Bionic Electronic Nose Based on MOS Sensors Array and Machine Learning Algorithms Used for Wine Properties Detection

Abstract

1. Introduction

2. Materials and Methods

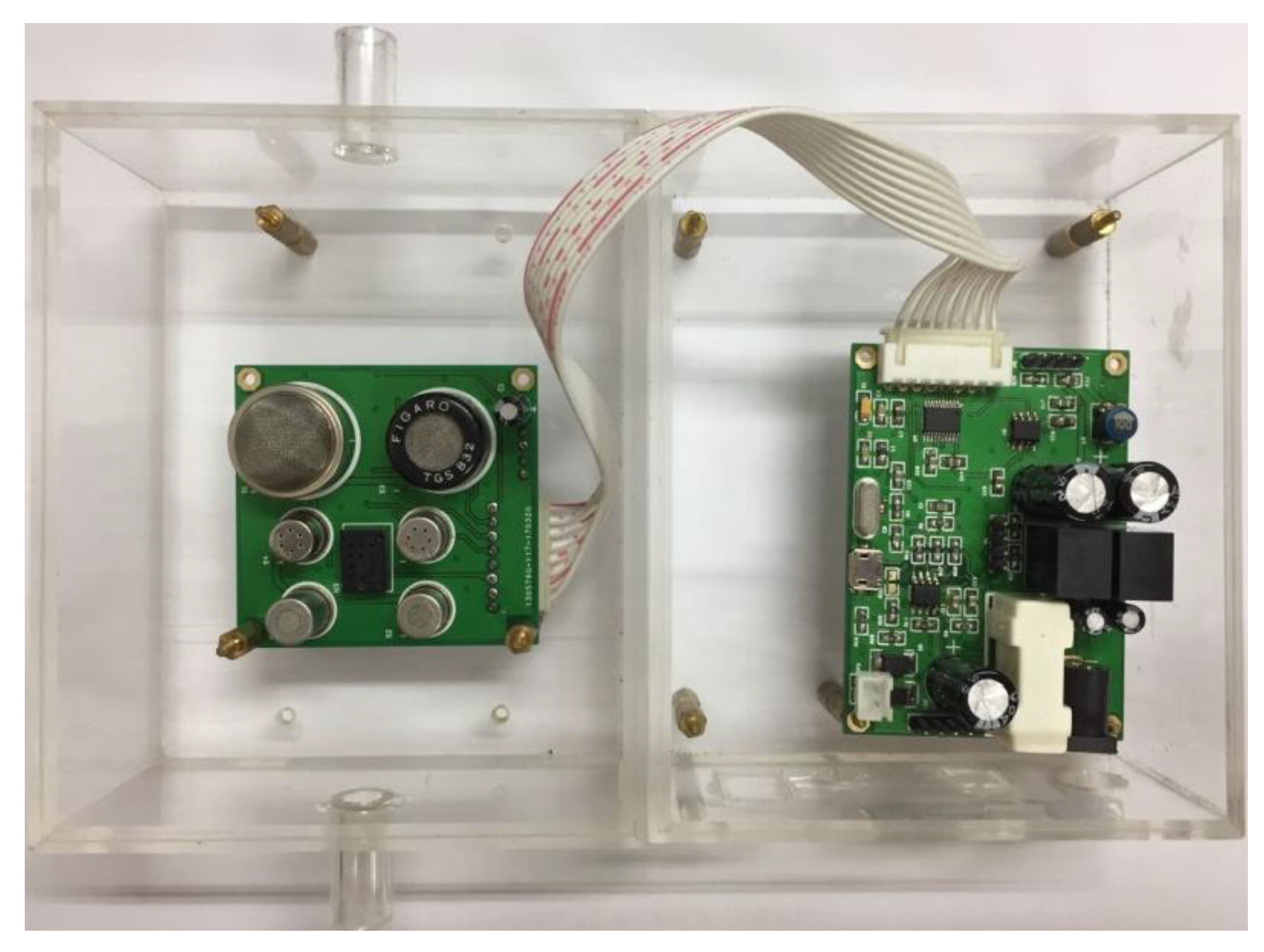

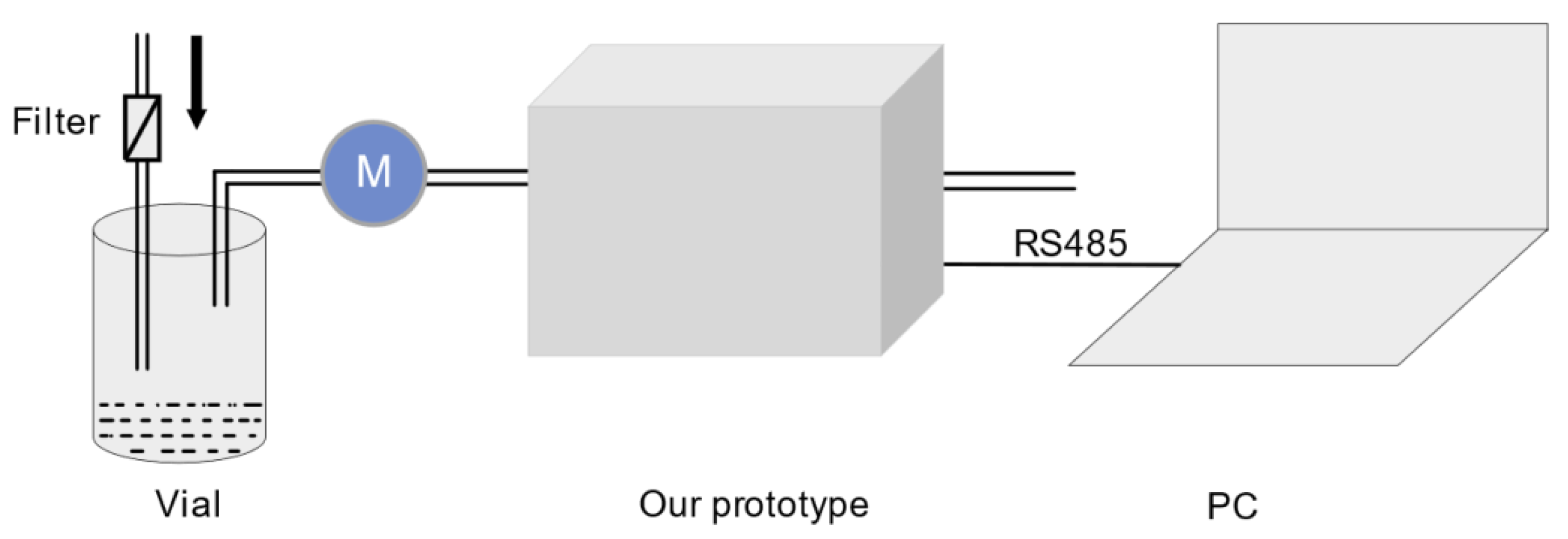

2.1. Independently Developed E-Nose Prototype

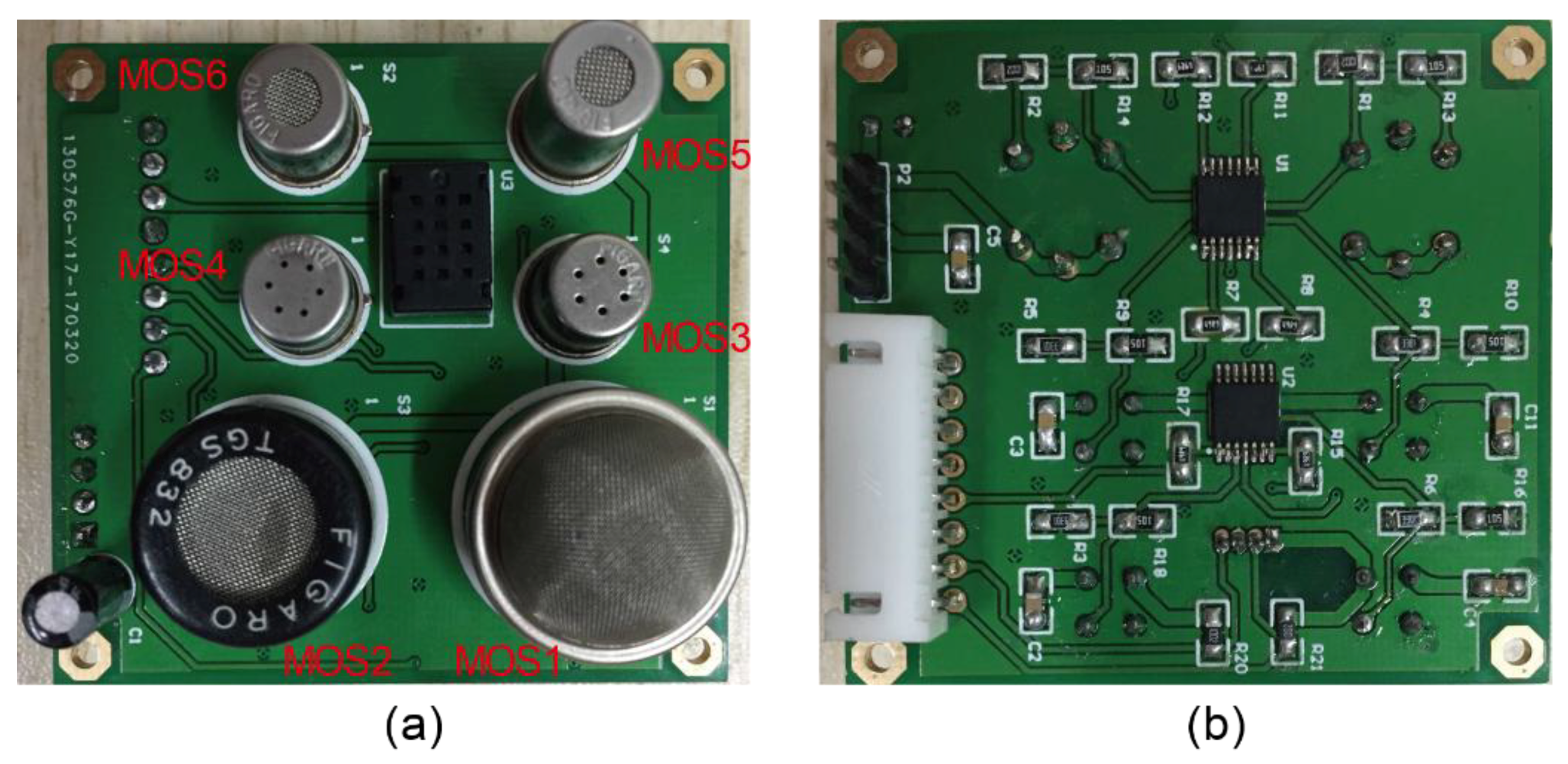

2.1.1. Sensor Array

2.1.2. Microprocessor and Peripheral Modules

2.2. Wine Samples

2.3. Pattern Recognition Methods

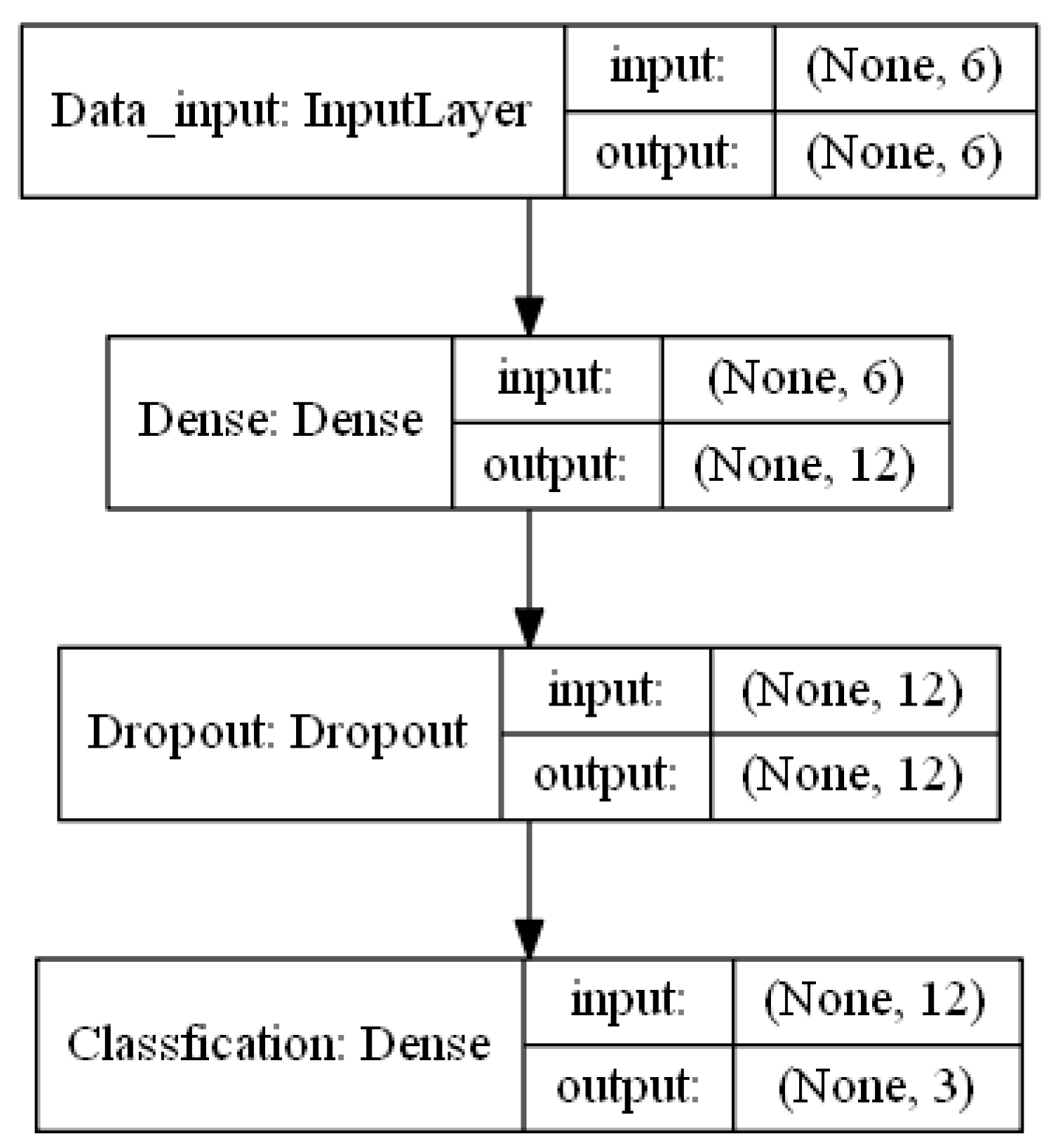

2.3.1. Back-Propagation Neural Network (BPNN)

2.3.2. Support Vector Machines (SVMs)

2.3.3. Random Forest (RF)

2.3.4. Extreme Gradient Boosting (XGBoost)

3. Results and Discussion

3.1. Response Curves and Features

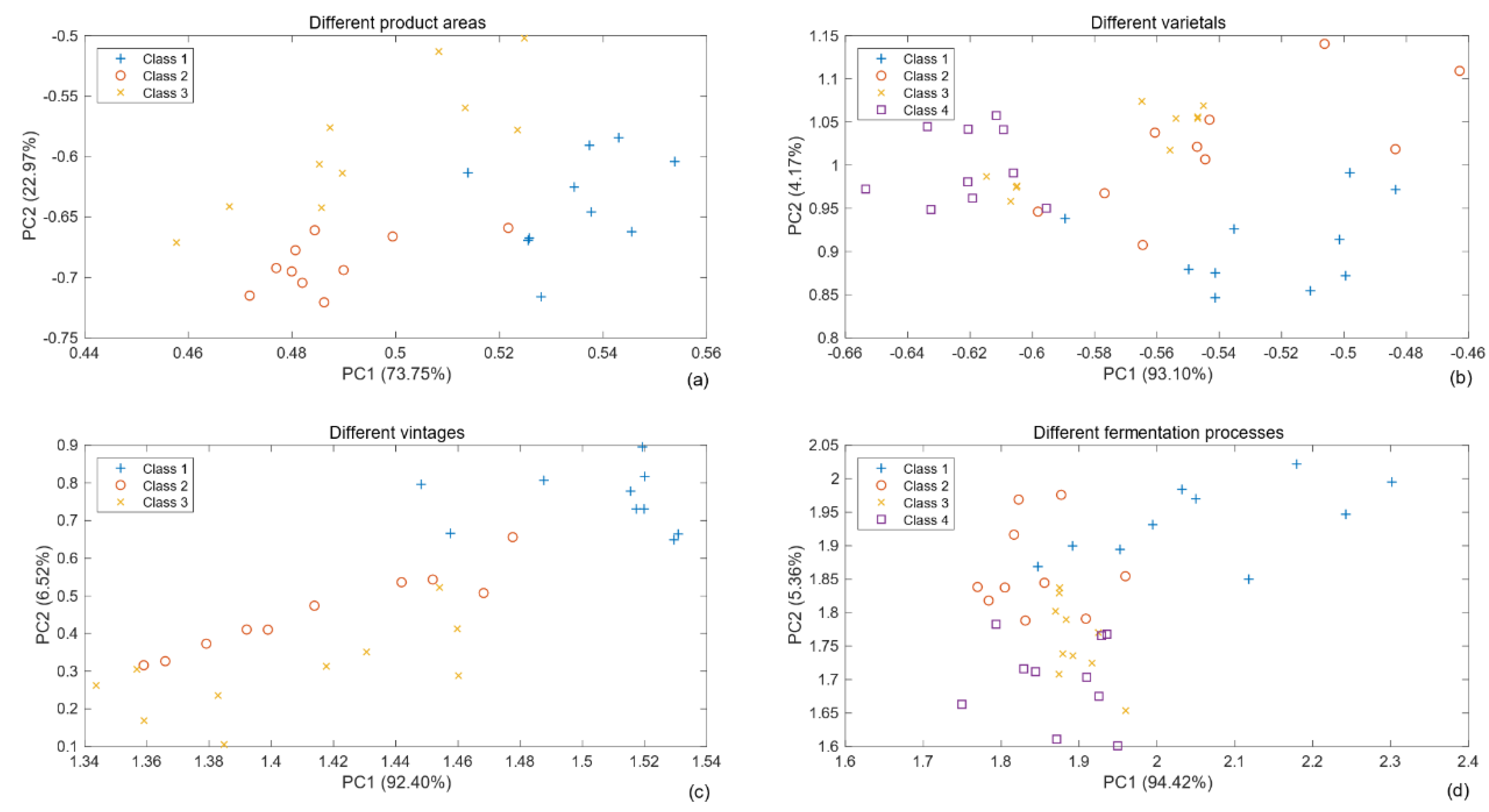

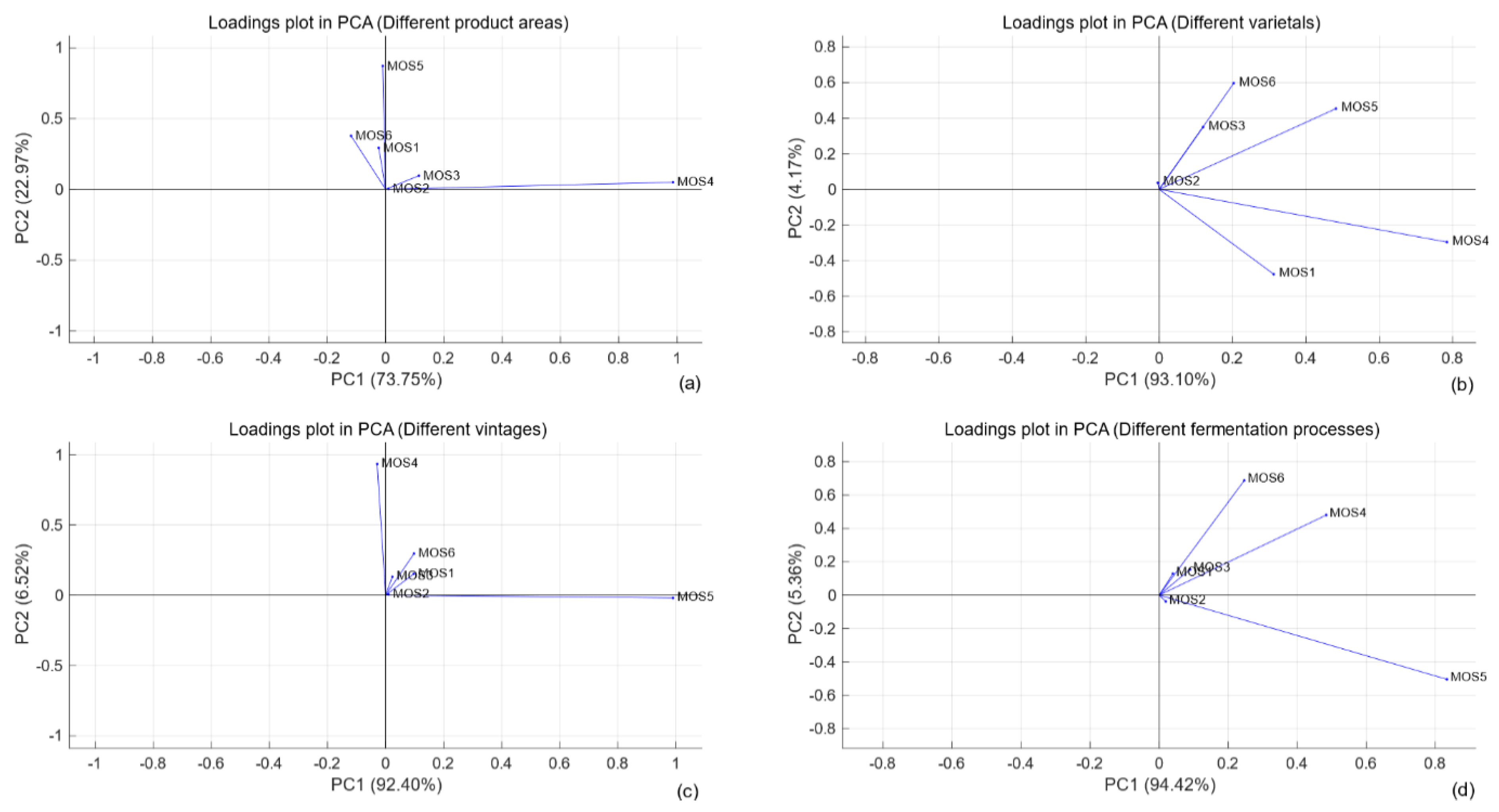

3.2. Principal Component Analysis (PCA) for Wine Volatiles

3.3. Comparison of Properties Classification Based on Four Methods

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yu, H.; Dai, X.; Yao, G.; Xiao, Z. Application of gas chromatography-based electronic nose for classification of Chinese rice wine by wine age. Food Anal. Methods 2014, 7, 1489–1497. [Google Scholar] [CrossRef]

- Vera, L.; Mestres, M.; Boqué, R.; Busto, O.; Guasch, J. Use of synthetic wine for models transfer in wine analysis by HS-MS e-nose. Sens. Actuators B 2010, 143, 689–695. [Google Scholar] [CrossRef]

- Berna, A. Metal oxide sensors for electronic noses and their application to food analysis. Sensors 2010, 10, 3882–3910. [Google Scholar] [CrossRef] [PubMed]

- Lozano, J.; Arroyo, T.; Santos, J.P.; Cabellos, J.M.; Horrillo, M.C. Electronic nose for wine ageing detection. Sens. Actuators B 2008, 133, 180–186. [Google Scholar] [CrossRef]

- Brudzewski, K.; Osowski, S.; Golembiecka, A. Differential electronic nose and support vector machine for fast recognition of tobacco. Expert Syst. Appl. 2012, 39, 9886–9891. [Google Scholar] [CrossRef]

- Zhu, J.C.; Chen, F.; Wang, L.Y.; Niu, Y.; Xiao, Z. Evaluation of the synergism among volatile compounds in Oolong tea infusion by odour threshold with sensory analysis and E-nose. Food Chem. 2017, 221, 1484–1490. [Google Scholar] [CrossRef] [PubMed]

- Kodogiannis, V.S. Application of an electronic nose coupled with fuzzy-wavelet network for the detection of meat spoilage. Food Bioprocess Technol. 2017, 10, 730–749. [Google Scholar] [CrossRef]

- Haddi, Z.; Mabrouk, S.; Bougrini, M.; Tahri, K.; Sghaier, K.; Barhoumi, H.; El Bari, N.E.; Maaref, A.; Jaffrezic-Renault, N.; Bouchikhi, B. E-Nose and e-Tongue combination for improved recognition of fruit juice samples. Food Chem. 2014, 150, 246–253. [Google Scholar] [CrossRef]

- Li, Q.; Gu, Y.; Wang, N.F. Application of random forest classifier by means of a QCM-based e-nose in the identification of Chinese liquor flavors. IEEE Sens. J. 2017, 17, 1788–1794. [Google Scholar] [CrossRef]

- Mei, C.; Yang, M.; Shu, D.; Jiang, H.; Liu, G. Monitoring the wheat straw fermentation process using an electronic nose with pattern recognition methods. Anal. Method 2015, 7, 6006–6011. [Google Scholar] [CrossRef]

- Jia, P.; Tian, F.; He, Q.; Fan, S.; Liu, J.; Yang, S.X. Feature extraction of wound infection data for electronic nose based on a novel weighted KPCA. Sens. Actuators B 2014, 201, 555–566. [Google Scholar] [CrossRef]

- De Cesare, F.; Pantalei, S.; Zampetti, E.; Macagnano, A. Electronic nose and SPME techniques to monitor phenanthrene biodegradation in soil. Sens. Actuators B 2008, 131, 63–70. [Google Scholar] [CrossRef]

- Brudzewski, K.; Osowski, S.; Pawlowski, W. Metal oxide sensor arrays for detection of explosives at sub-parts-per million concentration levels by the differential electronic nose. Sens. Actuators B 2012, 161, 528–533. [Google Scholar] [CrossRef]

- Wei, Y.J.; Yang, L.L.; Liang, Y.P.; Li, J.M. Application of electronic nose for detection of wine-aging methods. Adv. Mater. Res. 2014, 875–877. [Google Scholar] [CrossRef]

- Lozano, J.; Santos, J.P.; Suárez, J.I.; Cabellos, M.; Arroyo, T.; Horrillo, C. Automatic Sensor System for the Continuous Analysis of the Evolution of Wine. Am. J. Enol. Vitic. 2015, 66, 148–155. [Google Scholar] [CrossRef]

- Cortes, C.; Vapnik, V. Support-vector networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- Kuswanto, H.; Salamah, M.; Fachruddin, M.I. Random Forest Classification and Support Vector Machine for Detecting Epilepsyusing Electroencephalograph Records. Am. J. Appl. Sci. 2017, 14, 533–539. [Google Scholar] [CrossRef]

- Chen, T.; Guestrin, C. XGBoost: A Scalable Tree Boosting System. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; pp. 785–794. [Google Scholar]

- Aguilera, T.; Lozano, J.; Paredes, J.A.; Alvarez, F.J.; Suárez, J. Electronic nose based on independent component analysis combined with partial least squares and artificial neural networks for wine prediction. Sensors 2012, 12, 8055–8072. [Google Scholar] [CrossRef]

- Li, Q.; Gu, Y.; Jia, J. Classification of multiple Chinese liquors by means of a QCM-based e-nose and MDS-SVM classifier. Sensor 2017, 17, 272. [Google Scholar] [CrossRef]

- Fan, J.; Wang, X.; Wu, L.; Zhou, H.; Zhang, F.; Yu, X.; Liu, X.; Xiang, Y. Comparison of Support Vector Machine and Extreme Gradient Boosting for predicting daily global solar radiation using temperature and precipitation in humid subtropical climates: A case study in China. Energy Convers. Manag. 2018, 164, 102–111. [Google Scholar] [CrossRef]

- Jolliffe, I.T. Principal Component Analysis; Springer: New York, NY, USA, 2002. [Google Scholar]

- Zhao, Y.; Guo, Z.H.; Meng, F.L.; Liu, J.H. Dynamic detection and recognition system based on the segmental average differentiation. Chin. J. Sens. Actuators 2007, 8, 1706–1711. [Google Scholar]

- Wei, Z.; Wang, J.; Jin, W. Evaluation of varieties of set yogurts and their physical properties using a voltammetric electronic tongue based on various potential waveforms. Sens. Actuators B 2013, 177, 684–694. [Google Scholar] [CrossRef]

| Number | Sensor | Object Substances for Sensing | Cross-Sensitive Object |

|---|---|---|---|

| MOS1 | TGS826 | Ammonia | Isobutane, ethanol, etc. |

| MOS2 | TGS832 | Halocarbon gas | Ethanol, R134a refrigerant, etc. |

| MOS3 | TGS2600 | Air pollutants (hydrogen, ethanol, etc.) | Isobutane, carbon monoxide, etc. |

| MOS4 | TGS2602 | Air pollutants (VOCs, ammonia, H2S, etc.) | Ammonia, hydrogen sulfide, toluene, etc. |

| MOS5 | TGS2611 | Methane | Hydrogen |

| MOS6 | TGS2620 | Alcohol, Solvent vapors | Carbon monoxide, hydrogen, etc. |

| Label No. | Producing Area | Varietal | Vintage | Fermentation Processes (Yeast ID, Fermentation Container, Storage Container) |

|---|---|---|---|---|

| 1 | Huaxia | Cabernet sauvignon | 2016 | * |

| 2 | Renxuan | Cabernet sauvignon | 2016 | * |

| 3 | Zuimei | Cabernet sauvignon | 2016 | * |

| Label No. | Producing Area | Varietal | Vintage | Fermentation Processes (Yeast ID, Fermentation Container, Storage Container) |

|---|---|---|---|---|

| 4 | Huaxia | Cabernet sauvignon | 2017 | * |

| 5 | Huaxia | Marselan | 2017 | * |

| 6 | Huaxia | Long Zibao | 2017 | * |

| 7 | Huaxia | Merlot | 2017 | * |

| Label No. | Producing Area | Varietal | Vintage | Fermentation Processes (Yeast ID, Fermentation Container, Storage Container) |

|---|---|---|---|---|

| 8 | Renxuan | Marselan | 2017 | * |

| 9 | Renxuan | Marselan | 2016 | * |

| 10 | Renxuan | Marselan | 2014 | * |

| Label No. | Producing Area | Varietal | Vintage | Fermentation Processes (Yeast ID, Fermentation Container, Storage Container) |

|---|---|---|---|---|

| 11 | Huaxia | Cabernet sauvignon | 2017 | CC17, Stainless steel tank, Stainless steel tank |

| 12 | Huaxia | Cabernet sauvignon | 2017 | SC5, Stainless steel tank, Stainless steel tank |

| 13 | Huaxia | Cabernet sauvignon | 2017 | CC17, Stainless steel tank, Oak barrel |

| 14 | Huaxia | Cabernet sauvignon | 2017 | SC5, Stainless steel tank, Oak barrel |

| Producing Area | Varietal | Vintage | Fermentation Processes | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Original | 4-D | 2-D | Original | 4-D | 2-D | Original | 4-D | 2-D | Original | 4-D | 2-D | |

| BPNN | 94.0 | 33.3 | 33.3 | 92.5 | 50.0 | 46.0 | 52.7 | 32.7 | 30.7 | 52.0 | 38.5 | 50.0 |

| RF | 87.3 | 64.0 | 36.7 | 79.0 | 24.5 | 48.5 | 47.3 | 21.3 | 32.0 | 56.5 | 38.5 | 39.5 |

| SVM | 70.0 | 28.7 | 28.7 | 91.0 | 52.5 | 39.0 | 67.3 | 33.3 | 33.3 | 60.5 | 39.5 | 55.5 |

| XGBoost | 90.7 | 66.0 | 56.7 | 59.5 | 39.5 | 49.5 | 50.0 | 33.3 | 33.3 | 57.5 | 39.0 | 39.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Li, Q.; Yan, B.; Zhang, L.; Gu, Y. Bionic Electronic Nose Based on MOS Sensors Array and Machine Learning Algorithms Used for Wine Properties Detection. Sensors 2019, 19, 45. https://doi.org/10.3390/s19010045

Liu H, Li Q, Yan B, Zhang L, Gu Y. Bionic Electronic Nose Based on MOS Sensors Array and Machine Learning Algorithms Used for Wine Properties Detection. Sensors. 2019; 19(1):45. https://doi.org/10.3390/s19010045

Chicago/Turabian StyleLiu, Huixiang, Qing Li, Bin Yan, Lei Zhang, and Yu Gu. 2019. "Bionic Electronic Nose Based on MOS Sensors Array and Machine Learning Algorithms Used for Wine Properties Detection" Sensors 19, no. 1: 45. https://doi.org/10.3390/s19010045

APA StyleLiu, H., Li, Q., Yan, B., Zhang, L., & Gu, Y. (2019). Bionic Electronic Nose Based on MOS Sensors Array and Machine Learning Algorithms Used for Wine Properties Detection. Sensors, 19(1), 45. https://doi.org/10.3390/s19010045