Detecting and Monitoring the Flavor of Tomato (Solanum lycopersicum) under the Impact of Postharvest Handlings by Physicochemical Parameters and Electronic Nose

Abstract

1. Introduction

2. Materials and Methods

2.1. SamplePreparation

2.2. Postharvest Handlings

2.3. Physicochemical Parameters Detection

2.4. Electronic Nose Analysis

2.5. Data Analysis

3. Results

3.1. Physicochemical Index Changesof CS and BT Tomatoes

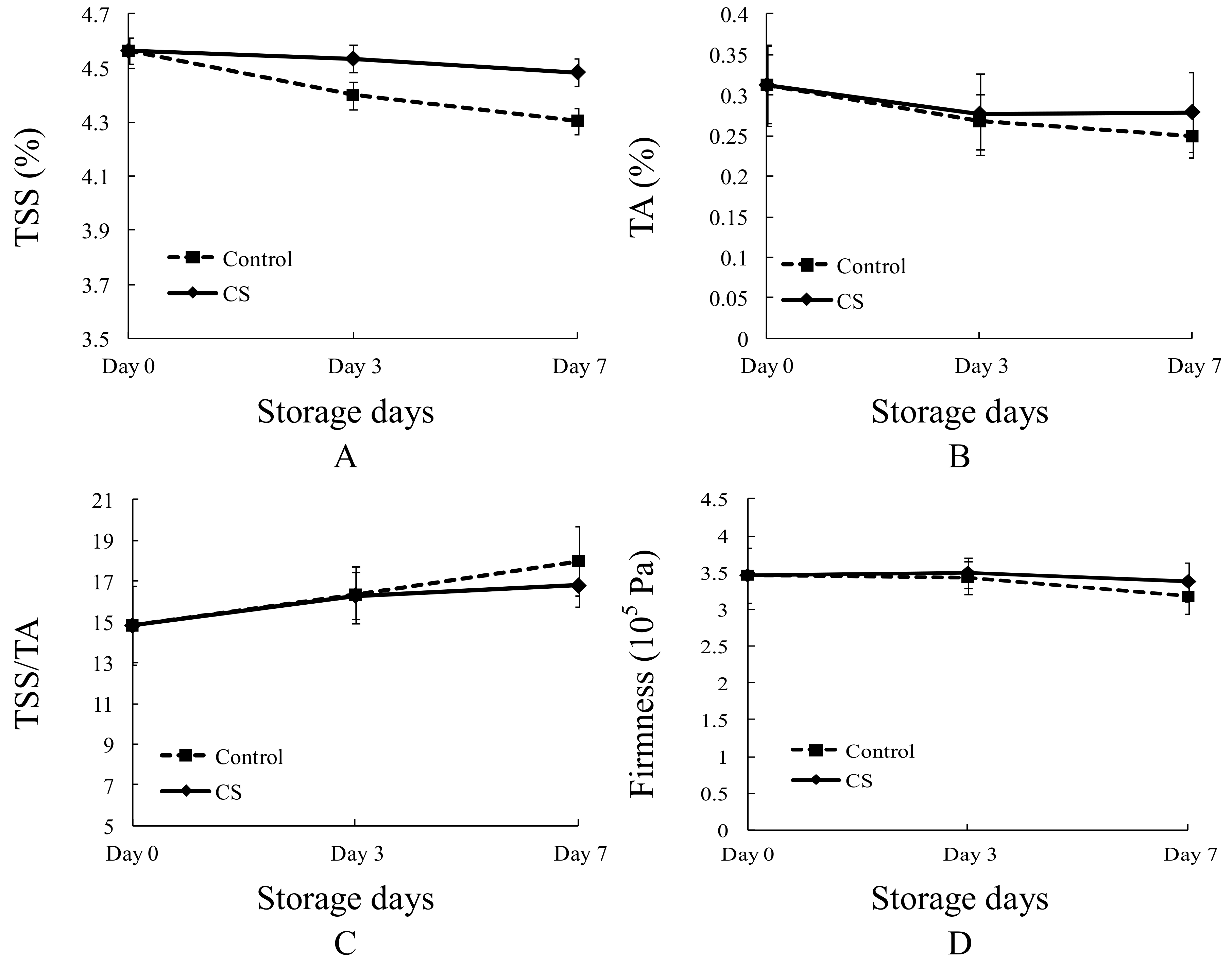

3.1.1. Physicochemical Index Changes of CS Tomatoes

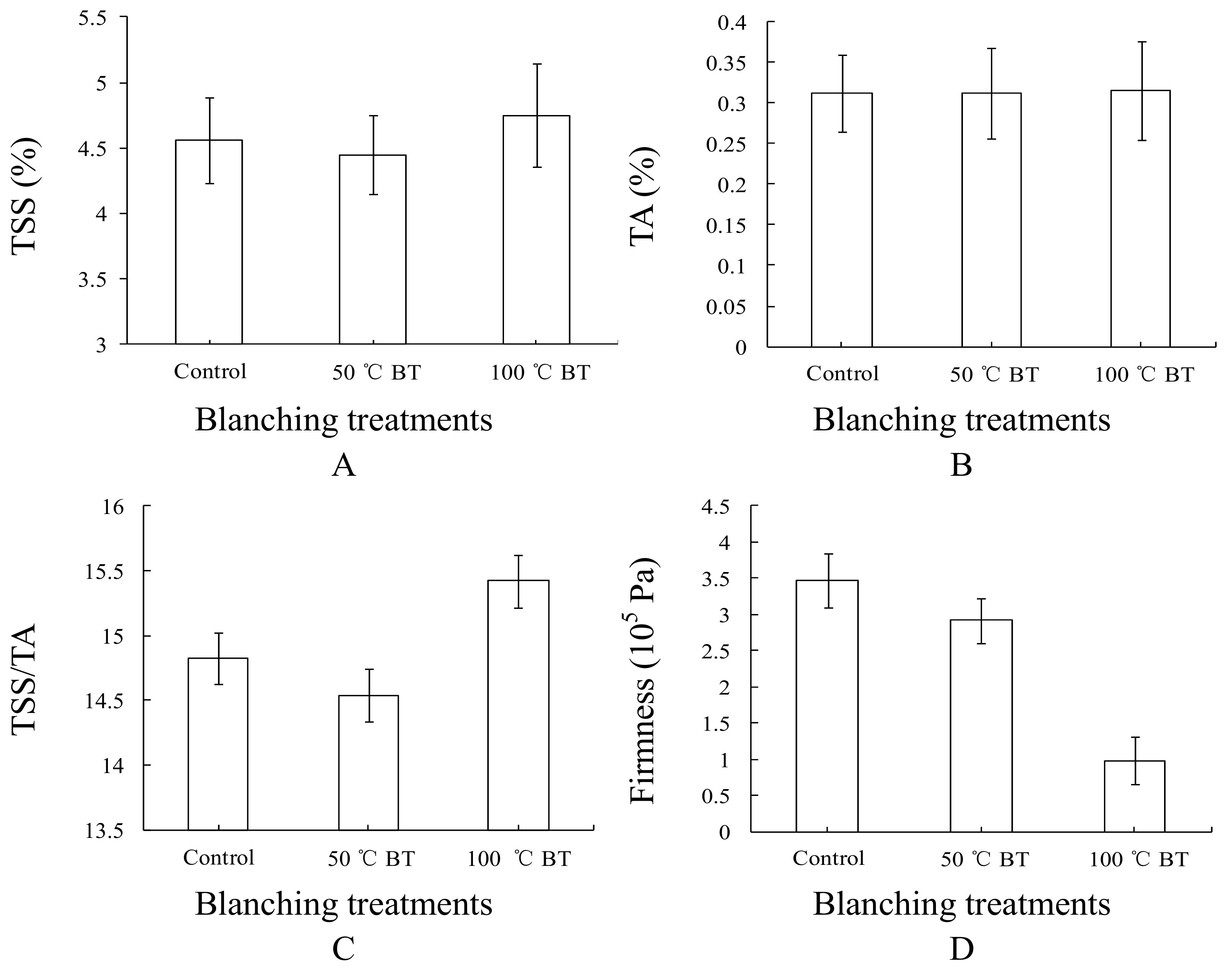

3.1.2. Physicochemical Parameters of BT Tomatoes

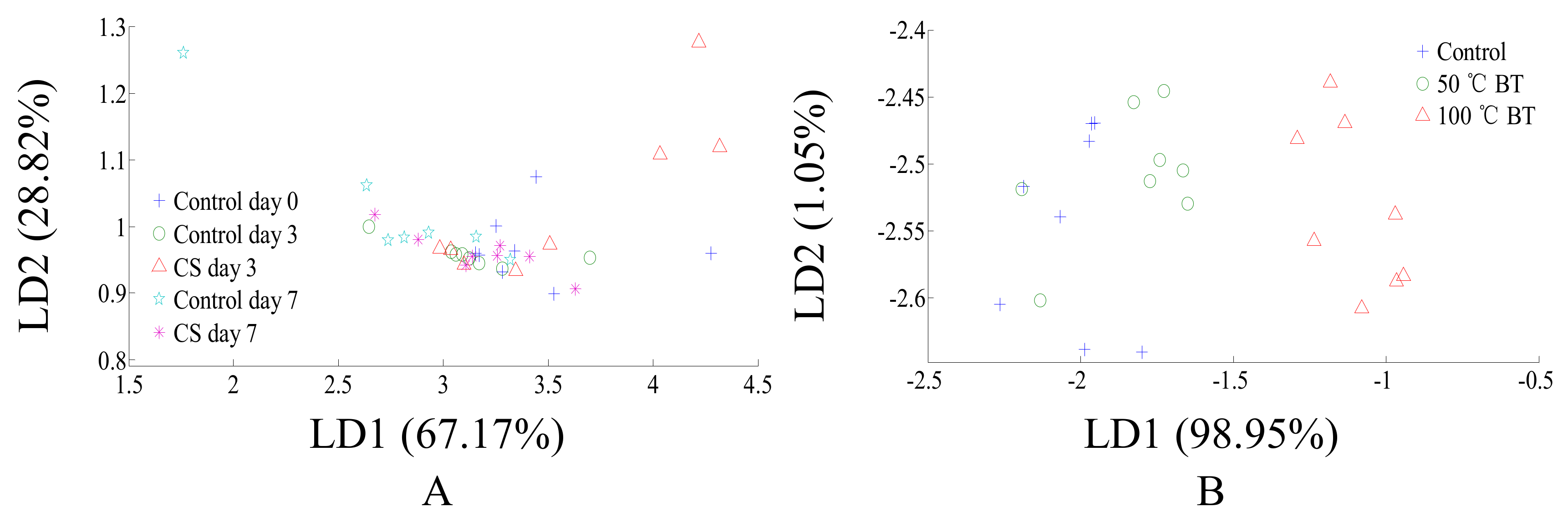

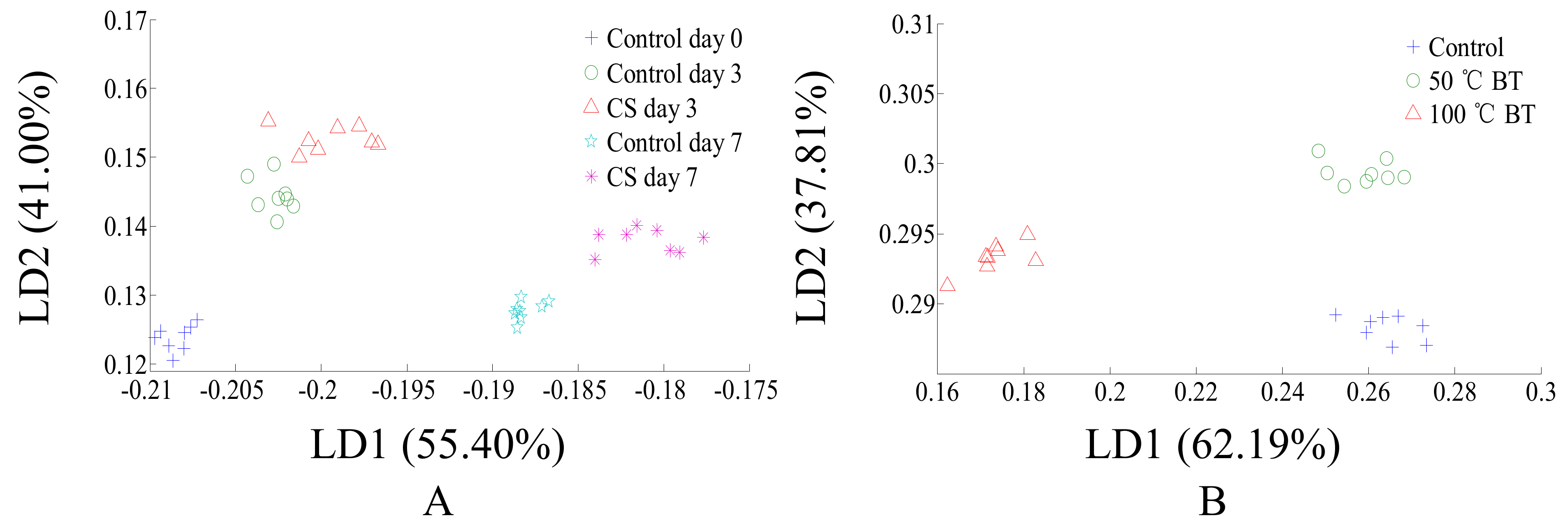

3.2. LDA Classification Results of CS and BT Tomatoes Based on Physicochemical Parameters

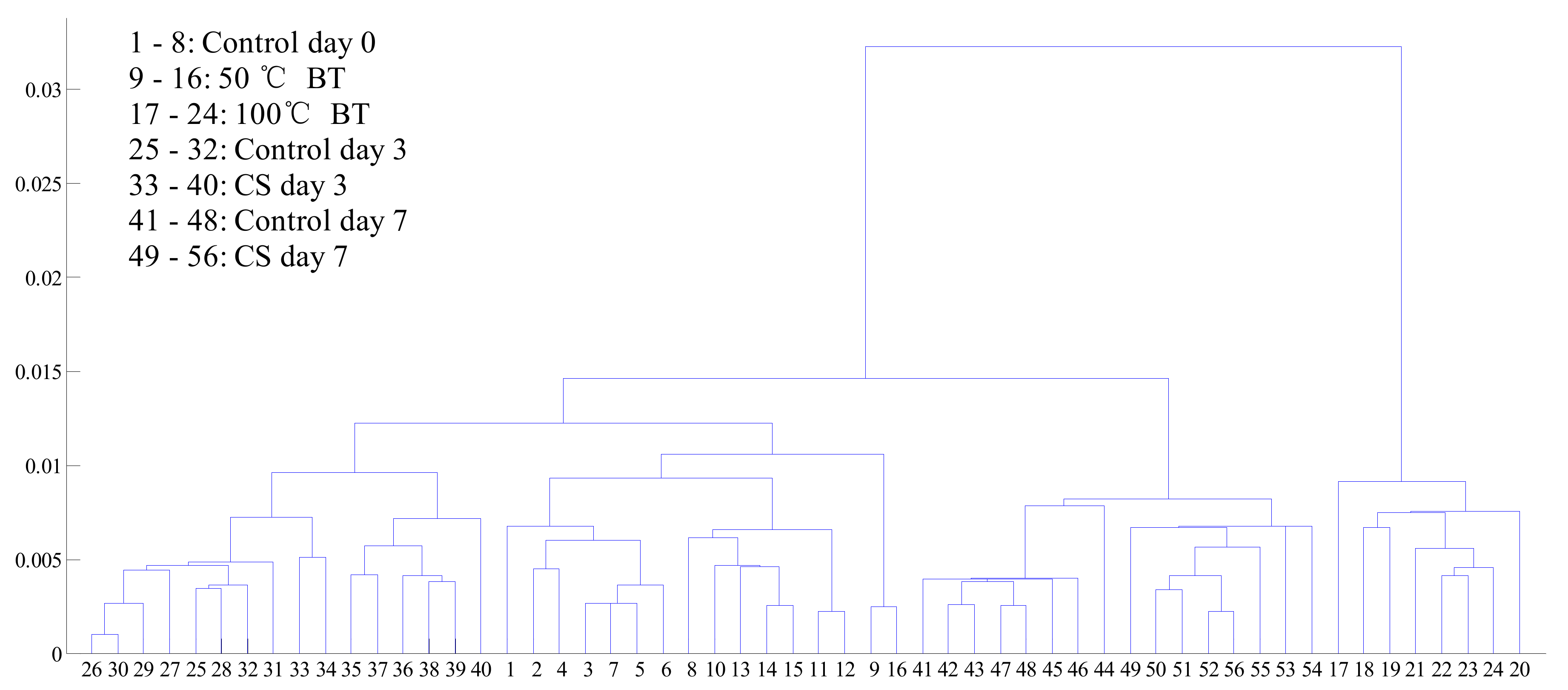

3.3. Raw Data of E-Nose Responses to CS and BT Tomatoes

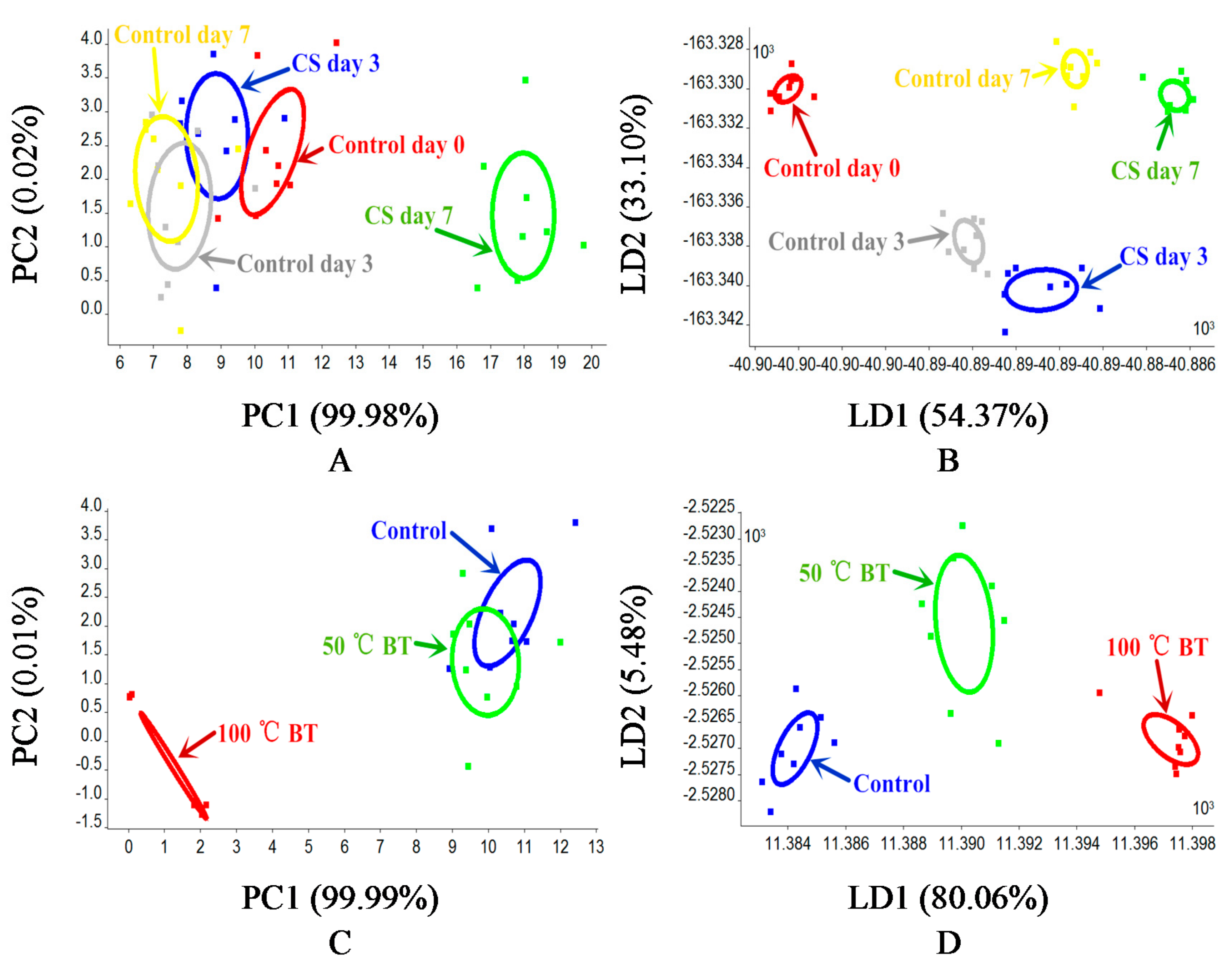

3.4. PCA and LDA Classification Results of CS and BT Tomato Based on E-Nose

3.5. Comprehensive Flavor Change of Tomatoes Impacted by Different Postharvest Treatments

3.6. KNN for Tomato Flavor Change Monitoringduring Postharvest Handlings

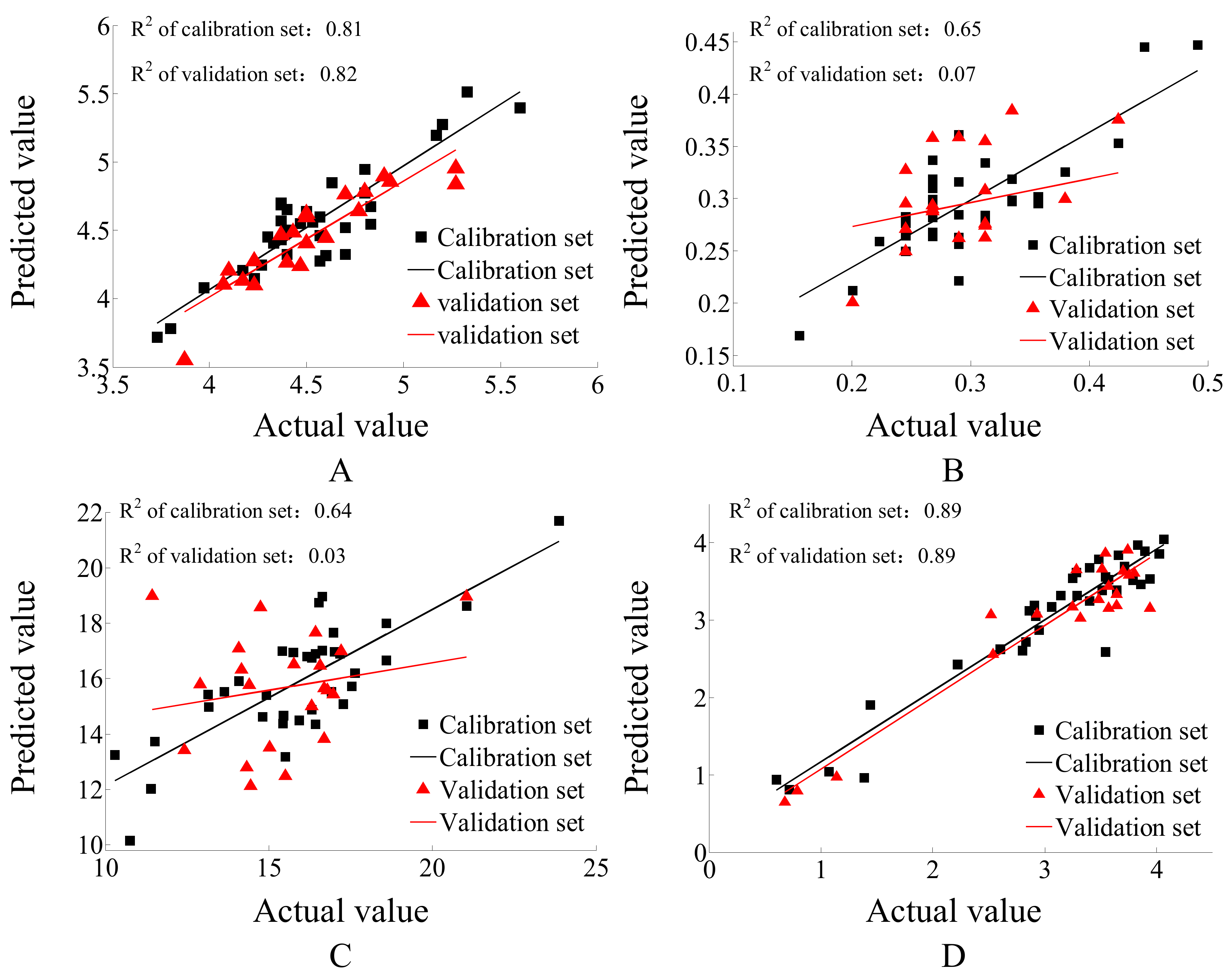

3.7. PLSR for Tomato Physicochemical Parameters Prediction Based on E-Nose

4. Discussion

4.1. Impacts of Postharvest Handlings on Physicochemical Parameters

4.2. Impacts of Postharvest Handlings on E-Nose Respoponse

4.3. Impacts of Postharvest Handlings on Comprehensive Flavor

4.4. Prediction of Physicochemical Parameters Based on E-Nose

4.5. Tomato Quality Assurance and Quality Control

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Raffo, A.; Leonardi, C.; Fogliano, V.; Ambrosino, P.; Salucci, M.; Gennaro, L.; Bugianesi, R.; Giuffrida, F.; Quaglia, G. Nutritional value of cherry tomatoes (Lycopersicon esculentum Cv. Naomi F1) harvested at different ripening stages. J. Agric. Food Chem. 2002, 50, 6550. [Google Scholar] [CrossRef] [PubMed]

- Guil-Guerrero, J.L.; Rebolloso-Fuentes, M.M. Nutrient composition and antioxidant activity of eight tomato (Lycopersicon esculentum) varieties. J. Food Compos. Anal. 2009, 22, 123–129. [Google Scholar] [CrossRef]

- Klee, H.J. Improving the flavor of fresh fruits: Genomics, biochemistry, and biotechnology. New Phytol. 2010, 187, 44–56. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Tieman, D.M.; Jiao, C.; Xu, Y.; Chen, K.; Fe, Z.; Giovannoni, J.J.; Klee, H.J. Chilling-induced tomato flavor loss is associated with altered volatile synthesis and transient changes in DNA methylation. Proc. Natl. Acad. Sci. USA 2016, 113, 12580. [Google Scholar] [CrossRef] [PubMed]

- Deltsidis, A.I.; Pliakoni, E.D.; Baldwin, E.A.; Bai, J.; Plotto, A.; Brecht, J.K. Tomato flavor changes at chilling and non-chilling temperatures as influenced by controlled atmospheres. Acta Hortic. 2015, 1071, 703–710. [Google Scholar] [CrossRef]

- Auerswald, H.; Peters, P.; Brückner, B.; Krumbein, A.; Kuchenbuch, R. Sensory analysis and instrumental measurements of short-term stored tomatoes (Lycopersicon esculentum Mill.). Postharvest Biol. Technol. 1999, 15, 323–334. [Google Scholar] [CrossRef]

- Renard, C.M.; Ginies, C.; Gouble, B.; Bureau, S.; Causse, M. Home conservation strategies for tomato (Solanum lycopersicum): Storage temperature vs. duration--is there a compromise for better aroma preservation? Food Chem. 2013, 139, 825. [Google Scholar] [CrossRef] [PubMed]

- Castro, S.M.; Saraiva, J.A.; Lopes-Da-Silva, J.A.; Delgadillo, I.; Loey, A.V.; Smout, C.; Hendrickx, M. Effect of thermal blanching and of high pressure treatments on sweet green and red bell pepper fruits (Capsicum annuum L.). Food Chem. 2008, 107, 1436–1449. [Google Scholar] [CrossRef]

- Hirayama, K. 50 °C Washing and Dipping, 1st ed.; Shufunotomo: Tokyo, Japan, 2012. [Google Scholar]

- Wang, L.; Song, S.; Jiang, P.; Liu, D. Effect of Different Peeling Methods on the Peeling Efficiency and Quality of Tomatoes. Food Sci. 2017, 38, 26–31. [Google Scholar]

- Rock, C.; Yang, W.; Goodrich-Schneider, R.; Feng, H. Conventional and Alternative Methods for Tomato Peeling. Food Eng. Rev. 2012, 4, 1–15. [Google Scholar] [CrossRef]

- Tieman, D.; Bliss, P.; McIntyre, L.M.; Blandon-Ubeda, A.; Bies, D.; Odabasi, A.Z.; Rodríguez, G.R.; van der Knaap, E.; Taylor, M.G.; Goulet, C. The chemical interactions underlying tomato flavor preferences. Curr. Biol. 2012, 22, 1035–1039. [Google Scholar] [CrossRef] [PubMed]

- Baldwin, E.A.; Scott, J.W.; Shewmaker, C.K.; Schuch, W. Flavor trivia and tomato aroma: Biochemistry and possible mechanisms for control of important aroma components. Hortscience 2000, 35, 1013–1021. [Google Scholar]

- Lesage, P.; Destain, M.F. Measurement of tomato firmness by using a non-destructive mechanical sensor. Postharvest Biol. Technol. 1996, 8, 45–55. [Google Scholar] [CrossRef]

- Hoehn, E.; Gasser, F.; Guggenbühl, B.; Künsch, U. Efficacy of instrumental measurements for determination of minimum requirements of firmness, soluble solids, and acidity of several apple varieties in comparison to consumer expectations. Postharvest Biol. Technol. 2003, 27, 27–37. [Google Scholar] [CrossRef]

- Röck, F.; Barsan, N.; Weimar, U. Electronic nose: Current status and future trends. Chem. Rev. 2008, 108, 705–725. [Google Scholar] [CrossRef] [PubMed]

- Gomez, A.H.; Wang, J.; Hu, G.; Pereira, A.G. Monitoring storage shelf life of tomato using electronic nose technique. J. Food Eng. 2008, 85, 625–631. [Google Scholar] [CrossRef]

- Maul, F.; Sargent, S.A.; Sims, C.A.; Baldwin, E.A.; Balaban, M.O.; Huber, D.J. Tomato flavor and aroma quality as affected by storage temperature. J. Food Sci. 2000, 65, 1228–1237. [Google Scholar] [CrossRef]

- Sinesio, F.; Di Natale, C.; Quaglia, G.B.; Bucarelli, F.M.; Moneta, E.; Macagnano, A.; Paolesse, R.; D Amico, A. Use of electronic nose and trained sensory panel in the evaluation of tomato quality. J. Sci. Food Agric. 2000, 80, 63–71. [Google Scholar] [CrossRef]

- Berna, A.Z.; Lammertyn, J.; Saevels, S.; Di Natale, C.; Nicolaï, B.M. Electronic nose systems to study shelf life and cultivar effect on tomato aroma profile. Sens. Actuators B Chem. 2004, 97, 324–333. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, Y.; Li, J. Browning control, shelf life extension and quality maintenance of frozen litchi fruit by hydrochloric acid. J. Food Eng. 2004, 63, 147–151. [Google Scholar] [CrossRef]

- Capone, S.; Epifani, M.; Quaranta, F.; Siciliano, P.; Taurino, A.; Vasanelli, L. Monitoring of rancidity of milk by means of an electronic nose and a dynamic PCA analysis. Sens. Actuators B Chem. 2001, 78, 174–179. [Google Scholar] [CrossRef]

- Radzol, A.R.M.; Lee, Y.K.; Mansor, W.; Twon Tawi, F.M. Signal processing for raman spectra for disease detection. Int. J. Pharm. Pharm. Sci. 2016, 8, 4–10. [Google Scholar]

- Rodríguez, S.D.; Barletta, D.A.; Wilderjans, T.F.; Bernik, D.L. Fast and Efficient Food Quality Control Using Electronic Noses: Adulteration Detection Achieved by Unfolded Cluster Analysis Coupled with Time-Window Selection. Food Anal. Method 2014, 7, 2042–2050. [Google Scholar] [CrossRef]

- Cetó, X.; Gutiérrezcapitán, M.; Calvo, D.; Del, V.M. Beer classification by means of a potentiometric electronic tongue. Food Chem. 2013, 141, 2533–2540. [Google Scholar] [CrossRef] [PubMed]

- Güney, S.; Atasoy, A. Multiclass classification of n -butanol concentrations with k -nearest neighbor algorithm and support vector machine in an electronic nose. Sens. Actuators B Chem. 2012, 166, 721–725. [Google Scholar] [CrossRef]

- Ali, S.; Khan, A.S.; Malik, A.U. Postharvest l -cysteine application delayed pericarp browning, suppressed lipid peroxidation and maintained antioxidative activities of litchi fruit. Postharvest Biol. Technol. 2016, 121, 135–142. [Google Scholar] [CrossRef]

- Paula, J.T.; Figueiredo, A.S.; Schwarz, K.; Neumann, E.R.; Paula, J.T.; Figueiredo, A.S.; Schwarz, K.; Neumann, E.R. Physicochemical characteristics and bioactive compounds in tomato fruits harvested at different ripening stages. Hortic. Bras. 2015, 33, 434–440. [Google Scholar] [CrossRef]

- Zhang, W.; Pan, L.; Zhao, X.; Tu, K. A Study on Soluble Solids Content Assessment Using Electronic Nose: Persimmon Fruit Picked on Different Dates. Int. J. Food Prop. 2016, 19, 53–62. [Google Scholar] [CrossRef]

- Zhou, B.; Wang, J. Use of electronic nose technology for identifying rice infestation by Nilaparvata lugens. Sens. Actuators B Chem. 2011, 160, 15–21. [Google Scholar] [CrossRef]

- Majidi, H.; Minaei, S.; Almassi, M.; Mostofi, Y. Tomato quality in controlled atmosphere storage, modified atmosphere packaging and cold storage. J. Food Sci. Technol. 2014, 51, 2155–2161. [Google Scholar] [CrossRef] [PubMed]

- Bai, J.; Baldwin, E.A.; Imahori, Y.; Kostenyuk, I.; Burns, J.; Brecht, J.K. Chilling and heating may regulate C6 volatile aroma production by different mechanisms in tomato. Postharvest Biol. Technol. 2011, 60, 111–120. [Google Scholar] [CrossRef]

- Wang, L.; Baldwin, E.A.; Zhao, W.; Plotto, A.; Sun, X.; Wang, Z.; Brecht, J.K.; Bai, J.; Yu, Z. Suppression of volatile production in tomato fruit exposed to chilling temperature and alleviation of chilling injury by a pre-chilling heat treatment. LWT Food Sci. Technol. 2015, 62, 115–121. [Google Scholar] [CrossRef]

- Wang, L.B.; Baldwin, E.A.; Yu, Z.F.; Bai, J.H. The impact of kitchen and food service preparation practices on the volatile aroma profile in ripe tomatoes: Effects of refrigeration and blanching. Hortscience 2015, 50, 1358–1364. [Google Scholar]

- Xu, S.; Lu, H.; Zhou, Z.; Lü, E.; Jiang, Y. Identification for guava mechanical damage based on combined hyper-spectrometer and electronic nose. Trans. Chin. Soc. Agric. Mach. 2015, 46, 214–219. [Google Scholar]

- Boilot, P.; Hines, E.L.; Gongora, M.A.; Folland, R.S. Electronic noses inter-comparison, data fusion and sensor selection in discrimination of standard fruit solutions. Sens. Actuators B Chem. 2003, 88, 80–88. [Google Scholar] [CrossRef]

- Tian, X.; Wang, C.; Wang, J.; Hong, X. Fast Determination of Lycopene Content and Soluble Solid Content of Cherry Tomatoes Using Metal Oxide Sensors Based Electronic Nose. Acta Aliment. 2016, 45, 182–189. [Google Scholar] [CrossRef]

- Durán-Acevedo, C.M.; Gualdron-Guerrero, O.E.; Hernández-Ordoñez, M. Electronic Nose to Determine the Maturity Index of the Tree Tomato (Cyphomandra Betacea Sendt). Ing. Investig. Tecnol. 2014, 15, 351–362. [Google Scholar]

- Wang, J.; Zhou, Y. Electronic-Nose Technique: Potential for Monitoring Maturity and Shelf Life of Tomatoes. In Proceedings of the International Conference on Computers and Computing Technologies in Agriculture, Wuyishan, China, 18–20 August 2007; pp. 1219–1228. [Google Scholar]

| Major Axis (cm) | Minor Axis (cm) | Weight (g) | TSS (%) | TA (%) | Firmness (105 Pa) |

|---|---|---|---|---|---|

| 69.40 ± 2.91 | 58.21 ± 3.50 | 152.30 ± 24.50 | 4.56 ± 0.33 | 0.31 ± 0.05 | 3.46 ± 0.38 |

| Number in Array | Sensor Name | Object Substances for Sensing | Threshold Value (mL·m−3) |

|---|---|---|---|

| R1 | W1C | Aromatics | 10 |

| R2 | W5S | Nitrogen oxides | 1 |

| R3 | W3C | Ammonia and aromatic molecules | 10 |

| R4 | W6S | Hydrogen | 100 |

| R5 | W5C | Methane, propane and aliphatic non-polar molecules | 1 |

| R6 | W1S | Broad methane | 100 |

| R7 | W1W | Sulfur-containing organics | 1 |

| R8 | W2S | Broad alcohols | 100 |

| R9 | W2W | Aromatics, sulfur-and chlorine-containing organics | 1 |

| R10 | W3S | Methane and aliphatics | 10 |

| R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | R10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Control | 0.20 | 16.48 | 0.40 | 1.08 | 0.39 | 11.95 | 3821.13 | 7.35 | 16.54 | 1.20 |

| Control day 3 | 0.19 | 18.02 | 0.34 | 1.08 | 0.40 | 11.96 | 4187.14 | 7.73 | 16.89 | 1.194 |

| CS day 3 | 0.19 | 20.60 | 0.33 | 1.08 | 0.41 | 12.44 | 4473.86 | 8.14 | 17.43 | 1.19 |

| Control day 7 | 0.20 | 17.20 | 0.34 | 1.07 | 0.42 | 9.93 | 4796.91 | 6.80 | 15.76 | 1.176 |

| CS day 7 | 0.21 | 13.52 | 0.34 | 1.05 | 0.43 | 9.27 | 4481.40 | 6.78 | 13.61 | 1.14 |

| 50 °CBT | 0.21 | 10.52 | 0.35 | 1.09 | 0.40 | 12.10 | 4408.62 | 7.45 | 13.10 | 1.20 |

| 100 °CBT | 0.34 | 2.03 | 0.51 | 1.09 | 0. 60 | 7.01 | 2644.86 | 5.046 | 3.25 | 1.18 |

| Monitoring Mehtods | K | Predicted Value (Actual Value) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Control | Control day 3 | Control day 7 | CS day 3 | CS day 7 | 50 °C BT | 100 °C BT | Accuracy | ||

| Physicochemical parameters | 3 | 5, 4 (0, 0) | 1, 1 (1,1) | 1, 2 (2, 2) | 1, 1 (3, 3) | 2, 1 (4, 4) | 5, 1 (5, 5) | 6, 6 (6, 6) | 42.86% |

| E-nose | 3 | 0, 0 (0, 0) | 1, 1 (1,1) | 2, 2 (2, 2) | 3, 3 (3, 3) | 4, 4 (4, 4) | 5, 5 (5, 5) | 6, 6 (6, 6) | 100% |

| Physicochemical parameters & E-nose | 3 | 0, 0 (0, 0) | 1, 1 (1,1) | 2, 2 (2, 2) | 3, 3 (3, 3) | 4, 4 (4, 4) | 5, 5 (5, 5) | 6, 6 (6, 6) | 100% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, S.; Sun, X.; Lu, H.; Yang, H.; Ruan, Q.; Huang, H.; Chen, M. Detecting and Monitoring the Flavor of Tomato (Solanum lycopersicum) under the Impact of Postharvest Handlings by Physicochemical Parameters and Electronic Nose. Sensors 2018, 18, 1847. https://doi.org/10.3390/s18061847

Xu S, Sun X, Lu H, Yang H, Ruan Q, Huang H, Chen M. Detecting and Monitoring the Flavor of Tomato (Solanum lycopersicum) under the Impact of Postharvest Handlings by Physicochemical Parameters and Electronic Nose. Sensors. 2018; 18(6):1847. https://doi.org/10.3390/s18061847

Chicago/Turabian StyleXu, Sai, Xiuxiu Sun, Huazhong Lu, Hui Yang, Qingsong Ruan, Hao Huang, and Minglin Chen. 2018. "Detecting and Monitoring the Flavor of Tomato (Solanum lycopersicum) under the Impact of Postharvest Handlings by Physicochemical Parameters and Electronic Nose" Sensors 18, no. 6: 1847. https://doi.org/10.3390/s18061847

APA StyleXu, S., Sun, X., Lu, H., Yang, H., Ruan, Q., Huang, H., & Chen, M. (2018). Detecting and Monitoring the Flavor of Tomato (Solanum lycopersicum) under the Impact of Postharvest Handlings by Physicochemical Parameters and Electronic Nose. Sensors, 18(6), 1847. https://doi.org/10.3390/s18061847