A Bimetallic-Coated, Low Propagation Loss, Photonic Crystal Fiber Based Plasmonic Refractive Index Sensor

Abstract

1. Introduction

2. Sensor Design and Brief Theory

3. Numerical Performance Analysis and Brief Discussion

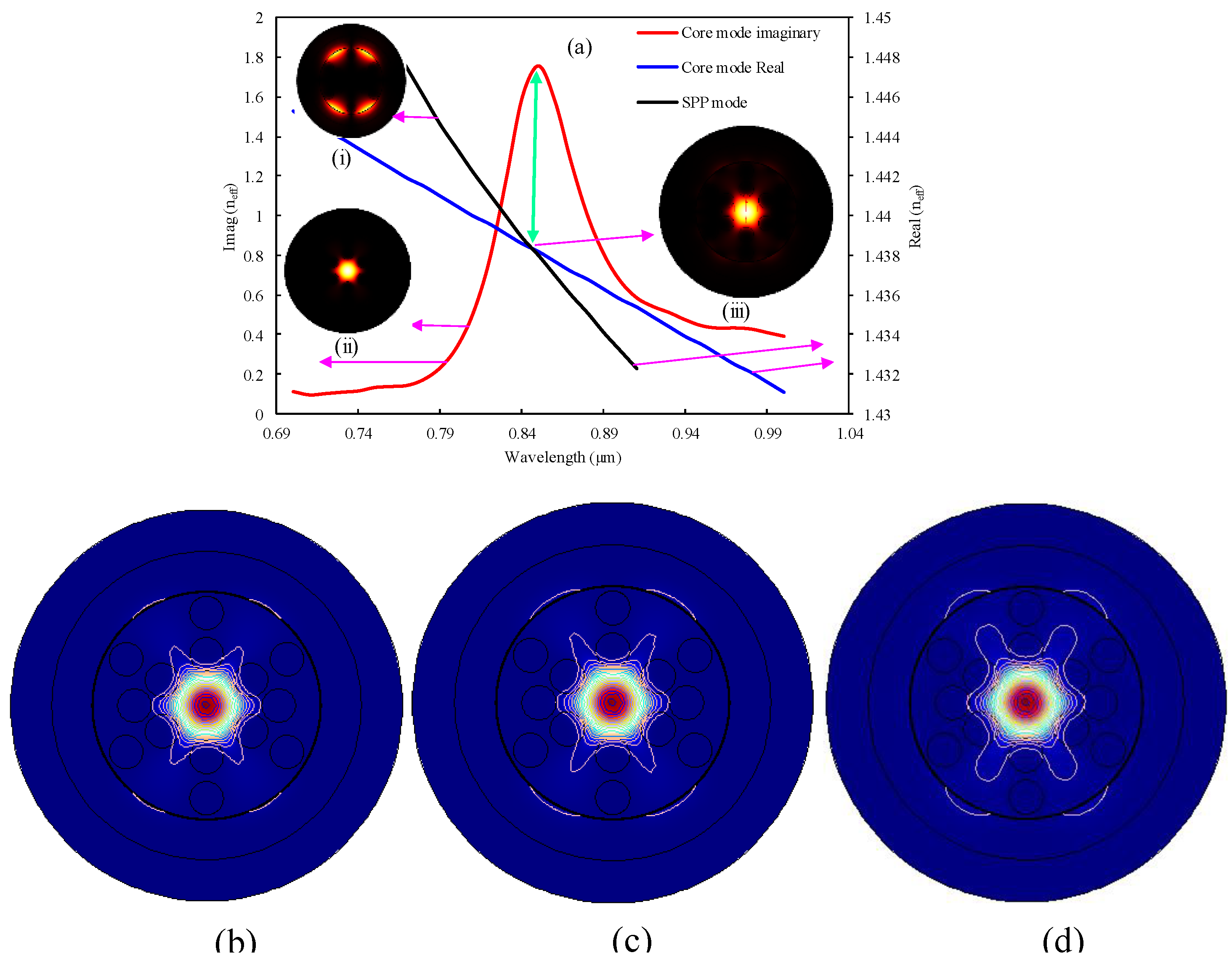

3.1. Dispersion Relation and Optical Field Distribution with Coupling Strength

3.2. Influence of Analyte RI (na) Variations on Sensing Characteristics

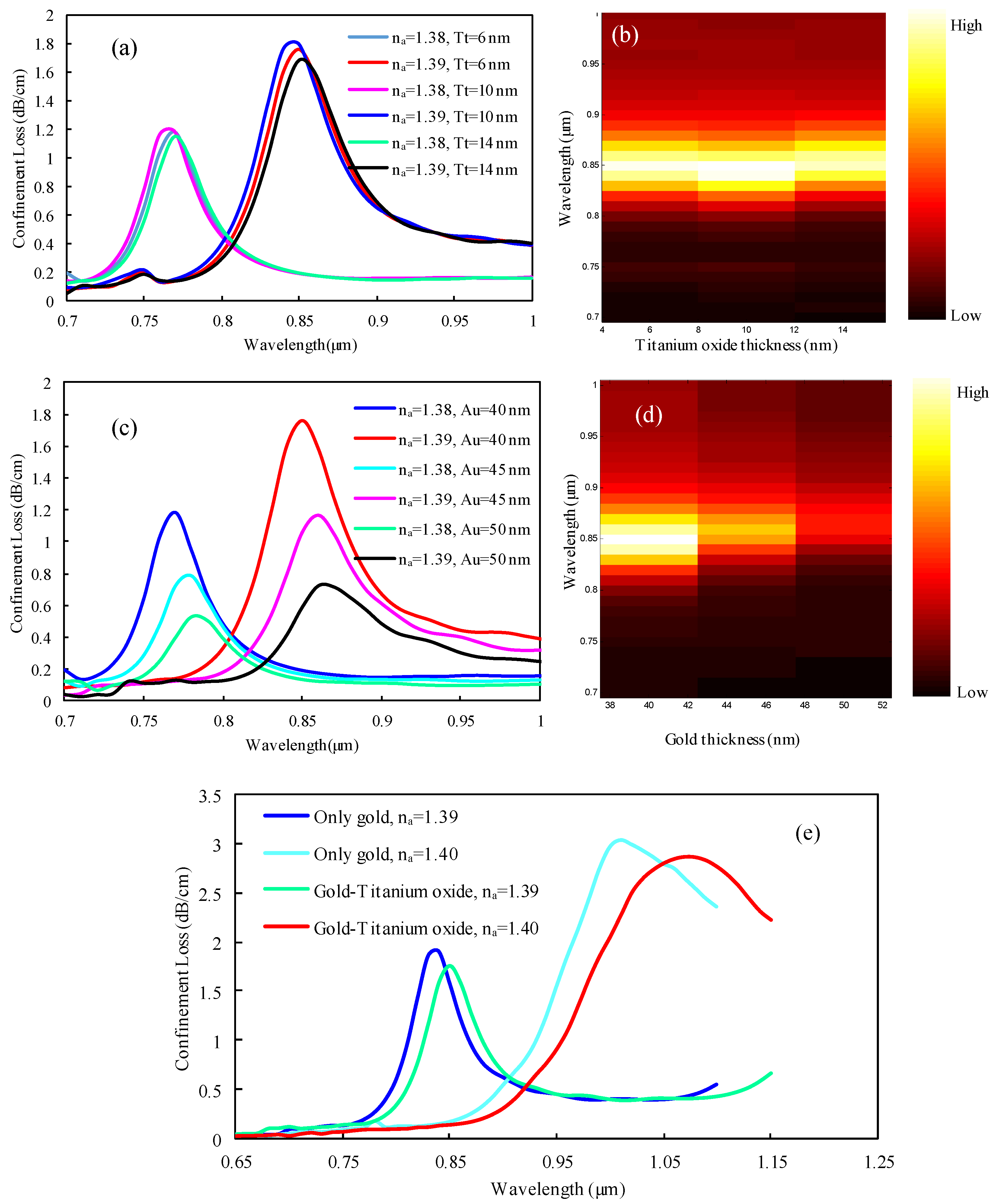

3.3. Impact of Plasmonic Material Thicknesses on the Sensing Performance

3.4. Influence of Λ and d Variations on the Sensing Performance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sharma, A.K.; Pandey, A.K.; Kaur, B. A Review of advancements (2007–2017) in plasmonics- based optical fiber sensors. Opt. Fiber Technol. 2018, 43, 20–34. [Google Scholar] [CrossRef]

- Azman, M.F.; Mahdirazi, G.A.; Wong, W.R.; Aoni, R.A.; Adikan, F.M.R. Design and fabrication of copper-filled photonic crystal fiber based polarization filters. Appl. Opt. 2019, 58, 2068–2075. [Google Scholar] [CrossRef] [PubMed]

- Zao, L.; Han, H.; Lian, Y.; Luan, N.; Liu, J. Theoretical analysis of all-solid D-type photonic crystal fiber based plasmonic sensor for refractive index and temperature sensing. Opt. Fiber Technol. 2019, 50, 165–171. [Google Scholar] [CrossRef]

- Momota, M.R.; Hasan, M.R. Hollow-core silver coated photonic crystal fiber plasmonic sensor. Opt. Mater. 2018, 76, 287–294. [Google Scholar] [CrossRef]

- Mahfuz, M.A.; Mollah, M.A.; Momota, M.R.; Paul, A.K.; Masud, A.; Akter, S.; Hasan, M.R. Highly sensitive photonic crystal fiber plasmonic biosensor: Design and analysis. Opt. Mater. 2019, 90, 315–321. [Google Scholar] [CrossRef]

- Liu, C.; Su, W.; Liu, Q.; Lu, X.; Wang, F.; Sun, T.; Chu, P.K. Symmetrical dual d-shape photonic crystal fibers for surface plasmon resonance sensing. Opt. Express 2018, 26, 9039–9049. [Google Scholar] [CrossRef]

- Rifat, A.A.; Ahmed, R.; Mahdiraji, G.A.; Adikan, F.R.M. Highly sensitive D-shaped photonic crystal fiber based plasmonic biosensor in visible to near-IR. IEEE Sens. J. 2017, 17, 2776–2783. [Google Scholar] [CrossRef]

- Rifat, A.A.; Ahmed, R.; Yetisen, A.K.; Butt, H.; Saburi, A.; Mahdiraji, G.A.; Yun, S.H.; Adikan, F.R.M. Photonic crystal fiber based plasmonic sensors. Sens. Actuator. B. Chem. 2017, 243, 311–325. [Google Scholar] [CrossRef]

- Hasan, M.R.; Akter, S.; Rifat, A.A.; Rana, S.; Ali, S. A Highly Sensitive Gold-Coated Photonic Crystal Fiber Biosensor Based on Surface Plasmon Resonance. Photonics 2017, 4, 18. [Google Scholar] [CrossRef]

- Wang, Y.; Li, S.; Chen, H.; Shi, M.; Liu, Y. Ultra-wide bandwidth polarization filter based on gold-coated photonic crystal fiber around the wavelength of 1.55 µm. Opt. Laser Tech. 2018, 106, 22–28. [Google Scholar] [CrossRef]

- Paul, A.K.; Sarkar, A.K.; Rahman, A.B.S.; Khaleque, A. Twin core photonic crystal fiber plasmonic refractive index sensor. IEEE Sens. J. 2018, 18, 5761–5769. [Google Scholar] [CrossRef]

- Lu, J.; Li, Y.; Han, Y.; Liu, Y.; Gao, J. D-shaped photonic crystal fiber plasmonic refractive index sensor based on gold grating. Appl. Opt. 2018, 57, 5268–5272. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.S.; Sultana, J.; Rifat, A.A.; Ahmed, R.; Dinovitser, A.; Ng, B.W.H.; Ebendorff-Heidepriem, H.; Abbott, D. Dual-polarized highly sensitive plasmonic sensor in the visible to near-IR spectrum. Opt. Express 2018, 26, 30347–30361. [Google Scholar] [CrossRef] [PubMed]

- Dash, J.N. On the Performance of Graphene-Based D-Shaped Photonic Crystal Fibre Biosensor Using Surface Plasmon Resonance. Plasmonics 2015, 10, 1123–1131. [Google Scholar] [CrossRef]

- Khalil, A.E.; EI-Saeed, A.H. Highly sensitive photonic crystal fiber biosensor based on titanium nitride. Opt. Quant. Electron. 2018, 50, 158. [Google Scholar] [CrossRef]

- Huang, T. Highly sensitive SPR sensor based on d-shaped photonic crystal fiber coated with indium tin oxide at near-infrared wavelength. Plasmonics 2016, 12, 583–588. [Google Scholar] [CrossRef]

- Hasan, M.R.; Akter, S.; Ahmed, K.; Abbott, D. Plasmonic refractive index sensor employing niobium nanofilm on photonic crystal fiber. IEEE Photon. Tech. Lett. 2018, 30, 315–318. [Google Scholar] [CrossRef]

- Islam, M.S.; Cordeiro, C.M.B.; Sultana, J.; Aoni, R.A.; Feng, S.; Ahmed, R.; Dorraki, M.; Dinouitser, A.; Ng, B.W.H.; Abbott, D. A Hi-Bi Ultra-Sensitive Surface Plasmon Resonance Fiber Sensor. IEEE Access 2019, 7, 79085–79094. [Google Scholar] [CrossRef]

- Rifat, A.A.; Haider, F.; Ahmed, R.; Mahdiraji, G.A.; Adikan, F.R.M.; Miroshnichenko, A.E. Highly sensitive selectively coated photonic crystal fiber-based plasmonic sensor. Opt. Lett. 2018, 43, 891–894. [Google Scholar] [CrossRef]

- An, G.; Shuguang, G.A.; Yan, L.X.; Zhang, X.; Yuan, Z.; Wang, H.; Zhang, Y.; Hao, X.; Shao, Y.; Han, Z. Extra-broad photonic crystal fiber refractive index sensor based on surface plasmon resonance. Plasmonics 2017, 12, 465–471. [Google Scholar] [CrossRef]

- Dash, J.N.; Jha, R. Highly sensitive side-polished birefringent PCF based SPR sensor in near IR. Plasmonics 2016, 11, 1505–1509. [Google Scholar] [CrossRef]

- Luan, N.; Wang, R.; Lv, W.; Yao, J. Surface plasmon resonance sensor based on D-shaped microstructured optical fiber with hollow core. Opt. Express 2015, 23, 85768582. [Google Scholar] [CrossRef] [PubMed]

- Haque, E.; Hossain, M.A.; Ahmed, F.; Namihira, Y. Surface plasmon resonance sensor based on modified D-shaped photonic crystal fiber for wider range of refractive index detection. IEEE Sens. J. 2018, 18, 8287–8293. [Google Scholar] [CrossRef]

- Akter, S.; Razzak, S.M.A. Highly Sensitive Open-Channels Based Plasmonic Biosensor in Visible to Near-Infrared Wavelength. Results Phys. 2019, 13, 102328. [Google Scholar] [CrossRef]

- Hassani, A.; Skorobogatiy, M. Photonic crystal fiber-based plasmonic sensors for the detection of bio layer thickness. J. Opt. Soc. Am. B 2009, 26, 1550. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, S.; Liu, Q.; Feng, X.; Zhang, S.; Wang, Y.; Wu, J. Groove micro-structure optical fiber refractive index sensor with nanoscale gold film based on surface plasmon resonance. Opt. Fiber Tech. 2018, 43, 45–48. [Google Scholar] [CrossRef]

- Liu, M.; Yang, X.; Shum, P.; Yuan, H. High-sensitivity birefringent and single-layer coating photonic crystal fiber biosensor based on surface plasmon resonance. Appl. Opt. 2018, 57, 1883–1886. [Google Scholar] [CrossRef]

- Lou, J.; Cheng, T.; Li, S.; Zhang, X. Surface plasmon resonance photonic crystal fiber biosensor based on gold graphene layers. Opt. Fiber Tech. 2019, 50, 206–211. [Google Scholar] [CrossRef]

- Hasan, M.R.; Akter, S.; Rifat, A.A.; Rana, S.; Ahmed, K.; Ahmed, R.; Subbaraman, H.; Abbott, D. Spiral photonic crystal fiber based dual-polarized surface plasmon resonance biosensor. IEEE Sens. J. 2018, 18, 133–140. [Google Scholar] [CrossRef]

- Mahfuz, M.A.; Hasan, M.R.; Momota, M.R.; Masud, A.; Akter, S. Asymmetrical photonic crystal fiber based plasmonic sensor using the lower birefringence peak method. OSA Continuum 2019, 2, 1713–1725. [Google Scholar] [CrossRef]

- Agrawal, A.; Azabi, Y.O.; Rahman, B.M.A. Stacking the equiangular spiral. IEEE Photon. Technol. Lett. 2013, 25, 291–294. [Google Scholar] [CrossRef]

- Haque, E.; Hossain, M.A.; Namihira, Y.; Ahmed, F. Microchannel-based plasmonic refractive index sensor for low refractive index detection. Appl. Opt. 2019, 58, 1547–1554. [Google Scholar] [CrossRef] [PubMed]

| Analyte RI | Resonance Mode Loss (dB/cm) | Resonance Wavelength (µm) | Wavelength Peak Shift (nm) | Wavelength Sensitivity (nm/RIU) | Wavelength Resolution (RIU) |

|---|---|---|---|---|---|

| 1.32 | 0.2219 | 0.6 | 10 | 1000 | 1 × 10−4 |

| 1.33 | 0.2853 | 0.61 | 20 | 2000 | 5 × 10−5 |

| 1.34 | 0.36246 | 0.63 | 20 | 2000 | 5 × 10−5 |

| 1.35 | 0.46932 | 0.65 | 30 | 3000 | 3.33 × 10−5 |

| 1.36 | 0.62095 | 0.68 | 40 | 4000 | 2.5 × 10−5 |

| 1.37 | 0.81593 | 0.72 | 50 | 5000 | 2 × 10−5 |

| 1.38 | 1.1814 | 0.77 | 80 | 8000 | 1.25 × 10−5 |

| 1.39 | 1.7546 | 0.85 | 230 | 23,000 | 4.34 × 10−6 |

| 1.40 | 2.87033 | 1.08 | ----- | ---------- | -------- |

| References | Sensing Range | Maximum Peak Loss (dB/cm) | Wavelength Sensitivity (nm/RIU) | Wavelength Resolution (RIU) |

|---|---|---|---|---|

| Ref. [5] Au coated | 1.33–1.40 | 180 | 12,000 | 8.33 × 10−6 |

| Ref. [7] Au-TiO2 Coated | 1.33–1.43 | 23.18 | 9800 | 2.2 × 10−6 |

| Ref. [11] Au Coated | 1.33–1.40 | 65 | 9000 | 1.1 × 10−5 |

| Ref. [18] Au-TiO2 Coated | 1.33–1.38 | 80 | 25,000 | 4 × 10−6 |

| Ref. [24] Au Coated | 1.33–1.39 | 375.85 | 5000 | 2 × 10−5 |

| Ref. [26] Au Coated | 1.4–1.43 | 140.3 | 15,933 | 3.5 × 10−8 |

| Ref. [27] Au Coated | 1.40–1.43 | 110 | 15,180 | 5.68 × 10−6 |

| Ref. [28] Au-graphene Coated | 1.33–1.38 | 185.5 | 8600 | ------- |

| [proposed] Au-TiO2 Coated | 1.32–1.40 | 2.87 | 23,000 | 4.34 × 10−6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahfuz, M.A.; Hossain, M.A.; Haque, E.; Hai, N.H.; Namihira, Y.; Ahmed, F. A Bimetallic-Coated, Low Propagation Loss, Photonic Crystal Fiber Based Plasmonic Refractive Index Sensor. Sensors 2019, 19, 3794. https://doi.org/10.3390/s19173794

Mahfuz MA, Hossain MA, Haque E, Hai NH, Namihira Y, Ahmed F. A Bimetallic-Coated, Low Propagation Loss, Photonic Crystal Fiber Based Plasmonic Refractive Index Sensor. Sensors. 2019; 19(17):3794. https://doi.org/10.3390/s19173794

Chicago/Turabian StyleMahfuz, Mohammad Al, Md. Anwar Hossain, Emranul Haque, Nguyen Hoang Hai, Yoshinori Namihira, and Feroz Ahmed. 2019. "A Bimetallic-Coated, Low Propagation Loss, Photonic Crystal Fiber Based Plasmonic Refractive Index Sensor" Sensors 19, no. 17: 3794. https://doi.org/10.3390/s19173794

APA StyleMahfuz, M. A., Hossain, M. A., Haque, E., Hai, N. H., Namihira, Y., & Ahmed, F. (2019). A Bimetallic-Coated, Low Propagation Loss, Photonic Crystal Fiber Based Plasmonic Refractive Index Sensor. Sensors, 19(17), 3794. https://doi.org/10.3390/s19173794