Effects of Applying Different Resonance Amplitude on the Performance of the Impedance-Based Health Monitoring Technique Subjected to Damage

Abstract

:1. Introduction

2. The EMI Method

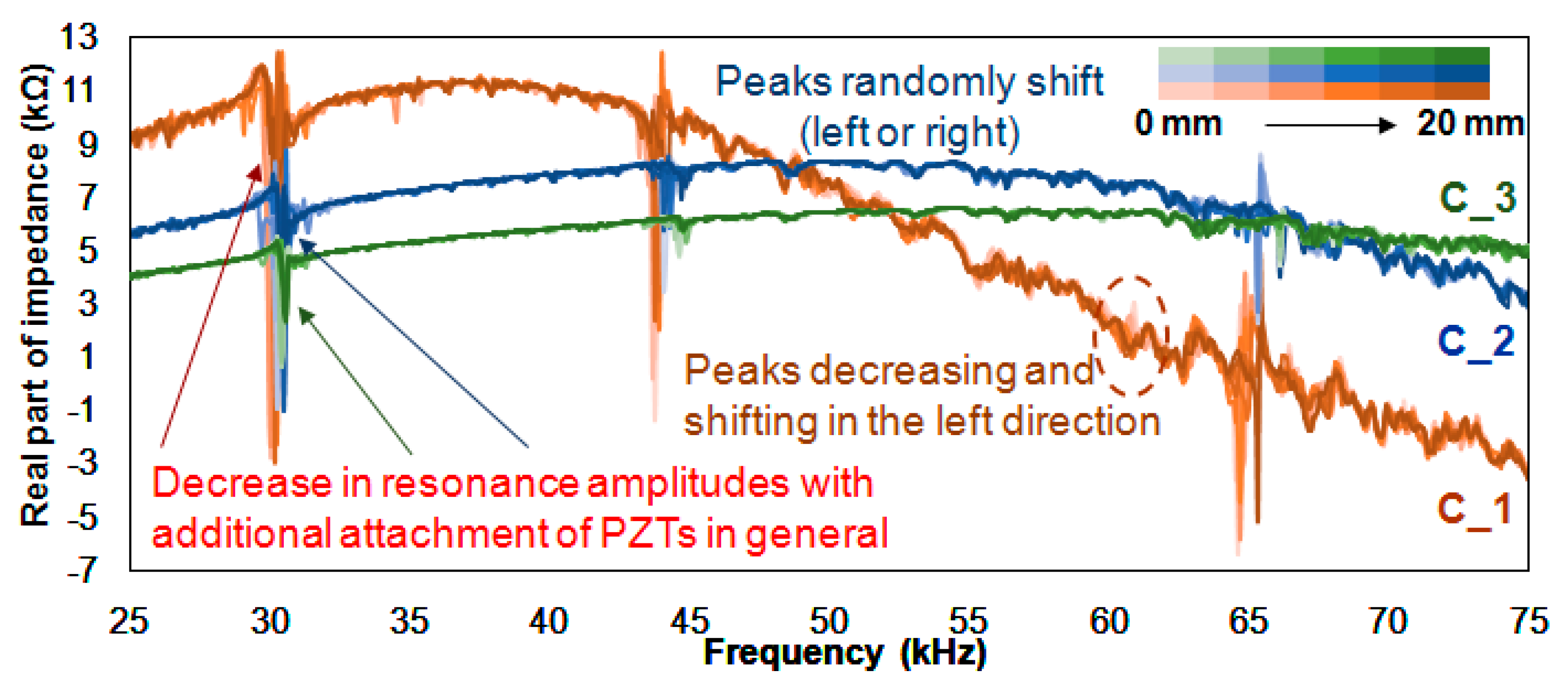

3. Impedance Signature Peak Reduction Effect on EMI Performance

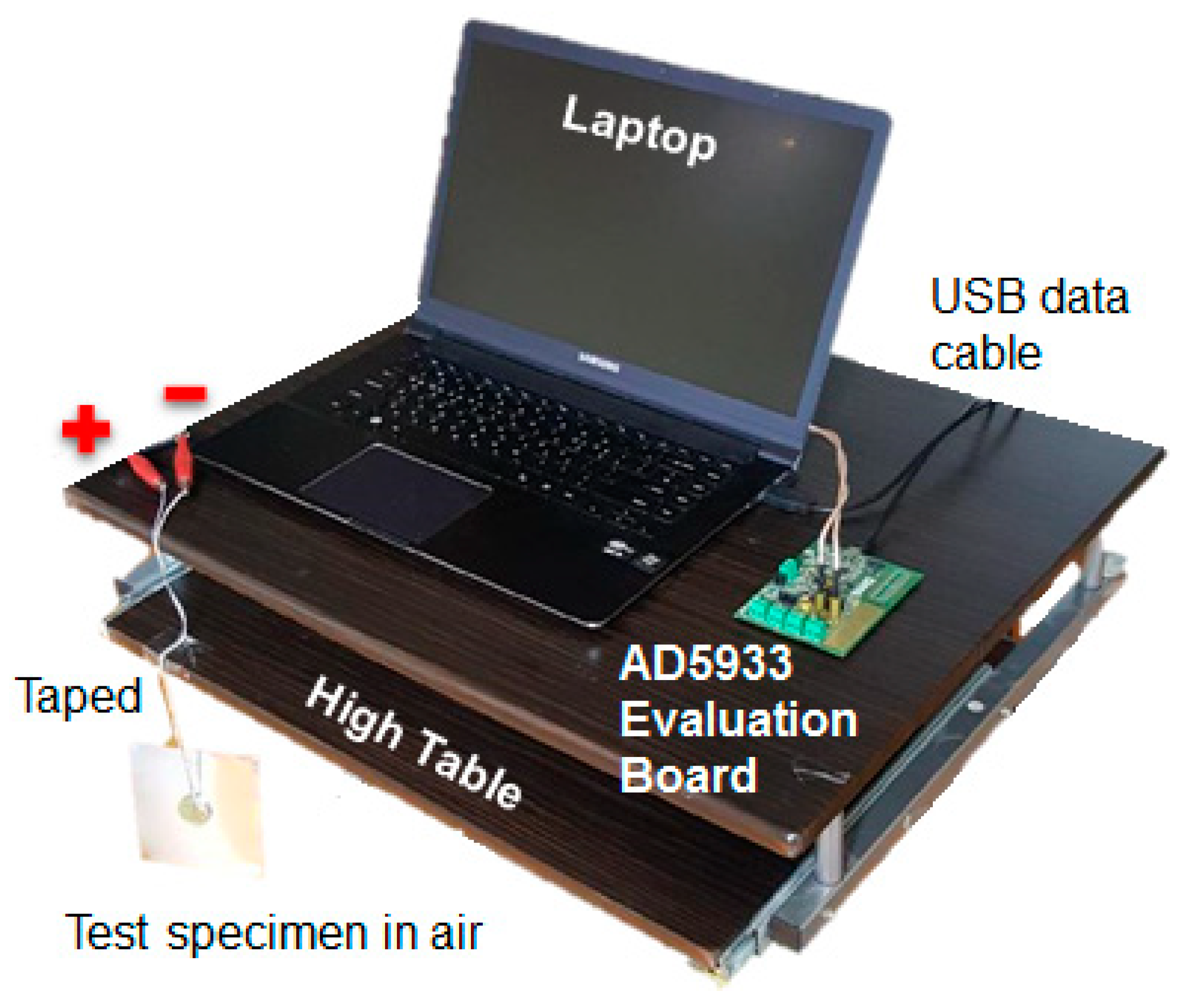

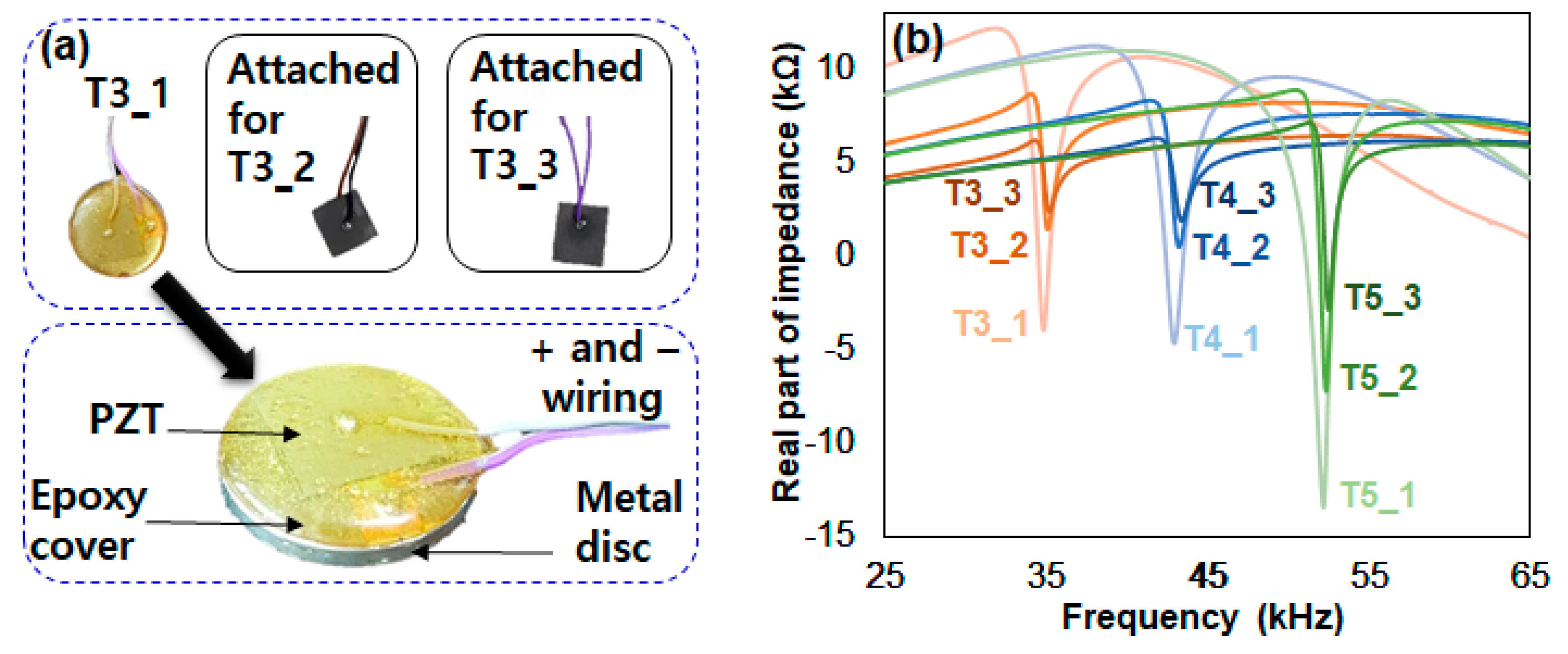

4. Creating Various Resonance Frequency Ranges

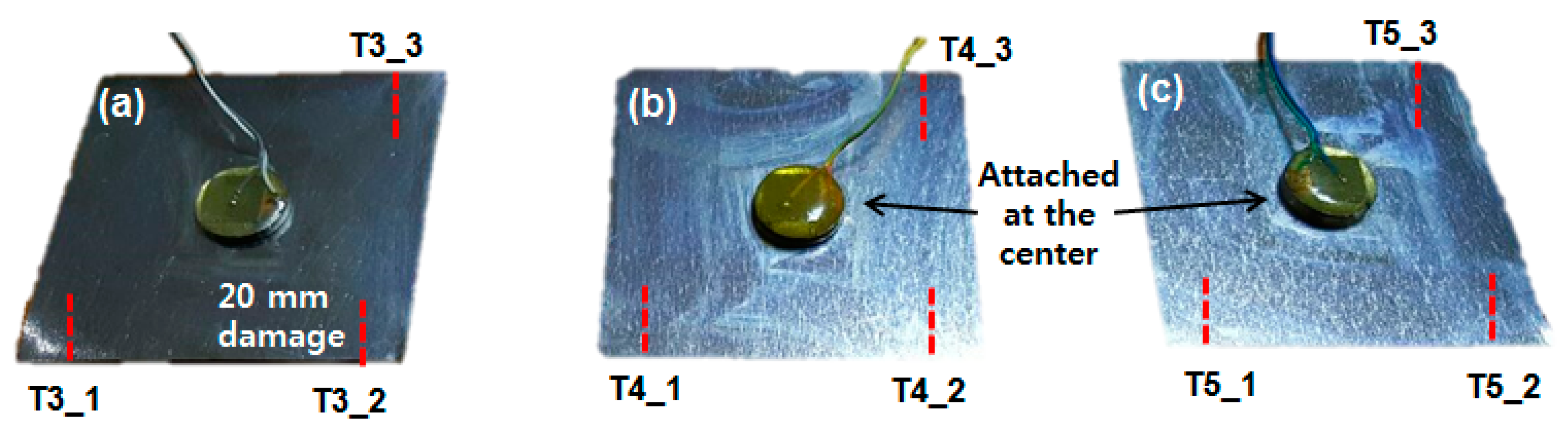

5. Conducting the EMI Method with Various Signature Amplitudes

6. Results and Discussion

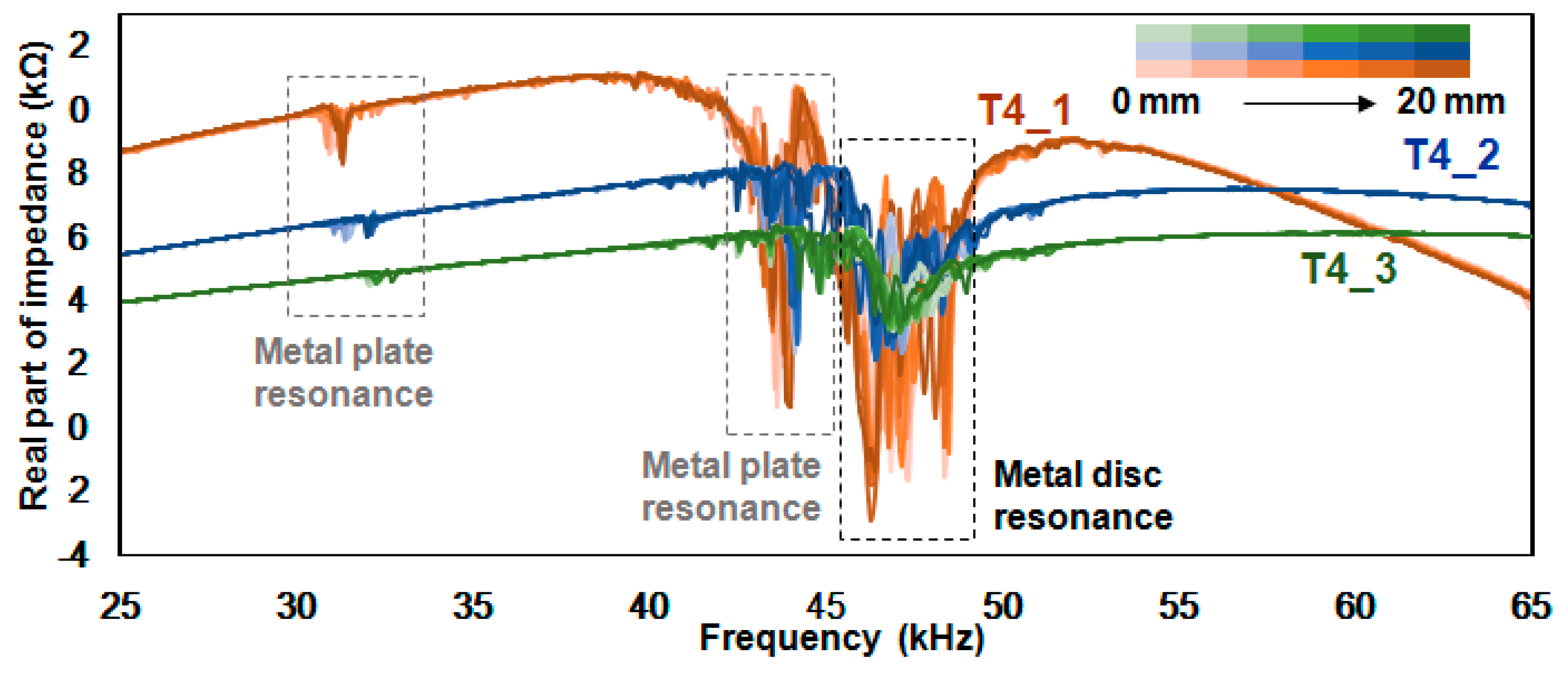

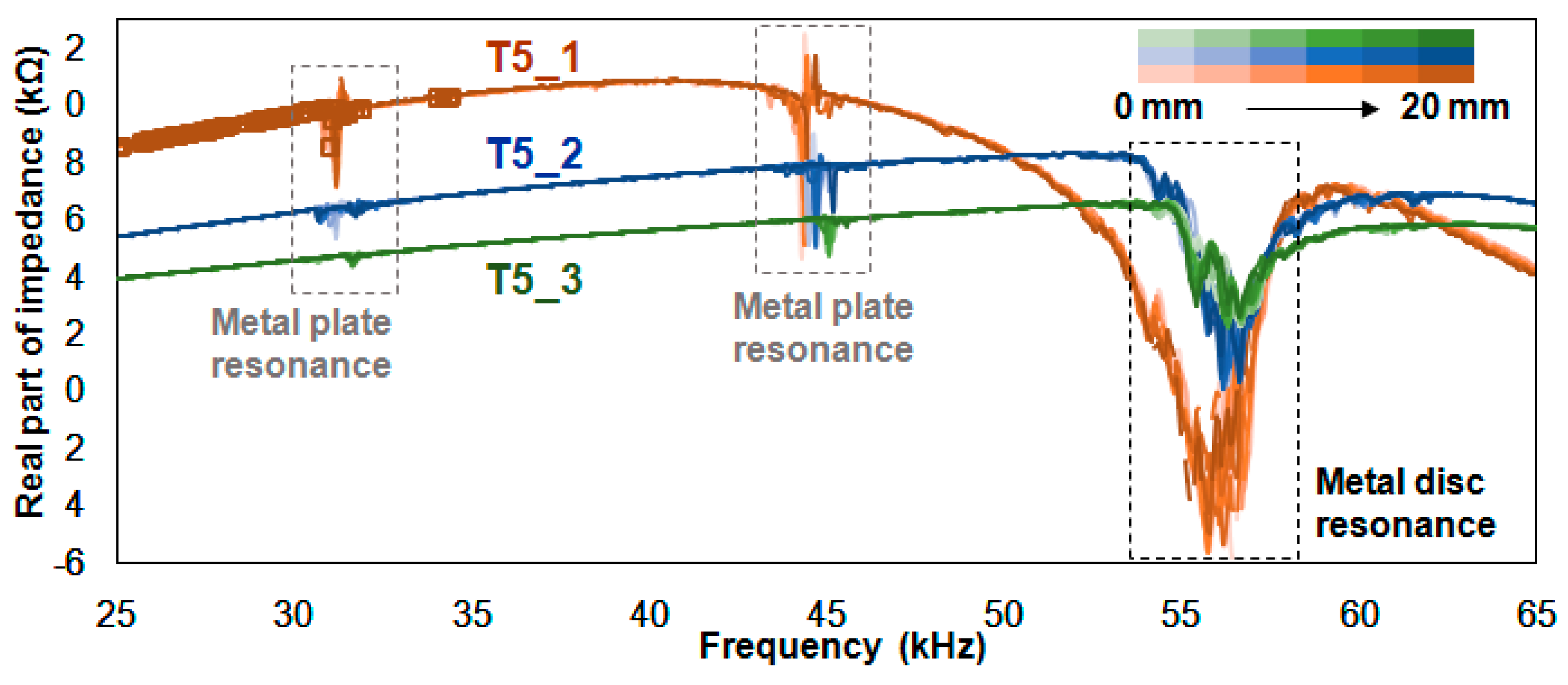

6.1. Analyzing the Data for T3_x, T4_x and T5_x Cases

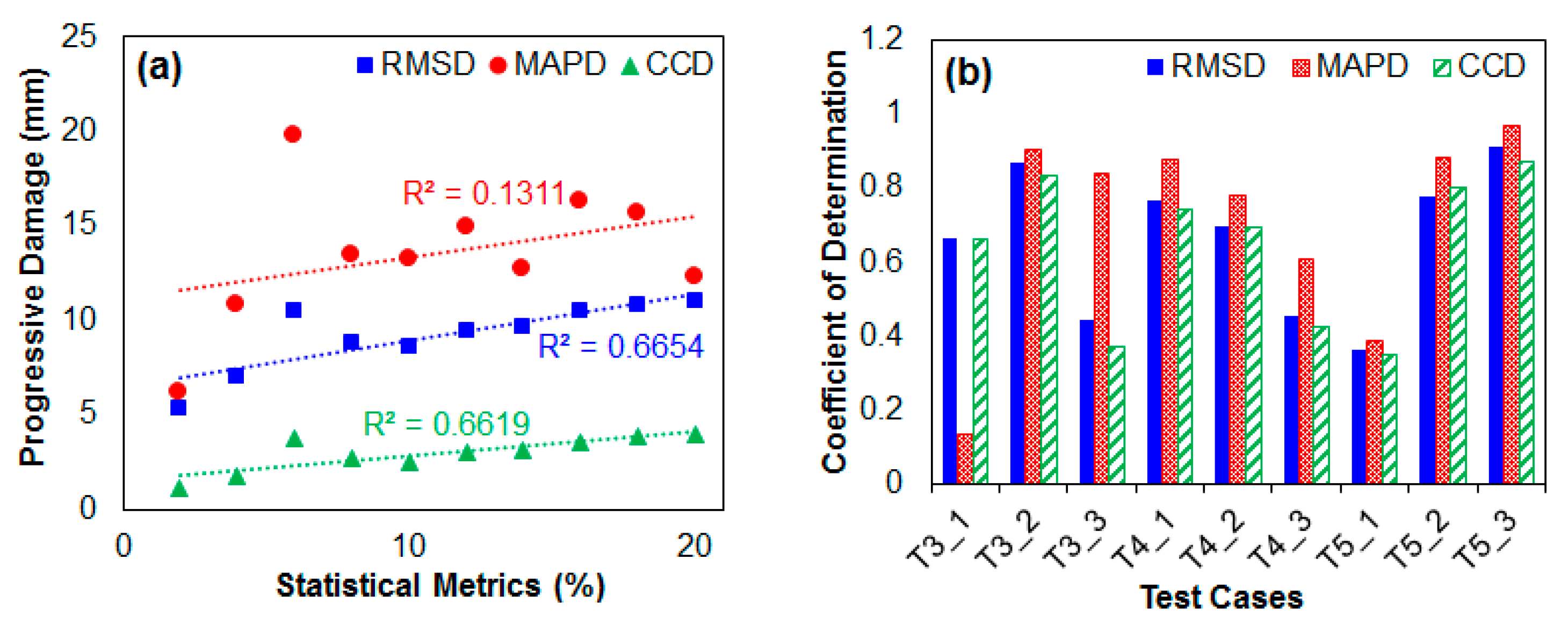

6.2. Regression Analysis on Experimental Data

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Liang, C.; Sun, F.P.; Rogers, C.A. Coupled electromechanical analysis of adaptive material system determination of the actuator power consumption and system energy transfer. J. Intell. Mater. Syst. Struct. 1994, 5, 12–20. [Google Scholar] [CrossRef]

- Na, W.S. Distinguishing crack damage from debonding damage of glass fiber reinforced polymer plate using a piezoelectric transducer based nondestructive testing method. Compos. Struct. 2017, 159, 517–527. [Google Scholar] [CrossRef]

- Na, W.S.; Lee, H. Experimental investigation for an isolation technique on conducting the electromechanical impedance method in high-temperature pipeline facilities. J. Sound Vib. 2016, 383, 210–220. [Google Scholar] [CrossRef]

- Na, S.; Tawie, R.; Lee, H.K. Electromechanical impedance method of fiber-reinforced plastic adhesive joints in corrosive environment using a reusable piezoelectric device. J. Intell. Mater. Syst. Struct. 2012, 23, 737–747. [Google Scholar] [CrossRef]

- Wandowski, T.; Malinowski, P.H.; Ostachowicz, W.M. Delamination detection in CFRP panels using EMI method with temperature compensation. Compos. Struct. 2016, 151, 99–107. [Google Scholar] [CrossRef]

- Yang, Y.; Lim, Y.Y.; Soh, C.K. Practical issues related to the application of the electromechanical impedance technique in the structural health monitoring of civil structures: I. Experiment. Smart Mater. Struct. 2008, 17, 035008. [Google Scholar] [CrossRef]

- Baptista, F.G.; Vieira Filho, J. A new impedance measurement system for PZT-based structural health monitoring. IEEE Trans. Instrum. Meas. 2009, 58, 3602–3608. [Google Scholar] [CrossRef]

- Bhalla, S.; Gupta, A.; Bansal, S.; Garg, T. Ultra low-cost adaptations of electro-mechanical impedance technique for structural health monitoring. J. Intell. Mater. Syst. Struct. 2009, 20, 991–999. [Google Scholar] [CrossRef]

- Panigrahi, R.; Bhalla, S.; Gupta, A. A low-cost variant of electro-mechanical impedance (EMI) technique for structural health monitoring. Exp. Tech. 2010, 34, 25–29. [Google Scholar] [CrossRef]

- Wandowski, T.; Malinowski, P.; Ostachowicz, W. Calibration problem of AD5933 device for electromechanical impedance measurements. In Proceedings of the EWSHM-7th European Workshop on Structural Health Monitoring, Nantes, France, 8–11 July 2014. [Google Scholar]

- Sun, F.P.; Chaudhry, Z.; Liang, C.; Rogers, C.A. Truss structure integrity identification using PZT sensor-actuator. J. Intell. Mater. Syst. Struct. 1995, 6, 134–139. [Google Scholar] [CrossRef]

| Damage (mm) | RMSD (%) | MAPD (%) | CCD (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| RC_1 | RC_2 | RC_3 | MC_1 | MC_2 | MC_3 | CC_1 | CC_2 | CC_3 | |

| 2 | 7.38 | 5.78 | 1.63 | 11.51 | 1.58 | 0.71 | 0.90 | 4.66 | 1.06 |

| 4 | 10.61 | 3.92 | 2.29 | 16.10 | 1.70 | 1.03 | 1.63 | 2.37 | 1.90 |

| 6 | 10.06 | 5.50 | 2.09 | 15.07 | 2.20 | 1.08 | 1.49 | 4.51 | 1.62 |

| 8 | 10.95 | 4.72 | 3.25 | 15.77 | 2.33 | 1.68 | 1.73 | 3.37 | 3.68 |

| 10 | 11.68 | 5.94 | 4.19 | 17.38 | 2.80 | 2.05 | 1.94 | 5.20 | 6.05 |

| 12 | 14.24 | 7.03 | 3.41 | 19.58 | 3.16 | 1.75 | 2.77 | 7.06 | 4.05 |

| 14 | 13.32 | 6.43 | 3.72 | 18.36 | 2.96 | 1.91 | 2.46 | 6.07 | 4.81 |

| 16 | 11.59 | 6.92 | 3.84 | 21.12 | 2.95 | 1.97 | 1.91 | 6.75 | 5.10 |

| 18 | 11.22 | 6.93 | 3.86 | 21.79 | 3.07 | 2.05 | 1.81 | 6.94 | 5.13 |

| 20 | 13.53 | 7.27 | 4.18 | 27.55 | 3.46 | 2.12 | 2.54 | 7.64 | 5.97 |

| Average | 11.46 | 6.04 | 3.25 | 18.42 | 2.62 | 1.64 | 1.92 | 5.46 | 3.94 |

| Damage (mm) | RMSD (%) | MAPD (%) | CCD (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| RT3_1 | RT3_2 | RT3_3 | MT3_1 | MT3_2 | MT3_3 | CT3_1 | CT3_2 | CT3_3 | |

| 2 | 5.33 | 1.82 | 1.39 | 6.21 | 0.69 | 0.55 | 1.11 | 1.56 | 0.92 |

| 4 | 7.09 | 2.12 | 1.18 | 10.87 | 0.88 | 0.55 | 1.81 | 2.03 | 0.73 |

| 6 | 10.53 | 2.36 | 2.04 | 19.77 | 0.99 | 0.88 | 3.73 | 2.49 | 1.78 |

| 8 | 8.82 | 2.86 | 2.89 | 13.50 | 1.28 | 0.99 | 2.69 | 3.51 | 3.37 |

| 10 | 8.61 | 3.13 | 2.21 | 13.24 | 1.37 | 0.86 | 2.53 | 4.25 | 2.04 |

| 12 | 9.41 | 2.92 | 2.11 | 14.91 | 1.33 | 0.94 | 3.00 | 3.75 | 1.89 |

| 14 | 9.65 | 2.93 | 2.30 | 12.76 | 1.33 | 1.01 | 3.12 | 3.74 | 2.22 |

| 16 | 10.46 | 3.25 | 2.58 | 16.29 | 1.46 | 1.15 | 3.61 | 4.57 | 2.72 |

| 18 | 10.87 | 4.24 | 2.20 | 15.66 | 1.90 | 1.08 | 3.88 | 7.56 | 2.03 |

| 20 | 11.03 | 3.83 | 2.65 | 12.34 | 1.79 | 1.27 | 4.02 | 6.31 | 2.76 |

| Average | 9.18 | 2.95 | 2.16 | 13.56 | 1.30 | 0.93 | 2.95 | 3.98 | 2.05 |

| Damage (mm) | RMSD (%) | MAPD (%) | CCD (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| RT4_1 | RT4_2 | RT4_3 | MT4_1 | MT4_2 | MT4_3 | CT4_1 | CT4_2 | CT4_3 | |

| 2 | 5.61 | 2.86 | 2.19 | 8.85 | 1.13 | 0.81 | 2.12 | 2.46 | 1.66 |

| 4 | 7.39 | 2.92 | 3.57 | 14.82 | 1.21 | 1.27 | 3.56 | 2.55 | 4.14 |

| 6 | 9.38 | 5.66 | 3.05 | 13.76 | 2.15 | 1.25 | 5.69 | 9.48 | 2.98 |

| 8 | 8.85 | 5.67 | 3.13 | 15.61 | 2.34 | 1.18 | 5.06 | 9.14 | 3.14 |

| 10 | 9.25 | 6.36 | 3.27 | 15.05 | 2.57 | 1.37 | 5.41 | 11.47 | 3.43 |

| 12 | 7.67 | 5.97 | 3.14 | 17.54 | 2.27 | 1.30 | 3.81 | 10.20 | 3.18 |

| 14 | 9.06 | 5.49 | 3.05 | 18.54 | 2.23 | 1.25 | 5.21 | 8.68 | 3.01 |

| 16 | 10.94 | 5.20 | 3.30 | 24.93 | 2.34 | 1.37 | 7.62 | 7.93 | 3.52 |

| 18 | 13.28 | 7.63 | 3.48 | 29.70 | 3.44 | 1.37 | 11.12 | 17.55 | 3.90 |

| 20 | 13.77 | 8.30 | 4.66 | 32.27 | 3.60 | 1.89 | 11.90 | 20.56 | 6.88 |

| Average | 9.52 | 5.61 | 3.28 | 19.11 | 2.33 | 1.31 | 6.15 | 10.00 | 3.58 |

| Damage (mm) | RMSD (%) | MAPD (%) | CCD (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| RT5_1 | RT5_2 | RT5_3 | MT5_1 | MT5_2 | MT5_3 | CT5_1 | CT5_2 | CT5_3 | |

| 2 | 5.67 | 1.66 | 2.38 | 22.36 | 0.89 | 0.80 | 1.29 | 0.61 | 1.42 |

| 4 | 4.97 | 3.17 | 2.24 | 25.02 | 1.39 | 0.85 | 1.04 | 1.71 | 1.29 |

| 6 | 7.09 | 3.32 | 2.81 | 35.83 | 1.88 | 1.01 | 1.92 | 1.85 | 1.91 |

| 8 | 8.07 | 3.49 | 3.21 | 43.96 | 2.15 | 1.17 | 2.43 | 2.02 | 2.43 |

| 10 | 8.44 | 3.39 | 3.25 | 42.95 | 2.48 | 1.26 | 2.64 | 1.92 | 2.50 |

| 12 | 8.39 | 3.37 | 3.26 | 29.65 | 2.29 | 1.38 | 2.62 | 1.91 | 2.52 |

| 14 | 6.35 | 4.35 | 3.56 | 26.86 | 3.43 | 1.37 | 1.58 | 3.06 | 2.98 |

| 16 | 8.18 | 4.91 | 3.52 | 37.23 | 5.75 | 1.45 | 2.50 | 3.83 | 2.91 |

| 18 | 7.44 | 4.23 | 4.24 | 50.54 | 4.90 | 1.69 | 2.09 | 2.90 | 4.16 |

| 20 | 8.23 | 4.68 | 4.72 | 45.11 | 5.73 | 1.88 | 2.53 | 3.50 | 5.13 |

| Average | 7.28 | 3.66 | 3.32 | 35.95 | 3.09 | 1.29 | 2.06 | 2.33 | 2.73 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Na, W.S.; Seo, D.-W.; Kim, B.-C.; Park, K.-T. Effects of Applying Different Resonance Amplitude on the Performance of the Impedance-Based Health Monitoring Technique Subjected to Damage. Sensors 2018, 18, 2267. https://doi.org/10.3390/s18072267

Na WS, Seo D-W, Kim B-C, Park K-T. Effects of Applying Different Resonance Amplitude on the Performance of the Impedance-Based Health Monitoring Technique Subjected to Damage. Sensors. 2018; 18(7):2267. https://doi.org/10.3390/s18072267

Chicago/Turabian StyleNa, Wongi S., Dong-Woo Seo, Byeong-Cheol Kim, and Ki-Tae Park. 2018. "Effects of Applying Different Resonance Amplitude on the Performance of the Impedance-Based Health Monitoring Technique Subjected to Damage" Sensors 18, no. 7: 2267. https://doi.org/10.3390/s18072267

APA StyleNa, W. S., Seo, D.-W., Kim, B.-C., & Park, K.-T. (2018). Effects of Applying Different Resonance Amplitude on the Performance of the Impedance-Based Health Monitoring Technique Subjected to Damage. Sensors, 18(7), 2267. https://doi.org/10.3390/s18072267