Low-Power and Low-Cost Environmental IoT Electronic Nose Using Initial Action Period Measurements

Abstract

1. Introduction

2. Methods

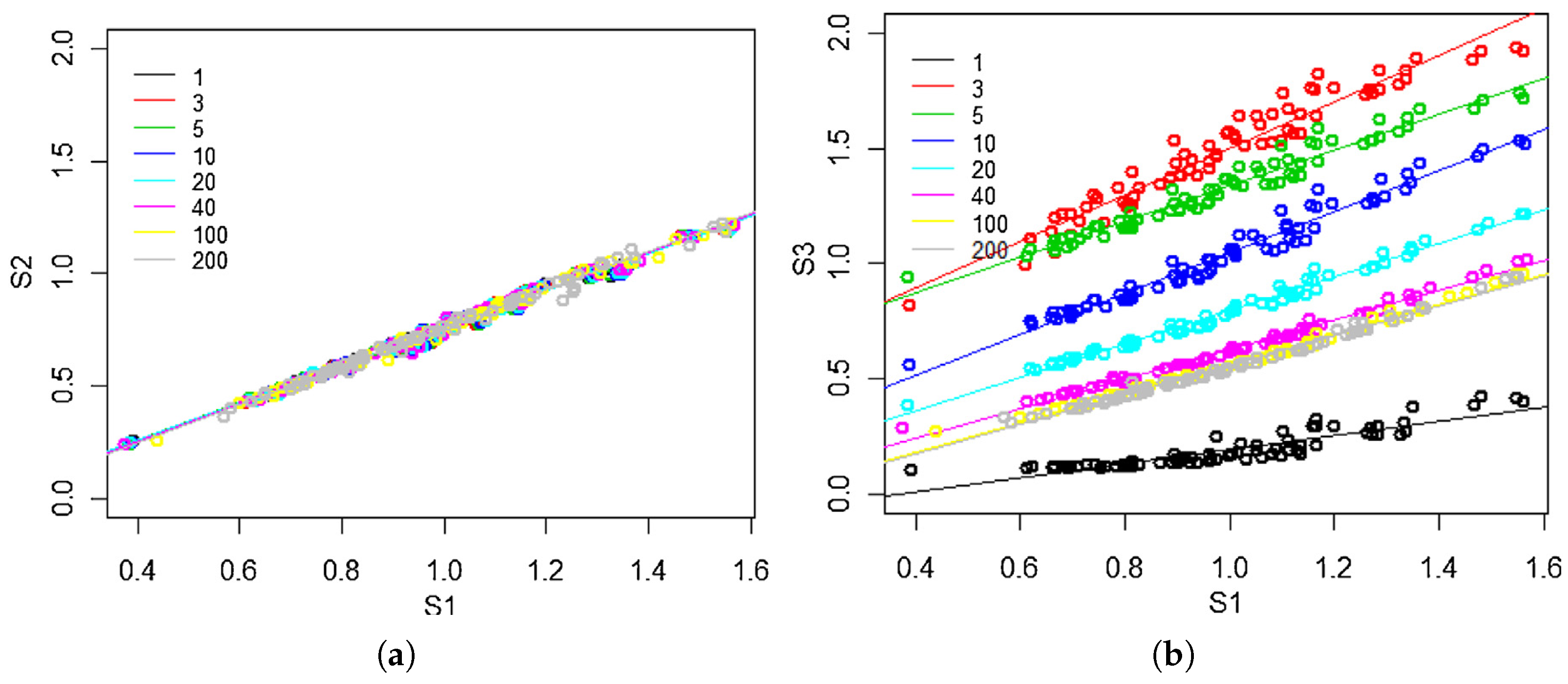

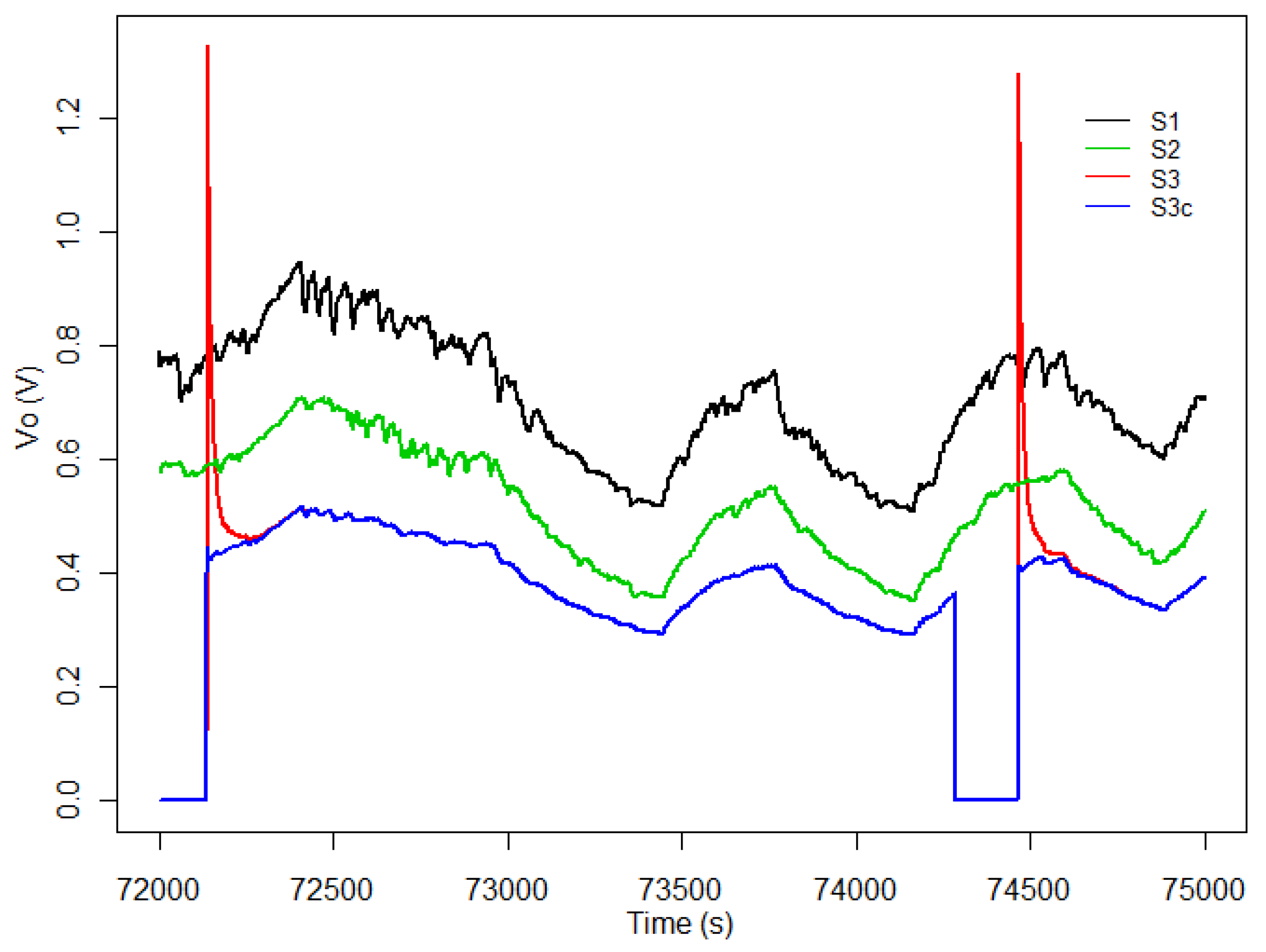

2.1. Measuring in the Initial Action Period

2.2. Main Components

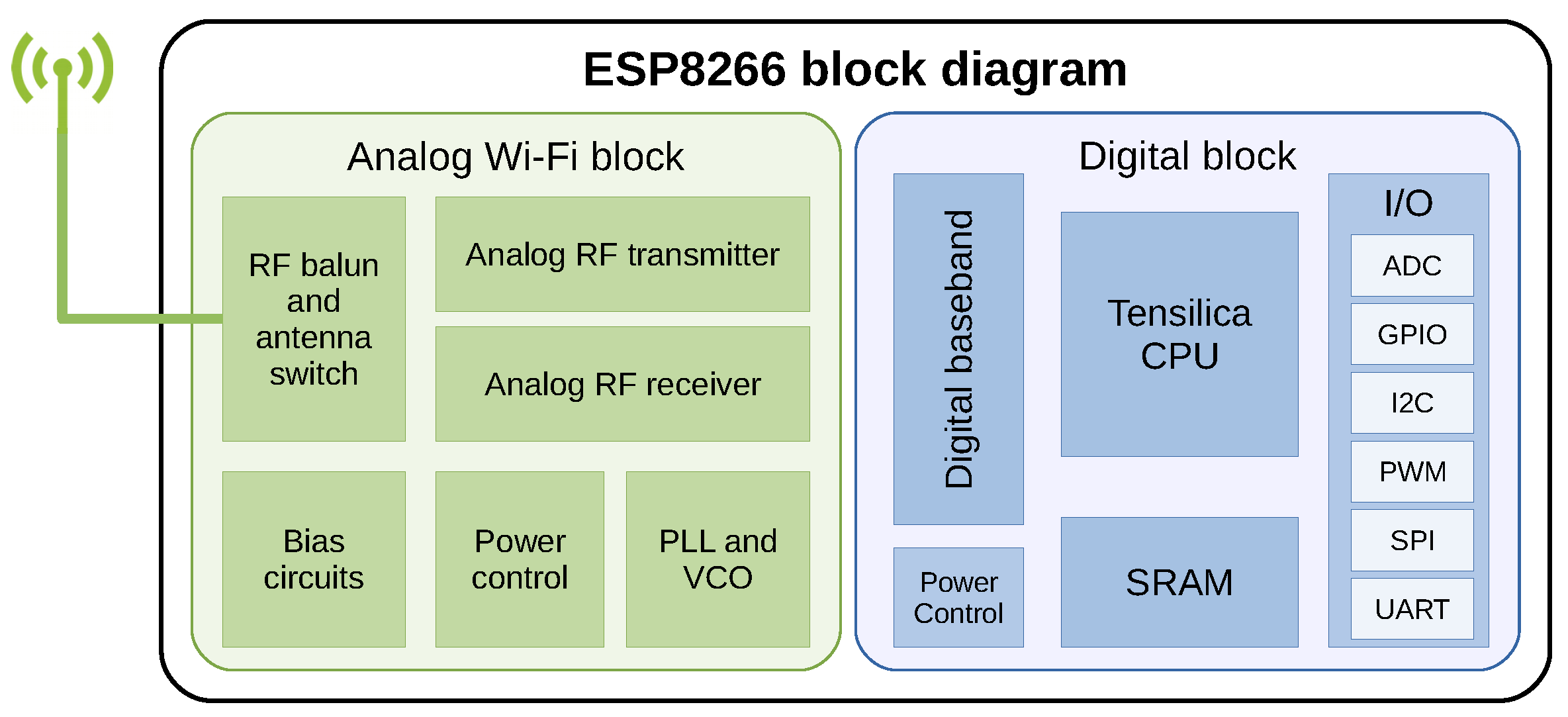

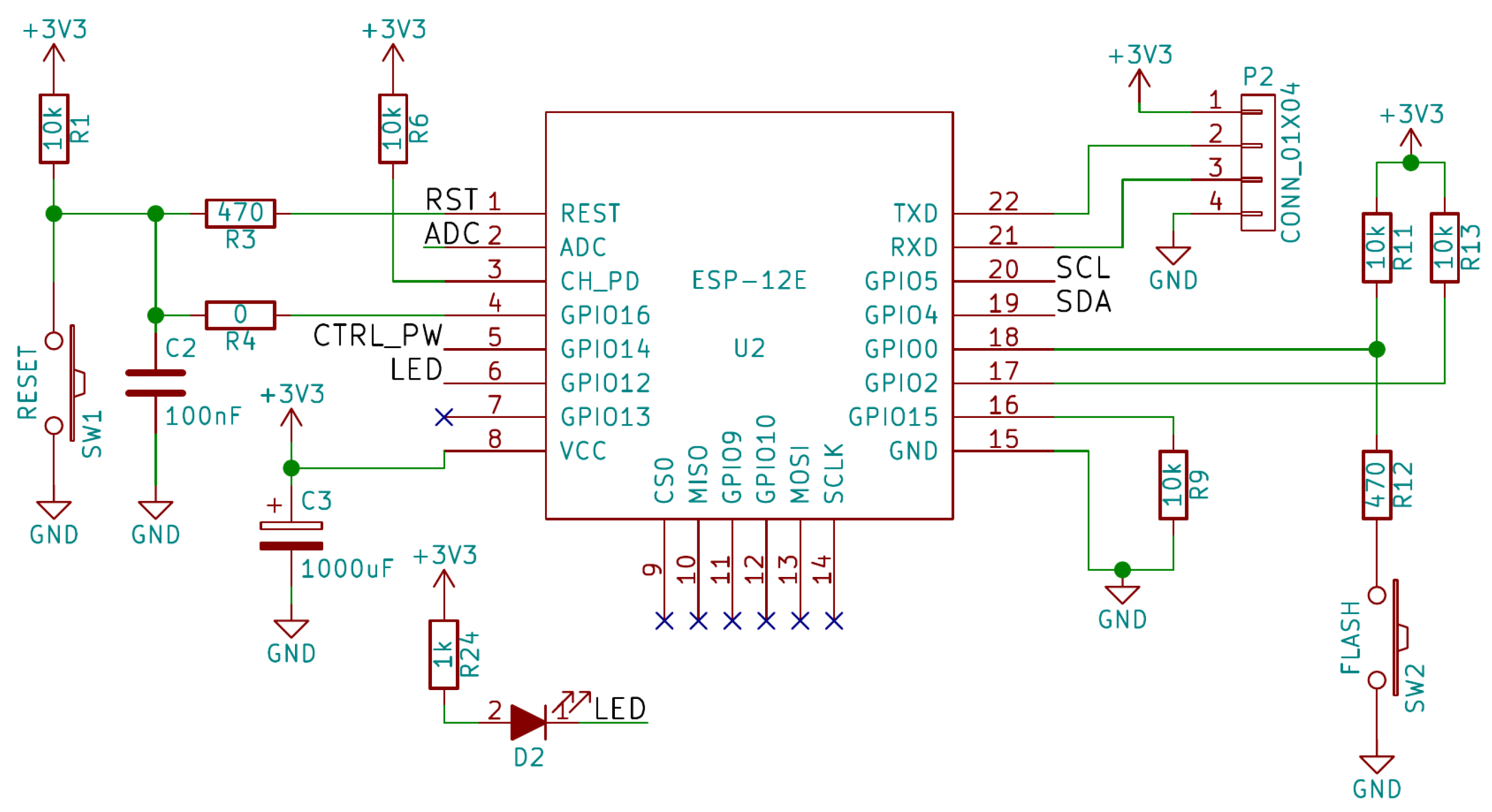

2.2.1. SoC ESP8266

- Tensilica 32 bits microcontroller, 80 or 160 MHz clock speed.

- 64 KB program memmory, and 96 KB for data.

- Power supply from 2.5 to 3.6 V.

- Wi-Fi transceiver with 802.11 b/g/n support.

- Low power consumption modes.

- Common peripheral interfaces (SPI, I2C, UART, etc...)

- One ADC (Analog Digital Converter) pin with 10-bit precision.

- OTA (Over the Air programming) support.

Low Power Modes

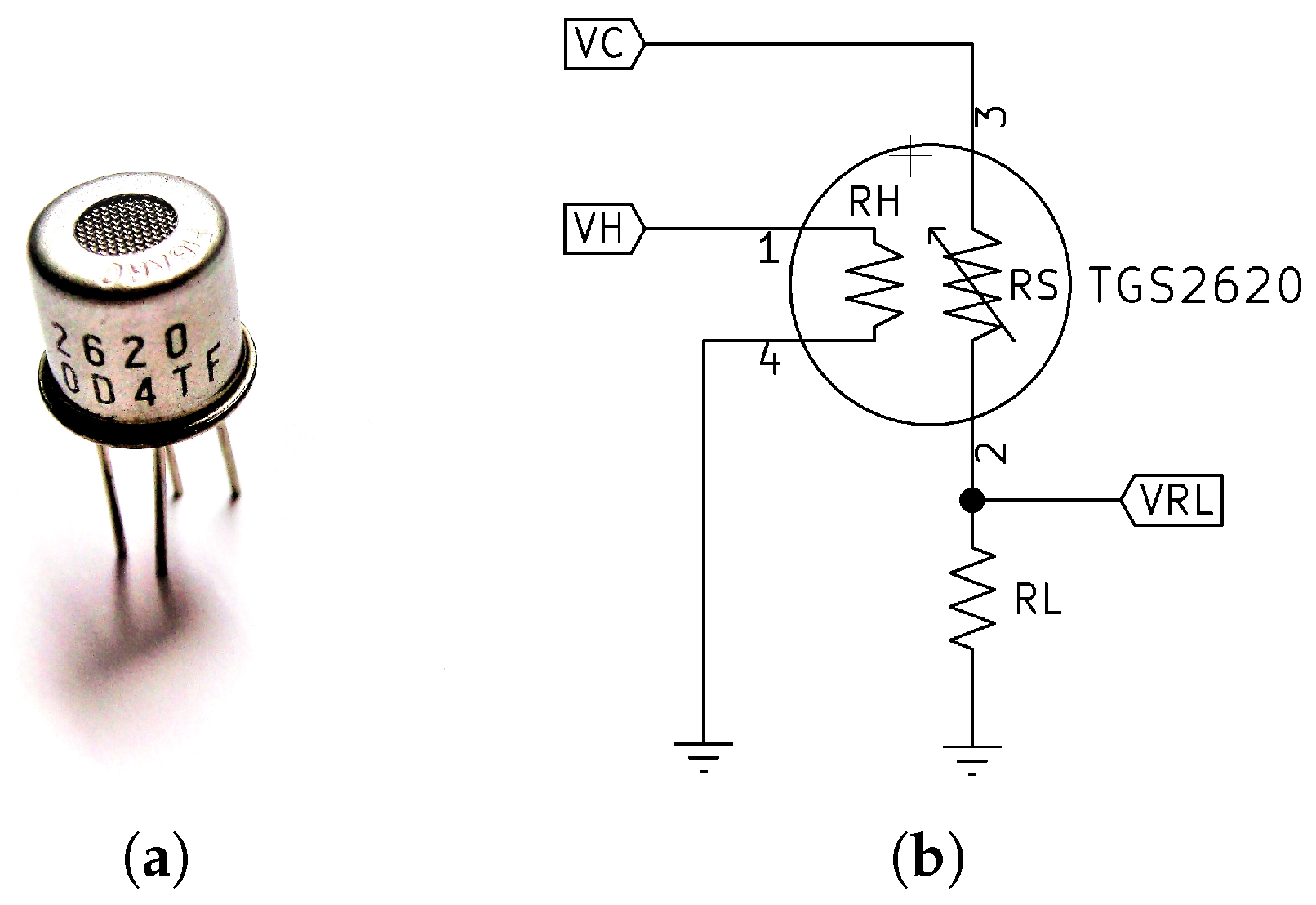

2.2.2. TGS 2620 Gas Sensor

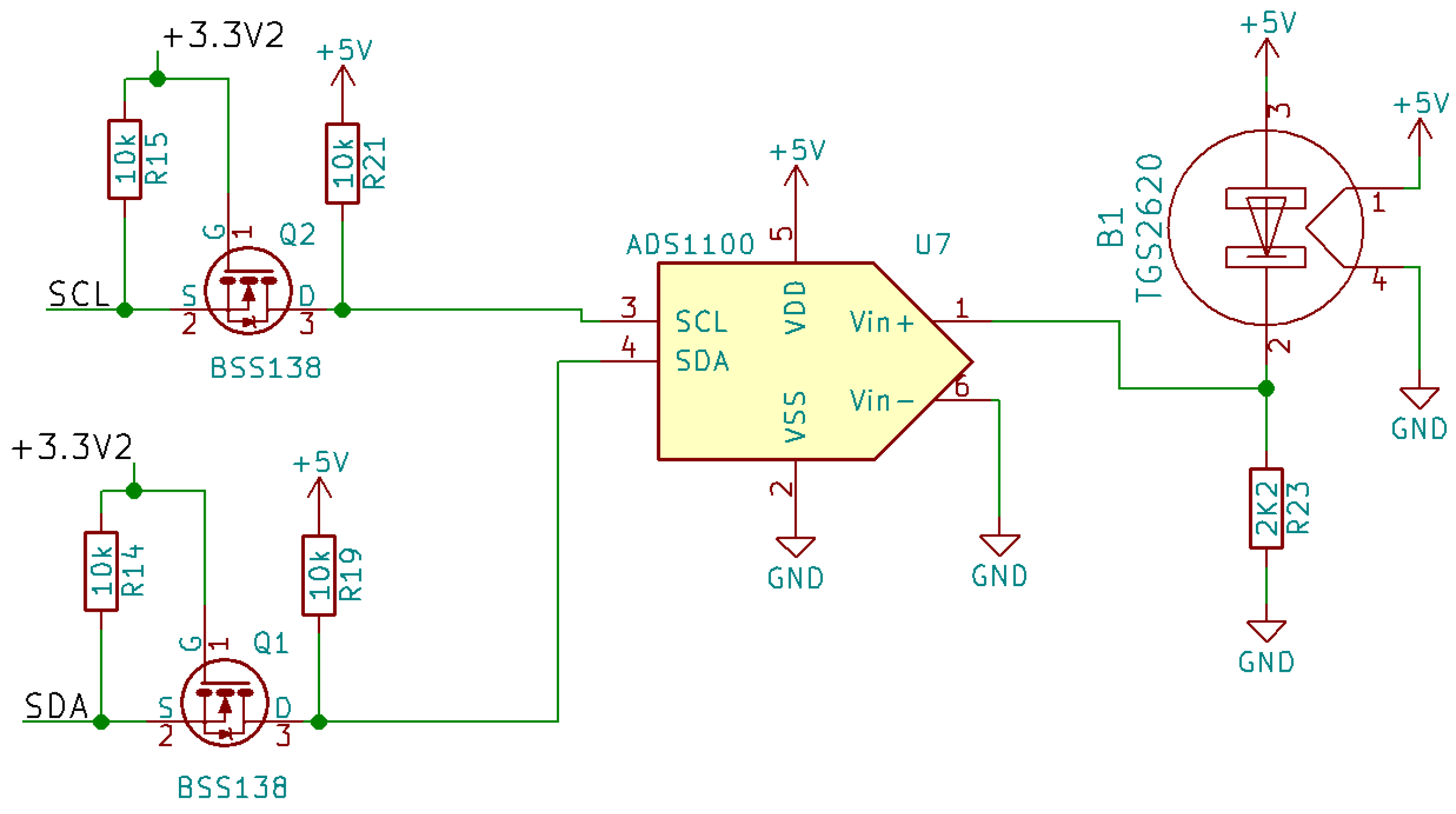

2.2.3. Precision Analog to Digital Converter

2.2.4. ThingSpeak

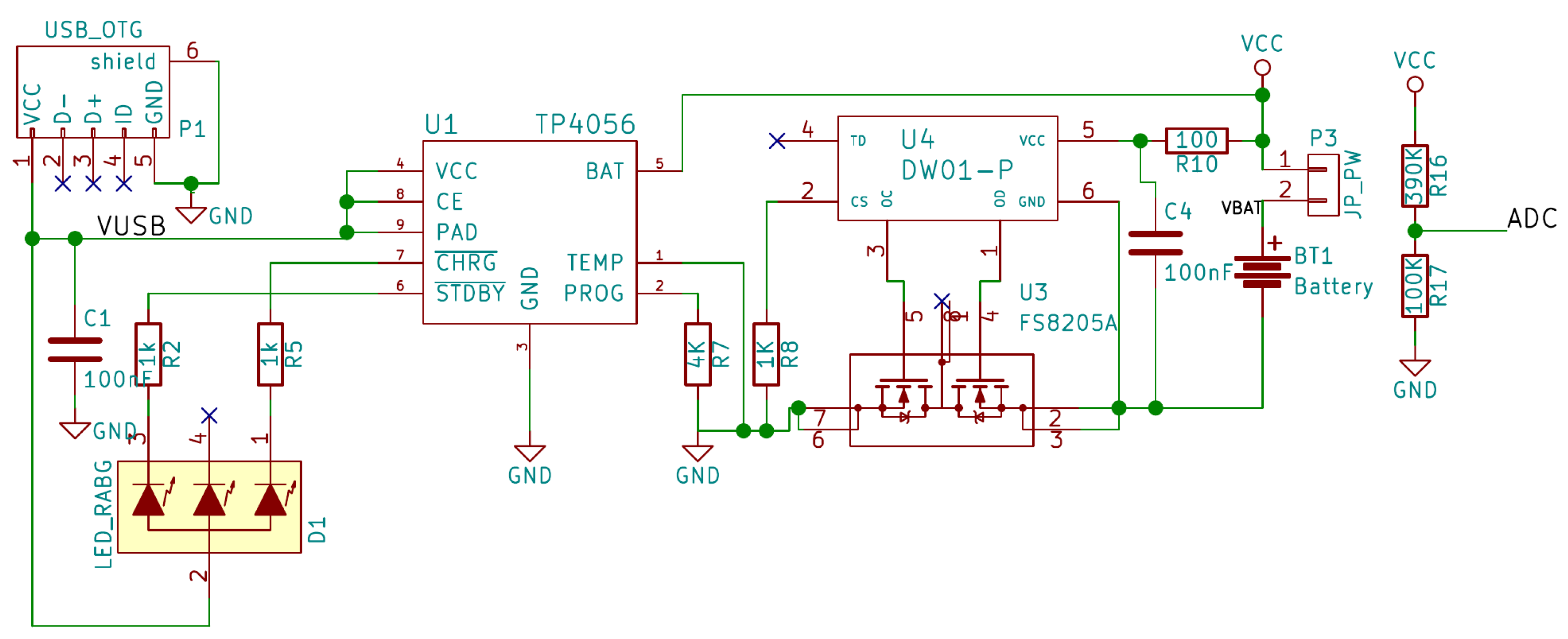

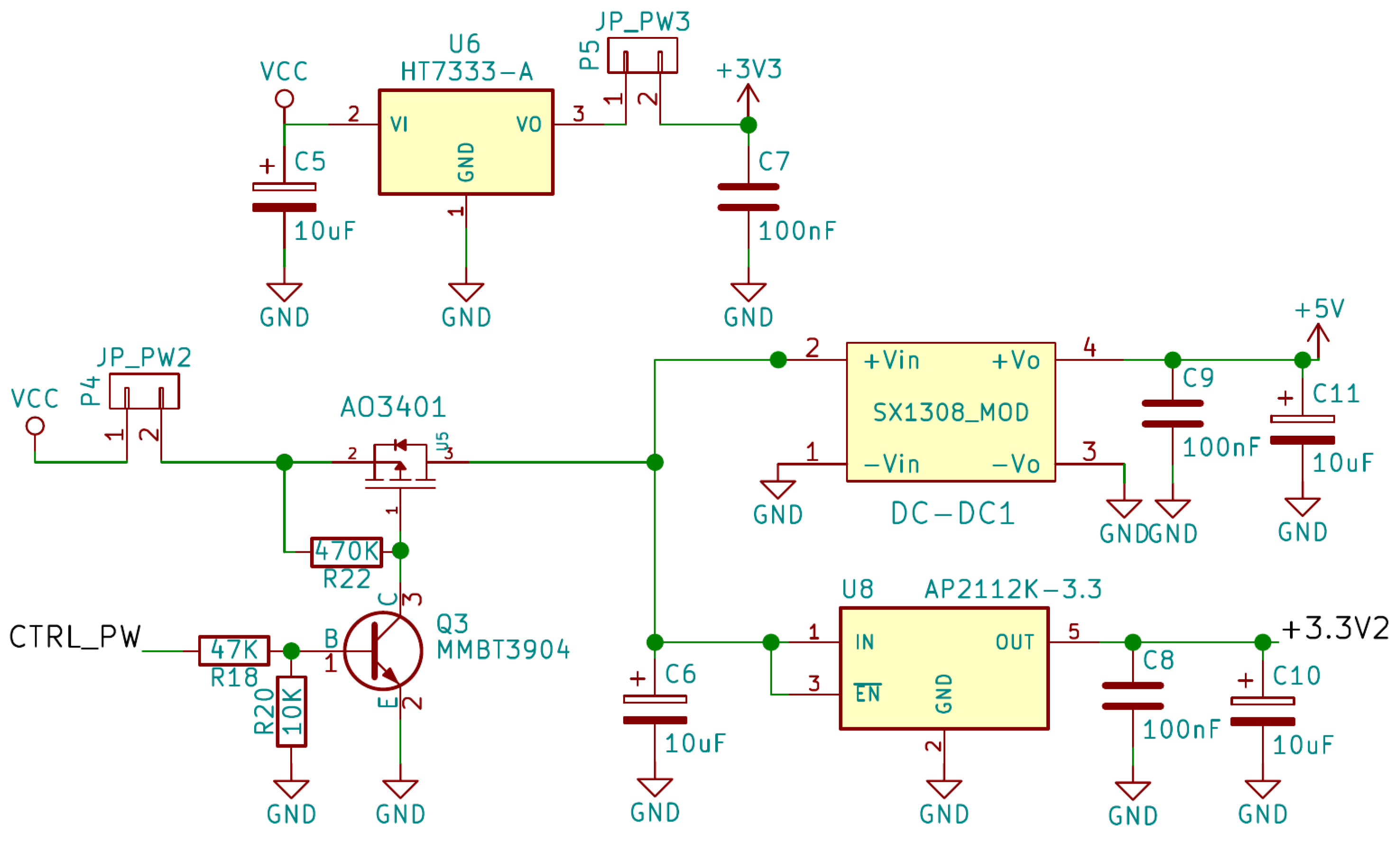

2.3. Proposed Circuit

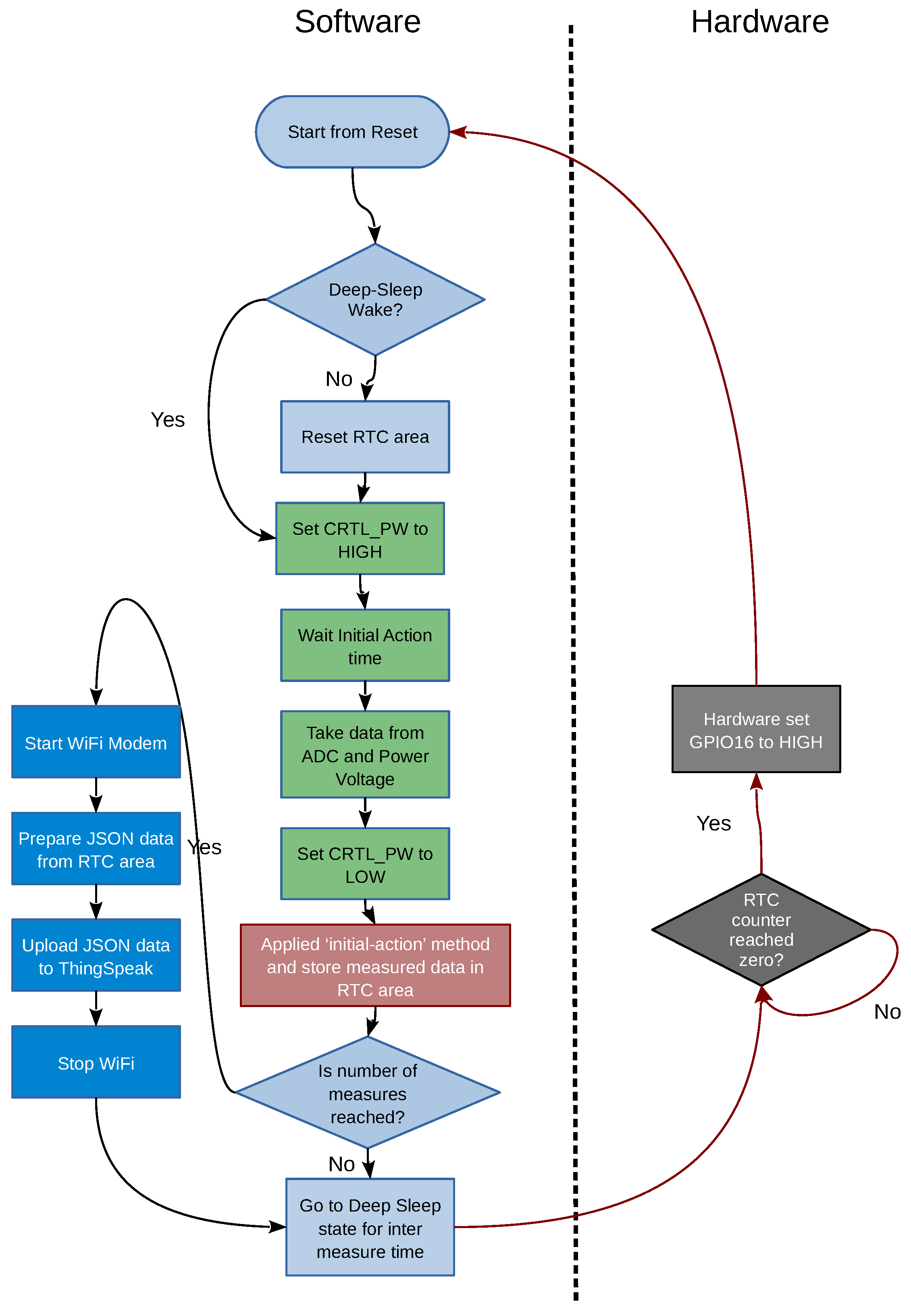

2.4. Software Details

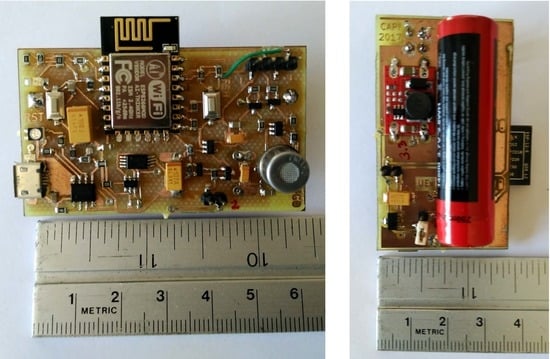

2.5. PCB and Assembly

3. Results

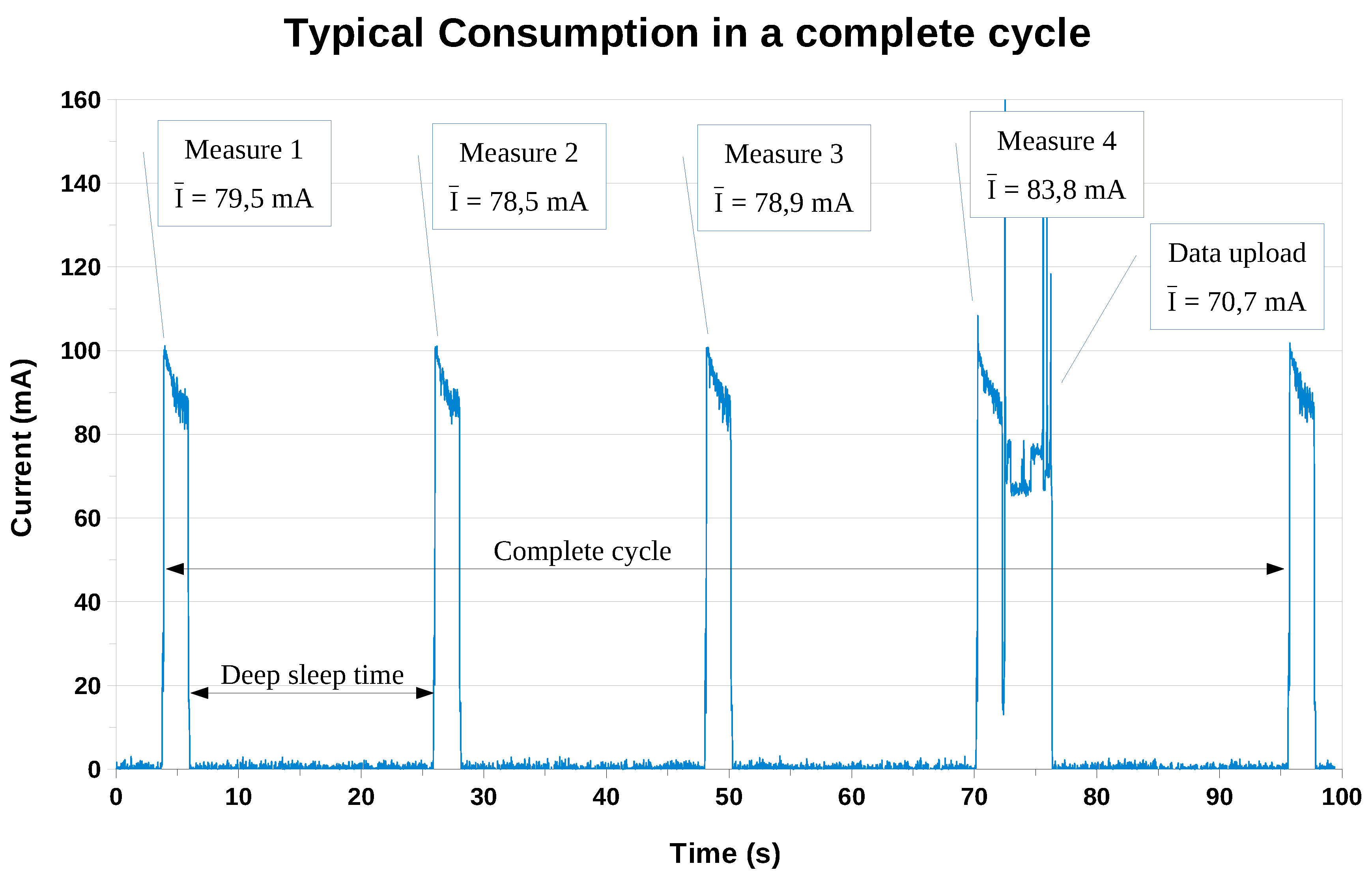

3.1. Study of Consumption in Each of the States

3.1.1. Consumption in “Deep-Sleep” State

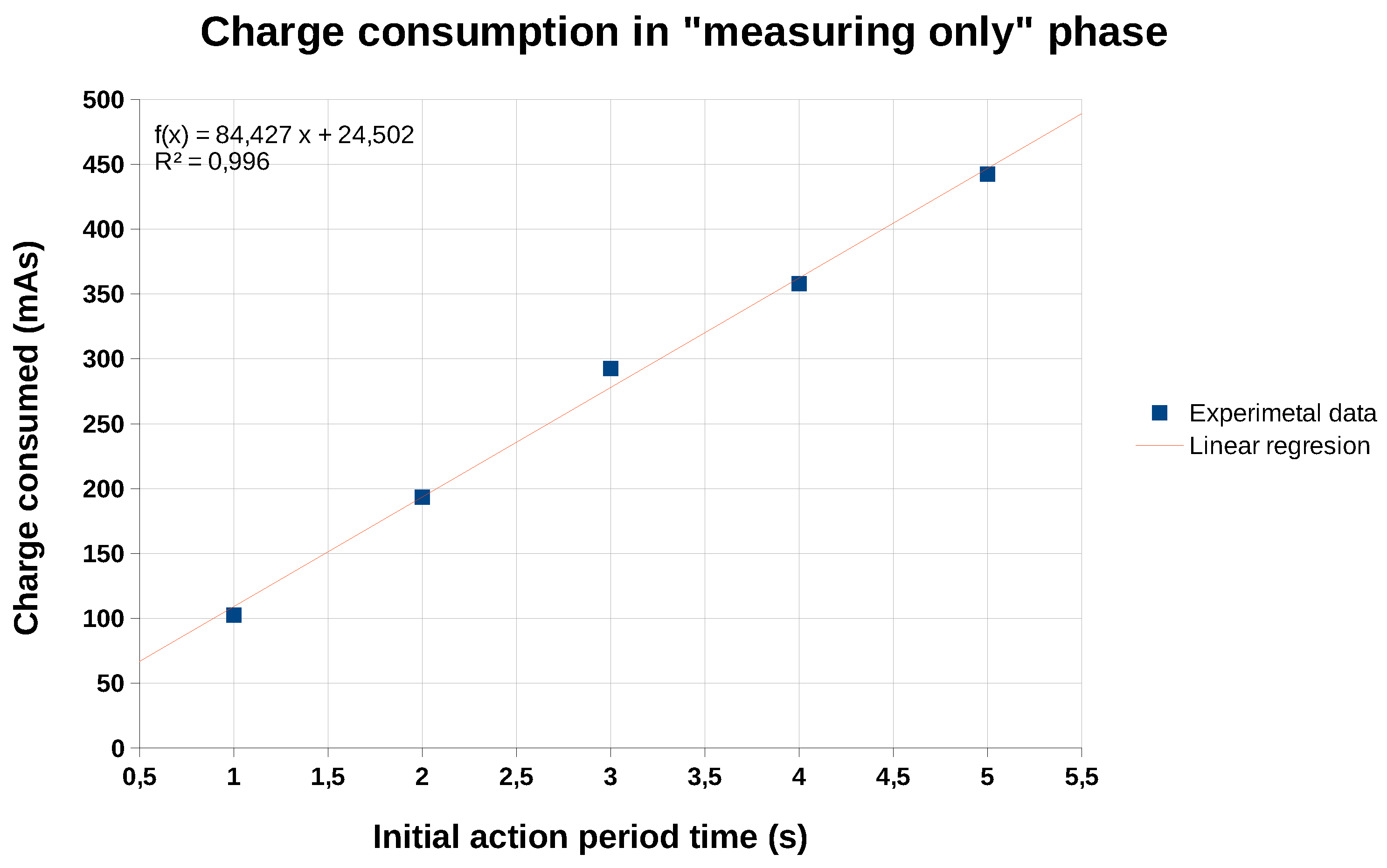

3.1.2. “Measuring-Only” Consumption

3.1.3. “Measuring-and-Uploading” Consumption

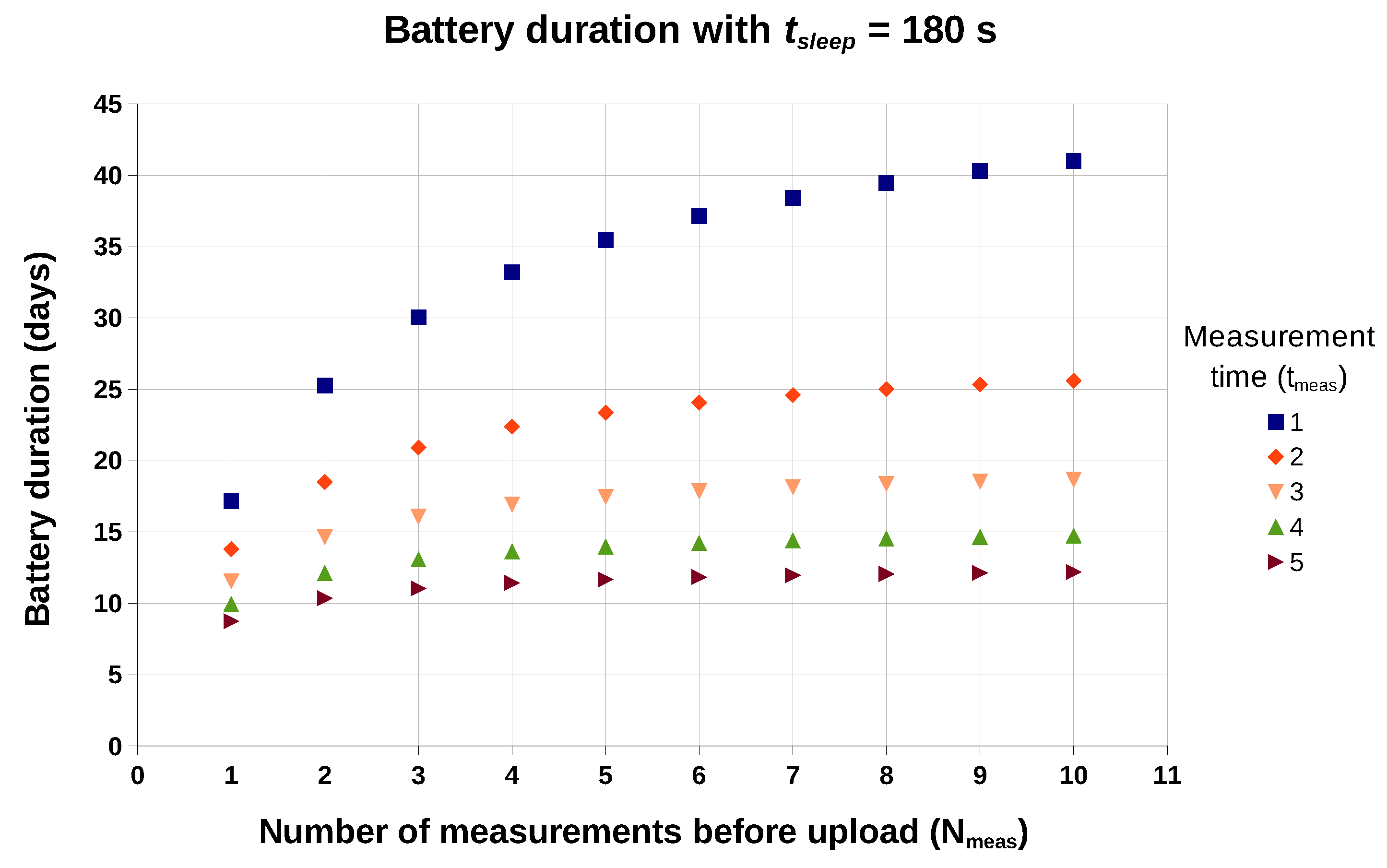

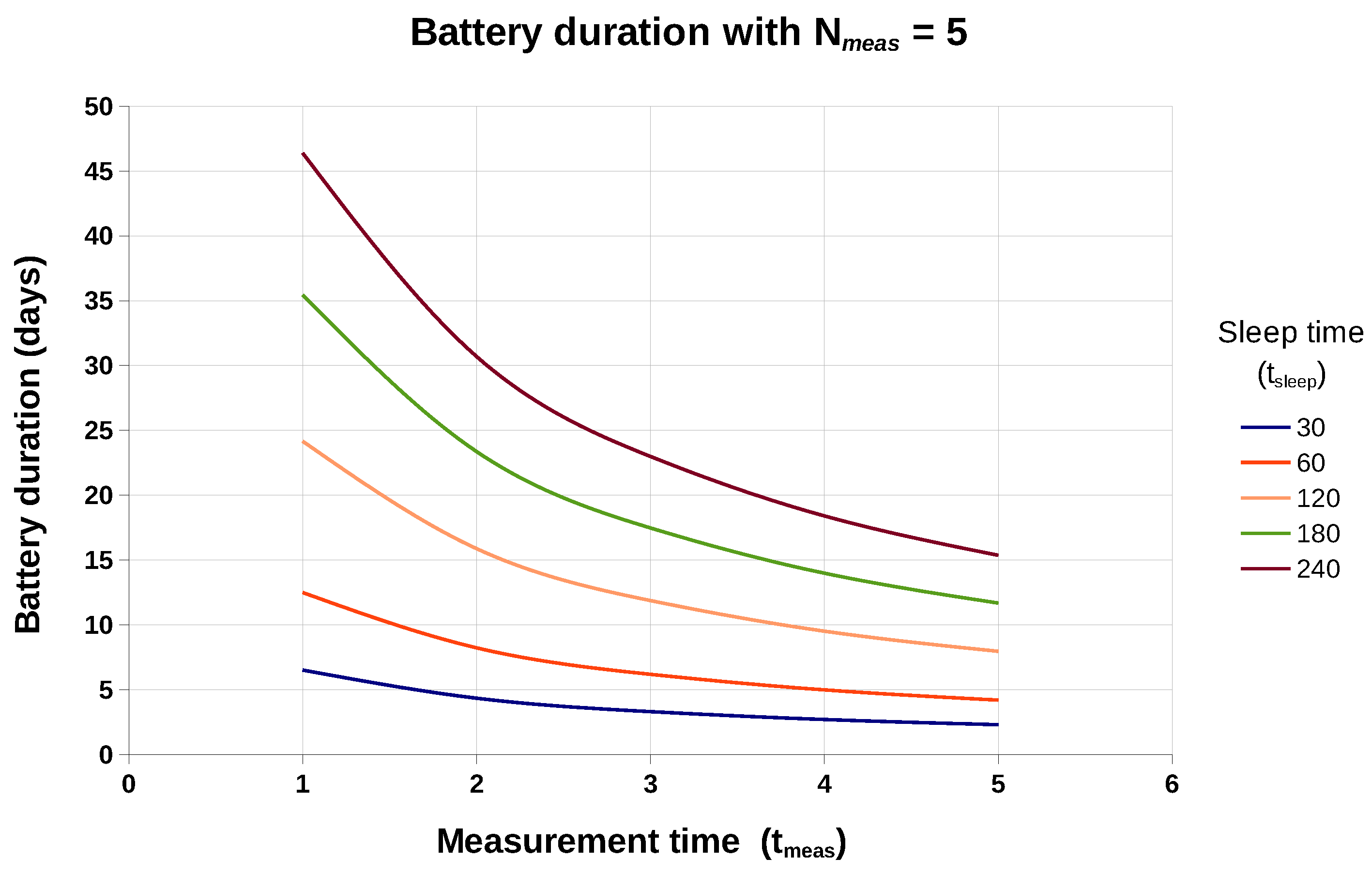

3.2. Global Consumption and Estimation of Battery Life

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ADC | Analog Digital Converter |

| GPIO | General Purpose Input Output |

| I2C | Inter-Integrated Circuit Bus |

| ICA | Independent Component Analysis |

| IoT | Internet of Things |

| JSON | JavaScript Object Notation |

| MEMS | Microelectromechanical systems |

| MOX | Metal Oxide Semiconductor |

| OTA | Over the Air programming |

| PCA | Principal Component Analysis |

| PCB | Printed Circuit Board |

| RTC | Real-Time Clock |

| SoC | System on Chip |

| SPI | Serial Peripheral Interface |

| SVM | Support Vector Machines |

| WSN | Wireless sensor network |

References

- Yick, J.; Mukherjee, B.; Ghosal, D. Wireless sensor network survey. Comput. Netw. 2008, 52, 2292–2330. [Google Scholar] [CrossRef]

- Mukherjee, N.; Neogy, S.; Roy, S. Building Wireless Sensor Networks: Theoretical and Practical Perspectives; CRC Press: Boca Raton, FL, USA, 2015; p. 254. [Google Scholar]

- Burgués, J.; Marco, S. Low Power Operation of Temperature-Modulated Metal Oxide Semiconductor Gas Sensors. Sensors 2018, 18, 339. [Google Scholar] [CrossRef] [PubMed]

- Peterson, P.J.D.; Aujla, A.; Grant, K.H.; Brundle, A.G.; Thompson, M.R.; Vande Hey, J.; Leigh, R.J. Practical Use of Metal Oxide Semiconductor Gas Sensors for Measuring Nitrogen Dioxide and Ozone in Urban Environments. Sensors 2017, 17, 1653. [Google Scholar] [CrossRef] [PubMed]

- Baranov, A.; Spirjakin, D.; Akbari, S.; Somov, A. Optimization of power consumption for gas sensor nodes: A survey. Sens. Actuators A Phys. 2015, 233, 279–289. [Google Scholar] [CrossRef]

- Figaro Engineering Inc. Figaro Combustible Gas Sensors. 2019. Available online: http://www.figarosensor.com/feature/combustible-gas-sensors.html (accessed on 28 June 2019).

- Standard EN50194-2000. Electrical Apparatus for the Detection of Combustible Gases in Domestic Premises: Test Methods and Performance Requirements; CENELEC: Brussels, Belgium, 2000. [Google Scholar]

- Ihokura, K.; Watson, J. The Stannic Oxide Gas Sensor Principles and Applications; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Piyare, R.; Murphy, A.L.; Magno, M.; Benini, L. On-Demand LoRa: Asynchronous TDMA for Energy Efficient and Low Latency Communication in IoT. Sensors 2018, 18, 3718. [Google Scholar] [CrossRef] [PubMed]

- Darroudi, S.M.; Caldera-Sànchez, R.; Gomez, C. Bluetooth Mesh Energy Consumption: A Model. Sensors 2019, 19, 1238. [Google Scholar] [CrossRef] [PubMed]

- Addabbo, T.; Fort, A.; Mugnaini, M.; Parri, L.; Parrino, S.; Pozzebon, A.; Vignoli, V. A low power IoT architecture for the monitoring of chemical emissions. Acta IMEKO 2019, 8, 53–61. [Google Scholar] [CrossRef]

- Yin, X.; Zhang, L.; Tian, F.; Zhang, D. Temperature Modulated Gas Sensing E-Nose System for Low-Cost and Fast Detection. IEEE Sens. J. 2016, 16, 464–474. [Google Scholar] [CrossRef]

- Baek, Y.; Atiq, M.K.; Kim, H.S. Adaptive Preheating Duration Control for Low-Power Ambient Air Quality Sensor Networks. Sensors 2014, 14, 5536–5551. [Google Scholar] [CrossRef] [PubMed]

- Macías, M.M.; Orellana, C.J.G.; Velasco, H.M.G.; Manso, A.G.; Garzón, J.E.A.; Santamaría, H.S. Gas sensor measurements during the initial action period of duty-cycling for power saving. Sens. Actuators B Chem. 2017, 239, 1003–1009. [Google Scholar] [CrossRef]

- Dutta, P.K.; Culler, D.E. System software techniques for low-power operation in wireless sensor networks. In Proceedings of the IEEE/ACM International Conference on Computer-Aided Design, Digest of Technical Papers, ICCAD, San Jose, CA, USA, 6–10 November 2005; Volume 2005, pp. 924–931. [Google Scholar]

- Alippi, C.; Anastasi, G.; Di Francesco, M.; Roveri, M. Energy management in wireless sensor networks with energy-hungry sensors. IEEE Instrum. Meas. Mag. 2009, 12, 16–23. [Google Scholar] [CrossRef]

- Figaro Engineering Inc. Technical Information on Usage of TGS Sensors for Toxic and Explosive Gas Leak Detectors; Figaro Engineering Inc.: Osaka, Japan, 2005. [Google Scholar]

- Espressif IOT Team. ESP8286EX Datasheet. 2018. Available online: https://www.espressif.com/sites/default/files/documentation/0a-esp8266ex_datasheet_en.pdf (accessed on 15 March 2019).

- Espressif IOT Team. ESP8286 Low Power Solutions. 2018. Available online: https://www.espressif.com/sites/default/files/documentation/9b-esp8266-low_power_solutions_en.pdf (accessed on 15 March 2019).

- Figaro Engineering Inc. Technical Information for TGS2620. 2013. Available online: http://www.figarosensor.com/product/data/Long%202620C00%20Layout%201013.pdf (accessed on 10 June 2019).

- Dutta, L.; Talukdar, C.; Hazarika, A.; Bhuyan, M. A Novel Low-Cost Hand-Held Tea Flavor Estimation System. IEEE Trans. Ind. Electron. 2018, 65, 4983–4990. [Google Scholar] [CrossRef]

- Itoh, T.; Akamatsu, T.; Tsuruta, A.; Shin, W. Selective detection of target volatile organic compounds in contaminated humid air using a sensor array with principal component analysis. Sensors 2017, 17, 1662. [Google Scholar]

- Kiani, S.; Minaei, S.; Ghasemi-Varnamkhasti, M. Real-time aroma monitoring of mint (Mentha spicata L.) leaves during the drying process using electronic nose system. Measurement 2018, 124, 447–452. [Google Scholar] [CrossRef]

- Romain, A.; Nicolas, J. Long term stability of metal oxide-based gas sensors for e-nose environmental applications: An overview. Sens. Actuators B Chem. 2010, 146, 502–506. [Google Scholar] [CrossRef]

- Macías Macías, M.; Agudo, J.E.; García Manso, A.; Orellana García, C.J.; González Velasco, H.M.; Gallardo Caballero, R. Improving Short Term Instability for Quantitative Analyses with Portable Electronic Noses. Sensors 2014, 14, 10514–10526. [Google Scholar] [CrossRef] [PubMed]

- Texas Instruments. ADS1100 Datasheet. 2003. Available online: http://www.ti.com/lit/ds/symlink/ads1100.pdf (accessed on 25 March 2019).

- ThingSpeak Home Page. Available online: http://www.thingspeak.com (accessed on 15 March 2019).

| Item | Modem-Sleep | Light-Sleep | Deep-Sleep |

|---|---|---|---|

| GPIO state | unchanged | unchanged | unchanged |

| Wi-Fi | OFF | OFF | OFF |

| System clock | ON | OFF | OFF |

| RTC | ON | ON | ON |

| CPU | ON | Pending | OFF |

| Substrate current | 15 mA | 0.4 mA | ≈20 A |

| Item | Measuring | Uploading to IoT | Waiting between Measurements |

|---|---|---|---|

| ESP8266-CPU | ON | ON | Deep-Sleep |

| ESP8266-Wi-Fi | OFF | ON | OFF |

| Measurement circuit | ON | OFF | OFF |

| Expected consumption | ≈60 mA | ≈85 mA (with peaks) | ≈20 A |

| Jumper | Expected Current | Measured Real Value | Consumed Charge in 60 s | Consumed Charge in 120 s | Consumed Charge in 240 s |

|---|---|---|---|---|---|

| JP_PW (Global) | ≈46 A | 42.8 A | 2.57 mAs | 5.14 mAs | 10.27 mAs |

| JP_PW2 (Meas. Circuit) | ≈0 A | 0.02 A | 1.2 As | 2.4 As | 4.8 As |

| JP_PW3 (ESP8266) | ≈20 A | 28.6 A | 1.72 mAs | 3.43 mAs | 6.9 mAs |

| Measurement Time () | Average Current | Average Active Time | Consumed Charge |

|---|---|---|---|

| 1 s | 69.3 mA | 1.48 s | 102.6 mAs |

| 2 s | 79.1 mA | 2.44 s | 193.9 mAs |

| 3 s | 84.3 mA | 3.47 s | 292.5 mAs |

| 4 s | 80.5 mA | 4.45 s | 358.1 mAs |

| 5 s | 81.5 mA | 5.43 s | 443.4 mAs |

| Measurement Time () | Number of Measurements () | Deep-Sleep Time () | Cycle Time () | Cycle Charge () | Battery Duration () in Days |

|---|---|---|---|---|---|

| 1 | 5 | 60 s | 310.4 s | 776.8 mAs | 12.5 |

| 2 | 1 | 120 s | 120.6 s | 417.8 mAs | 9.4 |

| 2 | 5 | 120 s | 615.4 s | 1211.8 mAs | 15.9 |

| 2 | 5 | 180 s | 915.4 s | 1225.6 mAs | 23.4 |

| 1 | 10 | 180 s | 1827.6 s | 2229.94 mAs | 25.6 |

| 2 | 5 | 240 s | 1215.4 s | 1237.5 mAs | 30.7 |

| 3 | 5 | 240 s | 1220.4 s | 1659.6 mAs | 23.0 |

| 1 | 10 | 240 s | 2417.4 s | 1411.3 mAs | 53.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Orellana, C.J.; Macías-Macías, M.; González-Velasco, H.M.; García-Manso, A.; Gallardo-Caballero, R. Low-Power and Low-Cost Environmental IoT Electronic Nose Using Initial Action Period Measurements. Sensors 2019, 19, 3183. https://doi.org/10.3390/s19143183

García-Orellana CJ, Macías-Macías M, González-Velasco HM, García-Manso A, Gallardo-Caballero R. Low-Power and Low-Cost Environmental IoT Electronic Nose Using Initial Action Period Measurements. Sensors. 2019; 19(14):3183. https://doi.org/10.3390/s19143183

Chicago/Turabian StyleGarcía-Orellana, Carlos J., Miguel Macías-Macías, Horacio M. González-Velasco, Antonio García-Manso, and Ramón Gallardo-Caballero. 2019. "Low-Power and Low-Cost Environmental IoT Electronic Nose Using Initial Action Period Measurements" Sensors 19, no. 14: 3183. https://doi.org/10.3390/s19143183

APA StyleGarcía-Orellana, C. J., Macías-Macías, M., González-Velasco, H. M., García-Manso, A., & Gallardo-Caballero, R. (2019). Low-Power and Low-Cost Environmental IoT Electronic Nose Using Initial Action Period Measurements. Sensors, 19(14), 3183. https://doi.org/10.3390/s19143183