Tool Wear Prediction in Ti-6Al-4V Machining through Multiple Sensor Monitoring and PCA Features Pattern Recognition

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Setup

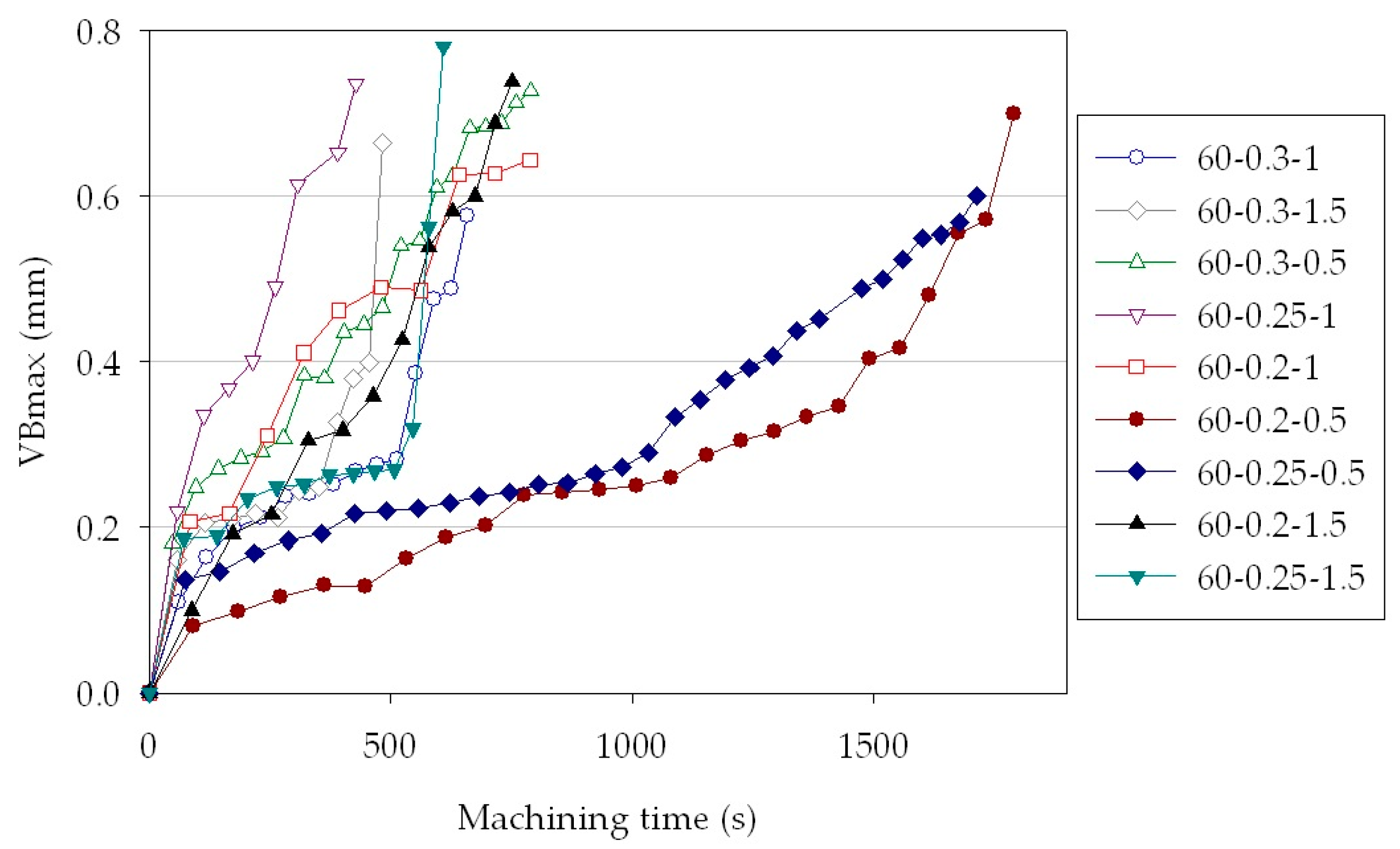

2.2. Tool Wear Measurement

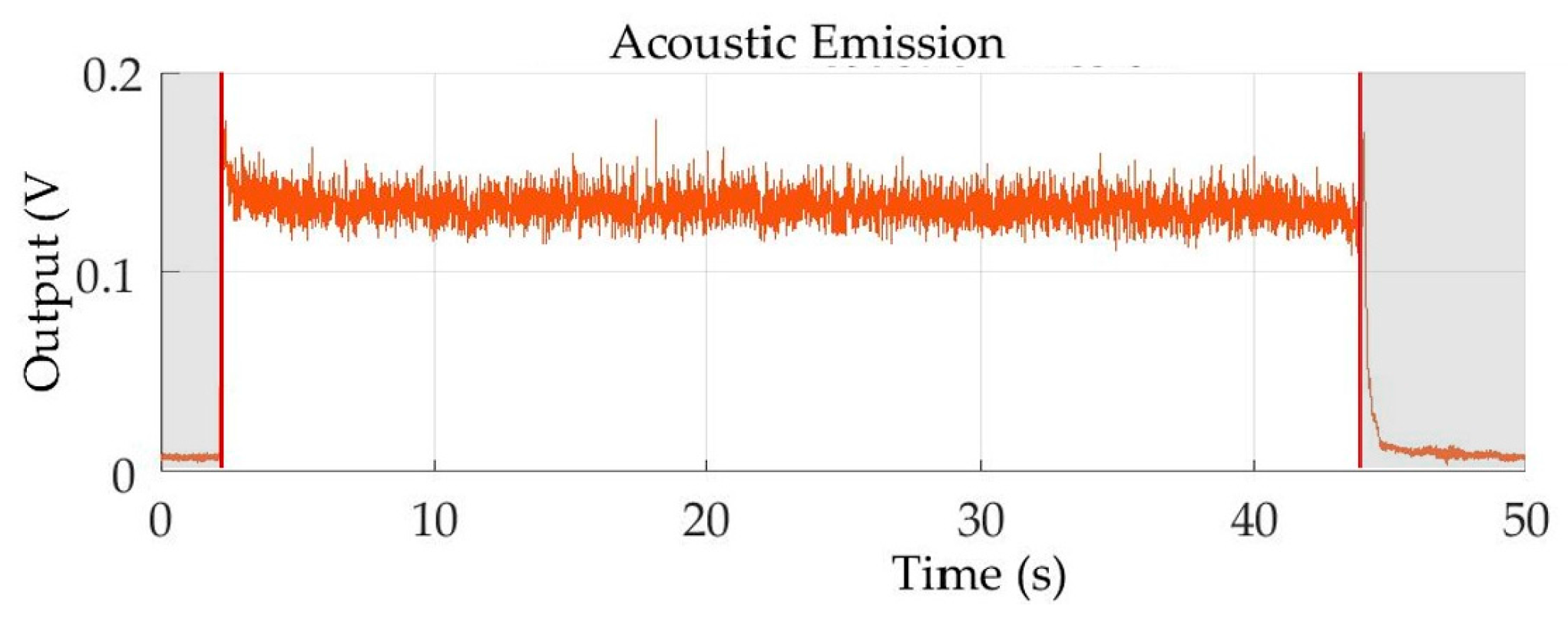

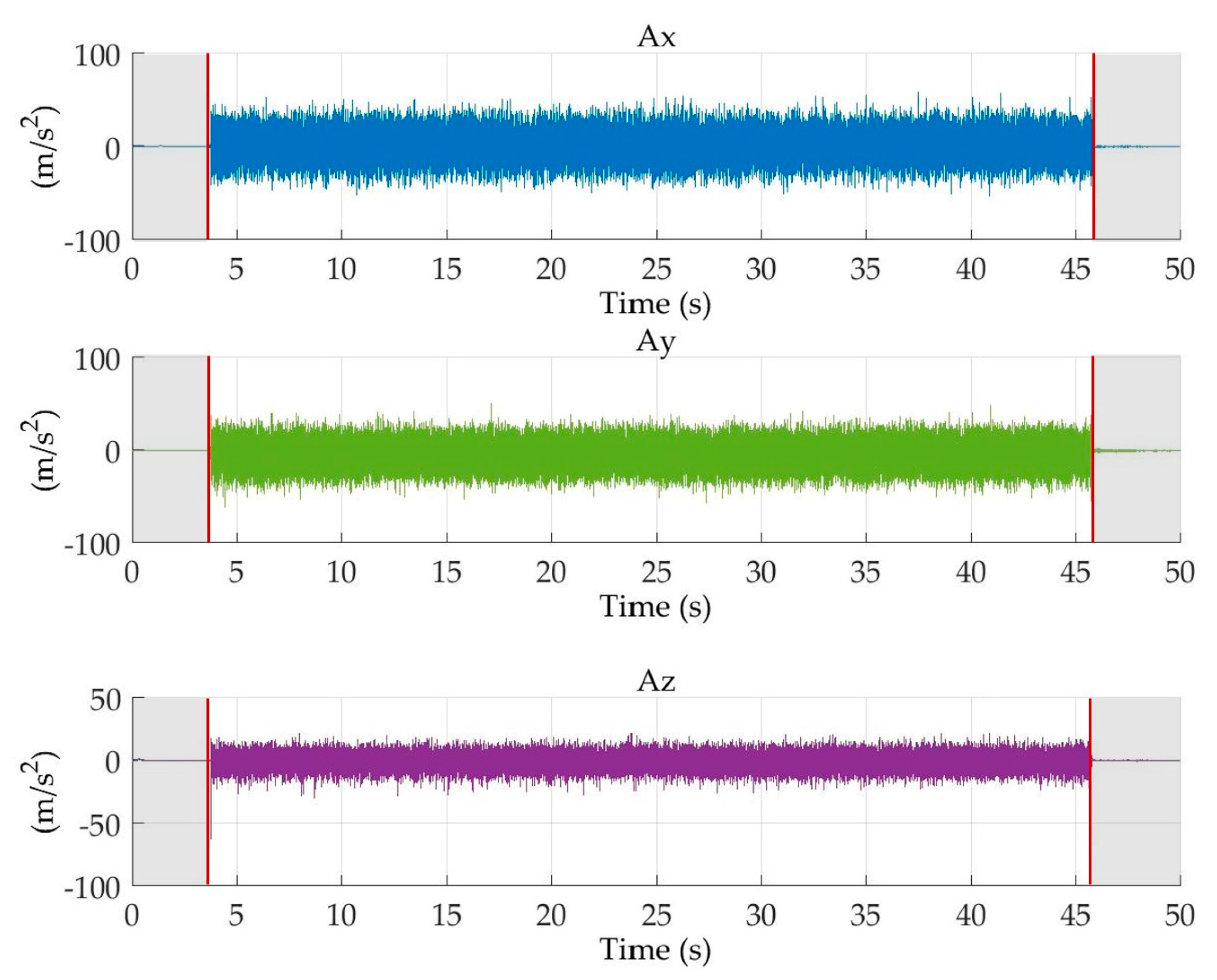

3. Sensor Signal Pre-Processing

4. Sensor Signal Features Extraction

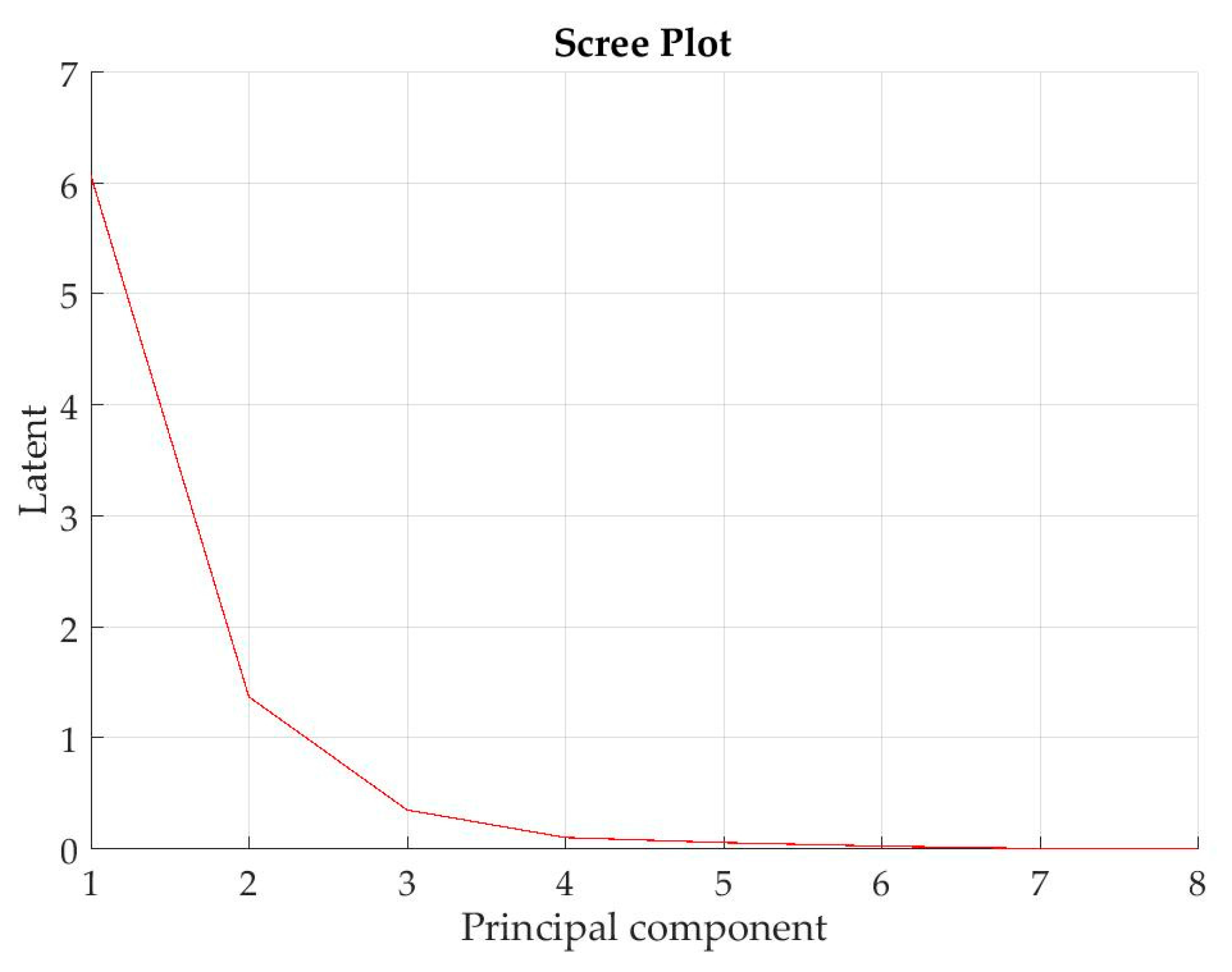

5. Feature Dimensionality Reduction

5.1. Feature Selection Based on Pearson’s Correlation

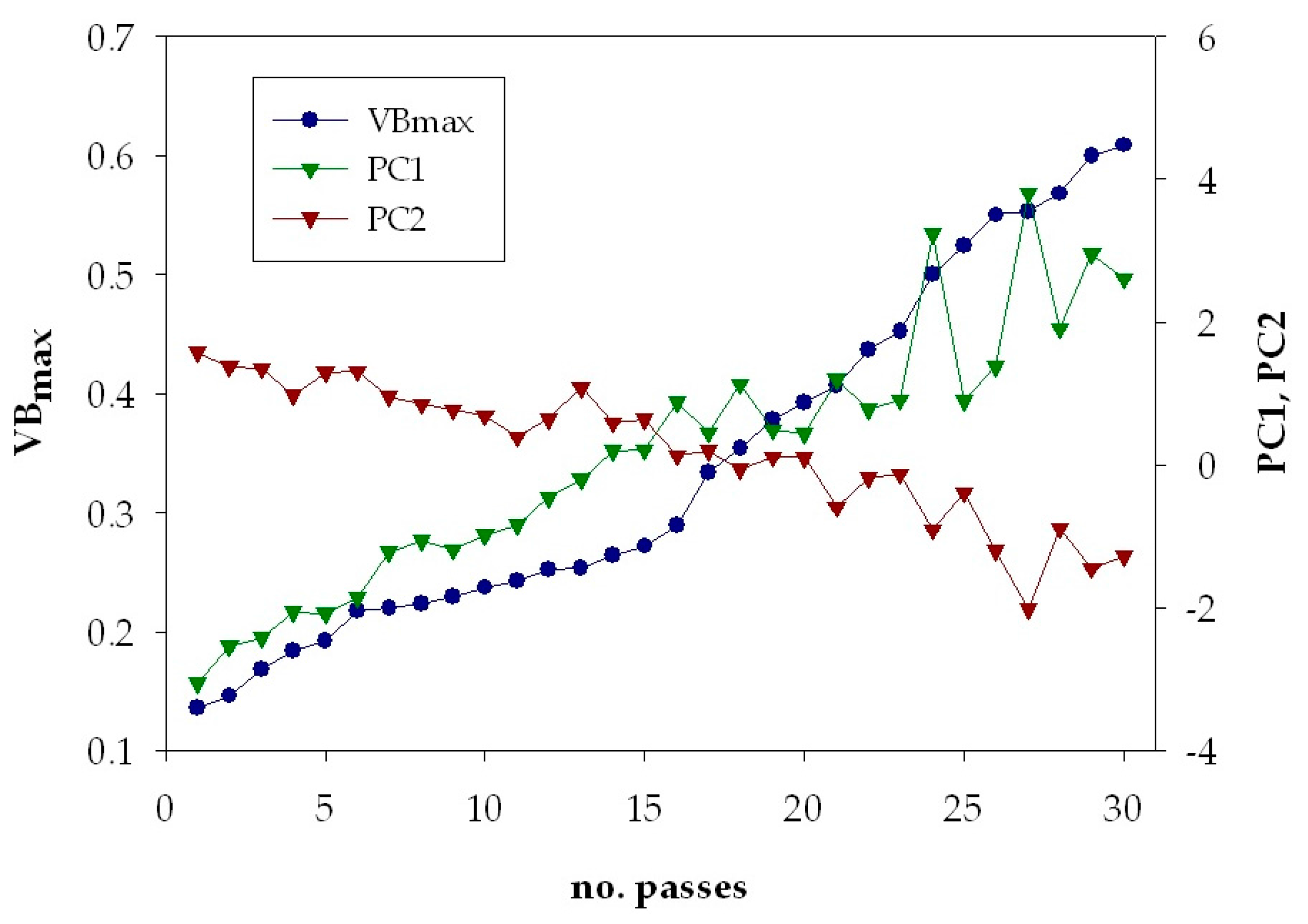

5.2. Features Extraction via Principal Component Analysis

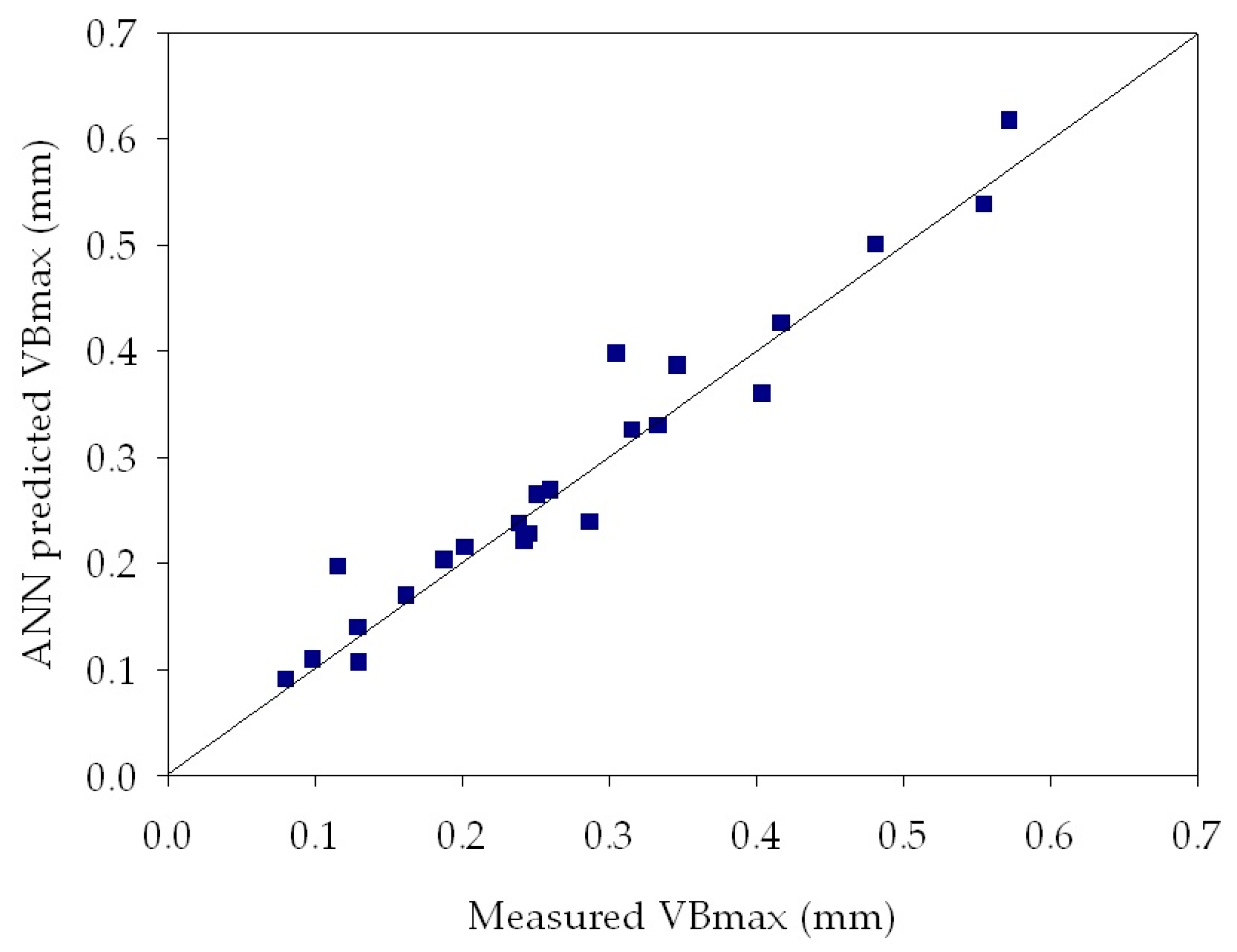

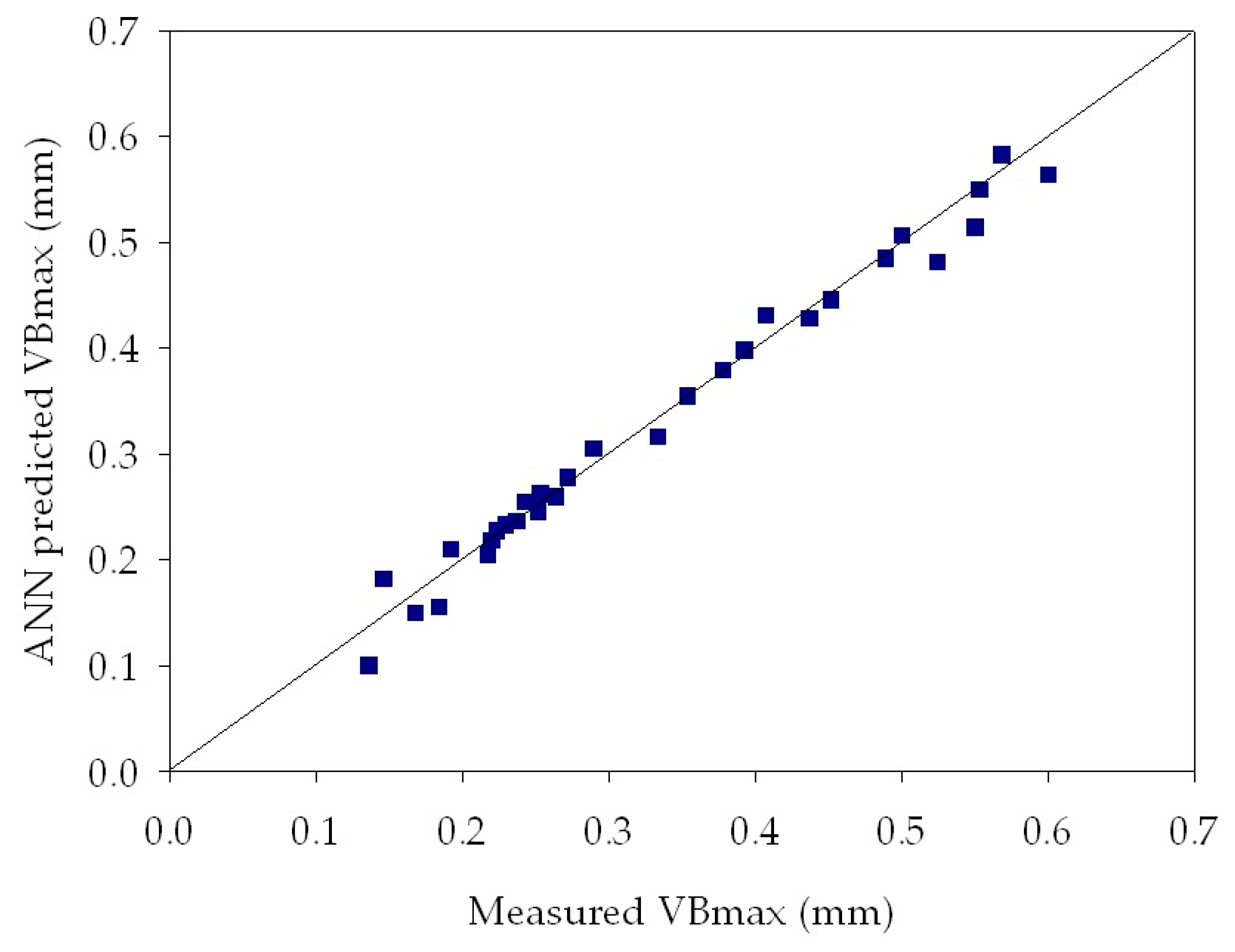

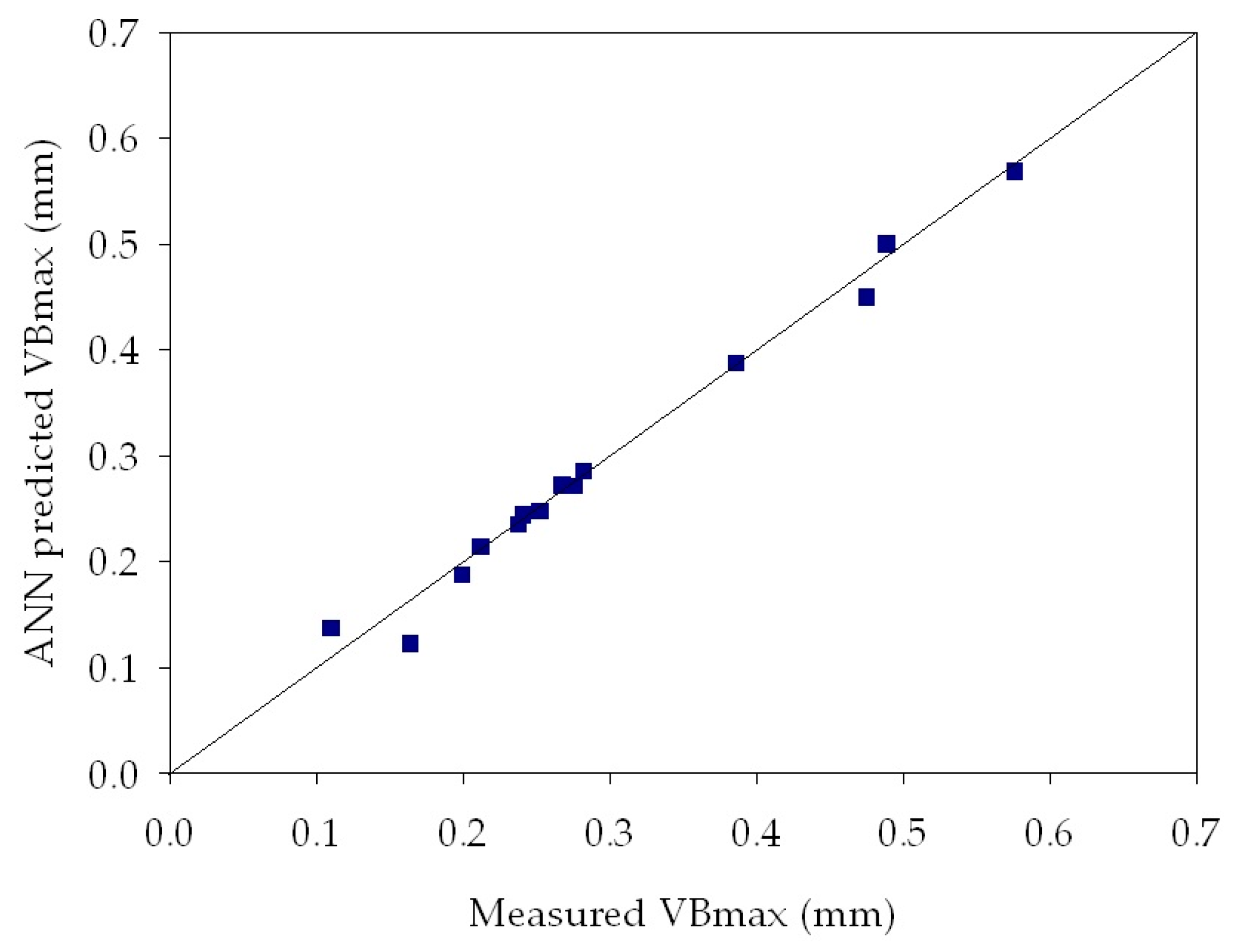

6. Machine Learning for Tool Wear Diagnosis Based on Artificial Neural Network

7. Results

8. Conclusions

Acknowledgments

Conflicts of Interest

References

- M’Saoubi, R.; Axinte, D.; Soo, S.L.; Nobel, C.; Attia, H.; Kappmeyer, G.; Sim, W.M. High performance cutting of advanced aerospace alloys and composite materials. CIRP Ann. Manuf. Technol. 2015, 64, 557–580. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Bonney, J.; Yamane, Y. An overview of the machinability of aeroengine alloys. J. Mater. Process. Technol. 2003, 134, 233–253. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Wang, Z.M. Titanium alloys and their machinability—A review. J. Mater. Process. Technol. 1997, 68, 262–274. [Google Scholar] [CrossRef]

- Lopez de Lacalle, L.N.; Perez, J.; Llorente, J.I.; Sanchez, J.A. Advanced cutting conditions for the milling of aeronautical alloys. J. Mater. Process. Technol. 2000, 100, 1–11. [Google Scholar] [CrossRef]

- Teti, R.; Jemielniak, K.; O’Donnell, G.; Dornfeld, D. Advanced monitoring of machining operations. CIRP Ann. Manuf. Technol. 2010, 59, 717–739. [Google Scholar] [CrossRef]

- Teti, R. Advanced IT methods of signal processing and decision making for zero defect manufacturing in machining. Procedia CIRP 2015, 28, 3–15. [Google Scholar] [CrossRef]

- Wang, L.; Gao, R.X. Condition Monitoring and Control for Intelligent Manufacturing; Springer: London, UK, 2006. [Google Scholar]

- Segreto, T.; Caggiano, A.; Karam, S.; Teti, R. Vibration Sensor Monitoring of Nickel-Titanium Alloy Turning for Machinability Evaluation. Sensors 2017, 17, 2885. [Google Scholar] [CrossRef] [PubMed]

- Dimla, D.E. Sensor signals for tool-wear monitoring in metal cutting: A review of methods. Int. J. Mach. Tools Manuf. 2000, 40, 1073–1098. [Google Scholar] [CrossRef]

- Jemielniak, K.; Urbański, T.; Kossakowska, J.; Bombiński, S. Tool condition monitoring based on numerous signal features. Int. J. Adv. Manuf. Technol. 2012, 59, 73–81. [Google Scholar] [CrossRef]

- Caggiano, A. Cloud-based manufacturing process monitoring for smart diagnosis services. Int. J. Comput. Integr. Manuf. 2018, in press. [Google Scholar] [CrossRef]

- Kosaraju, S.; Anne, V.G.; Popuri, B.B. Online tool condition monitoring in turning titanium (grade 5) using acoustic emission: modeling. Int. J. Adv. Manuf. Technol. 2013, 67, 1947–1954. [Google Scholar] [CrossRef]

- Jemielniak, K. Some aspects of acoustic emission signal pre-processing. J. Mater. Process. Technol. 2001, 109, 242–247. [Google Scholar] [CrossRef]

- Jie, S.; San, W.Y.; Soon, H.G.; Rahman, M.; Zhigang, W. Identification of Feature Set for Effective Tool Condition Monitoring—A Case Study in Titanium Machining. In Proceedings of the 4th IEEE Conference on Automation Science and Engineering, Key Bridge Marriott, Washington, DC, USA, 23–26 August 2008; pp. 273–278. [Google Scholar]

- Stavropoulos, P.; Papacharalampopoulos, A.; Vasiliadis, E.; Chryssolouris, G. Tool wear predictability estimation in milling based on multi-sensorial data. Int. J. Adv. Manuf. Technol. 2016, 82, 509. [Google Scholar] [CrossRef]

- Jemielniak, K.; Otman, O. Catastrophic Tool Failure Detection Based on Acoustic Emission Signal Analysis. CIRP Ann. Manuf. Technol. 1998, 47, 31–34. [Google Scholar] [CrossRef]

- Jemielniak, K.; Otman, O. Tool failure detection based on analysis of acoustic emission signals. J. Mater. Process. Technol. 1998, 76, 192–197. [Google Scholar] [CrossRef]

- Balsamo, V.; Caggiano, A.; Jemielniak, K.; Kossakowska, J.; Nejman, M.; Teti, R. Multi Sensor Signal Processing for Catastrophic Tool Failure Detection in Turning. Procedia CIRP 2016, 41, 939–944. [Google Scholar] [CrossRef]

- Caggiano, A.; Segreto, T.; Teti, R. Cloud Manufacturing Framework for Smart Monitoring of Machining. Procedia CIRP 2016, 55, 248–253. [Google Scholar] [CrossRef]

- Deiab, I.; Assaleh, K.; Hammad, F. On modeling of tool wear using sensor fusion and polynomial classifiers. Mech. Syst. Signal Process. 2009, 23, 1719–1729. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). Tool-Life Testing with Single-Point Turning Tools; ISO 3685:1993; International Organization for Standardization: Geneva, Switzerland, 1993. [Google Scholar]

- Caggiano, A.; Napolitano, F.; Teti, R. Dry Turning of Ti6Al4V: Tool Wear Curve Reconstruction Based on Cognitive Sensor Monitoring. Procedia CIRP 2017, 62, 209–214. [Google Scholar] [CrossRef]

- Alpaydin, E. Introduction to Machine Learning; MIT Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Bishop, C.M. Neural Networks for Pattern Recognition; Clarendon Press: Oxford, UK, 1995. [Google Scholar]

- Jolliffe, I.T. Principal Component Analysis, 2nd ed.; Springer: New York, NY, USA, 2002. [Google Scholar]

- Gao, R.; Wang, L.; Teti, R.; Dornfeld, D.; Kumara, S.; Mori, M.; Helu, M. Cloud-enabled Prognosis for Manufacturing. CIRP Ann. Manuf. Technol. 2015, 64, 749–772. [Google Scholar] [CrossRef]

- Abe, S. Pattern Classification: Neuro-Fuzzy Methods and Their Comparison; Springer: London, UK, 2001. [Google Scholar]

| Test ID | Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) | No. of Passes |

|---|---|---|---|---|

| Test 1 | 60 | 0.20 | 0.5 | 24 |

| Test 2 | 60 | 0.20 | 1.0 | 10 |

| Test 3 | 60 | 0.20 | 1.5 | 12 |

| Test 4 | 60 | 0.25 | 0.5 | 30 |

| Test 5 | 60 | 0.25 | 1.0 | 8 |

| Test 6 | 60 | 0.25 | 1.5 | 12 |

| Test 7 | 60 | 0.30 | 0.5 | 20 |

| Test 8 | 60 | 0.30 | 1.0 | 14 |

| Test 9 | 60 | 0.30 | 1.5 | 11 |

| Sensor Signal | Fx | Fy | Fz | AERMS | Ax | Ay | Az |

|---|---|---|---|---|---|---|---|

| Extracted features per pass | Fx_mean, Fx_var, Fx_skew, Fx_kurt | Fy_mean, Fy_var, Fy_skew, Fy_kurt | Fz_mean, Fz_var, Fz_skew, Fz_kurt | AERMS_mean, AERMS _var, AERMS_skew, AERMS_kurt | Ax_mean, Ax_var, Ax_skew, Ax_kurt | Ay_mean, Ay_var, Ay_skew, Ay_kurt | Az_mean, Az_var, Az_skew, Az_kurt |

| MSE | |||

|---|---|---|---|

| 3 Hidden Nodes | 6 Hidden Nodes | 9 Hidden Nodes | |

| Test 1 | 5.31 × 10−3 | 2.48 × 10−3 | 2.51 × 10−2 |

| Test 2 | 5.22 × 10−3 | 8.66 × 10−3 | 2.94 × 10−3 |

| Test 3 | 2.93 × 10−3 | 5.48 × 10−3 | 1.31 × 10−2 |

| Test 4 | 8.12 × 10−4 | 1.95 × 10−3 | 1.87 × 10−3 |

| Test 5 | 2.23 × 10−3 | 1.63 × 10−3 | 6.56 × 10−3 |

| Test 6 | 2.12 × 10−2 | 3.69 × 10−2 | 5.17 × 10−2 |

| Test 7 | 8.67 × 10−3 | 4.19 × 10−4 | 3.71 × 10−2 |

| Test 8 | 2.54 × 10−4 | 1.22 × 10−3 | 3.20 × 10−3 |

| Test 9 | 3.48 × 10−3 | 2.16 × 10−3 | 3.02 × 10−3 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caggiano, A. Tool Wear Prediction in Ti-6Al-4V Machining through Multiple Sensor Monitoring and PCA Features Pattern Recognition. Sensors 2018, 18, 823. https://doi.org/10.3390/s18030823

Caggiano A. Tool Wear Prediction in Ti-6Al-4V Machining through Multiple Sensor Monitoring and PCA Features Pattern Recognition. Sensors. 2018; 18(3):823. https://doi.org/10.3390/s18030823

Chicago/Turabian StyleCaggiano, Alessandra. 2018. "Tool Wear Prediction in Ti-6Al-4V Machining through Multiple Sensor Monitoring and PCA Features Pattern Recognition" Sensors 18, no. 3: 823. https://doi.org/10.3390/s18030823

APA StyleCaggiano, A. (2018). Tool Wear Prediction in Ti-6Al-4V Machining through Multiple Sensor Monitoring and PCA Features Pattern Recognition. Sensors, 18(3), 823. https://doi.org/10.3390/s18030823