Study of Current Measurement Method Based on Circular Magnetic Field Sensing Array

Abstract

:1. Introduction

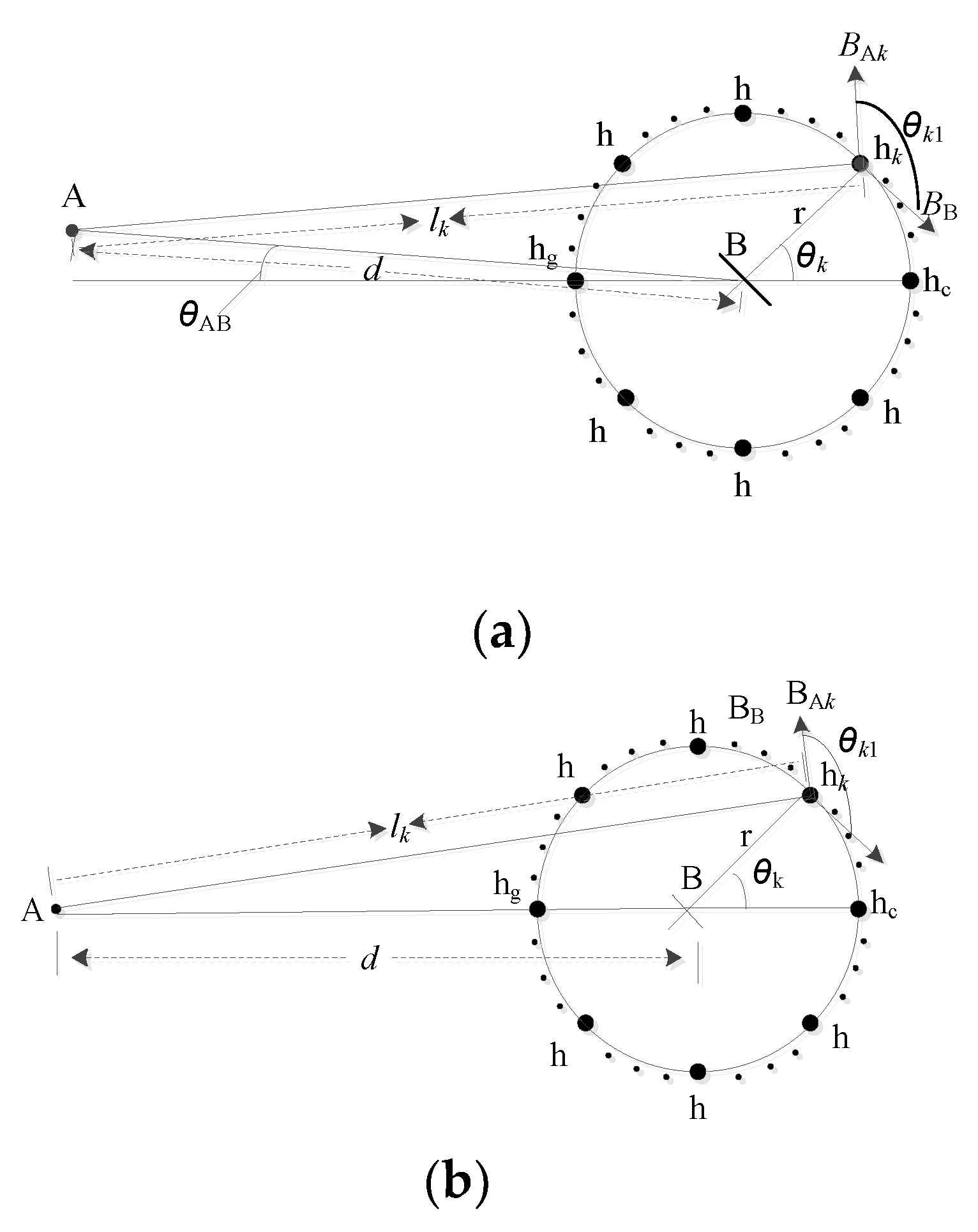

2. Measurement Accuracy Analysis of Circular Magnetic Field Sensing Array

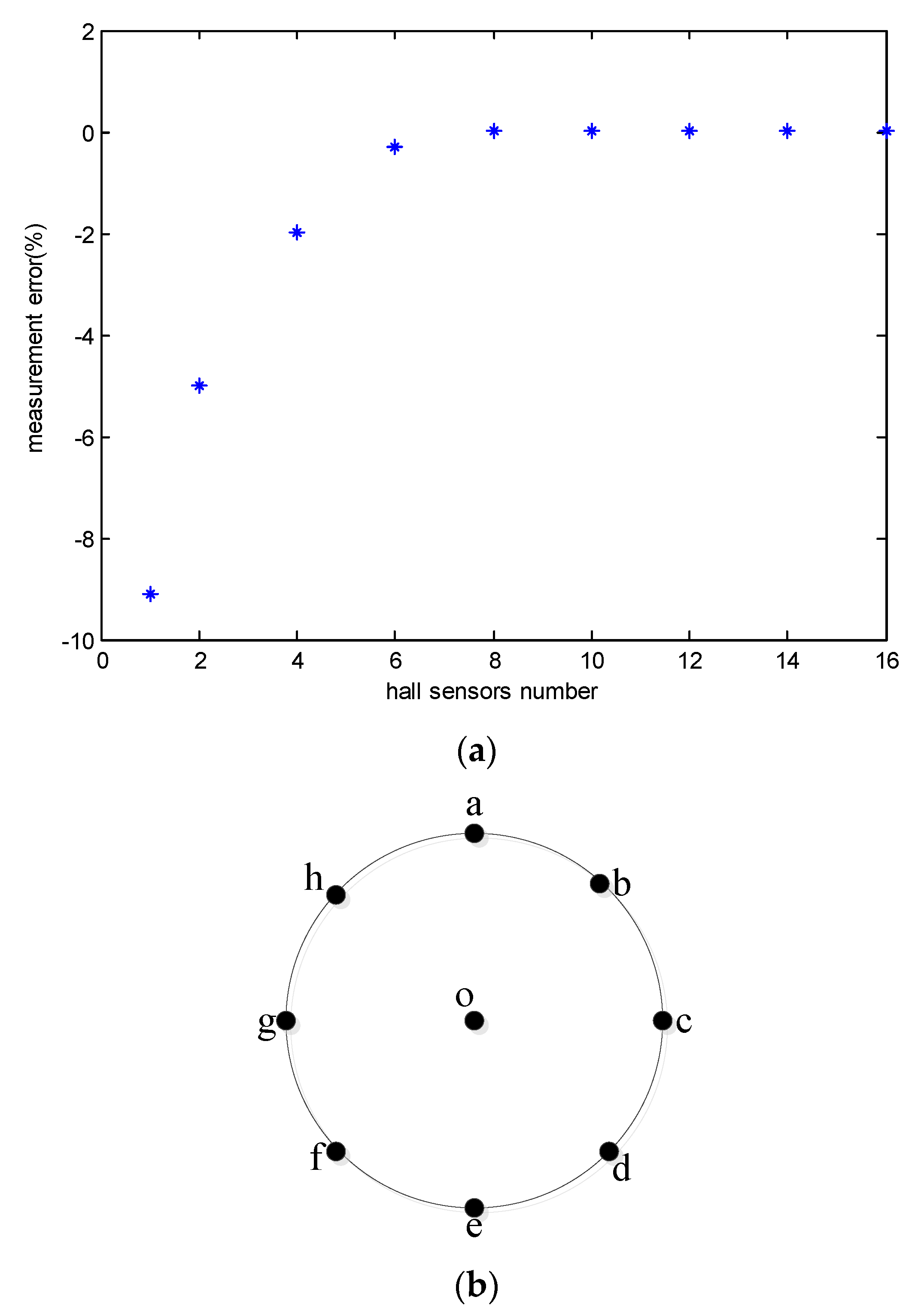

2.1. Correlation of the Measurement Error and the Number of Hall Sensors

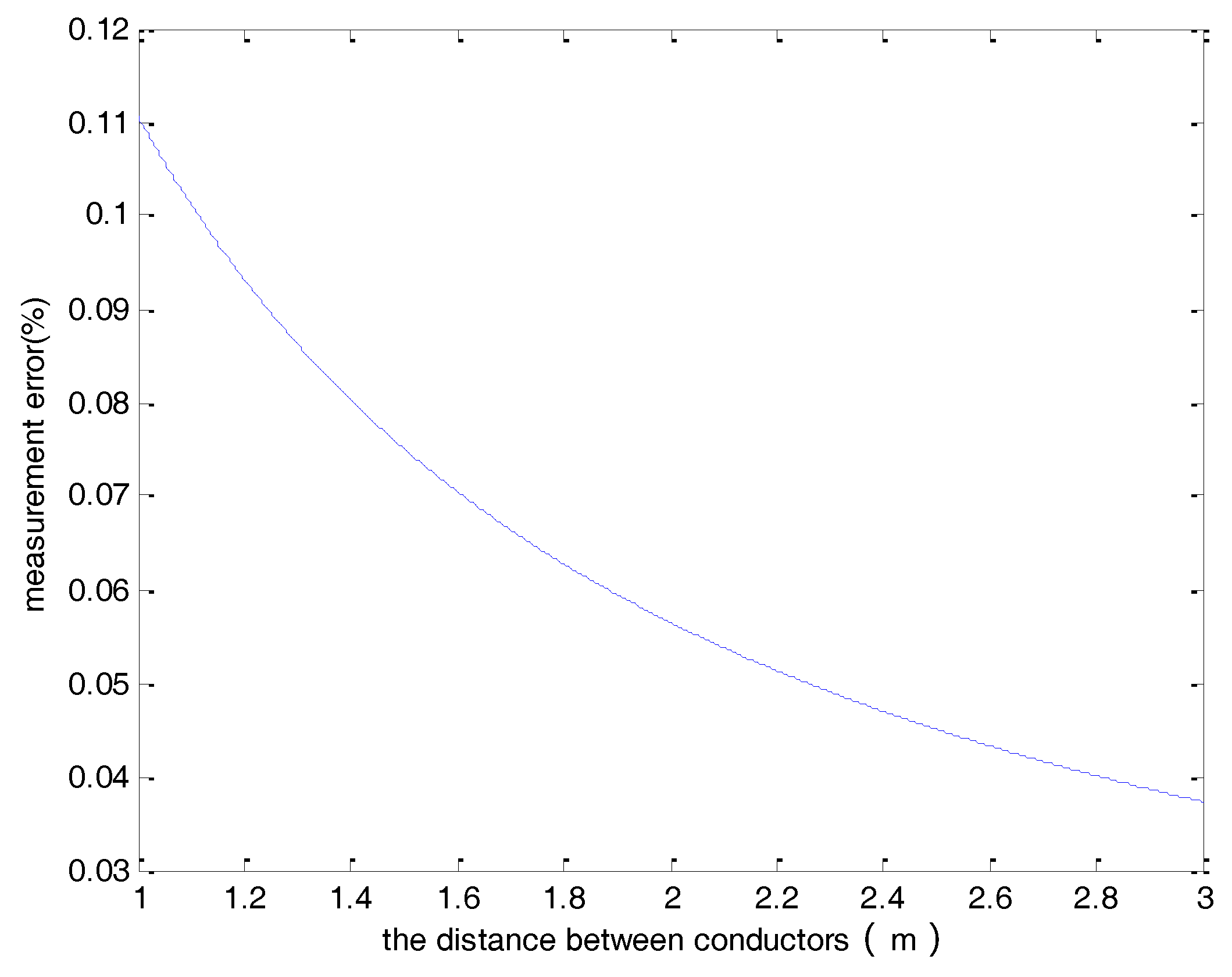

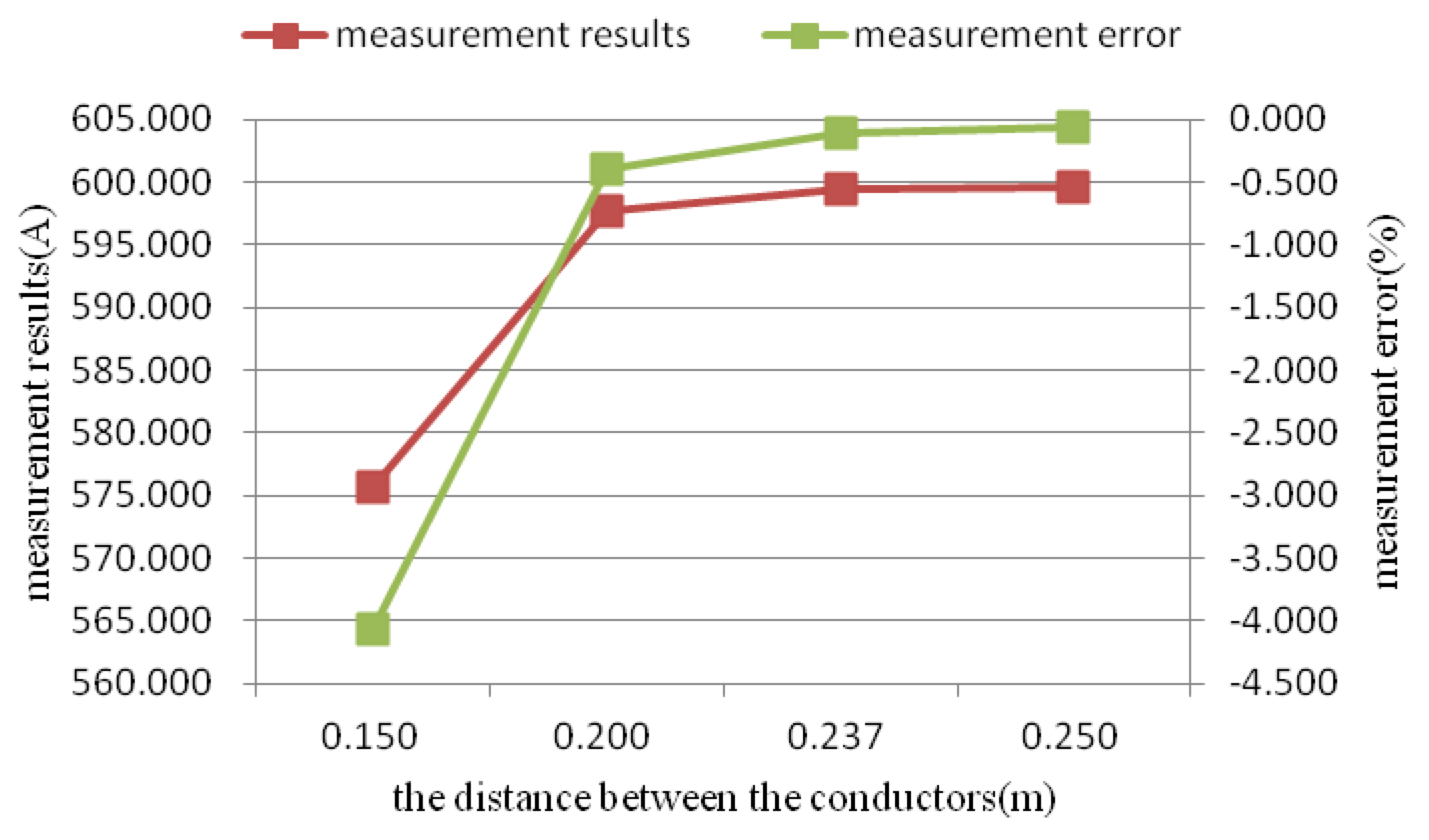

2.2. Correlation of the Measurement Error and the Distance between the Conductors

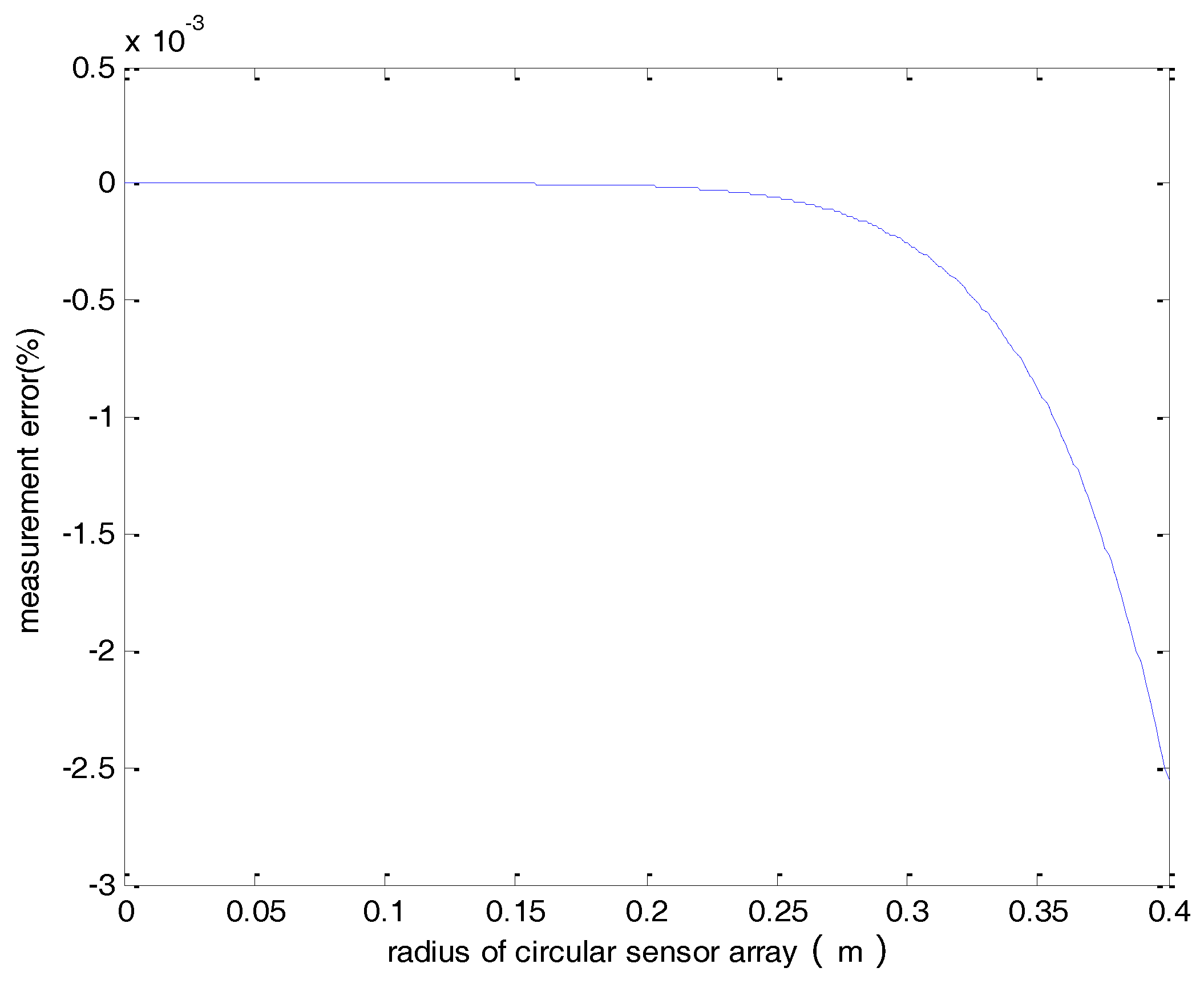

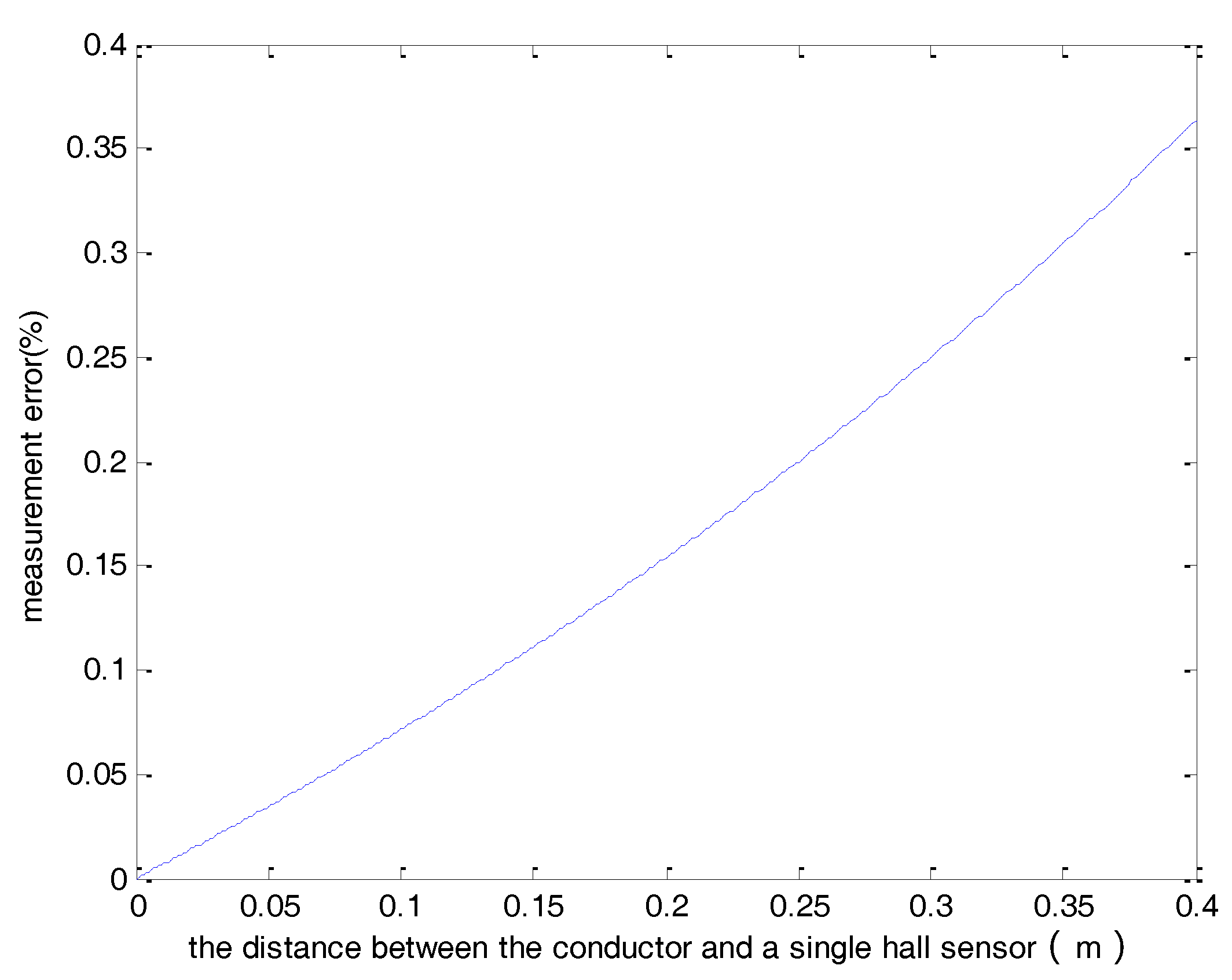

2.3. Correlation of the Measurement Error and the Circle Radius

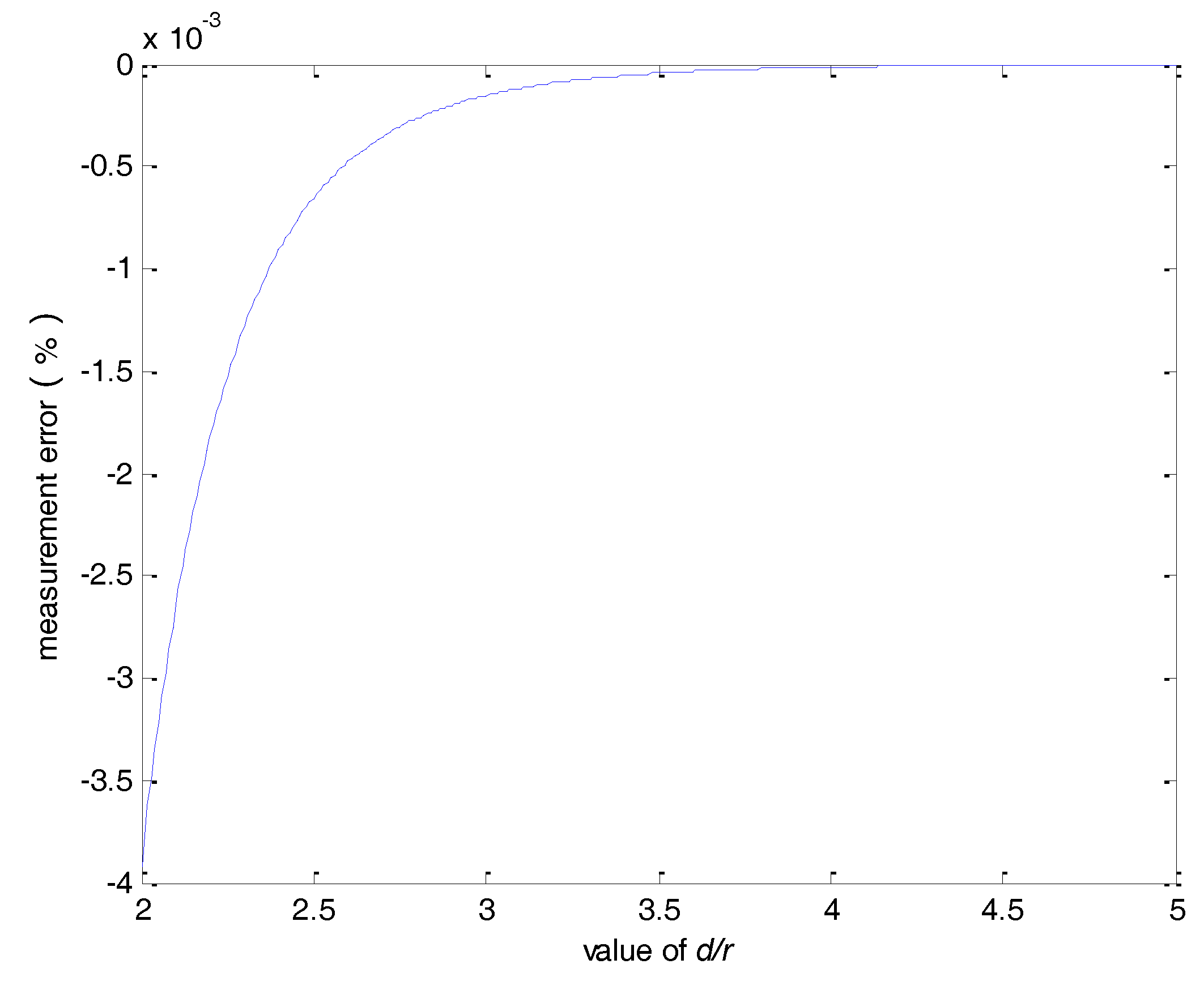

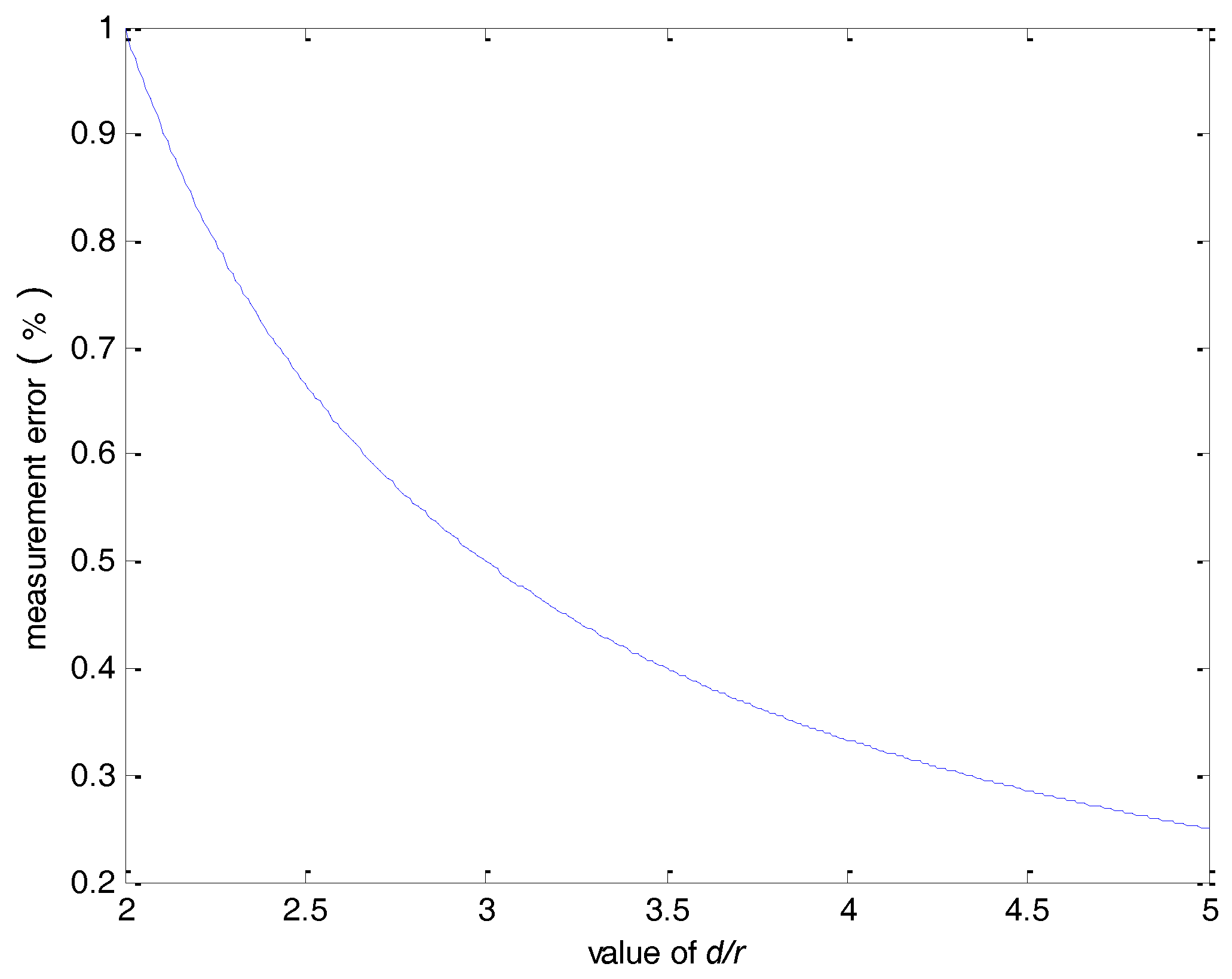

2.4. Analysis of the Measurement Error with d and r

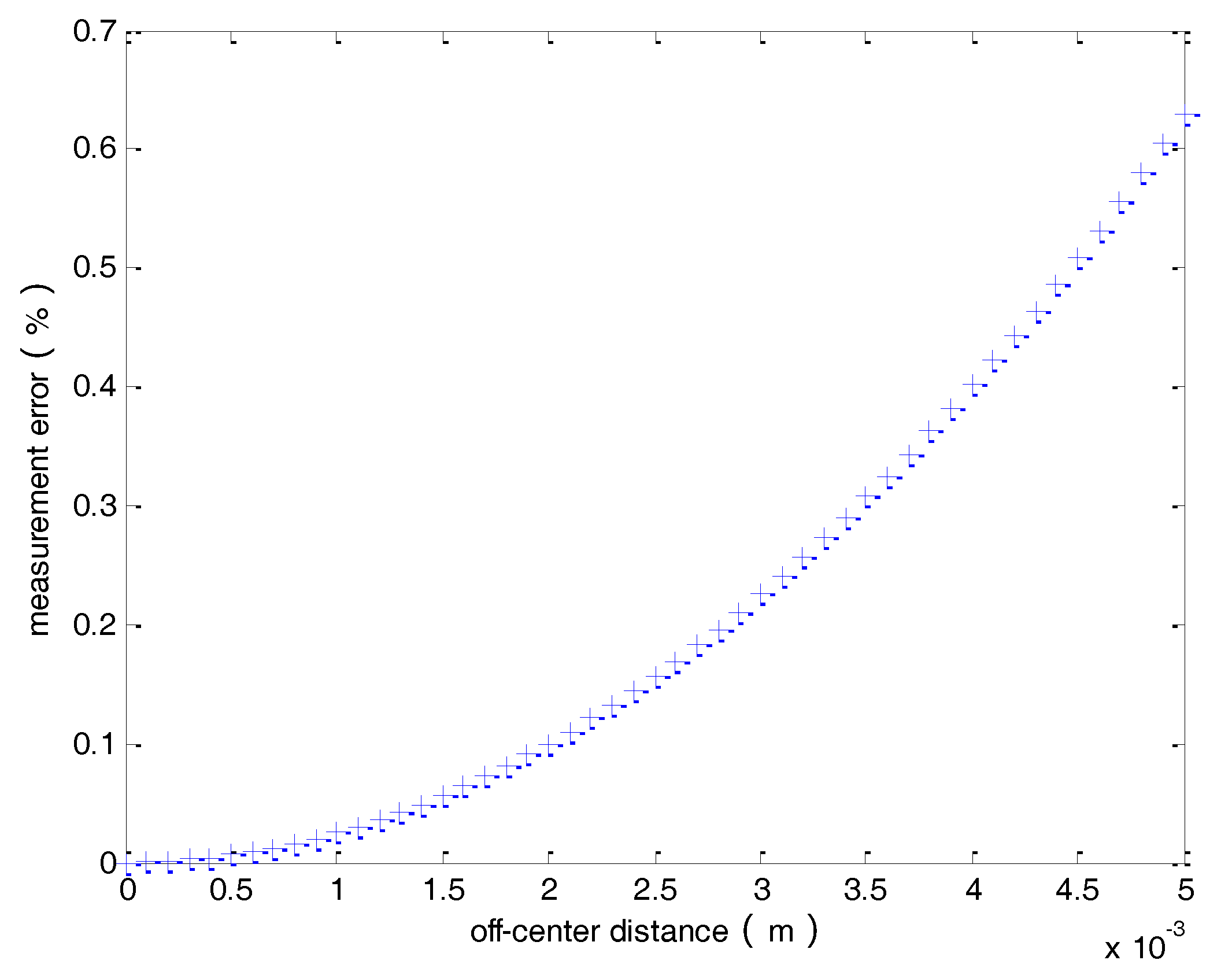

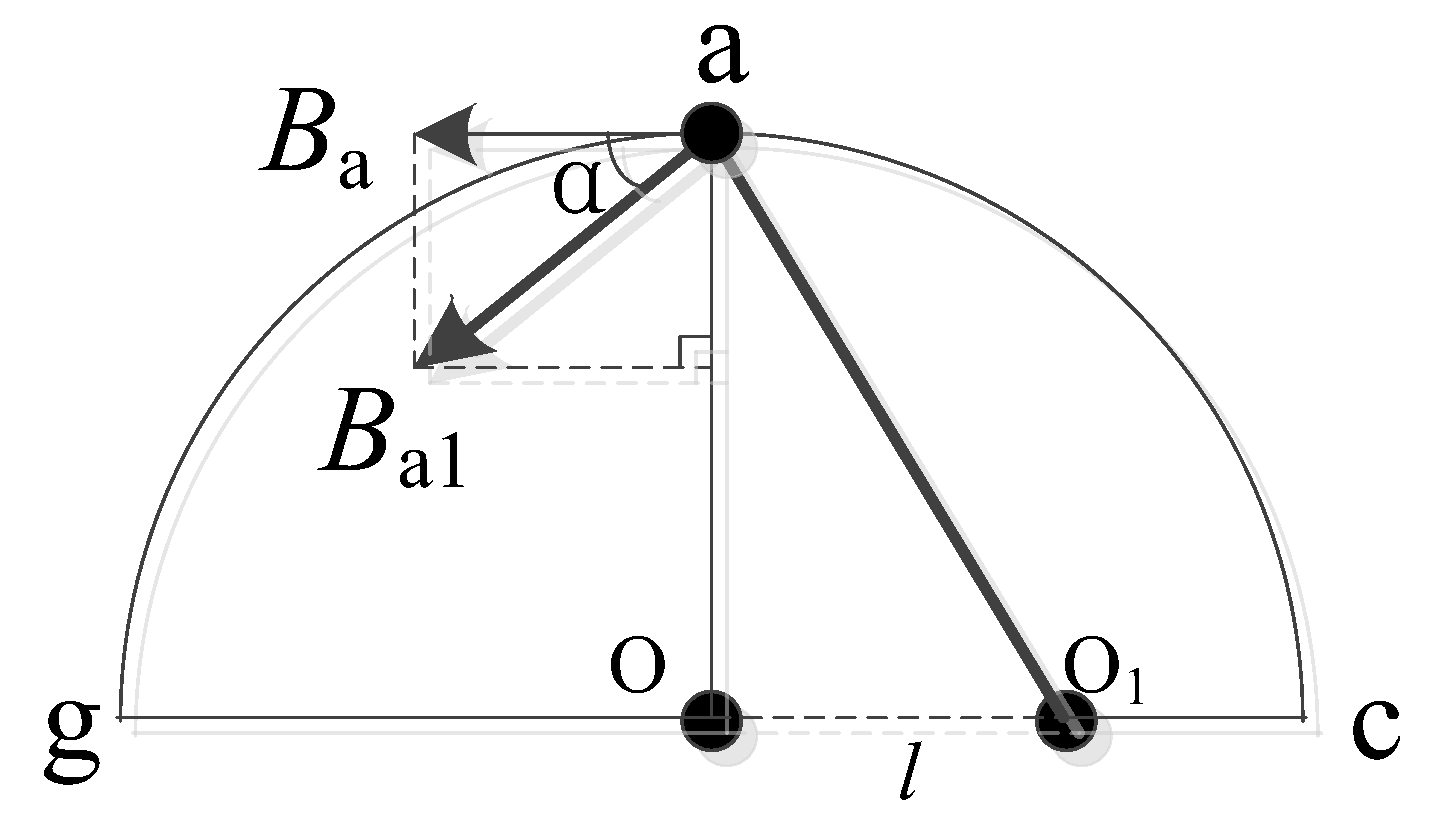

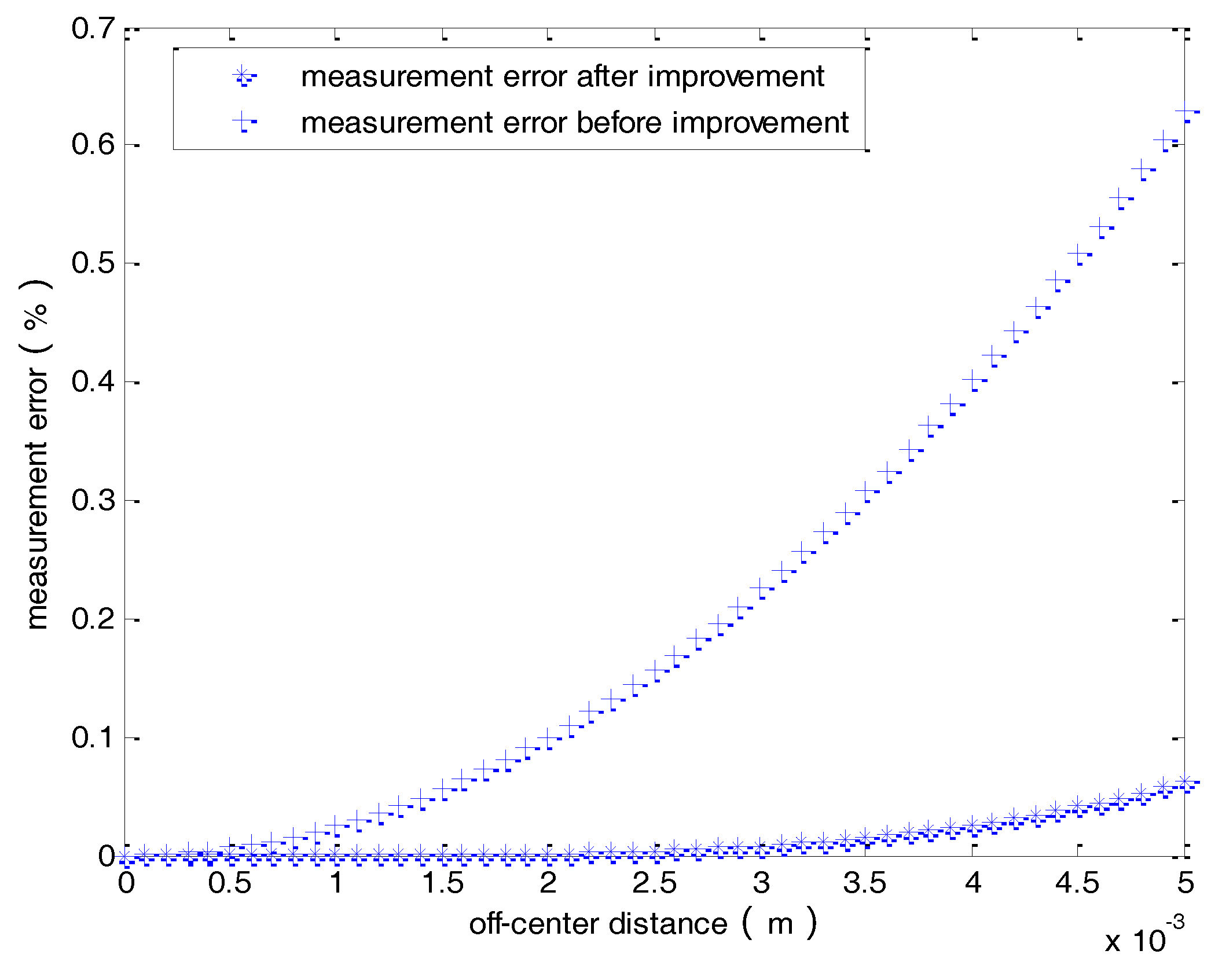

3. Error Analysis of Off-Center Distance

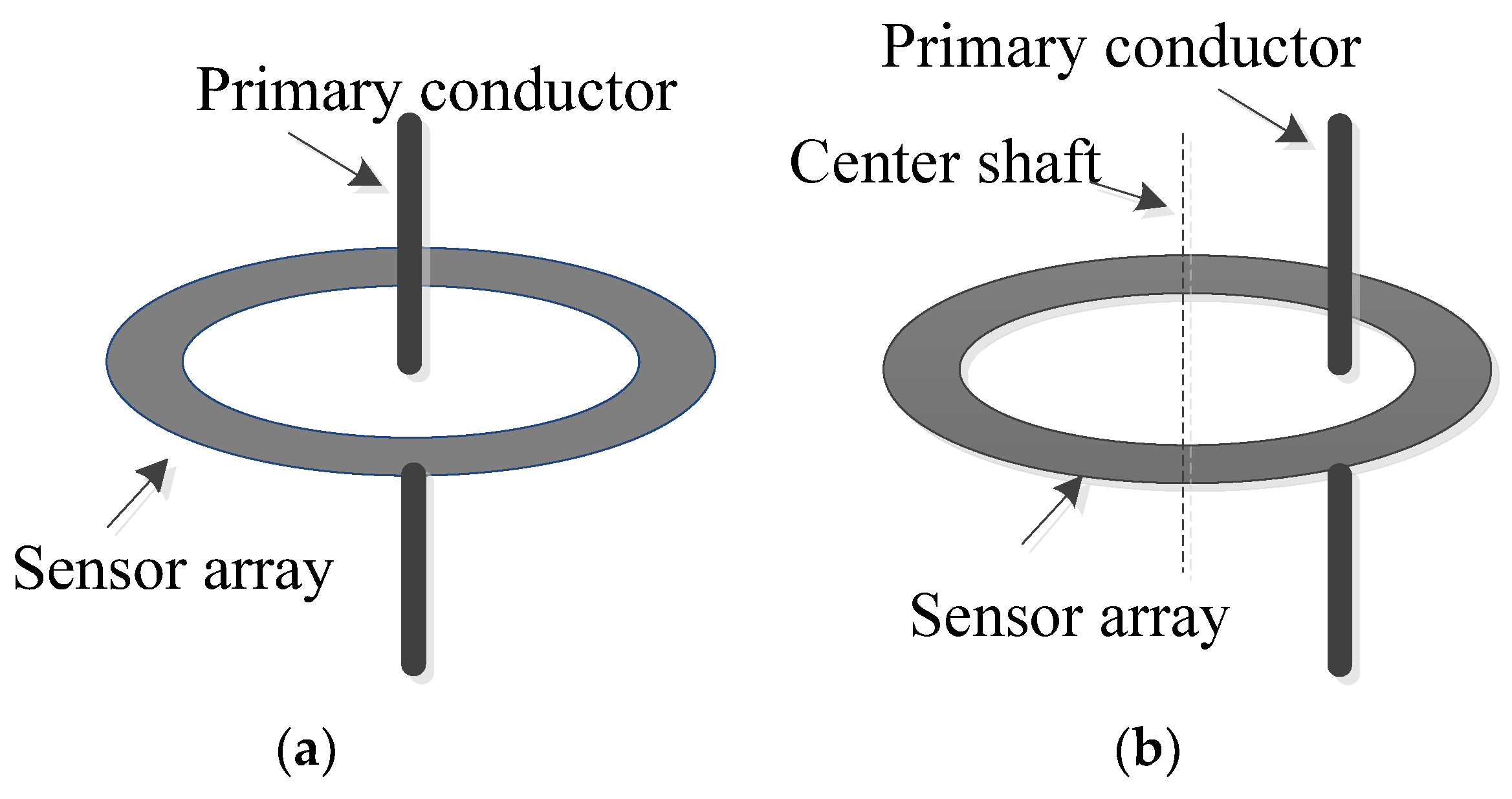

4. Performance Test

4.1. Influence of Magnetic Field due to a Parallel Conductor

4.2. Off-Center Conductor Analysis

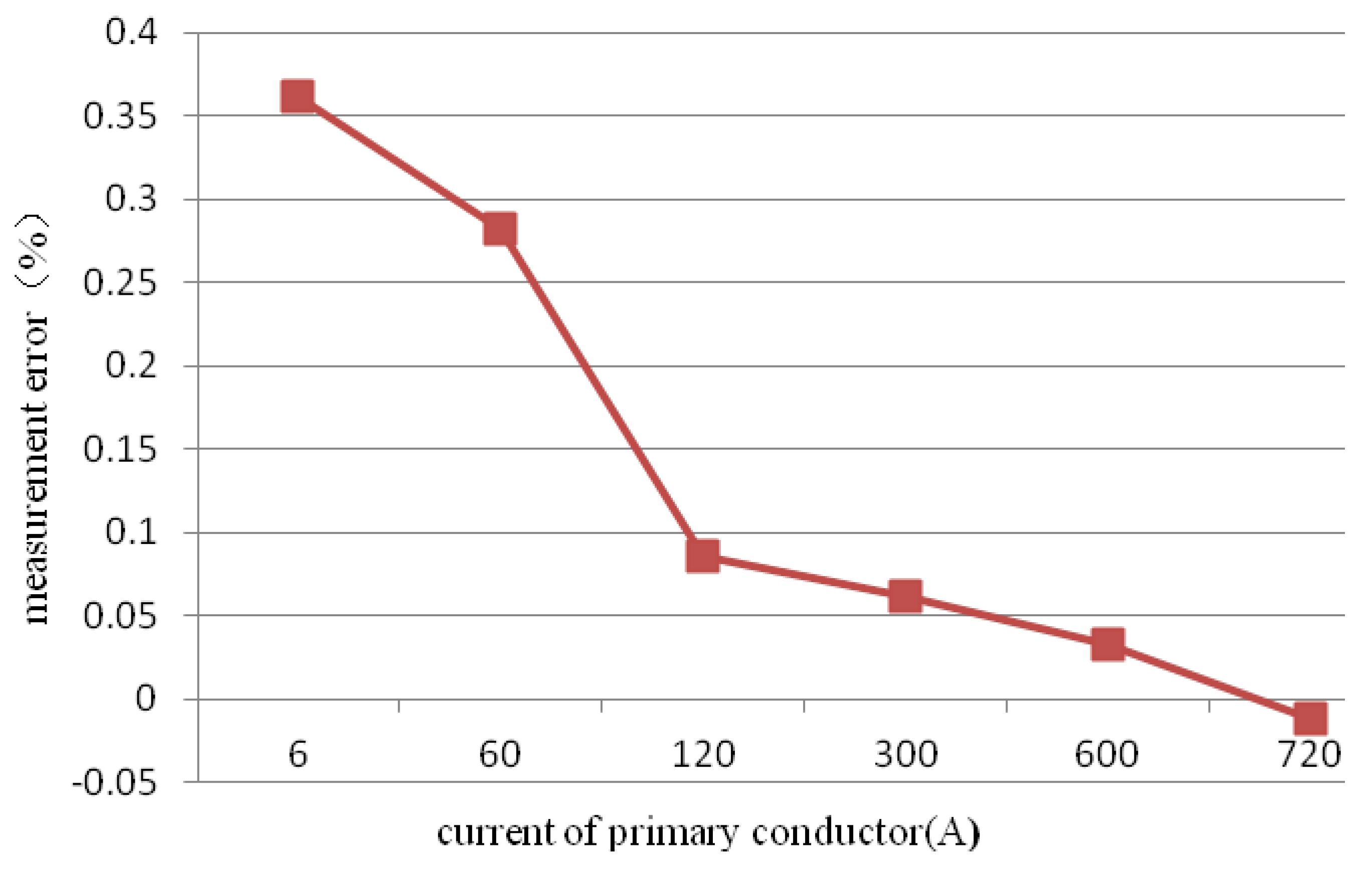

4.3. Basic Accuracy Test

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Matsumoto, H.; Shibako, Y.; Shiihara, Y.; Nagata, R.; Neba, Y. Three-phase lines to Single-phase Coil Planar Contactless Power Transformer. IEEE Trans. Ind. Electron. 2018, 65, 2904–2914. [Google Scholar] [CrossRef]

- Dave, M.; Bhagdev, M. Design and Analysis of Adaptable Power Electronic Transformer. In Proceedings of the 2017 2nd IEEE International Conference on Electrical Computer and Communication Technology (ICECCT), Coimbatore, India, 22–24 February 2017; pp. 1–6. [Google Scholar]

- Sabahi, M.; Hosseini, S.H.; Sharifian, M.B.B.; Goharrizi, A.Y.; Gharehpetian, G.B. A three-phase dimmable lighting system using a bidirectional power electronic transformer. IEEE Trans. Power Electron. 2009, 24, 830–837. [Google Scholar] [CrossRef]

- Sabahi, M.; Goharrizi, A.Y.; Hosseini, S.H.; Sharifian, M.B.B.; Gharehpetian, G.B. Flexible Power Electronic Transformer. IEEE Trans. Power Electron. 2010, 25, 2159–2169. [Google Scholar] [CrossRef]

- Zhao, J.Y.; Yao, F.; Mi, Y.Z.; Qin, N. Research on Optimization Technology of Electromagnetic Transformer. Energy Power Technol. 2013, 805, 818–821. [Google Scholar] [CrossRef]

- Warrier, P.V.; Preetha, P.K. Electromagnetic analysis of transformer using Solid works. In Proceedings of the 2015 International Conference on Technological Advancements in Power and Energy (TAP Energy), Kollam, India, 24–26 June 2015; pp. 427–431. [Google Scholar]

- Li, Z.H.; Yan, S.H.; Hu, W.Z. High Accuracy On-Line Calibration System for Current Transformers Based on Clamp-Shape Rogowski Coil and Improved Digital Integrator. Mapan-J. Metrol. Soc. India 2016, 31, 119–127. [Google Scholar] [CrossRef]

- Li, Z.H.; Hu, W.Z. A high-precision digital integrator based on the Romberg algorithm. Rev. Sci. Instrum. 2017, 88, 138–142. [Google Scholar] [CrossRef] [PubMed]

- Dubickas, V.; Edin, H. High-Frequency Model of the Rogowski Coil with a Small Number of Turns. IEEE Trans. Instrum. Meas. 2007, 56, 2284–2288. [Google Scholar] [CrossRef]

- Lehtonen, T.A.; Hällström, J. Optimizing Temperature Coefficient and Frequency Response of Rogowski Coils. IEEE Sens. J. 2017, 17, 6646–6651. [Google Scholar] [CrossRef]

- Oosthuysen, N.J.; Walker, J.J. Optimizing the Properties of the Optical Current Transformer with Special Reference to faster transient response. In Proceedings of the International Conference on High Voltage Engineering and Application, Poznan, Poland, 8–11 September 2014; pp. 1–4. [Google Scholar]

- Ashraf, H.M.; Abbas, G.; Ali, U.; Rehman, S.U. Modeling and Simulation of Optical Current Transformer using operational amplifiers. In Proceedings of the 5th International Conference on Electrical Engineering(ICEE), Boumerdes, Algeria, 29–31 October 2017; pp. 1–6. [Google Scholar]

- Araujo, Z.; Davila, M.; Mora, E.; Maldonado, L.; Ferraz, G. Analysis of the Behavior of an Optical Current Transformer using an Equivalent circuit. In Proceedings of the 6th Andean Region International Conference, Cuenca, Ecuador, 7–9 November 2012; pp. 81–84. [Google Scholar]

- Sasaki, K.; Takahashi, M.; Hirata, Y. Temperature-Insensitive Sagnac-Type Optical Current Transformer. J. Lightwave Technol. 2015, 33, 2463–2467. [Google Scholar] [CrossRef]

- Santos, J.C.; Sillos, A.C.; Nascimento, C.G.S. On-Field Instrument Transformers Calibration Using Optical Current and Voltage Transformers. In Proceedings of the IEEE International Workshop on Applied Measurements for Power Systems (AMPS), Aachen, Germany, 24–26 September 2014; pp. 1–5. [Google Scholar]

- Santos, J.C.; Almeida, J.C.J.; Silva, L.P.C. White Light Interferometry High Voltage Optical Fiber Sensor Systems with Compensation for Optical Power Fluctuations. In Proceedings of the Third European Workshop on Optical Fibre Sensors, Napoli, Italy, 4–6 July 2007; pp. 1–5. [Google Scholar]

- Samimi, M.H.; Bahrami, S.; Akmal, A.A.S.; Mohseni, H. Effect of Nonideal Linear Polarizers, Stray Magnetic Field, and Vibration on the Accuracy of Open-Core Optical Current Transducers. IEEE Sens. J. 2014, 14, 3508–3515. [Google Scholar] [CrossRef]

- Ouyang, Y.; He, J.L.; Hu, J.; Wang, S.X. A Current Sensor Based on the Giant Magnetoresistance Effect: Design and Potential Smart Grid Applications. Sensors 2012, 12, 15520–15541. [Google Scholar] [CrossRef] [PubMed]

- Ziegler, S.; Woodward, R.C.; Iu, H.H.C.; Borle, L.J. Current Sensing Techniques: A Review. IEEE Sens. J. 2009, 9, 354–376. [Google Scholar] [CrossRef]

- Andrea, M.H.; Marc, P.; Maher, K. A Fully Integrated Hall Sensor Microsystem for Contactless Current Measurement. IEEE Sens. J. 2013, 13, 2271–2278. [Google Scholar] [CrossRef]

- Nama, T.; Gogoi, A.K.; Tripathy, P. Application of a Smart Hall Effect Sensor System for 3-Phase BLDC Drives. In Proceedings of the IEEE 5th International Symposium on Robotics and Intelligent Sensors(IRIS), Ottawa, ON, Canada, 5–7 October 2017; pp. 1–28. [Google Scholar]

- Fernandez, D.; Hyun, D.; Park, Y.; Reigosa, D.D.; Lee, S.B.; Lee, D.M.; Briz, F. Permanent Magnet Temperature Estimation in PM Synchronous Motors Using Low-Cost Hall Effect Sensors. IEEE Trans. Ind. Appl. 2017, 53, 4515–4525. [Google Scholar] [CrossRef]

- Song, K.J.; Lim, J.C.; Ko, R.K.; Park, C.; Schwartz, J. A Noncontact Tc Evaluation Technique Using a Hall Probe Array. IEEE Trans. Appl. Superconduct. 2017, 27, 1–4. [Google Scholar] [CrossRef]

- Jiang, J.F.; Makinwa, K.A.A. Multipath Wide-Bandwidth CMOS Magnetic Sensors. IEEE J. Solid State Circuits 2017, 52, 198–209. [Google Scholar] [CrossRef]

- Sen, M.; Balabozov, I.; Yatchev, I.; Ivanov, R. Modelling of Current Sensor Based on Hall Effect. In Proceedings of the 2017 15th International Conference on Electrical Machines, Drives and Power Systems (ELMA), Yekaterinburg, Russia, 1–3 June 2017; pp. 457–460. [Google Scholar]

- Li, C.S.; Cui, H.; Zhang, X. Optical Magnetic Field Sensor Based on Electrogyratory and Electrooptic Compensation in Single Quartz Crystal. IEEE Sens. J. 2018, 18, 1427–1434. [Google Scholar] [CrossRef]

- Salzer, S.; Röbisch, V.; Klug, M.; Durdaut, P.; McCord, J.; Meyners, D.; Reermann, J.; Höft, M.; Knöchel, R. Noise Limits in Thin-Film Magnetoelectric Sensors With Magnetic Frequency Conversion. IEEE Sens. J. 2018, 18, 596–604. [Google Scholar] [CrossRef]

- Bazzocchi, R.; Rienzo, L.D. Interference Rejection Algorithm for Current Measurement using Magnetic Sensors Array. Sens. Actuators A. Phys. 2000, 85, 38–41. [Google Scholar] [CrossRef]

- Rienzo, L.D.; Bazzocchi, R.; Manara, A. Circular Arrays of Magnetic Sensors for Current Measurement. IEEE Trans. Instrum. Meas. 2001, 50, 1093–1096. [Google Scholar] [CrossRef]

| Current of Primary Conductor (A) | Off-Center Distance (mm) | Measurement Results before Improvement (A) | Measurement Results after Improvement (A) | Measurement Error before Improvement (%) | Measurement Error after Improvement (%) |

|---|---|---|---|---|---|

| 600 | 1 | 599.85 | 599.99 | 0.025 | 0.001 |

| 600 | 2 | 599.34 | 599.93 | 0.110 | 0.012 |

| 600 | 3 | 598.74 | 599.89 | 0.210 | 0.019 |

| 600 | 4 | 597.42 | 599.78 | 0.430 | 0.036 |

| 600 | 5 | 596.16 | 599.63 | 0.640 | 0.062 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Zhang, S.; Wu, Z.; Abu-Siada, A.; Tao, Y. Study of Current Measurement Method Based on Circular Magnetic Field Sensing Array. Sensors 2018, 18, 1439. https://doi.org/10.3390/s18051439

Li Z, Zhang S, Wu Z, Abu-Siada A, Tao Y. Study of Current Measurement Method Based on Circular Magnetic Field Sensing Array. Sensors. 2018; 18(5):1439. https://doi.org/10.3390/s18051439

Chicago/Turabian StyleLi, Zhenhua, Siqiu Zhang, Zhengtian Wu, Ahmed Abu-Siada, and Yuan Tao. 2018. "Study of Current Measurement Method Based on Circular Magnetic Field Sensing Array" Sensors 18, no. 5: 1439. https://doi.org/10.3390/s18051439

APA StyleLi, Z., Zhang, S., Wu, Z., Abu-Siada, A., & Tao, Y. (2018). Study of Current Measurement Method Based on Circular Magnetic Field Sensing Array. Sensors, 18(5), 1439. https://doi.org/10.3390/s18051439