Performance Comparison of Three Fibre-Based Reflective Optical Sensors for Aero Engine Monitorization

Abstract

1. Introduction

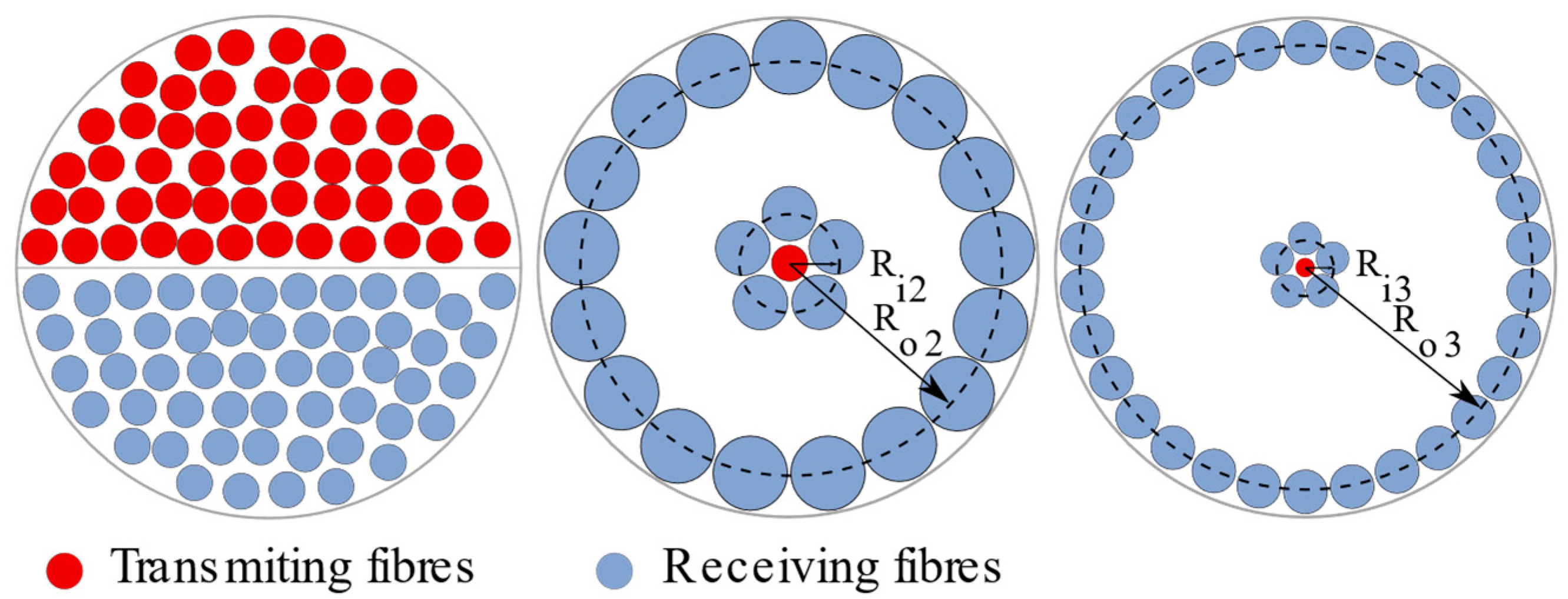

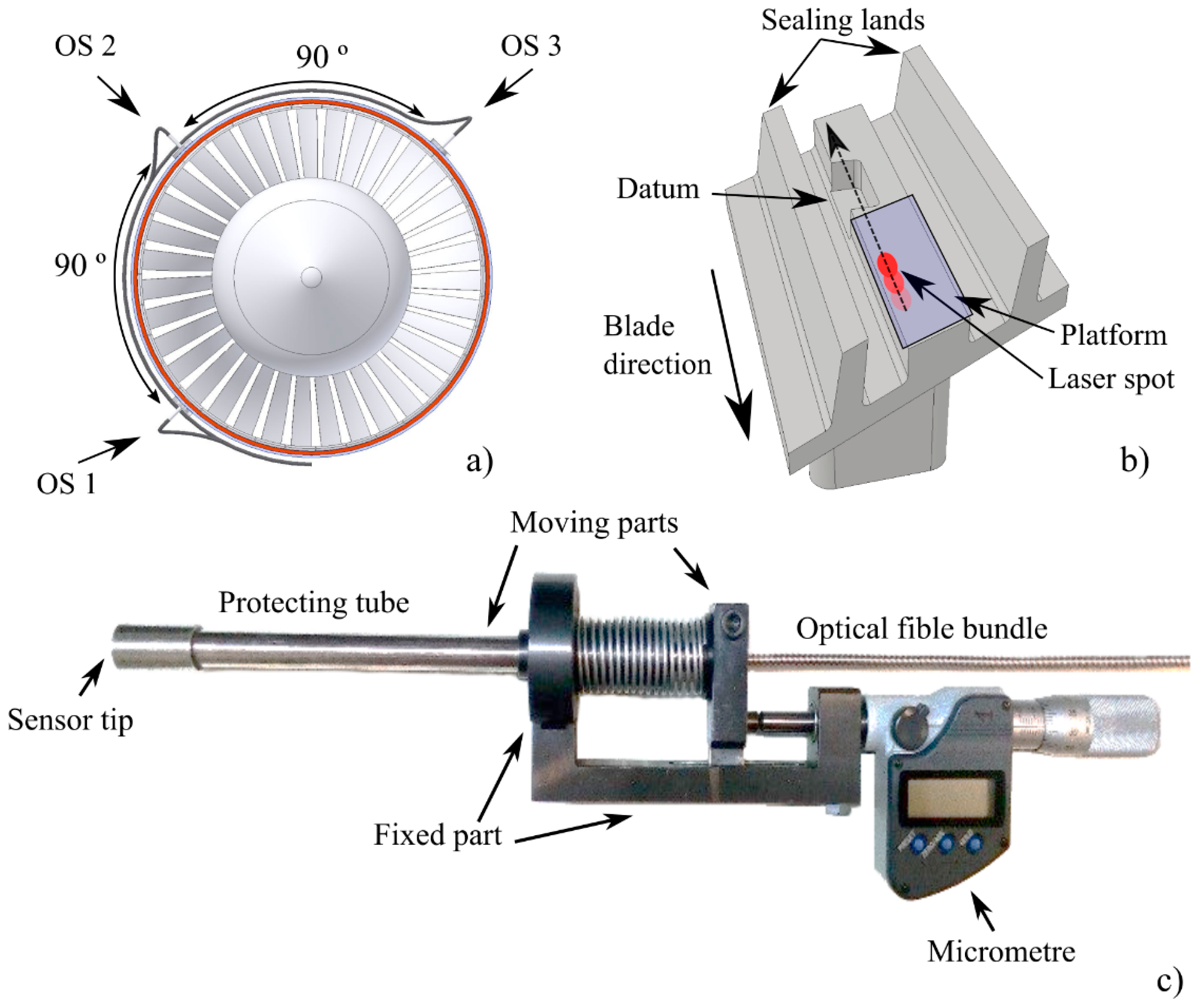

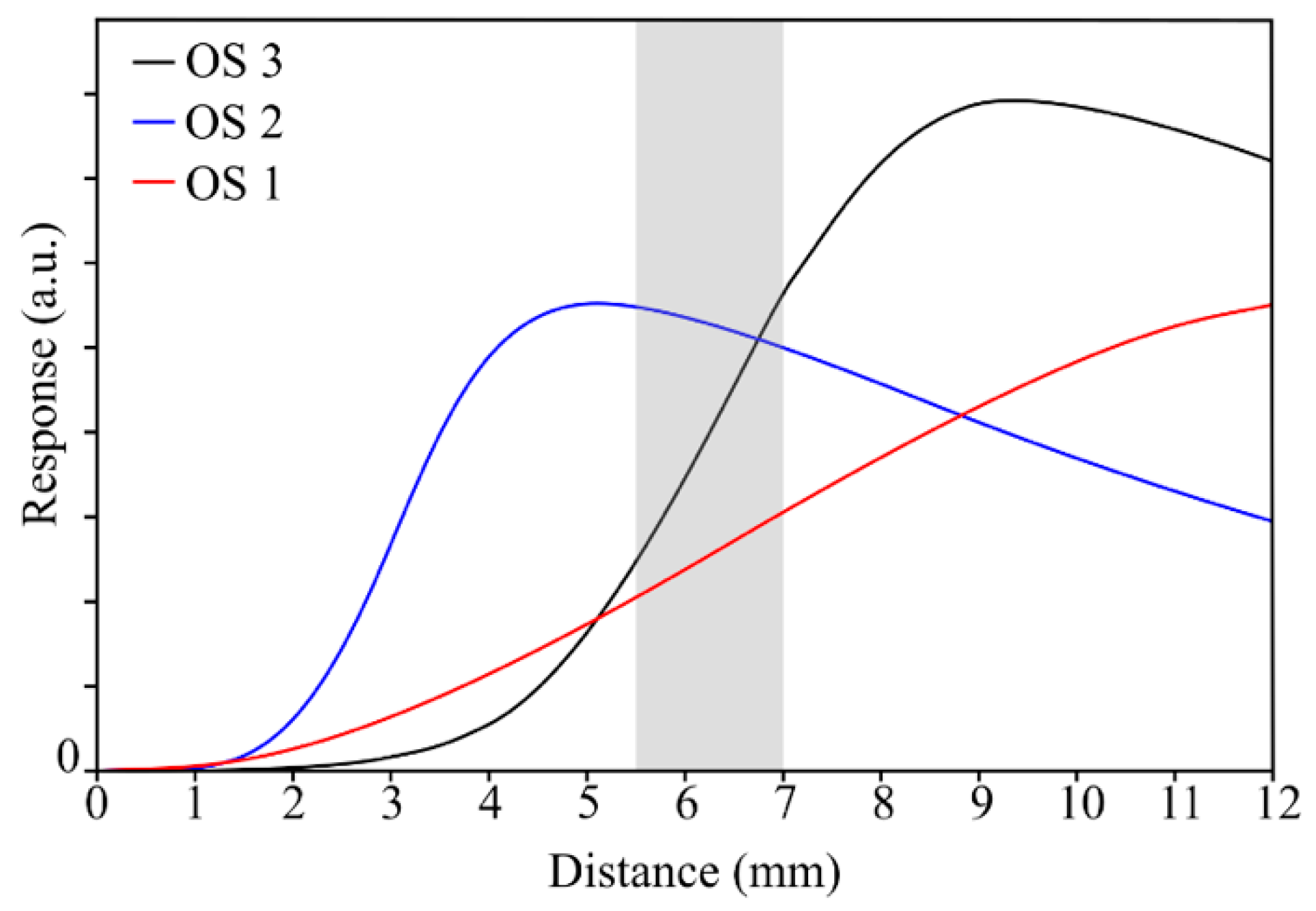

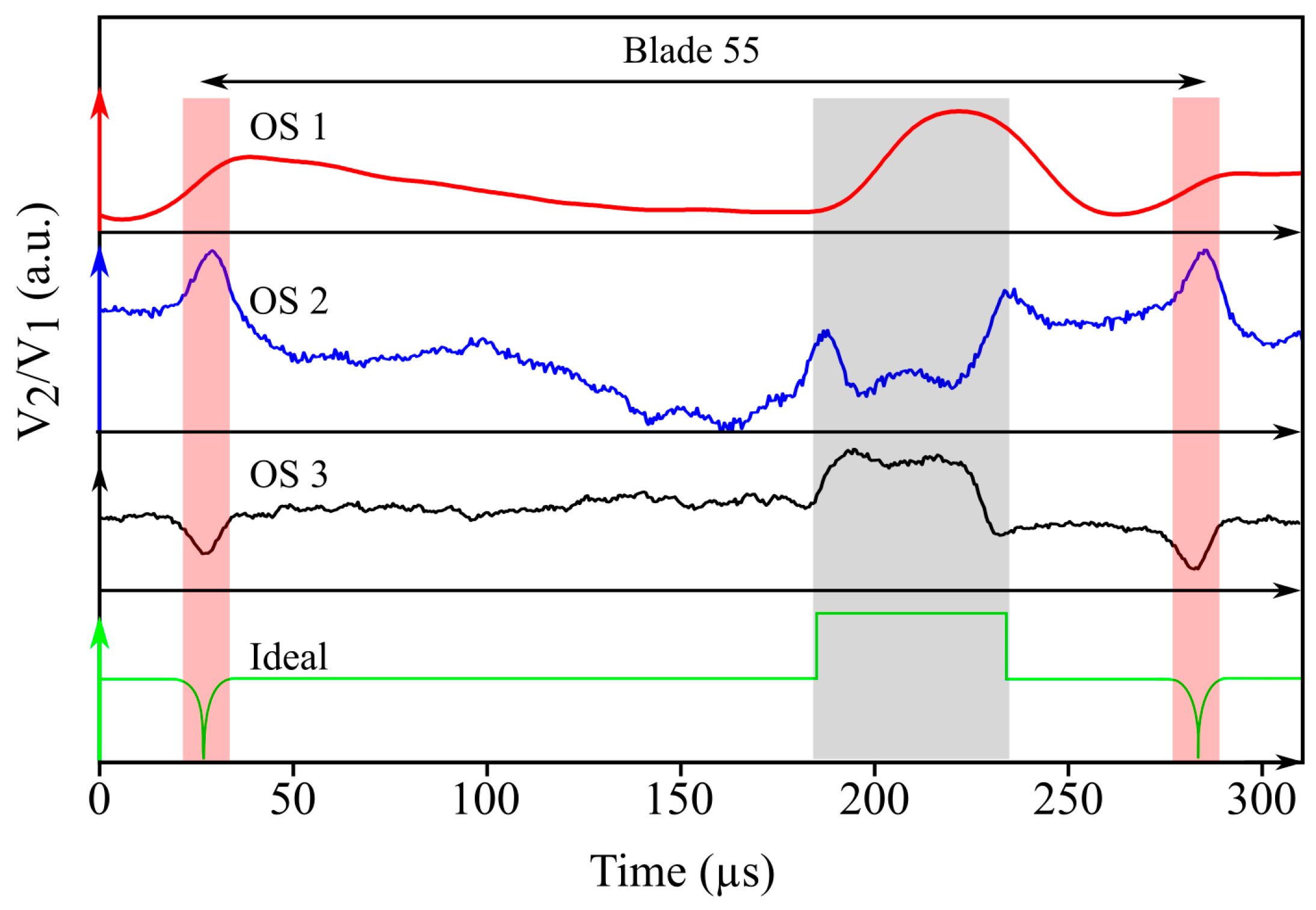

2. Materials and Methods

2.1. Description of the Setup

2.2. Assembly, Calibration, and Tests Program

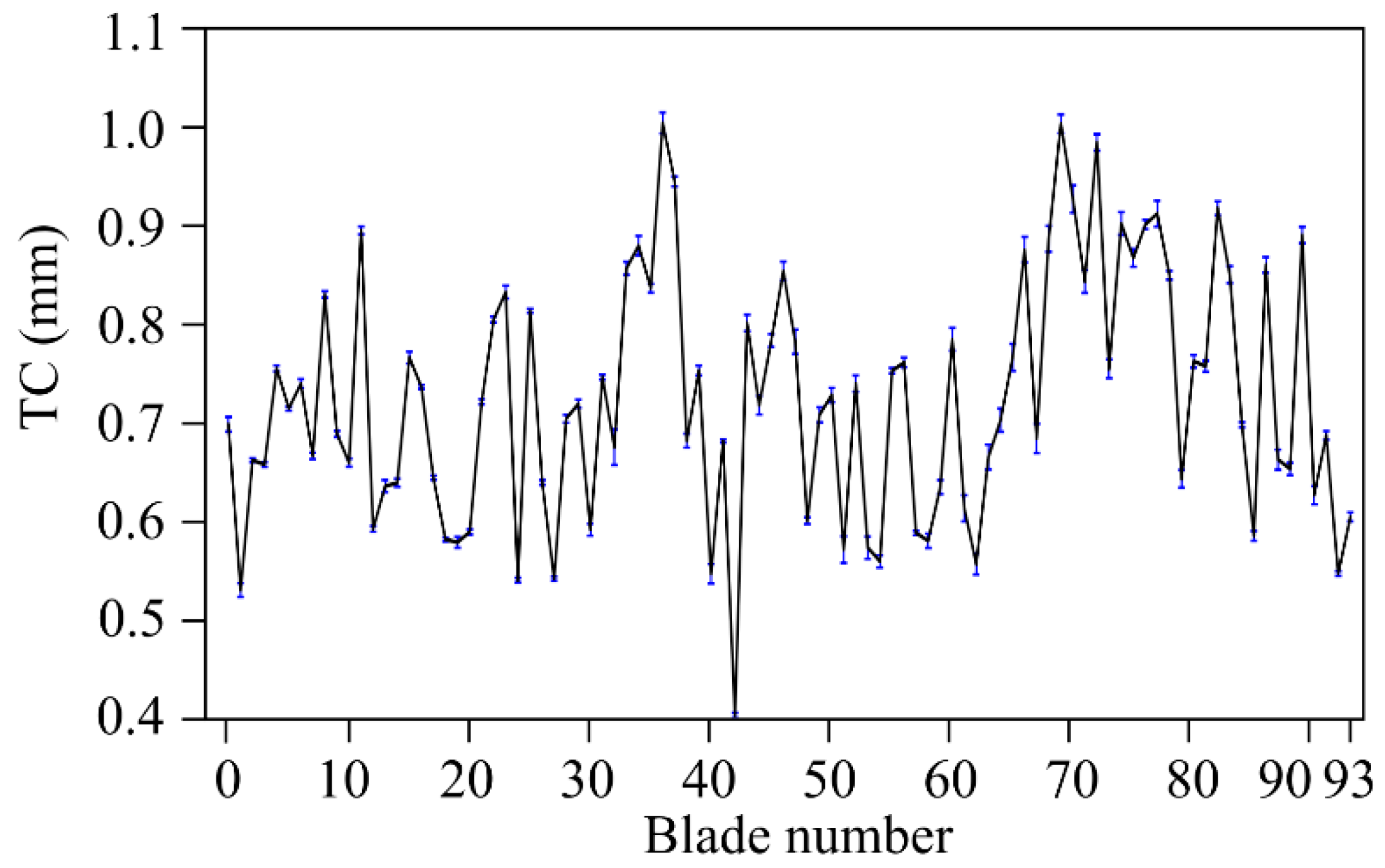

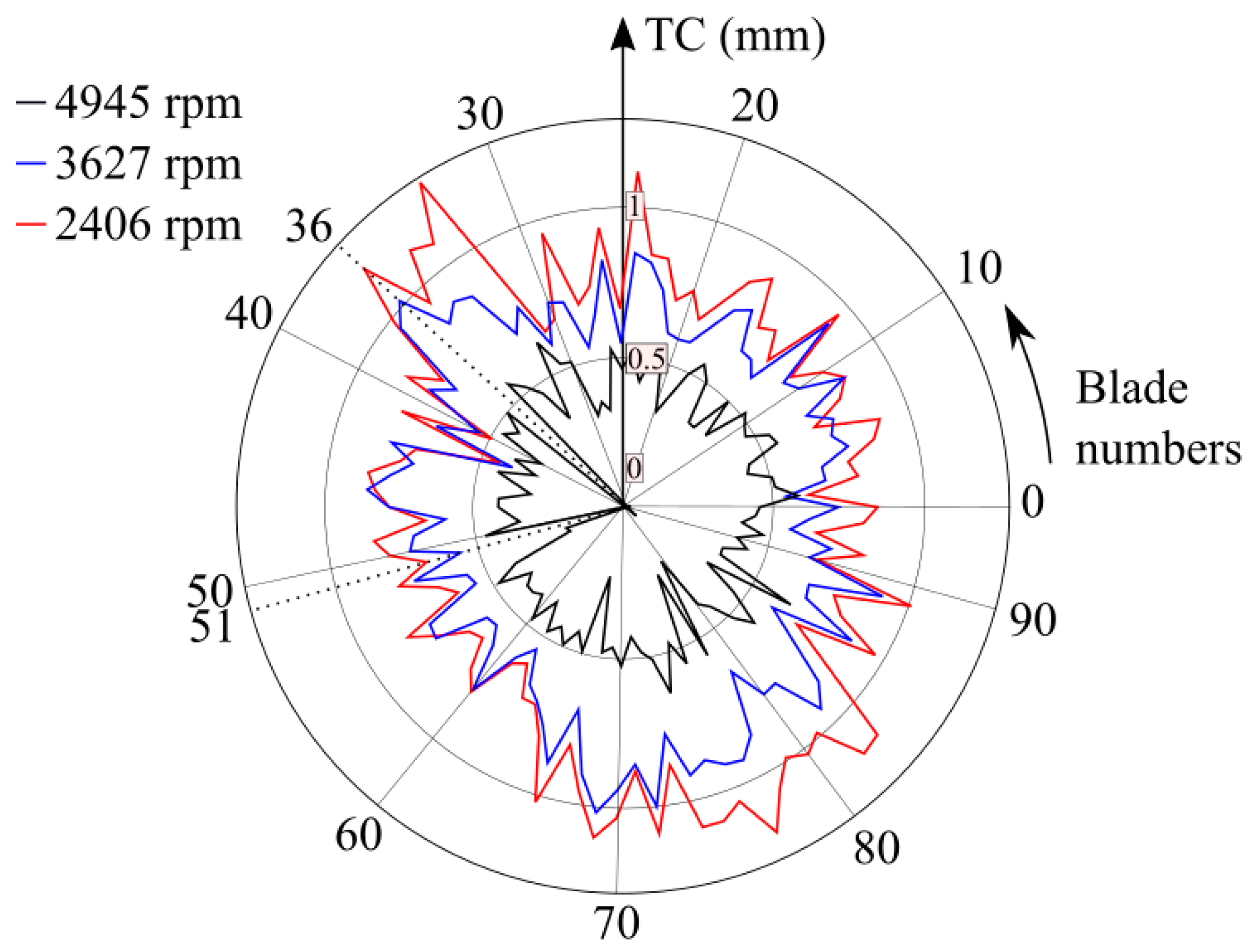

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Holeski, D.E.; Futral, S.M., Jr. Effect of Rotor Tip Clearance on the Performance of a 5-Inch Single-Stage Axial-Flow Turbine; NASA Scientific and Technical Publications: Springfield, VA, USA, March 1969.

- Venter, S.J.; Kröger, D.G. The effect of tip clearance on the performance of an axial flow fan. Energy Convers. Manag. 1992, 33, 89–97. [Google Scholar] [CrossRef]

- Durana, G.; Amorebieta, J.; Fernández, R.; Beloki, J.; Arrospide, E.; García, I.; Zubia, J. Design, fabrication and testing of a high-sensitive fibre sensor for tip clearance measurements. Sensors 2018, 18, 2610. [Google Scholar] [CrossRef] [PubMed]

- Wiseman, M.W.; Guo, T.-H. An investigation of life extending control techniques for gas turbine engines. In Proceedings of the 2001 American Control Conference (Cat. No.01CH37148), Arlington, VA, USA, 25–27 June 2001; Volume 5, pp. 3706–3707. [Google Scholar] [CrossRef]

- Lattime, S.B.; Steinetz, B.M. High-Pressure-Turbine Clearance Control Systems: Current Practices and Future Directions. J. Propuls. Power 2004, 20, 302–311. [Google Scholar] [CrossRef]

- Miller, K.; Key, N.; Fulayter, R. Tip Clearance Effects on the Final Stage of an HPC. In Proceedings of the 45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Denver, CO, USA, 2–5 August 2009. [Google Scholar] [CrossRef]

- Neuhaus, L.; Neise, W. Active Control to Improve the Aerodynamic Performance and Reduce the Tip Clearance Noise of Axial Turbomachines. In Proceedings of the 11th AIAA/CEAS Aeroacoustics Conference, Monterey, CA, USA, 23–25 May 2005. [Google Scholar] [CrossRef]

- Steinetz, B.M.; Taylor, S.; Jay, O.; DeCastro, J.A. Seal Investigations of an Active Clearance Control System Concept; NASA/TM—2006-214114; NASA Glenn Research Center: Cleveland, OH, USA, 2006.

- Sheard, A.G. Blade by Blade Tip Clearance Measurement. Int. J. Rotating Mach. 2011, 2011, 516128. [Google Scholar] [CrossRef]

- Haase, W.C.; Haase, Z.S. High-Speed, capacitance-based tip clearance sensing. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 2–9 March 2013; pp. 1–8. [Google Scholar] [CrossRef]

- Ye, D.C.; Duan, F.J.; Guo, H.T.; Li, Y.; Wang, K. Turbine blade tip clearance measurement using a skewed dual-beam fiber optic sensor. Opt. Eng. 2012, 51, 081514. [Google Scholar] [CrossRef]

- Sheard, A.; O’Donnell, S.; Stringfellow, J. High Temperature Proximity Measurement in Aero and Industrial Turbomachinery. J. Eng. Gas Turbines Power 1999, 121, 167–173. [Google Scholar] [CrossRef]

- Roeseler, C.; von Flotow, A.; Tappert, P. Monitoring blade passage in turbomachinery through the engine case (no holes). In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 9–16 March 2002; Volume 6, pp. 3125–3129. [Google Scholar] [CrossRef]

- Du, L.; Zhu, X.; Zhe, J. A high sensitivity inductive sensor for blade tip clearance measurement. Smart Mater. Struct. 2014, 23. [Google Scholar] [CrossRef]

- Cao, S.Z.; Duan, F.J.; Zhang, Y.G. Measurement of rotating blade tip clearance with fiber-optic probe. J. Phys. Conf. Ser. 2006, 48, 873–877. [Google Scholar] [CrossRef]

- Vakhtin, A.B.; Chen, S.J.; Massick, S.M. Optical probe for monitoring blade tip clearance. In Proceedings of the 47th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009. [Google Scholar] [CrossRef]

- Dhadwal, H.S.; Kurkov, A.P. Dual-Laser Probe Measurement of Blade-Tip Clearance. ASME J. Turbomach. 1999, 121, 481–485. [Google Scholar] [CrossRef]

- Sinha, J.K. Vibration Engineering and Technology of Machinery; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar]

- Davidson, D.P.; DeRose, R.D.; Wennerstrom, A.J. The Measurement of Turbomachinery Stator-to-Drum Running Clearances. In Proceedings of the ASME 1983 International Gas Turbine Conference and Exhibit, Phoenix, AZ, USA, 27–31 March 1983; ASME: New York, NY, USA, 1983; Volume 1, p. V001T01A054. [Google Scholar] [CrossRef]

- Schicht, A.; Schwarzer, S.; Schmidt, L.P. Tip clearance measurement technique for stationary gas turbines using an autofocusing millimeter-wave synthetic aperture radar. IEEE Trans. Instrum. Meas. 2012, 61, 1778–1785. [Google Scholar] [CrossRef]

- Violetti, M.; Skrivervik, A.K.; Xu, Q.; Hafner, M. New microwave sensing system for blade tip clearance measurement in gas turbines. In Proceedings of the 2012 IEEE Sensors, Taipei, Taiwan, 28–31 October 2012; pp. 1–4. [Google Scholar] [CrossRef]

- Szczepanik, R.; Przysowa, R.; Spychała, J.; Rokicki, E.; Kaźmierczak, K.; Majewski, P. Application of Blade-Tip Sensors to Blade-Vibration Monitoring in Gas Turbines; INTECH Open Access Publisher: Rijeka, Croatia, 2012. [Google Scholar]

- Chivers, J.W.H. Microwave Interferometer. U.S. Patent 4,359,683, 16 November 1982. [Google Scholar]

- Woolcock, S.C.; Brown, E.G. Checking the Location of Moving Parts in a Machine. U.S. Patent 4,346,383, 24 August 1982. [Google Scholar]

- Kempe, A.; Schlamp, S.; Rósben, T.; Haffner, K. Spatial and Temporal High-Resolution Optical Tip-Clearance Probe for Harsh Environments. In Proceedings of the 13th International Symposium on Applications of Laser Techniques to Fluid Mechanics, Lisbon, Portugal, 26–29 June 2006. [Google Scholar]

- García, I.; Zubia, J.; Durana, G.; Aldabaldetreku, G.; Illarramendi, M.A.; Villatoro, J. Optical Fiber Sensors for Aircraft Structural Health Monitoring. Sensors 2015, 15, 15494–15519. [Google Scholar] [CrossRef]

- López-Higuera, J.M. (Ed.) Handbook of Optical Fibre Sensing Technology; Wiley: New York, NY, USA, 2002; ISBN 978-0-471-82053-6. [Google Scholar]

- García, I.; Beloki, J.; Zubia, J.; Durana, G.; Aldabaldetreku, G. Turbine-blade tip clearance and tip timing measurements using an optical fiber bundle sensor. In Proceedings of the SPIE 87883H Optical Measurement Systems for Industrial Inspection VIII, Munich, Germany, 13 May 2013. [Google Scholar] [CrossRef]

- García, I.; Beloki, J.; Zubia, J.; Aldabaldetreku, G.; Illarramendi, M.A.; Jiménez, F. An Optical Fiber Bundle Sensor for Tip Clearance and Tip Timing Measurements in a Turbine Rig. Sensors 2013, 13, 7385–7398. [Google Scholar] [CrossRef] [PubMed]

- Pfister, T.; Büttner, L.; Czarske, J.; Krain, H.; Schodl, R. Turbo machine tip clearance and vibration measurements using a fiber optic laser Doppler position sensor. Meas. Sci. Technol. 2006, 17, 1693–1705. [Google Scholar] [CrossRef]

- Kempe, A.; Schlamp, S.; Rösgen, T.; Haffner, K. Low-coherence interferometric tip-clearance probe. Opt. Lett. 2003, 28, 1323–1325. [Google Scholar] [CrossRef] [PubMed]

- Barranger, J.P.; Ford, M.J. Laser-Optical Blade Tip Clearance Measurement System. J. Eng. Power 1981, 103, 457–460. [Google Scholar] [CrossRef]

- Matsuda, Y.; Tagashira, T. Optical Blade-Tip Clearance Sensor for Non-Metal Gas Turbine Blade. J. Gas Turbine Soc. Jpn. 2001, 29, 479–484. [Google Scholar]

- García, I.; Zubia, J.; Berganza, A.; Beloki, J.; Arrue, J.; Illarramendi, M.A.; Mateo, J.; Vázquez, C. Different Configurations of a Reflective Intensity-Modulated Optical Sensor to Avoid Modal Noise in Tip-Clearance Measurements. J. Lightwave Technol. 2015, 33, 2663–2669. [Google Scholar] [CrossRef]

- Ma, Y.-Z.; Zhang, Y.-K.; Li, G.-P.; Liu, H.-G. Tip Clearance Optical Measurement for Rotating Blades; MSIE: Harbin, China, 2011; pp. 1206–1208. [Google Scholar]

- García, I.; Przysowa, R.; Amorebieta, J.; Zubia, J. Tip-Clearance Measurement in the First Stage of the Compressor of an Aircraft Engine. Sensors 2016, 16, 1897. [Google Scholar] [CrossRef] [PubMed]

- Xie, S.; Zhang, X.; Wu, B.; Xiong, Y. Output characteristics of two-circle coaxial optical fiber bundle with regard to three-dimensional tip clearance. Opt. Express 2018, 26, 25244–25256. [Google Scholar] [CrossRef] [PubMed]

- Xie, S.; Zhang, X.; Xiong, Y.; Liu, H. Demodulation technique for 3-D tip clearance measurements based on output signals from optical fiber probe with three two-circle coaxial optical fiber bundles. Opt. Express 2019, 27, 12600–12615. [Google Scholar] [CrossRef] [PubMed]

- Philtec RC171. Available online: http://www.webcitation.org/78Bh7gnm9 (accessed on 7 May 2019).

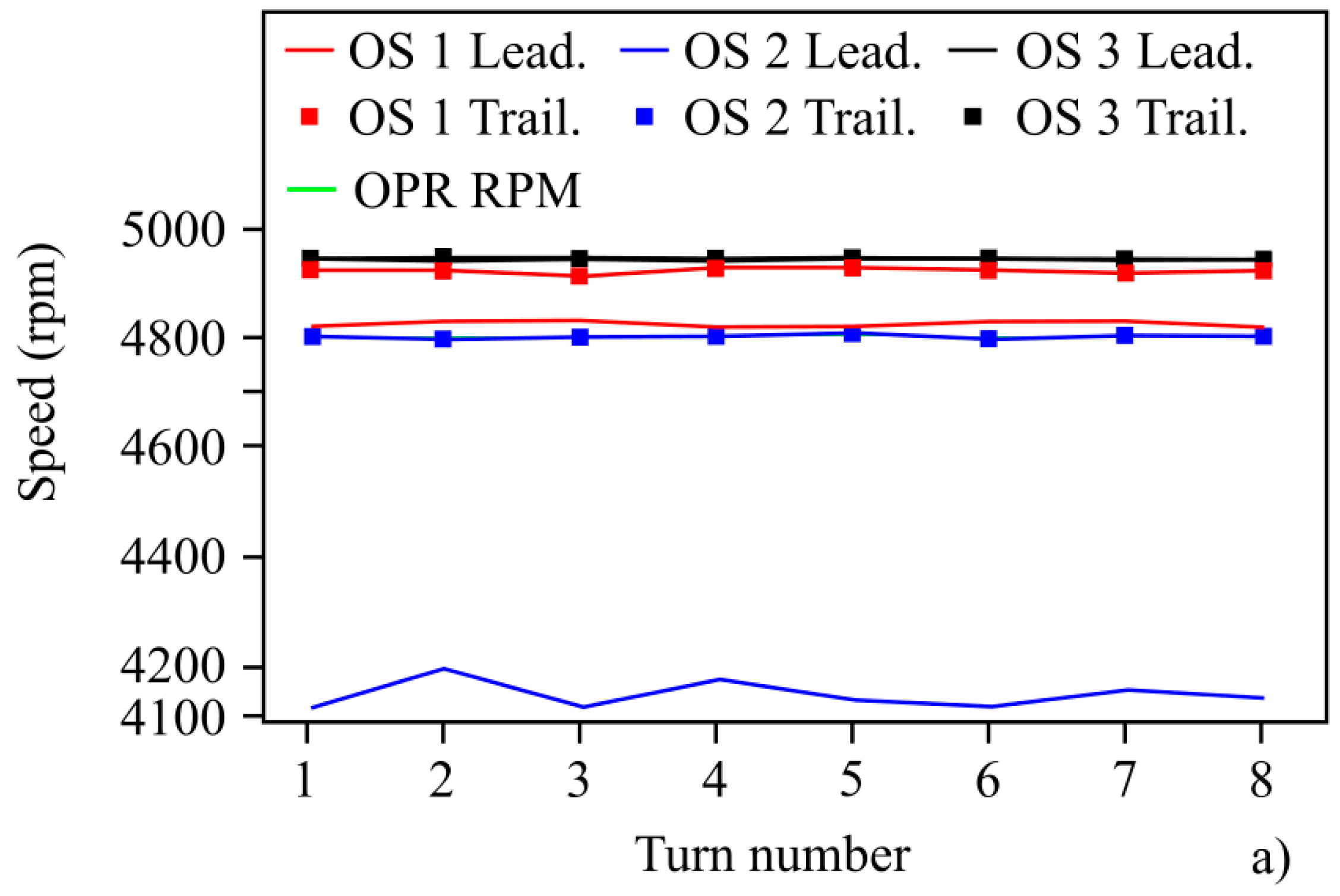

| Sensor | Mean (rpm) | Standard Deviation of the Mean (rpm) |

|---|---|---|

| OS 1 | −21.37 | ±3.06 |

| OS 2 | −141.74 | ±7.13 |

| OS 3 | 0.09 | ±0.40 |

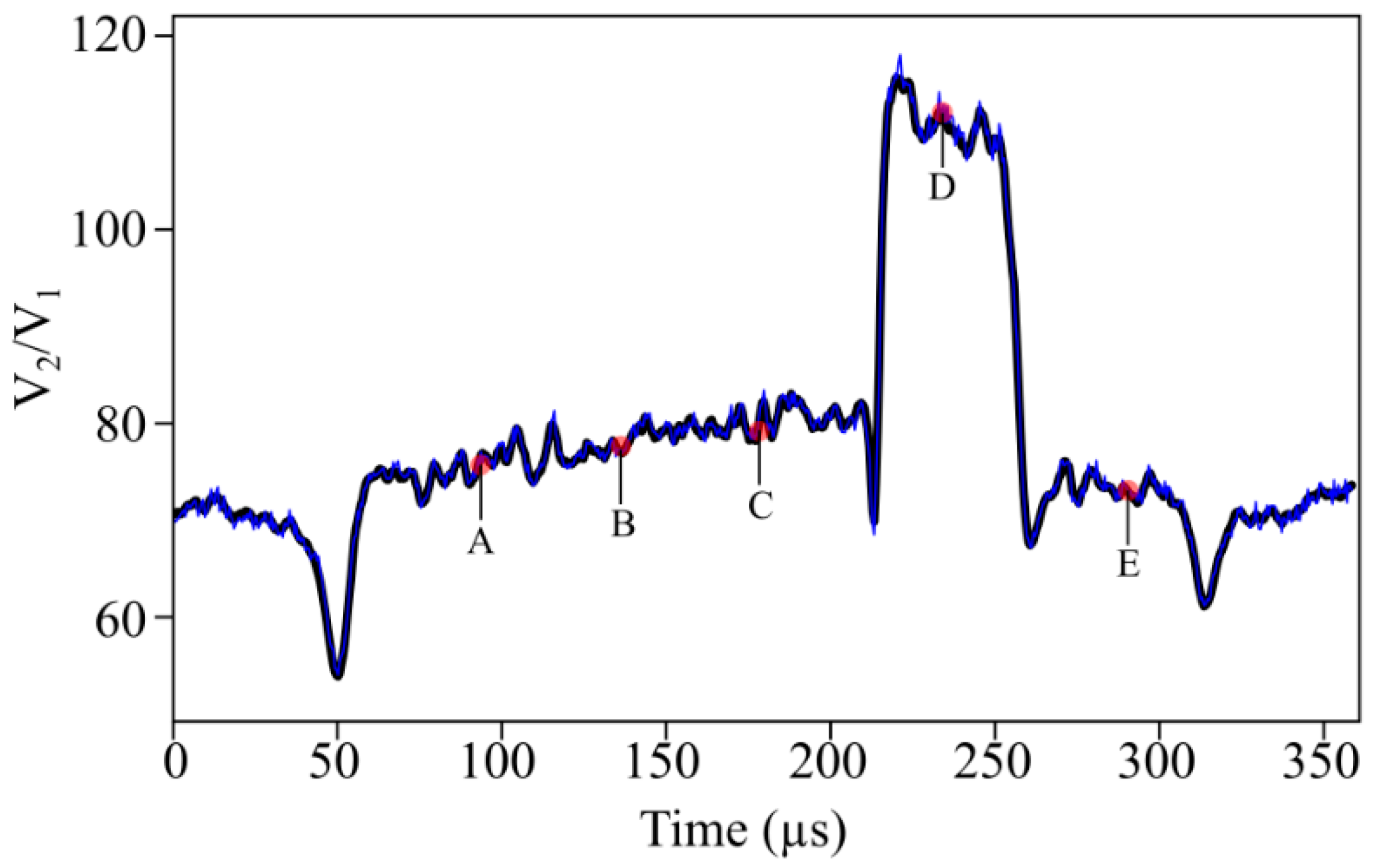

| Point | Mean Value and Standard Deviation (V2/V1) | Relative Standard Deviation (%) |

|---|---|---|

| A | 74.21 ± 0.53 | 3.5 |

| B | 77.91 ± 0.54 | 2.8 |

| C | 79.28 ± 0.64 | 3.3 |

| D | 114.62 ± 0.73 | 1.3 |

| E | 73.05 ± 0.64 | 4.6 |

| Rpm | TC without Correction (mm) | TC with Correction (mm) |

|---|---|---|

| 2406 | 0.2 | 0.6 |

| 3627 | 0.3 | 0.5 |

| 4945 | −0.2 | 0.4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández-Bello, R.; Amorebieta, J.; Beloki, J.; Aldabaldetreku, G.; García, I.; Zubia, J.; Durana, G. Performance Comparison of Three Fibre-Based Reflective Optical Sensors for Aero Engine Monitorization. Sensors 2019, 19, 2244. https://doi.org/10.3390/s19102244

Fernández-Bello R, Amorebieta J, Beloki J, Aldabaldetreku G, García I, Zubia J, Durana G. Performance Comparison of Three Fibre-Based Reflective Optical Sensors for Aero Engine Monitorization. Sensors. 2019; 19(10):2244. https://doi.org/10.3390/s19102244

Chicago/Turabian StyleFernández-Bello, Rubén, Josu Amorebieta, Josu Beloki, Gotzon Aldabaldetreku, Iker García, Joseba Zubia, and Gaizka Durana. 2019. "Performance Comparison of Three Fibre-Based Reflective Optical Sensors for Aero Engine Monitorization" Sensors 19, no. 10: 2244. https://doi.org/10.3390/s19102244

APA StyleFernández-Bello, R., Amorebieta, J., Beloki, J., Aldabaldetreku, G., García, I., Zubia, J., & Durana, G. (2019). Performance Comparison of Three Fibre-Based Reflective Optical Sensors for Aero Engine Monitorization. Sensors, 19(10), 2244. https://doi.org/10.3390/s19102244