A Force-Sensor-Based Method to Eliminate Deformation of Large Crankshafts during Measurements of Their Geometric Condition

Abstract

1. Introduction

2. Overview of Crankshaft Geometry Measurement Systems

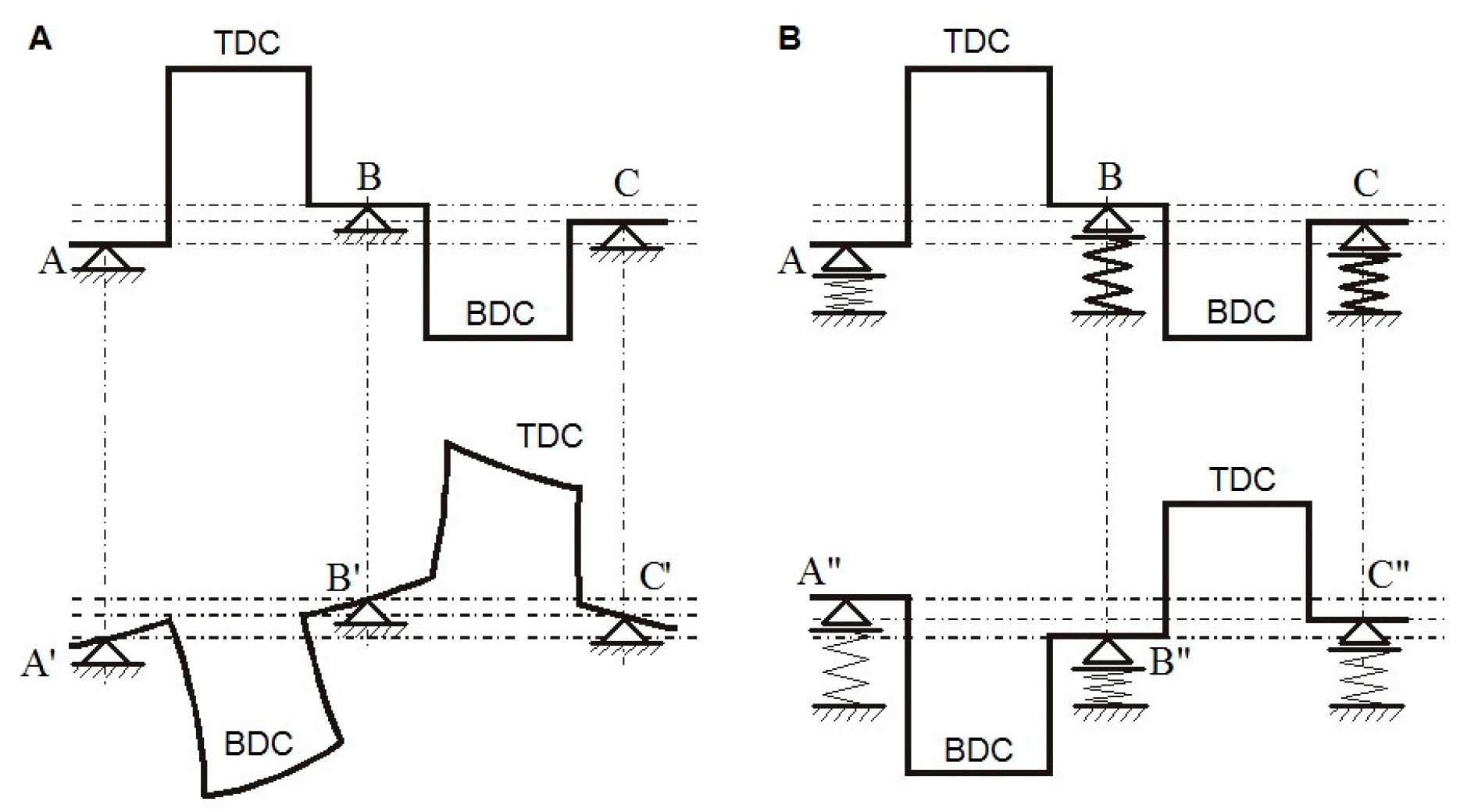

3. The Effect of the Support Method on Elastic Deformation in the Object Being Measured

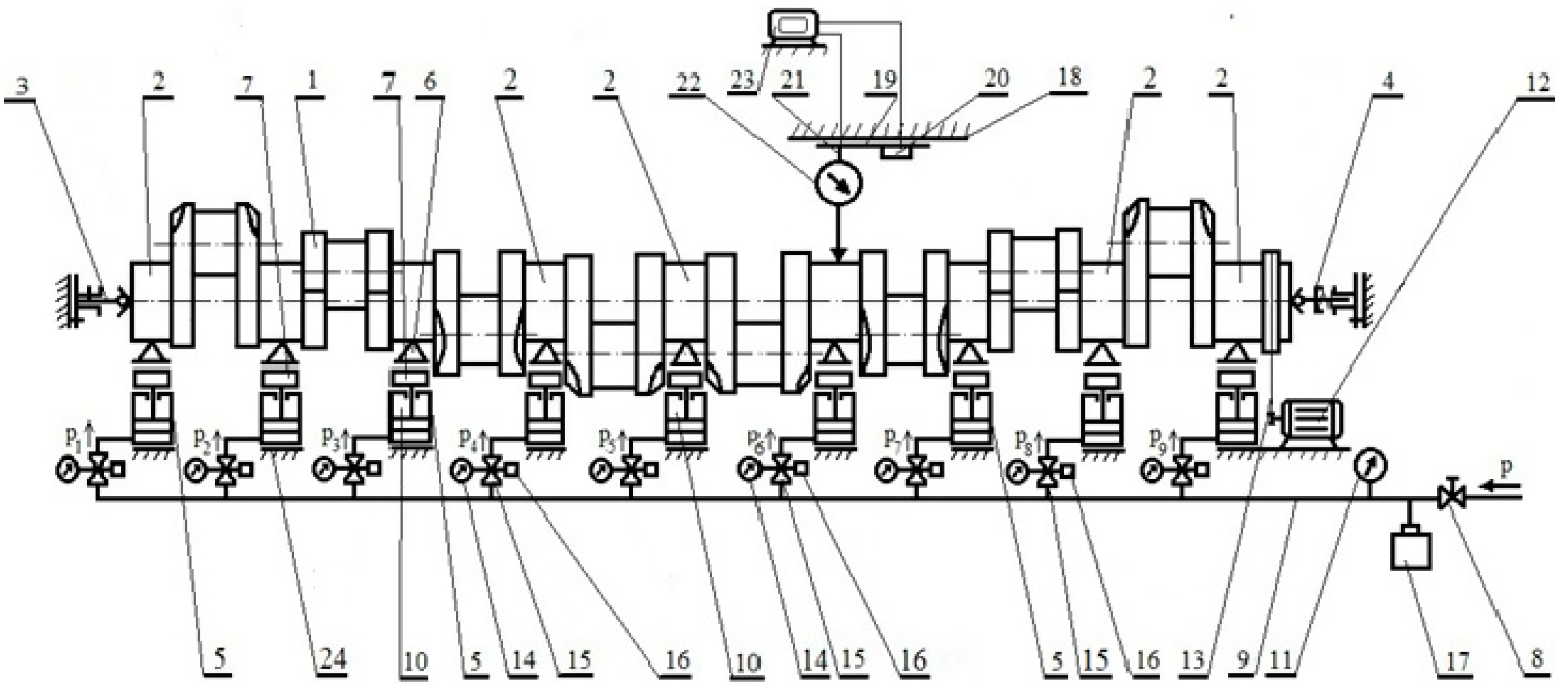

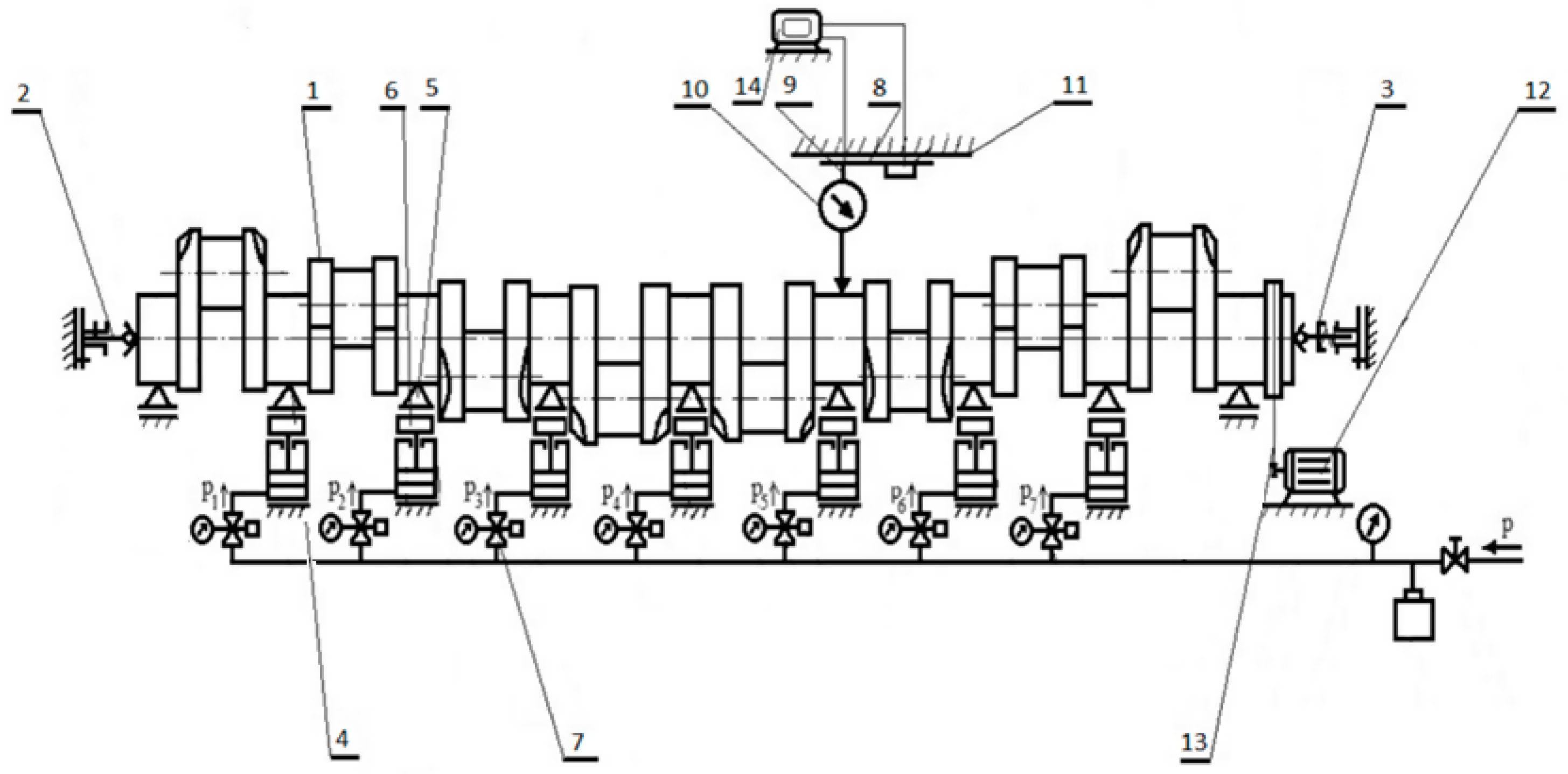

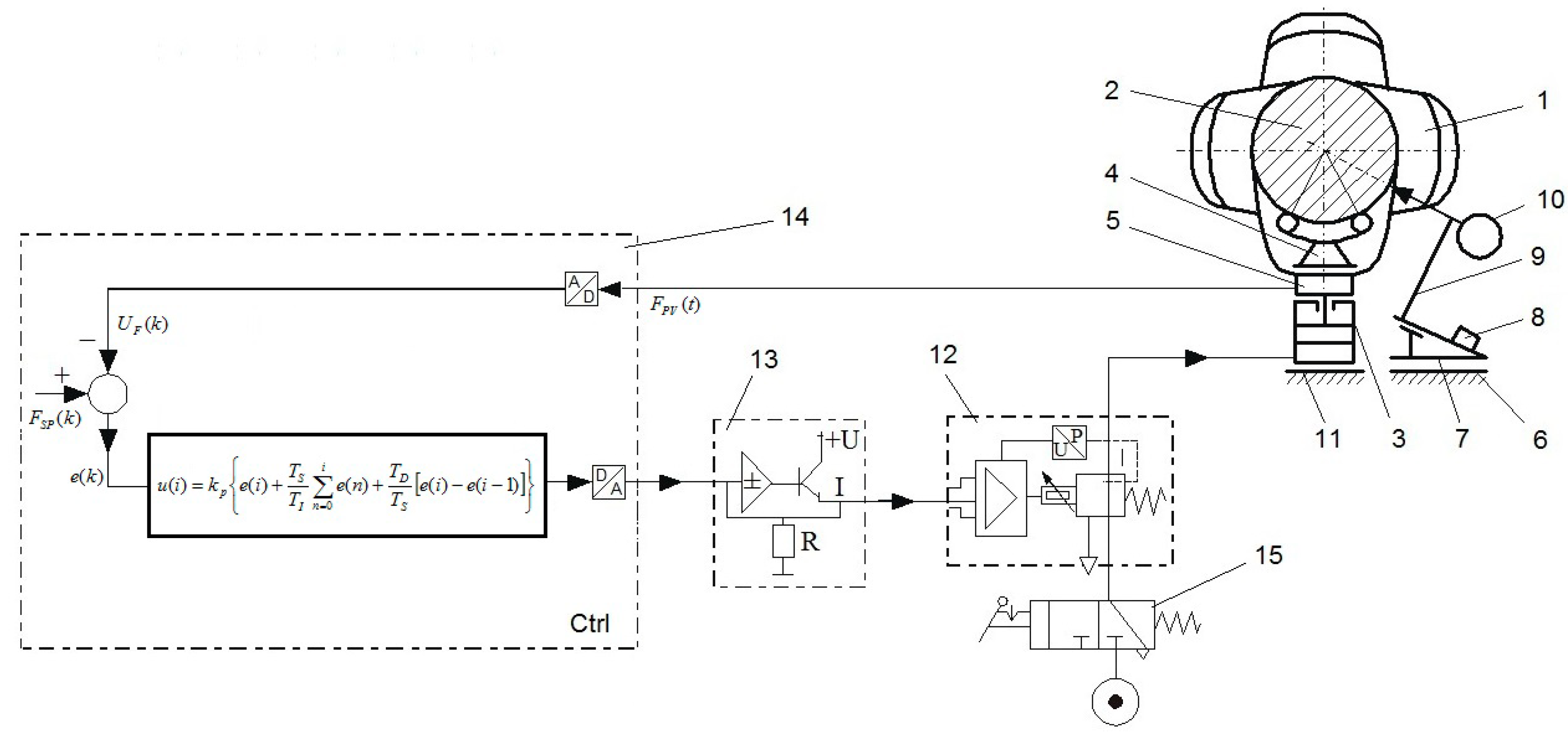

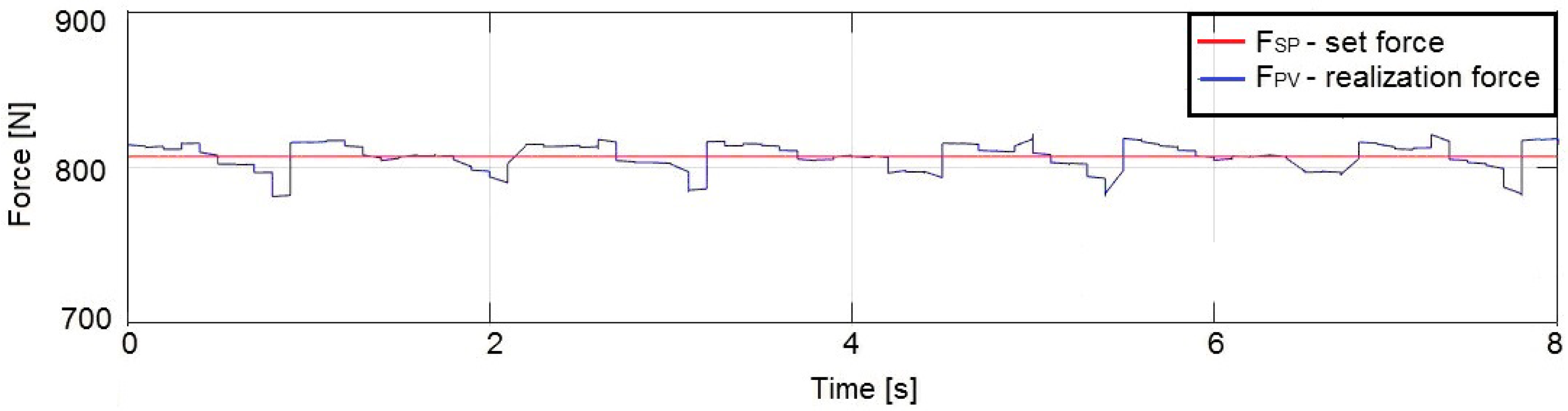

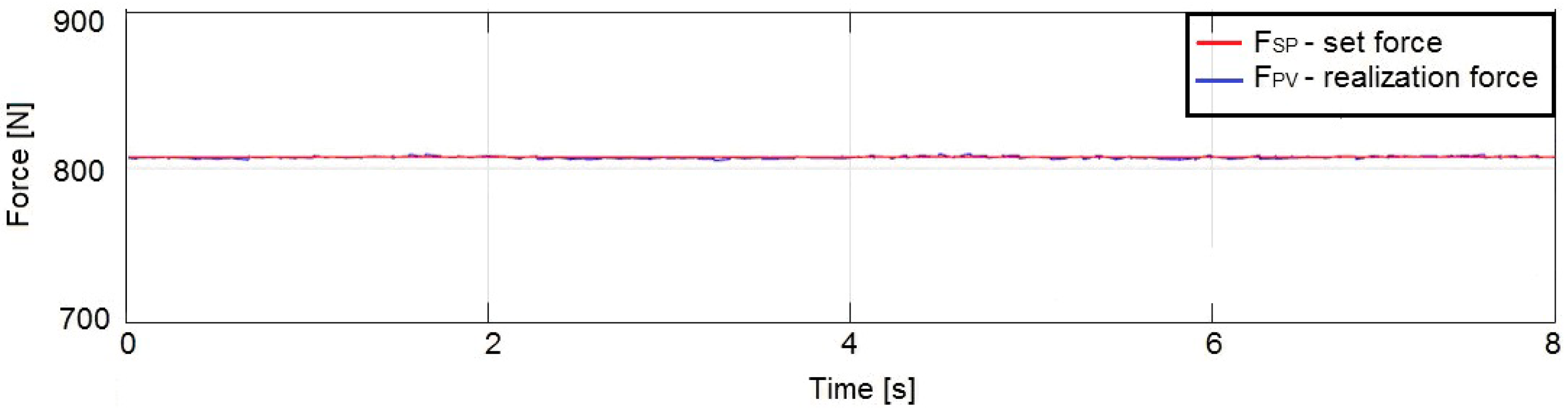

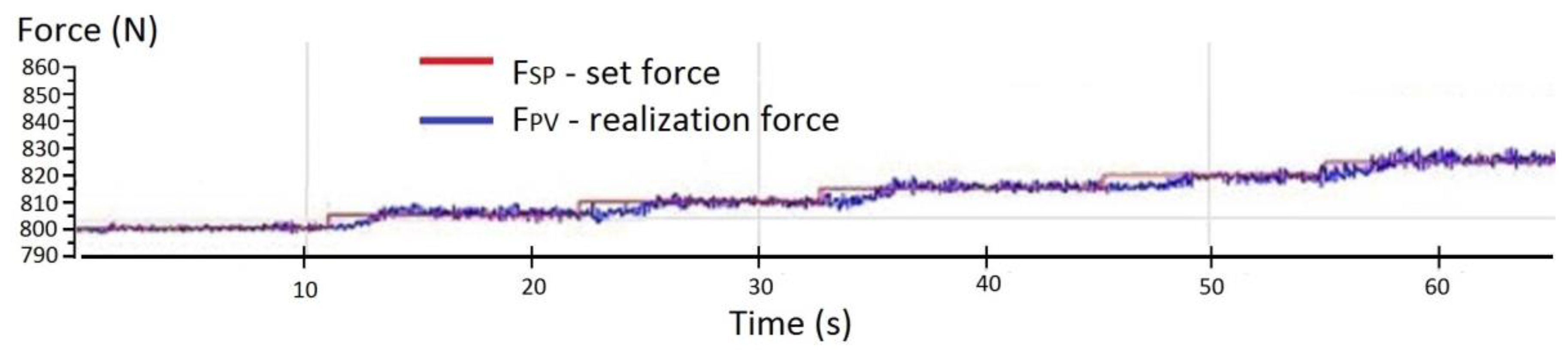

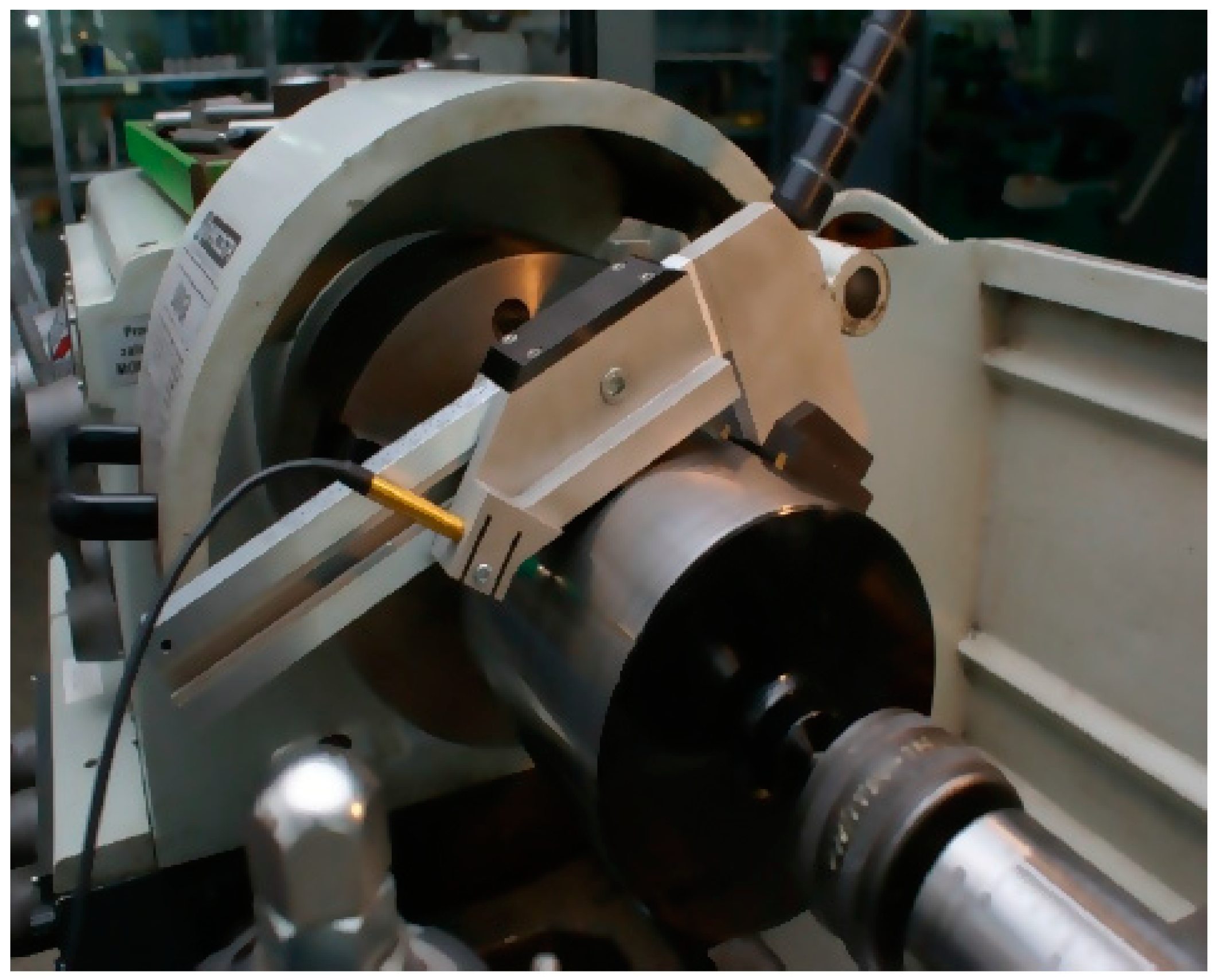

4. Measurement System with Controlled Exertion of the Supports’ Reaction Forces

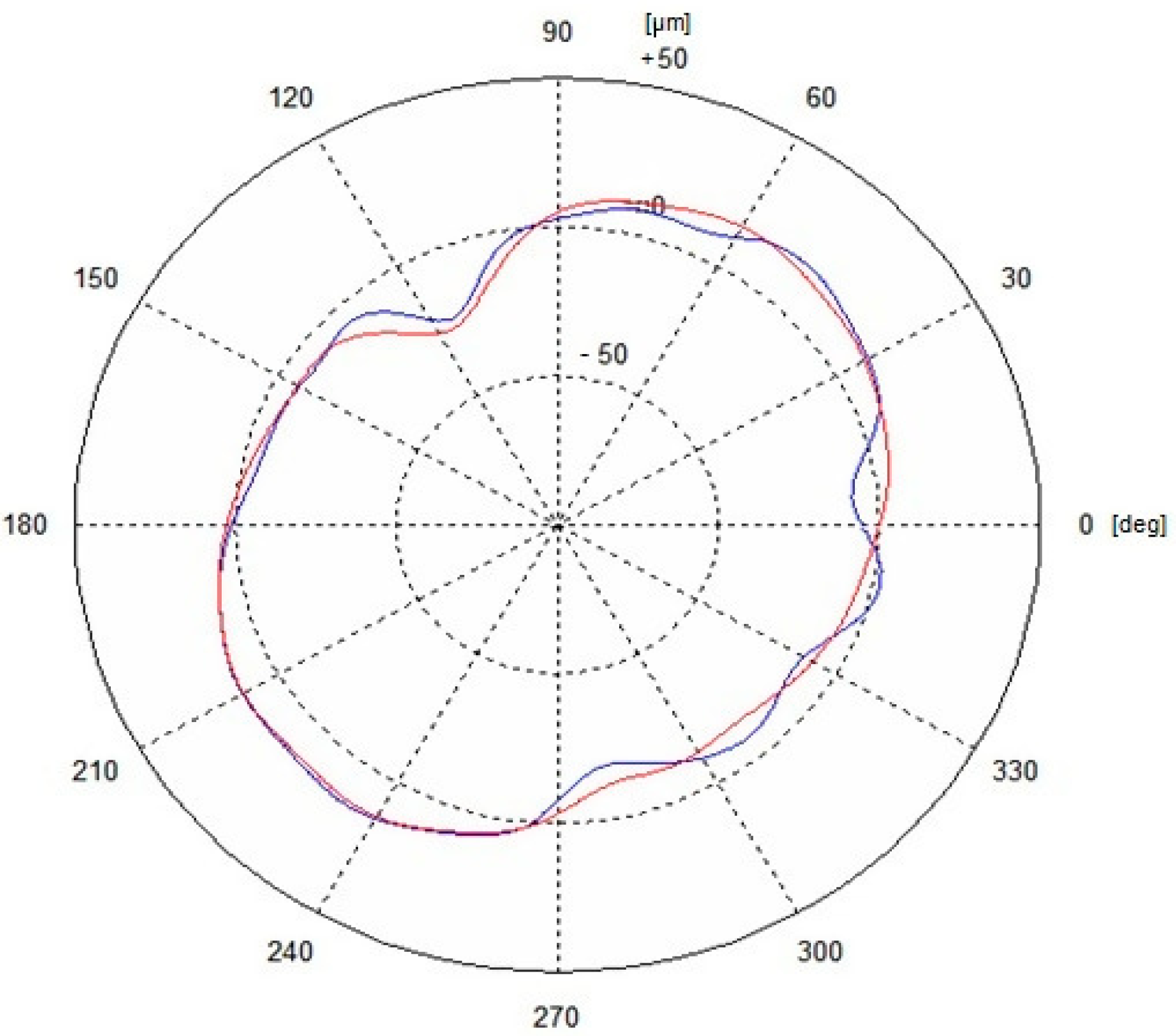

5. Prototype Flexible Support Control System

5.1. Basic Assumptions

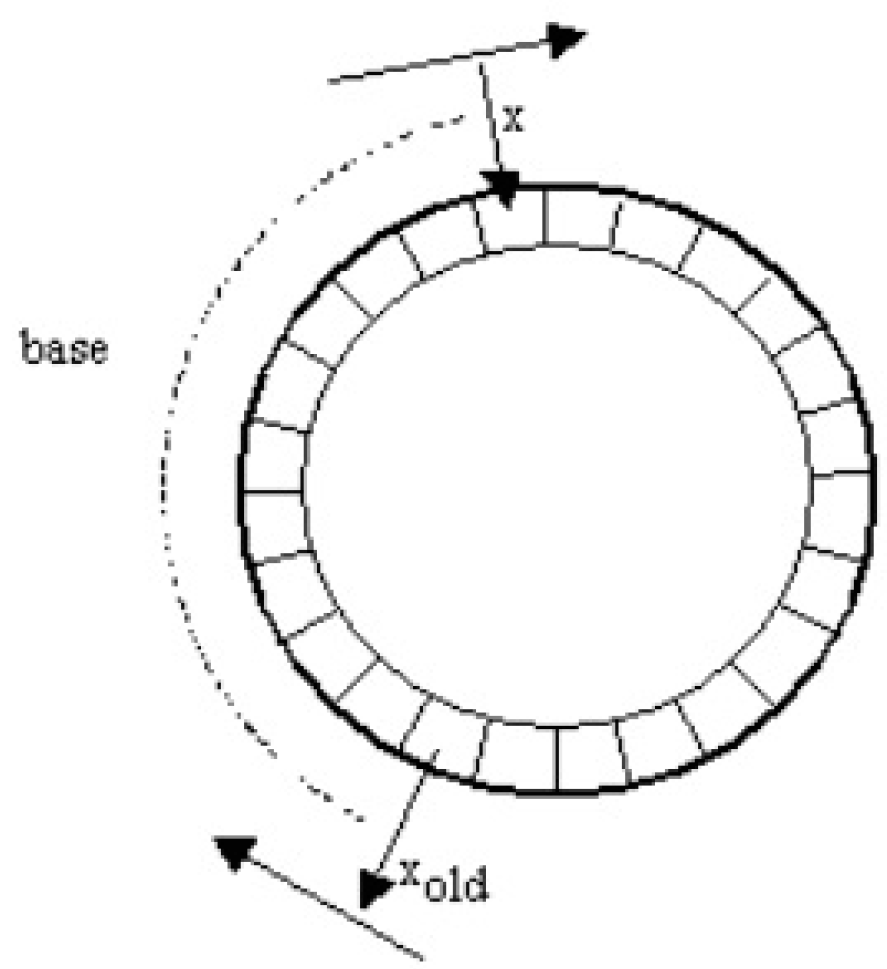

5.2. Filtration of the Signal from the Transducer

- sold—sum of the samples of the signal x,

- b—number of samples of the signal x to be summed (averaging base),

- x—value of the current signal sample,

- xold—value of the historical sample at a distance equal to the base

- y—averaged value of the signal x.

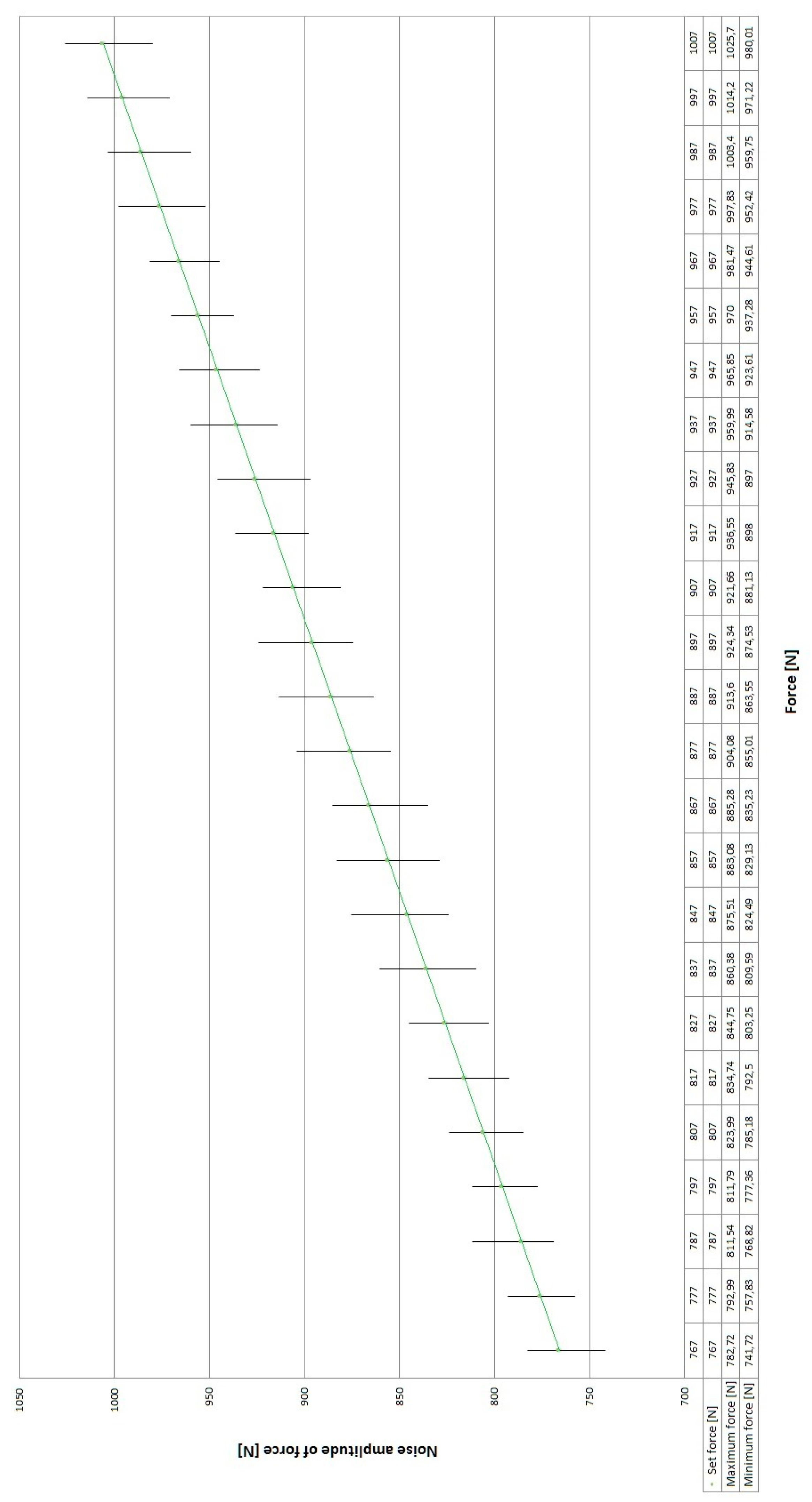

5.3. Selection of the Operating Parameters of the Controller

6. Results and Discussion

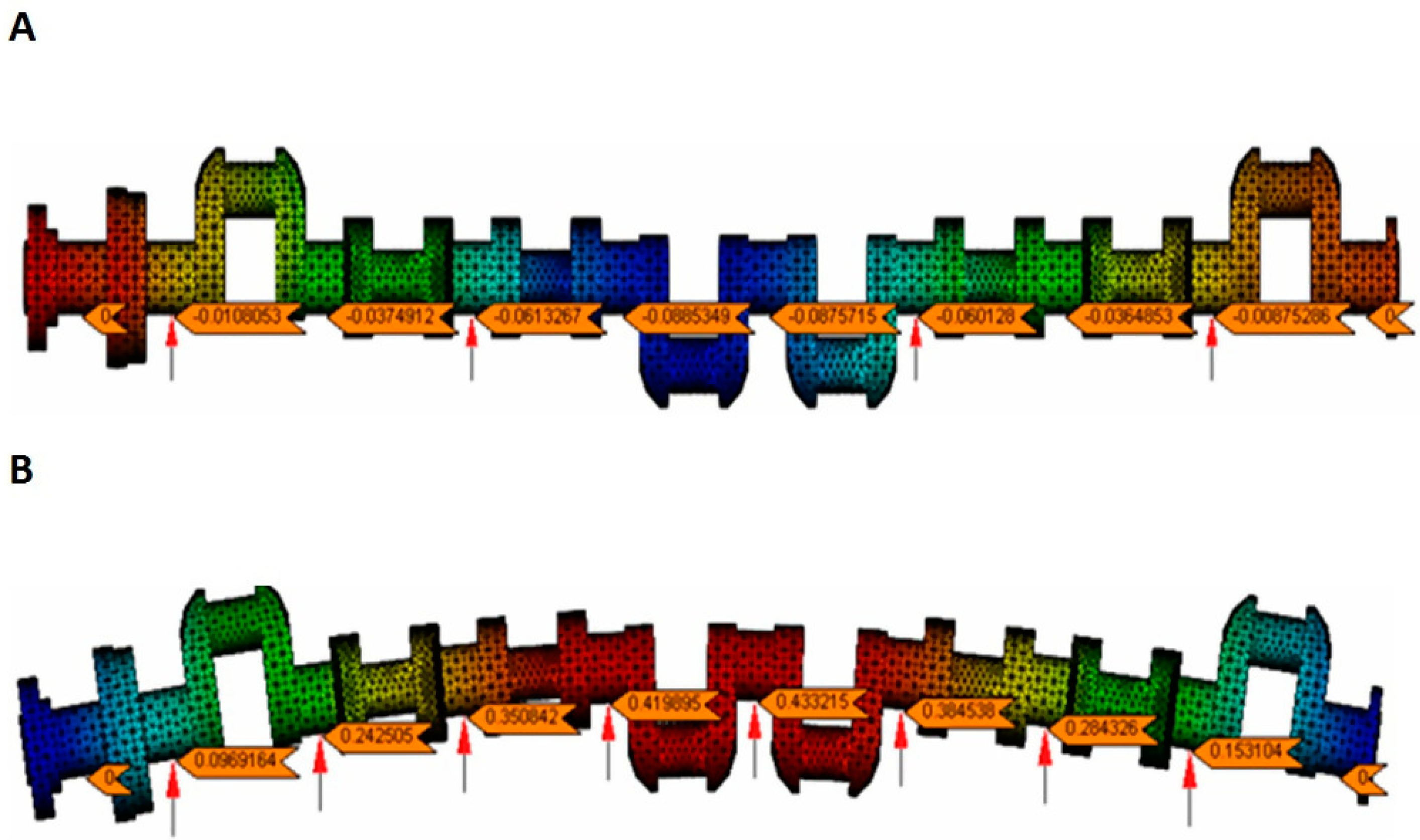

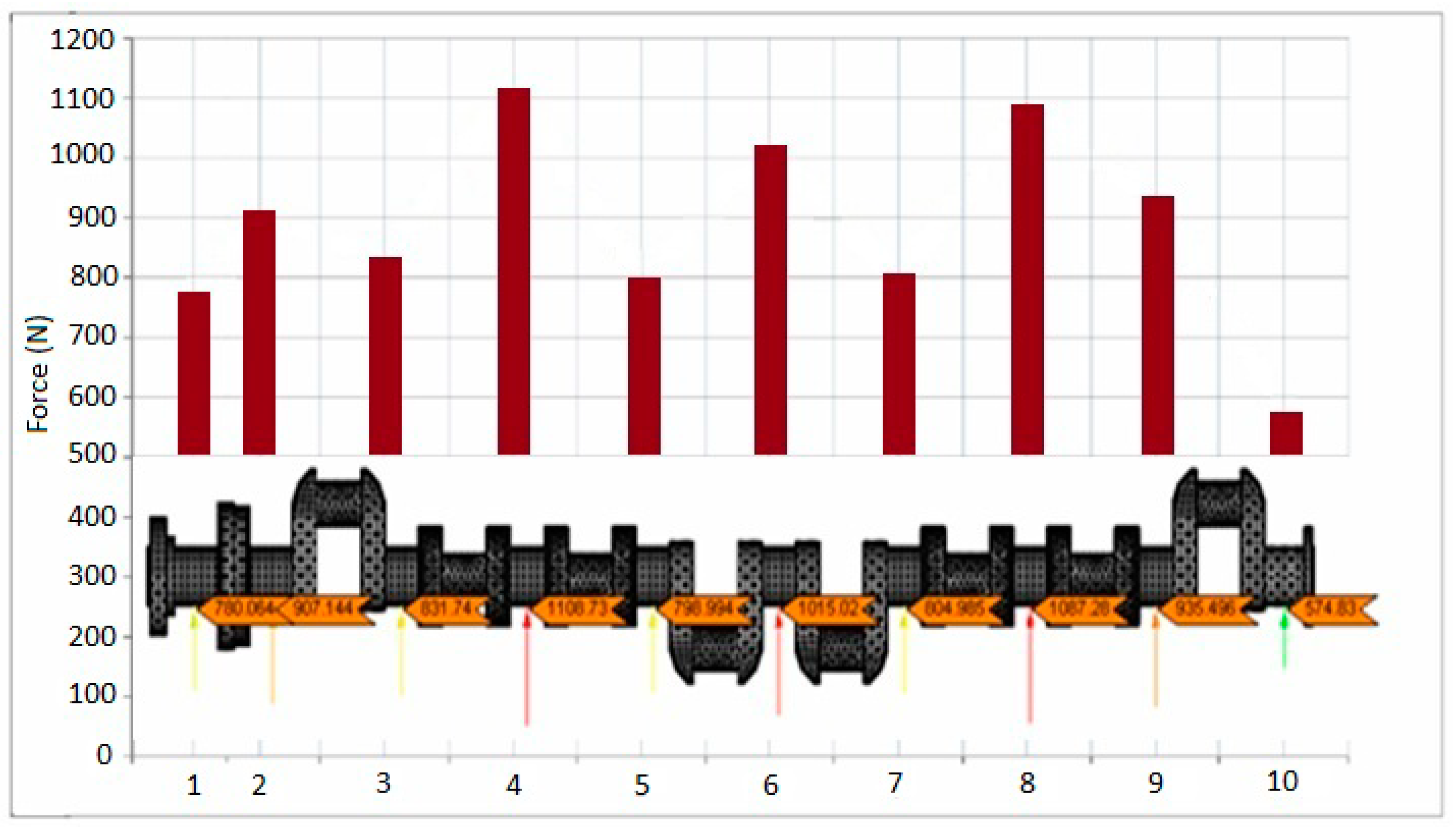

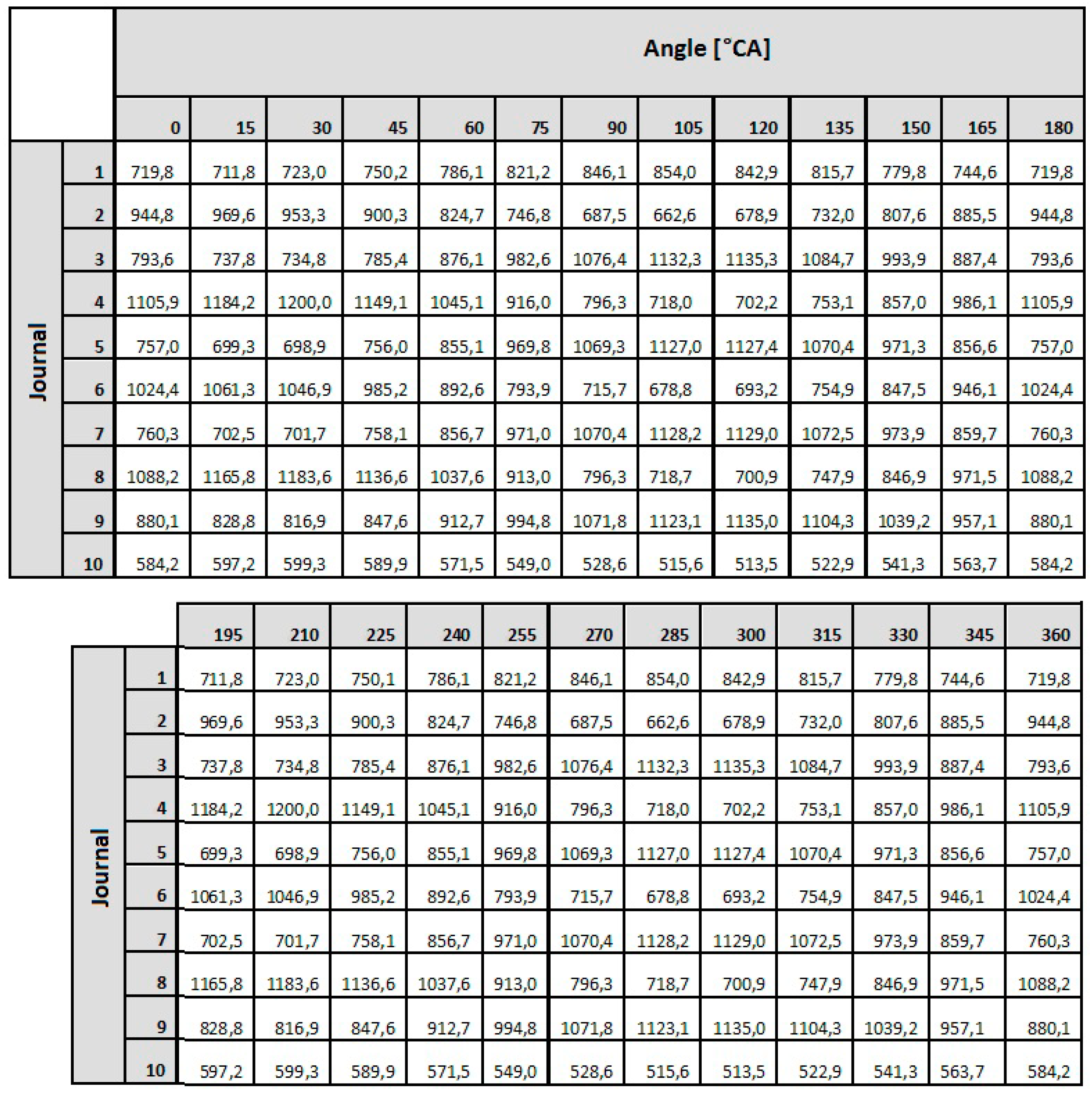

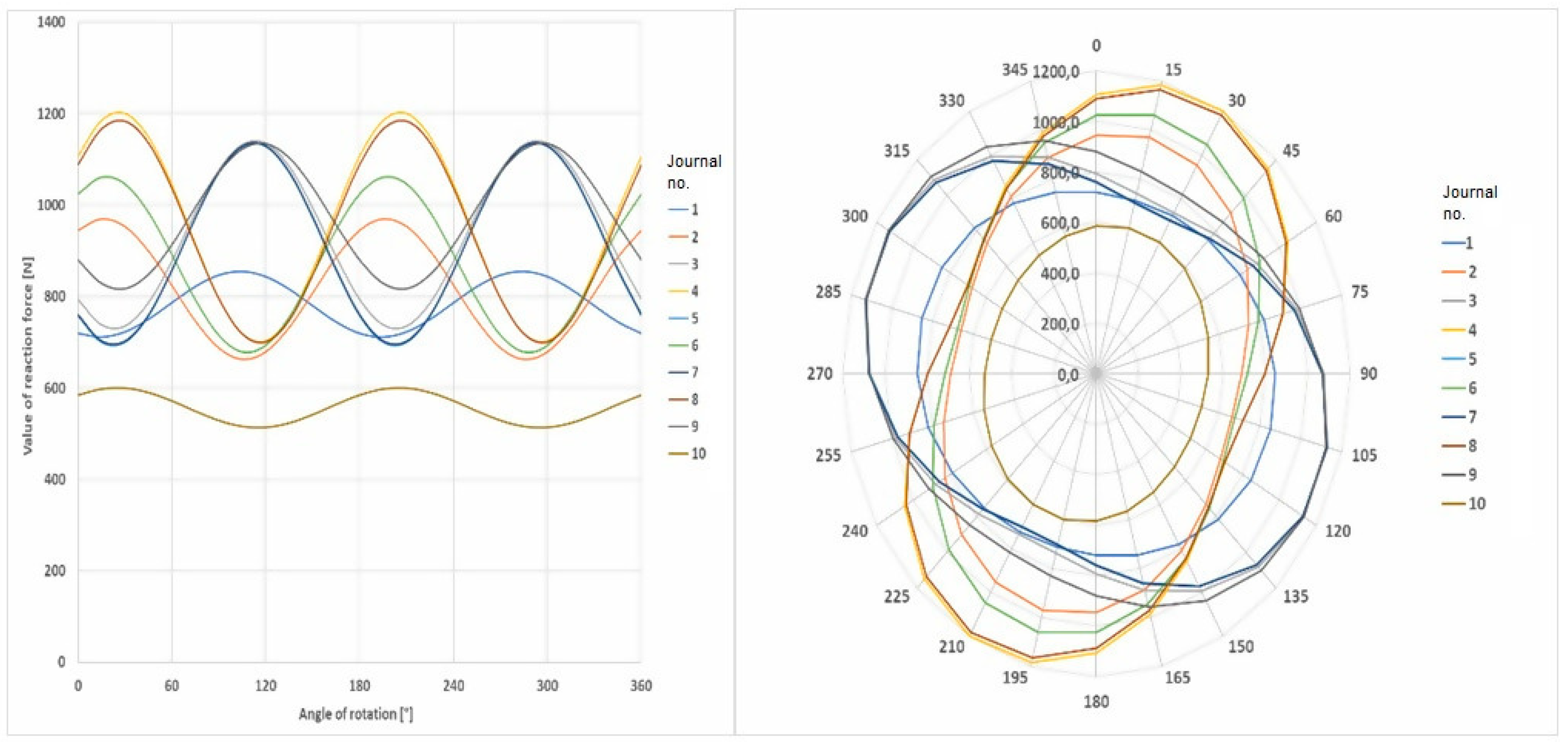

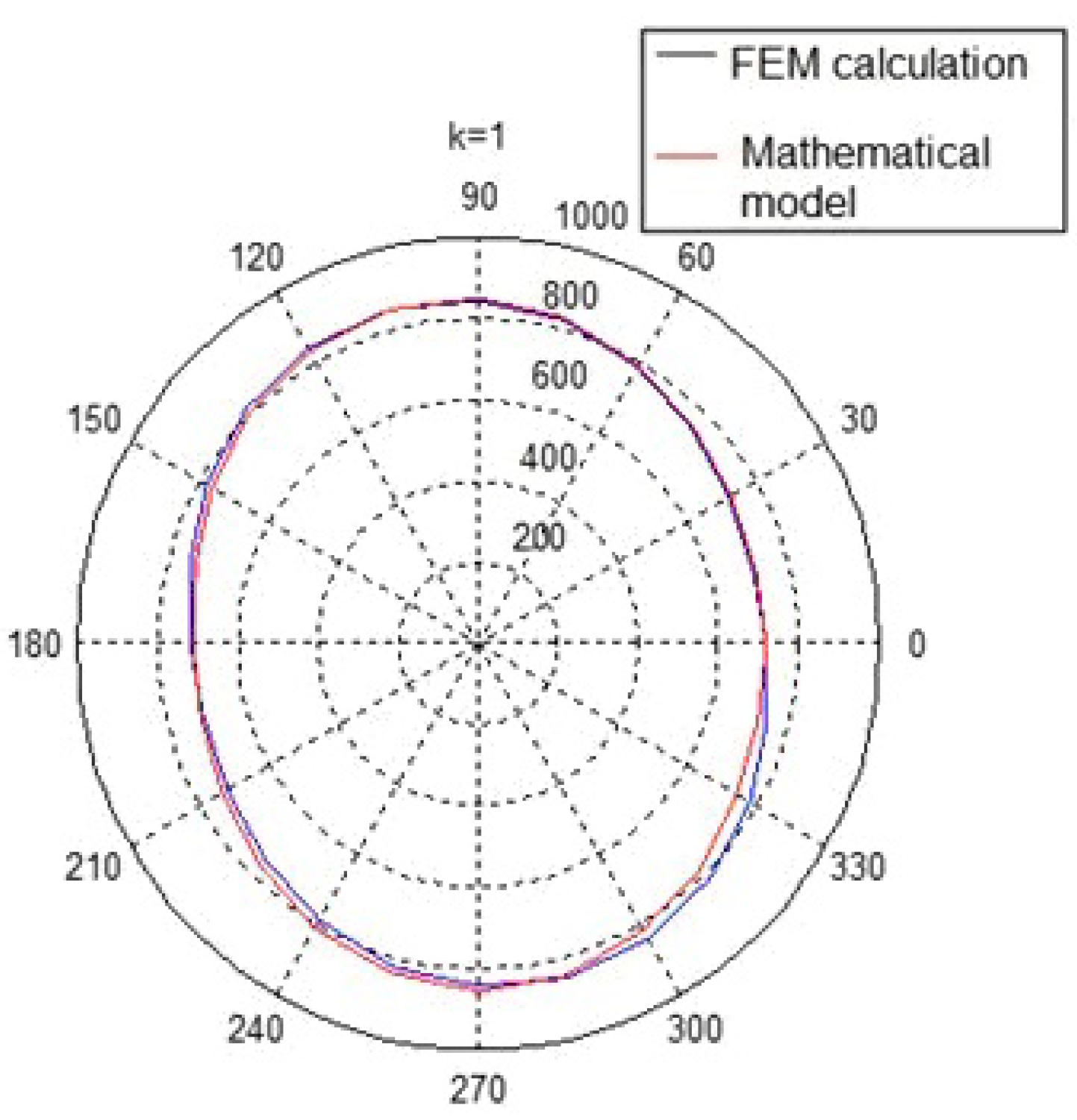

6.1. Preliminary Calculations

- Ro—averaged value of the calculated reaction force,

- CRn—amplitude of the successive, n-th harmonic component of the reaction force function,

- φRn—phase shift of the successive n-th harmonic component of the reaction force function.

- r1(φ)—the chart obtained by means of the strength calculations,

- r2(φ)—the charts obtained using mathematical notation,

- —the phase shift between the charts being compared.

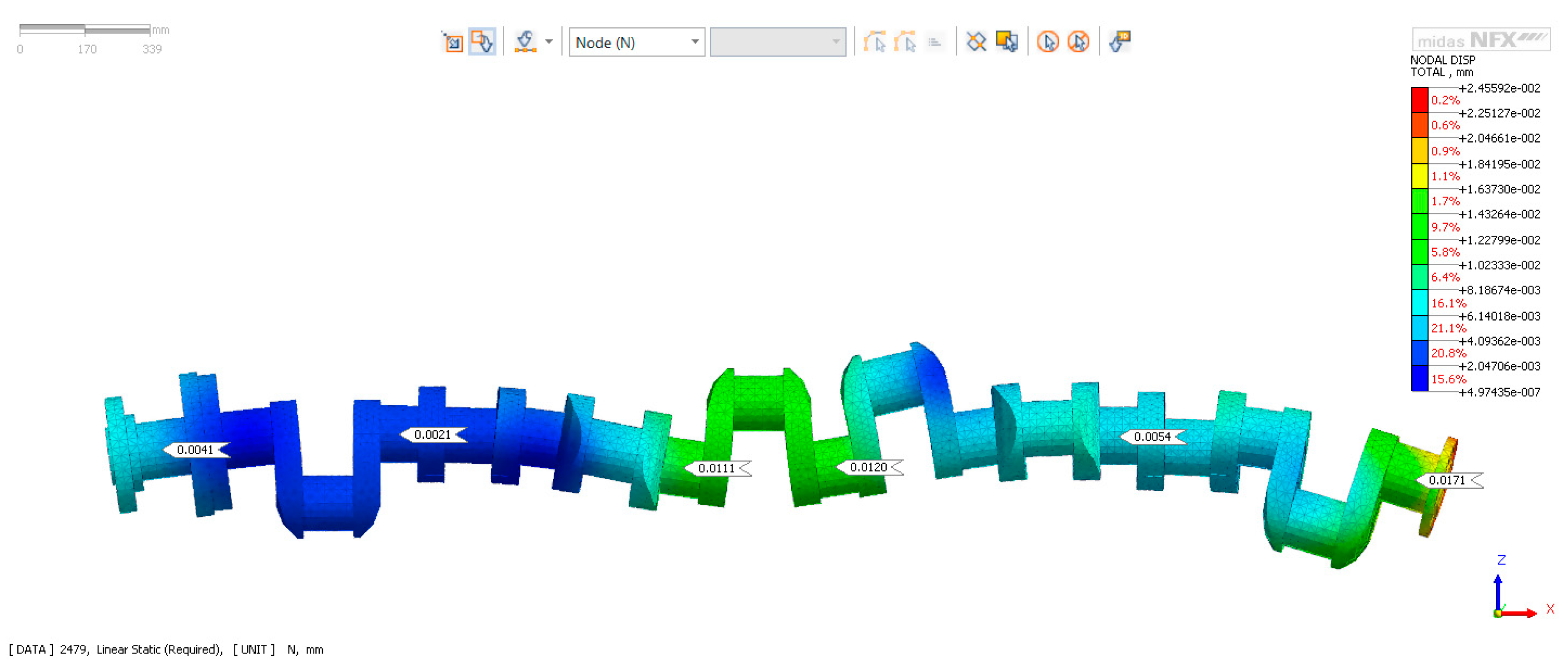

6.2. Experimental Verification of the Elimination of Crankshaft Deflection

7. Conclusions

8. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

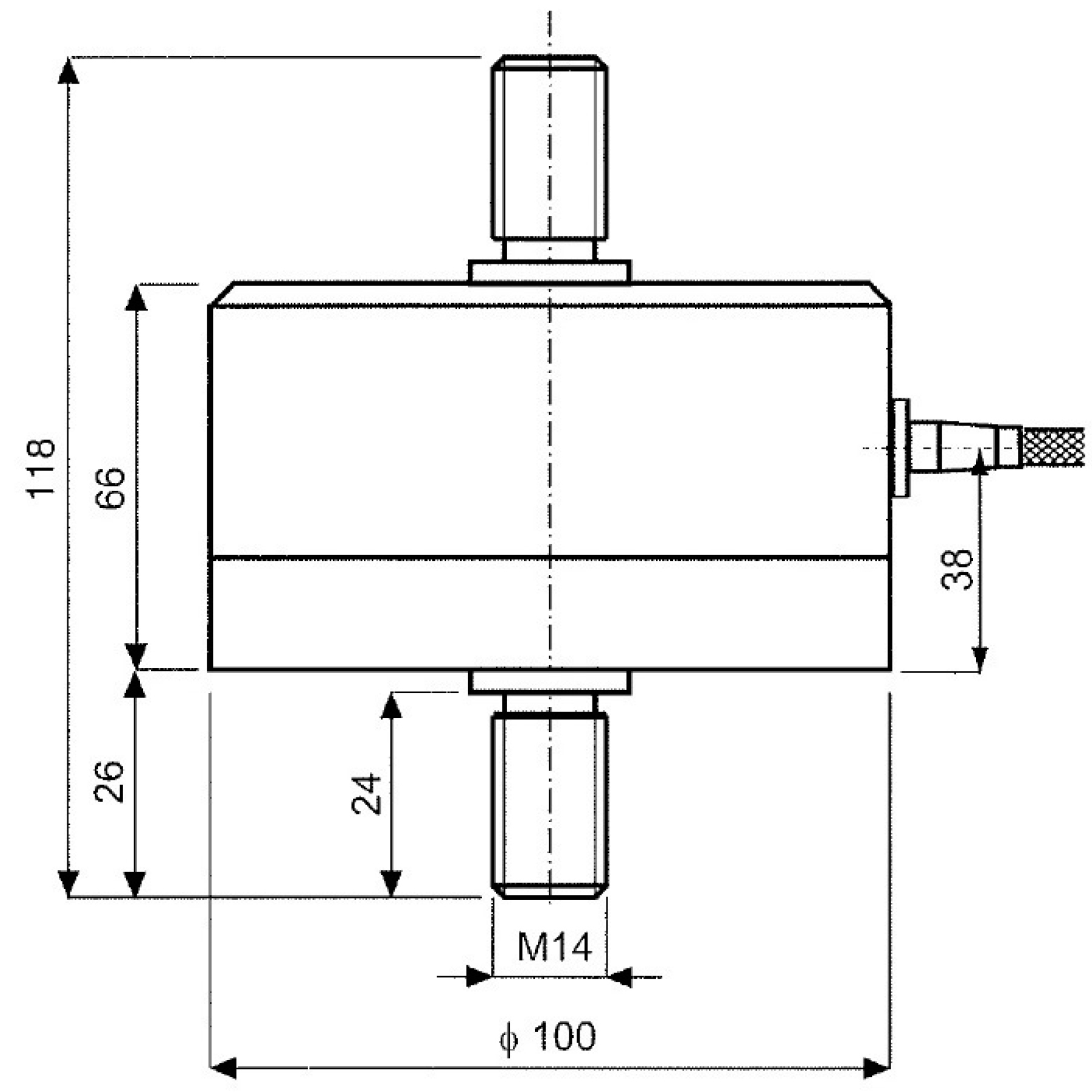

| Specific Characteristic | Description |

|---|---|

| Material of the bearing elements | Stainless steel 1.4057 |

| Measuring range | 0 ÷ ±4 kN |

| Measuring overload | 1.25 × measuring range |

| Strength overload capacity | 2.5 × measuring range |

| Supply voltages | 24 V DC (12 ~ 30 V DC) |

| Output signal | 0 ÷ ±5 V |

| Accuracy class | 1% (acc. to PN-EN ISO 7500-1) |

| Tolerance of zero signal | ±1% |

| Temperature instability | ±0.01%/K |

| Ambient temperature range | −25 ÷ +45 °C |

| Degree of protection | IP68 |

| Output cable | 3 × 0.50 mm2, shielded |

| Cable length | 6 m |

References

- Humienny, Z. Specyfikacje Geometrii Wyrobów (GPS)—Wykład dla Uczelni Technicznych [Specifications of Product Geometry (GPS)—Lecture for Technical Universities]; Oficyna Wydawnicza Politechniki Warszawskiej: Warszawa, Poland, 2001. [Google Scholar]

- Adamczak, S. Pomiary Geometryczne Powierzchni, Zarysy Kształtu, Falistości i Chropowatości [Measurements of Geometrical Surfaces, Outlines of Shape, Waviness, and Roughness]; WNT: Warszawa, Poland, 2008. [Google Scholar]

- Niezgodziński, M.E.; Niezgodziński, T. Obliczenia Zmęczeniowe Elementów Maszyn [Fatigue Calculations of Machine Elements]; PWN: Warszawa, Poland, 1973. [Google Scholar]

- Niezgodziński, M.E.; Niezgodziński, T. Wytrzymałość Materiałów [Resistance of Materials]; PWN: Warszawa, Poland, 1979. [Google Scholar]

- Lang, R.O. Formzahlen von Kurbelwellen. Mot. Z. 1968, 3, 91–95. [Google Scholar]

- Polish Register of Shipping. Calculation of Crankshafts for Marine Diesel Engines; Publication 8/P: Gdańsk, Poland, 2012. [Google Scholar]

- Al-Azirjawi, B.S.K. New design solution for crankshaft. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Tampa, FL, USA, 3–9 November 2017; Volume 2, pp. 1–8. [Google Scholar] [CrossRef]

- Bulatović, Ž.M.; Štavljanin, M.S.; Tomic, M.; Knežević, D.M.; Biočanin, S.L. Measurement and analysis of angular velocity variations of twelve-cylinder diesel engine crankshaft. Mech. Syst. Signal Process. 2011, 25, 3043–3061. [Google Scholar] [CrossRef]

- Cao, W.; Xue, C.; Bai, X.; Li, L.; An, Z. Research on the measuring system for crankshaft based on laser principle. In Proceedings of the SPIE—The International Society for Optical Engineering, Beijing, China, 19 February 2008; Volume 662521, pp. 1–6. [Google Scholar] [CrossRef]

- Dai, S.P.; Gao, L.; Gao, K. The applications of measurement system for crankshaft. J. Wuhan Univ. Technol. 2006, 8, 833–836. [Google Scholar]

- Łukomski, Z. Technologia Spalinowa Silników Kolejowych i Okrętowych [Exhaust Gas Technology of Railway and Marine Engines]; Wydawnictwa Komunikacji i Łączności: Warszawa, Poland, 1972. [Google Scholar]

- Adamczak, S. Odniesieniowe Metody Pomiaru Zarysów Okrągłości Części Maszyn [Reference Methods for Measuring the Roundness Profiles of Machine Parts]; Politechnika Świętokrzyska: Kielce, Poland, 1998. [Google Scholar]

- Kim, J.-K.; Lee, M.C. Development of Wireless Device for Inspecting Crankshaft Deflection Using Linear Encoder. J. Korean Soc. Precis. Eng. 2009, 26, 104–111. [Google Scholar]

- Nwagboso, C.O. Sensors and systems for crankshaft position measurement. In Automotive Sensory Systems; Springer: New Dehli, India, 1993; pp. 61–94. [Google Scholar] [CrossRef]

- Novac, G. Crank Web Deflections of Marine Diesel Engines. Fiability Durab. 2014, 1, 145–150. [Google Scholar]

- Quan, W.; Wei, J.; Zhao, Y.W.; Sun, L.H.; Bianl, X.Y. Development of an Automatic Optical Measurement System for Engine Crankshaft. In Proceedings of the International Conference on Computational Science and Its Applications, Santander, Spain, 20–23 June 2011; pp. 68–75. [Google Scholar]

- Taylor Hobson. Available online: https://www.taylor-hobson.com/ (accessed on 12 April 2019).

- Mahr. Available online: https://www.mahr.com/ (accessed on 12 April 2019).

- ITA. Available online: https://www.ita-polska.com.pl/ (accessed on 12 April 2019).

- ADCOLE Maryland Aerospace. Available online: https://www.adcole.com/ (accessed on 12 April 2019).

- Marciniak, L.; Grzelka, M.; Gapiński, B.; Wieczorkowski, M.; Chajda, J.; Maliński, K.; Olszewska, I. Analiza Zdolności Procesu Pomiaru Wałów Korbowych z Wykorzystaniem Techniki Współrzędnościowej. Postępy w Metrologii Współrzędnościowej [Analysis of Crankshaft Measurement Process Capability Using a Coordinate Technique. Advances in Coordinate Metrology]; Akademia Techniczno-Humanistyczna w Bielsku-Białej: Bielsko-Biała, Poland, 2010; pp. 101–114. [Google Scholar]

- Zeiss Poland. Available online: https://www.zeiss.pl/ (accessed on 12 April 2019).

- Hexagon Manufacvturing Intelligence. Available online: https://www.hexagonmi.com/ (accessed on 12 April 2019).

- Exa Pro. Available online: www.exapro.pl/urządzenie-pomiarowe-leitz-pom-g (accessed on 1 April 2019).

- Desbazeille, M.; Randall, R.B.; Guillet, F.; El Badaoui, M.; Hoisnard, C. Identification of the crankshaft torsional properties of a large diesel engine from a single point measurement of angular speed. In Proceedings of the 3rd International Conference on Integrity, Reliability and Failure, Porto, Portugal, 20–24 July 2009; pp. 20–24. [Google Scholar]

- Fonte, M.; Duarte, P.; Anes, V.; Freitas, M.; Reis, L. On the assessment of fatigue life of marine diesel engine crankshafts. Eng. Fail. Anal. 2015, 56, 51–57. [Google Scholar] [CrossRef]

- Sun, J.; Wang, J.; Gui, C. Whole crankshaft beam-element finite-element method for calculating crankshaft deformation and bearing load of an engine. Proc. Inst. Mech. Eng. Part J 2010, 224, 299–303. [Google Scholar] [CrossRef]

- Zhao, Y.; Cao, S.Q. Modal Analysis of Large Marine Crankshaft. In Frontiers of Manufacturing and Design Science III; parts 1 and 2; Trans Tech Publications: Zurich, Switzerland, 2013; Volume 271–272, pp. 1022–1026. [Google Scholar]

- Król, K.; Wikło, M.; Olejarczyk, K.; Kołodziejczyk, K.; Siemiątkowski, Z.; Żurowski, W.; Rucki, M. Residual Stresses Assessment in the Marine Diesel Engine Crankshaft 12V38 Type. J. Kones Powertrain Transp. 2017, 24, 117–123. [Google Scholar] [CrossRef]

- Metkar, R.M.; Sunnapwar, V.K.; Hiwase, S.D. A fatigue analysis and life estimation of crankshaft—A review. Int. J. Mech. Mater. Eng. (IJMME) 2011, 6, 425–430. [Google Scholar]

- Mitianiec, W.; Buczek, K. Torsional vibration analysis of crankshaft in heavy duty six cylinder inline engine. Czasopismo Techniczne Mechanika 2008, 8-M, 193–207. [Google Scholar]

- Nowoczesna metoda trasowania odkuwki monolitycznego wału korbowego [Modern Method of Marking out a Forged Monolithic Crankshaft]. Available online: http://www.konstrukcje%20inżynierskie.pl/2015 (accessed on 1 April 2019).

- Barth, U. Kombinierte Zweipunkt-Dreipunkt-Messung zum gleichzeitigen. Bestimmen von Mass-Kreisformabweichungen. Feingerätetechnik 1984, 1, 21–23. [Google Scholar]

- Diakov, D.; Kalimanova, I.; Minakov, T. System for measurements of roundness of large scaled objcects. In Konferencja Naukowo-Techniczna Metrologia w Technikach Wytwarzania; Cracow University of Technology: Kraków, Poland, 2003; Volume 1, pp. 121–128. [Google Scholar]

- Nyberg, T.R.; Kotamaki, M. Cylindricity Measurement of Large Rollers by Combined 3-point-method and Sequential 2-point-metod. In Proceedings of the 4th International Symposium on Dimensional Metrology in Production and Quality Control, Tampere, Finland, 22–25 June 1992. Paper no. 16. [Google Scholar]

- Sonozaki, S.; Fujiwara, H. Simultaneous Measurement of Cylindrycal Parts Profile and Rotating Accuracy Using Multi-Three-Point-Method. Jpn. Soc. Prec. Eng. 1989, 23, 286–291. [Google Scholar]

- Westkamper, E. Prozessnahe Rundheitsmesstechnik mit 3-Punktmessystemen. In Proceedings of the 6-th International DAAAM Symposium, Kraków, Poland, 26–28 October 1995; pp. 363–364. [Google Scholar]

- HHI. Available online: http://www.english.hhi.co.kr/main/ (accessed on 1 April 2019).

- Technical Materials of HHI Co. Ltd.; HHI: Ulsan, South Korea, 2018.

- H. Cegielski S.A. Tolerancje Kształtu i Położenia dla Wału Korbowego—Specyfikacja Technologiczna Silników MAN B&W [Shape and Postion Tolerances of Crankshafts—Engine Technology Specification MAN]; HCP: Poznań, Poland, 2010. [Google Scholar]

- Chybowski, L.; Gawdzińska, K. On the Present State-of-the-Art of a Component Importance Analysis for Complex Technical Systems. In New Advances in Information Systems and Technologies; Springer: Cham, Switzerland, 2016; Volume 445, pp. 691–700. [Google Scholar] [CrossRef]

- Chybowski, L.; Gawdzińska, K. On the Possibilities of Applying the AHP Method to a Multi-criteria Component Importance Analysis of Complex Technical Objects. In New Advances in Information Systems and Technologies; Springer: Cham, Switzerland, 2016; Volume 445, pp. 701–710. [Google Scholar] [CrossRef]

- Chybowski, L.; Twardochleb, M.; Wiśnicki, B. Multi-criteria Decision making in Components Importance Analysis applied to a Complex Marine System. Naše More 2016, 63, 264–270. [Google Scholar] [CrossRef]

- Nozdrzykowski, K. Metodyka Pomiarów Geometrycznych Odchyłek Powierzchni Walcowych Wielkogabarytowych Elementów Maszyn na Przykładzie Wałów Korbowych Silników Okrętowych [Methodology of Geometric Measurements of Deviations of Cylindrical Surfaces of Large-Size Machine Elements Based on the Example of Ship Engine Crankshafts]; Wydawnictwo Naukowe Akademii Morskiej w Szczecinie: Szczecin, Poland, 2013. [Google Scholar]

- Jadhav, A.; Chalwa, V.; Gaikwad, P. Fatigue Failure Analysis of Engine Crankshaft. Int. J. Eng. Res. Technol. 2013, 2, 614–621. [Google Scholar]

- Schagerberg, S.; Mckelvey, T. Instantaneous Crankshaft Torque Measurements—Modeling and Validation. In Proceedings of the SAE 2003 World Congress & Exhibition, Detroit, MI, USA, 3 March 2003; pp. 1–16. [Google Scholar] [CrossRef]

- Tian, Y.Z.; Li, M.; He, Y.; Wu, G.; Li, W.; Fang, M. Research on In-Process Measuring Method for Crankshaft. In Proceedings of the 2006 6th World Congress on Intelligent Control and Automation, Dalian, China, 21–23 June 2006; pp. 4995–4998. [Google Scholar] [CrossRef]

- Walczyk, W.; Milenin, A.; Pietrzyk, M. Computer Aided Dasign of New Forging Technology for Crankshafts. Steel Res. Int. 2011, 82, 187–194. [Google Scholar] [CrossRef]

- Nozdrzykowski, K. Adjustment and analysis of forces in a flexible crankshaft support system [System for measuring the geometric deviations of the set of central pins of a crankshaft]. J. Mach. Constr. Maint. Problemy Eksploatacji 2017, 4, 63–70. [Google Scholar]

- Nozdrzykowski, K. Prevention of Elastic Strains in Flexible Large Size Machine Parts with the Use of Elastic Support. Mach. Dyn. Res. 2015, 39, 11–122. [Google Scholar]

- Nozdrzykowski, K. System do pomiarów odchyłek geometrycznych zespołu czopów głównych wału korbowego. Pomiary Automatyka Kontrola 2011, 57, 1592–1594. [Google Scholar]

- Nozdrzykowski, K. Sposób i Urządzenie do Pomiaru Odchyłek Kształtu i Położenia osi Czopów Wału Korbowego [Method and Apparatus for Measuring Deviations in the Shape and Position of Crankshaft Pins Axes]. Patent no. PL218653, 2 February 2011. [Google Scholar]

- Chybowski, L.; Grządziel, Z.; Gawdzińska, K. Simulation and Experimental Studies of a Multi-Tubular Floating Sea Wave Damper. Energies 2018, 11, 1012. [Google Scholar] [CrossRef]

- Kaczyński, P.; Ptak, M.; Fernandes, F.A.O.; Chybowski, L.; Wilhelm, J.; Alves de Sousa, R.J. Development and Testing of Advanced Cork Composite Sandwiches for Energy-Absorbing Structures. Materials 2019, 12, 697. [Google Scholar] [CrossRef]

- Karliński, J.; Ptak, M.; Działak, P. Simulation tests of roll-over protection structure. Arch. Civ. Mech. Eng. 2012, 13, 57–63. [Google Scholar] [CrossRef]

- Ratajczak, M.; Ptak, M.; Chybowski, L.; Gawdzińska, K.; Będziński, R. Material and Structural Modeling Aspects of Brain Tissue Deformation under Dynamic Loads. Materials 2019, 12, 271. [Google Scholar] [CrossRef] [PubMed]

- Technical Data Sheet. Force Transducer FT-5367-4 kN; SPAIS Sp. z o.o.: Gdańsk, Poland, 2018. [Google Scholar]

- Leigh, J.R. Applied Digital Control: Theory, Design and Implementation; Dover Publications: Exeter, Devon, UK, 2006. [Google Scholar]

- B&R Help Tutorial to Automation Studio; B&R Industrial Automation: Eggelsberg, Austria, 2018.

- Dorf, R.C.; Bishop, R.H. Modern Control Systems; Pearson Education Limited: London, UK, 2017. [Google Scholar]

- Jaszczak, S.; Kołodziejczyk, J. A method of fast application of the fuzzy PID algorithm using industrial control device. Lect. Notes Comput. Sci. 2012, 7267, 237–246. [Google Scholar]

- Nozdrzykowski, K. Procedures of determining and realization of reaction forces in an elastic support system for crankshafts. Mechanik 2018, 12, 1129–1131. [Google Scholar] [CrossRef]

- Nozdrzykowski, K.; Grządziel, Z.; Harušinec, J. Determining and Analysing Support Conditions at Variable Construction of Crankshafts. New Trends Prod. Eng. 2018, 1, 553–560. [Google Scholar] [CrossRef][Green Version]

- Nozdrzykowski, K. Applying Harmonic Analysis in the Measurements of Geometrical Deviations of the Crankshafts—Selecting Support Conditions. MAPE 2018, 1, 191–195. [Google Scholar] [CrossRef][Green Version]

- Adamczak, S.; Janusiewicz, A.; Makieła, W.; Stępień, K. Statistical validation of the method for measuring radius variations of components on the machine tool. Metrol. Meas. Syst. 2011, XVIIII, 35–46. [Google Scholar] [CrossRef]

- Nozdrzykowski, K.; Janecki, D. Comparatiye studies of reference measurements of cylindrical surface roundness profiles of large machine components. Metrol. Meas. Syst. 2014, XXI, 67–76. [Google Scholar] [CrossRef]

- Nozdrzykowski, K.; Bejger, A. Aspects of using correlation calculus in comparative measurements of geometric deviations and shape profiles of main crankshaft bearing journals. Sci. J. Marit. Univ. Szczec. 2013, 35, 114–117. [Google Scholar]

- Guilford, J.P. Fundamental Statistics in Psychology and Education; McGraw-Hill: New York, NY, USA, 1965. [Google Scholar]

- Adamczak, A.; Janecki, D.; Świderski, J.; Dobrowolski, T. Pomiary Weryfikacyjne Zarysów Okrągłości Czopów Wału Korbowego w Oparciu o System Pomiarowy MUK 25–600 z Oprogramowaniem SAJD [Verification of Outlines of Crankshaft Pins Roundness Based on the MUK 25–600 Measuring System with SAJD Software from Research Commissioned by the Maritime University of Szczecin]; Kielce University of Technology: Kielce, Poland, 2011. [Google Scholar]

- Żebrowska-Łucyk, S. Wpływ rodzaju okręgu odniesienia na wyniki oceny odchyłki kołowości [Impact of the type of reference circle on the results of the assessment of circularity deviation]. Mechanik 1979, 1, 207–210. [Google Scholar]

- Adamczak, S. Struktura geometryczna powierzchni. Cz. 2. Badania porównawcze przyrządów [Geometric structure of the surface. Part 2: Comparative tests of instruments. Method of correlation calculation]. Metoda rachunku korelacyjnego. Mechanik 2008, 5–6, 514–518. [Google Scholar]

- Nowicki, B. Struktura Geometryczna. In Chropowatość i Falistość Powierzchni [Geometric Structure. Roughness and Waviness of the Surface]; WNT: Warszawa, Poland, 1991. [Google Scholar]

- Żółkiewski, S.; Pioskowik, D. Robot control and online programming by human gestures using a kinect motion sensor. In New Perspectives in Information Systems and Technologies; Springer: Cham, Switzerland, 2014; Volume 1, pp. 593–604. [Google Scholar]

- Gawdzińska, K.; Chybowski, L.; Przetakiewicz, W. Study of Thermal Properties of Cast Metal-Ceramic Composite Foams. Arch. Foundry Eng. 2017, 17, 47–50. [Google Scholar] [CrossRef]

- Gawdzińska, K.; Chybowski, L.; Przetakiewicz, W.; Laskowski, R. Application of FMEA in the Quality Estimation of Metal Matrix Composite Castings Produced by Squeeze Infiltration. Arch. Metall. Mater. 2017, 62, 2171–2182. [Google Scholar] [CrossRef]

| Methods of Measurement | Crankshaft Type | ||||||

|---|---|---|---|---|---|---|---|

| Small | Medium | Large | |||||

| Positioning of the Shaft Axis during Measurement | |||||||

| Horizontally | Vertically | Horizontally | Vertically | Horizontally | Vertically | ||

| non-reference | in centres | W | - | - | - | - | - |

| in a device: – with a rotary spindle – with a rotary table | - | S | - | S | - | - | |

| - | S | - | S | - | - | ||

| reference | in 2 V-blocks | W | - | - | - | - | - |

| in 4 V-blocks | - | - | W | - | - | - | |

| in n V-blocks | - | - | - | - | W | - | |

| Others: – scanning – photometry | in n V-blocks | - | - | - | - | S | - |

| Signal | Description | Range | Unit |

|---|---|---|---|

| FSP (t) | The value corresponding to the set force | 0–2000 | N |

| FPV (t) | The value corresponding to the current force. | 0–2000 | N |

| PCV(t) | The value corresponding to the pressure signal | 0–200 | kPa |

| Journal Number | Mutual Correlation Factor ρ(φ) |

|---|---|

| 1 | 0.9578 |

| 2 | 0.9568 |

| 3 | 0.9548 |

| 4 | 0.9543 |

| 5 | 0.9549 |

| 6 | 0.9562 |

| 7 | 0.9549 |

| 8 | 0.9542 |

| 9 | 0.9542 |

| 10 | 0.9544 |

| Journal Number | Deviation in Roundness ΔRz [μm] | Deviation in Roundness ΔRw [μm] | Correlation Factor ρ [-] |

|---|---|---|---|

| 7 | 42.682 | 42.038 | 0.9662 |

| No. | Analysed Parameter of Relative Error of the Method | Sample Name | |||

|---|---|---|---|---|---|

| Journal 4 | Journal 5 | Collective Sample | |||

| 1 | Sample size ns | 20 | 20 | 40 | |

| 2 | Observable value—relative measurement error wΔR | wΔRmax | 0.056670 | 0.070230 | 0.070230 |

| wΔRmin | –0.06764 | –0.09030 | –0.09030 | ||

| 3 | Mean value of the experimental measurement error | 0.0022845 | –0.015136 | –0.006426 | |

| 4 | Confidence interval for the mean error value of the measurement at β = 0.95 | 0.0022845 ± 0.01736 | –0.015136 ± 0.02098 | –0.006426 ± 0.01330 | |

| 5 | Significance test for average value measurement error | Drop H0 in favour of H1 | Drop H0 in favour of H1 | Drop H0 in favour of H1 | |

| 6 | Variation in sample s2 for error | 0.0013776 | 0.0020145 | 0.001730 | |

| 7 | Mean deviation s for error | 0.0371160 | 0.0448842 | 0.041599 | |

| 8 | Significance test for variance of method error | Drop H0 in favour of H1 | Drop H0 in favour of H1 | Drop H0 in favour of H1 | |

| 9 | Confidence interval for a single measurement error at β = 0.95 | 0.0022845 ± 0.07760 | –0.015136 ± 0.09380 | –0.006426 ± 0.08415 | |

| 10 | Measurement accuracy of the DPM method | 7.9% | 10.9% | 9.06% | |

| Measuring Accuracy of the Method in % | Type of Measurement |

|---|---|

| 2–5 | Measurements of roughness, surface waveformity, and shape outline standards and basic research |

| 5–15 | Scientific research |

| 10–25 | Technical inspection and industrial measurements |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nozdrzykowski, K.; Chybowski, L. A Force-Sensor-Based Method to Eliminate Deformation of Large Crankshafts during Measurements of Their Geometric Condition. Sensors 2019, 19, 3507. https://doi.org/10.3390/s19163507

Nozdrzykowski K, Chybowski L. A Force-Sensor-Based Method to Eliminate Deformation of Large Crankshafts during Measurements of Their Geometric Condition. Sensors. 2019; 19(16):3507. https://doi.org/10.3390/s19163507

Chicago/Turabian StyleNozdrzykowski, Krzysztof, and Leszek Chybowski. 2019. "A Force-Sensor-Based Method to Eliminate Deformation of Large Crankshafts during Measurements of Their Geometric Condition" Sensors 19, no. 16: 3507. https://doi.org/10.3390/s19163507

APA StyleNozdrzykowski, K., & Chybowski, L. (2019). A Force-Sensor-Based Method to Eliminate Deformation of Large Crankshafts during Measurements of Their Geometric Condition. Sensors, 19(16), 3507. https://doi.org/10.3390/s19163507