Structured-Light Based 3D Reconstruction System for Cultural Relic Packaging

Abstract

:1. Introduction

2. Three-Dimensional Measurement Based on Three Wavelength Grating Projection

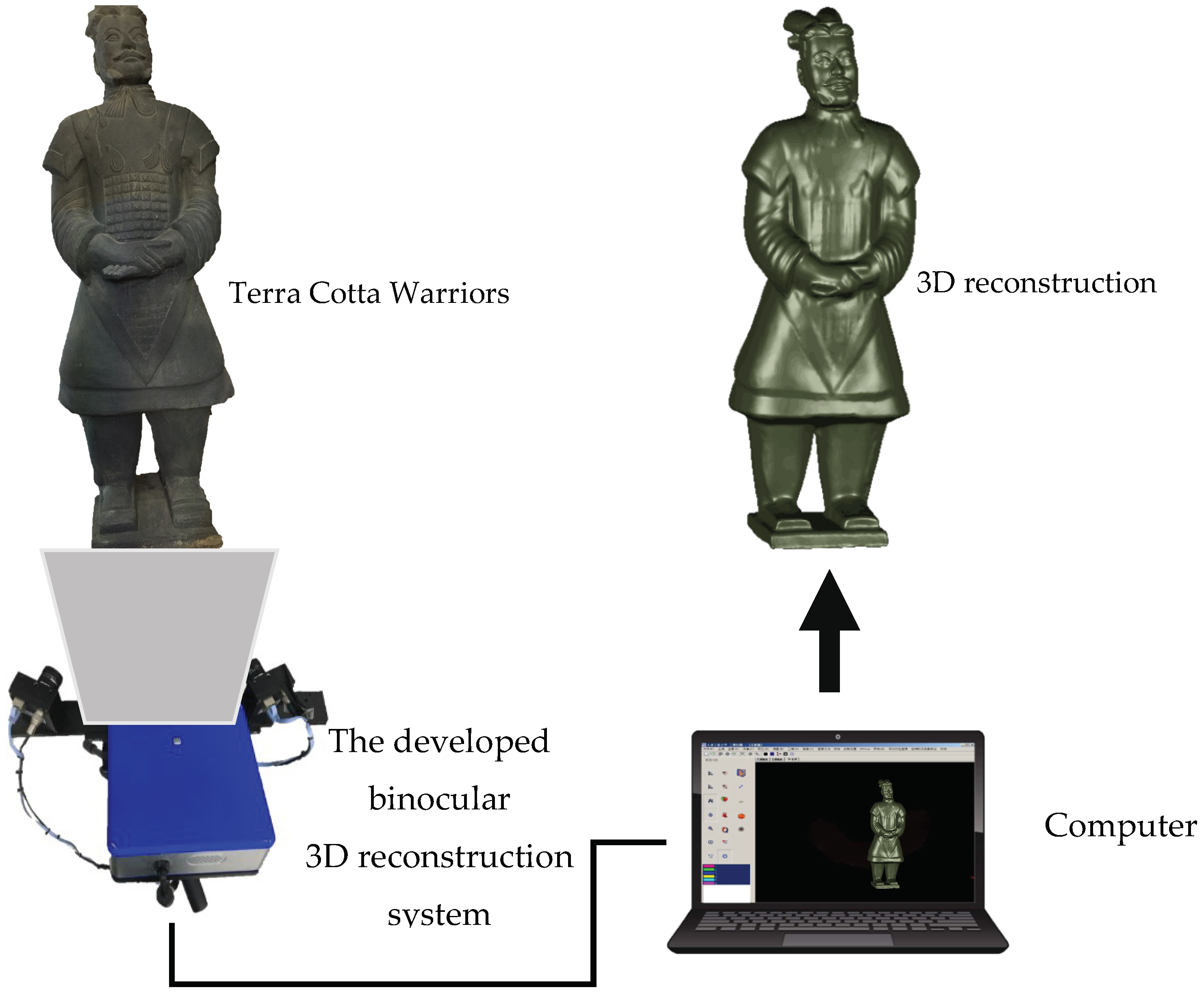

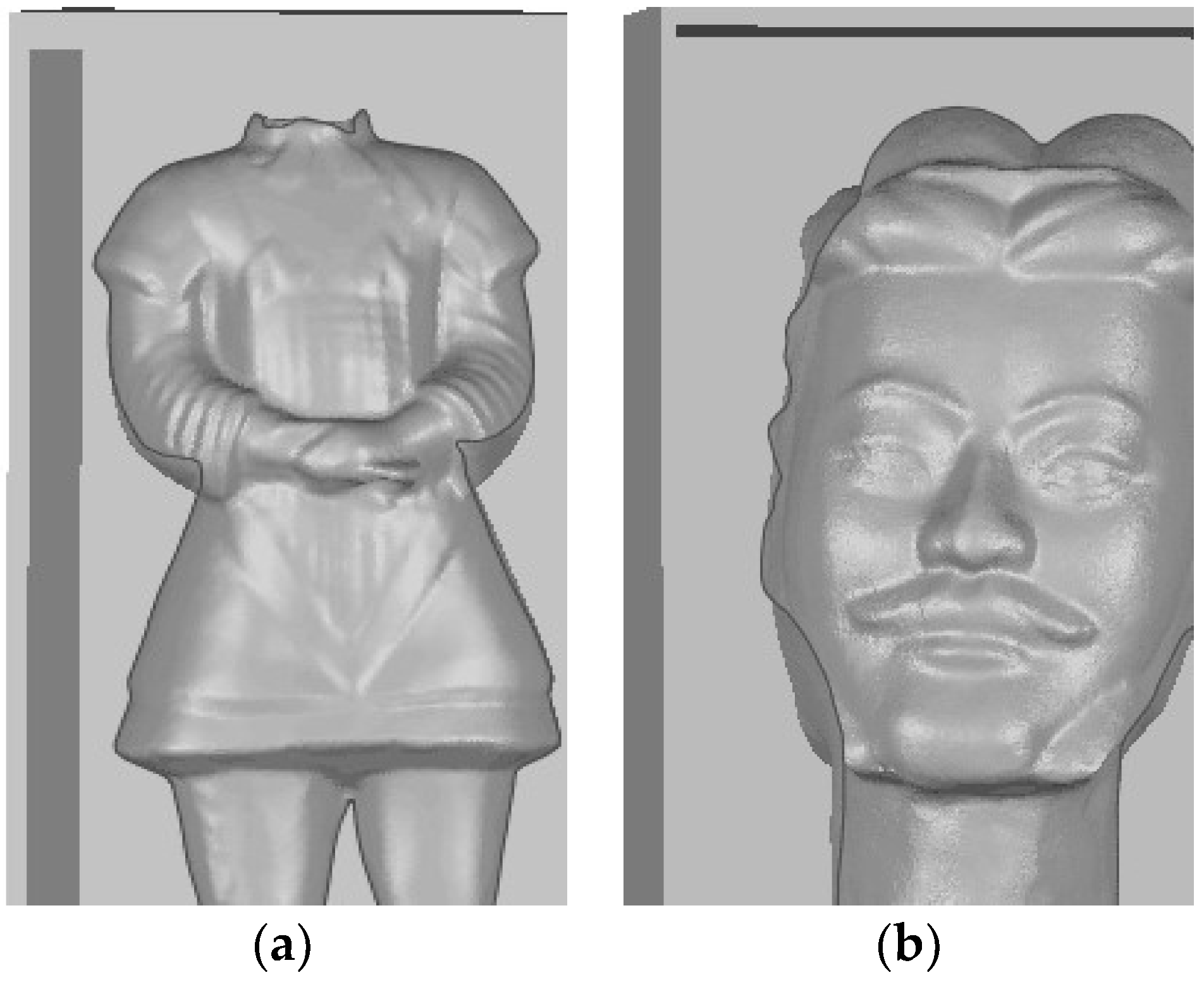

3. Three-Dimensional Reconstruction

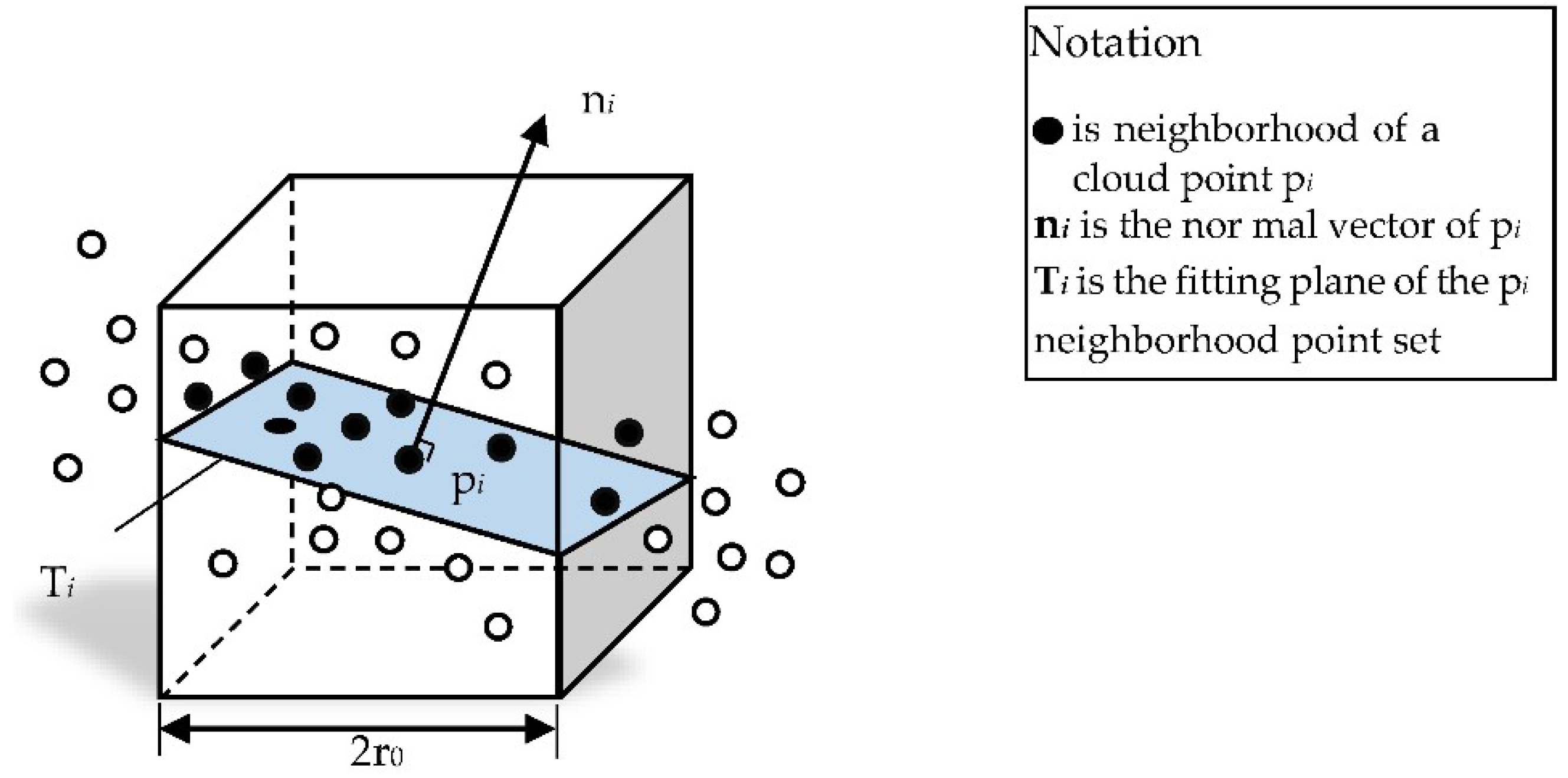

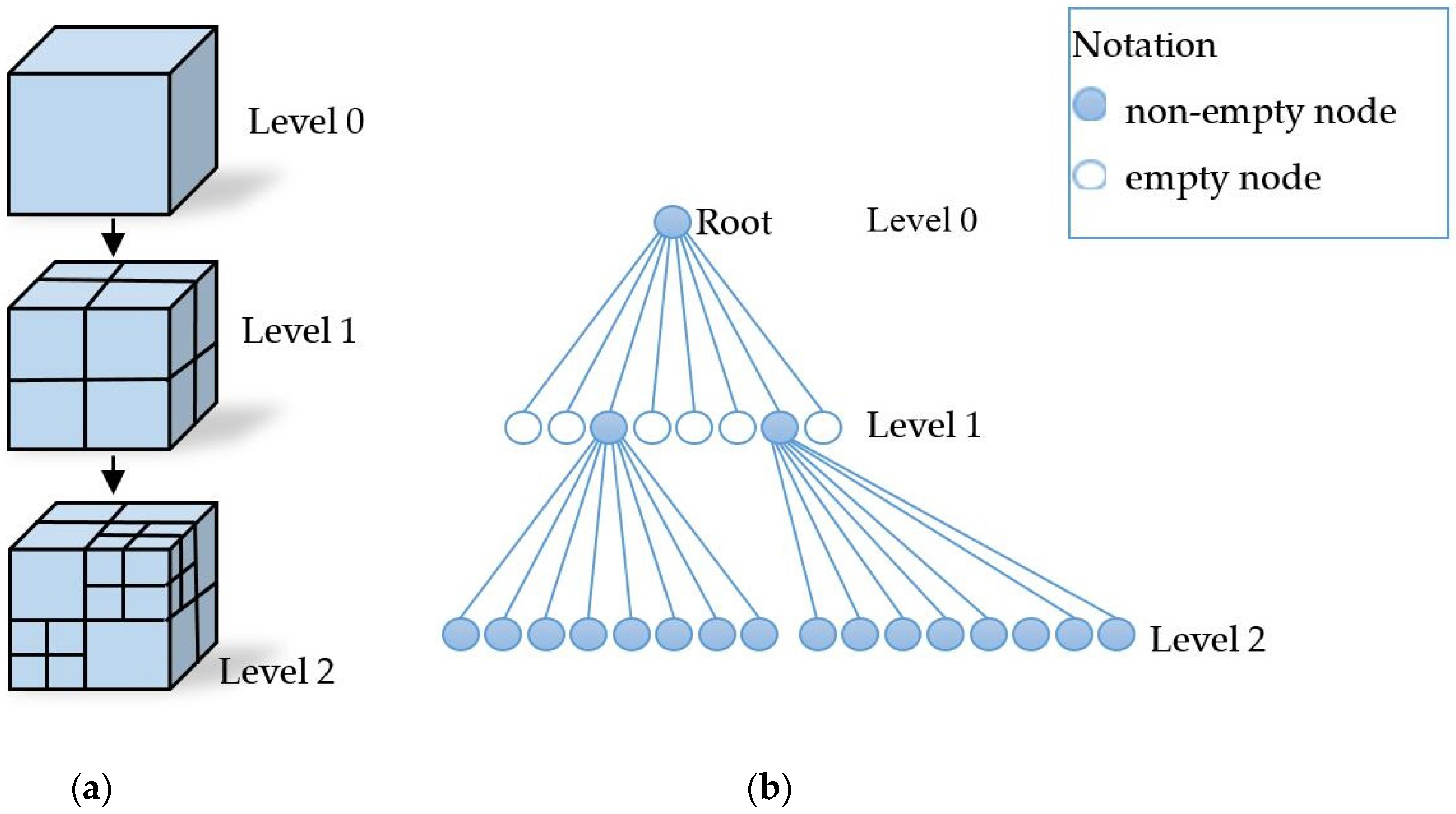

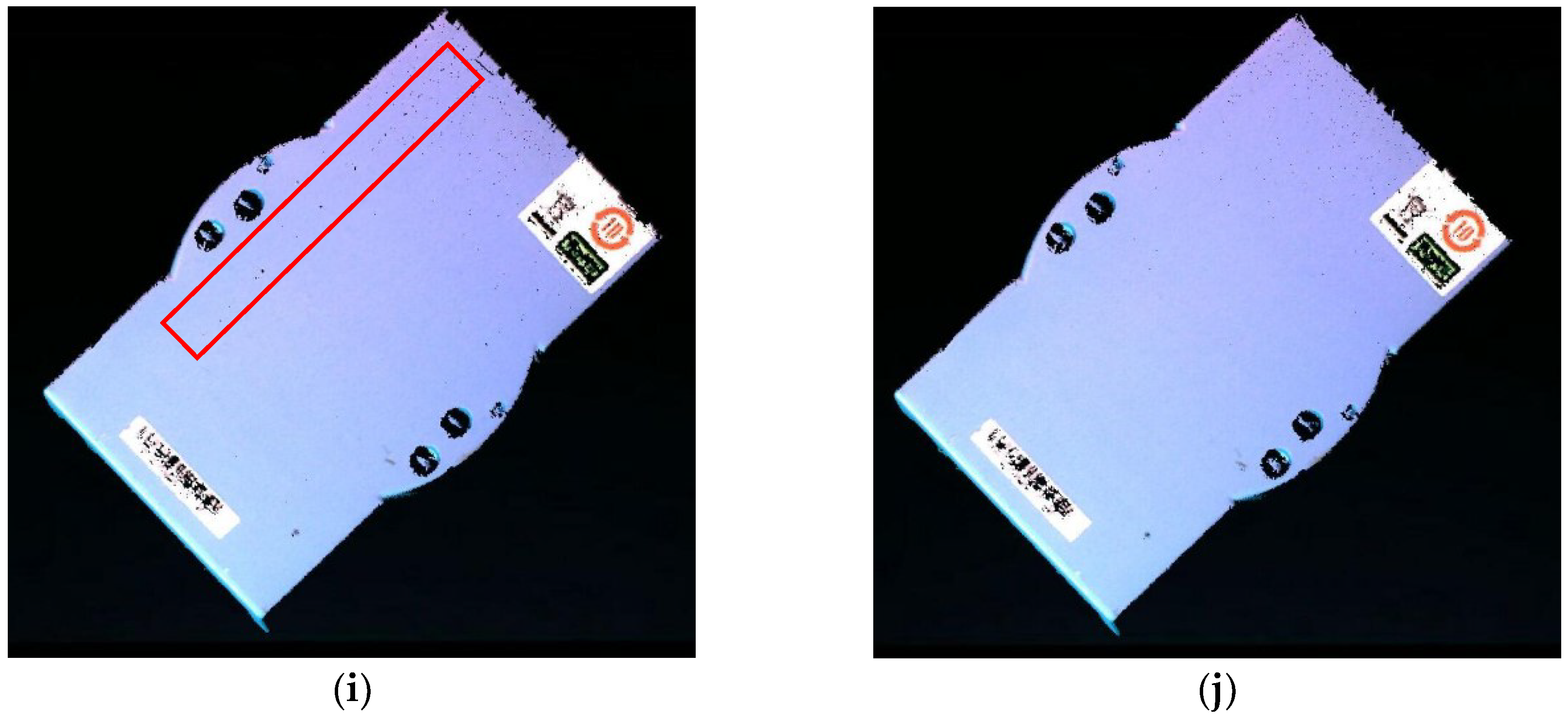

3.1. Point cloud preprocessing

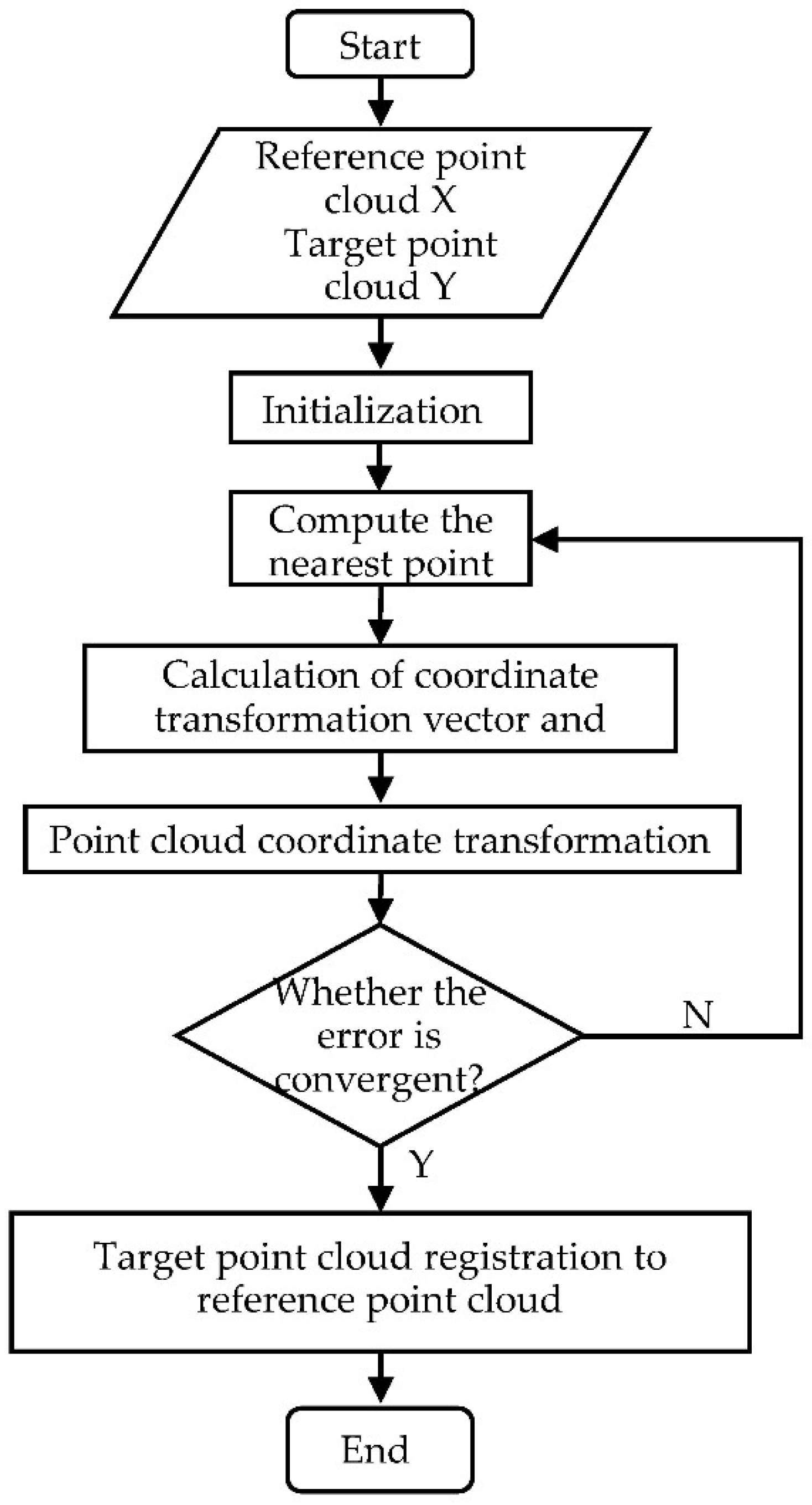

3.2. Registration

3.3. Merging

3.4. Thinning

3.5. Grid reconstruction

4. Experimental Section

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yan, H.S. On the protection and restoration of cultural relics in the medium and small museums. In Proceedings of the 12th National Cultural Heritage Restoration Technical Seminar, Guanghan, China, 1 September 2014; pp. 238–241. (In Chinese). [Google Scholar]

- Li, H. How to protect precious cultural relics in packaging and transportation. China Packag. Ind. 2015, 6, 148. (In Chinese) [Google Scholar] [CrossRef]

- ASTM International. Standard Guide for Transport Packaging Design; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar] [CrossRef]

- Gomes, L.; Bellon, O.R.P.; Silva, L. 3D reconstruction methods for digital preservation of cultural heritage: A survey. Pattern Recognit. Lett. 2014, 50, 3–14. [Google Scholar] [CrossRef]

- Reznicek, J.; Pavelka, K. New low-cost 3D scanning techniques for cultural heritage documentation. 2008. Available online: http://citeseerx.ist.psu.edu/viewdoc/summary?doi=10.1.1.614.9015 (accessed on 5 September 2018).

- Liu, S.; Zhao, L.; Li, J. The applications and summary of three dimensional reconstruction based on stereo vision. In Proceedings of the 2012 International Conference on Industrial Control and Electronics Engineering, Xi’an, China, 23–25 August 2012; pp. 620–623. [Google Scholar]

- Zhu, J.; Wu, D.; Fan, W.; Chen, T.; Chen, Y. Three-dimensional reconstruction of ancient Chinese architecture. In Proceedings of the 2014 6th International Conference on Measuring Technology and Mechatronics Automation, Zhangjiajie, China, 10–11 January 2014; pp. 787–790. [Google Scholar]

- Aristipini, P.; Colao, F.; Fantoni, R.; Fiorani, L.; Palucci, A. Compact scanning lidar fluorosensor for cultural heritage diagnostics. Proc. SPIE 2005, 5850, 196–203. [Google Scholar]

- Rodríguez-Navarro, P. Automated Digital Photogrammetry versus the systems based on active 3D sensors. EGA 2012, 17, 100–111. [Google Scholar]

- Remondino, F.; Spera, M.G.; Nocerino, E.; Menna, F.; Nex, F. State of the art in high density image matching. Photogramm. Rec. 2014, 29, 144–166. [Google Scholar] [CrossRef]

- Guidi, G.; Barsanti, S.G.; Micoli, L.L.; Russo, M. Massive 3D Digitization of Museum Contents. In Built Heritage: Monitoring Conservation Management; Springer: Cham, Switzerland, 2015; pp. 335–346. [Google Scholar]

- Wu, Y.; Zhou, M. Application of 3D scanning technology in the protection of cultural reli. Comput. Technol. Dev. 2009, 19, 173–176. (In Chinese) [Google Scholar] [CrossRef]

- Xu, K.; He, H.M.; Guo, Y.X. Establishment of 3D Relic Model Based on 3D Laser Scanner. Beijing Surv. Mapp. 2014, 4, 120–122. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, P.; Takeda, T.; Toque, J.A.; Murayama, Y.; Ide-Ektessabi, A. A line scan camera based stereo method for high resolution 3D image reconstruction. Proc. SPIE 2014, 9018, 901807. [Google Scholar]

- Dongseok, K.; Gyesoo, K.; Siro, K.; Eunhwa, K. Digital inventory and documentation of Korea’s important cultural properties using 3D Laser Scanning. In Proceedings of the 25th International CIPA Symposium, Taipei, Taiwan, 31 August–4 September 2015; pp. 123–131. [Google Scholar]

- Doi, J.; Shimizu, K.; Sato, W. High-density scanning combined with digital image of real objects for complete reproduction of cultural artifacts. In Proceedings of the 2006 IEEE International Conference on Multisensor Fusion and Integration for Intelligent Systems, Heidelberg, Germany, 3–6 September 2006; pp. 341–346. [Google Scholar]

- Dekeyser, F.; Gaspard, F.; Florenzano, M.; De Luca, L.; Chen, X.; Leray, P. Cultural heritage recording with laser scanning, computer vision and exploitation of architectural rules. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2003, 34, 145–149. [Google Scholar]

- Wang, C. Research on virtual demonstration of historical and cultural sites based on 3D laser scanning technology. Int. J. Digit. Content Technol. Its Appl. 2012, 6, 137–144. [Google Scholar]

- Shih, N.-J.; Diao, P.-H. The preservation of railroad-related cultural activities and subjects using 3D scans and photogrammetry. Comput. Aided Des. Appl. 2018, 15, 129–137. [Google Scholar] [CrossRef]

- Daniel, S.; Duguay, J.; Pouliot, J. Close-range photogrammetry experiments for 3D modelling of archaeological excavation site. Geomatica 2008, 62, 247–256. [Google Scholar]

- Menna, F.; Nocerino, E.; Remondino, F.; Dellepiane, M.; Callieri, M.; Scopigno, R. 3D Digitization of AN Heritage Masterpiece—A Critical Analysis on Quality Assessment. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2016, XLI-B5. [Google Scholar] [CrossRef]

- Guidi, G.; Micoli, L.L.; Gonizzi, S.; Brennan, M.; Frischer, B. Image-based 3D capture of cultural heritage artifacts an experimental study about 3D data quality. Digit. Herit. 2016, 2, 321–324. [Google Scholar]

- Han, P.-Y.; Da, F.-P.; Gai, S.-Y. Color structured light technology for high-speed 3D shape measurement based on gray code method. J. Optoelectron. Laser 2010, 21, 1359–1364. [Google Scholar]

- Zheng, S.; Zhou, Y.; Huang, R.; Zhou, L.; Xu, X.; Wang, C. A method of 3D measurement and reconstruction for cultural relics in museums. Sci. Surv. Mapp. 2014, XXXIX-B5, 145–149. [Google Scholar] [CrossRef]

- You, Y.; Shen, Y.; Zhang, G.; Xing, X. Real-Time and High-Resolution 3D Face Measurement via a Smart Active Optical Sensor. Sensors 2017, 17, 734. [Google Scholar] [CrossRef] [PubMed]

- Sun, B.; Zhu, J.; Yang, L.; Yang, S.; Guo, Y. Sensor for In-Motion Continuous 3D Shape Measurement Based on Dual Line-Scan Cameras. Sensors 2016, 16, 1949. [Google Scholar] [CrossRef] [PubMed]

- Song, L.; Chen, C.; Zhang, L.; Dong, X. Application of high precision global phase decomposition in multi frequency three dimensional measurement. Opto-Electron. Eng. 2012, 39, 18–25. [Google Scholar]

- Han, C.; Qin, G.H.; Gong, Y.; Zhang, C.; Xue, Y.H. Method for three-dimensional reconstruction based on color structured light. J. Jilin Univ. 2013, 43, 1343–1351. [Google Scholar]

- Song, L.; Chang, Y.; Li, Z.; Wang, P.; Xing, G.; Xi, J. Application of global phase filtering method in multi frequency measurement. Opt. Express 2014, 22, 13641–13647. [Google Scholar] [CrossRef] [PubMed]

- Pan, Z.; Wang, Y.; Ku, W. A new general nearest neighbor classification based on the mutual neighborhood information. Knowl.-Based Syst. 2017, 121, 142–152. [Google Scholar] [CrossRef]

- Clarkson, K.L. Nearest-neighbor searching and metric space dimensions. In Nearest-Neighbor Methods for Learning and Vision: Theory and Practice; MIT Press: Cambridge, MA, USA, 2006; pp. 15–59. [Google Scholar]

- Song, S.; Liu, J.; Yin, C. Data reduction for point cloud using octree coding. In Intelligent Computing Theories and Application; Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2017; Volume 10361, pp. 376–383. [Google Scholar]

- Huang, X.; Hu, M. 3D reconstruction based on model registration using RANSAC-ICP algorithm. In Transactions on Edutainment XI; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2015; Volume 8971, pp. 46–51. [Google Scholar]

- Tian, H.; Yang, P.; Su, C.; Dong, Z. ICP registration technology based on the coordinate system direction fit. Int. J. Secur. Its Appl. 2015, 9, 47–56. [Google Scholar] [CrossRef]

- Song, M.; Chang, Y.L.; Xi, J.T.; Li, X.J. Phase unwrapping method based on multiple fringe patterns without use of equivalent wavelengths. Opt. Commun. 2015, 355, 213–224. [Google Scholar] [CrossRef] [Green Version]

| Scanning Distance (cm) | Absolute Mean Value of Error (mm) | General Standard Deviation (mm) |

|---|---|---|

| 30 | 0.0227 | 0.0212 |

| 40 | 0.0229 | 0.0212 |

| 50 | 0.0300 | 0.0303 |

| 60 | 0.0336 | 0.0343 |

| Average Distance (mm) | Standard Deviation (mm) | Root Mean Square (mm) | |

|---|---|---|---|

| The traditional method | 0.0115 | 0.0501 | 0.0514 |

| The method in this paper | 0.0016 | 0.0493 | 0.0493 |

| Three-Dimensional Measurement Boundary Frame (mm) | Dimensions of Three-Dimensional Measurement (mm) | Actual Size of an Object (mm) | Error (mm) |

|---|---|---|---|

| X [−135.6255, 265.2018] | 400.8273 | 400.0 | 0.8273 |

| Y [−209.0496, 734.4292] | 943.4788 | 943.5 | 0.0212 |

| Z [−8.7729, 387.0705] | 395.8434 | 396.0 | 0.1566 |

| Three-Dimensional Measurement Boundary Frame (mm) | Dimensions of Three-Dimensional Measurement (mm) | Actual Size of an Object (mm) | Error (mm) |

|---|---|---|---|

| X [−64.2971, 207.2918] | 271.5889 | 271.0 | 0.5889 |

| Y [−25.8170, 264.2313] | 290.0483 | 290.0 | 0.0483 |

| Z [−108.8357, 63.6009] | 172.4366 | 172.0 | 0.4366 |

| X Axis (mm) | Y Axis (mm) | Z Axis (mm) | 3D Data (mm) | Actual Value (mm) | Error (mm) |

|---|---|---|---|---|---|

| 78.081 | 5.441 | 3.291 | 78.340 | 78.501 | 0.161 |

| 37.899 | 3.279 | 0.494 | 38.044 | 38.000 | 0.044 |

| 223.785 | 2.242 | 10.705 | 224.052 | 224.00 | 0.052 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, L.; Li, X.; Yang, Y.-g.; Zhu, X.; Guo, Q.; Liu, H. Structured-Light Based 3D Reconstruction System for Cultural Relic Packaging. Sensors 2018, 18, 2981. https://doi.org/10.3390/s18092981

Song L, Li X, Yang Y-g, Zhu X, Guo Q, Liu H. Structured-Light Based 3D Reconstruction System for Cultural Relic Packaging. Sensors. 2018; 18(9):2981. https://doi.org/10.3390/s18092981

Chicago/Turabian StyleSong, Limei, Xinyao Li, Yan-gang Yang, Xinjun Zhu, Qinghua Guo, and Hui Liu. 2018. "Structured-Light Based 3D Reconstruction System for Cultural Relic Packaging" Sensors 18, no. 9: 2981. https://doi.org/10.3390/s18092981

APA StyleSong, L., Li, X., Yang, Y.-g., Zhu, X., Guo, Q., & Liu, H. (2018). Structured-Light Based 3D Reconstruction System for Cultural Relic Packaging. Sensors, 18(9), 2981. https://doi.org/10.3390/s18092981