Research on Small Square PCB Rogowski Coil Measuring Transient Current in the Power Electronics Devices

Abstract

:1. Introduction

2. PCB Rogowski Coil Sensor

2.1. The Working Principle of the Coil, the Establishment of the Equivalent Circuit Model and the Determination of the Working Mode

2.2. Error Analysis of Rogowski Coil

2.3. Parameters and Frequency Characteristics of Rogowski Coil

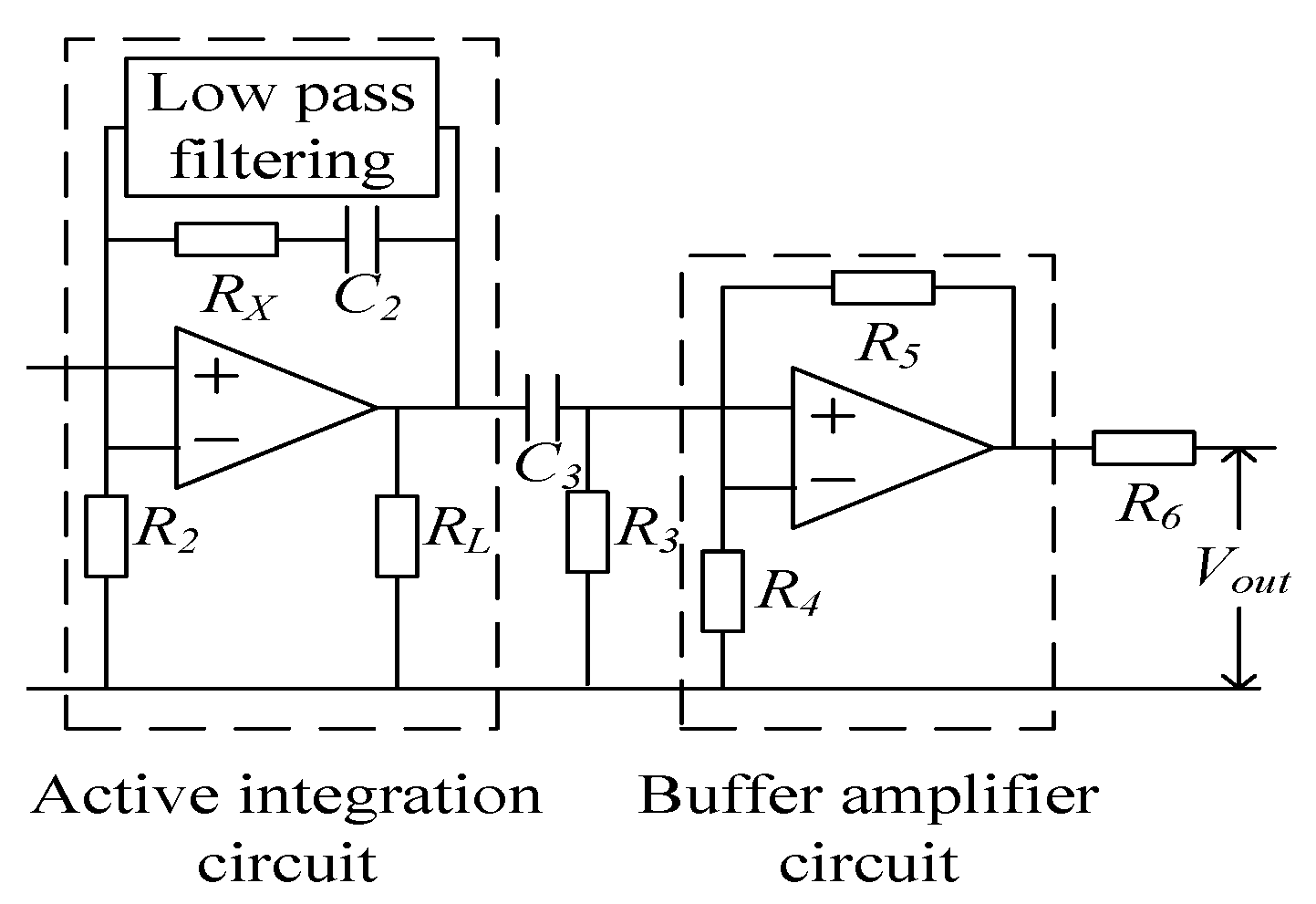

2.4. Subsequent Integration Circuit Design

3. Simulation and Experimental Verification

3.1. Simulation of PCB Rogowski Coil

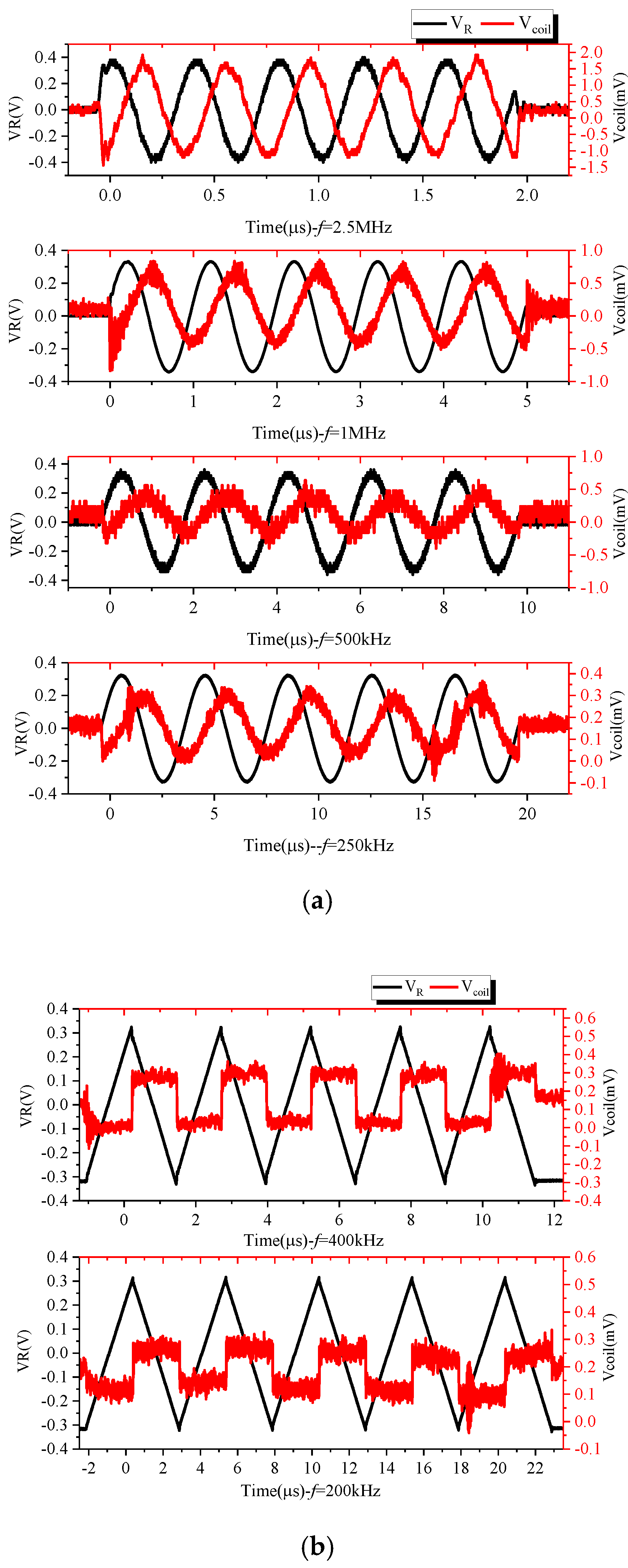

3.2. Experimental Verification of the PCB Rogowski Coil Current Transformer

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Shigekane, H.; Kirihata, H.; Uchida, Y. Developments in modern high power semiconductor devices. In Proceedings of the 5th International Symposium on Power Semiconductor Devices and ICs, Monterey, CA, USA, 18–20 May 1993; pp. 16–21. [Google Scholar]

- Chokhawala, R.; Danielsson, B.; Angquist, L. Power semiconductors in transmission and distribution applications. In Proceedings of the 13th International Symposium on Power Semiconductor Devices & ICs. IPSD ’01 (IEEE Cat. No.01CH37216), Osaka, Japan, 7 June 2001; pp. 3–10. [Google Scholar]

- Volke, A.; Wendt, J.; Hornkamp, M. IGBT Modules: Technologies, Driver and Application; Infineon: Munich, Germany, 2012. [Google Scholar]

- Müsing, A.; Ortiz, G.; Kolar, J.W. Optimization of the current distribution in press-pack high power IGBT modules. In Proceedings of the 2010 International Power Electronics Conference—ECCE ASIA-, Sapporo, Japan, 21–24 June 2010; pp. 1139–1146. [Google Scholar]

- Tang, X.; Cui, X.; Zhao, Z.; Zhang, P.; Wen, J.; Zhang, R. Analysis of Transient Current Distribution Characteristics of Parallel Chips in Press Pack IGBT. CSEE 2017, 37, 233–243. [Google Scholar]

- Bock, B.; Krafft, E.U.; Steimel, A. Measurement of multiple chip currents in a Press-Pack IGBT using Rogowski coils. Eur. Power Electron. Conf. 2003, 2003, 1–10. [Google Scholar]

- Furuya, M.; Ishiyama, Y. Current measurement inside press pack IGBTs. Fuji Electr. J. 2002, 75, 1–4. [Google Scholar]

- Gerber, D.; Guillod, T.; Biela, J. IGBT gate-drive with PCB Rogowski coil for improved short circuit detection and current turn-off capability. In Proceedings of the 2011 IEEE Pulsed Power Conference, Chicago, IL, USA, 19–23 June 2011; pp. 1359–1364. [Google Scholar]

- Gerber, D.; Guillod, T.; Leutwyler, R.; Biela, J. Gate Unit with Improved Short-Circuit Detection and Turn-Off Capability for 4.5-kV Press-Pack IGBTs Operated at 4-kA Pulse Current. IEEE Trans. Plasma Sci. 2013, 41, 2641–2648. [Google Scholar] [CrossRef]

- Tsukuda, M.; Koga, M.; Nakashima, K.; Omura, I. Micro PCB Rogowski coil for current monitoring and protection of high voltage power modules. Microelectron. Reliab. 2016, 64, 479–483. [Google Scholar] [CrossRef]

- Koga, M.; Tsukuda, M.; Nakashima, K.; Omura, I. Application-specific micro Rogowski coil for power modules-Design tool, novel coil pattern and demonstration. In Proceedings of the CIPS 2016 9th International Conference on Integrated Power Electronics Systems, Nuremberg, Germany, 8–10 March 2016; pp. 1–5. [Google Scholar]

- IXYS Is Now Part of Littelfuse. Available online: http://www.westcode.com/ (accessed on 25 September 2019).

- Rogowski, W.; Steinhaus, W. Die Messung der magnetischen Spannung. Arch. Für Elektrotechnik 1912, 1, 141–150. [Google Scholar] [CrossRef] [Green Version]

- Cooper, J. On the high-frequency response of a Rogowski coil. J. Nucl. Energy Part C Plasma Phys. Accel. Thermonucl. Res. 1963, 5, 285. [Google Scholar] [CrossRef]

- Ray, W.F.; Hewson, C.R.; Metcalfe, J.M. High frequency effects in current measurement using Rogowski coils. In Proceedings of the 2005 European Conference on Power Electronics and Applications, Dresden, Germany, 11–14 September 2005; Volume 9, p. 9. [Google Scholar]

- Ray, W.F.; Davis, R.M. Wide Bandwidth Rogowski Current Transducers: Part I: The Rogowski Coil. EPE J. 1993, 3, 51–59. [Google Scholar] [CrossRef]

- Ray, W.F. Wide Bandwidth Rogowski Current Transducers: Part II: The Integrator. EPE J. 1993, 3, 116–122. [Google Scholar] [CrossRef]

- Ray, W.F.; Hewson, C.R. High performance Rogowski current transducers. In Proceedings of the Conference Record of the 2000 IEEE Industry Applications Conference, Rome, Italy, 8–12 October 2000; Volume 5, pp. 3083–3090. [Google Scholar]

- Hewson, C.R.; Ray, W.F.; Metcalfe, J. Optimising high frequency integrator operation of rogowski current transducers. In Proceedings of the 2007 European Conference on Power Electronics and Applications, Aalborg, Denmark, 2–5 September 2007; pp. 1–9. [Google Scholar]

- Ray, W.F. Current Measuring Device. U.S. Patent 6,614,218 B1, 2003. [Google Scholar]

- Wang, B.; Wang, D.; Wu, W. Frequency Response Analysis of a Rogowski Coil Transducer and Its Design Method. Trans. China Electrotech. Soc. 2009, 24, 21–26. [Google Scholar]

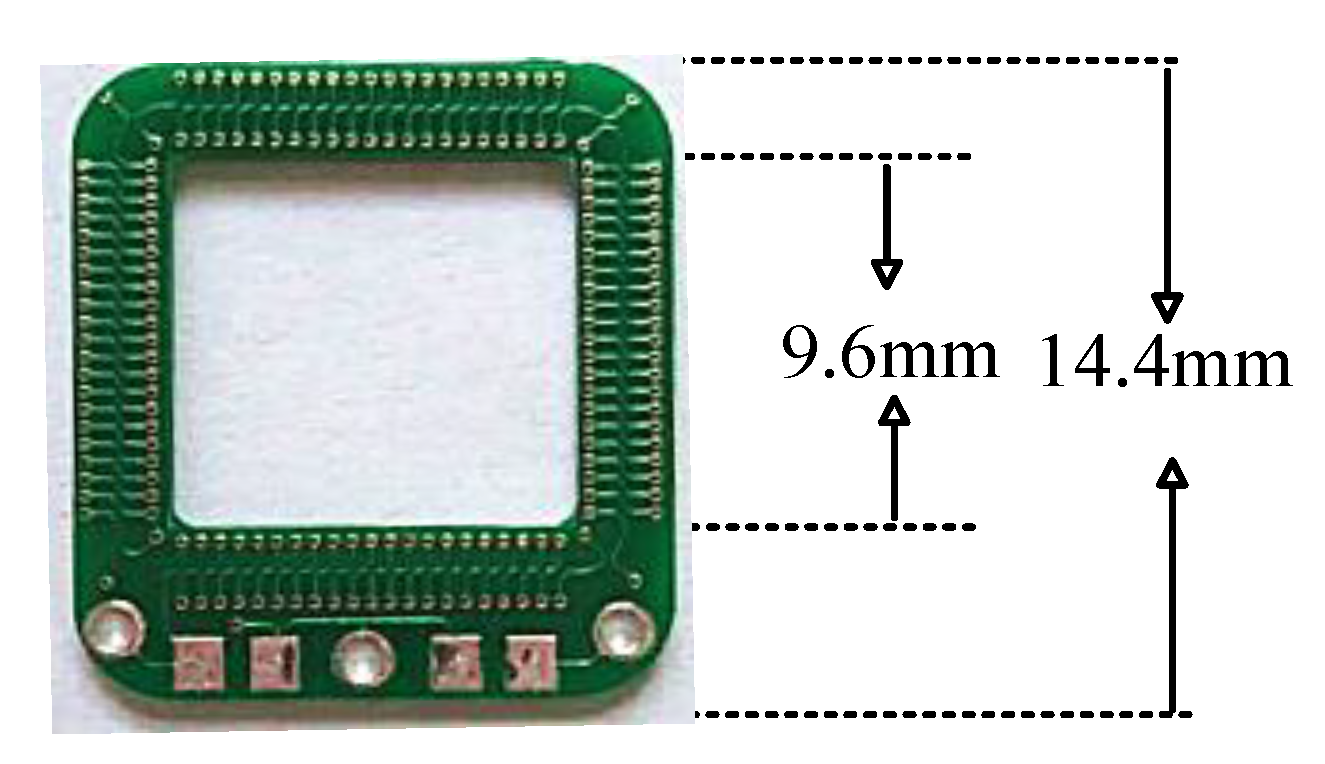

| Turns | Inside | Outside |

|---|---|---|

| 84 | 9.6 mm | 14.4 mm |

| Minimum aperture | Plate thickness | Trace width |

| 0.2 mm | 1 mm | 3.5 mil |

| Serial Number | #1 | #2 | #3 | #4 | #5 |

|---|---|---|---|---|---|

| Internal resistance r (Ω) | 4.28 | 4.14 | 4.07 | 4.85 | 4.63 |

| Self-induct L (nH) | 439 | 445 | 436 | 440 | 441 |

| Mutual sense M (nH) | 6.10 | 6.18 | 6.06 | 6.11 | 6.13 |

| Output Waveform | Integrated Waveform | |

|---|---|---|

| Open Circuit Voltage Wave | Short Circuit Current Wave | |

| cutting edge | 1.2 μs ± 30% | 8 μs ± 20% |

| Pulse width | 50 μs ± 20% | 20 μs ± 20% |

| Peak | 0~6 kV ± 10% | 0~3 kA ± 10% |

| Output impedance | 2Ω ± 10% | |

| Current Peak (A) | di/dt (kA/μs) | Bandwidth |

|---|---|---|

| 600 | 40 | 6.2–30 M |

| Sensitivity | Attenuation characteristic | Maximum noise |

| 10 | 6 | 10 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, C.; Zhang, J.; Zhao, Z.; Zhang, Z.; Fan, Y. Research on Small Square PCB Rogowski Coil Measuring Transient Current in the Power Electronics Devices. Sensors 2019, 19, 4176. https://doi.org/10.3390/s19194176

Jiao C, Zhang J, Zhao Z, Zhang Z, Fan Y. Research on Small Square PCB Rogowski Coil Measuring Transient Current in the Power Electronics Devices. Sensors. 2019; 19(19):4176. https://doi.org/10.3390/s19194176

Chicago/Turabian StyleJiao, Chaoqun, Juan Zhang, Zhibin Zhao, Zuoming Zhang, and Yuanliang Fan. 2019. "Research on Small Square PCB Rogowski Coil Measuring Transient Current in the Power Electronics Devices" Sensors 19, no. 19: 4176. https://doi.org/10.3390/s19194176