocontrol: Testing combined force- and electromyography | Proceeding |

| Sadarangani et al., 2017 [36] | Force Myography for Monitoring Grasping in Individuals with Stroke with Mild to Moderate Upper-Extremity Impairments: A Preliminary Investigation in a Controlled Environment | Journal |

| Sanford et al., 2017 [80] | Concurrent surface electromyography and force myography classification during times of prosthetic socket shift and user fatigue | Journal |

| Xiao et al., 2017 [45] | Performance of Forearm FMG and sEMG for Estimating Elbow, Forearm and Wrist Positions | Journal |

| Xiao et al., 2017 [29] | Counting Grasping Action Using Force Myography: An Exploratory Study with Healthy Individuals | Journal |

| Delva et al., 2017 [81] | FSR based Force Myography (FMG) Stability Throughout Non-Stationary Upper Extremity Tasks | Proceeding |

| Booth et al., 2018 [82] | A Wrist-Worn Piezoelectric Sensor Array for Gesture Input | Journal |

| Castellini et al., 2018 [14] | Tactile Myography: An Off-Line Assessment of Able-Bodied Subjects and One Upper-Limb Amputee | Journal |

| Delva et al., 2018 [83] | Investigation into the Potential to Create a Force Myography-based Smart-home Controller for Aging Populations | Proceeding |

| Ha et al., 2018 [57] | Force Myography Signal-Based Hand Gesture Classification for the Implementation of Real-Time Control System to a Prosthetic Hand | Proceeding |

| Fang et al., 2018 [58] | Fabrication, structure characterization, and performance testing of piezoelectret-film sensors for recording body motion | Journal |

| Fujiwara et al., 2018 [60] | Optical fiber force myography sensor for identification of hand postures | Journal |

| Fujiwara et al., 2018 [84] | Optical fiber force myography sensor for applications in prosthetic hand control | Proceeding |

| Godiyal et al., 2018 [26] | Force Myography Based Novel Strategy for Locomotion classification | Journal |

| Jiang et al., 2018 [85] | Force Exertion Affects Grasp classification Using Force Myography | Journal |

| Jiang et al., 2018 [51] | Exploration of Gait Parameters Affecting the Accuracy of Force Myography-Based Gait Phase Detection | Proceeding |

| Jiang et al., 2018 [67] | Virtual grasps recognition using fusion of Leap Motion and force myography | Journal |

| Truong et al., 2018 [59] | CapBand | Proceeding |

| Zhang et al., 2018 [86] | A Pilot Study on Using Forcemyography to Record Upper-limb Movements for Human-machine Interactive Control | Proceeding |

| Belyea et al., 2018 [48] | A Proportional Control Scheme for High Density Force Myography | Journal |

| Sadeghi et al., 2018 [33] | Regressing grasping using force myography: An exploratory study | Journal |

| Anvaripour et al., 2018 [62] | Hand gesture recognition using force myography of the forearm activities and optimized features | Proceeding |

| Godiyal et al., 2018 [49] | A force myography-based system for gait event detection in overground and ramp walking | Journal |

| Belbasis et al., 2018 [48] | Muscle performance investigated with a novel smart compression garment based on pressure sensor force myography and its validation against EMG | Journal |

| Esposito et al., 2018 [22] | A piezoresistive sensor to measure muscle contraction and mechanomyography | Journal |

| Sakr et al., 2018 [40] | Exploratory Evaluation of the Force Myography (FMG) Signals Usage for Admittance Control of a Linear Actuator | Proceeding |

| Stefanou et al., 2018 [72] | Wearable Tactile Sensor Brace for Motion Intent Recognition in Upper-Limb Rehabilitation | Proceeding |

| Ha et al., 2019 [87] | Performance of Forearm FMG for Estimating Hand Gestures and Prosthetic Hand Control | Journal |

| Xiao et al., 2019 [61] | Does force myography recorded at the wrist correlate to resistance load levels during bicep curls? | Journal |

| Xiao et al., 2019 [25] | An Investigation on the Sampling Frequency of the Upper-Limb Force Myographic Signals | Journal |

| Xiao et al., 2019 [39] | Towards an FMG based augmented musical instrument interface | Proceeding |

| Belyea et al., 2019 [71] | FMG vs EMG: A Comparison of Usability for Real-time Pattern Recognition Based Control | Journal |

| Anvaripour et al., 2019 [88] | Controlling robot gripper force by transferring human forearm stiffness using force myography | Proceeding |

| Herrera-Luna et al., 2019 [11] | Sensor Fusion Used in Applications for Hand Rehabilitation: a Systematic Review | Journal |

| Prakash et al., 2019 [44] | Novel force myography sensor to measure muscle contractions for controlling hand prostheses | Journal |

References

- Michael, W.W.; Nam-Hun, K. Craelius Pressure signature of forearm as predictor of grip force. J. Rehabil. Res. Dev. 2008, 45, 883–892. [Google Scholar]

- Lucaccini, L.F.; Kaiser, P.K.; Lyman, J. The French electric hand: Some observations and conclusions. Bull. Prosthet. Res. 1966, 10, 31–51. [Google Scholar]

- Abboudi, R.L.; Glass, C.A.; Newby, N.A.; Flint, J.A.; Craelius, W. A biomimetic controller for a multifinger prosthesis. IEEE Trans. Rehabil. Eng. 1999, 7, 121–129. [Google Scholar] [CrossRef] [PubMed]

- Phillips, S.L.; Craelius, W. Residual kinetic imaging: A versatile interface for prosthetic control. Robotica 2005, 23, 277–282. [Google Scholar] [CrossRef]

- Craelius, W. The bionic man: Restoring mobility. Science 2002, 295, 1018–1021. [Google Scholar] [CrossRef] [PubMed]

- Curcie, D.J.; Flint, J.A.; Craelius, W. Biomimetic finger control by filtering of distributed forelimb pressures. IEEE Trans. Neural Syst. Rehabil. Eng. 2001, 9, 69–75. [Google Scholar] [CrossRef]

- Lukowicz, P.; Hanser, F.; Szubski, C.; Sehobersberger, W. Detecting and interpreting muscle activity with wearable force sensors. In Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Berlin/Heidelberg, Germany, 2006; pp. 101–116. [Google Scholar]

- Amft, O.; Troster, G.; Lukowicz, P.; Schuster, C. Sensing Muscle Activities with Body-Worn Sensors. In Proceedings of the International Workshop on Wearable and Implantable Body Sensor Networks, Cambridge, MA, USA, 3–5 April 2006; pp. 138–141. [Google Scholar]

- Ogris, G.; Kreil, M.; Lukowicz, P. Using FSR based muscule activity monitoring to recognize manipulative arm gestures. In Proceedings of the 2007 11th IEEE International Symposium on Wearable Computers, Boston, MA, USA, 11–13 October 2007; pp. 1–4. [Google Scholar]

- Castellini, C.; Artemiadis, P.; Wininger, M.; Ajoudani, A.; Alimusaj, M.; Bicchi, A.; Caputo, B.; Craelius, W.; Dosen, S.; Englehart, K.; et al. Proceedings of the first workshop on Peripheral Machine Interfaces: Going beyond traditional surface electromyography. Front. Neurorobot. 2014, 8, 22. [Google Scholar] [CrossRef]

- Herrera-Luna, I.; Rechy-Ramirez, E.J.; Rios-Figueroa, H.V.; Marin-Hernandez, A. Sensor Fusion Used in Applications for Hand Rehabilitation: A Systematic Review. IEEE Sens. J. 2019, 19, 3581–3592. [Google Scholar] [CrossRef]

- Radmand, A.; Scheme, E.; Englehard, K. High-resolution muscle pressure mapping for upper-limb prosthetic control. In Proceedings of the MEC-Myoelectric Control Symposium, Fredericton, NB, Canada, 18–22 August 2014; pp. 189–193. [Google Scholar]

- Li, N.; Yang, D.; Jiang, L.; Liu, H.; Cai, H. Combined Use of FSR Sensor Array and SVM Classifier for Finger Motion Recognition Based on Pressure Distribution Map. J. Bionic Eng. 2012, 9, 39–47. [Google Scholar] [CrossRef]

- Castellini, C.; Kõiva, R.; Pasluosta, C.; Viegas, C.; Eskofier, B. Tactile Myography: An Off-Line Assessment of Able-Bodied Subjects and One Upper-Limb Amputee. Technologies 2018, 6, 38. [Google Scholar] [CrossRef]

- Wu, Y.T.; Fujiwara, E.; Suzuki, C.K. Evaluation of Optical Myography Sensor as Predictor of Hand Postures. IEEE Sens. J. 2019, 19, 5299–5306. [Google Scholar] [CrossRef]

- Ferrane, A.; Jiang, X.; Maiolo, L.; Pecora, A.; Colace, L.; Menon, C. A fabric-based wearable band for hand gesture recognition based on filament strain sensors: A preliminary investigation. In Proceedings of the 2016 IEEE Healthcare Innovation Point-Of-Care Technologies Conference (HI-POCT), Cancun, Mexico, 9–16 November 2016; pp. 113–116. [Google Scholar]

- Ng, H.W.; Jiang, X.; Merhi, L.-K.; Menon, C. Investigation of the Feasibility of Strain Gages as Pressure Sensors for Force Myography. In Proceedings of the International Conference on Bioinformatics and Biomedical Engineering, IWBBIO 2017, Granada, Spain, 26–28 April2017; pp. 261–270. [Google Scholar]

- Rekimoto, J. GestureWrist and GesturePad: unobtrusive wearable interaction devices. In Proceedings of the Fifth International Symposium on Wearable Computers, Zurich, Switzerland, 8–9 October 2001; pp. 21–27. [Google Scholar]

- Kato, A.; Matsumoto, Y.; Kato, R.; Kobayashi, Y.; Yokoi, H.; Fujie, M.G.; Sugano, S. Estimating wrist joint angle with limited skin deformation information. J. Biomech. Sci. Eng. 2018, 13, 1–11. [Google Scholar] [CrossRef][Green Version]

- Interlink Technologies FSR 402 Data Sheet. Available online: https://www.interlinkelectronics.com/fsr-402 (accessed on 19 October 2019).

- FlexiForce A201 Datasheet. Available online: https://www.tekscan.com/resources/product/flexiforce-a201-datasheet (accessed on 19 October 2019).

- Esposito, D.; Andreozzi, E.; Fratini, A.; Gargiulo, G.D.; Savino, S.; Niola, V.; Bifulco, P. A piezoresistive sensor to measure muscle contraction and mechanomyography. Sensors 2018, 18, 2553. [Google Scholar] [CrossRef] [PubMed]

- Connan, M.; Ruiz Ramírez, E.; Vodermayer, B.; Castellini, C. Assessment of a Wearable Force-and Electromyography Device and Comparison of the Related Signals for Myocontrol. Front. Neurorobot. 2016, 10, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Morganti, E.; Angelini, L.; Adami, A.; Lalanne, D.; Lorenzelli, L.; Mugellini, E. A Smart Watch with Embedded Sensors to Recognize Objects, Grasps and Forearm Gestures. Procedia Eng. 2012, 41, 1169–1175. [Google Scholar] [CrossRef]

- Xiao, Z.G.; Menon, C. An Investigation on the Sampling Frequency of the Upper-Limb Force Myographic Signals. Sensors 2019, 19, 2432. [Google Scholar] [CrossRef]

- Godiyal, A.K.; Mondal, M.; Joshi, S.D.; Joshi, D. Force Myography Based Novel Strategy for Locomotion Classification. IEEE Trans. Hum.-Mach. Syst. 2018, 48, 648–657. [Google Scholar] [CrossRef]

- Sadarangani, G.; Menon, C. A wearable sensor system for rehabilitation apllications. In Proceedings of the 2015 IEEE International Conference on Rehabilitation Robotics (ICORR), Singapore, 11–14 August 2015; pp. 672–677. [Google Scholar]

- Xiao, Z.G.; Menon, C. Towards the development of a wearable feedback system for monitoring the activities of the upper-extremities. J. Neuroeng. Rehabil. 2014, 11, 2. [Google Scholar] [CrossRef]

- Xiao, Z.G.; Menon, C. Counting Grasping Action Using Force Myography: An Exploratory Study With Healthy Individuals. JMIR Rehabil. Assist. Technol. 2017, 4, e5. [Google Scholar] [CrossRef]

- Dementyev, A.; Paradiso, J.A. WristFlex. In Proceedings of the 27th annual ACM symposium on User interface software and technology-UIST ’14, Honolulu, HI, USA, 5–8 October 2014; pp. 161–166. [Google Scholar]

- Ahmadizadeh, C.; Merhi, L.-K.; Pousett, B.; Sangha, S.; Menon, C. Toward Intuitive Prosthetic Control: Solving Common Issues Using Force Myography, Surface Electromyography, and Pattern Recognition in a Pilot Case Study. IEEE Robot. Autom. Mag. 2017, 24, 102–111. [Google Scholar] [CrossRef]

- Jiang, X.; Merhi, L.-K.; Xiao, Z.G.; Menon, C. Exploration of Force MyoGraphy and surface ElectroMyography in Hand Gesture Classification. Med. Eng. Phys. 2016, 41, 36–67. [Google Scholar] [CrossRef] [PubMed]

- Sadeghi Chegani, R.; Menon, C. Regressing grasping using force myography: An exploratory study. Biomed. Eng. Online 2018, 17, 1–22. [Google Scholar] [CrossRef] [PubMed]

- Yungher, D.; Craelius, W. Improving fine motor function after brain injury using gesture recognition biofeedback. Disabil. Rehabil. Assist. Technol. 2012, 7, 464–468. [Google Scholar] [CrossRef] [PubMed]

- Ravindra, V.; Castellini, C. A Comparative Analysis of Three Non-Invasive Human-Machine Interfaces for the Disabled. Front. Neurorobot. 2014, 8, 1–10. [Google Scholar] [CrossRef]

- Sadarangani, G.P.; Jiang, X.; Simpson, L.A.; Eng, J.J.; Menon, C. Force Myography for Monitoring Grasping in Individuals with Stroke with Mild to Moderate Upper-Extremity Impairments: A Preliminary Investigation in a Controlled Environment. Front. Bioeng. Biotechnol. 2017, 5, 42. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, J.; Yang, D.; Li, N.; Sun, C.; Liu, H. Biomechatronic approach to a multi-fingered hand prosthesis. In Proceedings of the 3rd IEEE RAS & EMBS International Conference on Biomedical Robotics and Biomechatronics, Tokyo, Japan, 26–29 September 2010; pp. 209–214. [Google Scholar]

- Yap, H.K.; Mao, A.; Goh, J.C.; Yeow, C.-H. Design of a wearable FMG sensing system for user intent detection during hand rehabilitation with a soft robotic glove. In Proceedings of the 6th IEEE International Conference on Biomedical Robotics and Biomechatronics, Singapore, 26–29 July 2006; pp. 781–786. [Google Scholar]

- Xiao, Z.G.; Chhatre, N.; Kuatsjah, E.; Menon, C. Towards an FMG based augmented musical instrument interface. In Proceedings of the IEEE 9th Annual Information Technology Electronics and Mobile Communication Conference, Vancouver, BC, Canada, 1–3 November 2019; pp. 582–587. [Google Scholar]

- Sakr, M.; Menon, C. Exploratory Evaluation of the Force Myography (FMG) Signals Usage for Admittance Control of a Linear Actuator. In Proceedings of the 7th IEEE International Conference on Biomedical Robotics and Biomechatronics, Enschede, The Netherlands, 26–29 August 2018; pp. 903–908. [Google Scholar]

- Cho, E.; Chen, R.; Merhi, L.-K.; Xiao, Z.; Pousett, B.; Menon, C. Force Myography to Control Robotic Upper Extremity Prostheses: A Feasibility Study. Front. Bioeng. Biotechnol. 2016, 4, 1–12. [Google Scholar] [CrossRef]

- Ferigo, D.; Merhi, L.-K.; Pousett, B.; Xiao, Z.G.; Menon, C. A Case Study of a Force-myography Controlled Bionic Hand Mitigating Limb Position Effect. J. Bionic Eng. 2017, 14, 692–705. [Google Scholar] [CrossRef]

- Ghataurah, J.; Ferigo, D.; Merhi, L.-K.; Pousett, B.; Menon, C. A Multi-sensor Approach for Biomimetic Control of a Robotic Prosthetic Hand. In Proceedings of the 5th International Work-Conference, IWBBIO 2017, Granada, Spain, 26–28 April 2017; pp. 74–84. [Google Scholar]

- Prakash, A.; Sharma, N.; Sharma, S. Novel force myography sensor to measure muscle contractions for controlling hand prostheses. Instrum. Sci. Technol. 2019, 1–20. [Google Scholar] [CrossRef]

- Xiao, Z.G.; Menon, C. Performance of Forearm FMG and sEMG for Estimating Elbow, Forearm and Wrist Positions. J. Bionic Eng. 2017, 14, 284–295. [Google Scholar] [CrossRef]

- Radmand, A.; Scheme, E.; Englehart, K. High-density force myography: A possible alternative for upper-limb prosthetic control. J. Rehabil. Res. Dev. 2016, 53, 443–456. [Google Scholar] [CrossRef]

- Yungher, D.A.; Wininger, M.T.; Barr, J.B.; Craelius, W.; Threlkeld, A.J. Surface muscle pressure as a measure of active and passive behavior of muscles during gait. Med. Eng. Phys. 2011, 33, 464–471. [Google Scholar] [CrossRef] [PubMed]

- Belyea, A.T.; Englehart, K.B.; Scheme, E.J. A proportional control scheme for high density force myography. J. Neural Eng. 2018, 15, 046029. [Google Scholar] [CrossRef] [PubMed]

- Godiyal, A.K.; Verma, H.K.; Khanna, N.; Joshi, D. A force myography-based system for gait event detection in overground and ramp walking. IEEE Trans. Instrum. Meas. 2018, 67, 2314–2323. [Google Scholar] [CrossRef]

- Jiang, X.; Chu, H.T.; Xiao, Z.G.; Merhi, L.-K.; Menon, C. Ankle positions classification using force myography: An exploratory investigation. In Proceedings of the IEEE Healthcare Innovation Point-Of-Care Technologies Conference (HI-POCT), Cancun, Mexico, 9–11 November 2016; pp. 29–32. [Google Scholar]

- Jiang, X.; Tory, L.; Khoshnam, M.; Chu, K.H.T.; Menon, C. Exploration of Gait Parameters Affecting the Accuracy of Force Myography-Based Gait Phase Detection. In Proceedings of the 7th IEEE International Conference on Biomedical Robotics and Biomechatronics, Enschede, The Netherlands, 26–29 August 2018; pp. 1205–1210. [Google Scholar]

- Wang, J.; Tang, L.; Bronlund, J.E. Surface EMG Signal Amplification and Filtering. Int. J. Comput. Appl. 2013, 82, 15–22. [Google Scholar]

- Islam, M.A.; Sundaraj, K.; Ahmad, R.B.; Ahamed, N.U.; Ali, M.A. Mechanomyography sensor development, related signal processing, and applications: A systematic review. IEEE Sens. J. 2013, 13, 2499–2516. [Google Scholar] [CrossRef]

- Fang, Y.; Hettiarachchi, N.; Zhou, D.; Liu, H. Multi-modal Sensing Techniques for Interfacing Hand Prostheses: A Review. IEEE Sens. J. 2015, 15, 6065–6076. [Google Scholar] [CrossRef]

- Rasouli, M.; Ghosh, R.; Lee, W.W.; Thakor, N.V.; Kukreja, S. Stable force-myographic control of a prosthetic hand using incremental learning. In Proceedings of the 37th Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Milan, Italy, 25–29 August 2015; pp. 4828–4831. [Google Scholar]

- Li, X.; Zhuo, Q.; Zhang, X.; Samuel, O.W.; Xia, Z.; Zhang, X.; Fang, P.; Li, G. FMG-based body motion registration using piezoelectret sensors. In Proceedings of the 38th Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Orlando, FL, USA, 16–20 August 2016; pp. 4626–4629. [Google Scholar]

- Ha, N.; Withanachchi, G.P.; Yihun, Y. Force Myography Signal-Based Hand Gesture Classification for the Implementation of Real-Time Control System to a Prosthetic Hand. In Proceedings of the Design of Medical Devices Conference, Minneapolis, MN, USA, 9–12 April 2018; pp. 1–4. [Google Scholar]

- Fang, P.; Ma, X.; Li, X.; Qiu, X.; Gerhard, R.; Zhang, X.; Li, G. Fabrication, structure characterization, and performance testing of piezoelectret-film sensors for recording body motion. IEEE Sens. J. 2018, 18, 401–412. [Google Scholar] [CrossRef]

- Truong, H.; Vu, T.; Zhang, S.; Muncuk, U.; Nguyen, P.; Bui, N.; Nguyen, A.; Lv, Q.; Chowdhury, K.; Dinh, T. CapBand. In Proceedings of the 16th ACM Conference on Embedded Networked Sensor Systems-SenSys ’18, Shenzhen, China, 4–7 November 2018; pp. 54–67. [Google Scholar]

- Fujiwara, E.; Suzuki, C.K. Optical fiber force myography sensor for identification of hand postures. J. Sens. 2018, 2018. [Google Scholar] [CrossRef]

- Xiao, Z.G.; Menon, C. Does force myography recorded at the wrist correlate to resistance load levels during bicep curls? J. Biomech. 2019, 83, 310–314. [Google Scholar] [CrossRef]

- Anvaripour, M.; Saif, M. Hand gesture recognition using force myography of the forearm activities and optimized features. In Proceedings of the IEEE International Conference on Industrial Technology, Lyon, France, 20–22 February 2018; pp. 187–192. [Google Scholar]

- Christ, M.; Braun, N.; Neuffer, J.; Kempa-Liehr, A.W. Time Series FeatuRe Extraction on basis of Scalable Hypothesis tests (tsfresh–A Python package). Neurocomputing 2018, 307, 72–77. [Google Scholar] [CrossRef]

- Fulcher, B.D.; Jones, N.S. hctsa: A Computational Framework for Automated Time-Series Phenotyping Using Massive Feature Extraction. Cell Syst. 2017, 5, 527–531. [Google Scholar] [CrossRef] [PubMed]

- Jaquier, N.; Connan, M.; Castellini, C.; Calinon, S. Combining Electromyography and Tactile Myography to Improve Hand and Wrist Activity Detection in Prostheses. Technologies 2017, 5, 64. [Google Scholar] [CrossRef]

- Nowak, M.; Eiband, T.; Castellini, C. Multi-modal myocontrol: Testing combined force-and electromyography. In Proceedings of the International Conference on Rehabilitation Robotics, London, UK, 17–20 July 2017; pp. 1364–1368. [Google Scholar]

- Jiang, X.; Xiao, Z.G.; Menon, C. Virtual grasps recognition using fusion of Leap Motion and force myography. Virtual Real. 2018, 22, 297–308. [Google Scholar] [CrossRef]

- Castellini, C.; Ravindra, V. A wearable low-cost device based upon Force-Sensing Resistors to detect single-finger forces. In Proceedings of the 5th IEEE RAS/EMBS International Conference on Biomedical Robotics and Biomechatronics, São Paulo, Brazil; 2014; pp. 199–203. [Google Scholar]

- Sakr, M.; Menon, C. On the estimation of isometric wrist/forearm torque about three axes using Force Myography. In Proceedings of the 6th IEEE International Conference on Biomedical Robotics and Biomechatronics, Singapore, 26–29 July 2016; pp. 827–832. [Google Scholar]

- Kadkhodayan, A.; Jiang, X.; Menon, C. Continuous Prediction of Finger Movements Using Force Myography. J. Med. Biol. Eng. 2016, 36, 594–604. [Google Scholar] [CrossRef]

- Belyea, A.; Englehart, K.; Scheme, E. FMG vs EMG: A Comparison of Usability for Real-time Pattern Recognition Based Control. IEEE Trans. Biomed. Eng. 2019, 1. [Google Scholar] [CrossRef]

- Stefanou, T.; Chance, G.; Assaf, T.; Lenz, A.; Dogramadzi, S. Wearable Tactile Sensor Brace for Motion Intent Recognition in Upper-Limb Rehabilitation. In Proceedings of the 7th IEEE International Conference on Biomedical Robotics and Biomechatronics, Enschede, The Netherlands, 26–29 August 2018; pp. 148–155. [Google Scholar]

- Bin Ambar, R.; Poad, H.B.M.; Ali, A.M.B.M.; Bin Ahmad, M.S.; Bin Abdul Jamil, M.M. Multi-sensor arm rehabilitation monitoring device. In Proceedings of the International Conference on Biomedical Engineering, Penang, Malasyia, 27–28 February 2012; pp. 424–429. [Google Scholar]

- Castellini, C.; Kõiva, R. Intention Gathering from Muscle Residual Activity for the Severely Disabled. In Proceedings of the IROS 2012, Workshop on Progress, Challenges and Future Perspectives in Navigation and Manipulation Assistance for Robotic Wheelchairs, Algarve, Portugal, 7–12 October 2012. [Google Scholar]

- Castellini, C.; Koiva, R. Using a high spatial resolution tactile sensor for intention detection. In Proceedings of the IEEE International Conference on Rehabilitation Robotics, Seattle, WA, USA, 24–26 June 2013; pp. 1–7. [Google Scholar]

- Carbonaro, N.; Anania, G.; Bacchereti, M.; Donati, G.; Ferretti, L.; Pellicci, G.; Parrini, G.; Vitetta, N.; De Rossi, D.; Tognetti, A. An Innovative Multisensor Controlled Prosthetic Hand. In Proceedings of the XIII Mediterranean Conference on Medical and Biological Engineering and Computing 2013, Seville, Spain, 25–28 September 2013. [Google Scholar]

- Koiva, R.; Riedenklau, E.; Viegas, C.; Castellini, C. Shape conformable high spatial resolution tactile bracelet for detecting hand and wrist activity. In Proceedings of the IEEE International Conference on Rehabilitation Robotics, Singapore, 11–14 August 2015; pp. 157–162. [Google Scholar]

- Sanford, J.; Patterson, R.; Popa, D. Surface EMG and Intra-Socket Force Measurement to Control a Prosthetic Device. In Proceedings of the SPIE 9494, Next-Generation Robotics II and machine intelligence and bio-inspired computation: Theory and applications IX, Baltimore, MD, USA, 22 April 2015. [Google Scholar]

- Chengani, R.; Delva, M.L.; Sakr, M.; Menon, C. Pilot study on strategies in sensor placement for robust hand/wrist gesture classification based on movement related changes in forearm volume. In Proceedings of the 2016 IEEE Healthcare Innovation Point-Of-Care Technologies Conference (HI-POCT), Cancun, Mexico, 9–11 November 2016; pp. 46–49. [Google Scholar]

- Sanford, J.; Patterson, R.; Popa, D.O. Concurrent surface electromyography and force myography classification during times of prosthetic socket shift and user fatigue. J. Rehabil. Assist. Technol. Eng. 2017, 4, 205566831770873. [Google Scholar] [CrossRef]

- Delva, M.L.; Menon, C. FSR based Force Myography (FMG) Stability Throughout Non-Stationary Upper Extremity Tasks. In Proceedings of the Future Technologies Conference, Vancouver, BC, Canada, 29–30 November 2017; pp. 891–896. [Google Scholar]

- Booth, R.; Goldsmith, P. A Wrist-Worn Piezoelectric Sensor Array for Gesture Input. J. Med. Biol. Eng. 2018, 38, 284–295. [Google Scholar] [CrossRef]

- Delva, M.L.; Sakr, M.; Chegani, R.S.; Khoshnam, M.; Menon, C. Investigation into the Potential to Create a Force Myography-based Smart-home Controller for Aging Populations. In Proceedings of the 7th IEEE International Conference on Biomedical Robotics and Biomechatronics, Enschede, The Netherlands, 26–29 August 2018; pp. 770–775. [Google Scholar]

- Fujiwara, E.; Wu, Y.T.; Suzuki, C.K.; De Andrade, D.T.G.; Neto, A.R.; Rohmer, E. Optical fiber force myography sensor for applications in prosthetic hand control. In Proceedings of the IEEE 15th International Workshop on Advanced Motion Control, Tokyo, Japan, 9–11 March 2018; pp. 342–347. [Google Scholar]

- Jiang, X.; Merhi, L.-K.K.; Menon, C. Force Exertion Affects Grasp Classification Using Force Myography. IEEE Trans. Hum. -Mach. Syst. 2018, 48, 219–226. [Google Scholar] [CrossRef]

- Zhang, N.; Li, X.; Samuel, O.W.; Huang, P.G.; Fang, P.; Li, G. A Pilot Study on Using Forcemyography to Record Upper-limb Movements for Human-machine Interactive Control. In Proceedings of the 40th Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Honolulu, HI, USA, 18–21 July 2018; pp. 3788–3791. [Google Scholar]

- Ha, N.; Withanachchi, G.P.; Yihun, Y. Performance of Forearm FMG for Estimating Hand Gestures and Prosthetic Hand Control. J. Bionic Eng. 2019, 16, 88–98. [Google Scholar] [CrossRef]

- Anvaripour, M.; Saif, M. Controlling robot gripper force by transferring human forearm stiffness using force myography. Midwest Symp. Circuits Syst. 2019, 2018, 672–675. [Google Scholar]

| FSR (FSR402) [20] | Flexiforce® (FLX-A201-F) [21] | |

|---|---|---|

| Minimum actuation force (Newtons) | 0.1 | N/A |

| Force sensitivity range (Newtons) | 0.1–10 | 0 to 4.4, 0 to 111, 0 to 445 |

| Single part force repeatability | ±2% | ±2.5% |

| Part to part force repeatability | +/−6% | ±40% |

| Hysteresis | +10% | <4.5% |

| Drift | <5% per log10 (time) | <5% per log10 (time) |

| Response time (micro seconds) | <3 | <5 |

| Linearity error | N/A | <±3% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Z.G.; Menon, C. A Review of Force Myography Research and Development. Sensors 2019, 19, 4557. https://doi.org/10.3390/s19204557

Xiao ZG, Menon C. A Review of Force Myography Research and Development. Sensors. 2019; 19(20):4557. https://doi.org/10.3390/s19204557

Chicago/Turabian StyleXiao, Zhen Gang, and Carlo Menon. 2019. "A Review of Force Myography Research and Development" Sensors 19, no. 20: 4557. https://doi.org/10.3390/s19204557

APA StyleXiao, Z. G., & Menon, C. (2019). A Review of Force Myography Research and Development. Sensors, 19(20), 4557. https://doi.org/10.3390/s19204557