Detection of 8-Hydroxy-2′-Deoxyguanosine Biomarker with a Screen-Printed Electrode Modified with Graphene

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Instruments

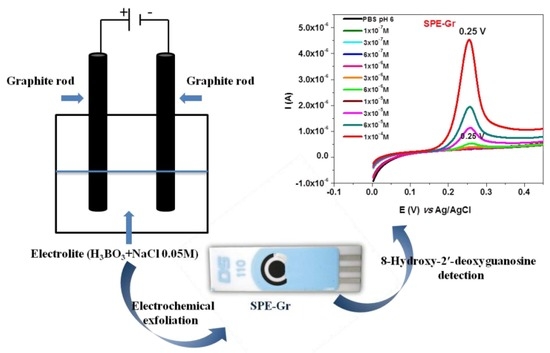

2.3. Graphene Synthesis by Pulse Exfoliation of Graphite Rods

2.4. Modification of Screen-Printing Electrode with Graphene (SPE-Gr)

3. Results and Discussions

3.1. Morphological and Structural Characterization of Graphene

3.2. Morphological Characterization of the Substrate

3.3. Electrochemical Studies

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Valavanidis, A.; Vlachogianni, T.; Fiotakis, C. 8-Hydroxy-2′-deoxyguanosine (8-OHdG): A critical biomarker of oxidative stress and carcinogenesis. J. Environ. Sci. Health-Part C Environ. Carcinog. Ecotoxicol. Rev. 2009, 27, 120–139. [Google Scholar] [CrossRef] [PubMed]

- Li, M.J.; Zhang, J.B.; Li, W.L.; Chu, Q.C.; Ye, J.N. Capillary electrophoretic determination of DNA damage markers: Content of 8-hydroxy-2′-deoxyguanosine and 8-nitroguanine in urine. J. Chromatogr. B Anal. Technol. Biomed. Life Sci. 2011, 879, 3818–3822. [Google Scholar] [CrossRef] [PubMed]

- Mei, S.; Yao, Q.; Wu, C.; Xu, G. Determination of urinary 8-hydroxy-2′-deoxyguanosine by two approaches—Capillary electrophoresis and GC/MS: An assay for in vivo oxidative DNA damage in cancer patients. J. Chromatogr. B Anal. Technol. Biomed. Life Sci. 2005, 827, 83–87. [Google Scholar] [CrossRef] [PubMed]

- Gug, I.T.; Tertis, M.; Hosu, O.; Cristea, C. Salivary biomarkers detection: Analytical and immunological methods overview. TrAC Trends Anal. Chem. 2019, 113, 301–316. [Google Scholar] [CrossRef]

- Wu, L.L.; Chiou, C.C.; Chang, P.Y.; Wu, J.T. Urinary 8-OHdG: A marker of oxidative stress to DNA and a risk factor for cancer, atherosclerosis and diabetics. Clin. Chim. Acta 2004, 339, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Sova, H.; Puistola, U.; Morin-Papunen, L.; Karihtala, P. Metformin decreases serum 8-hydroxy-2′-deoxyguanosine levels in polycystic ovary syndrome. Fertil. Steril. 2013, 99, 593–598. [Google Scholar] [CrossRef]

- Zhang, P.; Lian, K.; Wu, X.; Yao, M.; Lu, X.; Kang, W.; Jiang, L. Evaluation of the oxidative deoxyribonucleic acid damage biomarker 8-hydroxy-2′-deoxyguanosine in the urine of leukemic children by micellar electrokinetic capillary chromatography. J. Chromatogr. A 2014, 1336, 112–119. [Google Scholar] [CrossRef] [PubMed]

- Villa-Correa, Y.A.; Isaza-Guzmán, D.M.; Tobón-Arroyave, S.I. Prognostic value of 8-hydroxy-2′-deoxyguanosine and human neutrophil elastase/α1-proteinase inhibitor complex as salivary biomarkers of oxidative stress in chronic periodontitis. J. Periodontol. 2015, 86, 1260–1267. [Google Scholar] [CrossRef]

- Anusuya, S.; Mlv, P.; Lazarus, F. Estimation of 8-hydroxy-deoxyguanosine (8-OHdG) in saliva as a marker of oxidative stress in patients with chronic periodontitis: Preliminary data. J. Int. Acad. Period. 2017, 19, 95–100. [Google Scholar]

- Buduneli, N. Biomarkers in saliva and serum samples for periodontal disease and interactions with systemic health. Curr. Oral Heal. Reports 2019, 6, 31–36. [Google Scholar] [CrossRef]

- Zhang, C.; Nestorova, G.; Rissman, R.A.; Feng, J. Detection and quantification of 8-hydroxy-2′-deoxyguanosine in Alzheimer’s transgenic mouse urine using capillary electrophoresis. Electrophoresis 2013, 34, 2268–2274. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.S.; Jenner, A.M.; Ong, C.N.; Huang, S.H.; Whiteman, M.; Halliwell, B. A high-throughput and sensitive methodology for the quantification of urinary 8-hydroxy-2′-deoxyguanosine: measurement with gas chromatography-mass spectrometry after single solid-phase extraction. Biochem. J. 2004, 380, 541–548. [Google Scholar] [CrossRef] [PubMed]

- De Martinis, B.S.; De Lourdes Pires Bianchi, M. Methodology for urinary 8-hydroxy-2′-deoxyguanosine analysis by HPLC with electrochemical detection. Pharmacol. Res. 2002, 46, 129–131. [Google Scholar] [CrossRef]

- Lu, L.J.; Tasaka, F.; Hokanson, J.A.; Kohda, K. Detection of 8-hydroxy-2′-deoxyguanosine in deoxyribonucleic acid by the 32P-postlabeling method. Chem. Pharm. Bull. 1990, 38, 226. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Gutiérrez, A.; Gutiérrez, S.; García, G.; Galicia, L.; Rivas, G.A. Determinatiom of 8-hydroxy-2′-deoxyguanosine using electrodes modified with a dispersion of carbon nanotubes in polyethylenimine. Electroanalysis 2011, 23, 1221–1228. [Google Scholar] [CrossRef]

- Maduraiveeran, G.; Sasidharan, M.; Ganesan, V. Electrochemical sensor and biosensor platforms based on advanced nanomaterials for biological and biomedical applications. Biosens. Bioelectron. 2018, 103, 113–129. [Google Scholar] [CrossRef] [PubMed]

- Lawal, A.T. Progress in utilisation of graphene for electrochemical biosensors. Biosens. Bioelectron. 2018, 106, 149–178. [Google Scholar] [CrossRef]

- Adetayo, A.; Runsewe, D. Synthesis and Fabrication of Graphene and Graphene Oxide: A Review. Open J. Compos. Mater. 2019, 9, 207–229. [Google Scholar] [CrossRef]

- Abdelkader, A.M.; Cooper, A.J.; Dryfe, R.A.W.; Kinloch, I.A. How to Get Between the Sheets: A Review of Recent Works on the Electrochemical Exfoliation of Graphene Materials from Bulk Graphite. Nanoscale 2015, 7, 6944. [Google Scholar] [CrossRef]

- Kairi, M.I.; Dayou, S.; Kairi, N.I.; Bakar, S.A.; Vigolo, B.; Mohamed, A.R. Toward high production of graphene flakes—A review on recent developments in their synthesis methods and scalability. J. Mater. Chem. A 2018, 6, 15010–15026. [Google Scholar] [CrossRef]

- Beitollahi, H.; Safaei, M.; Tajik, S. Application of Graphene and Graphene Oxide for modification of electrochemical sensors and biosensors: A review. Int. J. Nano Dimens. 2019, 10, 125–140. [Google Scholar]

- Khan, M.Z.H.; Liu, X.; Tang, Y.; Liu, X. Ultra-sensitive electrochemical detection of oxidative stress biomarker 8-hydroxy-2′-deoxyguanosine with poly (l-arginine)/graphene wrapped Au nanoparticles modified electrode. Biosens. Bioelectron. 2018, 117, 508–514. [Google Scholar] [CrossRef] [PubMed]

- Jia, L.P.; Liu, J.F.; Wang, H.S. Electrochemical performance and detection of 8-Hydroxy-2′-deoxyguanosine at single-stranded DNA functionalized graphene modified glassy carbon electrode. Biosens. Bioelectron. 2015, 67, 139–145. [Google Scholar] [CrossRef] [PubMed]

- Pogacean, F.; Coros, M.; Magerusan, L.; Mirel, V.; Turza, A.; Katona, G.; Stefan-van Staden, R.I.; Pruneanu, S. Exfoliation of graphite rods via pulses of current for graphene synthesis: Sensitive detection of 8-hydroxy-2′-deoxyguanosine. Talanta 2019, 196, 182–190. [Google Scholar] [CrossRef]

- Stefan-van Staden, R.I.; Balahura, L.R.; Gugoasa, L.A.; van Staden, J.F.; Aboul-Enein, H.Y.; Rosu, M.C.; Pruneanu, S.M. Pattern recognition of 8-hydroxy-2′-deoxyguanosine in biological fluids. Anal. Bioanal. Chem. 2018, 410, 115–121. [Google Scholar] [CrossRef] [PubMed]

- Perumal, V.; Hashim, U. Advances in biosensors: Principle, architecture and applications. J. Appl. Biomed. 2014, 12, 1–15. [Google Scholar] [CrossRef]

- Tothill, I.E. Biosensors for cancer markers diagnosis. Semin. Cell. Dev. Biol. 2009, 20, 50–62. [Google Scholar] [CrossRef] [PubMed]

- Díaz-González, M.; Muñoz-Berbel, X.; Jiménez-Jorquera, C.; Baldi, A.; Fernández-Sánchez, C. Diagnostics using multiplexed electrochemical readout devices. Electroanalysis 2014, 26, 1154–1170. [Google Scholar] [CrossRef]

- Dorledo de Faria, R.A.; Messaddeq, Y.; Heneine, G.D.; Matencio, T. Application of screen-printed carbon electrode as an electrochemical transducer in biosensors. Int. J. Biosens. Bioelectron. 2019, 5, 1–2. [Google Scholar] [CrossRef][Green Version]

- Govindasamy, M.; Wang, S.F.; Subramanian, B.; Jothi Ramalingam, R.; Al-lohedan, H.; Sathiyan, A. A novel electrochemical sensor for determination of DNA damage biomarker (8-hydroxy-2′-deoxyguanosine) in urine using sonochemically derived graphene oxide sheets covered zinc oxide flower modified electrode. Ultrason. Sonochem. 2019, 58, 10462. [Google Scholar] [CrossRef]

- Manavalan, S.; Umamaheswari, R.; Chen, S.M.; Mani, S.P.S.; Chen, T.; Ali, M.A.; Al-Hemaid, F.M.A.; Elshikh, M.S. Determination of 8-hydroxy-2′-deoxyguanosine oxidative stress biomarker using dysprosium oxide nanoparticles@reduced graphene oxide. Inorg. Chem. Front. 2018, 5, 2885–2892. [Google Scholar] [CrossRef]

- Coates, J. Interpretation of infrared spectra, a practical approach. In Encyclopedia of Analytical Chemistry; Meyers, R.A., Ed.; John Wiley & Sons Ltd: Chichester, West Sussex, UK, 2000; pp. 10815–10837. [Google Scholar]

- Zanello, P. Inorganic Electrochemistry: Theory, Practice and Application; The Royal Society of Chemistry: Cambridge, UK, 2003. [Google Scholar]

- Bard, A.J.; Faulkner, L.R. Electrochemical Methods: Fundamentals and Applications; John Wiley: New York, NY, USA, 1980; pp. 324–353. [Google Scholar]

- Prathish, K.P.; Barsan, M.M.; Geng, D.; Sun, X.; Brett, C.M.A. Chemically modified graphene and nitrogen-doped graphene: Electrochemical characterisation and sensing applications. Electrochim. Acta 2013, 114, 533–542. [Google Scholar] [CrossRef]

- Nkosi, D.; Pillay, J.; Ozoemena, K.I.; Nouneh, K.; Oyama, M. Heterogeneous electron transfer kinetics and electrocatalytic behavior of mixed self-assembled ferrocenes and SWCNT layers. Phys. Chem. Chem. Phys. 2010, 12, 604–613. [Google Scholar] [CrossRef] [PubMed]

- Rice, R.J.; Pontikos, N.M.; McCreery, R.L. Quantitative correlations of heterogeneous electron-transfer kinetics with surface properties of glassy carbonelectrodes. J. Am. Chem. Soc. 1990, 112, 4617–4622. [Google Scholar] [CrossRef]

- Brownson, D.A.C.; Munro, L.J.; Kampouris, D.K.; Banks, C.E. Electrochemistry of graphene: not such a beneficial electrode material. RSC Adv. 2011, 1, 978–988. [Google Scholar] [CrossRef]

- Goyal, R.N. Determination of 8-Hydroxydeoxyguanosine: A potential biomarker of oxidative stress, using carbon-allotropic nanomaterials modified glassy carbon sensor. Talanta 2016, 161, 735–742. [Google Scholar]

- Jia, L.; Wang, H. Electrochemical reduction synthesis of graphene/Nafion nanocomposite film and its performance on the detection of 8-hydroxy-20-deoxyguanosine in the presence of uric acid. J. Electroanal. Chem. 2013, 705, 37–43. [Google Scholar] [CrossRef]

- Guo, Z.; Liu, X.; Liu, Y.; Wu, G.; Lu, X. Constructing a novel 8-hydroxy-2′-deoxyguanosine electrochemical sensor and application in evaluating the oxidative damages of DNA and guanine. Biosens. Bioelectron. 2016, 86, 671–676. [Google Scholar] [CrossRef] [PubMed]

| Sample | 2θ (°) | D (nm) | d (nm) | n | % |

|---|---|---|---|---|---|

| Gr | 20.7 (FLG) | 0.96 | 0.475 | ∼2 | 83 |

| 26.3 (MLG) | 22.19 | 0.376 | ~58 | 17 |

| Electrode/Sensing Material | Linear Range (In Standard PBS Solutions) | LOD (nM) | Ref. |

|---|---|---|---|

| GC/carbon nanotubes dispersed in polyethylenimine | 5 × 10−7 M–3 × 10−5 M | 100 | [15] |

| SPCE/multi-layer-based graphene oxide covered zinc oxide nanoflower | 0.05–536.5 μM | 36.6 | [30] |

| SPCE/dysprosium oxide nanoparticles@rGO | 0.05–315.3 μM | 1.02 | [31] |

| GC/electrochemically reduced graphene oxide/multiwalled carbon nanotubes | 3–75 µM | 35 | [39] |

| GC/Graphene/Nafion | 0.07–33.04 μM | 1.12 | [40] |

| GC/MWCNTs | 6.08 × 10−6−1.64 × 10−5 M | 18.8 | [41] |

| SPE-Gr | 3 × 10−7–1 × 10−4 M | 90 | This work |

| Electrode | Added (M) | Found (M) | Recovery (%) |

|---|---|---|---|

| SPE-Gr | 1 × 10−5 | 0.95 × 10−5 | 95 |

| 6 × 10−5 | 6.38 × 10−5 | 106 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Varodi, C.; Pogacean, F.; Coros, M.; Rosu, M.-C.; Stefan-van Staden, R.-I.; Gal, E.; Tudoran, L.-B.; Pruneanu, S.; Mirel, S. Detection of 8-Hydroxy-2′-Deoxyguanosine Biomarker with a Screen-Printed Electrode Modified with Graphene. Sensors 2019, 19, 4297. https://doi.org/10.3390/s19194297

Varodi C, Pogacean F, Coros M, Rosu M-C, Stefan-van Staden R-I, Gal E, Tudoran L-B, Pruneanu S, Mirel S. Detection of 8-Hydroxy-2′-Deoxyguanosine Biomarker with a Screen-Printed Electrode Modified with Graphene. Sensors. 2019; 19(19):4297. https://doi.org/10.3390/s19194297

Chicago/Turabian StyleVarodi, Codruta, Florina Pogacean, Maria Coros, Marcela-Corina Rosu, Raluca-Ioana Stefan-van Staden, Emese Gal, Lucian-Barbu Tudoran, Stela Pruneanu, and Simona Mirel. 2019. "Detection of 8-Hydroxy-2′-Deoxyguanosine Biomarker with a Screen-Printed Electrode Modified with Graphene" Sensors 19, no. 19: 4297. https://doi.org/10.3390/s19194297

APA StyleVarodi, C., Pogacean, F., Coros, M., Rosu, M.-C., Stefan-van Staden, R.-I., Gal, E., Tudoran, L.-B., Pruneanu, S., & Mirel, S. (2019). Detection of 8-Hydroxy-2′-Deoxyguanosine Biomarker with a Screen-Printed Electrode Modified with Graphene. Sensors, 19(19), 4297. https://doi.org/10.3390/s19194297