A Blockchain Implementation Prototype for the Electronic Open Source Traceability of Wood along the Whole Supply Chain

Abstract

:1. Introduction

2. Materials and Methods

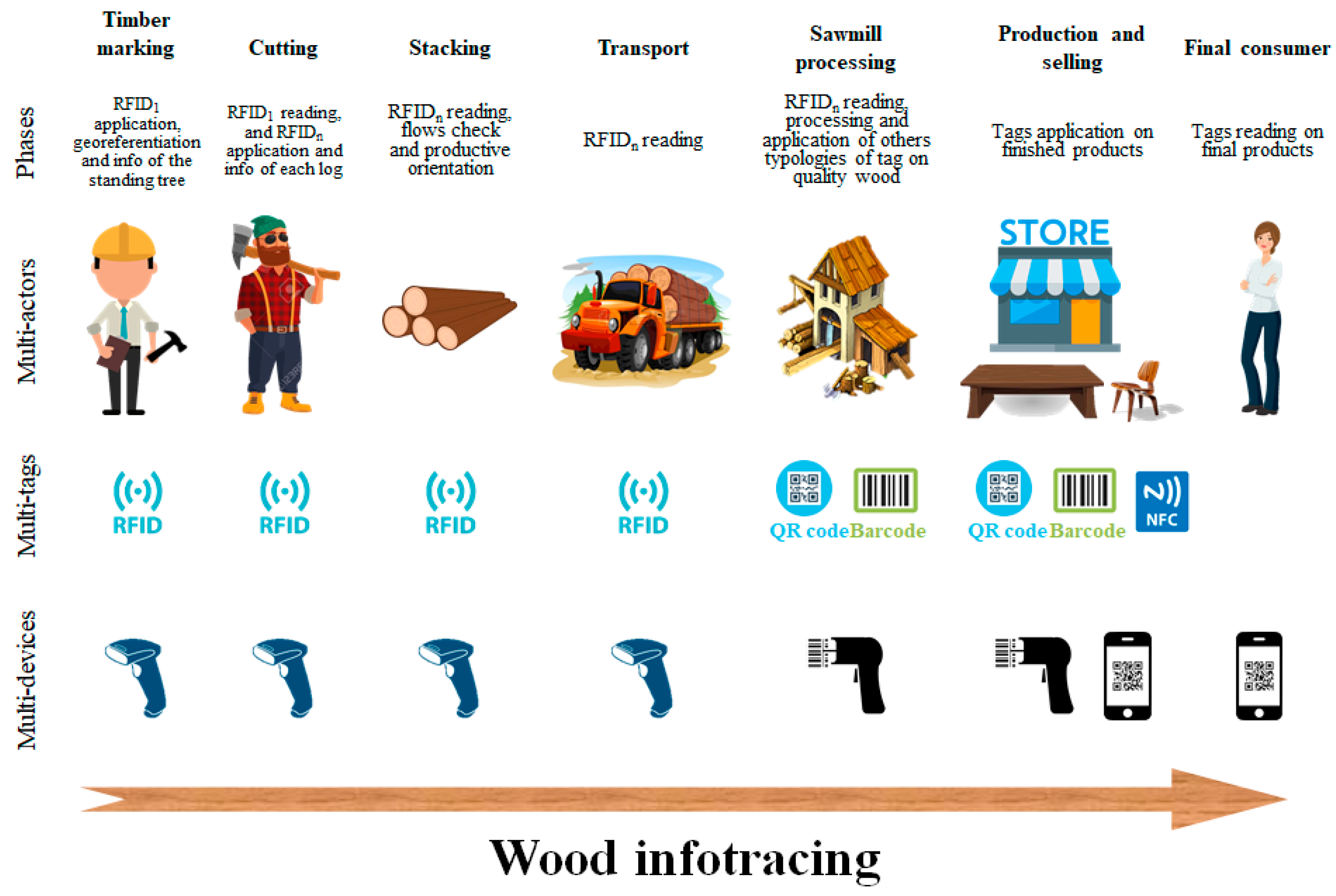

2.1. Wood Traceability Phases

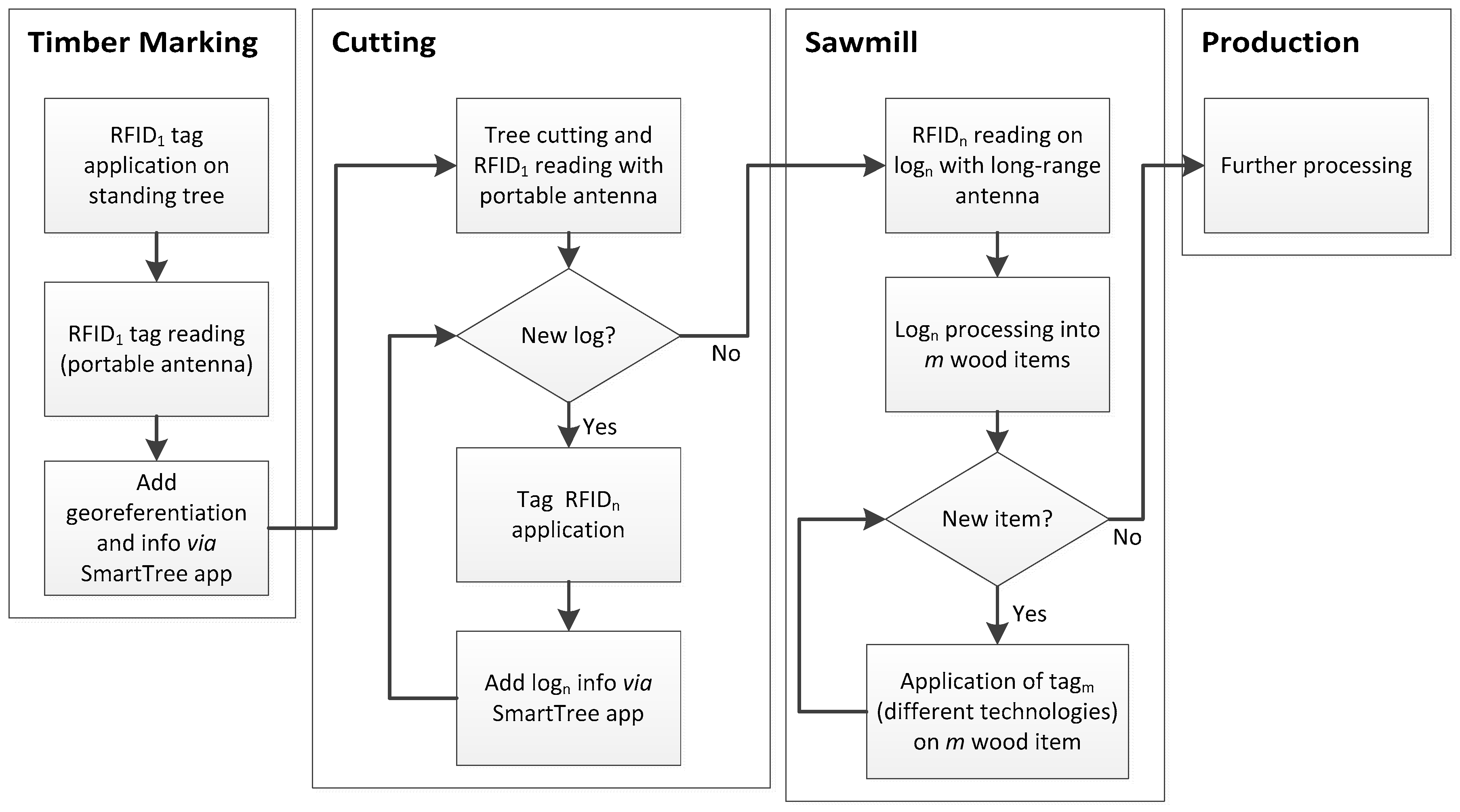

- Timber marking: application of the first RFID (RFID1) of the Class 1 Gen 2 (coin shaped with central hole) above the cut at the moment of the tree identification. This first tag associates the information on the database of the standing tree: tree marking date, tree GPS point, species, diameter at breast height, qualitative class, other information;

- Cutting: additional RFID (RFIDn) tags (one for each derived log; the same used for the timber marking), were applied on the cutting portion for each log (excluding branches and pieces of lesser quality). Each RFID is uniquely associated with the tree, thus preserves the association with the RFID information applied in the first phase, and adds the following data related to each single log: cutting date, log length, log average diameter, wood quality categories, other information;

- Stacking: RFID2 reading to check flows and to orient the production;

- Transport: RFID2 reading during the logs transport;

- Sawmill processing: each log is recognized by an antenna and the RFID2 information is associated to the database: date of entry into the sawmill; description and number of parts in which the log is decomposed; additional qualitative information; other information. The pieces of the best quality are then marked with QR code stickers, to enhance and certify the timber and its origin.

- Production and selling: tag application on the final products;

- Final consumer: Tag reading on the final product.

2.2. RFID Technologies

2.3. Blockchain Architecture

- One Event Grid Topic.

- One Service Bus Namespace.

- One Application Insights.

- One SQL Database (Standard S0).

- Two App Services (Standard).

- Two Azure Key Vaults.

- Two Azure Storage accounts (Standard Learning Record Store—LRS).

- Two Virtual machine scale sets (for validator and worker nodes).

- Two Virtual Networks (including load balancer, network security group, and public IP address for each virtual network).

- Optional: Azure Monitor.

2.4. Blockchain Interconnection

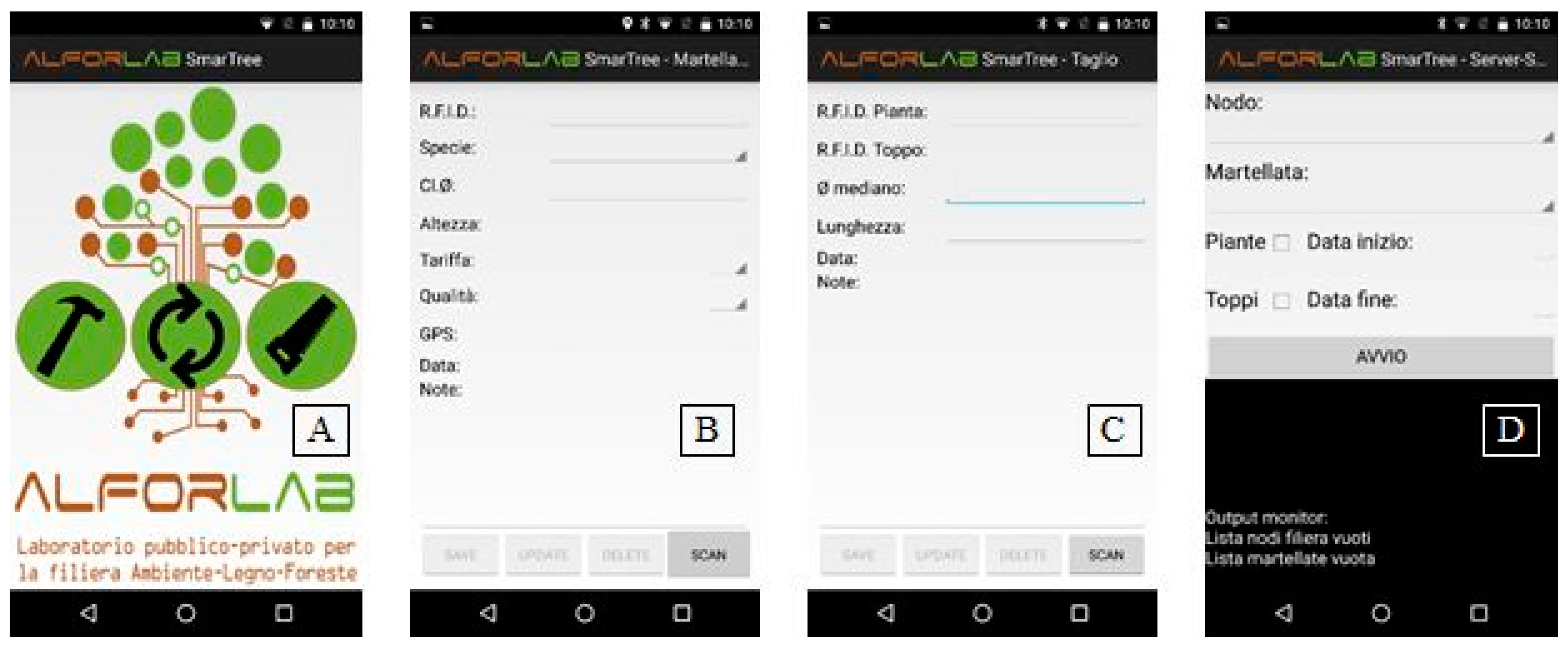

2.5. App (SmartTree) for In-Field Data Collection

- Main activity: the start page allows to select the phase to be executed (Timber marking or Cutting or Remote synchronization);

- Timber marking phase (Figure 6B): through the “scan” button, the Bluetooth connection of the smartphone to the customized portable RFID reader is linked. The device is in a waiting state ready to receive the tag RFID1 unique code that identifies the tree. When the RFID code is received, the app checks for the presence of the code. If it is an existing code, all data will be loaded and could be modified up to 2 h.; while, if it is a new code, the fields will be activated to enter the following information: Species (Specie), Diametric class (Cl. Ø), Height (Altezza), Tariffs (Tariffa; from 1 to 9), Quality (Qualità; A, B, C, D), GPS (automated inserted and unmodifiable), Date (Data; automatically inserted and unmodifiable), Note: once inserted, the data will be saved on an internal database. Data updating, and deletion functions have also been implemented and are available for up to 2 h;

- Cutting (Figure 6C): as reported above, the scan button allows the reading of a RFID tag via Bluetooth. The procedure consists in: i. reading the RFID1 positioned on the standing tree to be cut, ii. reading and insert the RFIDn tags on each log deriving from the cut tree, iii. filling the following information for each log: Median Diameter (Ø mediano), Length (Lunghezza), Date (Data; automated inserted and unmodifiable), Note: control procedures to verify the data consistence and coherence has been implemented. As above described, data updating, and deletion functions have also been implemented and are available for up to 2 h;

- Remote synchronization (Figure 6D): this section manages the synchronization with the remote server and the blockchain. It is activated into two steps: the first, before the in-field operation (timber marking or cutting), allows one to proceed with the operation once the activation code provided by the authoritative institution has been inserted, the second to send the information acquired during (if internet connection is available) or at the end of the specific in-field operation, specifying the temporal interval and the type of data (i.e., tree or log). In the first step the Azure Blockchain workbench login took place (Figure 3). This releases a token to authorize the app to operate in the Azure services. In the second step the data was adjusted in the form of the relative blockchain contract for sending it to the API service gateway and then, for writing it within the blockchain (Figure 3). During synchronization, the app checks to prevent the insertion of duplicate elements on the server and the insertion of unauthorized plants and logs. Another control is carried out on the data coherence, exploiting the blockchain and the supply chain database, through the control policies defined during the integration phase. All synchronization phases are displayed on the screen to get feedback progress.

3. Results

4. Discussion

4.1. Implications for Theory

4.2. Implications for Practice

4.3. Limitations and Further Research Directions

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tzoulis, I.; Andreopoulou, Z. Emerging traceability technologies as a tool for quality wood trade. Procedia Technol. 2013, 8, 606–611. [Google Scholar] [CrossRef]

- Costa, C.; Antonucci, F.; Pallottino, F.; Aguzzi, J.; Sarrià, D.; Menesatti, P. A review on agri-food supply chain traceability by means of RFID technology. Food Bioprocess Technol. 2013, 6, 353–366. [Google Scholar] [CrossRef]

- Timpe, D. RFID IN FORESTRY: Prospects of an RFID-Based Log Tracking System as an Alternative to Stamping; Mittuniversitetet: Sundsvall, Sweden, 2006; ISSN 1650-5387. [Google Scholar]

- Björk, A.; Erlandsson, M.; Häkli, J.; Jaakkola, K.; Nilsson, Å.; Nummila, K.; Puntanen, V.; Sirkka, A. Monitoring environmental performance of the forestry supply chain using RFID. Comput. Ind. 2011, 62, 830–841. [Google Scholar] [CrossRef]

- Corona, P.; Scrinzi, G. Sicurezza dell’approvvigionamento di materiale legnoso forestale in Italia e innovazioni per la tracciabilità dei prodotti legnosi. In Proceedings of the del Secondo Congresso Internazionale di Selvicoltura, Firenze, Italy, 26–29 November 2014; pp. 631–637. [Google Scholar]

- Picchi, G.; Kühmaier, M.; Marques, D.; de Dios, J. Survival Test of RFID UHF Tags in Timber Harvesting Operations. Croatian J. For. Eng. 2015, 36, 165–174. [Google Scholar]

- Abenavoli, L.; Cuzzupoli, F.; Chiaravalloti, V.; Proto, A.R. Traceability system of olive oil: A case study based on the performance of a new software cloud. Agron. Res. 2016, 14, 1247–1256. [Google Scholar]

- Sperandio, G.; Costa, C.; Figorilli, S.; Pallottino, F.; Scrinzi, G.; Colle, G.; Proto, A.; Macrì, G.; Antonucci, F.; Menesatti, P. Valutazione economica delle tecnologie RFID e open source per la tracciabilità del legno in Calabria. Forest@ 2017, 14, 124–134. [Google Scholar] [CrossRef]

- Pizzi, A.; Despres, A.; Mansouri, H.R.; Leban, J.M.; Rigolet, S. Wood joints by through-dowel rotation welding: Microstructure, 13C-NMR and water resistance. J. Adhes. Sci. Technol. 2006, 20, 427–436. [Google Scholar] [CrossRef]

- Angeles, R. RFID technologies: Supply-chain applications and implementation issues. Inf. Syst. Manag. 2005, 22, 51–65. [Google Scholar] [CrossRef]

- Qu, T.; Lei, S.P.; Wang, Z.Z.; Nie, D.X.; Chen, X.; Huang, G.Q. IoT-based real-time production logistics synchronization system under smart cloud manufacturing. Int. J. Adv. Manuf. Technol. 2016, 84, 147–164. [Google Scholar] [CrossRef]

- Kaul, C. Auto-ID in timber supply chain—Identifying single logs using RFID tags. In Proceedings of the FORMEC Conference, Padova, Italy, 11–14 July 2010; pp. 1–7. [Google Scholar]

- Kumar, M.V.; Iyengar, N.C.S. A Framework for Blockchain Technology in Rice Supply Chain Management. Adv. Sci. Technol. Lett. 2017, 146, 125–130. [Google Scholar]

- Pazaitis, A.; De Filippi, P.; Kostakis, V. Blockchain and Value Systems in the Sharing Economy: The Illustrative Case of Backfeed. Technol. Forecast. Soc. Chang. 2017, 125, 105–115. [Google Scholar] [CrossRef]

- Lin, Y.P.; Petway, J.R.; Anthony, J.; Mukhtar, H.; Liao, S.W.; Chou, C.F.; Ho, Y.F. Blockchain: The Evolutionary Next Step for ICT E-Agriculture. Environments 2017, 4, 50. [Google Scholar] [CrossRef]

- Xu, L.D. Information architecture for supply chain quality management. Int. J. Prod. Res. 2011, 49, 183–198. [Google Scholar] [CrossRef]

- Panarello, A.; Tapas, N.; Merlino, G.; Longo, F.; Puliafito, A. Blockchain and IoT Integration: A Systematic Survey. Sensors 2018, 18, 2575. [Google Scholar] [CrossRef] [PubMed]

- Tacconi, L. Illegal Logging: “Law Enforcement, Livelihoods and the Timber Trade”; Routledge: New York, NY, USA, 2012. [Google Scholar]

- Srinivasan, S.; Ranganathan, H. RFID sensor network-based automation system for monitoring and tracking of sandalwood trees. Int. J. Comput. Sci. Eng. 2013, 8, 154–161. [Google Scholar] [CrossRef]

- Pinna, A.; Ibba, S. A blockchain-based Decentralized System for proper handling of temporary Employment contracts. In Proceedings of the 2018 Computing Conference, London, UK, 10–12 July 2018. [Google Scholar]

- Paletto, A.; Notaro, S. Secondary wood manufactures’ willingness-to-pay for certified wood products in Italy. For. Policy Econ. 2018, 92, 65–72. [Google Scholar] [CrossRef]

- Tian, F. An information System for Food Safety Monitoring in Supply Chains Based on HACCP, Blockchain and Internet of Things. Ph.D. Thesis, WU Vienna University of Economics and Business, Wien, Austria, 2018. [Google Scholar]

- Gibbs, T.; Yordchim, S. Thai Perception on Bitcoin Value. Int. J. Social, Behav. Educ. Econ. Bus. Ind. Eng. 2014, 8, 2334–2336. [Google Scholar]

| Tags Type | Large Antenna | Small Antenna | |

|---|---|---|---|

| Tag Dimensions | Average ± | ||

| Coin shaped | 4 cm | 450.0 ± 17.0 | 4.4 ± 0.4 |

| 3 cm | 505.1 ± 14.3 | 18.2 ± 0.2 | |

| Nail shaped | 2 cm | 229.2 ± 16.3 | 1.5 ± 0.3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Figorilli, S.; Antonucci, F.; Costa, C.; Pallottino, F.; Raso, L.; Castiglione, M.; Pinci, E.; Del Vecchio, D.; Colle, G.; Proto, A.R.; et al. A Blockchain Implementation Prototype for the Electronic Open Source Traceability of Wood along the Whole Supply Chain. Sensors 2018, 18, 3133. https://doi.org/10.3390/s18093133

Figorilli S, Antonucci F, Costa C, Pallottino F, Raso L, Castiglione M, Pinci E, Del Vecchio D, Colle G, Proto AR, et al. A Blockchain Implementation Prototype for the Electronic Open Source Traceability of Wood along the Whole Supply Chain. Sensors. 2018; 18(9):3133. https://doi.org/10.3390/s18093133

Chicago/Turabian StyleFigorilli, Simone, Francesca Antonucci, Corrado Costa, Federico Pallottino, Luciano Raso, Marco Castiglione, Edoardo Pinci, Davide Del Vecchio, Giacomo Colle, Andrea Rosario Proto, and et al. 2018. "A Blockchain Implementation Prototype for the Electronic Open Source Traceability of Wood along the Whole Supply Chain" Sensors 18, no. 9: 3133. https://doi.org/10.3390/s18093133

APA StyleFigorilli, S., Antonucci, F., Costa, C., Pallottino, F., Raso, L., Castiglione, M., Pinci, E., Del Vecchio, D., Colle, G., Proto, A. R., Sperandio, G., & Menesatti, P. (2018). A Blockchain Implementation Prototype for the Electronic Open Source Traceability of Wood along the Whole Supply Chain. Sensors, 18(9), 3133. https://doi.org/10.3390/s18093133