A Regulated Temperature-Insensitive High-Voltage Charge Pump in Standard CMOS Process for Micromachined Gyroscopes

Abstract

:1. Introduction

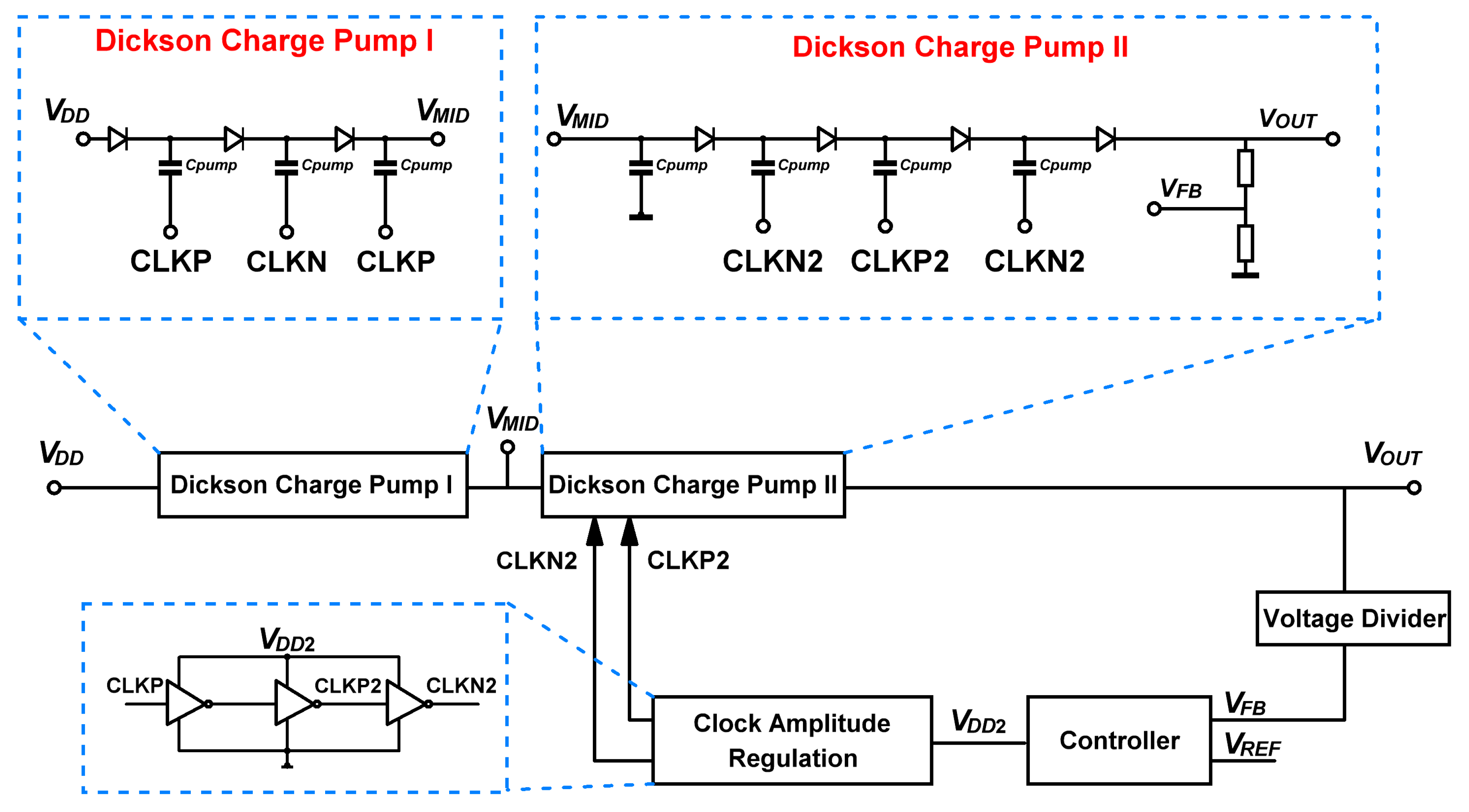

2. Design of the Charge Pump

2.1. Charge Pump Architecture

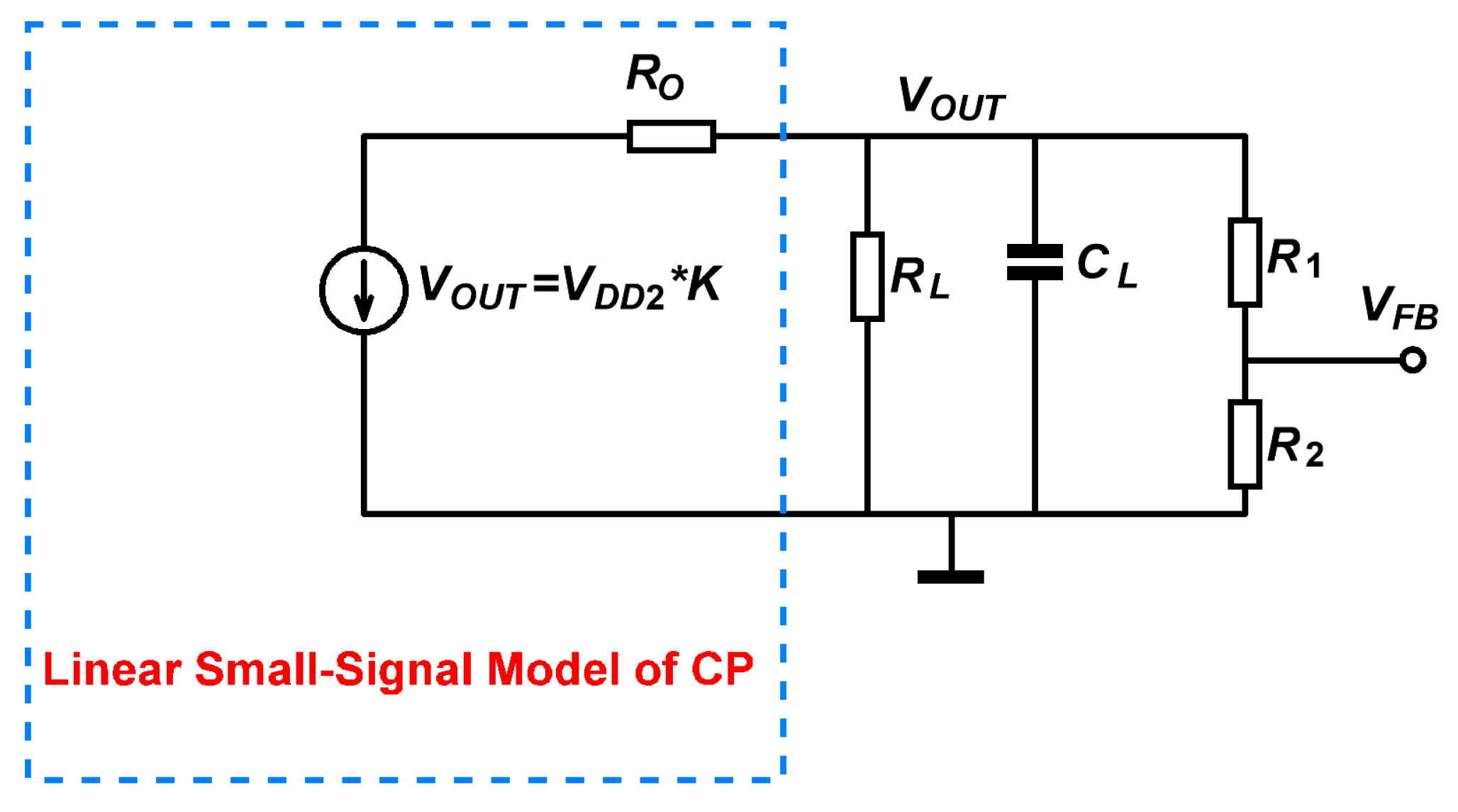

2.2. Closed-Loop Regulation

3. Experimental Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Finkbeiner, S. MEMS for automotive and consumer electronics. In Proceedings of the 2013 European Solid-State Device Research Conference (ESSDERC), Bucharest, Romania, 16–20 September 2013; pp. 9–14. [Google Scholar]

- Zhang, T.; Zhou, B.; Yin, P.; Chen, Z.; Zhang, R. Optimal Design of a Center Support Quadruple Mass Gyroscope (CSQMG). Sensors 2016, 16, 613. [Google Scholar]

- Sharma, A.; Zaman, M.F.; Ayazi, F. A Sub-0.2°/hr Bias Drift Micromechanical Silicon Gyroscope with Automatic CMOS Mode-Matching. IEEE J. Solid-State Circuits 2009, 44, 1593–1608. [Google Scholar]

- Sung, W.K.; Dalal, M.; Ayazi, F. A mode-matched 0.9 MHz single proof-mass dual-axis gyroscope. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011; pp. 2821–2824. [Google Scholar]

- Woo, J.; Boyd, C.; Cho, J.; Najafi, K. Ultra-low-noise transimpedance amplifier for high-performance MEMS resonant gyroscopes. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; pp. 1006–1009. [Google Scholar] [CrossRef]

- Saukoski, M.; Aaltonen, L.; Salo, T.; Halonen, K.A.I. Interface and control electronics for a bulk micromachined capacitive gyroscope. Sens. Actuators A Phys. 2008, 147, 183–193. [Google Scholar]

- Chen, W.; Fu, Q.; Yuan, Y.; Song, R.; Li, Y.; Liu, X. Design of charge-pump phase locked loop in micro-inertial sensor. In Proceedings of the 2011 Academic International Symposium on Optoelectronics and Microelectronics Technology, Harbin, China, 12–16 October 2011; pp. 246–250. [Google Scholar]

- Chu, Y.; Dong, J.; Chi, B.; Liu, Y. A Novel Digital Closed Loop MEMS Accelerometer Utilizing a Charge Pump. Sensors 2016, 16, 389. [Google Scholar]

- Guo, Z.Y.; Yang, Z.C.; Zhao, Q.C.; Lin, L.T.; Ding, H.T.; Liu, X.S.; Cui, J.; Xie, H.; Yan, G.Z. A lateral-axis micromachined tuning fork gyroscope with torsional Z-sensing and electrostatic force-balanced driving. J. Micromech. Microeng. 2009, 20, 025007. [Google Scholar]

- Marx, M.; Rombach, S.; Nessler, S.; de Dorigo, D.; Manoli, Y. A 141-μW High-Voltage MEMS Gyroscope Drive Interface Circuit Based on Flying Capacitors. IEEE J. Solid-State Circuits 2019, 54, 511–523. [Google Scholar]

- Rombach, S.; Marx, M.; Nessler, S.; de Dorigo, D.; Maurer, M.; Manoli, Y. An Interface ASIC for MEMS Vibratory Gyroscopes with a Power of 1.6 mW, 92 dB DR and 0.007 °/s/ Noise Floor Over a 40 Hz Band. IEEE J. Solid-State Circuits 2016, 51, 1915–1927. [Google Scholar]

- Tanzawa, T. System overview and key design considerations. In On-Chip High-Voltage Generator Design; Springer: New York, NY, USA, 2013; pp. 1–14. [Google Scholar]

- Prandi, L.; Caminada, C.; Coronato, L.; Cazzaniga, G.; Biganzoli, F.; Antonello, R.; Oboe, R. A low-power 3-axis digital-output MEMS gyroscope with single drive and multiplexed angular rate readout. In Proceedings of the 2011 IEEE International Solid-State Circuits Conference, San Francisco, CA, USA, 20–24 February 2011; pp. 104–106. [Google Scholar]

- Emira, A.; AbdelGhany, M.; Elsayed, M.; Elshurafa, A.M.; Sedky, S.; Salama, K.N. All-pMOS 50-V Charge Pumps Using Low-Voltage Capacitors. IEEE Trans. Ind. Electron. 2013, 60, 4683–4693. [Google Scholar]

- Trusov, A.A.; Prikhodko, I.P.; Rozelle, D.M.; Meyer, A.D.; Shkel, A.M. 1 PPM precision self-calibration of scale factor in MEMS Coriolis vibratory gyroscopes. In Proceedings of the 2013 Transducers Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS EUROSENSORS XXVII), Barcelona, Spain, 16–20 June 2013; pp. 2531–2534. [Google Scholar]

- Dalal, M. Low Noise, Low Power Interface Circuits and Systems for High Frequency Resonant Micro-Gyroscopes. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, August 2012. [Google Scholar]

- Aaltonen, L.; Kalanti, A.; Pulkkinen, M.; Paavola, M.; Kämäräinen, M.; Halonen, K. A 4.3 mm2 ASIC for a 300 °/s 2-axis capacitive micro-gyroscope. In Proceedings of the 2010 ESSCIRC, Seville, Spain, 14–16 September 2010; pp. 286–289. [Google Scholar]

- Lee, J.Y.; Kim, S.E.; Song, S.J.; Kim, J.K.; Kim, S.; Yoo, H.J. A Regulated Charge Pump with Small Ripple Voltage and Fast Start-Up. IEEE J. Solid-State Circuits 2006, 41, 425–432. [Google Scholar]

- Shen, B.; Bose, S.; Johnston, M.L. On-chip high-voltage SPAD bias generation using a dual-mode, closed-loop charge pump. In Proceedings of the 2017 IEEE International Symposium on Circuits and Systems (ISCAS), Baltimore, MD, USA, 28–31 May 2017; pp. 1–4. [Google Scholar]

- Hoque, M.R.; McNutt, T.; Zhang, J.; Mantooth, A.; Mojarradi, M. A high voltage Dickson charge pump in SOI CMOS. In Proceedings of the IEEE 2003 Custom Integrated Circuits Conference, San Jose, CA, USA, 24 September 2003; pp. 493–496. [Google Scholar]

- Ker, M.; Chen, S. Ultra-High-Voltage Charge Pump Circuit in Low-Voltage Bulk CMOS Processes with Polysilicon Diodes. IEEE Trans. Circ. Syst. II Express Briefs 2007, 54, 47–51. [Google Scholar]

- Aaltonen, L.; Halonen, K. On-chip charge-pump with continuous frequency regulation for precision high-voltage generation. In Proceedings of the 2009 Ph.D. Research in Microelectronics and Electronics, Cork, Ireland, 12–17 July 2009; pp. 68–71. [Google Scholar]

- Zhang, M.; Llaser, N. On-Chip High Voltage Generation with standard process for MEMS. In Proceedings of the 2007 14th IEEE International Conference on Electronics, Circuits and Systems, Marrakech, Morocco, 11–14 December 2007; pp. 18–21. [Google Scholar]

- Ismail, Y.; Lee, H.; Pamarti, S.; Yang, C.K. A 34V charge pump in 65nm bulk CMOS technology. In Proceedings of the 2014 IEEE International Solid-State Circuits Conference Digest of Technical Papers (ISSCC), San Francisco, CA, USA, 9–13 February 2014; pp. 408–409. [Google Scholar]

- Shirane, A.; Ito, H.; Ishihara, N.; Masu, K. A 21 V output charge pump circuit with appropriate well-bias supply technique in 0.18 μm Si CMOS. In Proceedings of the 2011 International SoC Design Conference, Jeju, Korea, 17–18 November 2011; pp. 28–31. [Google Scholar]

- Dickson, J.F. On-chip high-voltage generation in MNOS integrated circuits using an improved voltage multiplier technique. IEEE J. Solid-State Circuits 1976, 11, 374–378. [Google Scholar]

- Ismail, Y.; Lee, H.; Pamarti, S.; Yang, C.K.K. A 36-V 49% Efficient Hybrid Charge Pump in Nanometer-Scale Bulk CMOS Technology. IEEE J. Solid-State Circuits 2017, 52, 781–798. [Google Scholar]

- Tanzawa, T.; Tanaka, T. A dynamic analysis of the Dickson charge pump circuit. IEEE J. Solid-State Circuits 1997, 32, 1231–1240. [Google Scholar]

- Hong, D.; El-Gamal, M. Low operating voltage and short settling time CMOS charge pump for MEMS applications. In Proceedings of the 2003 International Symposium on Circuits and Systems, ISCAS 2003, Bangkok, Thailand, 25–28 May 2003; Volume 5, pp. 281–284. [Google Scholar] [CrossRef]

| Parameter | This Work | [19] | [22] | [29] |

|---|---|---|---|---|

| Process | 0.18-m CMOS | 0.13-m CMOS | 0.35-m HV CMOS | 0.18-m CMOS |

| Supply Voltage | 5 V | 1.8 V | 3.6 V | 1.2 V |

| Maximum Output | 16.95 V | 22 V | 10.4 V | 14.8 V |

| Stage Capacitor | 72 pF | N/A | 1.6–1.1 pF | 5.4 pF |

| Closed-loop Approach | Clock Amplitude | Digital Control | Clock Frequency | Open-loop |

| Temperature Variation | 1.1% (C) | N/A | N/A | 10% (C) |

| Area | 2.52 mm | 0.149 mm | 0.14 mm | N/A |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Li, R.; Ju, C.; Hou, B.; Wei, Q.; Zhou, B.; Chen, Z.; Zhang, R. A Regulated Temperature-Insensitive High-Voltage Charge Pump in Standard CMOS Process for Micromachined Gyroscopes. Sensors 2019, 19, 4149. https://doi.org/10.3390/s19194149

Li X, Li R, Ju C, Hou B, Wei Q, Zhou B, Chen Z, Zhang R. A Regulated Temperature-Insensitive High-Voltage Charge Pump in Standard CMOS Process for Micromachined Gyroscopes. Sensors. 2019; 19(19):4149. https://doi.org/10.3390/s19194149

Chicago/Turabian StyleLi, Xiang, Rui Li, Chunge Ju, Bo Hou, Qi Wei, Bin Zhou, Zhiyong Chen, and Rong Zhang. 2019. "A Regulated Temperature-Insensitive High-Voltage Charge Pump in Standard CMOS Process for Micromachined Gyroscopes" Sensors 19, no. 19: 4149. https://doi.org/10.3390/s19194149

APA StyleLi, X., Li, R., Ju, C., Hou, B., Wei, Q., Zhou, B., Chen, Z., & Zhang, R. (2019). A Regulated Temperature-Insensitive High-Voltage Charge Pump in Standard CMOS Process for Micromachined Gyroscopes. Sensors, 19(19), 4149. https://doi.org/10.3390/s19194149