Monitoring a Heatsink Temperature Field Using Raman-Based Distributed Temperature Sensor in a Vacuum and −173 °C Environment

Abstract

:1. Introduction

2. Principle of the Raman Distributed Temperature Sensing Method

2.1. Principle of the Raman Distributed Temperature Sensing Method in a Normal Environment

2.2. Principle of the Calibration Method in a Normal Environment

2.3. Principle of Optical Time Domain Reflectometer

3. Experiments and Results

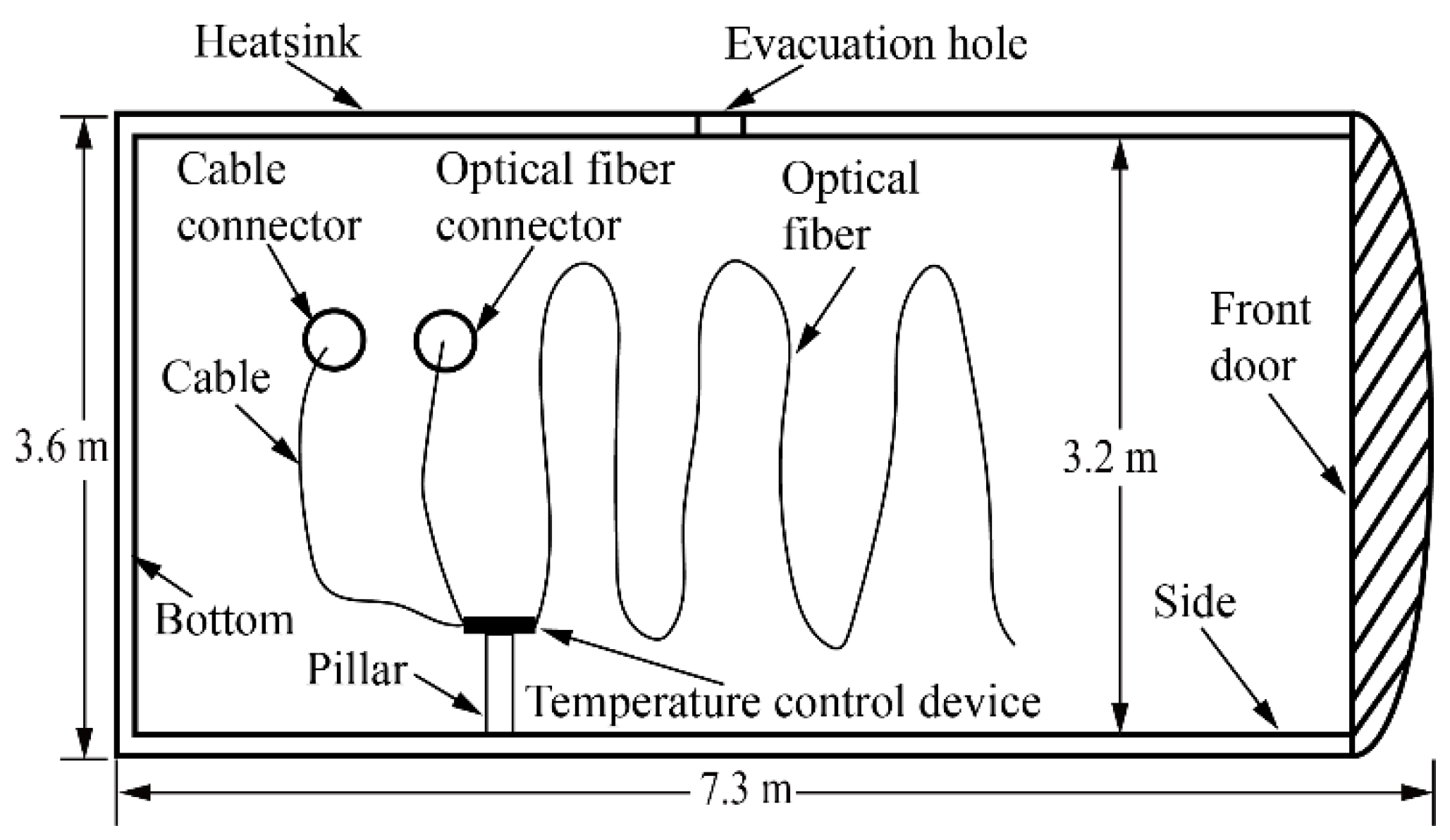

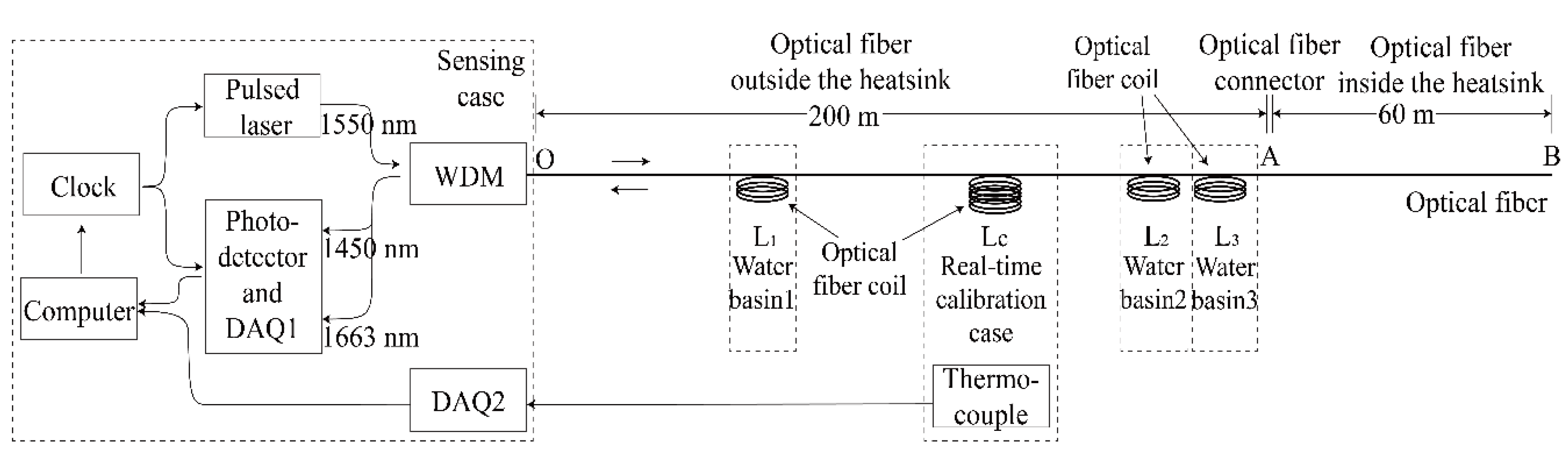

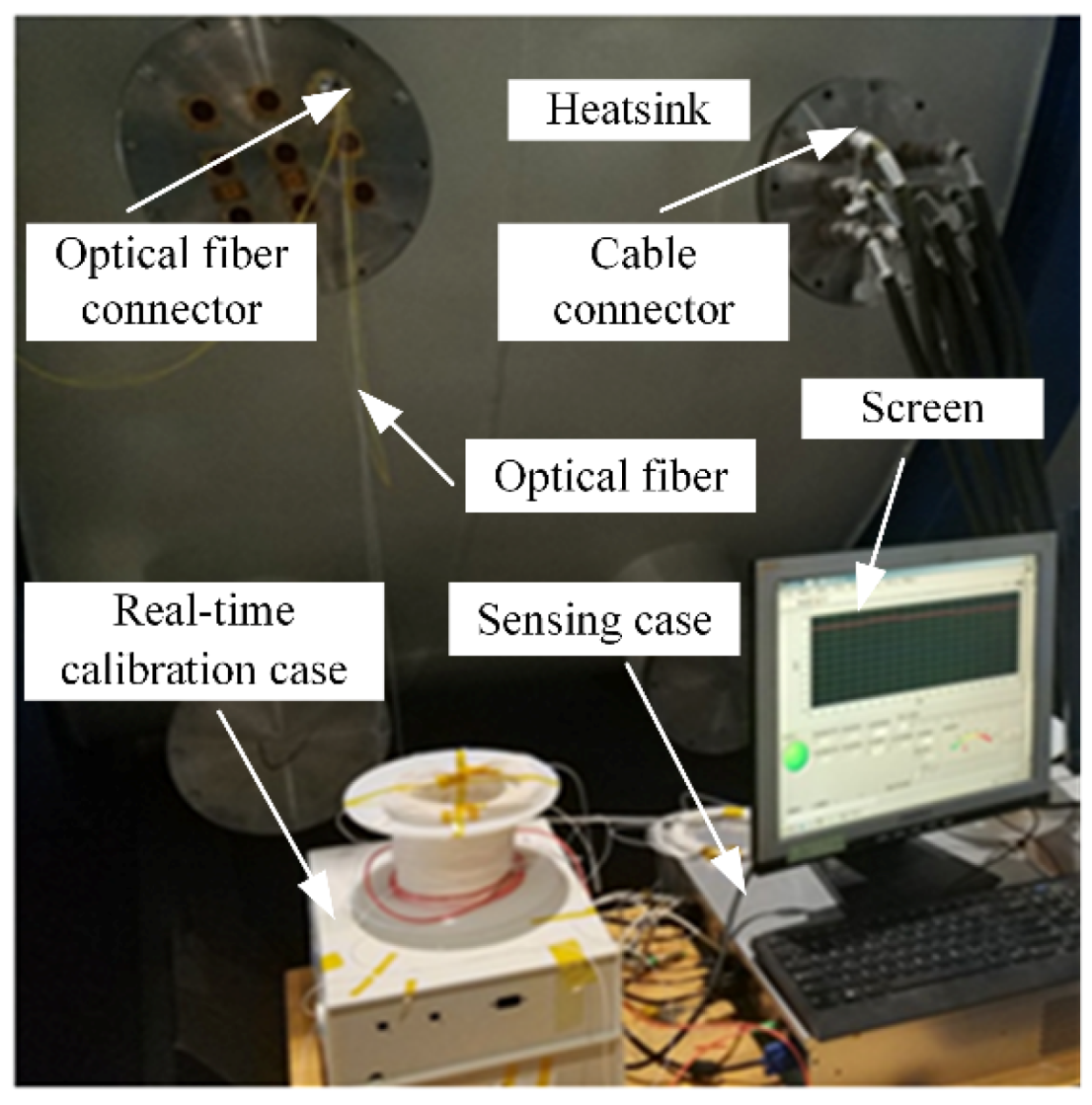

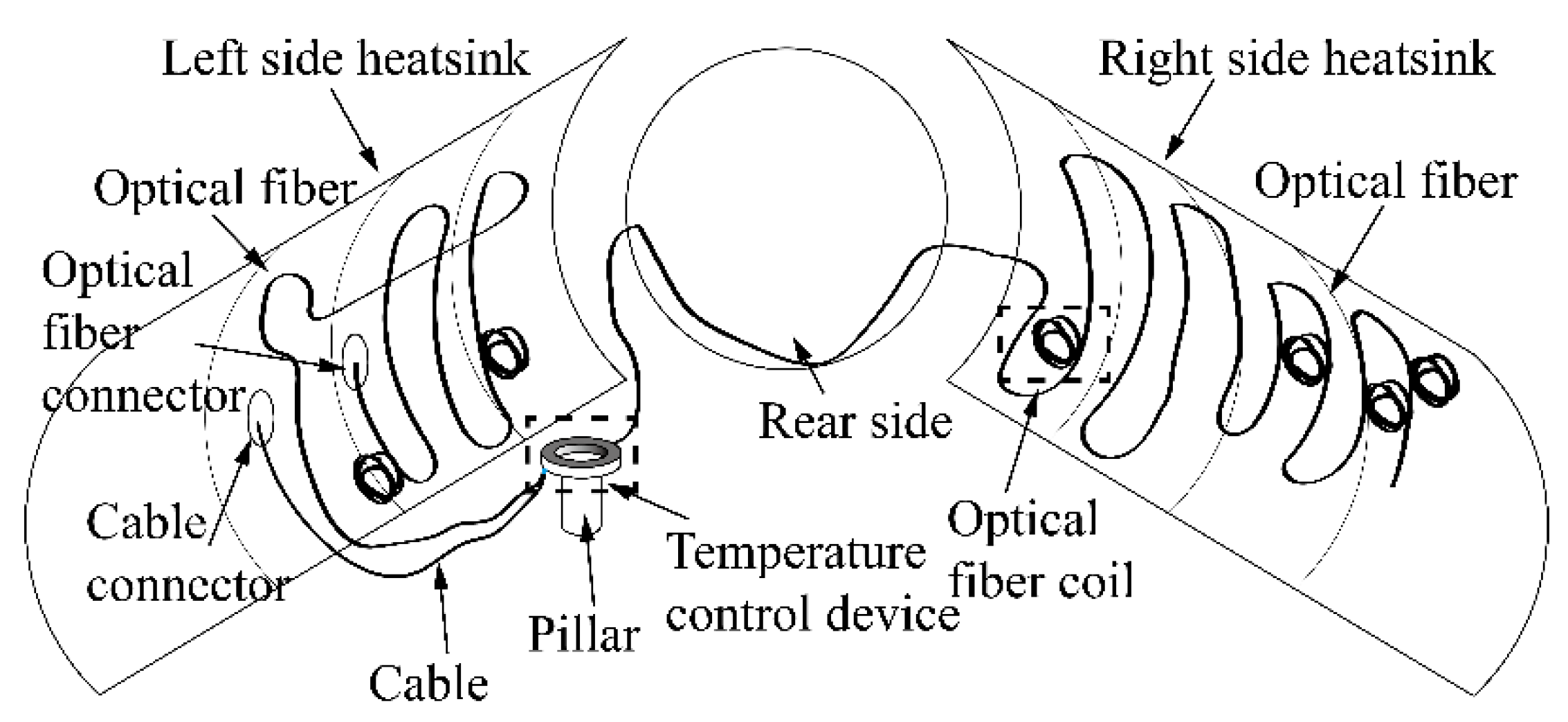

3.1. Experiments Environment

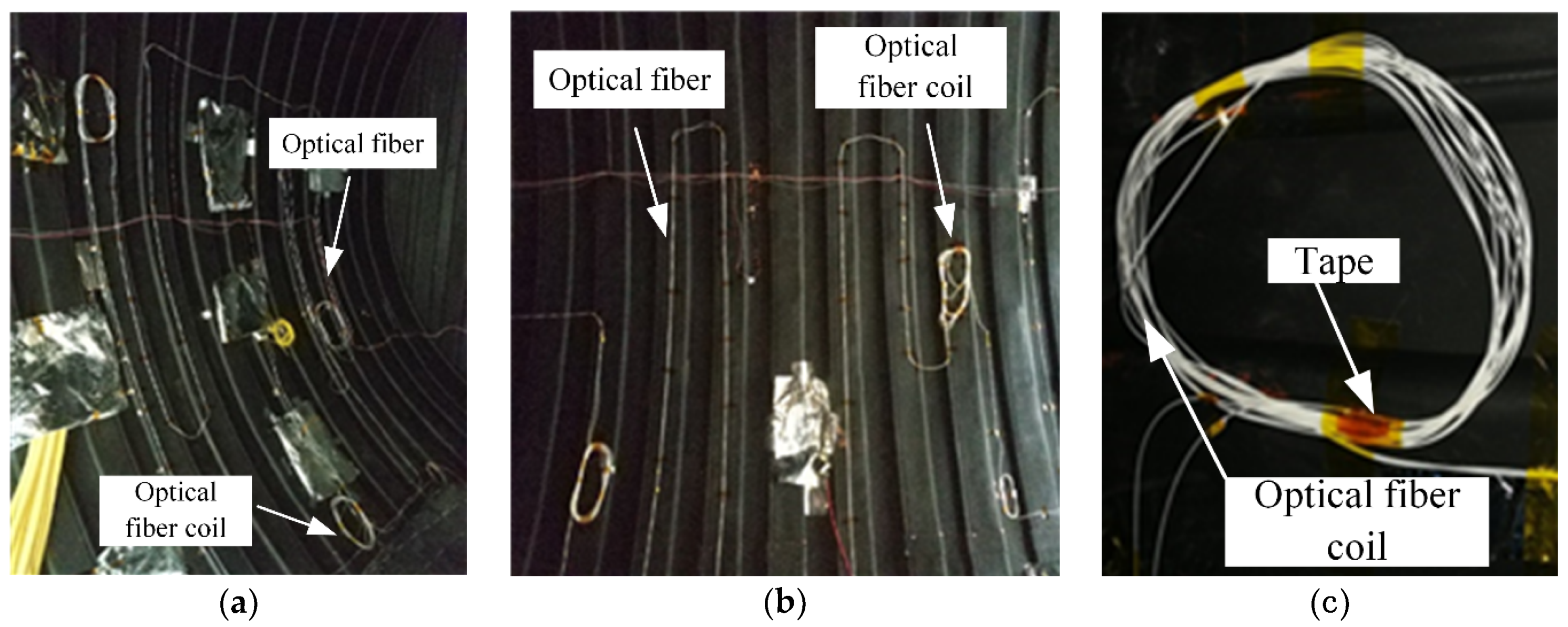

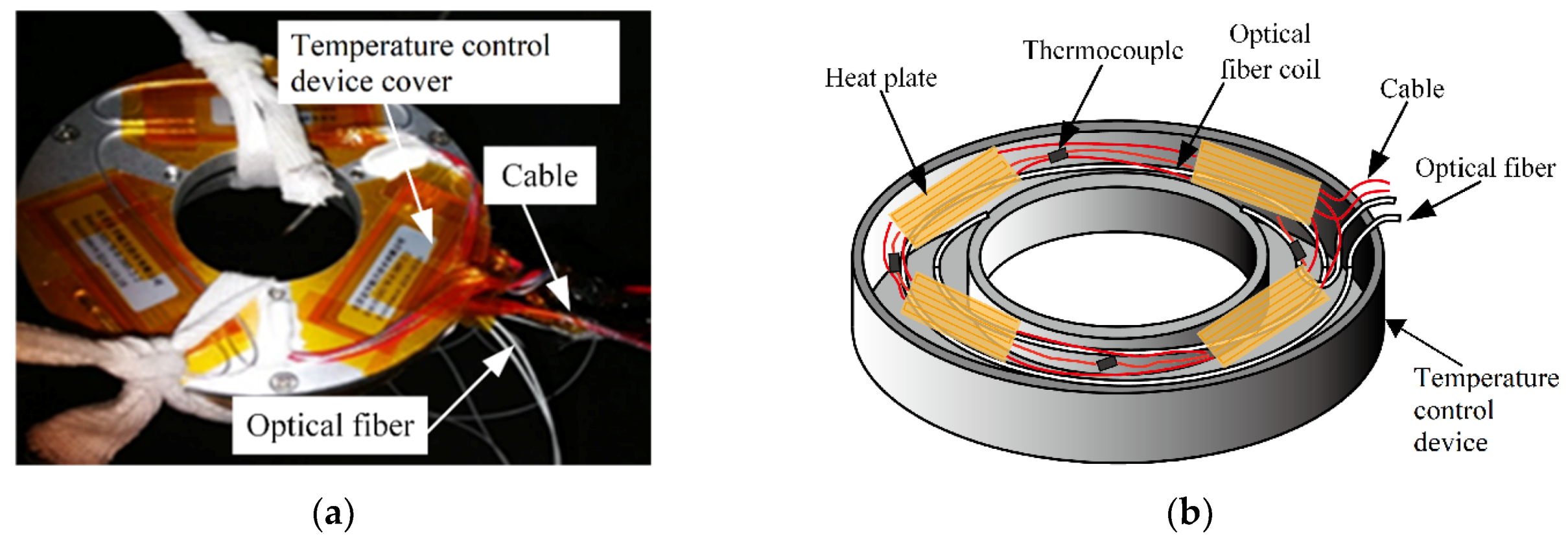

3.2. Experiments

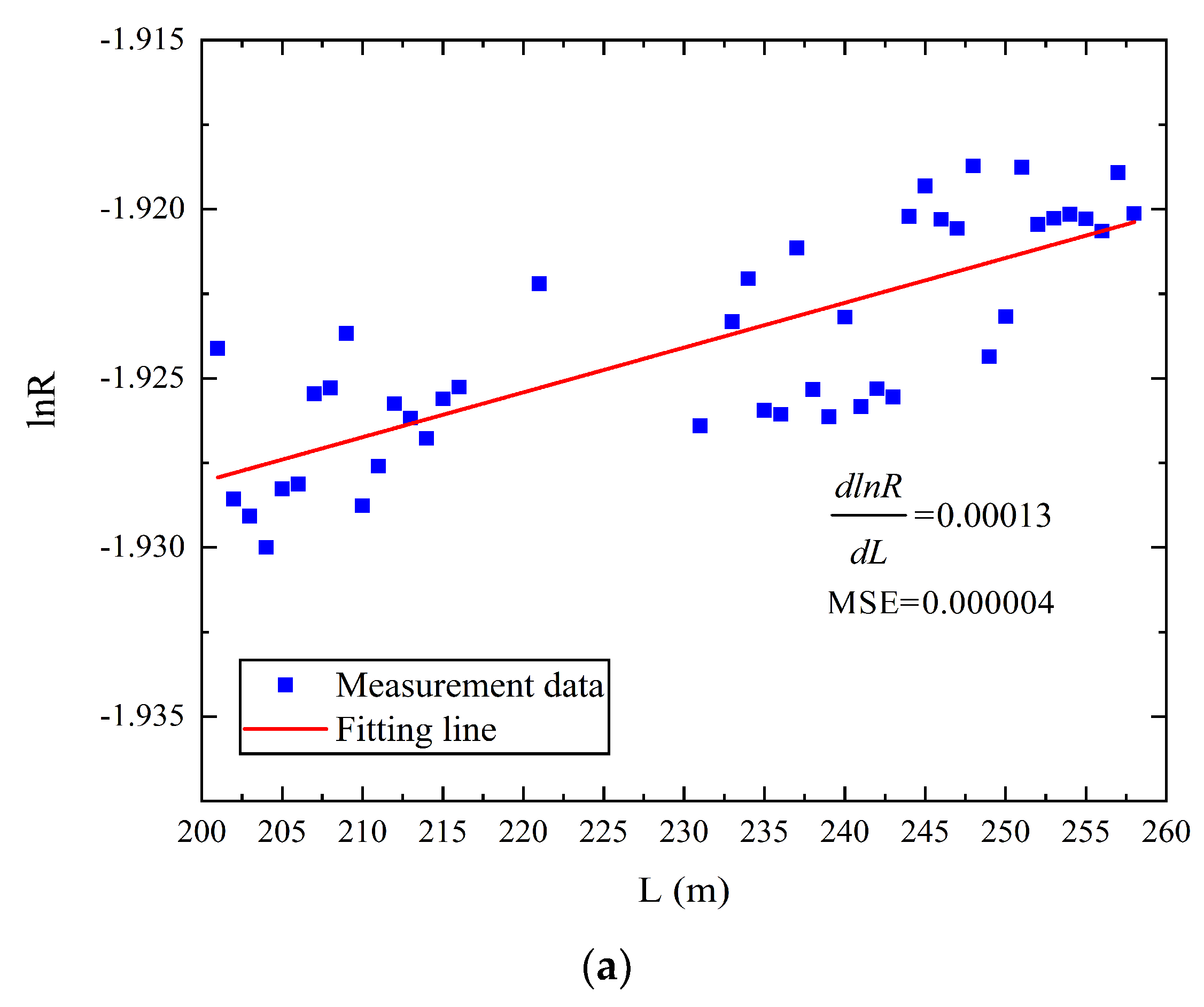

3.2.1. Calibration Experiments in a Normal Environment:

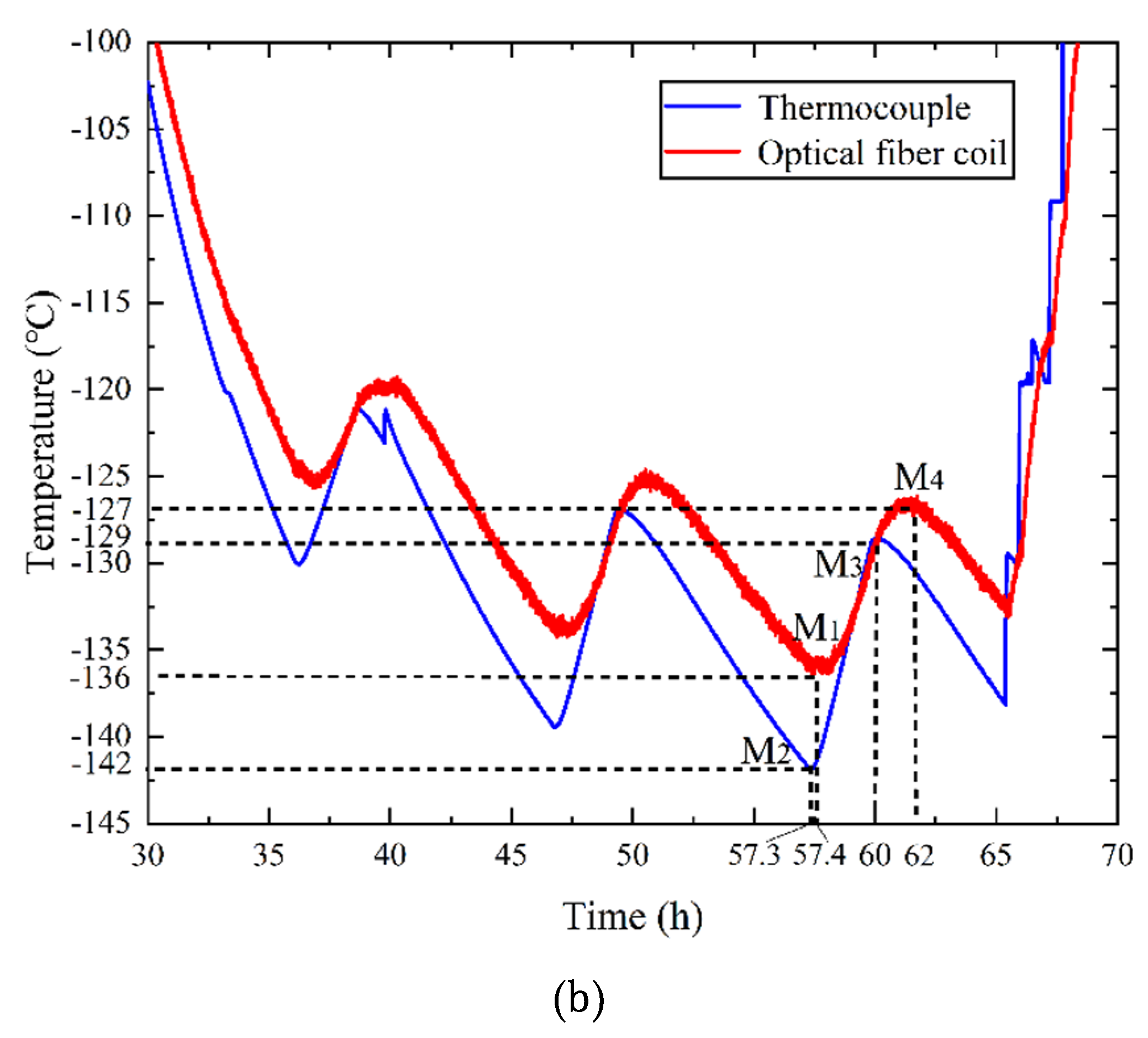

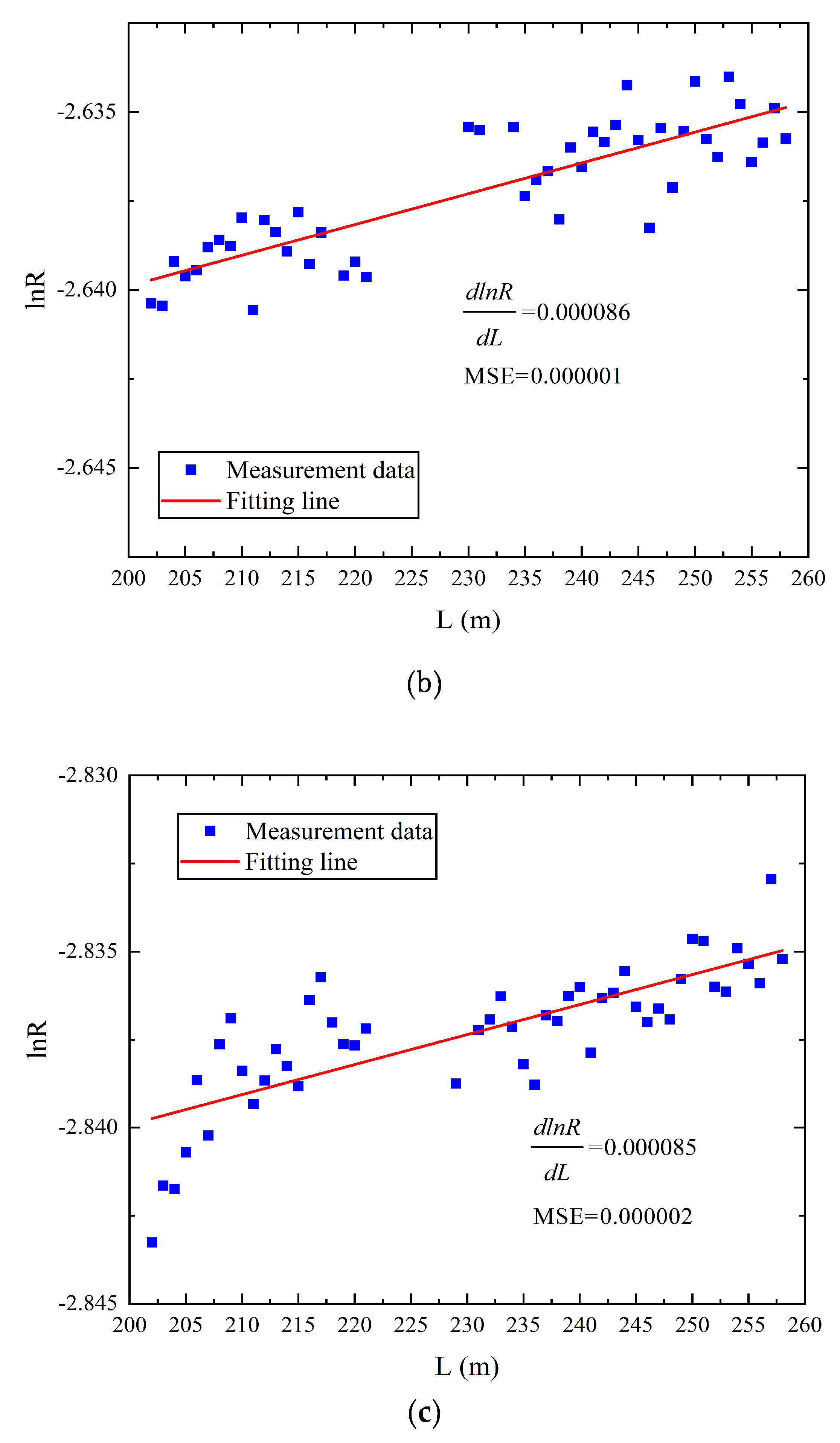

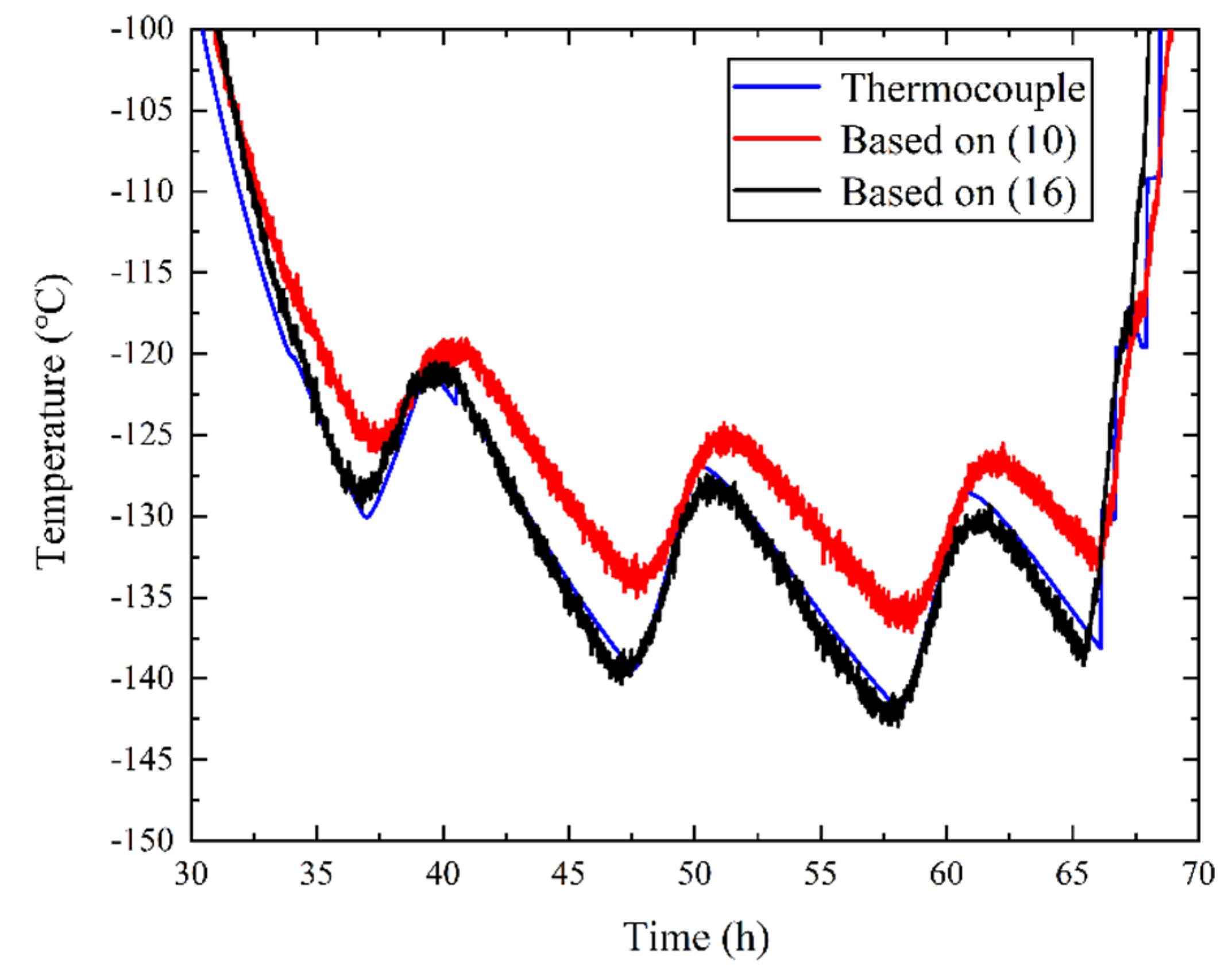

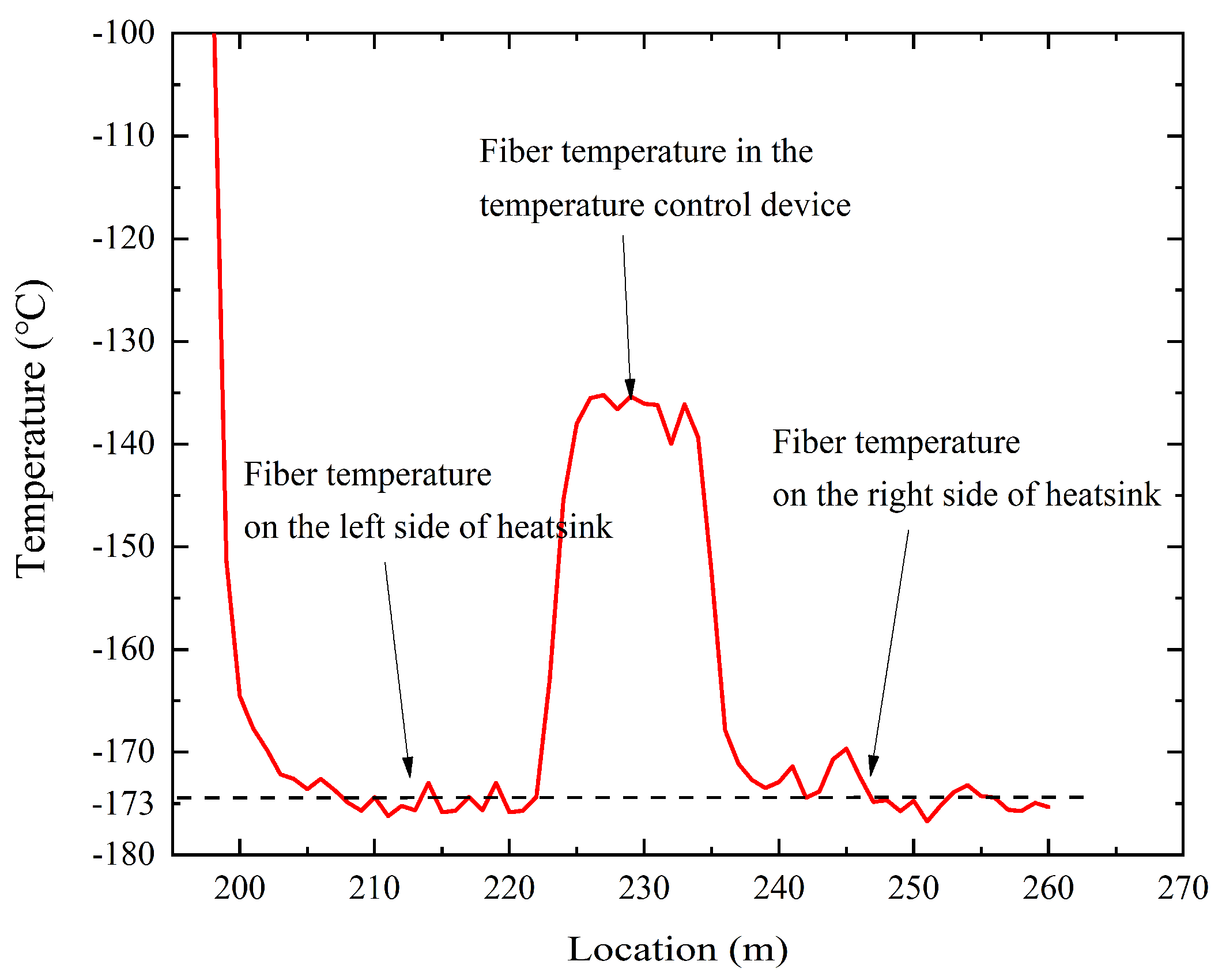

3.2.2. Calibration Experiments in the Heatsink

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wei, P.; Liu, J.; Dai, Z.; Li, M. Monitoring the shape of satellite wing frame using FBG sensors in high electronic noise, vacuum and −196 °C Environment. IEEE Trans. Ind. Electron. 2016, 64, 691–700. [Google Scholar] [CrossRef]

- Guo, T.; Jia, R.J.; Wang, D.M.; Xiao, Z.Y.; Fang, Z.K.; Cai, W. Thermocouple implementation technique of satellite thermal vacuum test based on reverse thinking. Equip. Environ. Eng. 2018, 15, 32–37. [Google Scholar]

- Gan, G. Temperature measurement system for spacecraft thermal vacuum tests. Spacecr. Environ. Eng. 2009, 26, 33–36. [Google Scholar]

- Xu, Z.; Li, Y.; Cui, L.; Chen, J. Laser welding of the KM8 stainless steel plate-style thermal shroud. Spacecr. Environ. Eng. 2015, 32, 549–553. [Google Scholar]

- Zhao, Y.; Xia, F.; Hu, H.F.; Du, C.; Zhao, Y.; Xia, F.; Hu, H.F.; Du, C. A ring-core optical fiber sensor with asymmetric LPG for highly sensitive temperature measurement. IEEE Trans. Instrum. Meas. 2017, 66, 3378–3386. [Google Scholar] [CrossRef]

- Olivero, M.; Vallan, A.; Orta, R.; Perrone, G. Single-mode-multimode-single-mode optical fiber sensing structure with quasi-two-mode fibers. IEEE Trans. Instrum. Meas. 2018, 67, 1223–1229. [Google Scholar] [CrossRef]

- Ding, Z.; Wang, C.; Liu, K.; Jiang, J.; Yang, D.; Pan, G.; Pu, Z.; Liu, T. Distributed optical fiber sensors based on optical frequency domain reflectometry: A review. Sensors 2018, 18, 1072. [Google Scholar] [CrossRef]

- Tong, J.; Jin, B.; Wang, D.; Wang, Y.; Hui, Y.U.; Bai, L. Distributed optical fiber temperature measurement system for pipeline safety monitoring based on R-OTDR. Chin. J. Sens. Actuators 2018, 31, 158–162. [Google Scholar]

- Shan, Y. Application of distributed optical fiber temperature measurement system in coal mine fire monitoring system. Chin. J. Sens. Actuators 2018, 31, 704–708. [Google Scholar]

- Toccafondo, I.; Nannipieri, T.; Signorini, A.; Guillermain, E.; Kuhnhenn, J.; Brugger, M.; Pasquale, F.D. Raman distributed temperature sensing at CERN. IEEE Photonics Technol. Lett. 2015, 27, 2182–2185. [Google Scholar] [CrossRef]

- Saxena, M.K.; Raju, S.D.V.S.J.; Arya, R.; Pachori, R.B.; Kher, S. Instantaneous area based on-line detection of bend generated error in a raman optical fiber distributed temperature sensor. IEEE Sens. Lett. 2017, 1, 1–4. [Google Scholar] [CrossRef]

- Ukil, A.; Braendle, H.; Krippner, P. Distributed temperature sensing: Review of technology and applications. IEEE Sens. J. 2012, 12, 885–892. [Google Scholar] [CrossRef]

- Cangialosi, C.; Ouerdane, Y.; Girard, S.; Boukenter, A.; Cannas, M. Development of a temperature distributed monitoring system based on Raman scattering in harsh environment. IEEE Trans. Nucl. Sci. 2014, 61, 3315–3322. [Google Scholar] [CrossRef]

- Jiang, J.; Zhong, L.; Duan, X.; Song, M.; Li, L.; Wu, Z.; Li, Z.; Huang, Z.; Hong, Z.; Jin, Z. Bend limitation of a polyimide-coated optical fiber at cryogenic temperature of 77 K. IEEE Trans. Appl. Supercond. 2019, 29, 1–5. [Google Scholar] [CrossRef]

- Laarossi, I.; Ruiz-Lombera, R.; Quintela, M.A.; Mirapeix, J.; Lima, D.; Solana, D.; Lopez-Higuera, J.M. Ultra-high temperature Raman-based distributed optical fiber sensor with gold-coated fiber. IEEE J. Sel. Top. Quantum Electron. 2016, 23, 296–301. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, W.; Lv, J.; Liang, S.; Wang, L.; Li, X. Analysis on the impact of FBG reflectance spectrum with different optical fiber connection in vacuum thermal environment. In Proceedings of the Society of Photo-Optical Instrumentation Engineers, Beijing, China, 28–30 October 2017. [Google Scholar]

- Junfeng, J.; Luyao, S.; Tiegen, L.; Jingchuan, Z.; Kun, L.; Shuang, W.; Jinde, Y.; Peng, Z.; Jihui, X.; Fan, W. Performance characterization of fiber Bragg grating thermal response in space vacuum thermal environment. Rev. Sci. Instrum. 2013, 84, S387–S659. [Google Scholar]

- Yan, B.; Li, J.; Zhang, M.; Zhang, J.; Qiao, L.; Wang, T. Raman distributed temperature sensor with optical dynamic difference compensation and visual localization technology for tunnel fire detection. Sensors 2019, 19, 2320. [Google Scholar] [CrossRef]

- Laarossi, I.; Quintela-Incera, M.Á.; López-Higuera, J.M. Comparative Experimental Study of a High-Temperature Raman-Based Distributed Optical Fiber Sensor with Different Special Fibers. Sensors 2019, 19, 574. [Google Scholar] [CrossRef]

- Liu, B. Design and implementation of distributed ultra-high temperature sensing system with a single crystal fiber. J. Lightwave Technol. 2018, 36, 5511–5520. [Google Scholar] [CrossRef]

- Zhang, J. Design and experimental verification of multicore fiber optic penetration connector with high air-tightness. Chin. J. Vac. Sci. Technol. 2015, 35, 1396–1401. [Google Scholar]

- Wang, Y.; Guo, W. Chaotic-FH code prediction method based on LS-SVM. J. Electron. Meas. Instrum. 2007, 5, 64–68. [Google Scholar]

| Temperature (°C) | Location (m) | Logarithmic Ratio of the Optical Power |

|---|---|---|

| = 77 | = 75 | = −1.037 |

| = 188 | = −1.013 | |

| = 190 | = −1.221 |

| Temperature (°C) | |

|---|---|

| 20 | 0.00010 |

| −40 | 0.00013 |

| −60 | 0.00011 |

| −110 | 0.000086 |

| −120 | 0.000085 |

| (°C) | (°C) | (°C) | (°C) | (°C) |

|---|---|---|---|---|

| −139.326 | −134.303 | −140.111 | 0.785 | 5.023 |

| −137.285 | −132.861 | −137.984 | 0.699 | 4.424 |

| −135.748 | −130.656 | −135.759 | 0.011 | 5.092 |

| −133.608 | −128.447 | −132.992 | 0.616 | 5.161 |

| −128.265 | −125.756 | −128.867 | 0.602 | 2.509 |

| −127.531 | −123.203 | −127.466 | 0.065 | 4.328 |

| −123.758 | −120.356 | −123.012 | 0.746 | 3.402 |

| −118.912 | −118.208 | −119.587 | 0.675 | 0.704 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Wei, P.; Liu, Q. Monitoring a Heatsink Temperature Field Using Raman-Based Distributed Temperature Sensor in a Vacuum and −173 °C Environment. Sensors 2019, 19, 4186. https://doi.org/10.3390/s19194186

Zhang J, Wei P, Liu Q. Monitoring a Heatsink Temperature Field Using Raman-Based Distributed Temperature Sensor in a Vacuum and −173 °C Environment. Sensors. 2019; 19(19):4186. https://doi.org/10.3390/s19194186

Chicago/Turabian StyleZhang, Jingchuan, Peng Wei, and Qingbo Liu. 2019. "Monitoring a Heatsink Temperature Field Using Raman-Based Distributed Temperature Sensor in a Vacuum and −173 °C Environment" Sensors 19, no. 19: 4186. https://doi.org/10.3390/s19194186

APA StyleZhang, J., Wei, P., & Liu, Q. (2019). Monitoring a Heatsink Temperature Field Using Raman-Based Distributed Temperature Sensor in a Vacuum and −173 °C Environment. Sensors, 19(19), 4186. https://doi.org/10.3390/s19194186