Implementation of Virtual Sensors for Monitoring Temperature in Greenhouses Using CFD and Control

Abstract

1. Introduction

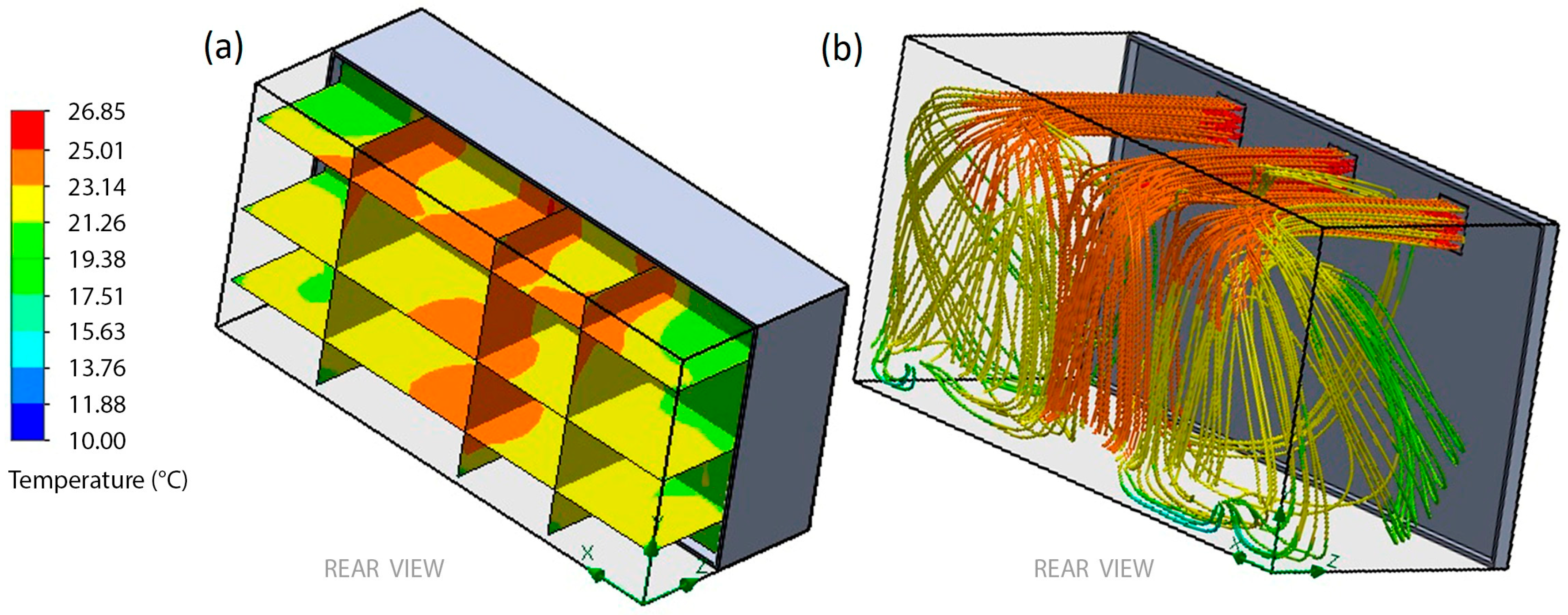

2. Materials and Methods

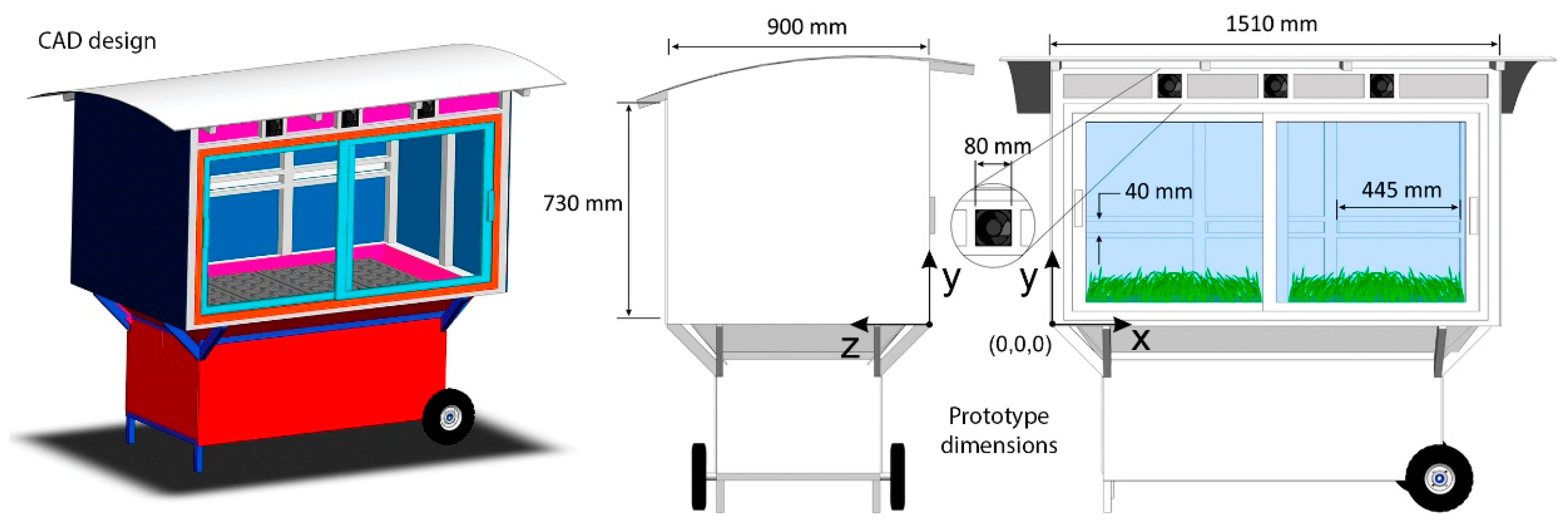

2.1. Greenhouse Design

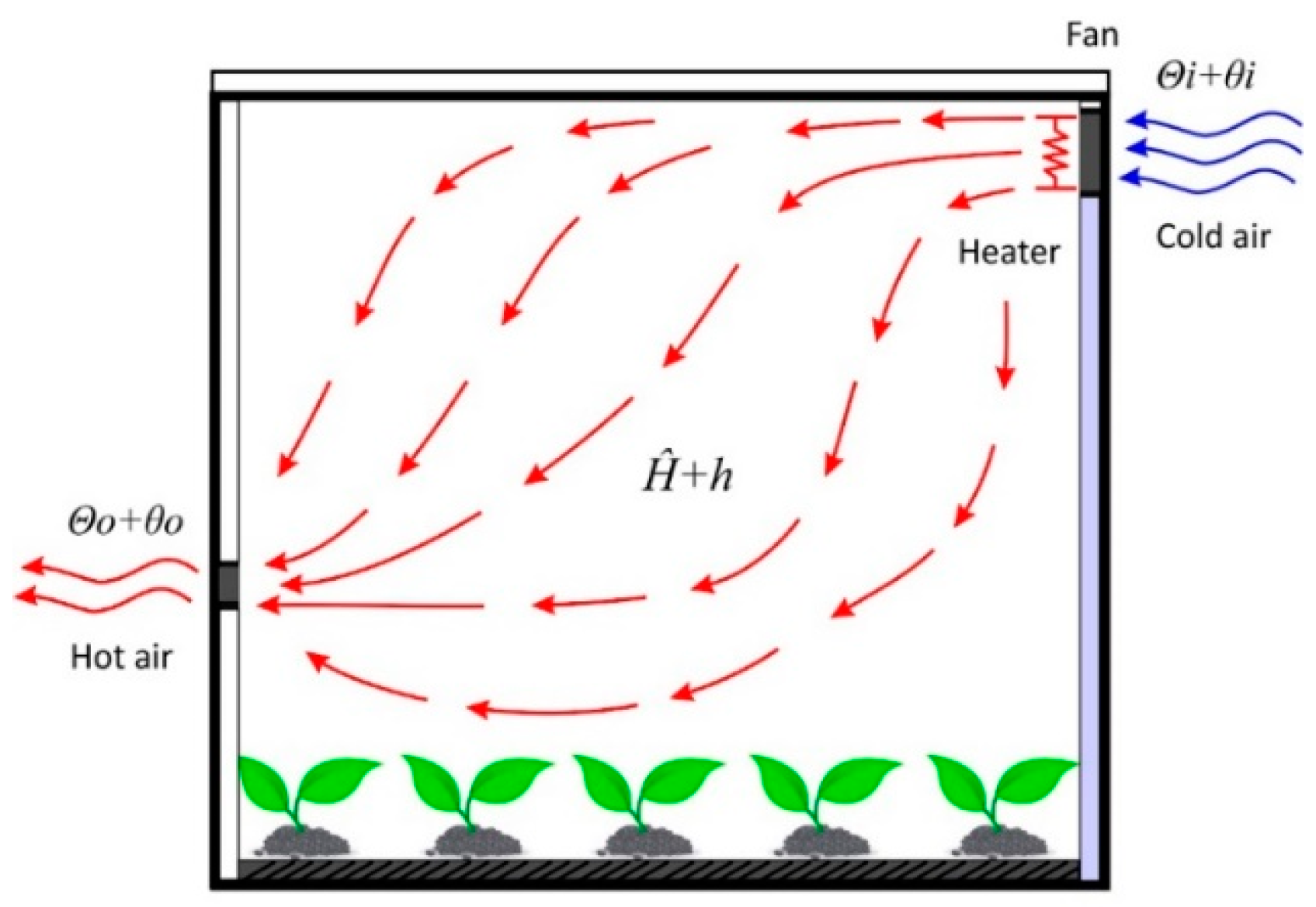

2.2. Modeling

2.3. Governing Equations

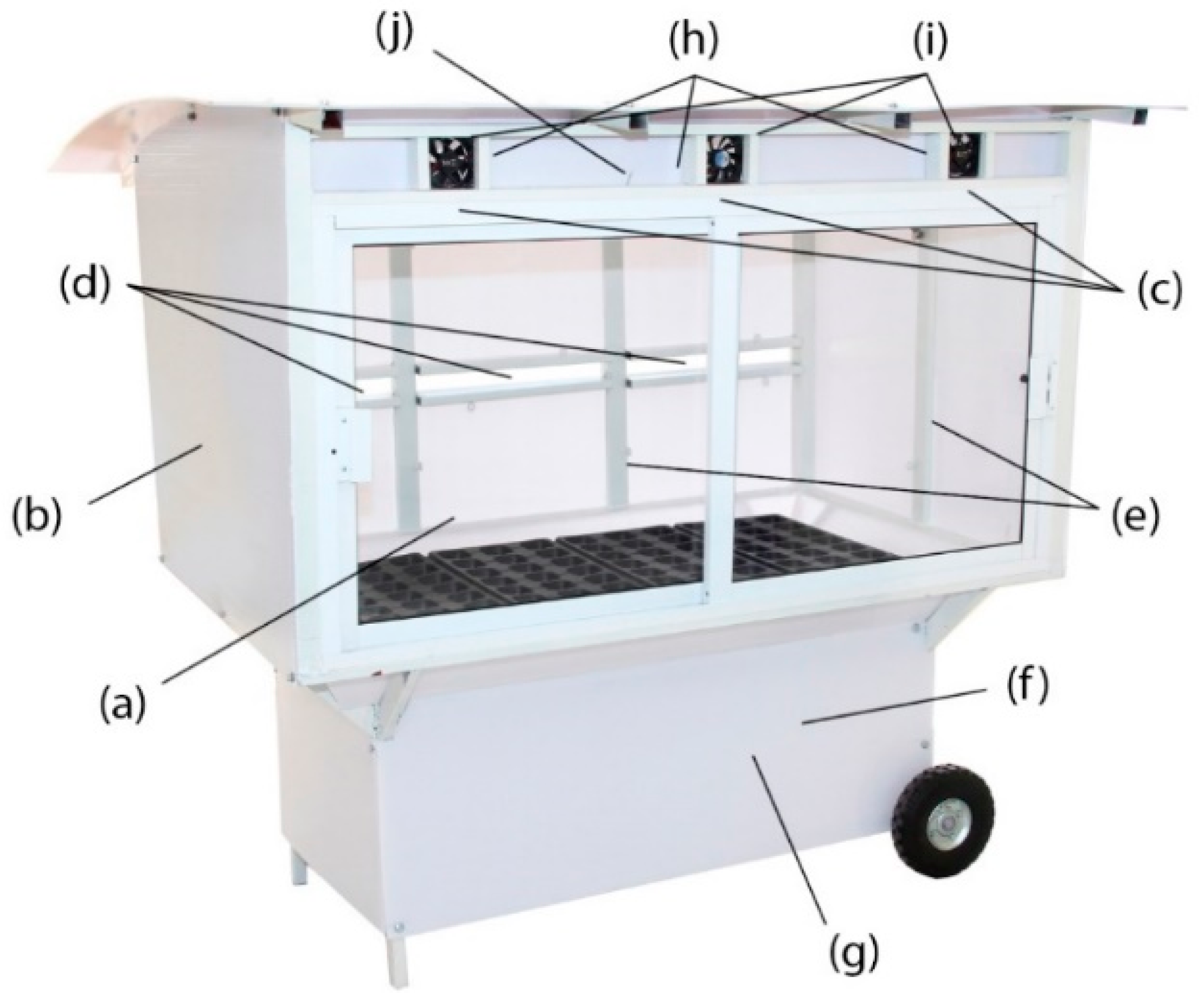

2.4. Greenhouse Fabrication

3. Results

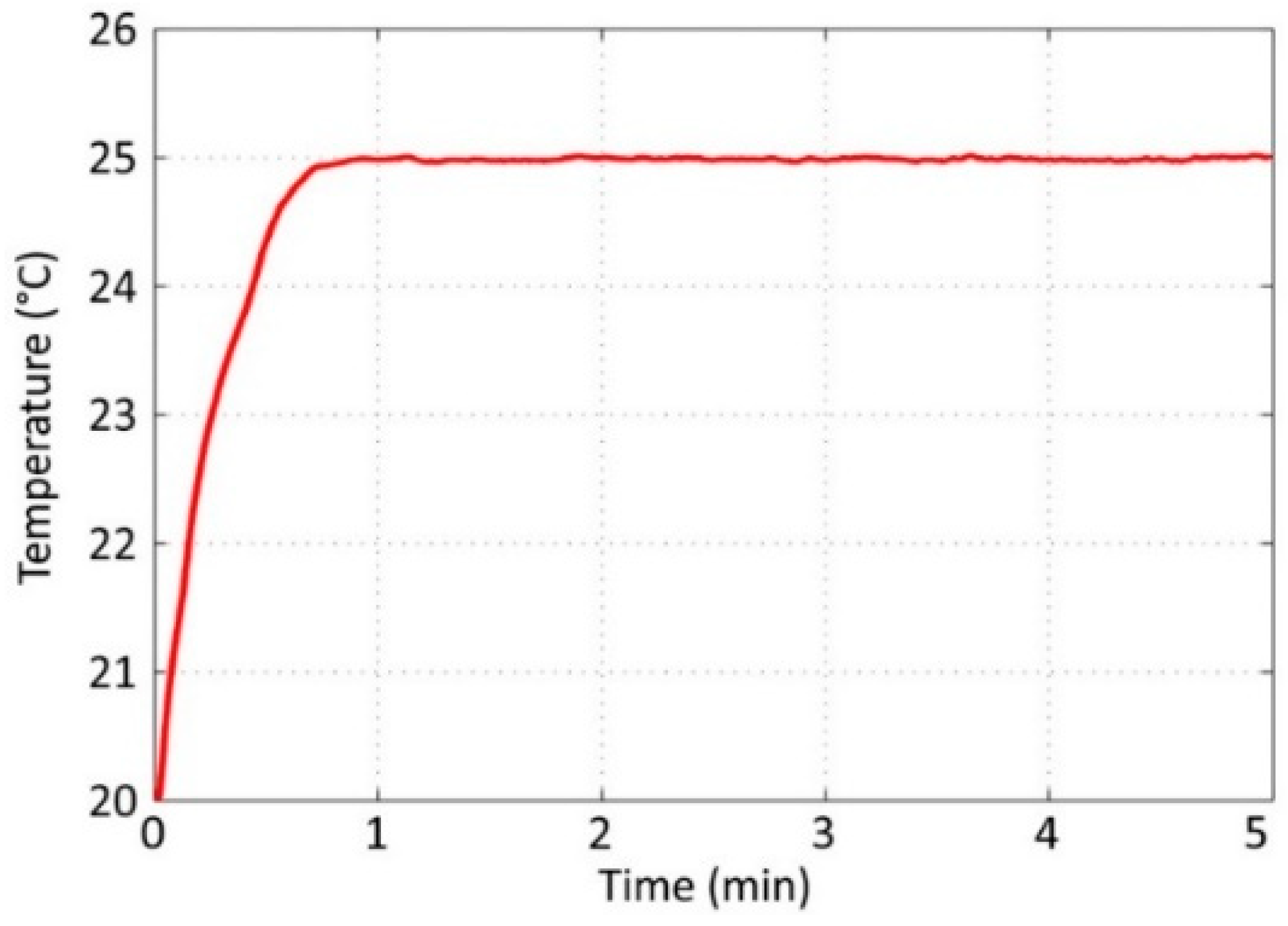

3.1. Temperature Control

3.2. CFD Simulation

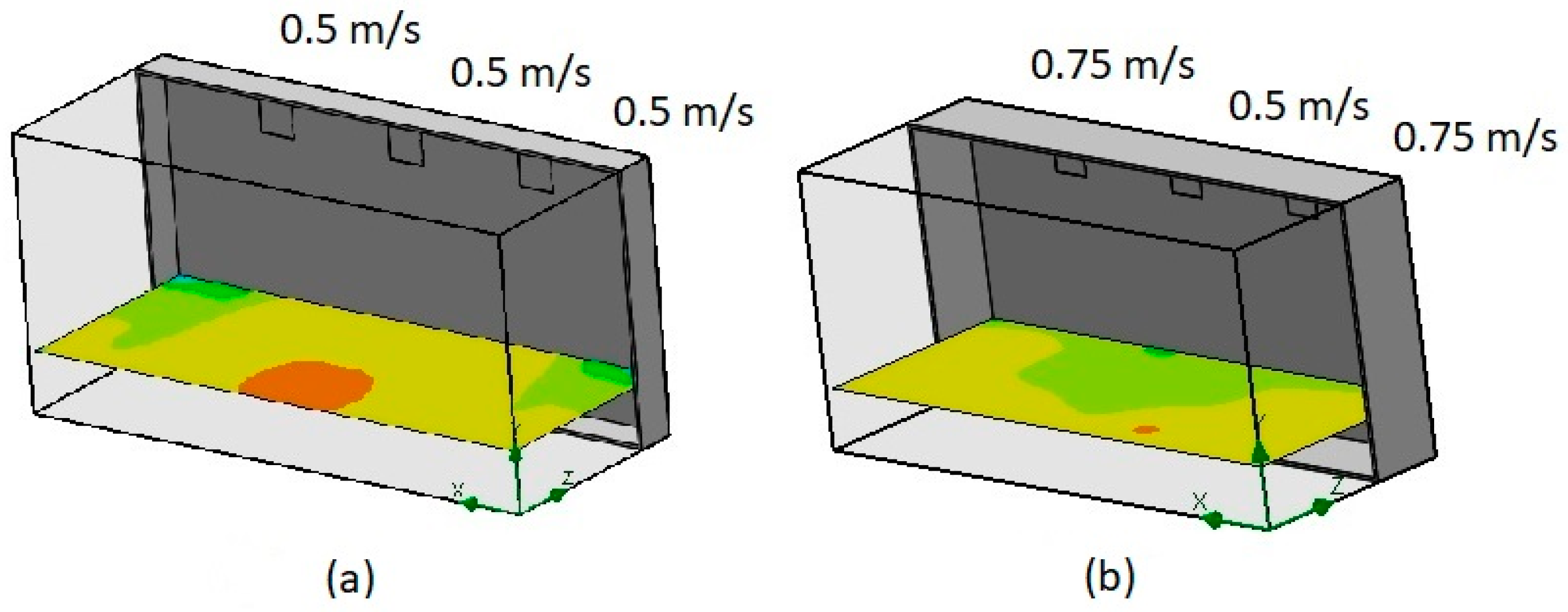

3.2.1. Boundary Conditions

- Walls: A no-slip shear condition was selected; the wall temperature was set to 10.00 °C

- Inlet: The inlet air velocity was set to 0.5 m/s

- Outlet: The atmospheric pressure was set to 101 kPa and the outlet temperature was set to 10.00 °C

- Chamber: The dimensions were 1510 mm × 900 mm × 730 mm

- Inlets: The dimensions were 80 mm × 80 mm

- Outlets: The dimensions were 445 mm × 40 mm

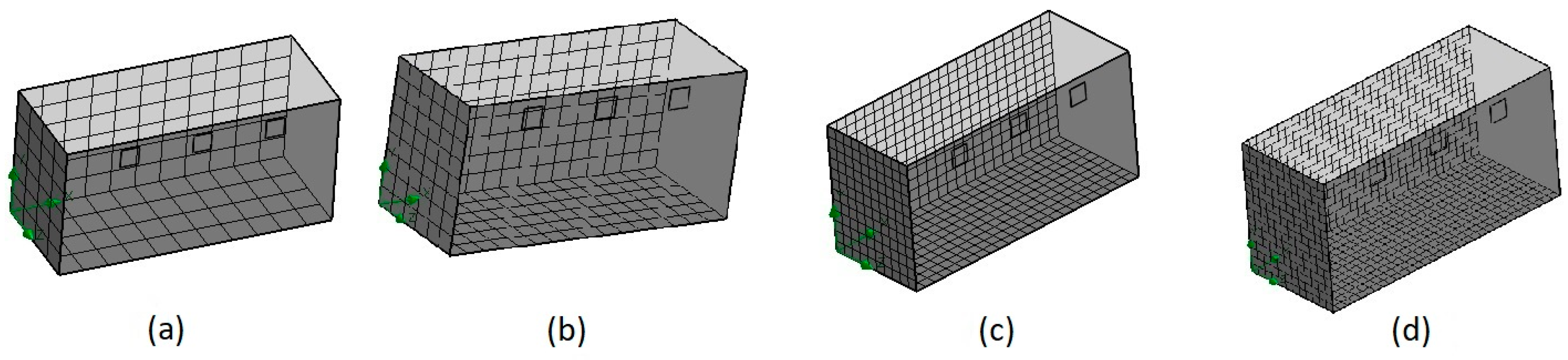

3.2.2. Grid Convergence Study

3.2.3. Inlet Air Velocity

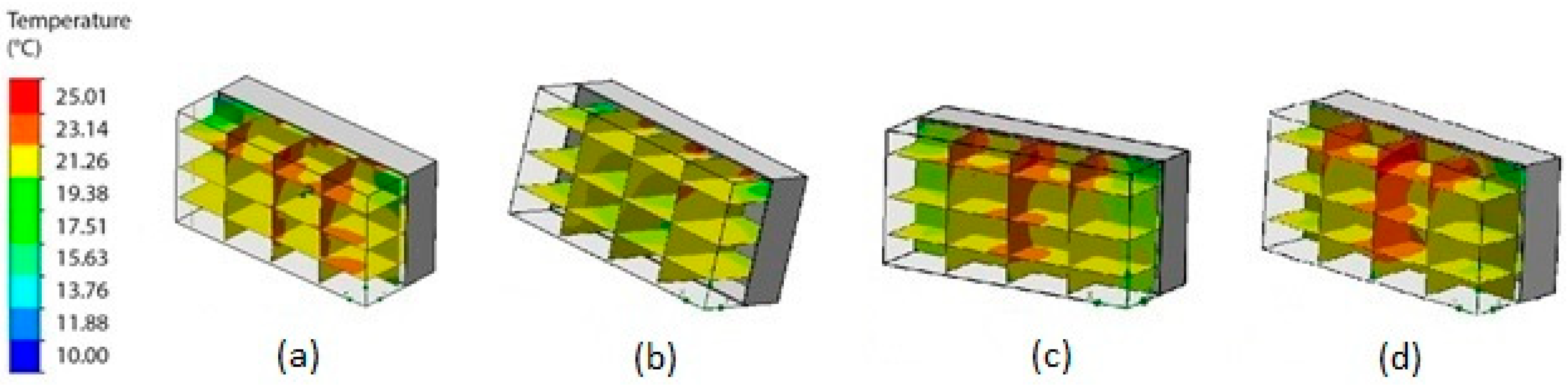

3.2.4. Temperature Distribution

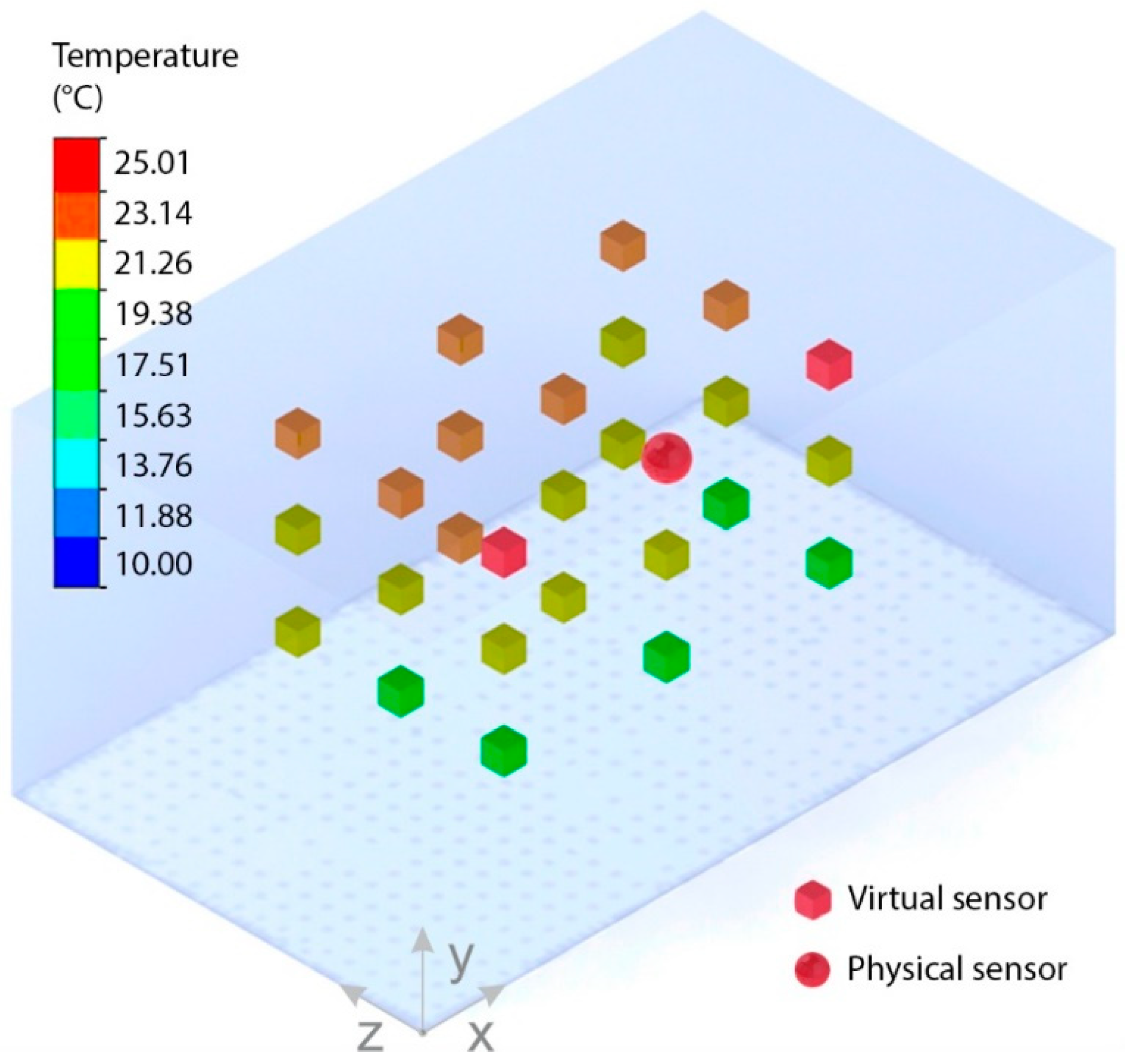

3.3. Temperature Monitoring

4. Conclusions and Future Work

Author Contributions

Conflicts of Interest

References

- Parry, M.L.; Rosenzweig, C.; Iglesias, A.; Livermore, M.; Fischer, G. Effects of climate change on global food production under SRES emissions and socio-economic scenarios. Glob. Environ. Chang. 2004, 14, 53–67. [Google Scholar] [CrossRef]

- Crist, E.; Mora, C.; Engelman, R. The interaction of human population, food production, and biodiversity protection. Science 2017, 356, 260–264. [Google Scholar] [CrossRef] [PubMed]

- Hanan, J.J. Greenhouses: Advanced Technology for Protected Horticulture; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Oliveira, J.; Boaventura-Cunha, J.; Oliveira, P.M. Automation and control in greenhouses: State-of-the-art and future trends. In CONTROLO 2016, Lecture Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2017; Volume 402, pp. 597–606. [Google Scholar]

- Hassanien, R.H.E.; Li, M.; Lin, W.D. Advanced applications of solar energy in agricultural greenhouses. Renew. Sustain. Energy Rev. 2016, 54, 989–1001. [Google Scholar] [CrossRef]

- Kumar, K.; Tiwari, K.; Jha, M.K. Design and technology for greenhouse cooling in tropical and subtropical regions: A review. Energy Build. 2009, 41, 1269–1275. [Google Scholar] [CrossRef]

- Shamshiri, R.; Kalantari, F.; Ting, K.; Thorp, K.R.; Hameed, I.A.; Weltzien, C.; Ahmad, D.; Shad, Z.M. Advances in greenhouse automation and controlled environment agriculture: A transition to plant factories and urban agriculture. Int. J. Agric. Biol. Eng. 2018, 11, 1–22. [Google Scholar] [CrossRef]

- Van Beveren, P.; Bontsema, J.; Van Straten, G.; Van Henten, E. Minimal heating and cooling in a modern rose greenhouse. Appl. Energy 2015, 137, 97–109. [Google Scholar] [CrossRef]

- Carvajal-Arango, R.; Zuluaga-Holguín, D.; Mejía-Gutiérrez, R. A systems-engineering approach for virtual/real analysis and validation of an automated greenhouse irrigation system. Int. J. Interact. Des. Manuf. 2016, 10, 355–367. [Google Scholar] [CrossRef]

- Márquez-Vera, M.A.; Ramos-Fernández, J.C.; Cerecero-Natale, L.F.; Lafont, F.; Balmat, J.-F.; Esparza-Villanueva, J.I. Temperature control in a MISO greenhouse by inverting its fuzzy model. Comput. Electron. Agric. 2016, 124, 168–174. [Google Scholar] [CrossRef]

- Bennis, N.; Duplaix, J.; Enéa, G.; Haloua, M.; Youlal, H. Greenhouse climate modelling and robust control. Comput. Electron. Agric. 2008, 61, 96–107. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.C. Smart Sensing Technology for Agriculture and Environmental Monitoring; Springer: Berlin, Germany, 2012. [Google Scholar]

- Ruiz-Garcia, L.; Lunadei, L.; Barreiro, P.; Robla, I. A review of wireless sensor technologies and applications in agriculture and food industry: State of the art and current trends. Sensors 2009, 9, 4728–4750. [Google Scholar] [CrossRef]

- Akshay, C.; Karnwal, N.; Abhfeeth, K.; Khandelwal, R.; Govindraju, T.; Ezhilarasi, D.; Sujan, Y. Wireless sensing and control for precision Greenhouse management. In Proceedings of the 2012 Sixth International Conference on Sensing Technology, Kolkata, India, 18–21 December 2012; pp. 52–56. [Google Scholar]

- Rodriguez, S.; Gualotuna, T.; Grilo, C. A System for the monitoring and predicting of data in precision agriculture in a rose greenhouse based on wireless sensor networks. Procedia Comput. Sci. 2017, 121, 306–313. [Google Scholar] [CrossRef]

- Ferentinos, K.P.; Katsoulas, N.; Tzounis, A.; Bartzanas, T.; Kittas, C. Wireless sensor networks for greenhouse climate and plant condition assessment. Biosyst. Eng. 2017, 153, 70–81. [Google Scholar] [CrossRef]

- Calderon-Cordova, C.; Bustamante, B.; Delgado, J.; Febres, C.; Montano, V.; Saritama, C.; Ramirez, C. Wireless sensor network for real-time monitoring of temperature, humidity and illuminance in an orchid greenhouse. In Proceedings of the 13th Iberian Conference on Information Systems and Technologies, Caceres, Spain, 13–16 June 2018; pp. 1–7. [Google Scholar]

- Wilson, E. Virtual sensor technology for process optimization. In Proceedings of the Symposium on Computers and Controls in the Metals Industry in Iron and Steel Society, St. Petersburg Beach, CA, USA, December 1997; Available online: http://www.intellization.com/files/virtual_sensors_presentation_ISSCAC_97.pdf (accessed on 21 December 2018).

- Liu, L.; Kuo, S.M.; Zhou, M. Virtual sensing techniques and their applications. In Proceedings of the International Conference on Networking, Sensing and Control, Okayama, Japan, 26–29 March 2009; pp. 31–36. [Google Scholar]

- Lin, B.; Recke, B.; Knudsen, J.K.; Jorgensen, S.B. A systematic approach for soft sensor development. Comput. Chem. Eng. 2007, 31, 419–425. [Google Scholar] [CrossRef]

- Prasad, V.; Schley, M.; Russo, L.P.; Bequette, B.W. Product property and production rate control of styrene polymerization. J. Process Control 2002, 12, 353–372. [Google Scholar] [CrossRef]

- Park, S.; Han, C. A nonlinear soft sensor based on multivariate smoothing procedure for quality estimation in distillation columns. Comput. Chem. Eng. 2000, 24, 871–877. [Google Scholar] [CrossRef]

- Radhakrishnan, V.; Mohamed, A. Neural networks for the identification and control of blast furnace hot metal quality. J. Process Control 2000, 10, 509–524. [Google Scholar] [CrossRef]

- Costantini, R.; Susstrunk, S. Virtual sensor design. In Sensors and Camera Systems for Scientific, Industrial, and Digital Photography Applications; International Society for Optics and Photonics: San Jose, CA, USA, 2004; pp. 408–420. [Google Scholar]

- Kano, M.; Ogawa, M. The state of the art in chemical process control in Japan: Good practice and questionnaire survey. J. Process Control 2010, 20, 969–982. [Google Scholar] [CrossRef]

- Wenzel, T.; Burnham, K.; Blundell, M.; Williams, R. Kalman filter as a virtual sensor: Applied to automotive stability systems. Trans. Inst. Meas. Control 2007, 29, 95–115. [Google Scholar] [CrossRef]

- Canale, M.; Fagiano, L.; Ruiz, F.; Signorile, M.C. A study on the use of virtual sensors in vehicle control. In Proceedings of the 47th IEEE Conference on Decision and Control, Cancun, Mexico, 9–11 December 2008; pp. 4402–4407. [Google Scholar]

- Ankara, Z.; Kammerer, T.; Gramm, A.; Schütze, A. Low power virtual sensor array based on a micromachined gas sensor for fast discrimination between H2, CO and relative humidity. Sens. Actuators B Chem. 2004, 100, 240–245. [Google Scholar] [CrossRef]

- Xue, W.; Guo, Y.-Q.; Zhang, X.-D. Application of a bank of Kalman filters and a robust Kalman filter for aircraft engine sensor/actuator fault diagnosis. Int. J. Innov. Comput. Inf. Control 2008, 4, 3161–3168. [Google Scholar]

- Fekih, A.; Xu, H.; Chowdhury, F.N. Neural networks based system identification techniques for model based fault detection of nonlinear systems. Int. J. Innovat. Comput. Inf. Control 2007, 3, 1073–1085. [Google Scholar]

- Bellas, F.; Becerra, J.; Santos, J.; Duro, R.J. Applying synaptic delays for virtual sensing and actuation in mobile robots. In Proceedings of the International Joint Conference on Neural Networks, Como, Italy, 27 July 2000; pp. 144–149. [Google Scholar]

- Davis, P. A technique of adaptive control of the temperature in a greenhouse using ventilator adjustments. J. Agric. Eng. Res. 1984, 29, 241–248. [Google Scholar] [CrossRef]

- Piñón, S.; Camacho, E.; Kuchen, B.; Peña, M. Constrained predictive control of a greenhouse. Comput. Electron. Agric. 2005, 49, 317–329. [Google Scholar] [CrossRef]

- Speetjens, S.; Stigter, J.; Van Straten, G. Towards an adaptive model for greenhouse control. Comput. Electron. Agric. 2009, 67, 1–8. [Google Scholar] [CrossRef]

- Hameed, I.A. Using the extended Kalman filter to improve the efficiency of greenhouse climate control. Int. J. Innovat. Comput. Inf. Control 2010, 6, 2671–2680. [Google Scholar]

- De la Torre-Gea, G.; Soto-Zarazúa, G.M.; López-Crúz, I.; Torres-Pacheco, I.; Rico-García, E. Computational fluid dynamics in greenhouses: A review. Afr. J. Biotechnol. 2011, 10, 17651–17662. [Google Scholar] [CrossRef]

- Alvarez-Sánchez, E.; Leyva-Retureta, G.; Portilla-Flores, E.; López-Velázquez, A. Evaluation of thermal behavior for an asymmetric greenhouse by means of dynamic simulations. Dyna 2014, 81, 152–159. [Google Scholar] [CrossRef]

- Reichrath, S.; Davies, T.W. Using CFD to model the internal climate of greenhouses: Past, present and future. Agronomie 2002, 22, 3–19. [Google Scholar] [CrossRef]

- Kittas, C.; Karamanis, M.; Katsoulas, N. Air temperature regime in a forced ventilated greenhouse with rose crop. Energy Build. 2005, 37, 807–812. [Google Scholar] [CrossRef]

- Molina-Aiz, F.; Fatnassi, H.; Boulard, T.; Roy, J.; Valera, D. Comparison of finite element and finite volume methods for simulation of natural ventilation in greenhouses. Comput. Electron. Agric. 2010, 72, 69–86. [Google Scholar] [CrossRef]

- Tong, G.; Christopher, D.; Li, B. Numerical modelling of temperature variations in a Chinese solar greenhouse. Comput. Electron. Agric. 2009, 68, 129–139. [Google Scholar] [CrossRef]

- Deltour, J.; De Halleux, D.; Nijskens, J.; Coutisse, S.; Nisen, A. Dynamic modelling of heat and mass transfer in greenhouses. In Proceedings of the Symposium Greenhouse Climate and Its Control, Wageningen, The Netherlands, 19–24 May 1985; pp. 119–126. [Google Scholar]

- Trigui, M.; Barrington, S.; Gauthier, L. A strategy for greenhouse climate control, Part II: Model validation. J. Agric. Eng. Res. 2001, 79, 99–105. [Google Scholar] [CrossRef]

- Longo, G.A.; Gasparella, A. Comparative experimental analysis and modelling of a flower greenhouse equipped with a desiccant system. Appl. Therm. Eng. 2012, 47, 54–62. [Google Scholar] [CrossRef]

- Sánchez-Molina, J.A.; Rodríguez, F.; Guzmán, J.L.; Arahal, M.R. Virtual sensors for designing irrigation controllers in greenhouses. Sensors 2012, 12, 15244–15266. [Google Scholar] [CrossRef]

- Roldán, J.J.; Joosen, G.; Sanz, D.; del Cerro, J.; Barrientos, A. Mini-UAV based sensory system for measuring environmental variables in greenhouses. Sensors 2015, 15, 3334–3350. [Google Scholar] [CrossRef]

- Pawlowski, A.; Guzman, J.L.; Rodríguez, F.; Berenguel, M.; Sánchez, J.; Dormido, S. Simulation of greenhouse climate monitoring and control with wireless sensor network and event-based control. Sensors 2009, 9, 232–252. [Google Scholar] [CrossRef]

- Guzmán-Valdivia, C.H.; Carrera-Escobedo, J.L.; García-Ruíz, M.A.; Ortíz-Rivera, A.; Désiga-Orenday, O. Design, development and control of a portable laboratory for the chili drying process study. Mechatronics 2016, 39, 160–173. [Google Scholar] [CrossRef]

- Guzmán, C.H.; Blanco, A.; Brizuela, J.A.; Gómez, F.A. Robust control of a hip–joint rehabilitation robot. Biomed. Signal Process. Control 2017, 35, 100–109. [Google Scholar] [CrossRef]

- Carrera-Escobedo, J.L.; Ortíz-Rivera, A.; Guzmán-Valdivia, C.H.; García-Ruíz, M.A.; Désiga-Orenday, O. CFD analysis for improving temperature distribution in a chili dryer. Therm. Sci. 2018, 22, 2615–2623. [Google Scholar] [CrossRef]

| No. | Type of Sensor | Coordinates X, Y, Z (mm) | No. | Type of Sensor | Coordinates X, Y, Z (mm) | No. | Type of Sensor | Coordinates X, Y, Z (mm) |

|---|---|---|---|---|---|---|---|---|

| 1 | virtual | 400, 172, 225 | 10 | virtual | 755, 172, 225 | 19 | virtual | 1110, 172, 225 |

| 2 | virtual | 400, 172, 450 | 11 | virtual | 755, 172, 450 | 20 | virtual | 1110, 172, 450 |

| 3 | virtual | 400, 172, 675 | 12 | virtual | 755, 172, 675 | 21 | virtual | 1110, 172, 675 |

| 4 | virtual | 400, 365, 225 | 13 | virtual | 755, 365, 225 | 22 | virtual | 1110, 365, 225 |

| 5 | virtual | 400, 365, 450 | 14 | virtual | 755, 365, 450 | 23 | virtual | 1110, 365, 450 |

| 6 | virtual | 400, 365, 675 | 15 | virtual | 755, 365, 675 | 24 | virtual | 1110, 365, 675 |

| 7 | virtual | 400, 547, 225 | 16 | real | 755, 547, 225 | 25 | virtual | 1110, 547, 225 |

| 8 | virtual | 400, 547, 450 | 17 | virtual | 755, 547, 450 | 26 | virtual | 1110, 547, 450 |

| 9 | virtual | 400, 547, 675 | 18 | virtual | 755, 547, 675 | 27 | virtual | 1110, 547, 675 |

| (a) | (b) | (c) | (d) | |

|---|---|---|---|---|

| Number of cells in X | 11 | 16 | 24 | 32 |

| Number of cells in Y | 6 | 8 | 12 | 16 |

| Number of cells in Z | 4 | 6 | 10 | 12 |

| Total Cells | 5070 | 7760 | 17,242 | 19,258 |

| Solid Cells | 2154 | 3344 | 8270 | 10,582 |

| Fluid Cells | 2916 | 4416 | 8972 | 8676 |

| No. | Temperature (°C) | No. | Temperature (°C) | No. | Temperature (°C) |

|---|---|---|---|---|---|

| 1 | 19.38 | 10 | 19.38 | 19 | 19.38 |

| 2 | 19.38 | 11 | 21.26 | 20 | 19.38 |

| 3 | 21.26 | 12 | 23.14 | 21 | 21.26 |

| 4 | 21.26 | 13 | 21.26 | 22 | 21.26 |

| 5 | 21.26 | 14 | 21.26 | 23 | 21.26 |

| 6 | 21.26 | 15 | 23.14 | 24 | 21.26 |

| 7 | 25.01 | 16 | 25.01 | 25 | 25.01 |

| 8 | 23.14 | 17 | 23.14 | 26 | 23.14 |

| 9 | 23.14 | 18 | 23.14 | 27 | 23.14 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guzmán, C.H.; Carrera, J.L.; Durán, H.A.; Berumen, J.; Ortiz, A.A.; Guirette, O.A.; Arroyo, A.; Brizuela, J.A.; Gómez, F.; Blanco, A.; et al. Implementation of Virtual Sensors for Monitoring Temperature in Greenhouses Using CFD and Control. Sensors 2019, 19, 60. https://doi.org/10.3390/s19010060

Guzmán CH, Carrera JL, Durán HA, Berumen J, Ortiz AA, Guirette OA, Arroyo A, Brizuela JA, Gómez F, Blanco A, et al. Implementation of Virtual Sensors for Monitoring Temperature in Greenhouses Using CFD and Control. Sensors. 2019; 19(1):60. https://doi.org/10.3390/s19010060

Chicago/Turabian StyleGuzmán, Cesar H., José L. Carrera, Héctor A. Durán, Javier Berumen, Arturo A. Ortiz, Omar A. Guirette, Angélica Arroyo, Jorge A. Brizuela, Fabio Gómez, Andrés Blanco, and et al. 2019. "Implementation of Virtual Sensors for Monitoring Temperature in Greenhouses Using CFD and Control" Sensors 19, no. 1: 60. https://doi.org/10.3390/s19010060

APA StyleGuzmán, C. H., Carrera, J. L., Durán, H. A., Berumen, J., Ortiz, A. A., Guirette, O. A., Arroyo, A., Brizuela, J. A., Gómez, F., Blanco, A., Azcaray, H. R., & Hernández, M. (2019). Implementation of Virtual Sensors for Monitoring Temperature in Greenhouses Using CFD and Control. Sensors, 19(1), 60. https://doi.org/10.3390/s19010060