Automated Inspection of Defects in Optical Fiber Connector End Face Using Novel Morphology Approaches

Abstract

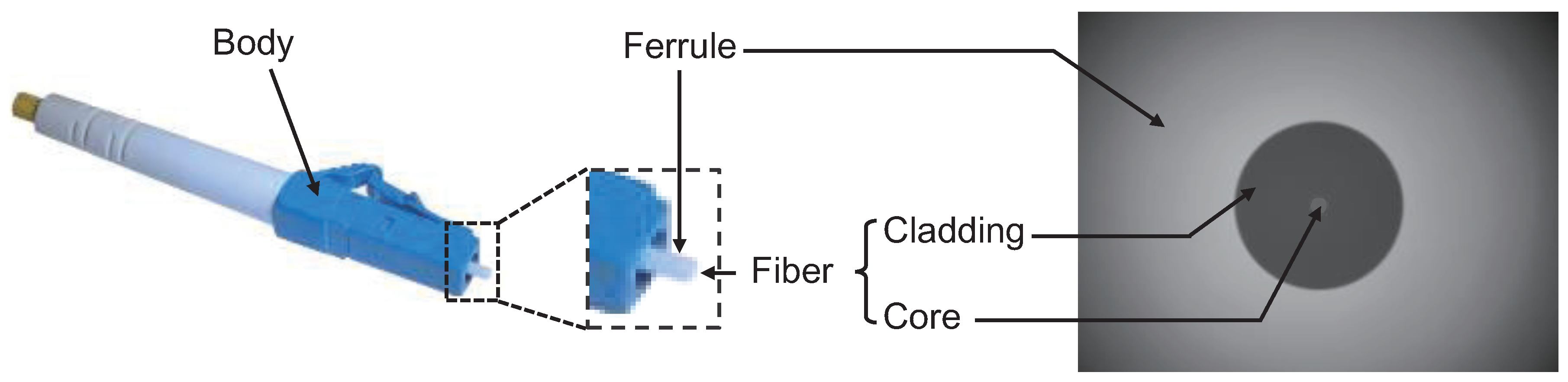

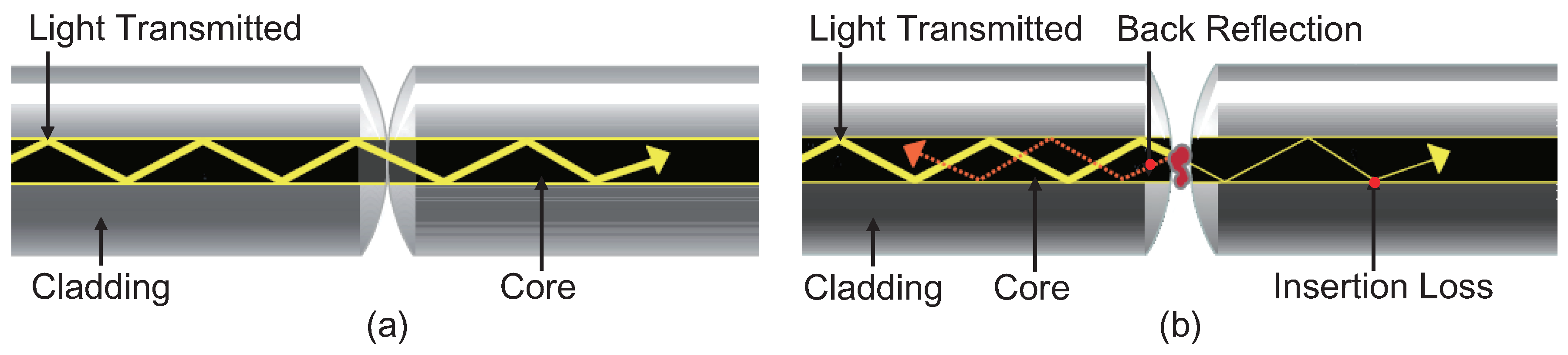

:1. Introduction

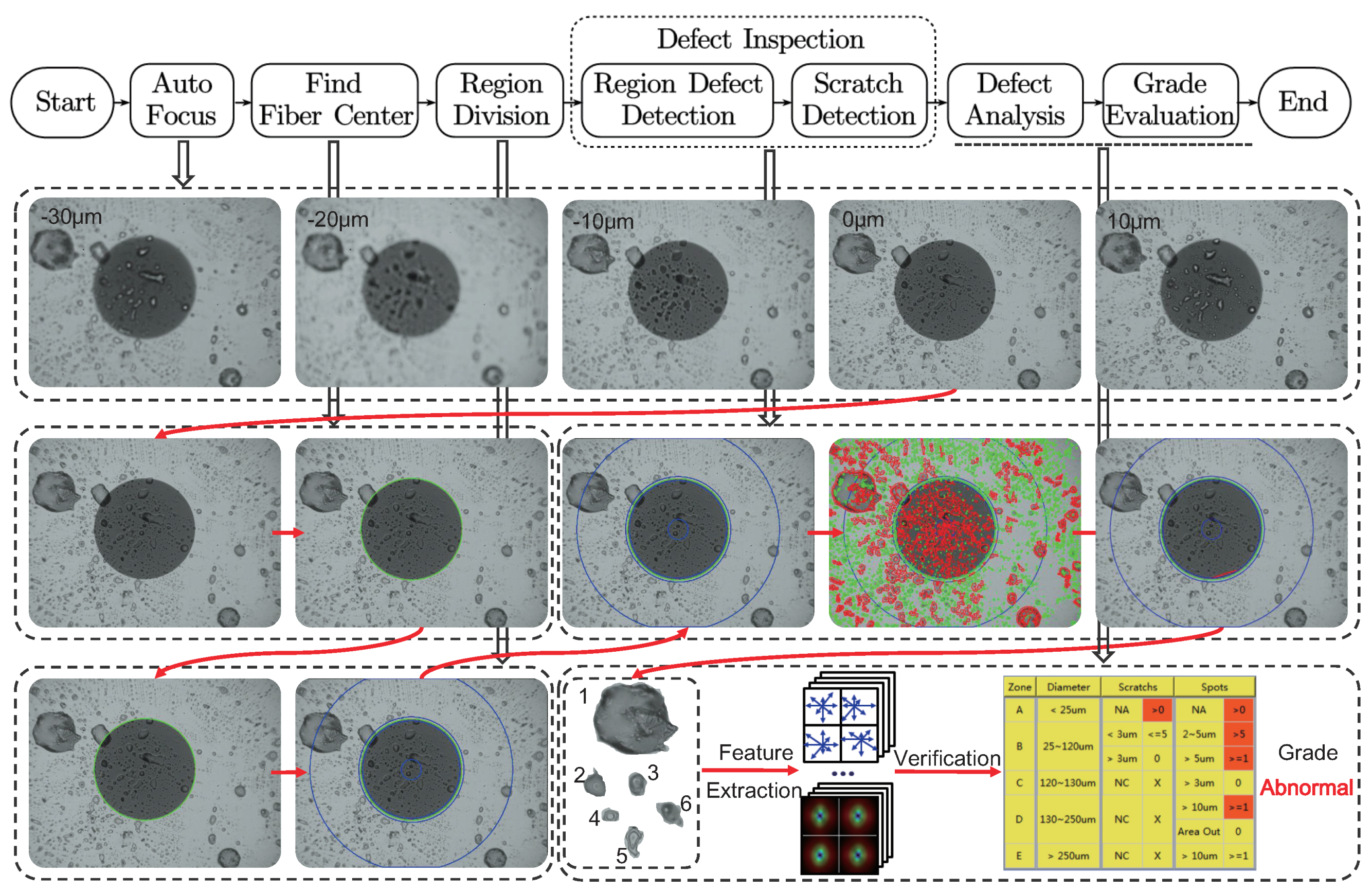

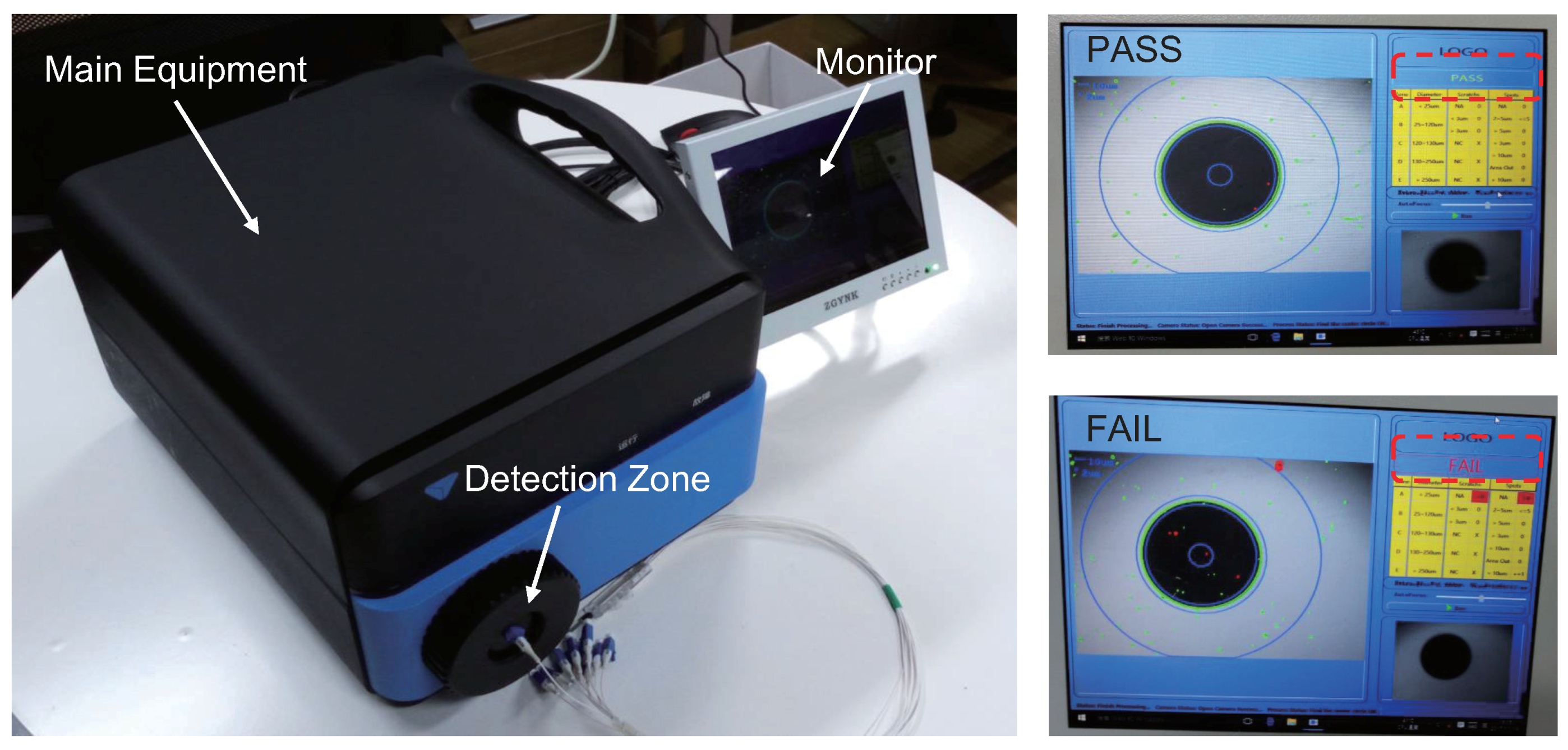

- As far as we know, this is the first time that complete defect detection algorithms for optical fiber end faces are available in the literature. Many device manufacturers introduce the function but do not illustrate how to implement the detection algorithm, which is the core of the inspection process [7,8]. As for the relevant patents, they are usually very abstract, and only general frameworks are introduced, without specific implementation strategies or algorithm parameters. We also present the quality assessment procedures used in our automatic optical inspection (AOI) equipment, as stated in Section 2.

- The DO2MR and LEI models are aimed at determining the characteristics of typical defects. Experimental results have shown that they have good performance. The average detection accuracies reach 96.0 and 89.3% for region-based defects and scratches, respectively.

- The DO2MR and LEI models can be conducted in a completely unsupervised condition such that no manual intervention is needed. They can be easily utilized in online defect detection lines.

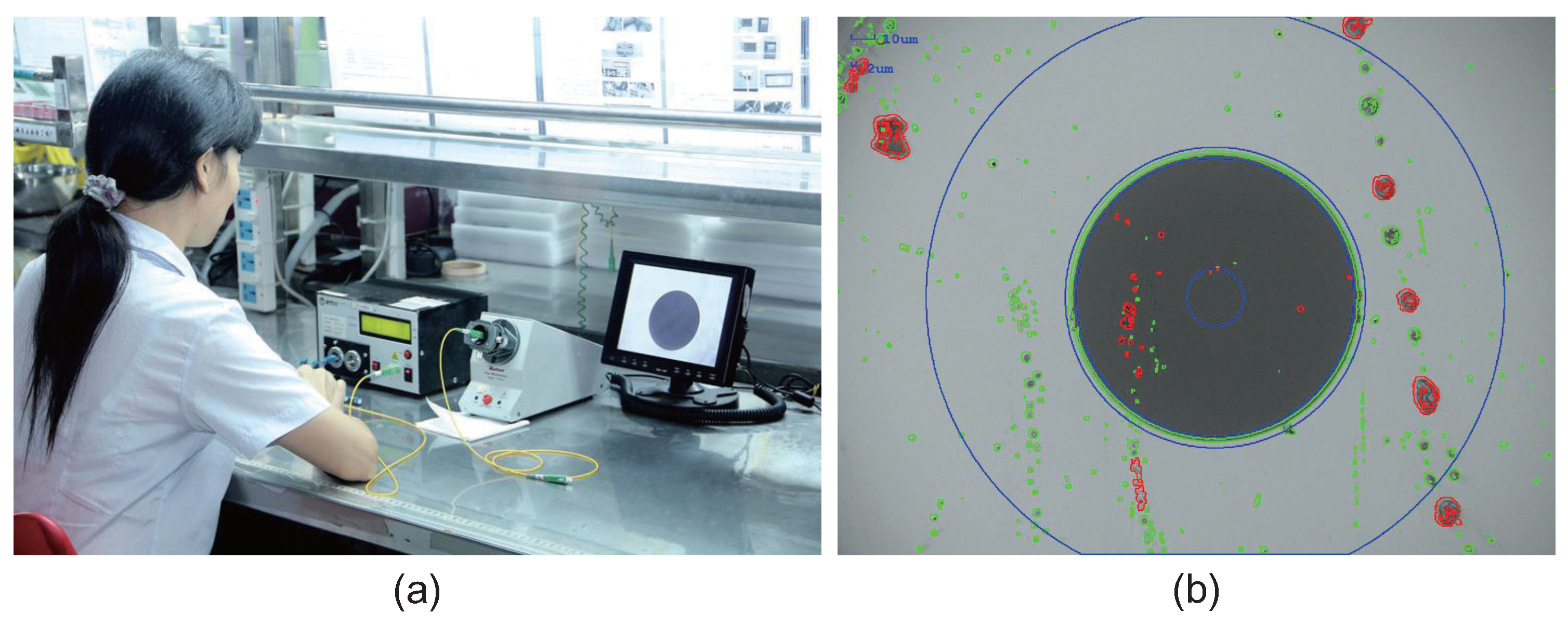

2. Automatic Quality Assessment for Optical Fiber End Faces

3. Proposed Methods

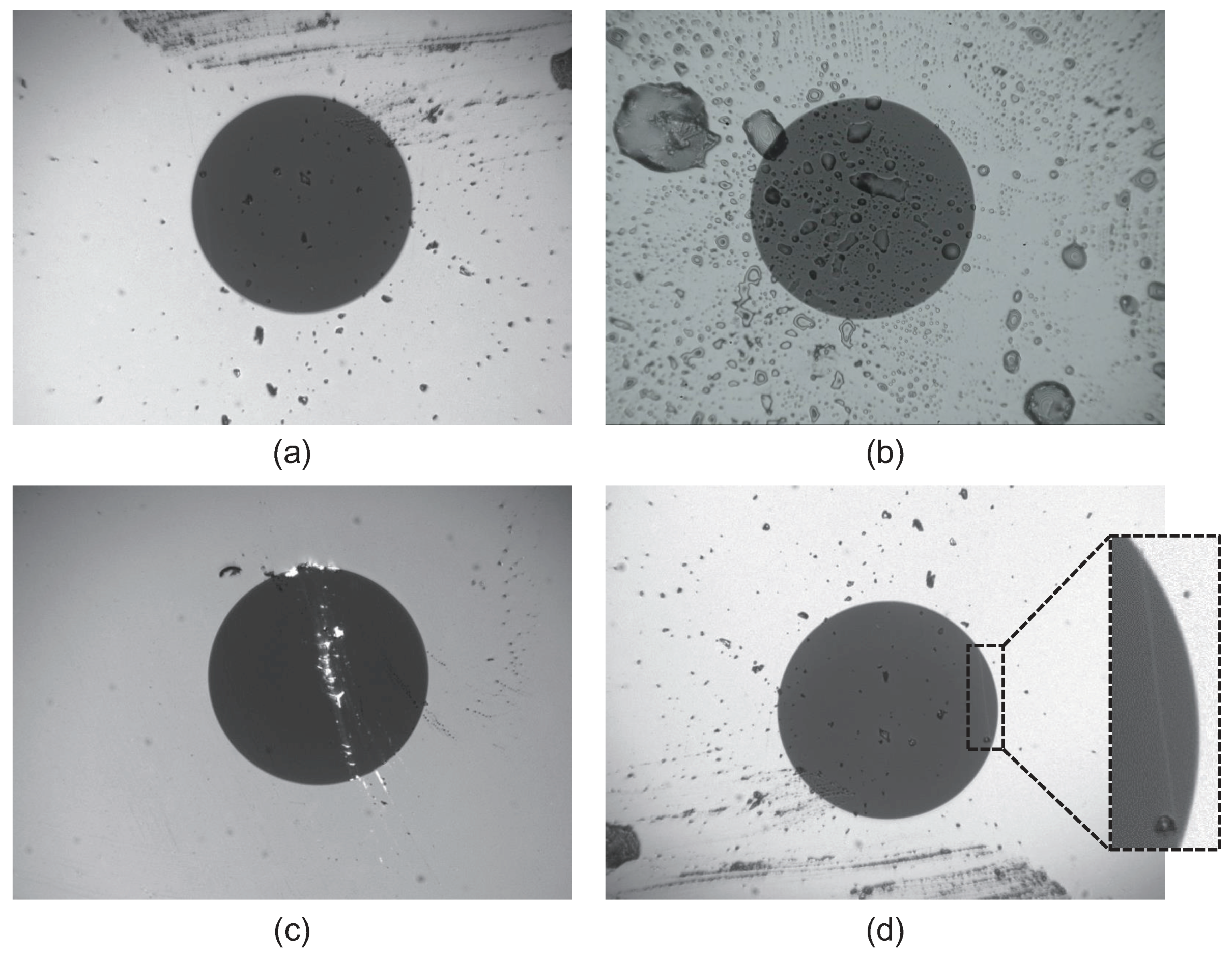

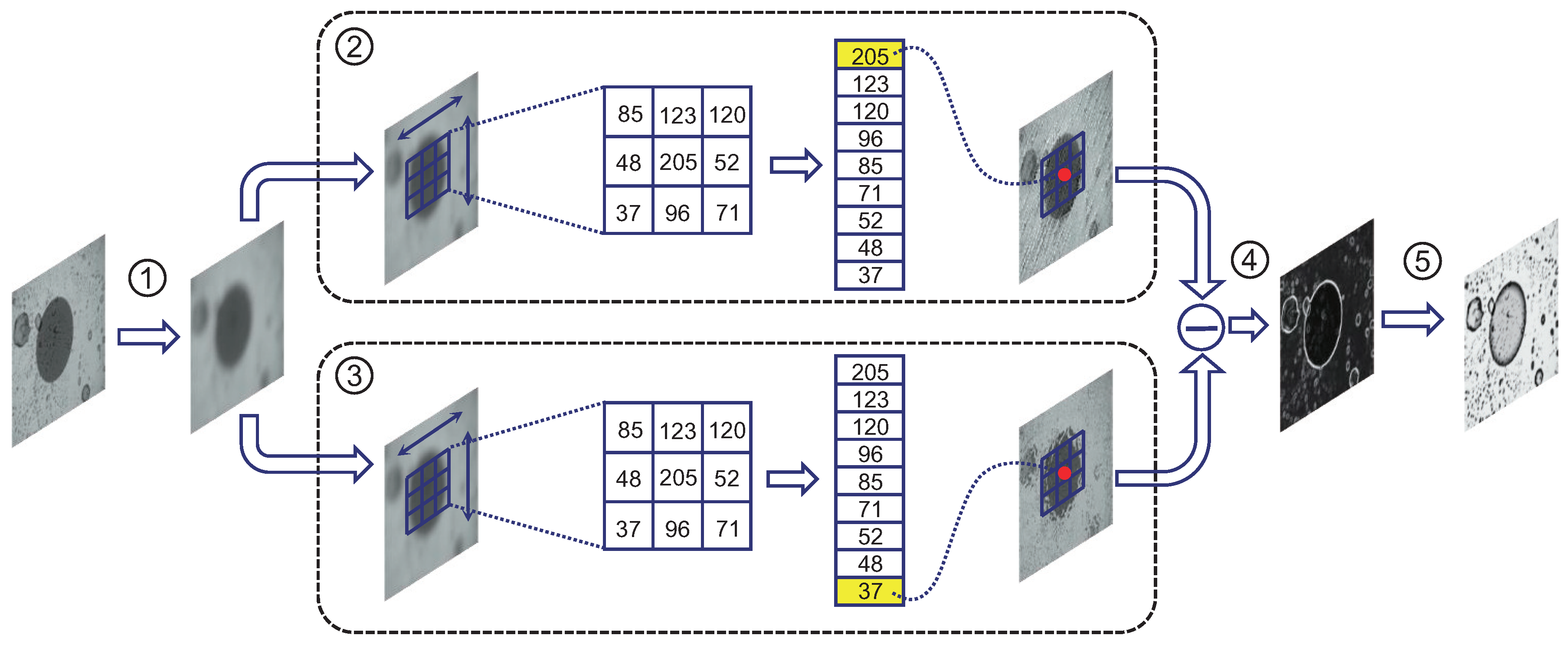

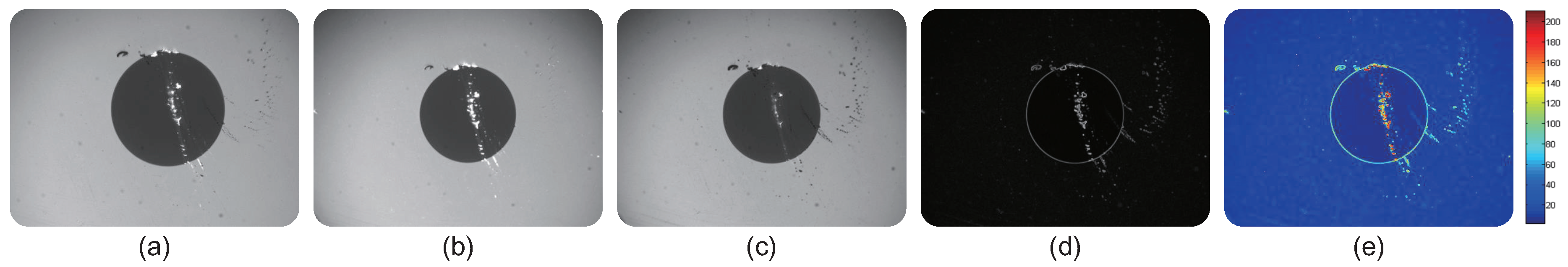

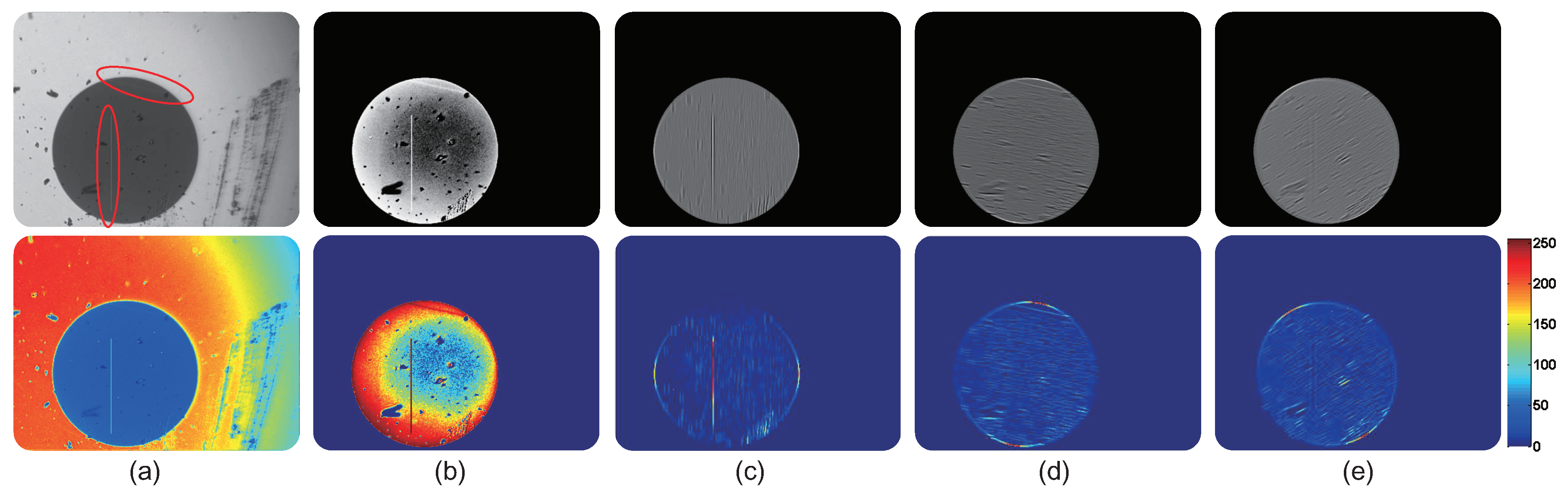

3.1. Detection of the Region-Based Defects: Difference of Min-Max Ranking Filter

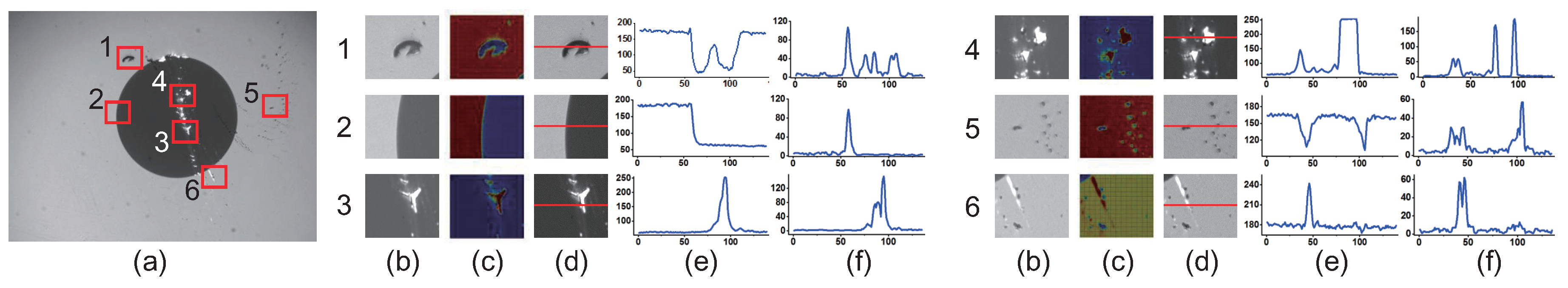

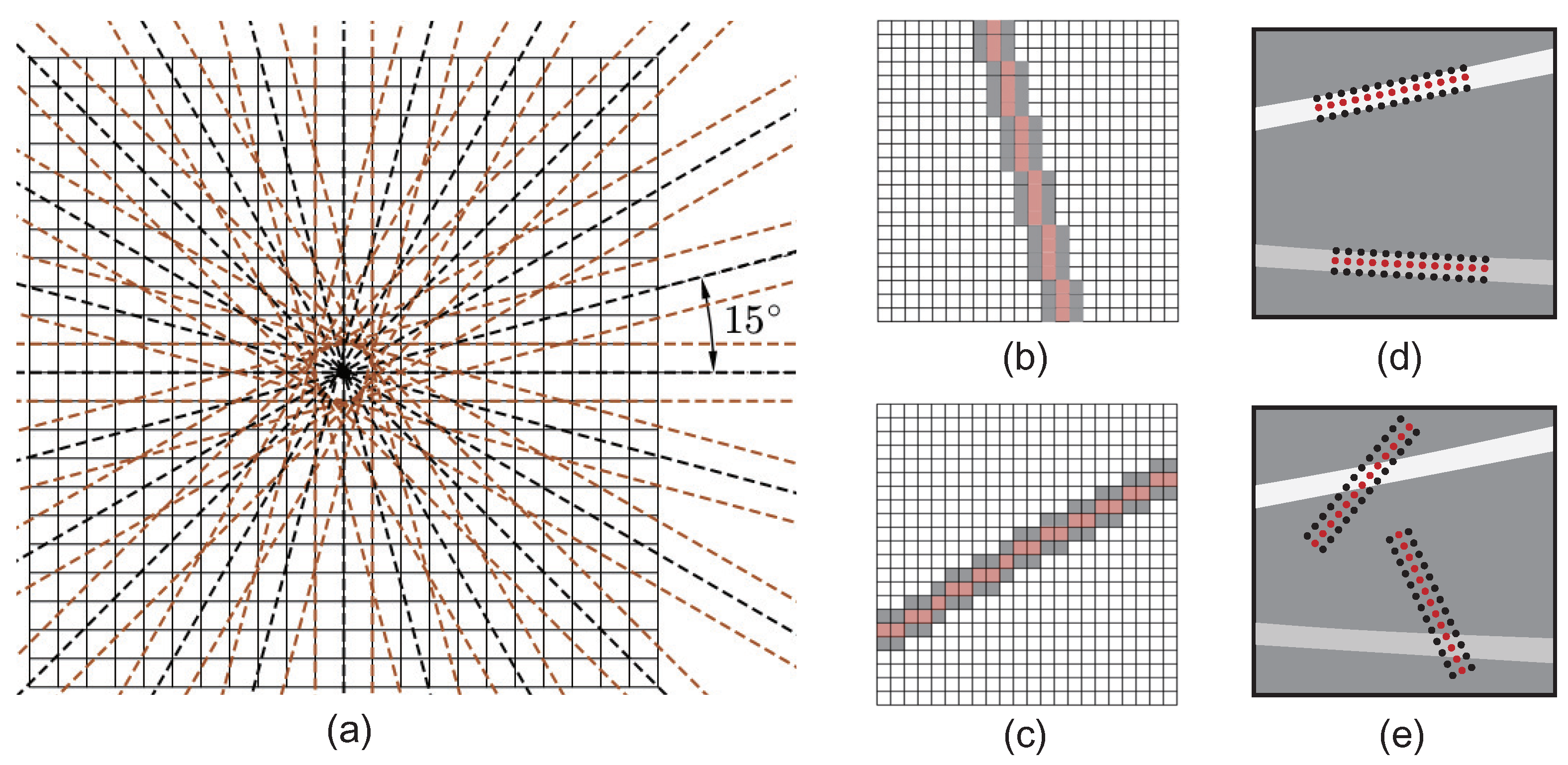

3.2. Detection of the Scratched Defects: Linear Enhancement Inspection

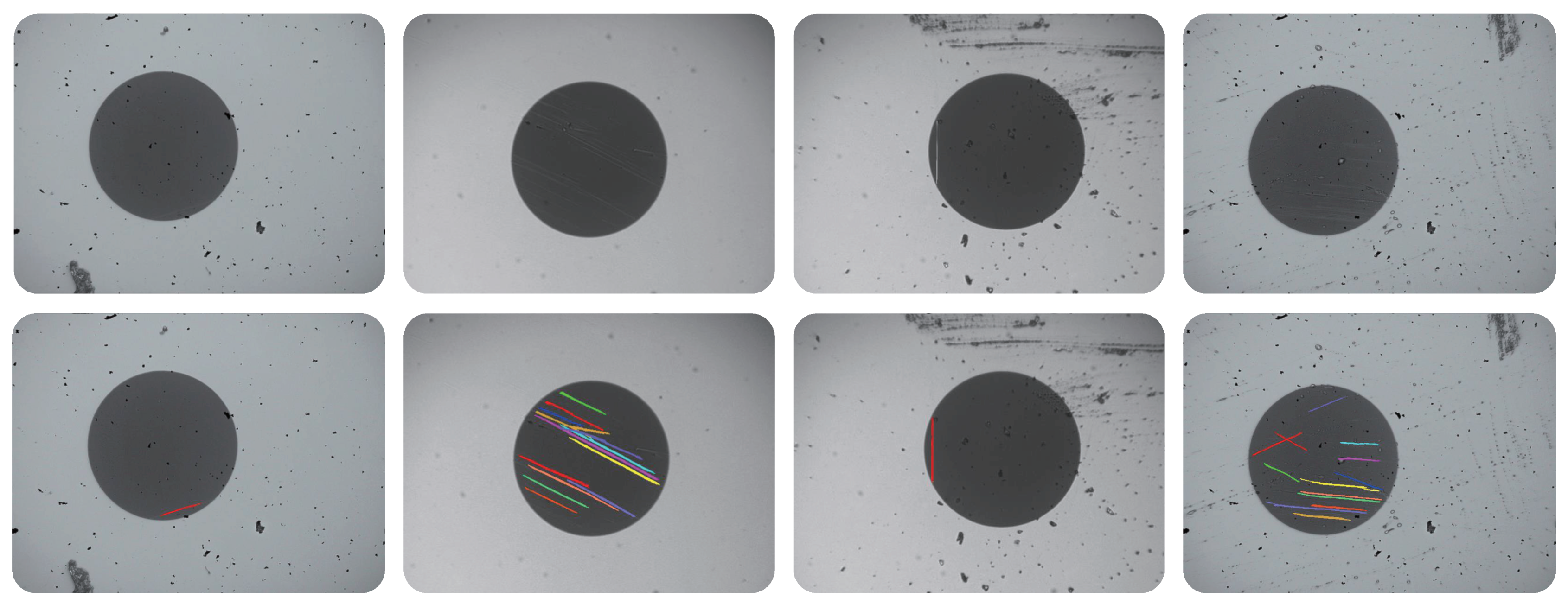

4. Experiments and Discussions

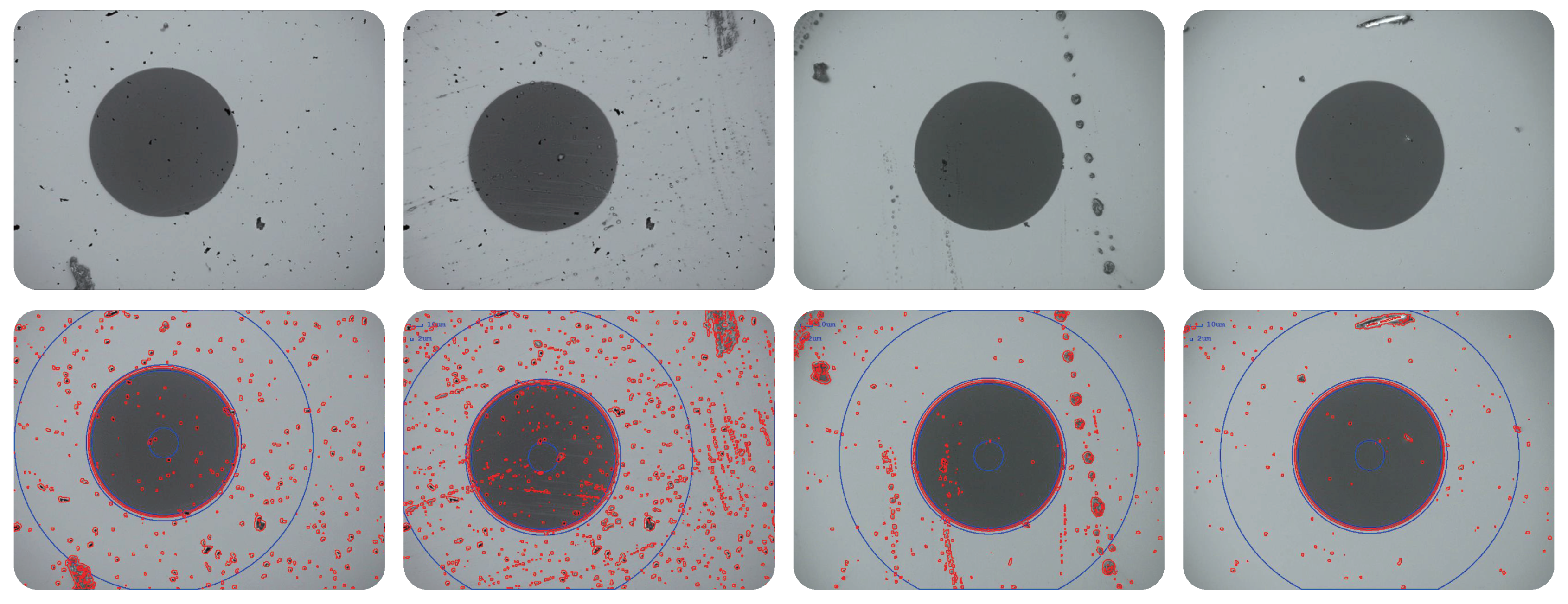

4.1. Datasets and Evaluation Criteria

4.2. Evaluation of the DO2MR Model (Region-Based Defects)

4.3. Evaluation of the LEI Model (Scratched Defects)

5. Implementation Details

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AOI | Automatic optical inspection |

| ASM | Adaptive segmentation method |

| DO2MR | Difference of min-max ranking filtering |

| IEC | International electro technical commission |

| LEI | Linear enhancement inspector |

| ROI | Region of interest |

| SBS | Sigma-based segmentation |

References

- Glenair. Optical end Face Inspection Guidelines for Ceramic Ferrule end Face Connectors. Available online: http://docplayer.net/40885734-Optical-end-face-inspection-guidelines.html (accessed on 1 March 2018).

- Artundo, I.; Tymecki, A.; Ortego, E.; Ortega, B. Cost forecasting of passive components for optical fiber network deployments. Opt. Fiber Technol. 2011, 17, 218–226. [Google Scholar] [CrossRef]

- Morris, D. Fiber Optic Tester with Go-No-Go Acceptance Criteria—Final Report; KITCO Optical Fibers: National City, CA, USA, 2011. [Google Scholar]

- NTT Advanced Technology Corporation. The impact of optical connector end face contamination and how to prevent it. In The 2nd Generation Series of Popular Optical Connector Related Materials; NTT Advanced Technology Corporation: Kanagawa, Japan, 2013. [Google Scholar]

- Leo, M.; Del Coco, M.; Carcagnì, P.; Spagnolo, P.; Mazzeo, P.; Distante, C.; Zecca, R. Automatic visual monitoring of welding procedure in stainless steel kegs. Opt. Lasers Eng. 2017, 104, 220–231. [Google Scholar] [CrossRef]

- INC, X.C. The Industry’s Strictest Quality Standards. Available online: http://xfsconnect.com/Quality/ (accessed on 10 March 2018).

- Brown, M. Achieving IEC Standard Compliance for Fiber Optic Connector Quality: Automated Inspection and Analysis Software Ensures Fiber Optic Connector Performance. Available online: https://www.fibre-systems.com/sites/default/files/content/white-paper/pdfs/Achieving-IEC-Standard.pdf (accessed on 15 April 2018).

- Herman, P. Fiber Optic Terminus End Face Quality Standards. Available online: http://www.fibersystems.com/pdf/whitepapers/Quality-Standards.pdf (accessed on 15 April 2018).

- Zhou, S.; Xing, M.; Xia, X.G.; Li, Y.; Zhang, L.; Bao, Z. An azimuth-dependent phase gradient autofocus (APGA) algorithm for airborne-stationary BiSAR imagery. IEEE Geosci. Remote Sens. Lett. 2013, 10, 1290–1294. [Google Scholar] [CrossRef]

- Pellizzari, C.J.; Bos, J.; Spencer, M.F.; Williams, S. Performance characterization of Phase Gradient Autofocus for inverse synthetic aperture LADAR. In Proceedings of the Aerospace Conference, Big Sky, MT, USA, 1–8 March 2014; pp. 1–11. [Google Scholar]

- Yue, J.; Xiang, X.Z. An improved algorithm of Hough circle detection. Appl. Sci. Technol. 2006, 6, 23. [Google Scholar]

- D’Orazio, T.; Guaragnella, C.; Leo, M.; Distante, A. A new algorithm for ball recognition using circle Hough transform and neural classifier. Pattern Recognit. 2004, 37, 393–408. [Google Scholar] [CrossRef]

- De Marco, T.; Cazzato, D.; Leo, M.; Distante, C. Randomized circle detection with isophotes curvature analysis. Pattern Recognit. 2015, 48, 411–421. [Google Scholar]

- International Electrotechnical Commission. Fibre Optic Interconnecting Devices and Passive Components—Basic Test and Measurement Procedures; IEC-61300-3-35; International Electrotechnical Commission: Geneva, Switzerland, 2012. [Google Scholar]

- Mei, S.; Yang, H.; Yin, Z. Discriminative feature representation for imageclassification via multimodal multitask deep neural networks. J. Electron. Imaging 2017, 26, 013023. [Google Scholar] [CrossRef]

- Guyon, I.; Elisseeff, A. An Introduction to Feature Extraction; Springer: Berlin/Heidelberg, Germany, 2006; pp. 1–25. [Google Scholar]

- Mei, S.; Yang, H.; Yin, Z. Unsupervised-learning-based feature-level fusion method for mura defect recognition. IEEE Trans. Semicond. Manuf. 2017, 30, 105–113. [Google Scholar] [CrossRef]

- Wikipedia. Histogram Equalization. Available online: https://en.wikipedia.org/wiki/Histogram_equalization (accessed on 12 March 2018).

- Ricci, E.; Perfetti, R. Retinal blood vessel segmentation using line operators and support vector classification. IEEE Trans. Med. Imaging 2007, 26, 1357–1365. [Google Scholar] [CrossRef] [PubMed]

- Zhu, N.; Wang, G.; Yang, G.; Dai, W. A fast 2D Otsu thresholding algorithm based on improved histogram. In Proceedings of the Chinese Conference on Pattern Recognition, Nanjing, China, 4–6 November 2009; pp. 1–5. [Google Scholar]

- Chiou, Y.C.; Wu, C.W. Detection of low-contrast defects in optical films using sigma-based segmentation technique. In Key Engineering Materials; Trans Tech Publications: Zürich, Switzerland, 2015; Volume 649, pp. 74–81. [Google Scholar]

- He, Z.; Sun, L. Surface defect detection method for glass substrate using improved Otsu segmentation. Appl. Opt. 2015, 54, 9823–9830. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Zheng, F.; Kong, B. An adaptive segmentation method for product surface inspection. In Proceedings of the IEEE Sixth World Congress on Intelligent Control and Automation, Dalian, China, 21–23 June 2006; Volume 2, pp. 10393–10397. [Google Scholar]

- Jia, L.; Chen, C.; Liang, J.; Hou, Z. Fabric defect inspection based on lattice segmentation and Gabor filtering. Neurocomputing 2017, 238, 84–102. [Google Scholar] [CrossRef]

- Zana, F.; Klein, J.C. Segmentation of vessel-like patterns using mathematical morphology and curvature evaluation. IEEE Trans. Image Process. 2001, 10, 1010–1019. [Google Scholar] [CrossRef] [PubMed]

| Criterion (%) | |||

|---|---|---|---|

| Partitioned-Otsu | 85.0 (51/60) | 42.5 (17/40) | 74.0 |

| SBS | 90.0 (54/60) | 55.0 (22/40) | 72.0 |

| improved-Otsu | 88.3 (53/60) | 32.5 (13/40) | 80.0 |

| ASM | 91.6 (55/60) | 27.5 (11/40) | 84.0 |

| DO2MR | 98.3 (59/60) | 7.5 (3/40) | 96.0 |

| Criterion (%) | |||

|---|---|---|---|

| Partitioned-Otsu | 87.4 | 63.8 | 73.8 |

| SBS | 86.3 | 57.7 | 69.2 |

| improved-Otsu | 89.2 | 73.4 | 80.5 |

| ASM | 88.6 | 79.5 | 83.8 |

| DO2MR | 94.2 | 88.7 | 91.4 |

| Criterion (%) | |||

|---|---|---|---|

| Zana’s | 93.8 (15/16) | 42.5 (17/40) | 67.9 |

| Ricci’s | 75.0 (12/16) | 25.0 (10/40) | 75.0 |

| LEI | 87.5 (14/16) | 10.0 (4/40) | 89.3 |

| Criterion (%) | |||

|---|---|---|---|

| Zana’s | 86.1 | 67.5 | 75.7 |

| Ricci’s | 83.8 | 75.3 | 79.3 |

| LEI | 89.4 | 81.3 | 85.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mei, S.; Wang, Y.; Wen, G.; Hu, Y. Automated Inspection of Defects in Optical Fiber Connector End Face Using Novel Morphology Approaches. Sensors 2018, 18, 1408. https://doi.org/10.3390/s18051408

Mei S, Wang Y, Wen G, Hu Y. Automated Inspection of Defects in Optical Fiber Connector End Face Using Novel Morphology Approaches. Sensors. 2018; 18(5):1408. https://doi.org/10.3390/s18051408

Chicago/Turabian StyleMei, Shuang, Yudan Wang, Guojun Wen, and Yang Hu. 2018. "Automated Inspection of Defects in Optical Fiber Connector End Face Using Novel Morphology Approaches" Sensors 18, no. 5: 1408. https://doi.org/10.3390/s18051408

APA StyleMei, S., Wang, Y., Wen, G., & Hu, Y. (2018). Automated Inspection of Defects in Optical Fiber Connector End Face Using Novel Morphology Approaches. Sensors, 18(5), 1408. https://doi.org/10.3390/s18051408