Design of a Portable Orthogonal Surface Acoustic Wave Sensor System for Simultaneous Sensing and Removal of Nonspecifically Bound Proteins

Abstract

1. Introduction

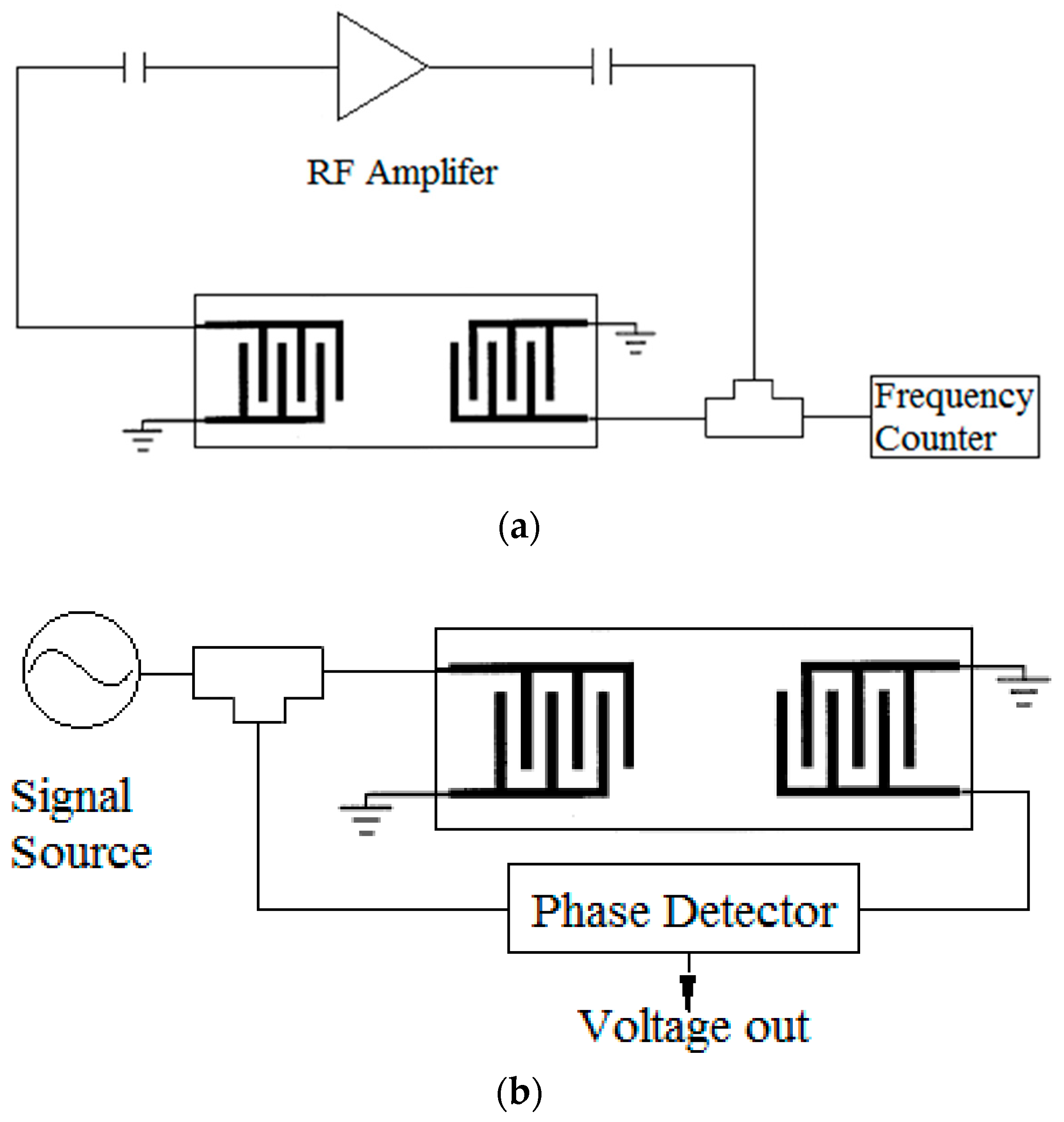

2. Orthogonal SAW Sensor

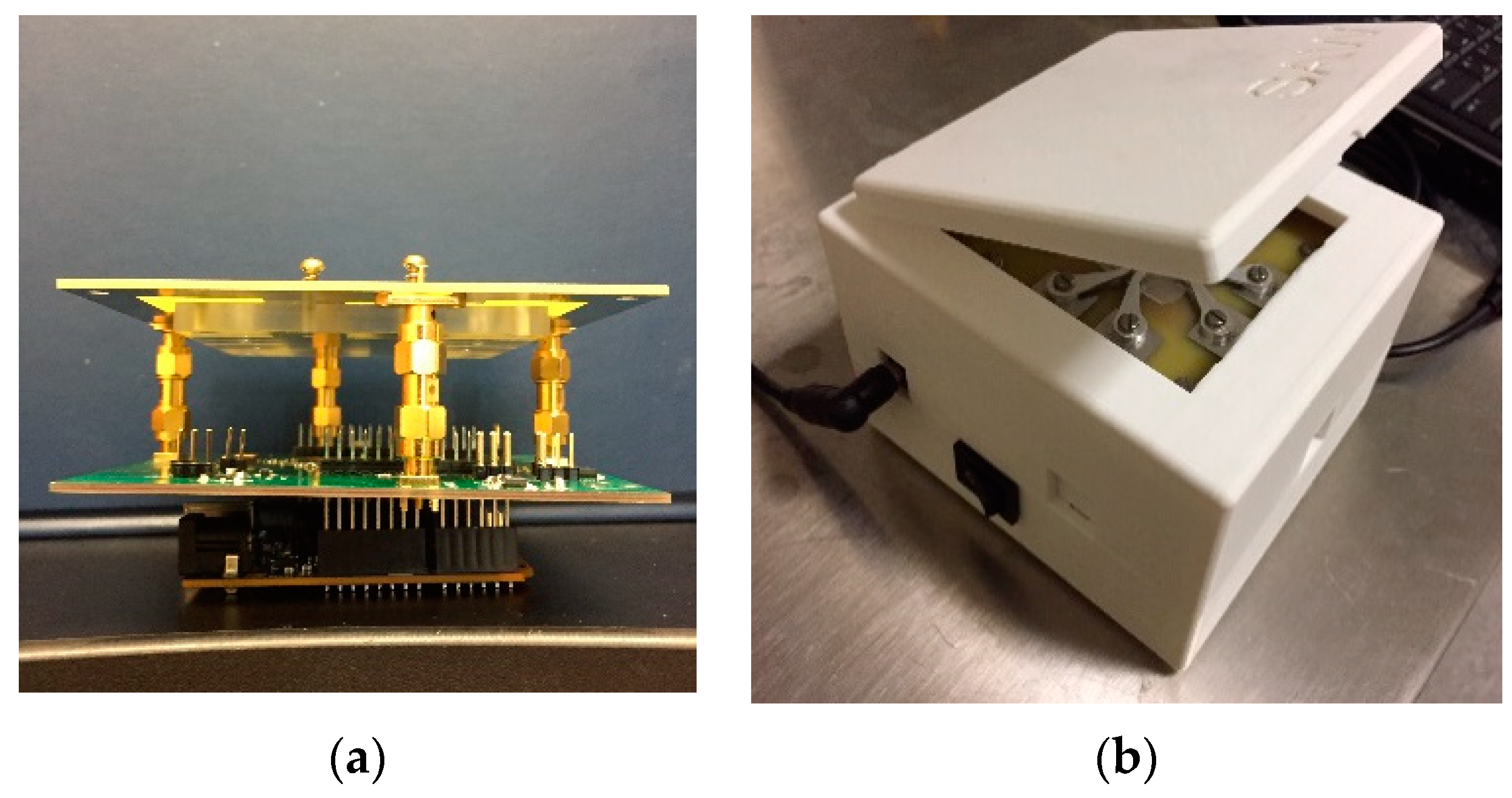

3. Portable System Design

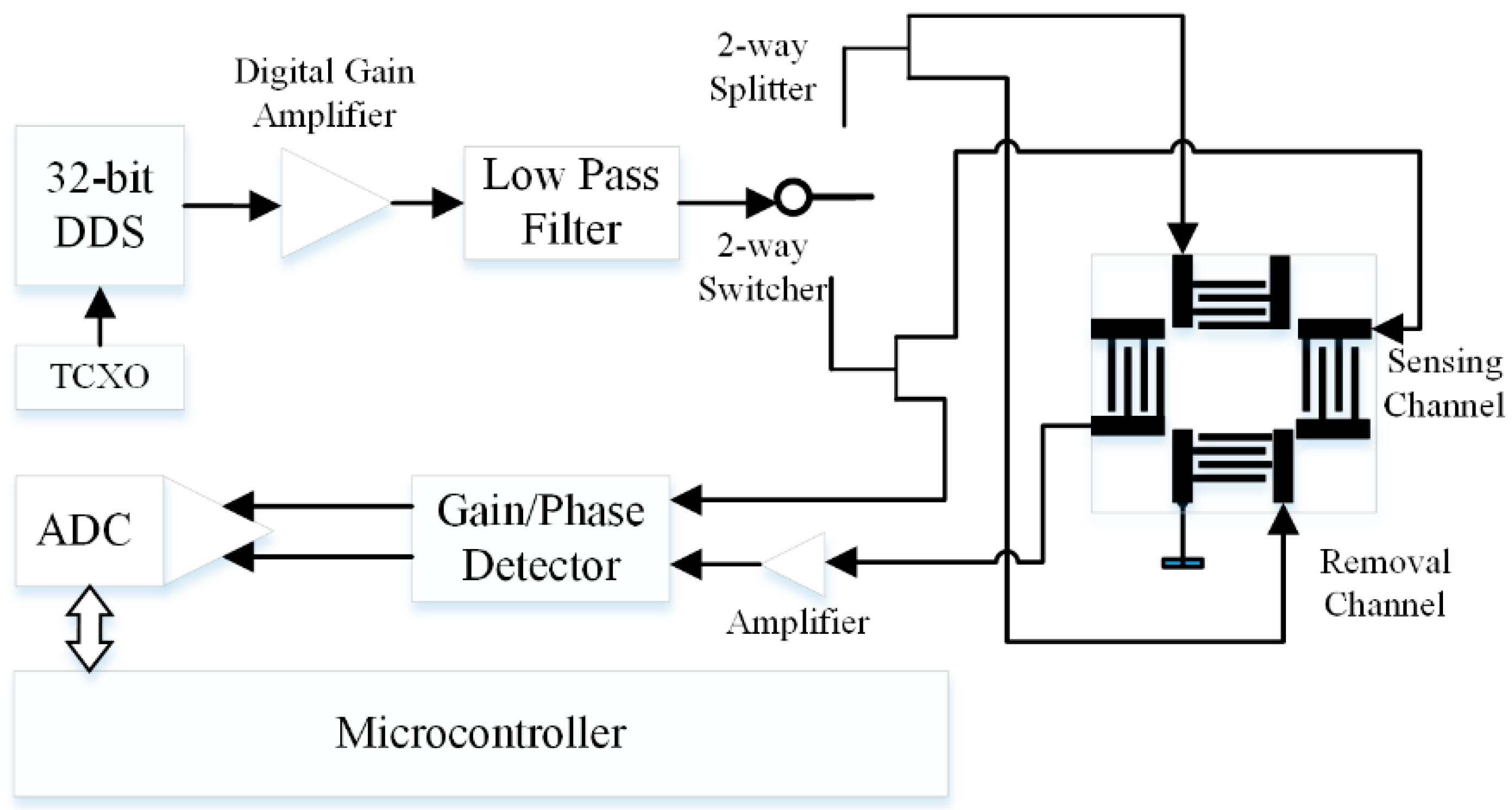

3.1. Overall System Design

3.2. Main Circuit Design

4. Experimental Sections

4.1. Reagents and Apparatus

4.2. Sensor Surface Preparation

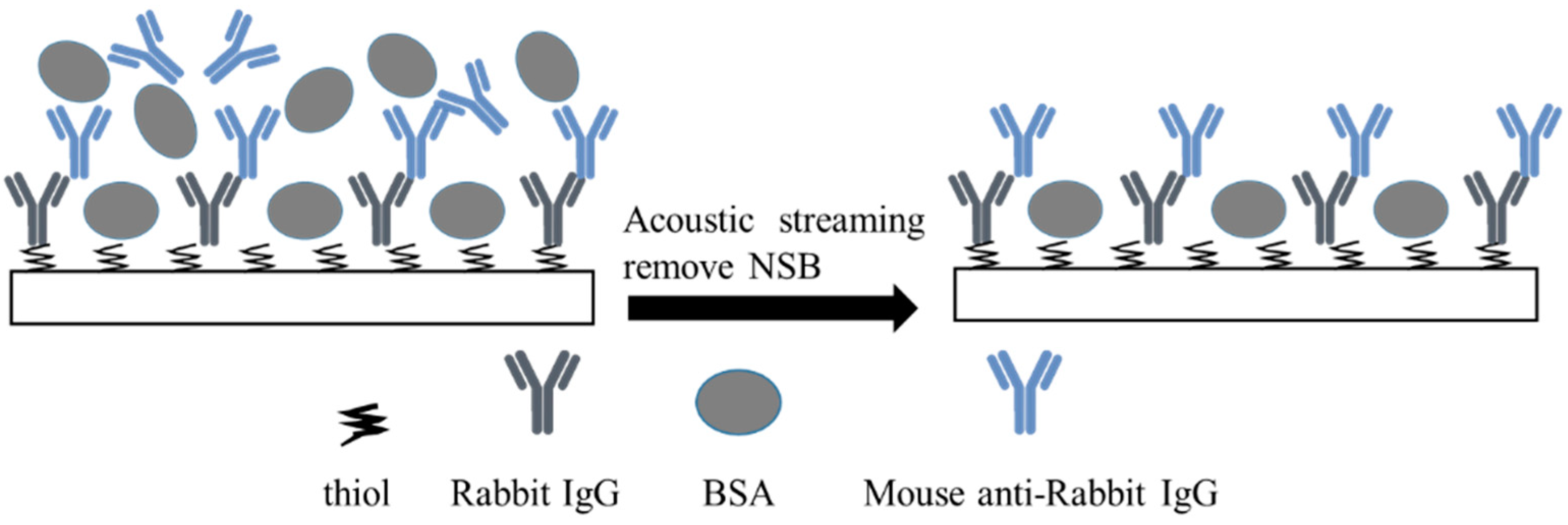

4.3. Biodetection Strategy

5. Results and Discussion

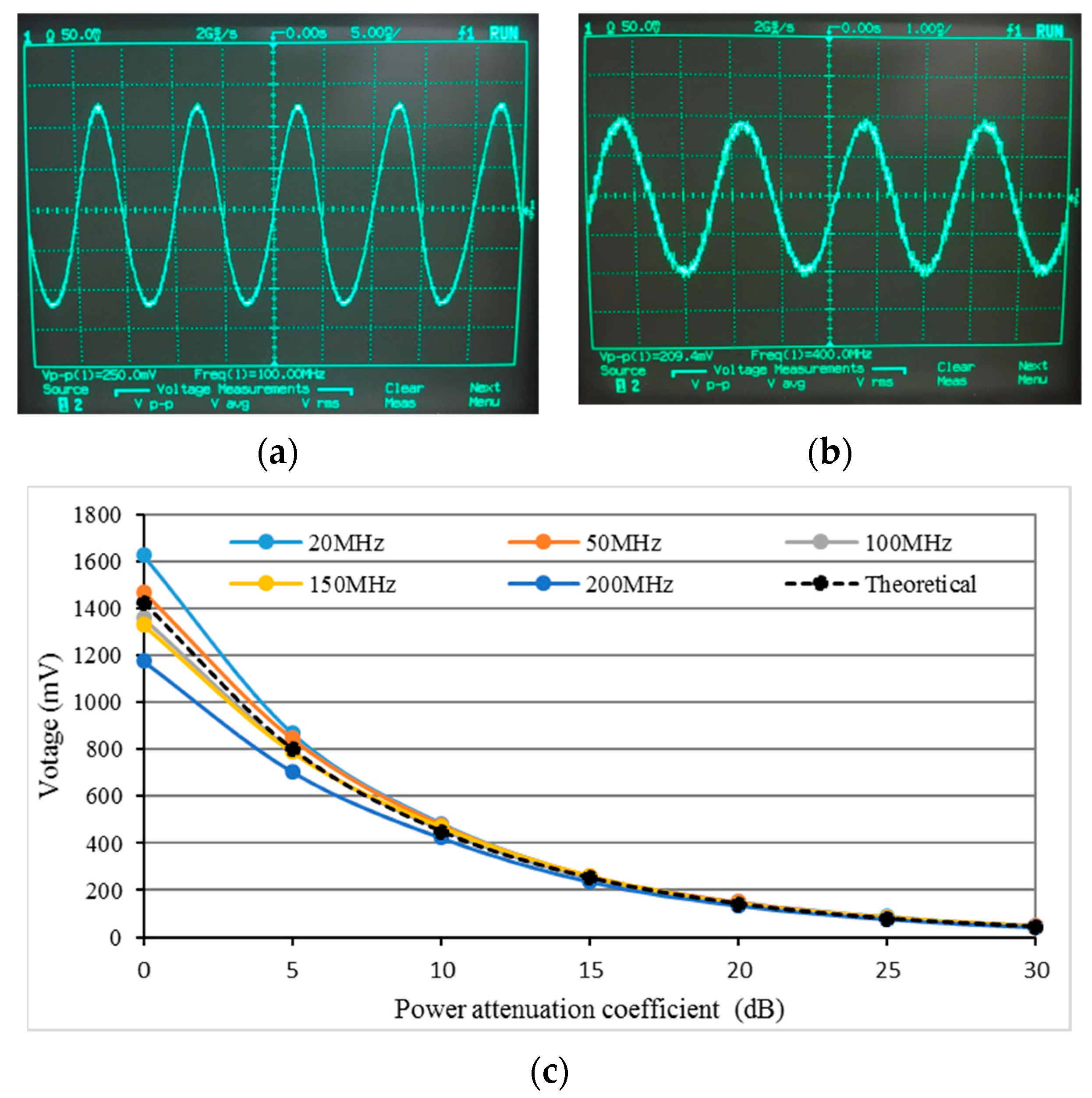

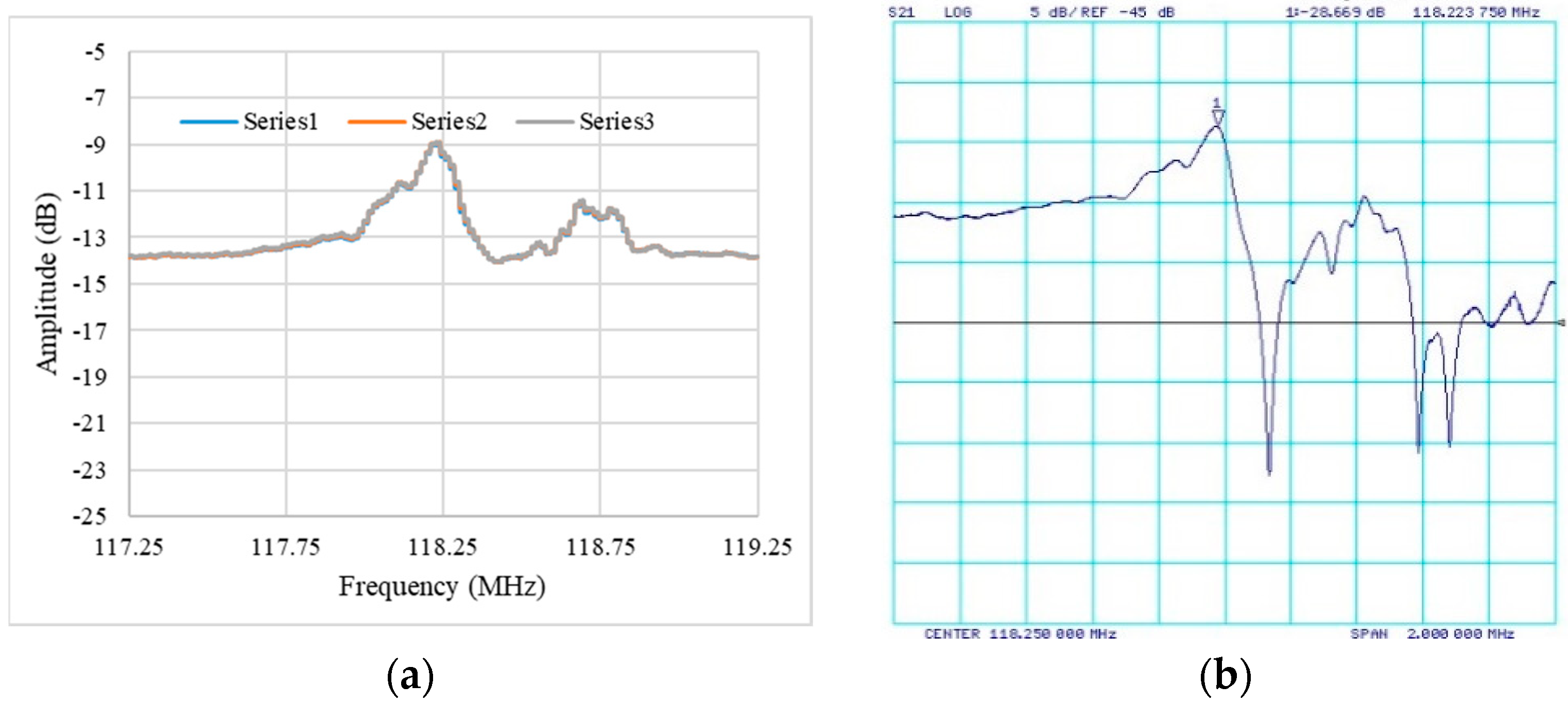

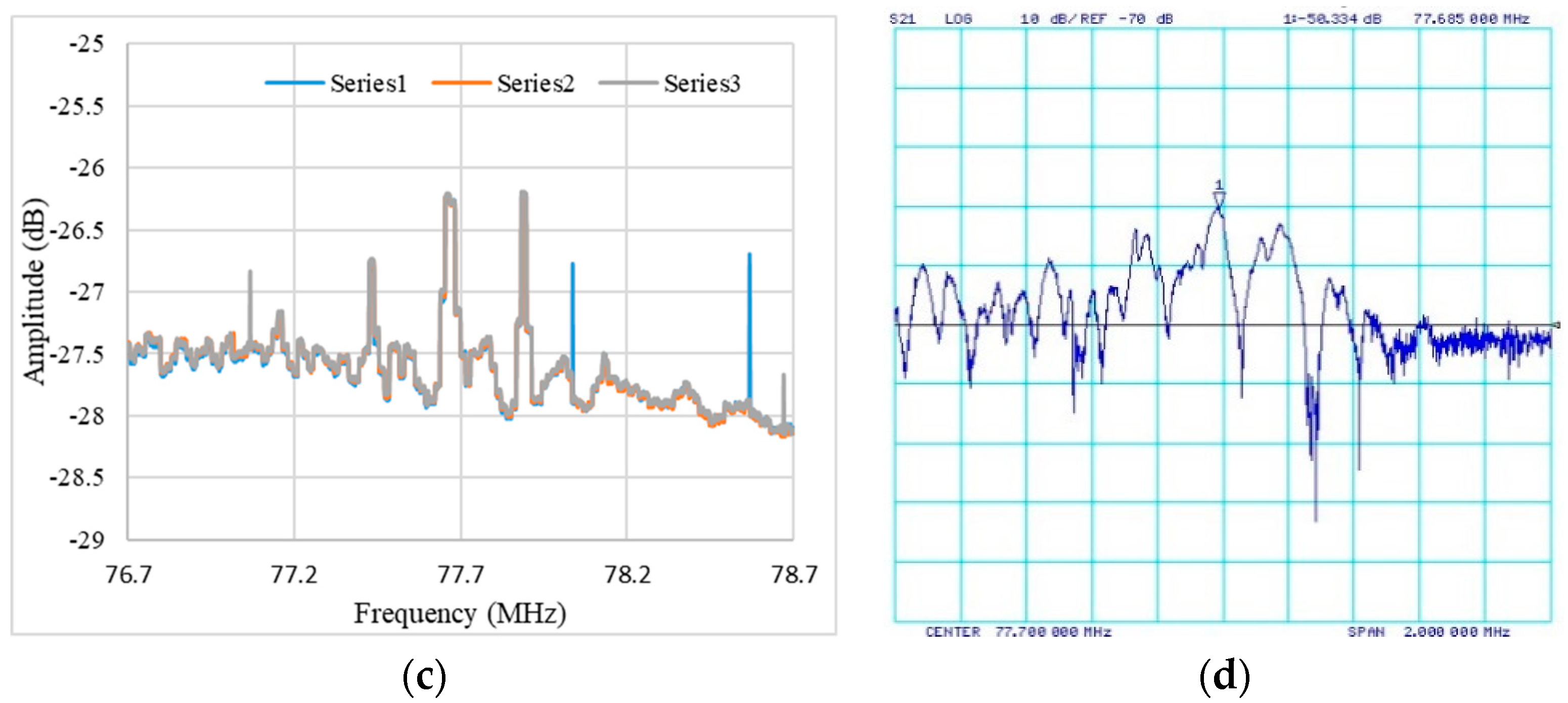

5.1. Circuit Performance Test

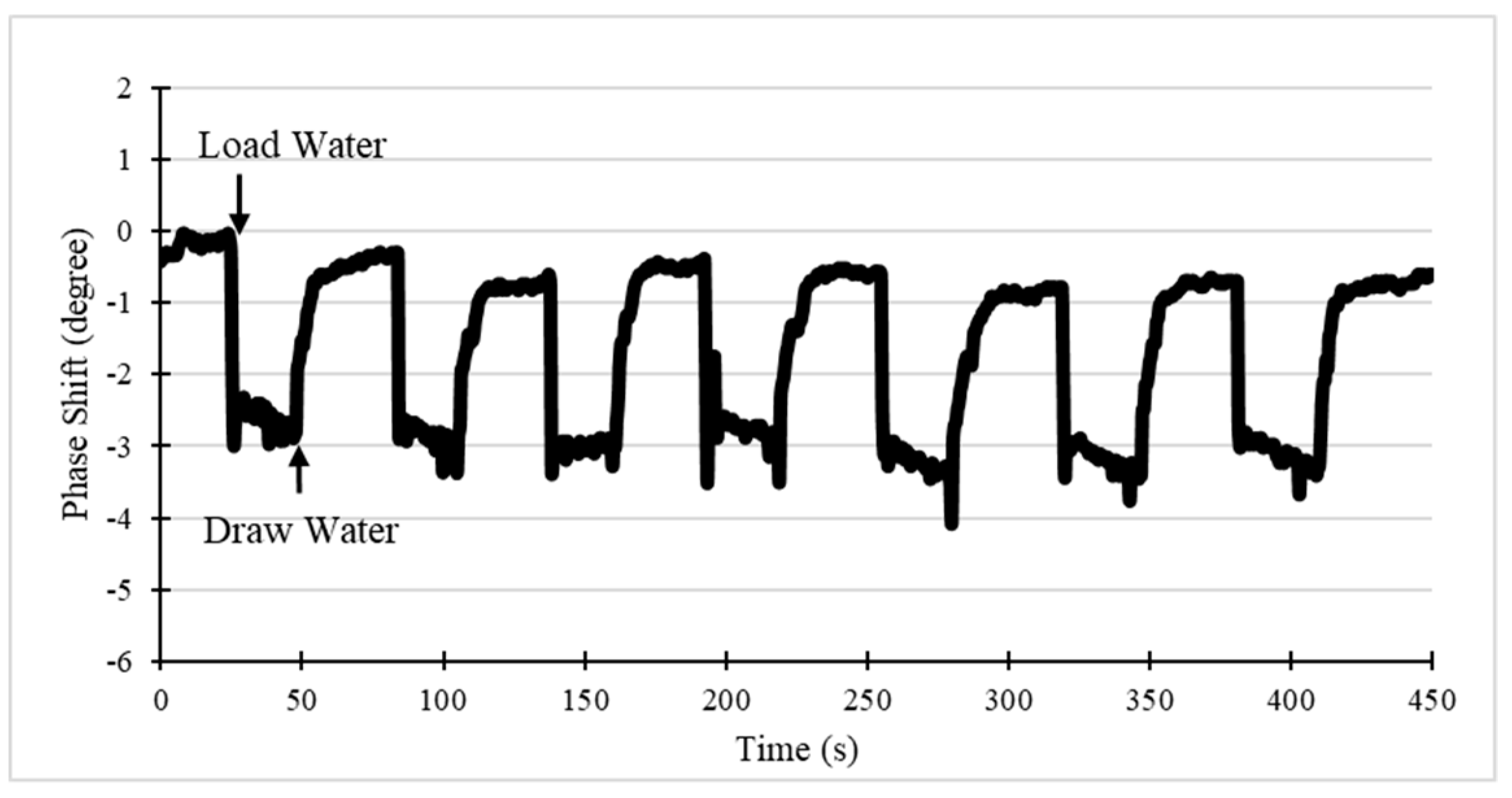

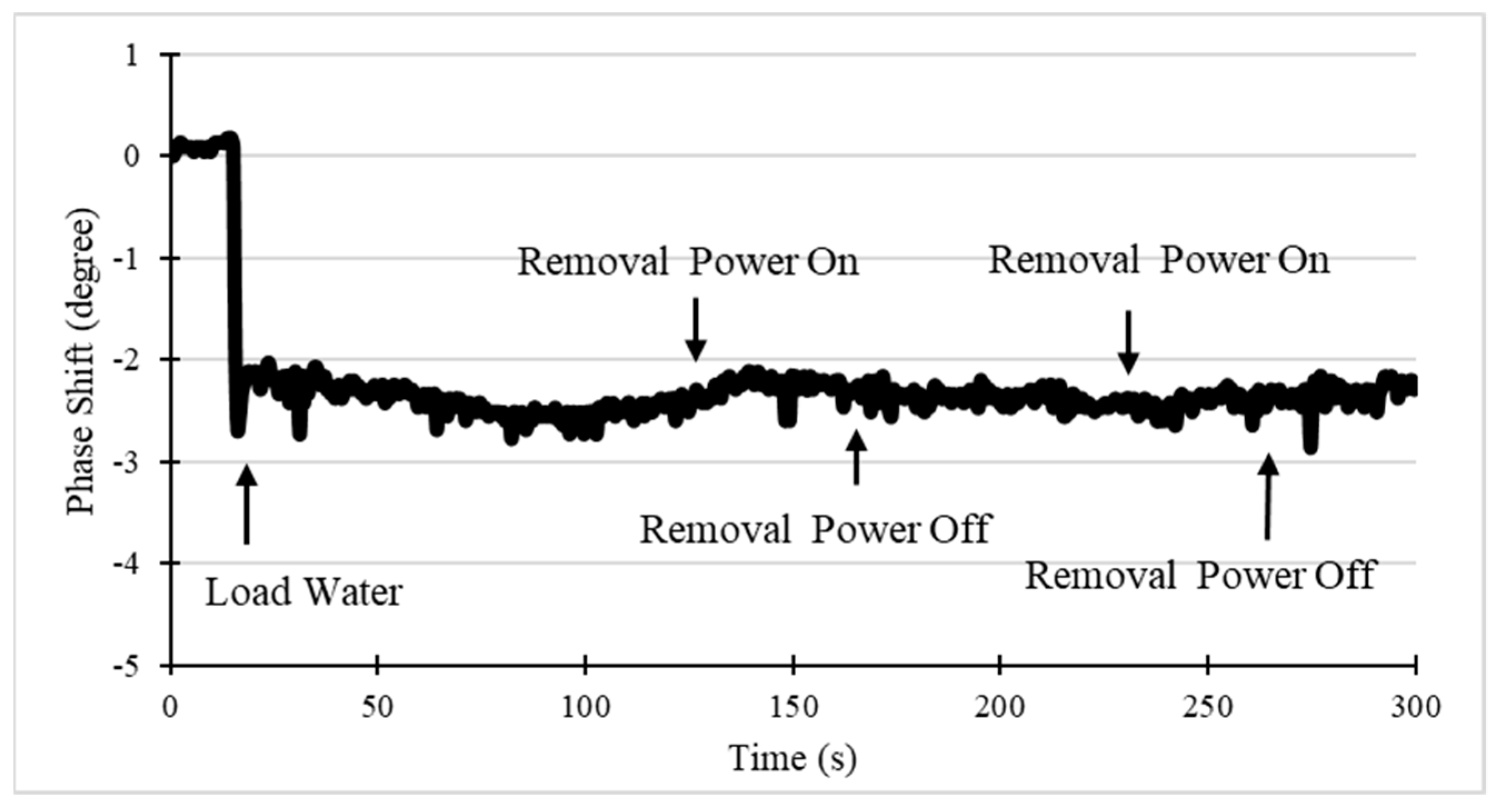

5.2. Dynamic Response

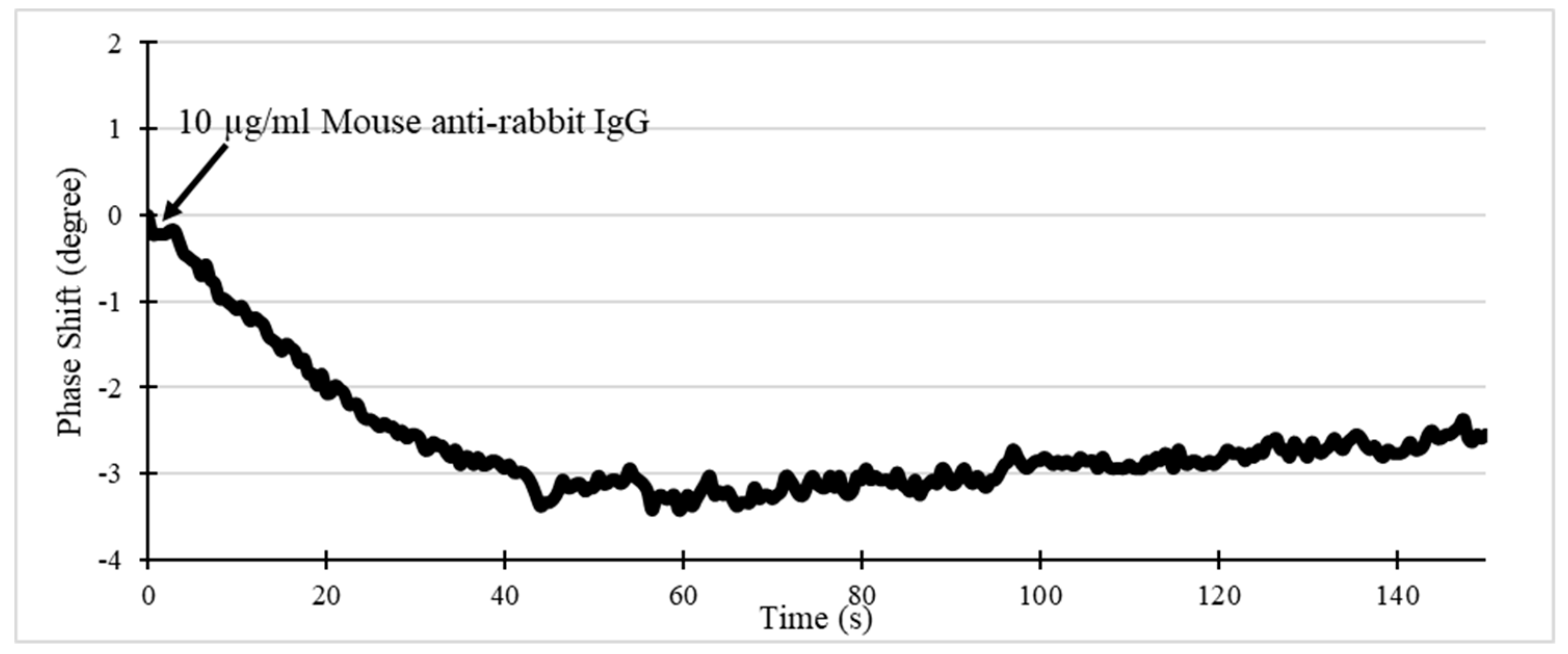

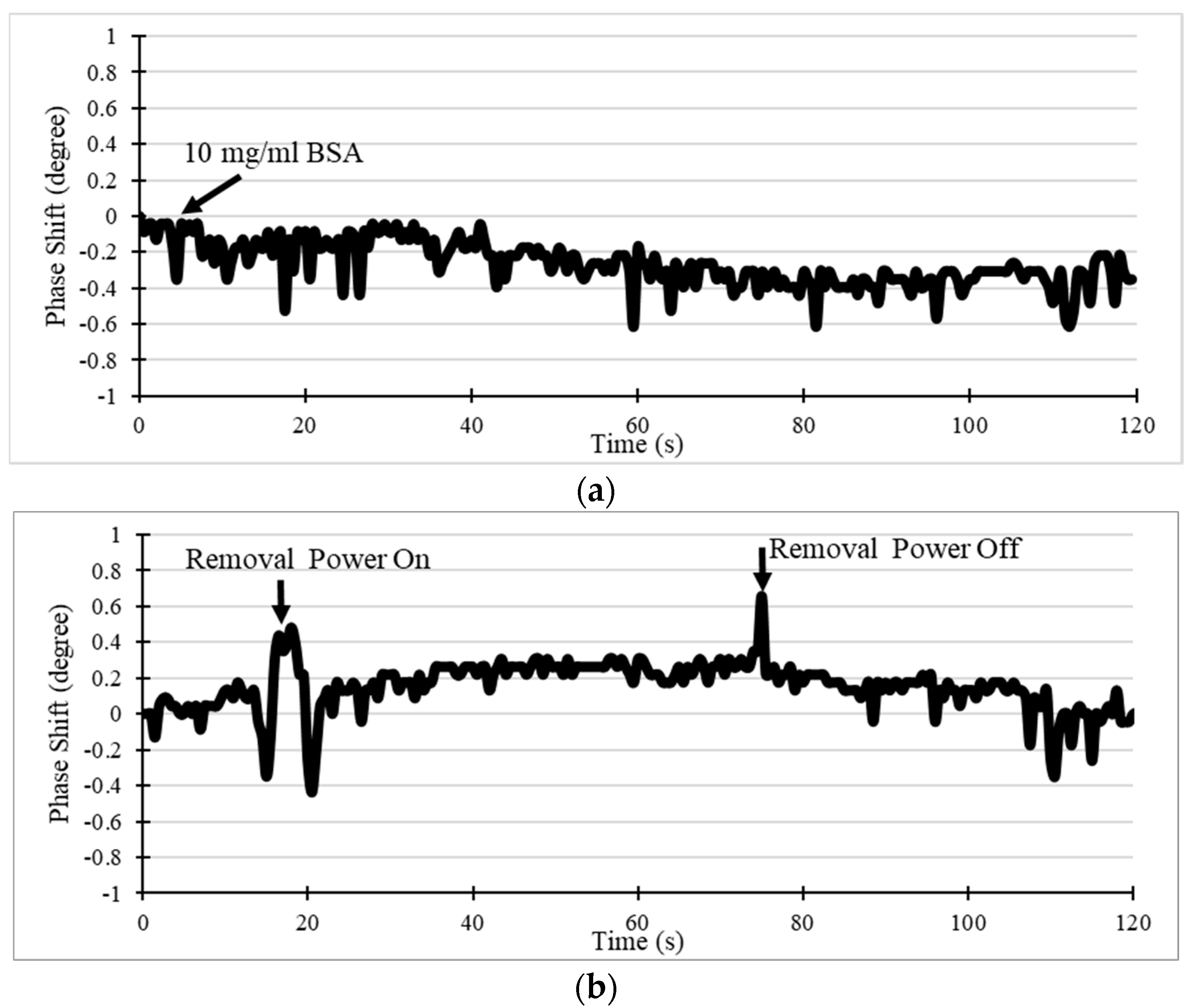

5.3. IgG and BSA Test Response

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Länge, K.; Rapp, B.E.; Rapp, M. Surface acoustic wave biosensors: A review. Anal. Bioanal. Chem. 2008, 391, 1509–1519. [Google Scholar] [CrossRef] [PubMed]

- Gronewold, T.M.A. Surface acoustic wave sensors in the bioanalytical field: Recent trends and challenges. Anal. Chim. Acta 2007, 603, 119–128. [Google Scholar] [CrossRef] [PubMed]

- Andle, J.C.; Vetelino, J.F. Acoustic wave biosensors. Sens. Actuators A Phys. 1994, 44, 167–176. [Google Scholar] [CrossRef]

- Ballantine, D.S., Jr.; White, R.M.; Martin, S.J.; Ricco, A.J.; Zellers, E.T.; Frye, G.C.; Wohltjen, H. Acoustic Wave Sensors: Theory, Design and Physico-chemical Applications; Elsevier: Amsterdam, The Netherlands, 21 October 1996. [Google Scholar]

- Kovacs, G.; Venema, A. Theoretical comparison of sensitivities of acoustic shear wave modes for (bio) chemical sensing in liquids. Appl. Phys. Lett. 1992, 61, 639–641. [Google Scholar] [CrossRef]

- Li, S.; Sankaranarayanan, S.; Fan, C.; Su, Y.; Bhethanabotla, V.R. Achieving lower insertion loss and higher sensitivity in a SAW biosensor via optimization of waveguide and microcavity structures. IEEE Sens. J. 2017, 17, 1608–1616. [Google Scholar] [CrossRef]

- Josse, F.; Bender, F.; Cernosek, R.W. Guided shear horizontal surface acoustic wave sensors for chemical and biochemical detection in liquids. Anal. Chem. 2001, 73, 5937–5944. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Wan, Y.; Fan, C.; Su, Y. Theoretical study of monolayer and double-layer waveguide love wave sensors for achieving high sensitivity. Sensors 2017, 17, 653. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.; Jung, J.; Hahn, Y.K.; Kim, S.K.; Lee, Y.; Lee, J.; Lee, T.-H.; Park, J.-Y.; Seo, H.; Lee, J.N. A centrifugally actuated point-of-care testing system for the surface acoustic wave immunosensing of cardiac troponin I. Analyst 2013, 138, 2558–2566. [Google Scholar] [CrossRef] [PubMed]

- Nirschl, M.; Reuter, F.; Vörös, J. Review of transducer principles for label-free biomolecular interaction analysis. Biosensors 2011, 1, 70–92. [Google Scholar] [CrossRef]

- Li, S.; Wan, Y.; Su, Y.; Fan, C.; Bhethanabotla, V.R. Gold nanoparticle-based low limit of detection Love wave biosensor for carcinoembryonic antigens. Biosens. Bioelectron. 2017, 95, 48–54. [Google Scholar] [CrossRef]

- Sankaranarayanan, S.K.R.S.; Singh, R.; Bhethanabotla, V.R. Acoustic streaming induced elimination of nonspecifically bound proteins from a surface acoustic wave biosensor: Mechanism prediction using fluid-structure interaction models. J. Appl. Phys. 2010, 108, 104507. [Google Scholar] [CrossRef]

- Cular, S.; Branch, D.W.; Bhethanabotla, V.R.; Meyer, G.D.; Craighead, H.G. Removal of nonspecifically bound proteins on microarrays using surface acoustic waves. IEEE Sens. J. 2008, 8, 314–320. [Google Scholar] [CrossRef]

- Sankaranarayanan, S.K.; Cular, S.; Bhethanabotla, V.R.; Joseph, B. Flow induced by acoustic streaming on surface-acoustic-wave devices and its application in biofouling removal: A computational study and comparisons to experiment. Phys. Rev. E 2008, 77, 066308. [Google Scholar] [CrossRef] [PubMed]

- Shiokawa, S.; Matsui, Y.; Ueda, T. Liquid streaming and droplet formation caused by leaky Rayleigh waves. In Proceedings of the 1989 IEEE Ultrasonics Symposium, Montreal, QC, Canada, 3–6 October 1989; pp. 643–646. [Google Scholar]

- Richardson, M.B.; Bhethanabotla, V.R. Orthogonal SAW Transducers on Substrate for Simultaneous Biofouling Removal and Biosensing. U.S. Patent App. 15/006,852, 24 July 2018. [Google Scholar]

- Richardson, M. Theoretical and Experimental Investigations to Improve the Performance of Surface Acoustic Wave (SAW) Biosensors; University of South Florida: Tampa, FL, USA, 2015. [Google Scholar]

- Kipling, A.L.; Thompson, M. Network analysis method applied to liquid-phase acoustic wave sensors. Anal. Chem. 1990, 62, 1514–1519. [Google Scholar] [CrossRef]

- Franke, T.; Abate, A.R.; Weitz, D.A.; Wixforth, A. Surface acoustic wave (SAW) directed droplet flow in microfluidics for PDMS devices. Lab Chip 2009, 9, 2625–2627. [Google Scholar] [CrossRef] [PubMed]

- Chang, K.; Pi, Y.; Lu, W.; Wang, F.; Pan, F.; Li, F.; Jia, S.; Shi, J.; Deng, S.; Chen, M. Label-free and high-sensitive detection of human breast cancer cells by aptamer-based leaky surface acoustic wave biosensor array. Biosens. Bioelectron. 2014, 60, 318–324. [Google Scholar] [CrossRef] [PubMed]

- Jeutter, D.; Josse, F.; Johnson, M.; Wenzel, M.; Hossenlopp, J.; Cernosek, R. Design of a portable guided SH-SAW chemical sensor system for liquid environments. In Proceedings of the 2005 IEEE International Frequency Control Symposium and Exposition, Vancouver, BC, Canada, 29–31 August 2005; pp. 59–68. [Google Scholar]

- Teramura, Y.; Iwata, H. Label-free immunosensing for α-fetoprotein in human plasma using surface plasmon resonance. Anal. Biochem. 2007, 365, 201–207. [Google Scholar] [CrossRef]

- Kane, R.S.; Deschatelets, P.; Whitesides, G.M. Kosmotropes form the basis of protein-resistant surfaces. Langmuir 2003, 19, 2388–2391. [Google Scholar] [CrossRef]

- Welsch, W.; Klein, C.; Öksüzoglu, R.M.; Von Schickfus, M.; Hunklinger, S. Immunosensing with surface acoustic wave sensors. Sens. Actuators A Phys. 1997, 62, 562–564. [Google Scholar] [CrossRef]

- Ladd, J.; Zhang, Z.; Chen, S.; Hower, J.C.; Jiang, S. Zwitterionic polymers exhibiting high resistance to nonspecific protein adsorption from human serum and plasma. Biomacromolecules 2008, 9, 1357–1361. [Google Scholar] [CrossRef]

- Holmlin, R.E.; Chen, X.; Chapman, R.G.; Takayama, S.; Whitesides, G.M. Zwitterionic SAMs that resist nonspecific adsorption of protein from aqueous buffer. Langmuir 2001, 17, 2841–2850. [Google Scholar] [CrossRef]

- Sternhagen, J.D.; Mitzner, K.; Berkenpas, E.; Karlgaard, M.; Wold, C.E.; Galipeau, D.W. A direct digital synthesis system for acoustic wave sensors. IEEE Sens. J. 2002, 2, 288–293. [Google Scholar] [CrossRef]

- Schmitt, R.F.; Allen, J.W.; Wright, R. Rapid design of SAW oscillator electronics for sensor applications. Sens. Actuators B Chem. 2001, 76, 80–85. [Google Scholar] [CrossRef]

- Vankka, J. Methods of mapping from phase to sine amplitude in direct digital synthesis. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1997, 44, 526–534. [Google Scholar] [CrossRef] [PubMed]

- Suthar, K.J.; Sankaranarayanan, S.K.R.S.; Richardson, M.; Bhethanabotla, V.R. Liquid heating can cause denaturation of sensing layer in SAW biosensors. In Proceedings of the 2013 IEEE Sensors, Baltimore, MD, USA, 3–6 November 2013; pp. 1–4. [Google Scholar]

- Li, S.; Desrosiers, J.; Bhethanabotla, V.R. Heating of Rayleigh surface acoustic wave devices in 128° YX LiNbO3 and ST X quartz substrates. In Proceedings of the 2017 IEEE Sensors, Glasgow, UK, 29 October–1 November 2017; pp. 1–3. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Bhethanabotla, V.R. Design of a Portable Orthogonal Surface Acoustic Wave Sensor System for Simultaneous Sensing and Removal of Nonspecifically Bound Proteins. Sensors 2019, 19, 3876. https://doi.org/10.3390/s19183876

Li S, Bhethanabotla VR. Design of a Portable Orthogonal Surface Acoustic Wave Sensor System for Simultaneous Sensing and Removal of Nonspecifically Bound Proteins. Sensors. 2019; 19(18):3876. https://doi.org/10.3390/s19183876

Chicago/Turabian StyleLi, Shuangming, and Venkat R. Bhethanabotla. 2019. "Design of a Portable Orthogonal Surface Acoustic Wave Sensor System for Simultaneous Sensing and Removal of Nonspecifically Bound Proteins" Sensors 19, no. 18: 3876. https://doi.org/10.3390/s19183876

APA StyleLi, S., & Bhethanabotla, V. R. (2019). Design of a Portable Orthogonal Surface Acoustic Wave Sensor System for Simultaneous Sensing and Removal of Nonspecifically Bound Proteins. Sensors, 19(18), 3876. https://doi.org/10.3390/s19183876