Fiber Bragg Grating Displacement Sensor with High Abrasion Resistance for a Steel Spring Floating Slab Damping Track

Abstract

:1. Introduction

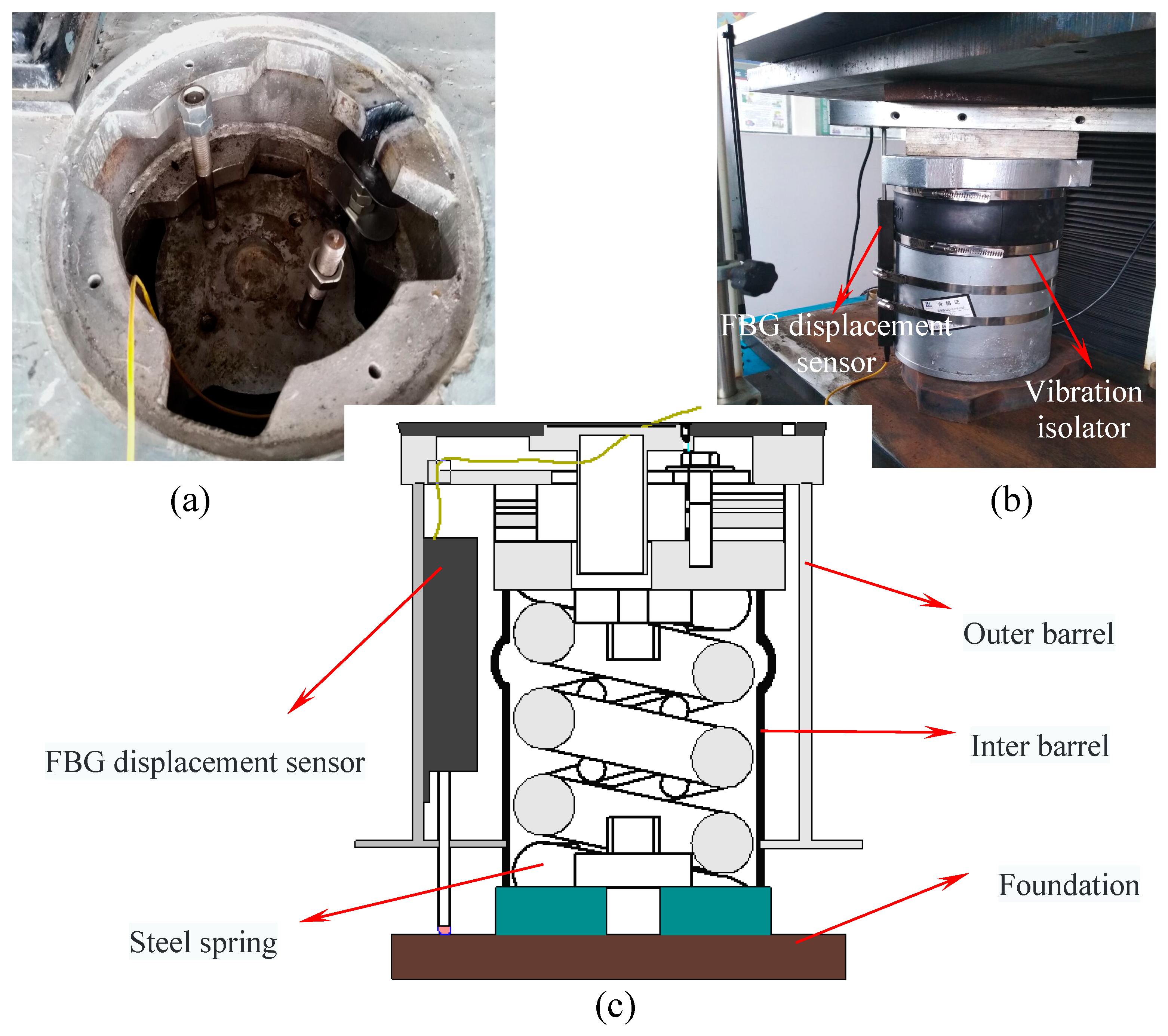

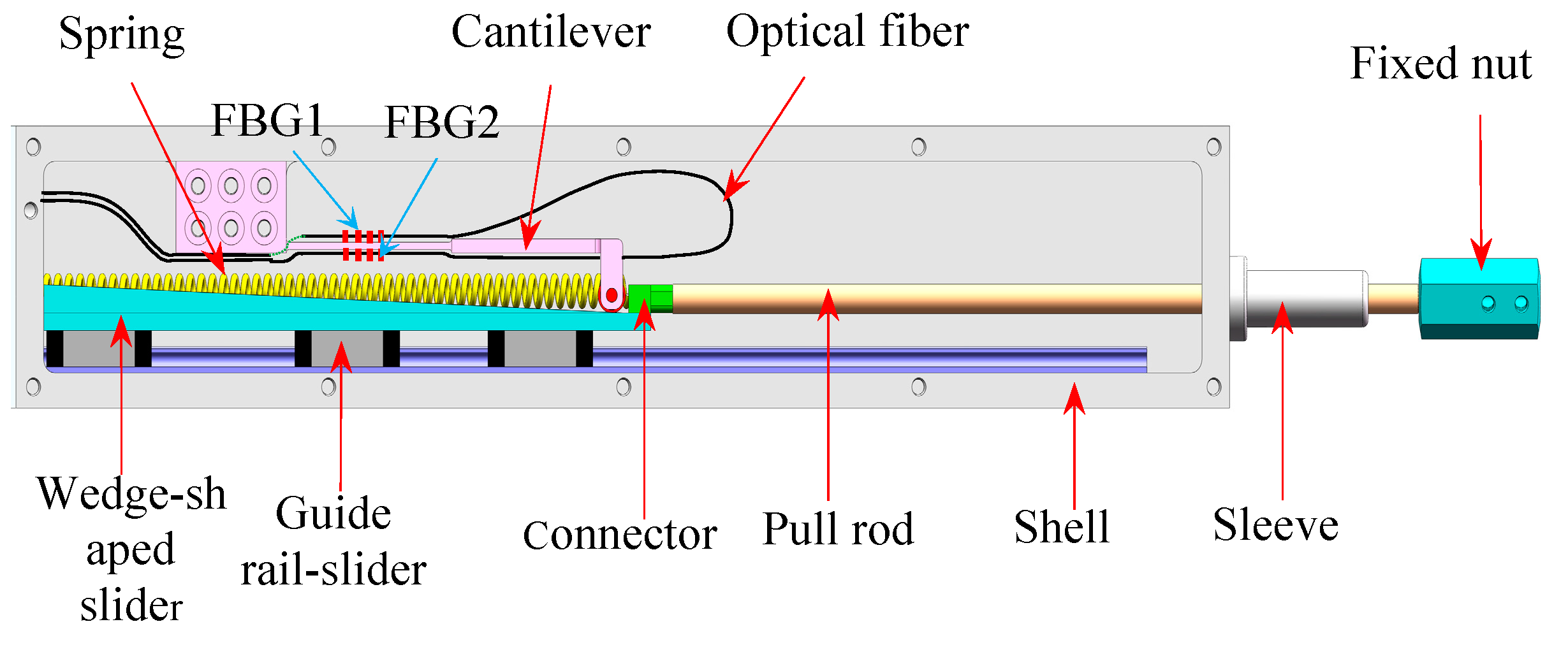

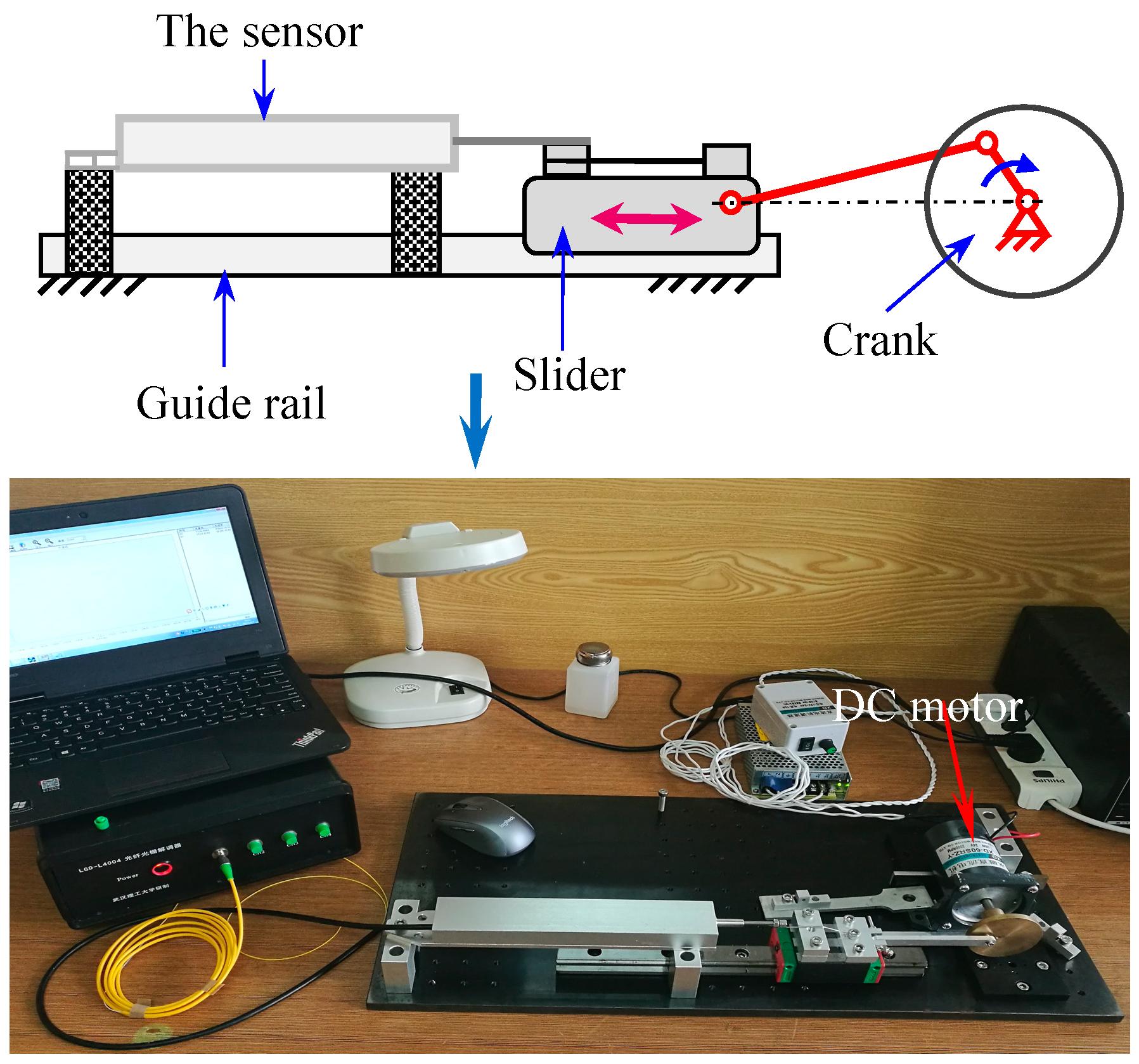

2. Principle and Structure Design

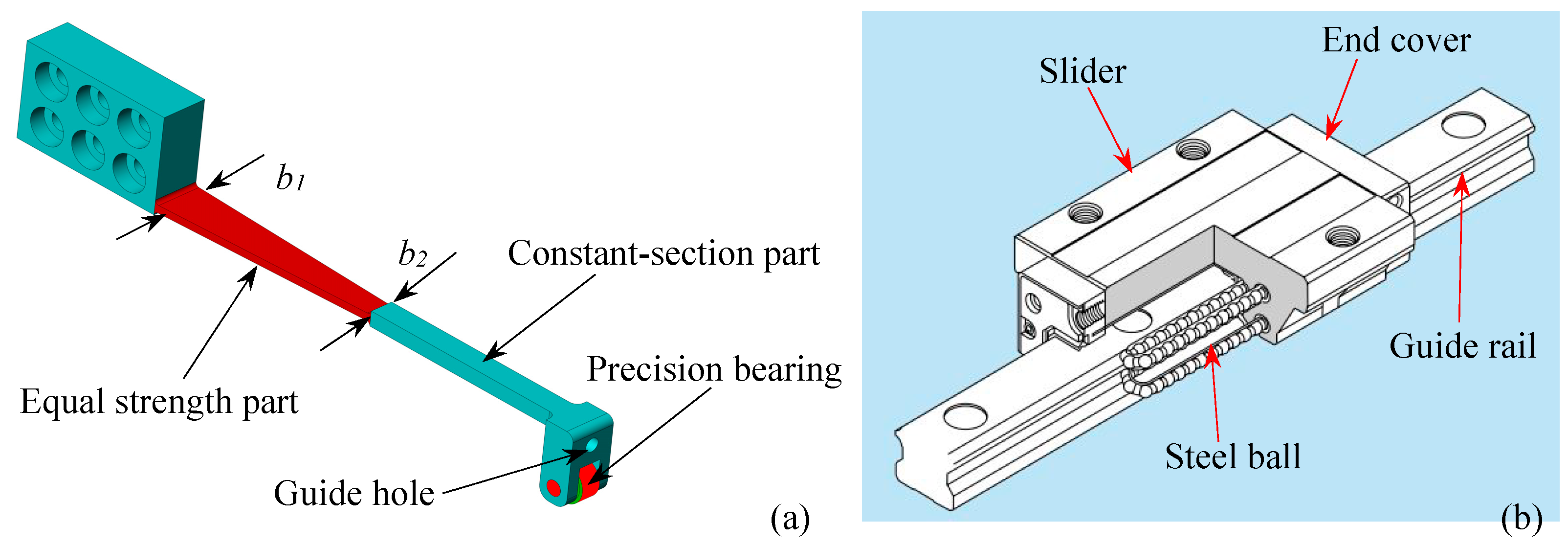

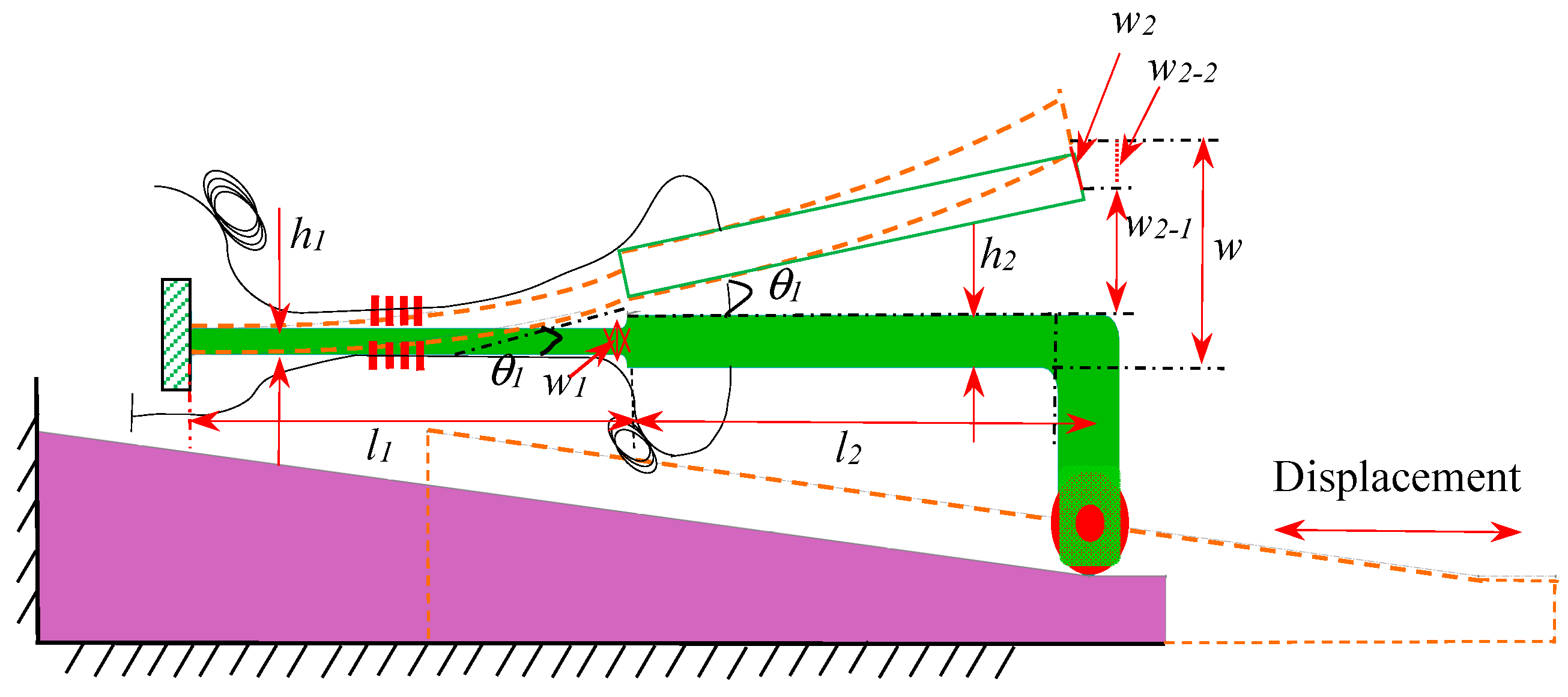

2.1. Mechanical Structure Design

2.2. Measuring Principle

3. Sensor Prototype Manufacturing and Experiments

3.1. Sensor Prototype Manufacturing

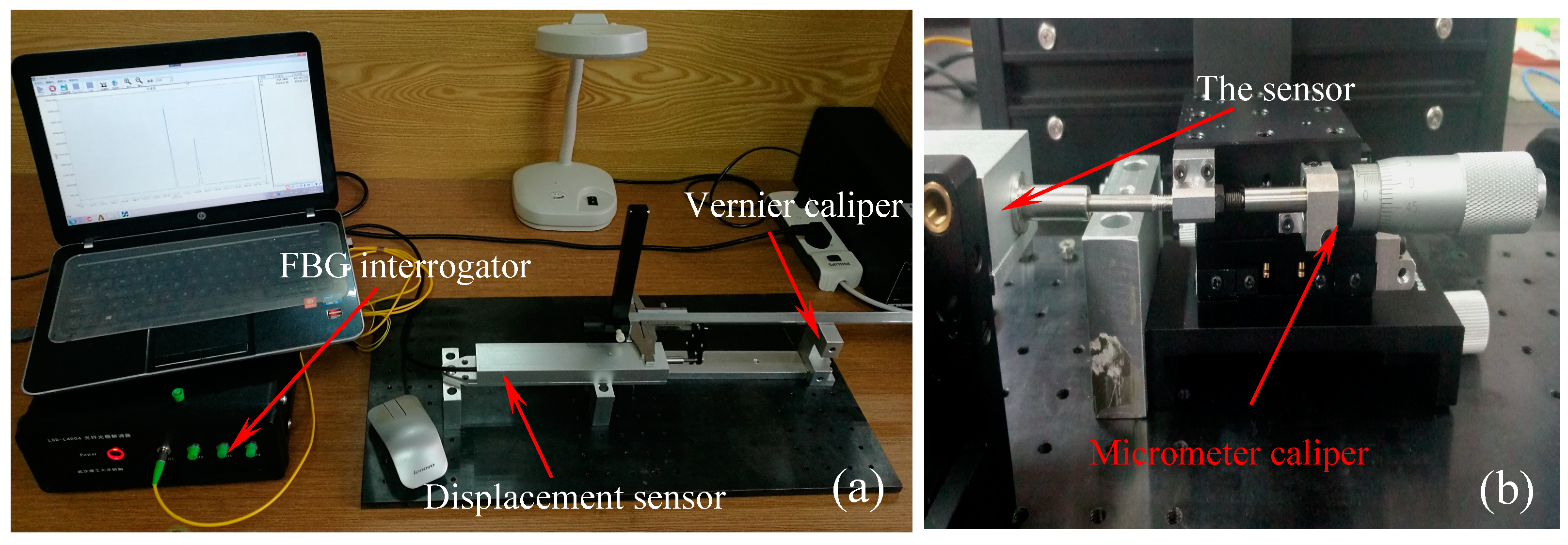

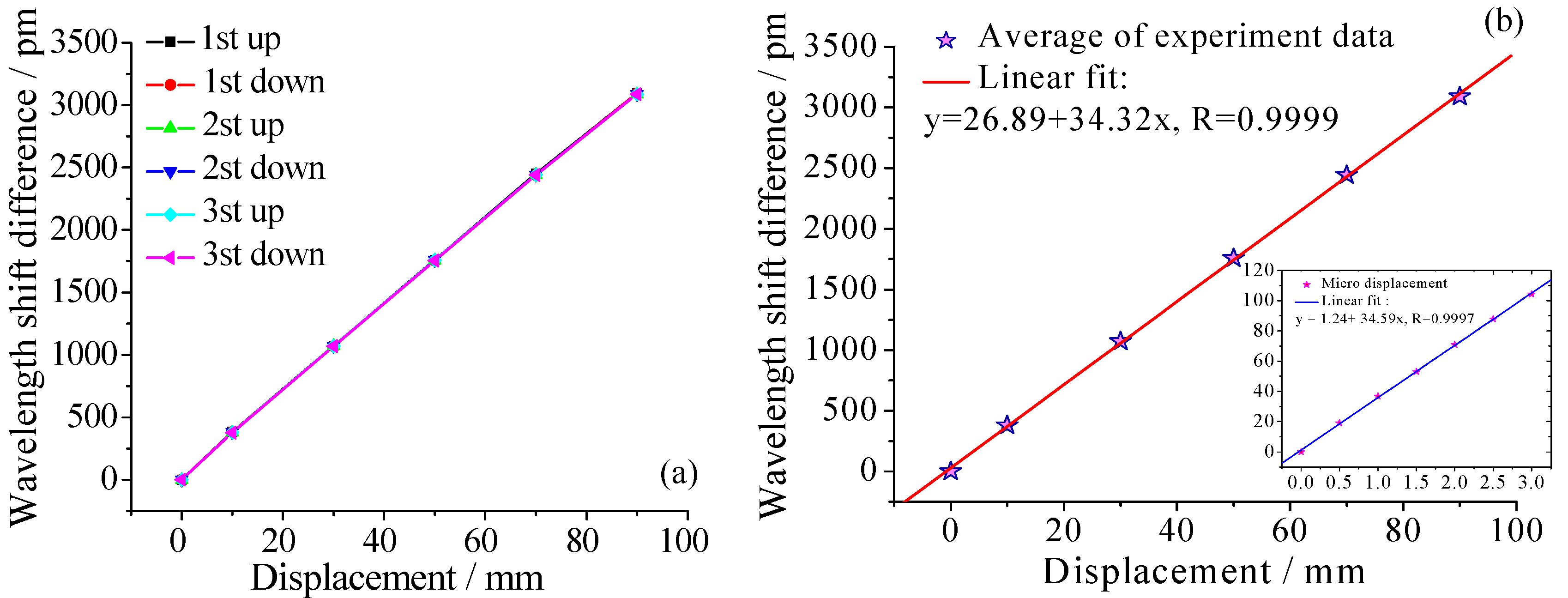

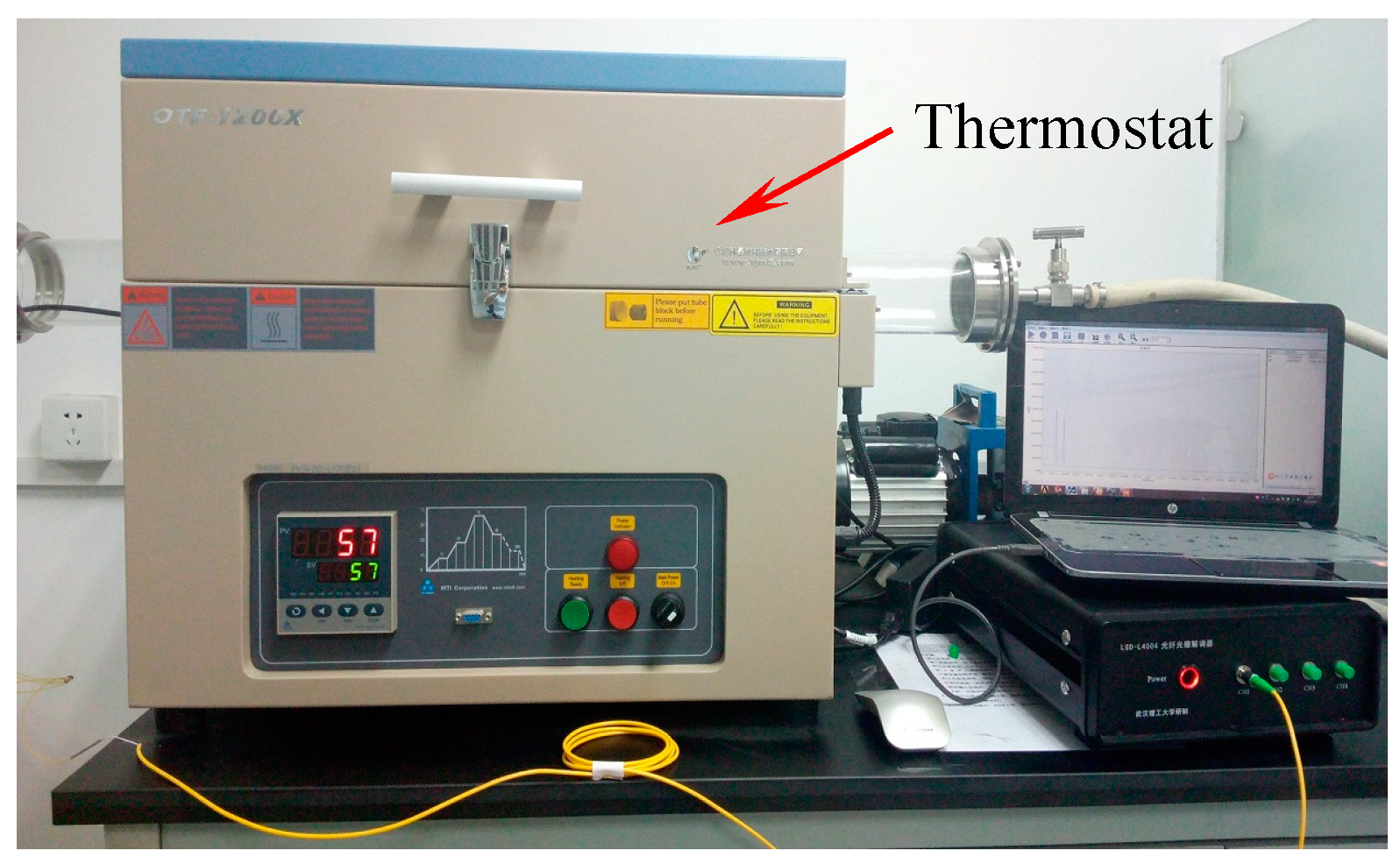

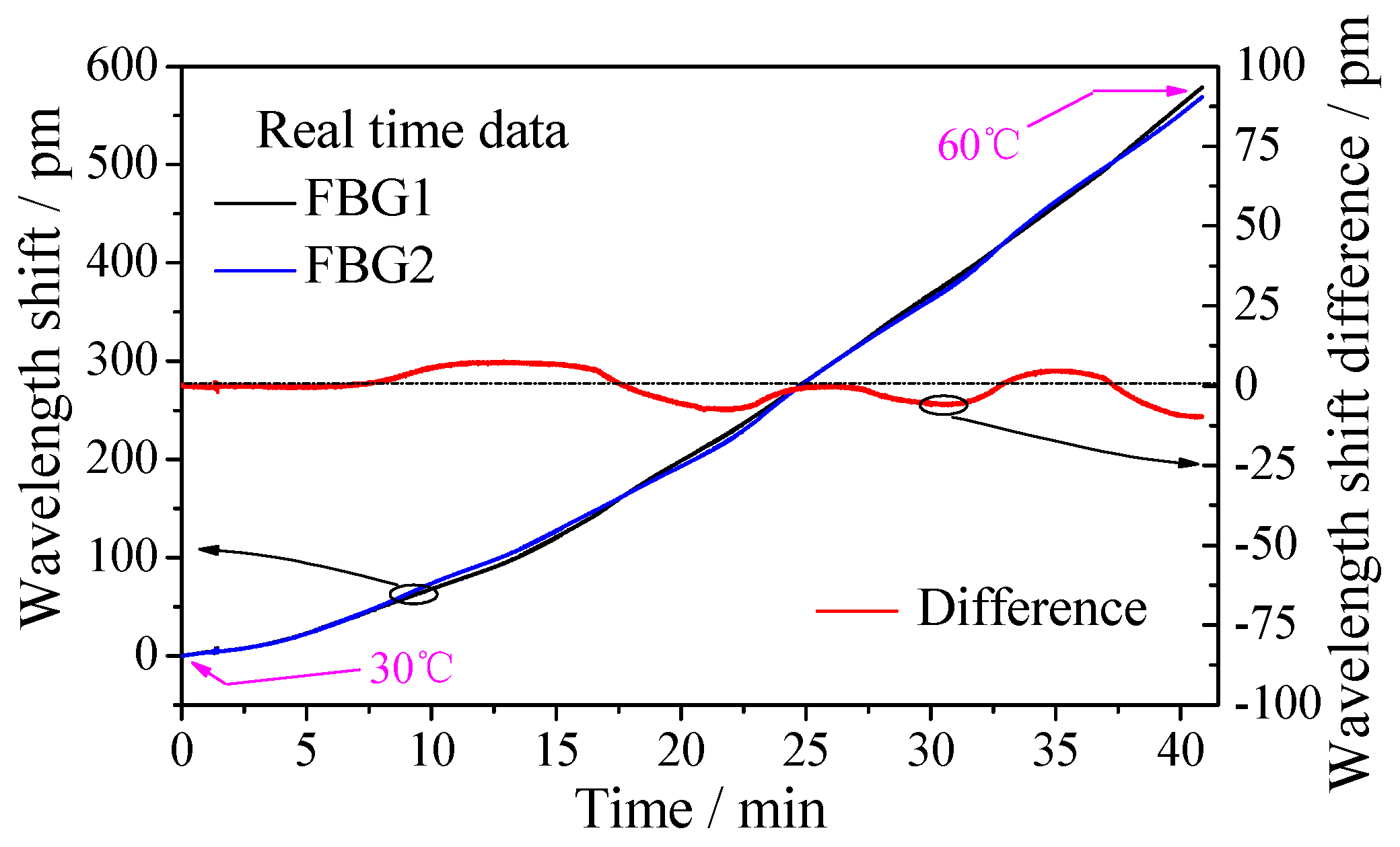

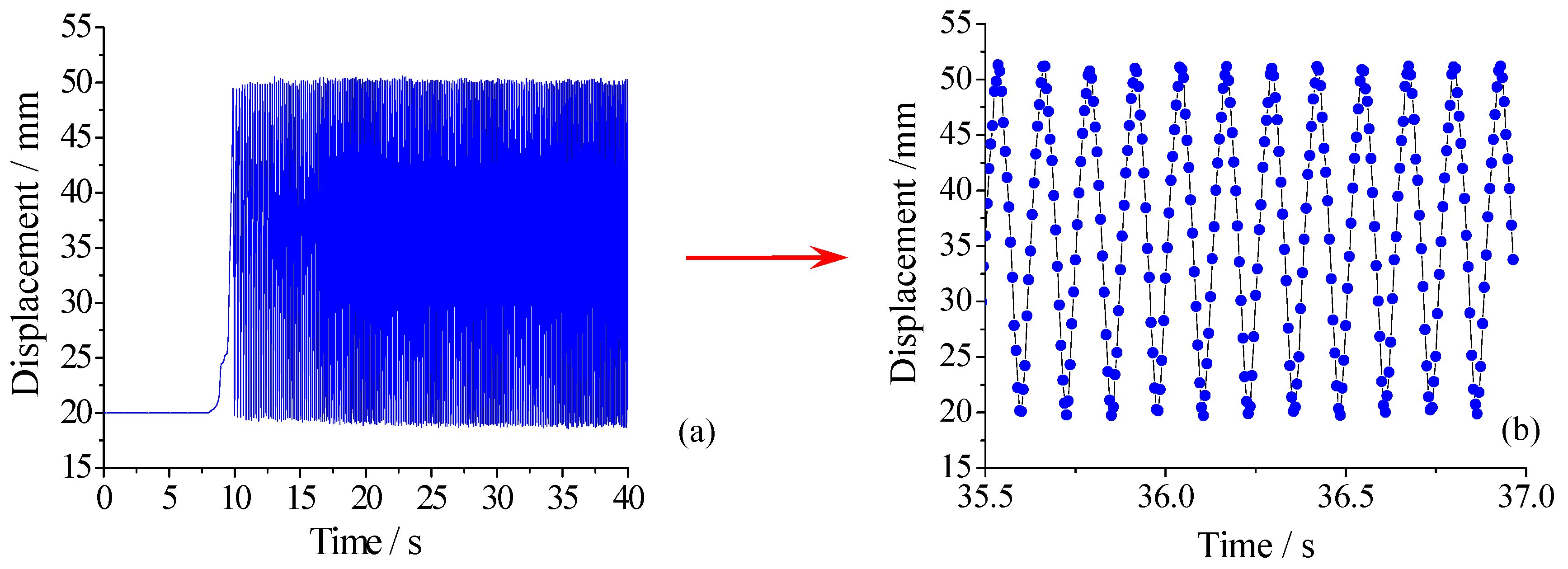

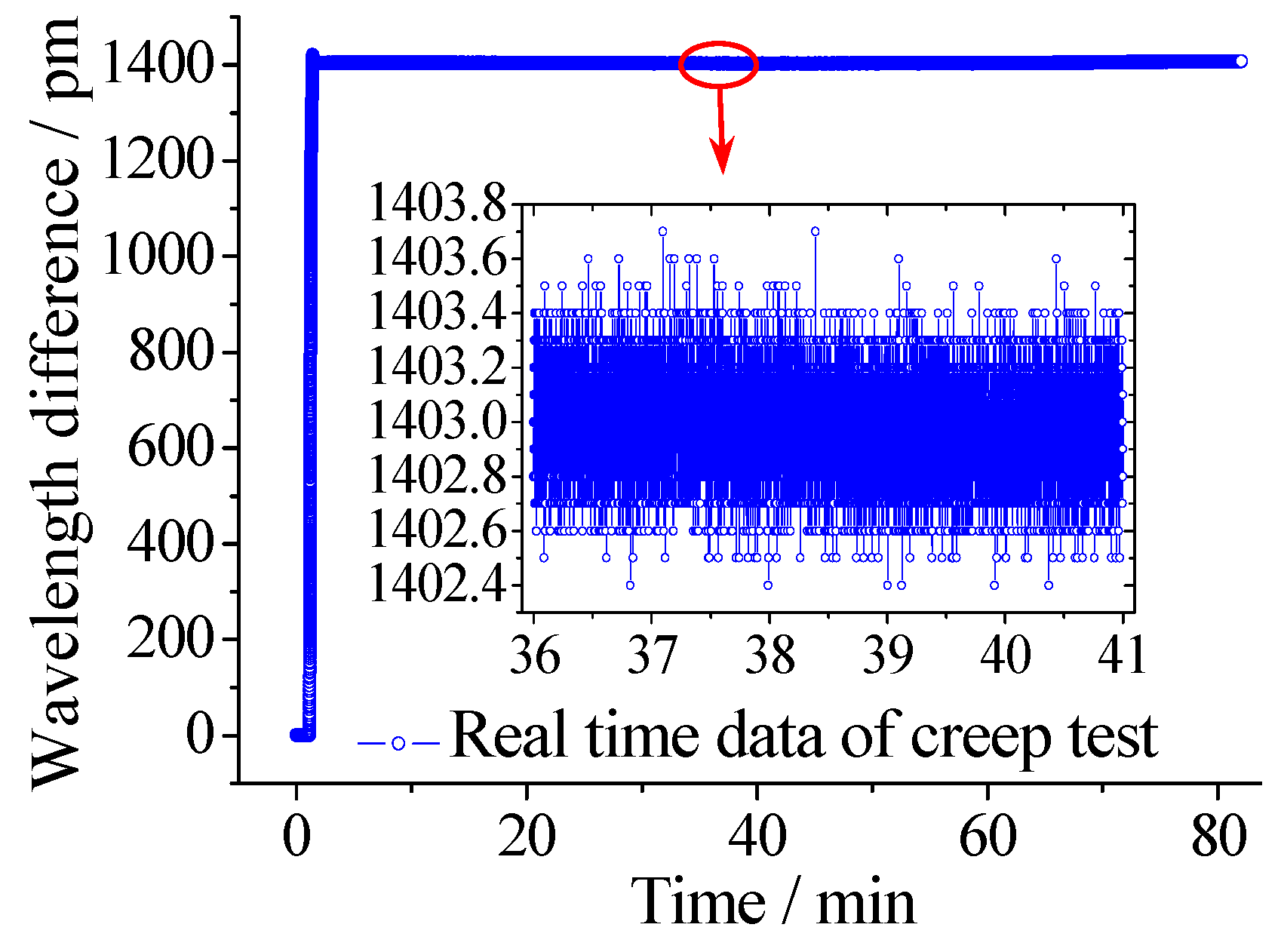

3.2. Experiments for Calibration and Test

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Majumder, M.; Gangopadhyay, T.K.; Chakraborty, A.K.; Dasgupta, K.; Bhattacharya, D.K. Fibre Bragg gratings in structural health monitoring—Present status and applications. Sens. Actuators A Phys. 2008, 147, 150–164. [Google Scholar] [CrossRef]

- Jia, D.D.; Zhang, Y.L.; Chen, Z.T.; Zhang, H.X.; Liu, T.G.; Zhang, Y.M. A self-healing passive fiber Bragg grating sensor network. J. Lightwave Technol. 2015, 33, 2062–2067. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, Y.N.; Yuan, M.D.; Wang, J.F.; Zhu, S.Y. A Laser-Based Fiber Bragg Grating Ultrasonic Sensing System for Structural Health Monitoring. IEEE Photonics Technol. Lett. 2016, 28, 2573–2576. [Google Scholar] [CrossRef]

- Yazdizadeh, Z.; Marzouk, H.; Hadianfard, M.A. Monitoring of concrete shrinkage and creep using Fiber Bragg Grating sensors. Constr. Build. Mater. 2017, 137, 505–512. [Google Scholar] [CrossRef]

- Kong, X.; Ho, S.C.M.; Song, G.B.; Cai, C.S. Scour Monitoring System Using Fiber Bragg Grating Sensors and Water-Swellable Polymers. J. Bridge Eng. 2017, 22, 04017029. [Google Scholar] [CrossRef]

- Guo, H.L.; Xiao, G.Z.; Mrad, N.; Yao, J.P. Fiber optic sensors for structural health monitoring of air platforms. Sensors 2011, 11, 3687–3705. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.X.; Kong, J.Y.; Liu, H.H.; Xiong, H.G.; Li, G.F.; Qin, L. A three-axis force fingertip sensor based on fiber Bragg grating. Sens. Actuators A Phys. 2016, 249, 141–148. [Google Scholar] [CrossRef]

- Xiong, L.; Jiang, G.Z.; Guo, Y.X.; Liu, H.H. A Three-dimensional Fiber Bragg Grating Force Sensor for Robot. IEEE Sens. J. 2018, 18, 3632–3639. [Google Scholar] [CrossRef]

- Li, D.S.; Li, H.N.; Ren, L.; Song, G.B. Strain transferring analysis of fiber Bragg grating sensors. Opt. Eng. 2006, 45, 024402. [Google Scholar] [CrossRef]

- Zhao, X.F.; Gou, J.H.; Song, G.B.; Ou, J.P. Strain monitoring in glass fiber reinforced composites embedded with carbon nanopaper sheet using Fiber Bragg Grating (FBG) sensors. Compos. Part B Eng. 2009, 40, 134–140. [Google Scholar] [CrossRef]

- Guo, Y.X.; Kong, J.Y.; Liu, H.H.; Hu, D.T.; Qin, L. Design and Investigation of a Reusable Surface-Mounted Optical Fiber Bragg Grating Strain Sensor. IEEE Sens. J. 2016, 16, 8456–8462. [Google Scholar] [CrossRef]

- Li, R.Y.; Tan, Y.G.; Bing, J.Y.; Li, T.L.; Hong, L.; Yan, J.W.; Hu, J.M.; Zhou, Z.D. A Diaphragm-type Highly Sensitive Fiber Bragg Grating Force Transducer with Temperature Compensation. IEEE Sens. J. 2018, 18, 1073–1083. [Google Scholar] [CrossRef]

- Li, R.Y.; Chen, Y.Y.; Tan, Y.G.; Zhou, Z.D.; Li, T.L. Sensitivity Enhancement of FBG-Based Strain Sensor. Sensors 2018, 18, 1607. [Google Scholar] [CrossRef] [PubMed]

- Li, J.C.; Neumann, H.; Ramalingam, R. Design, fabrication, and testing of fiber Bragg grating sensors for cryogenic long-range displacement measurement. Cryogenics 2015, 68, 36–43. [Google Scholar] [CrossRef]

- Li, W.L.; Zhang, Y.X.; Wang, Q.; Pan, J.J.; Liu, J.; Zhou, C.M. Displacement monitor with FBG deforming ring and its application in high speed railway. In Proceedings of the OFS2012 22nd International Conference on Optical Fiber Sensors, Beijing, China, 4 October 2012. [Google Scholar]

- Ciminello, M.; Ameduri, S.; Flauto, D. Design of an FBG based-on sensor device for large displacement deformation. In Proceedings of the 2013 SBMO/IEEE MTT-S International Microwave & Optoelectronics Conference (IMOC), Rio de Janeiro, Brazil, 4–7 August 2013. [Google Scholar]

- Zhao, Y.; Yu, C.B.; Liao, Y.B. Differential FBG sensor for temperature-compensated high-pressure (or displacement) measurement. Opt. Laser Technol. 2004, 36, 39–42. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, H.W.; Zhang, X.Y.; Meng, Q.Y.; Yuan, B. A novel double-arched-beam-based fiber Bragg grating sensor for displacement measurement. IEEE Photonics Technol. Lett. 2008, 20, 1296–1298. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Zhao, Y.; Wang, Q. Improved design of slow light interferometer and its application in FBG displacement sensor. Sens. Actuators A Phys. 2014, 214, 168–174. [Google Scholar] [CrossRef]

- Chang, Y.T.; Yen, C.T.; Wu, Y.S.; Cheng, H.C. Using a fiber loop and fiber Bragg grating as a fiber optic sensor to simultaneously measure temperature and displacement. Sensors 2013, 13, 6542–6551. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.M.; Liu, Y.; Liu, X.X.; Zhang, Y.; Peng, W. Self-Compensating Displacement Sensor Based on Hydramatic Structured Transducer and Fiber Bragg Grating. Photonic Sens. 2015, 5, 351–356. [Google Scholar] [CrossRef]

- Jiang, S.C.; Wang, J.; Sui, Q.M.; Cao, Y.Q. A novel wide measuring range FBG displacement sensor with variable measurement precision based on helical bevel gear. Optoelectron. Lett. 2015, 11, 81–83. [Google Scholar] [CrossRef]

- Zou, Y.; Dong, X.P.; Lin, G.B.; Adhami, R. Wide range FBG displacement sensor based on twin-core fiber filter. J. Lightwave Technol. 2012, 30, 337–343. [Google Scholar] [CrossRef]

- Tao, S.C.; Dong, X.P.; Lai, B.W. Temperature-insensitive fiber Bragg grating displacement sensor based on a thin-wall ring. Opt. Commun. 2016, 372, 44–48. [Google Scholar] [CrossRef]

- Tao, S.C.; Dong, X.P.; Lai, B.W. A sensor for Simultaneous Measurement of Displacement and Temperature Based on the Fabry-Pérot Effect of a Fiber Bragg Grating. IEEE Sens. J. 2017, 17, 261–266. [Google Scholar] [CrossRef]

- Wei, T.; Qiao, X.G.; Jia, Z.A. Simultaneous sensing of displacement and temperature with a single FBG. Optoelectron. Lett. 2011, 7, 26–29. [Google Scholar] [CrossRef]

- Shen, C.Y.; Zhong, C. Novel temperature-insensitive fiber Bragg grating sensor for displacement measurement. Sens. Actuators A Phys. 2011, 107, 51–54. [Google Scholar] [CrossRef]

- Zhong, C.; Shen, C.Y.; Chu, J.L.; Zou, X.; Li, K.; Jin, Y.X.; Wang, J.F. A displacement sensor based on a temperature-insensitive double trapezoidal structure with fiber Bragg grating. IEEE Sens. J. 2012, 12, 1280–1283. [Google Scholar] [CrossRef]

- Dong, X.Y.; Yang, X.F.; Zhao, C.L.; Ding, L.; Shum, P.; Ngo, N.Q. A novel temperature-insensitive fiber Bragg grating sensor for displacement measurement. Smart Mater. Struct. 2005, 14, N7–N10. [Google Scholar] [CrossRef]

- Li, T.L.; Shi, C.Y.; Ren, H.L. A Novel Fiber Bragg Grating Displacement Sensor with a Sub-micrometer Resolution. IEEE Photonics Technol. Lett. 2017, 29, 1199–1202. [Google Scholar] [CrossRef]

- Li, T.L.; Tan, Y.G.; Shi, C.Y.; Guo, Y.X.; Najdovski, Z.; Ren, H.L.; Zhou, Z.D. A High-Sensitivity Fiber Bragg Grating Displacement Sensor Based on Transverse Property of a Tensioned Optical Fiber Configuration and Its Dynamic Performance Improvement. IEEE Sens. J. 2017, 17, 5840–5848. [Google Scholar] [CrossRef]

- Guo, Y.X.; Xiong, L.; Kong, J.Y.; Zhang, Z.Y.; Qin, L. Sliding type fiber Bragg grating displacement sensor. Opt. Precis. Eng. 2017, 25, 50–58. [Google Scholar]

| Number of Cycles | Sensitivity (pm/mm) |

|---|---|

| 0 | 34.32 |

| 102 | 34.61 |

| 103 | 34.21 |

| 104 | 34.66 |

| 105 | 34.71 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Liu, W.; Xiong, L.; Kuang, Y.; Wu, H.; Liu, H. Fiber Bragg Grating Displacement Sensor with High Abrasion Resistance for a Steel Spring Floating Slab Damping Track. Sensors 2018, 18, 1899. https://doi.org/10.3390/s18061899

Guo Y, Liu W, Xiong L, Kuang Y, Wu H, Liu H. Fiber Bragg Grating Displacement Sensor with High Abrasion Resistance for a Steel Spring Floating Slab Damping Track. Sensors. 2018; 18(6):1899. https://doi.org/10.3390/s18061899

Chicago/Turabian StyleGuo, Yongxing, Wenlong Liu, Li Xiong, Yi Kuang, Heng Wu, and Honghai Liu. 2018. "Fiber Bragg Grating Displacement Sensor with High Abrasion Resistance for a Steel Spring Floating Slab Damping Track" Sensors 18, no. 6: 1899. https://doi.org/10.3390/s18061899

APA StyleGuo, Y., Liu, W., Xiong, L., Kuang, Y., Wu, H., & Liu, H. (2018). Fiber Bragg Grating Displacement Sensor with High Abrasion Resistance for a Steel Spring Floating Slab Damping Track. Sensors, 18(6), 1899. https://doi.org/10.3390/s18061899