Dynamic Outlier Detection in the Calibration by Comparison Method Applied to Strain Gauge Weight Sensors

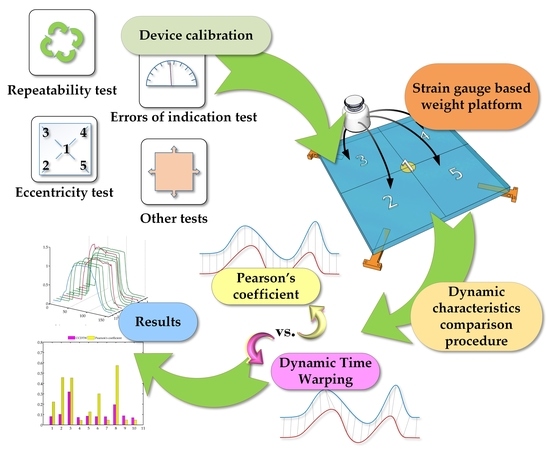

Abstract

1. Introduction

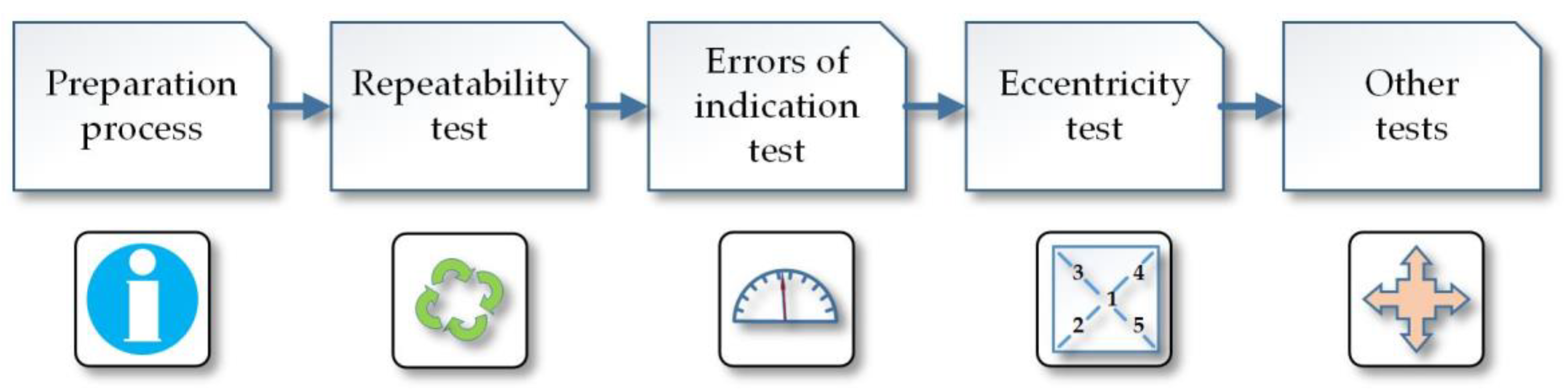

2. Weighting Instrument Calibration Procedure

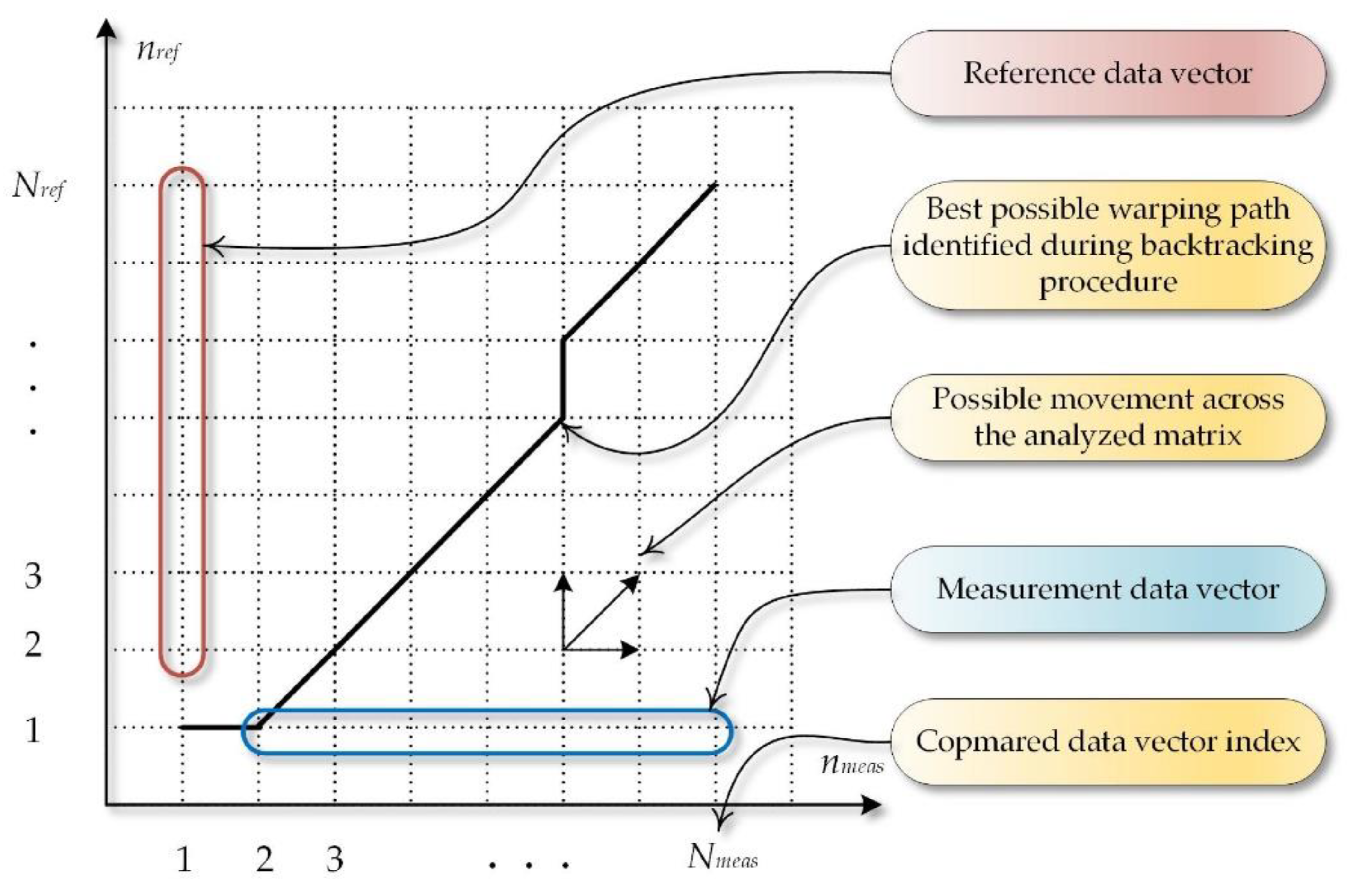

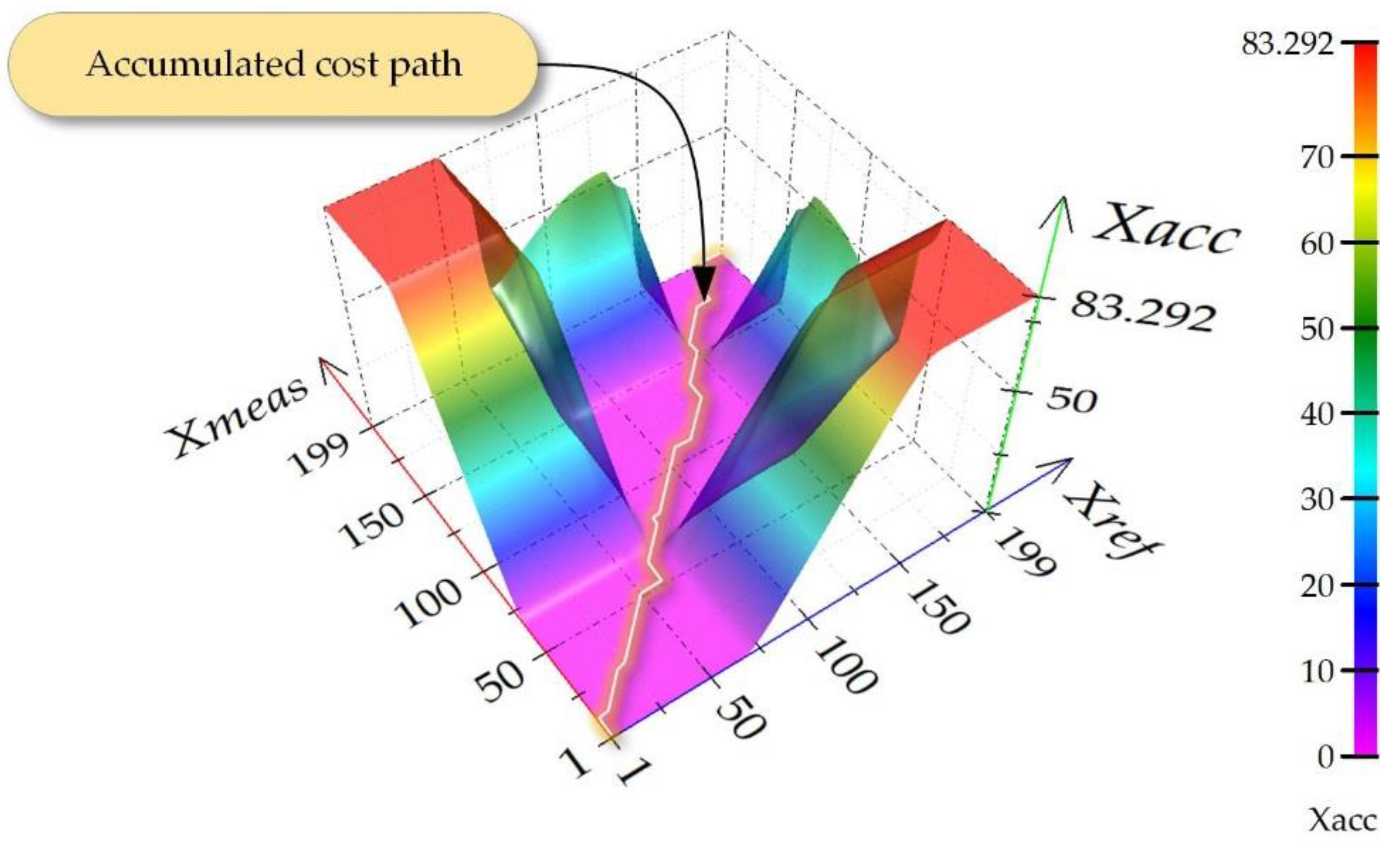

3. Application of the DTW to the Calibration by the Comparison

3.1. General Description of the DTW Method

- point (1, 1) is the origin of creating the path, and (Nref, Nmeas)—its end;

- we can shift by one step preserving the condition of function continuity and monotonicity;

- the path will only run forward as particular samples are taken in time which we cannot reverse.

3.2. Reference Time Series Generation

4. Simulation and Experimental Research

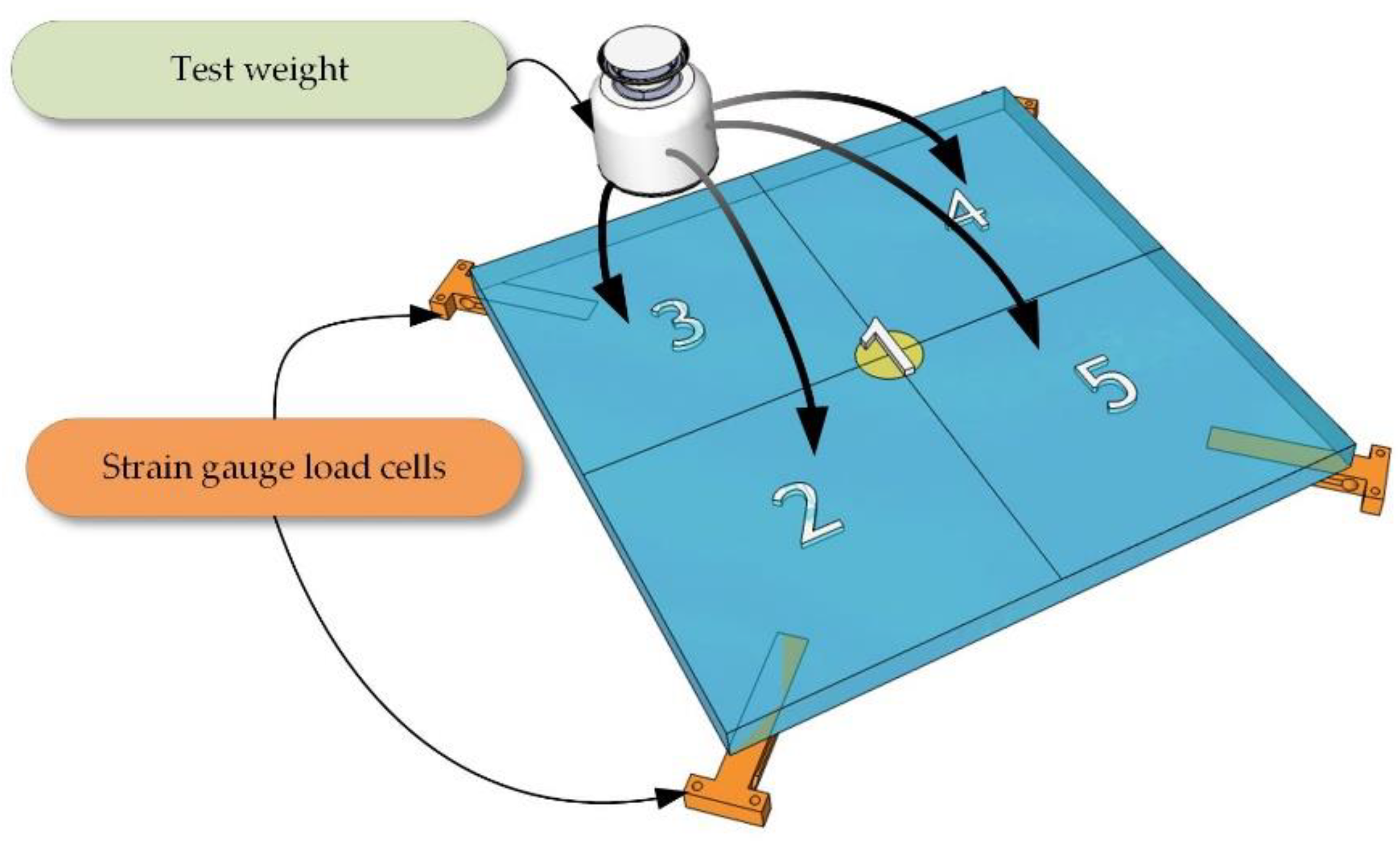

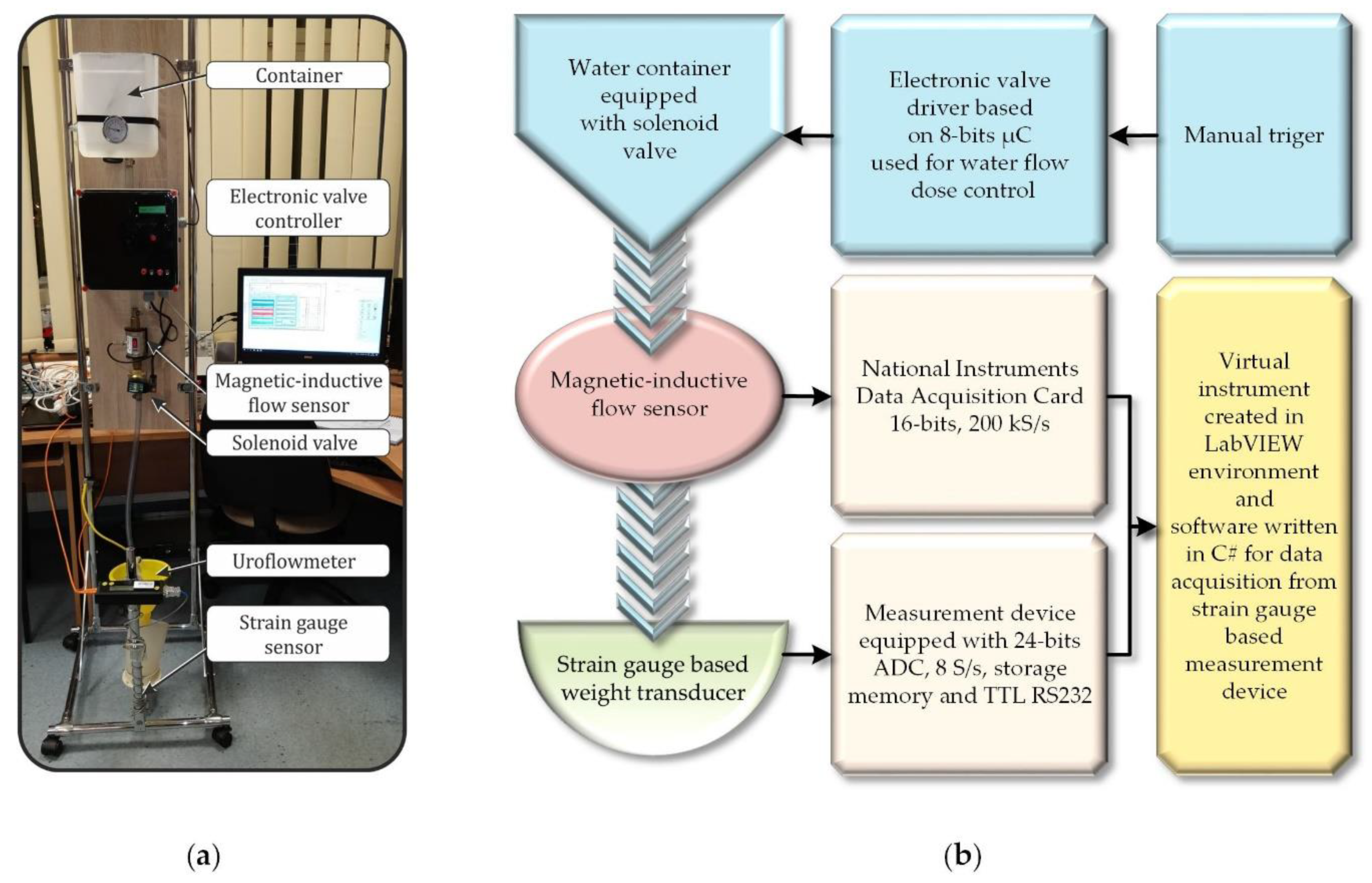

4.1. Test Bench Used in the CCDTW Evaluation

4.2. Data Acquisition

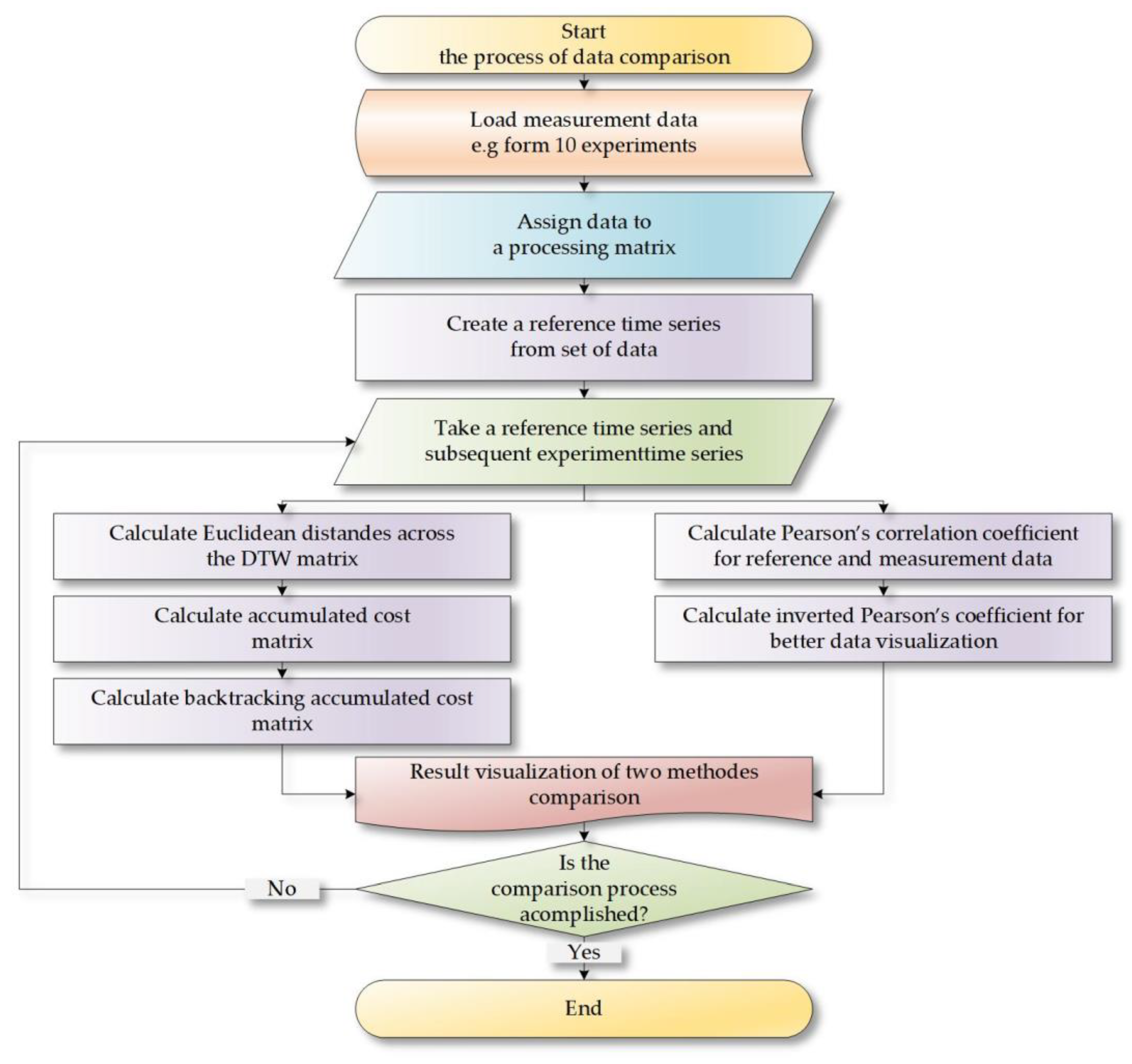

4.3. Analysis Procedure

5. Results of Method Analysis

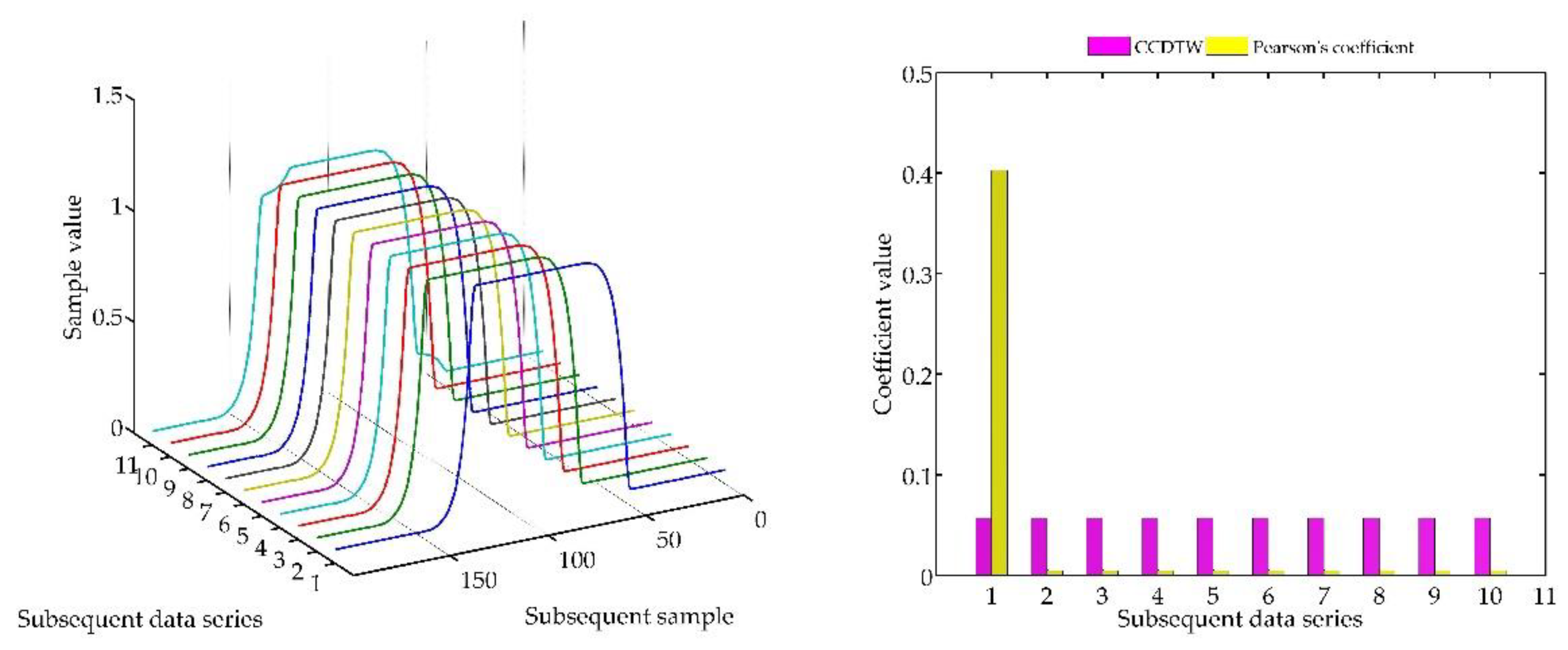

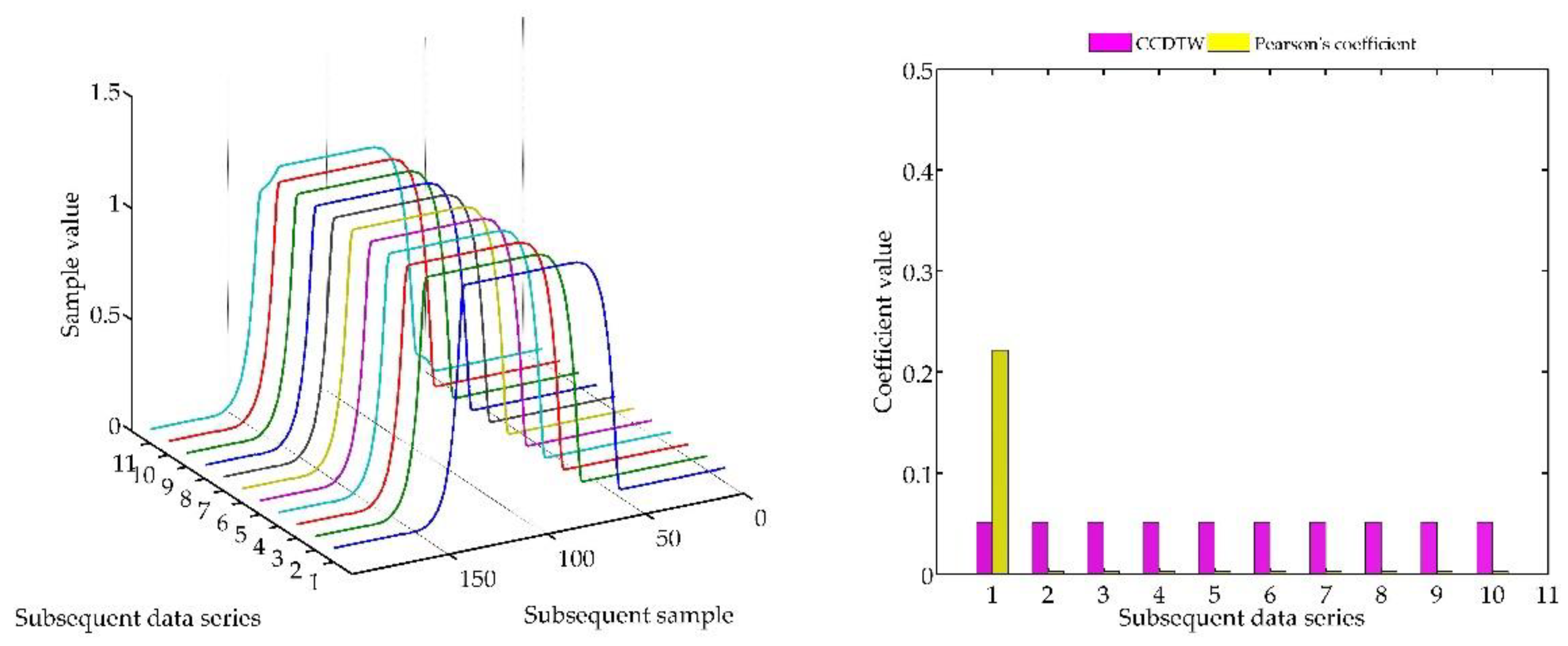

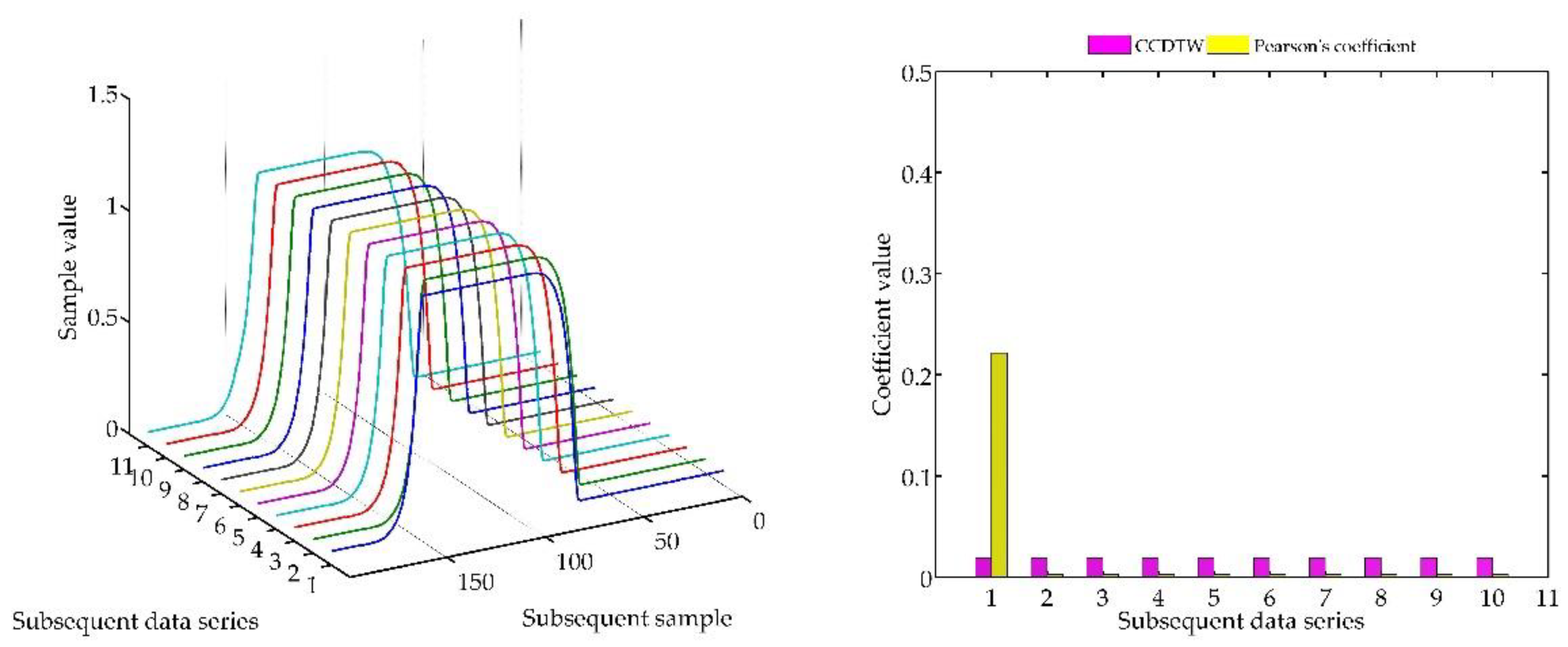

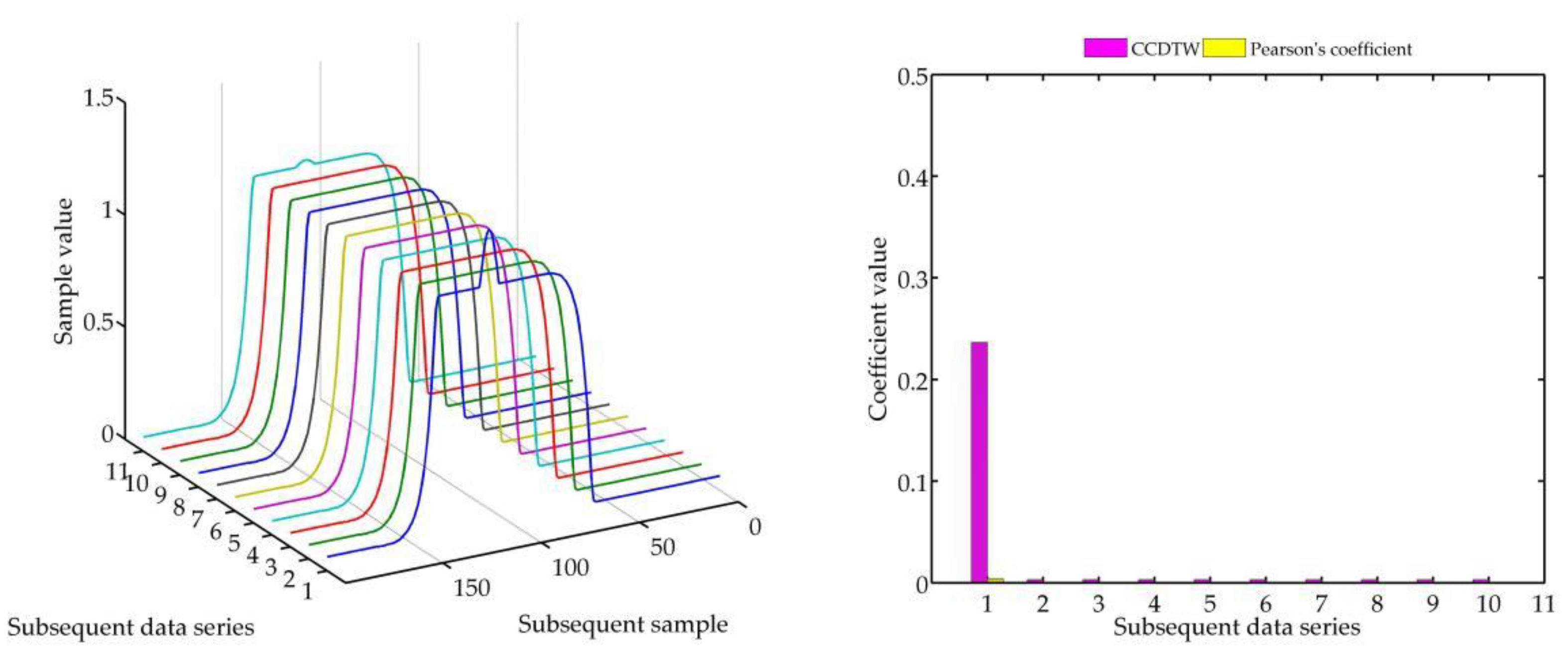

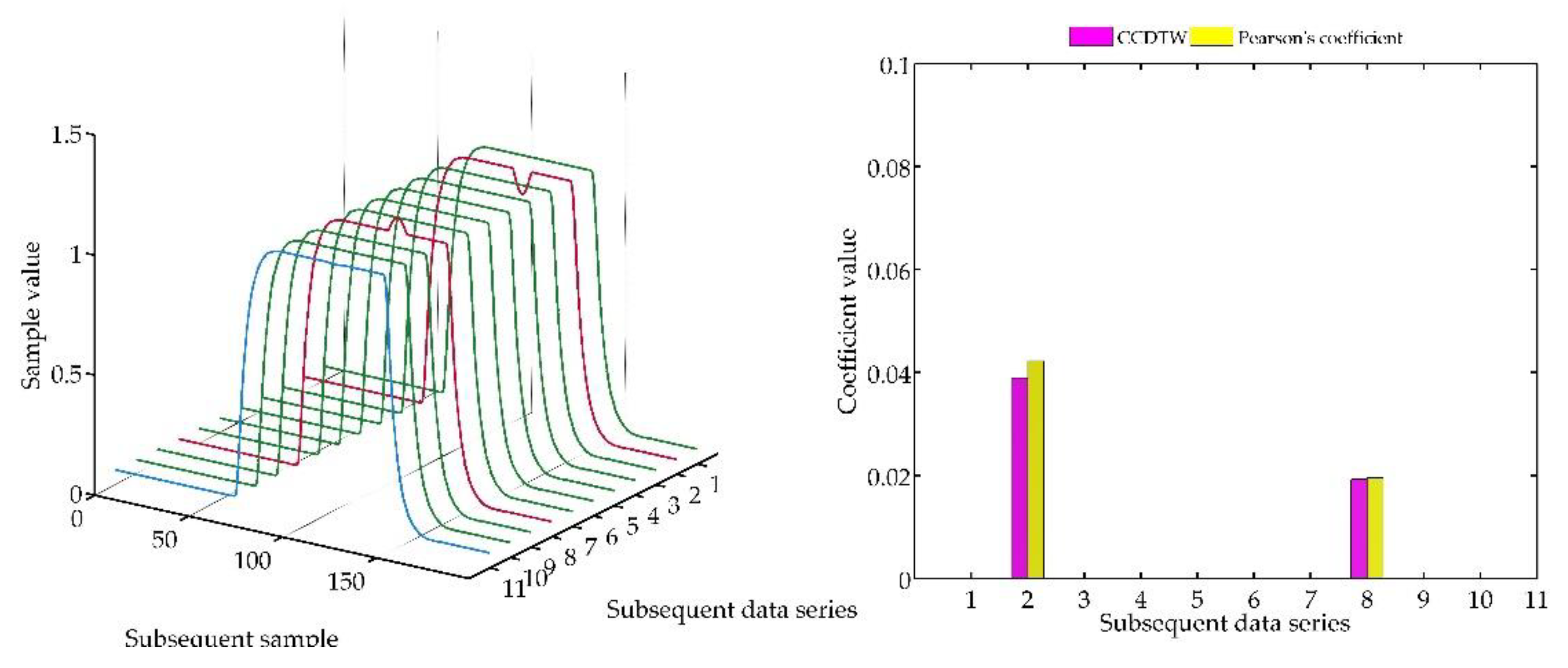

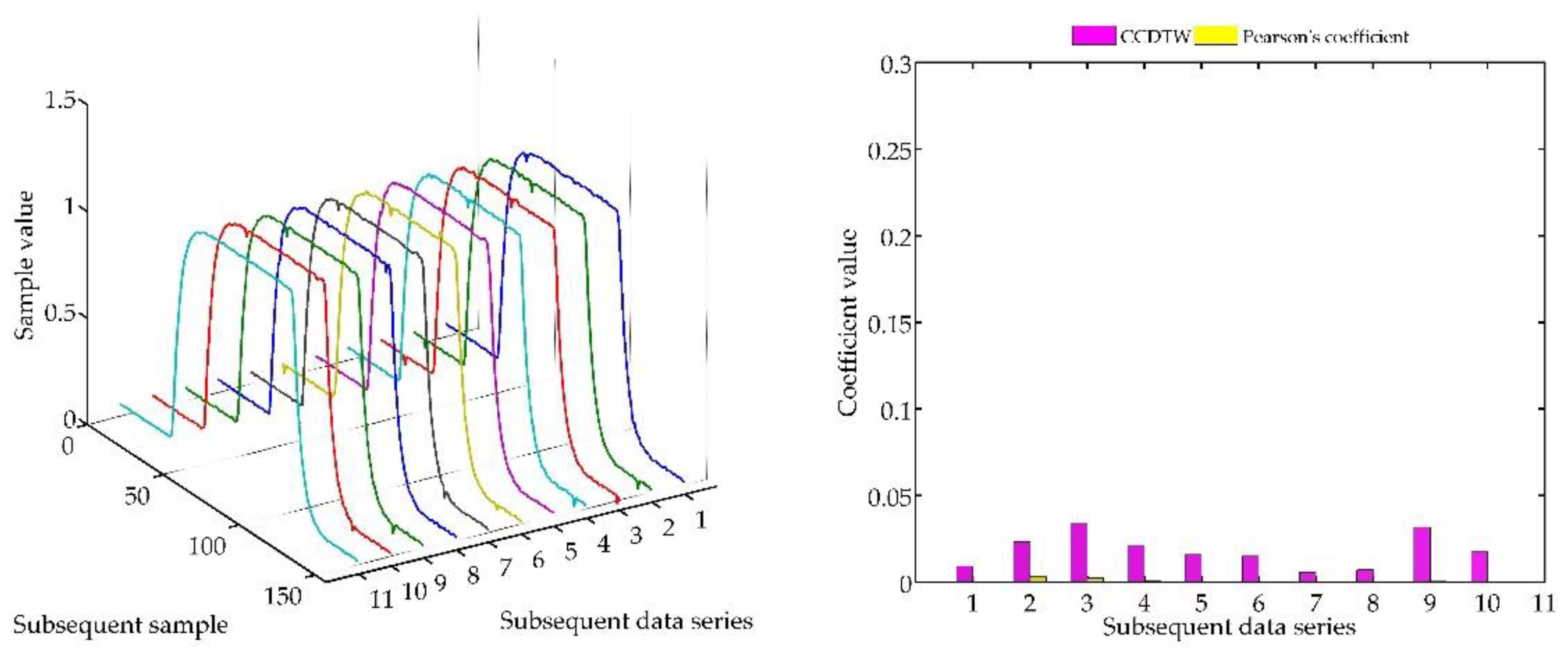

5.1. Simulation Results of Comparison of Pearson’s Correlation Coefficient Method vs. Calibration-by-Comparison Dynamic Time Warping for Ideal Time Series Without Disturbances

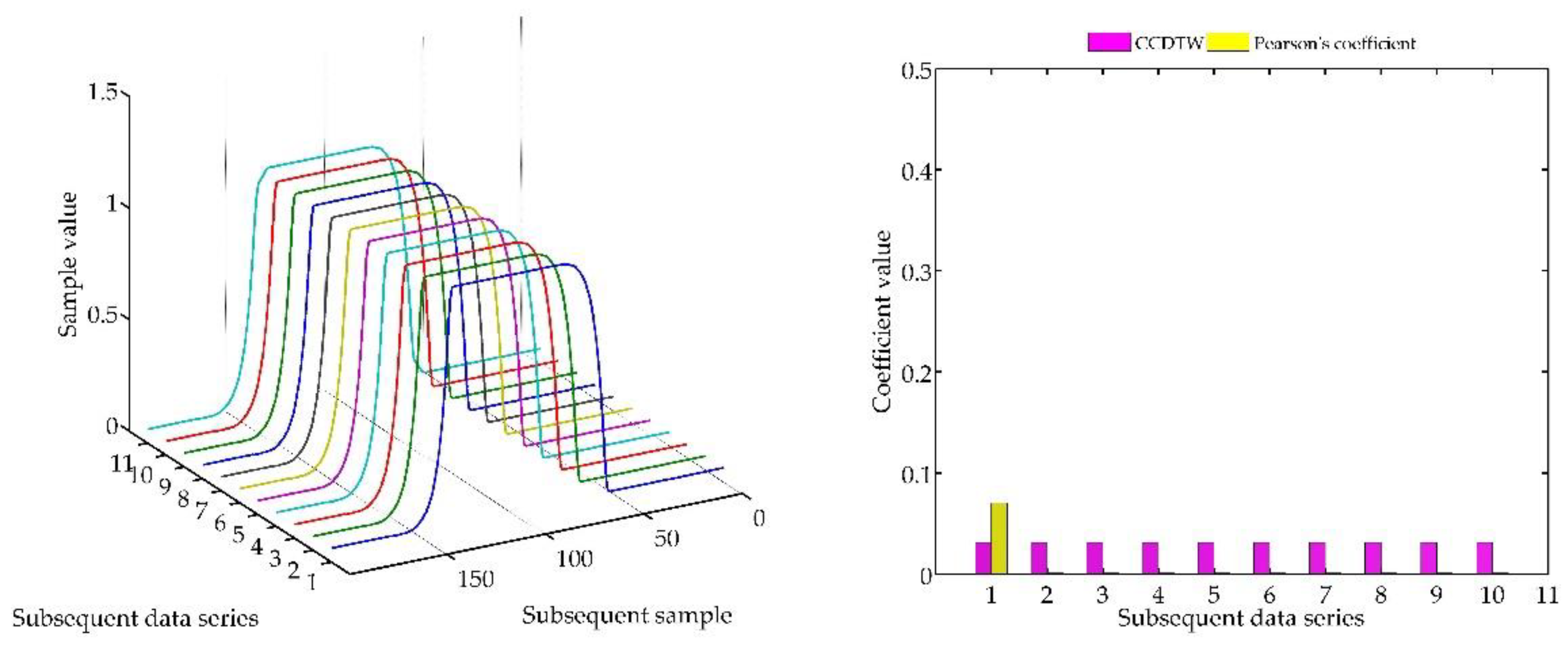

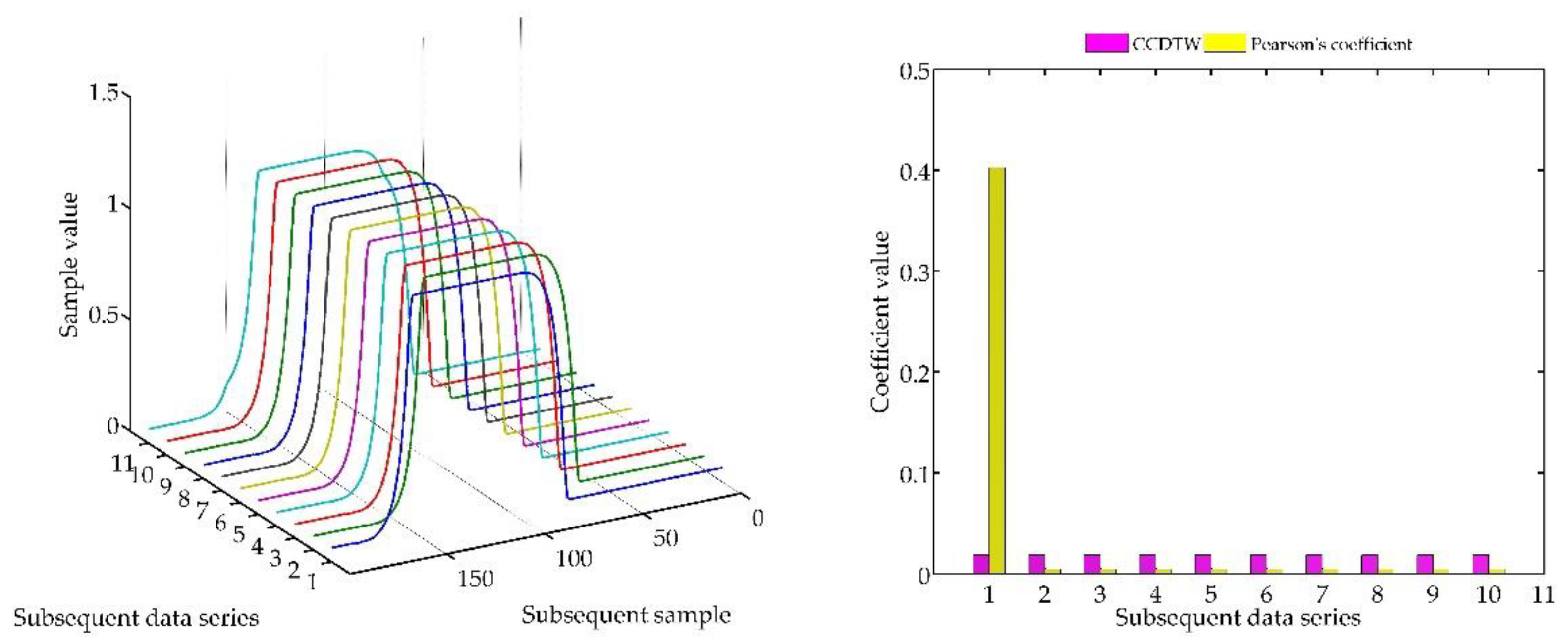

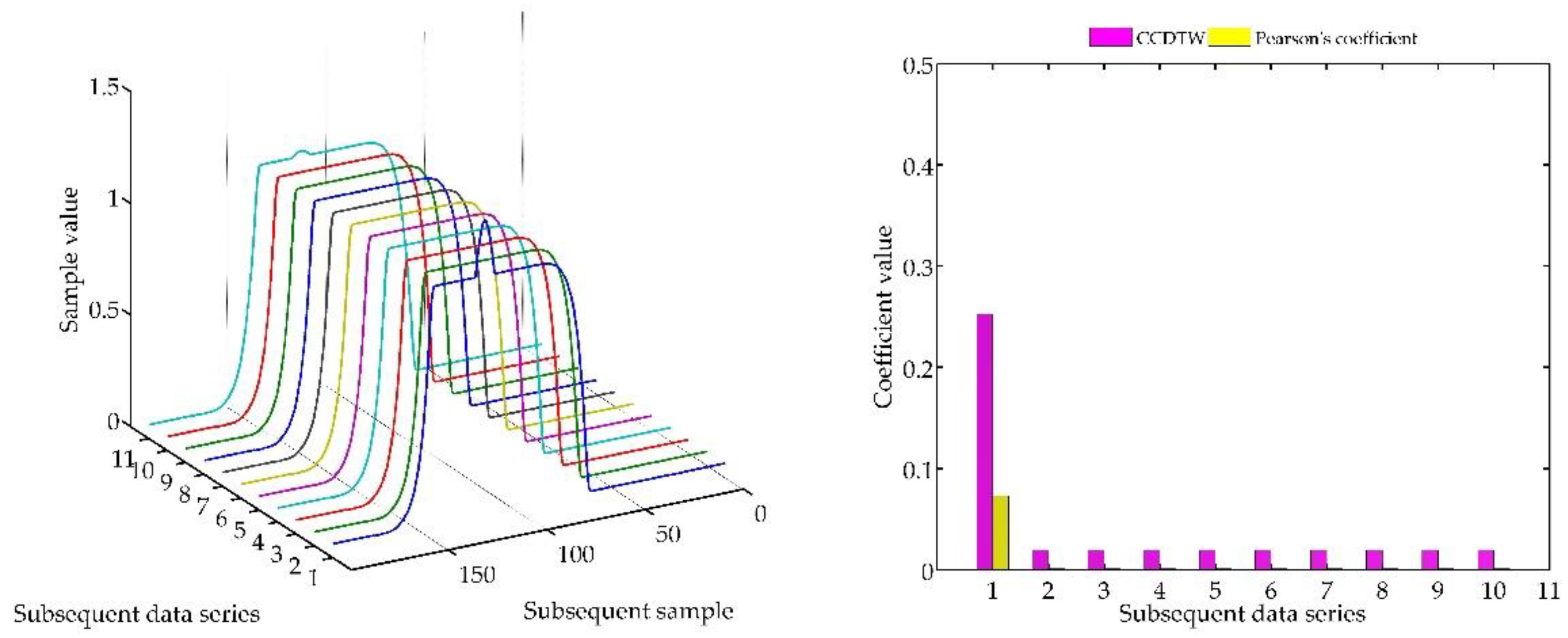

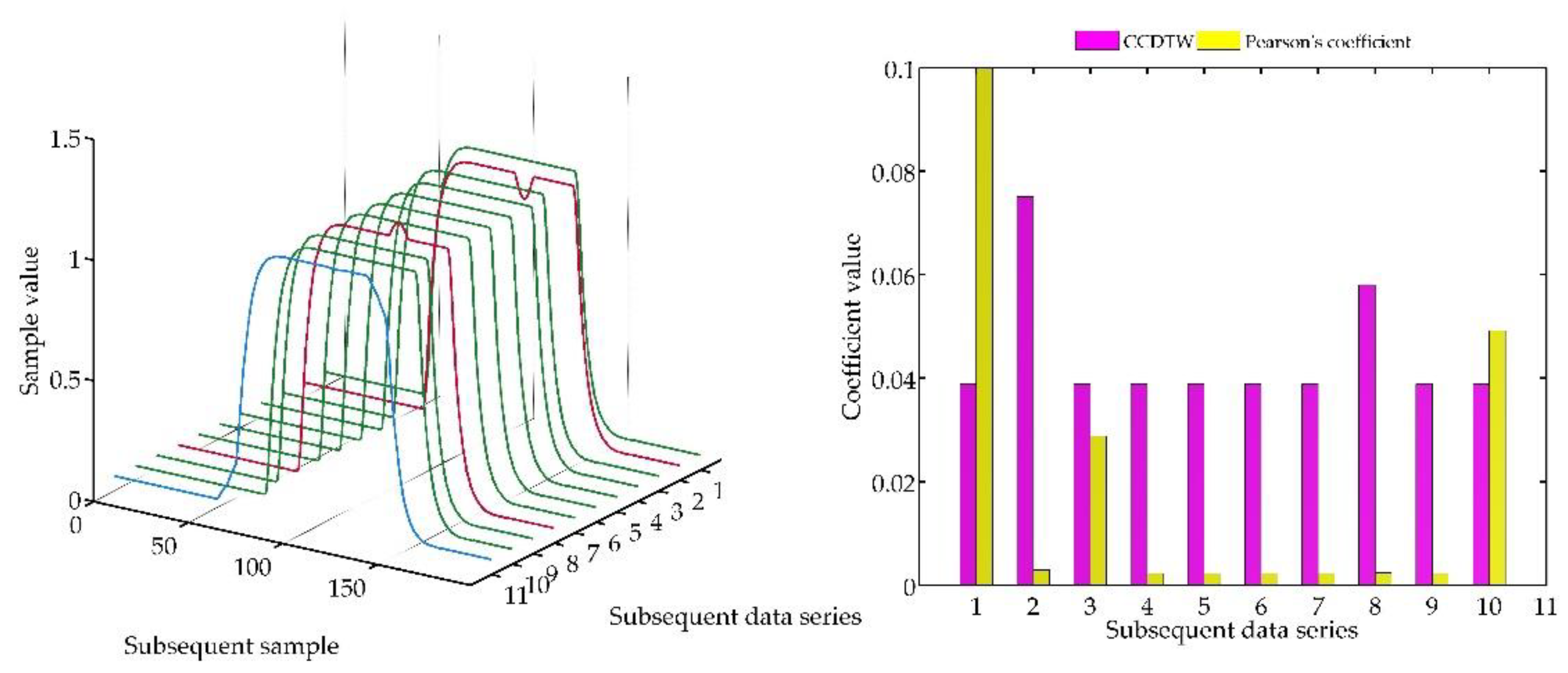

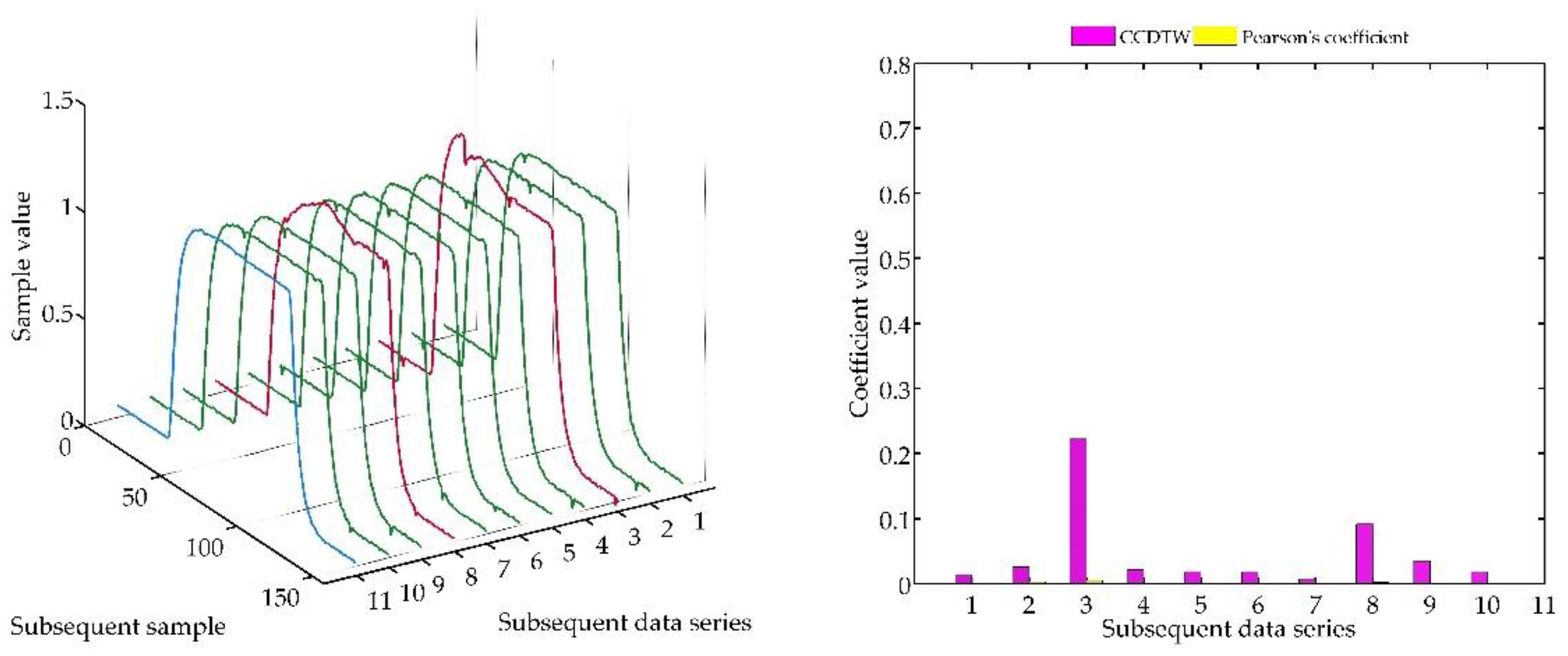

5.2. Simulation Results of Comparison of Pearson’s Correlation Coefficient Method vs. Calibration-by-Comparison Dynamic Time Warping for Ideal Time Series with One Disturbed Series

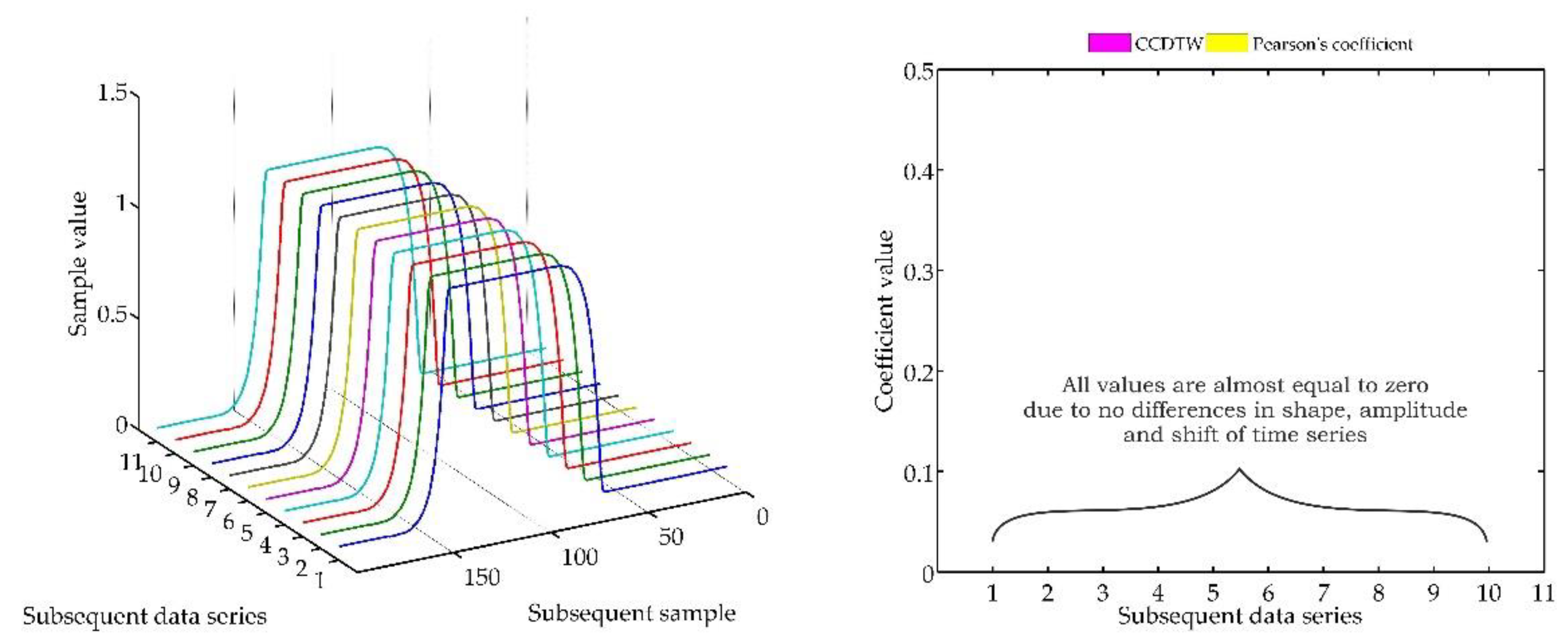

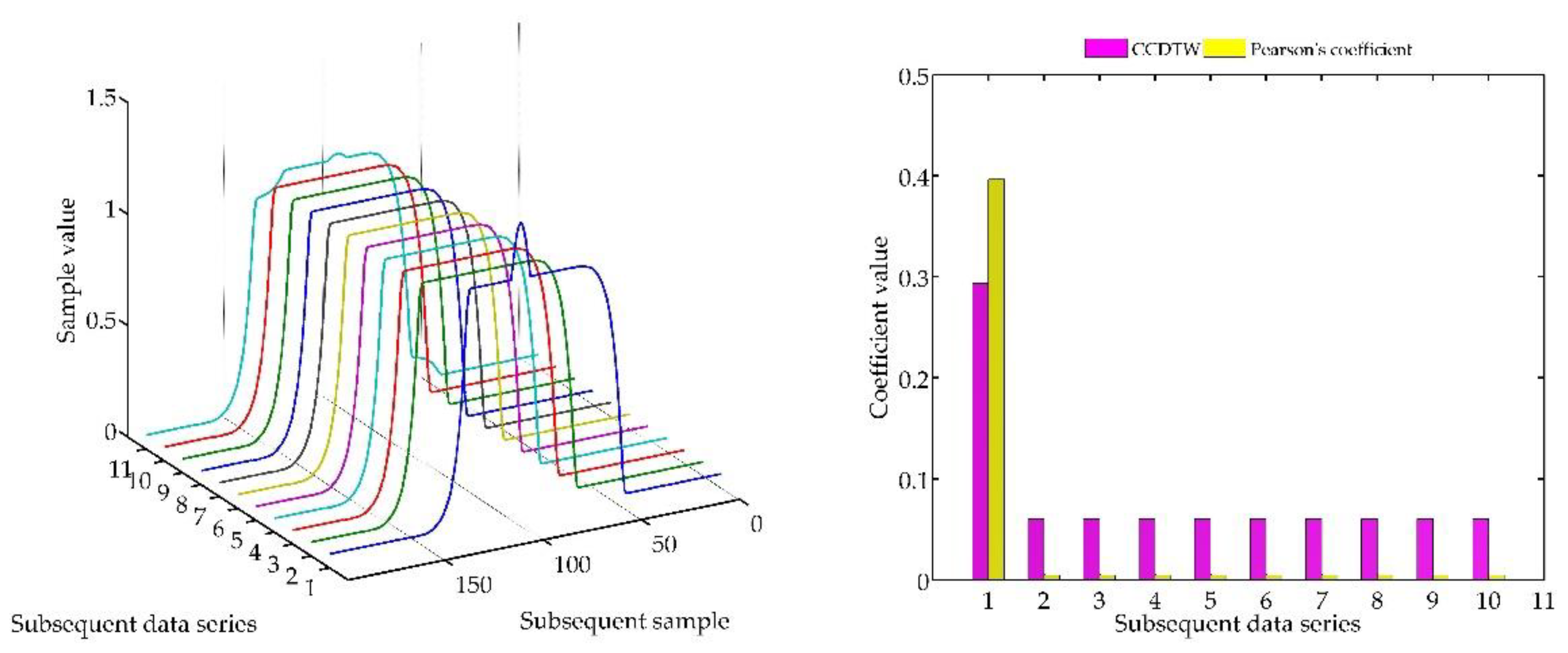

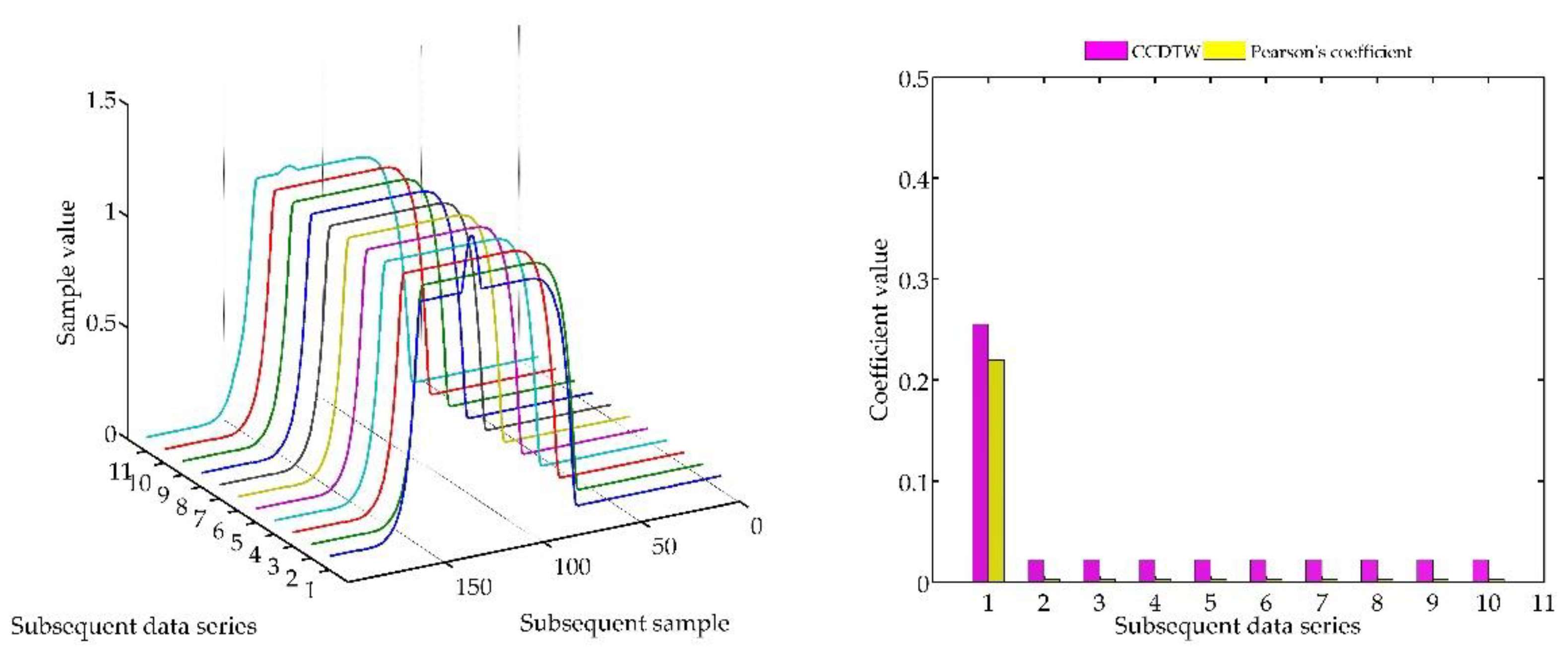

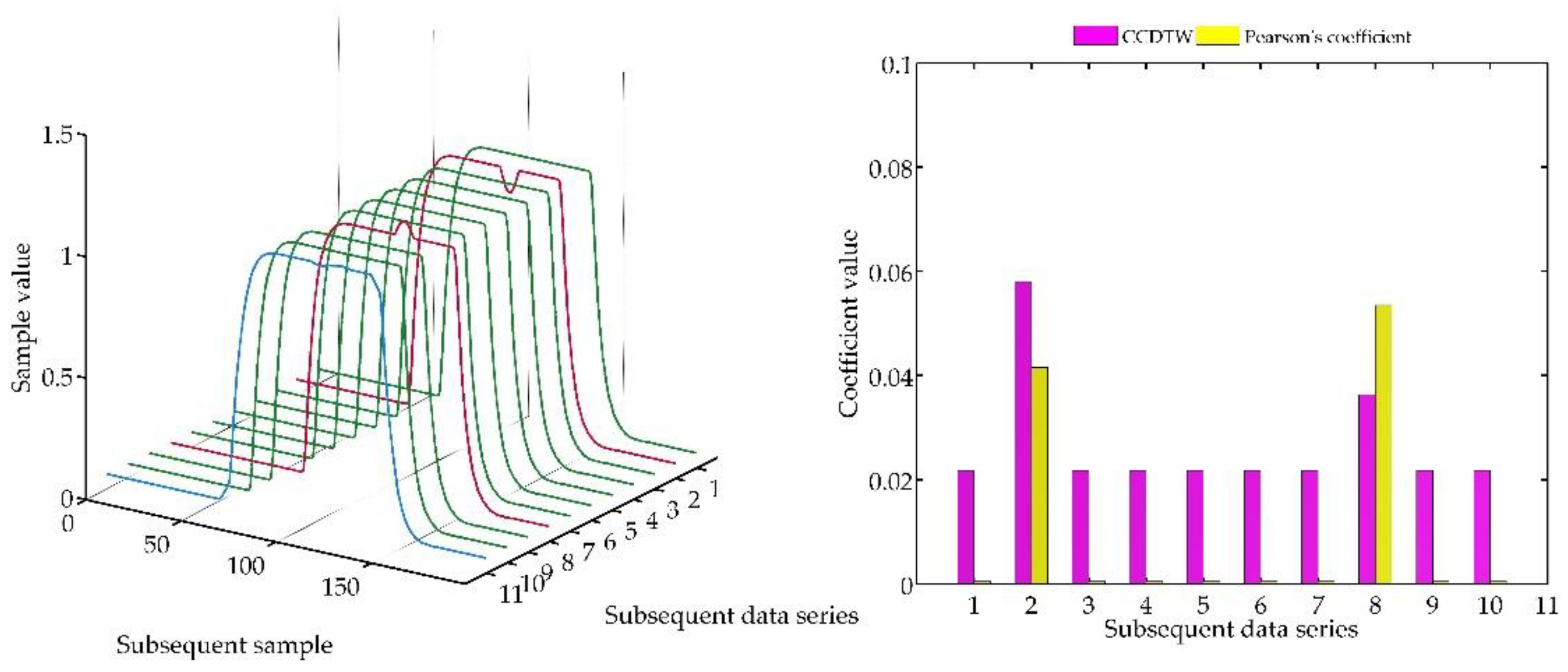

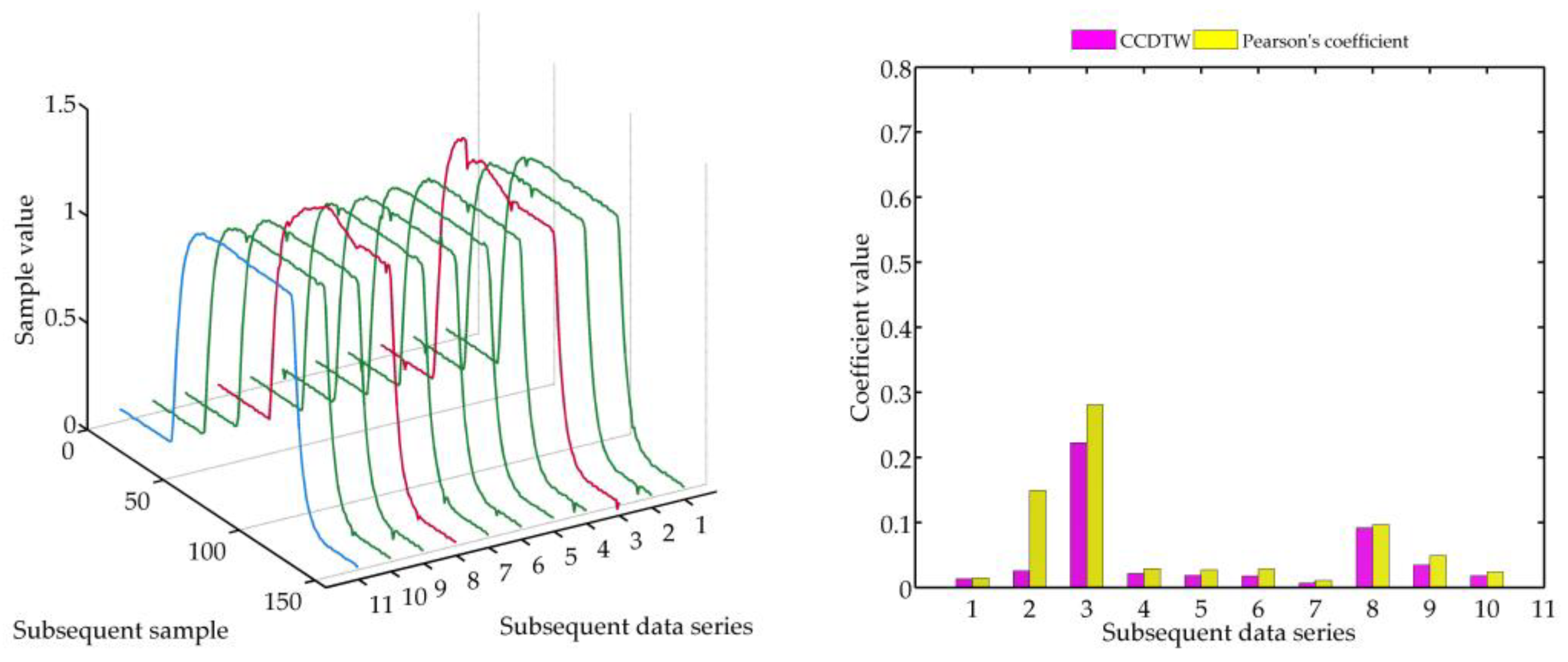

5.3. Simulation Results of Comparing the Pearson’s Correlation Coefficient Method and the Calibration-by-Comparison Dynamic Time Warping for an Ideal Time Series with Two Disturbed Series

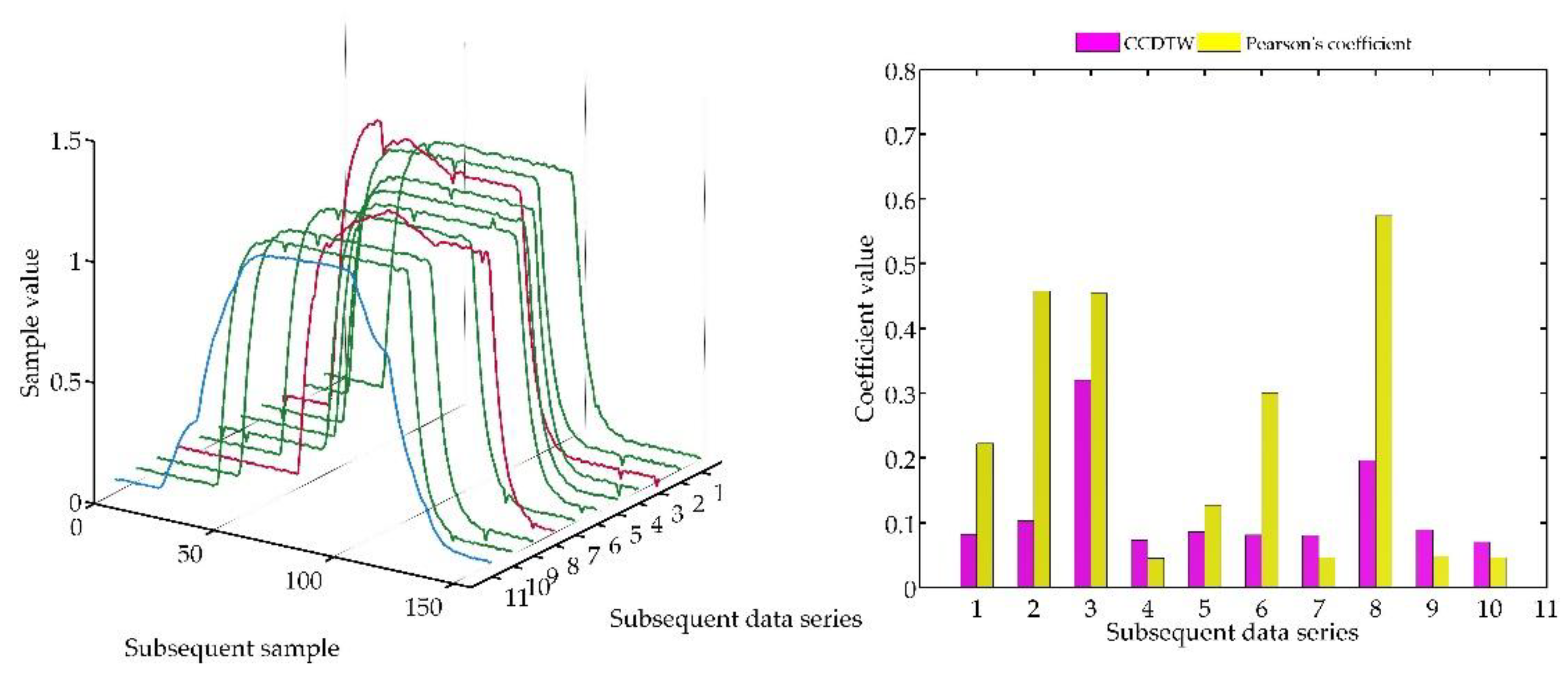

5.4. Real Experiment of the Weight Sensor Data Comparison of Pearson’s Correlation Coefficient Method vs. Calibration-by-Comparison Dynamic Time Warping

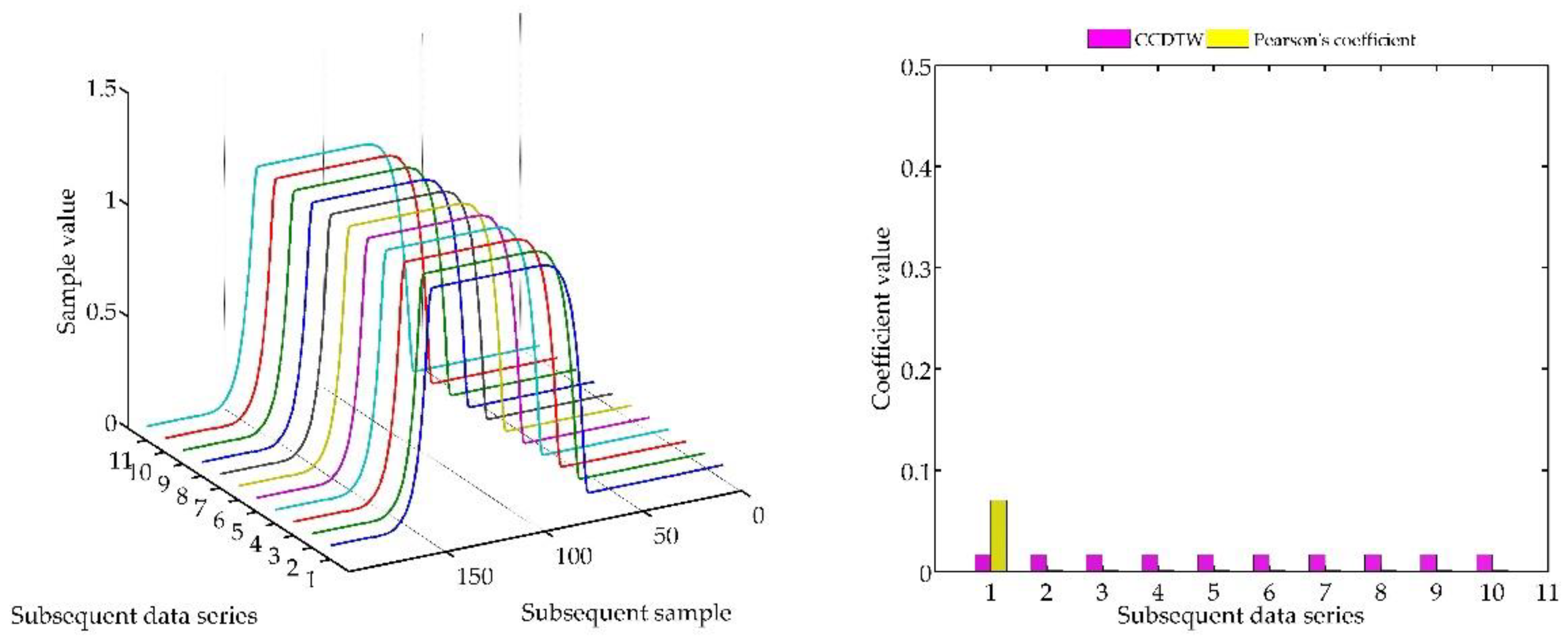

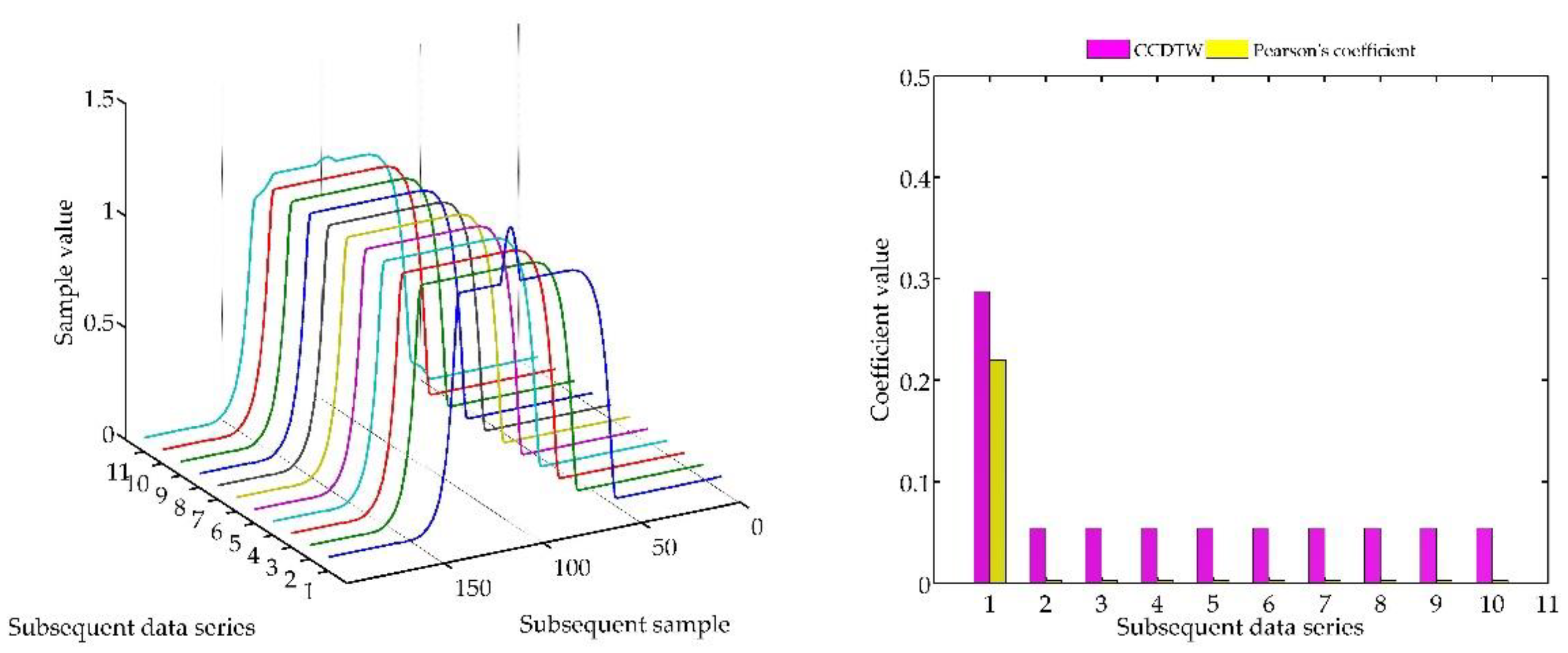

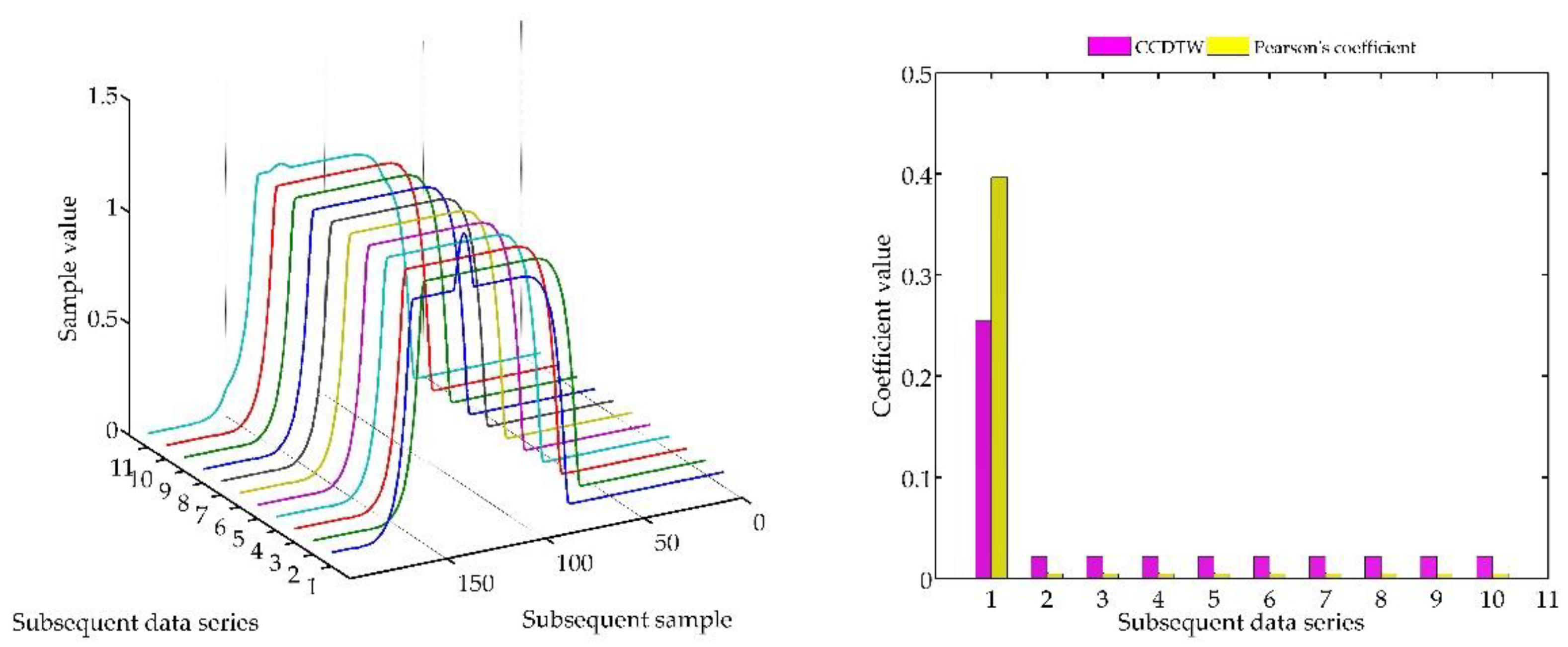

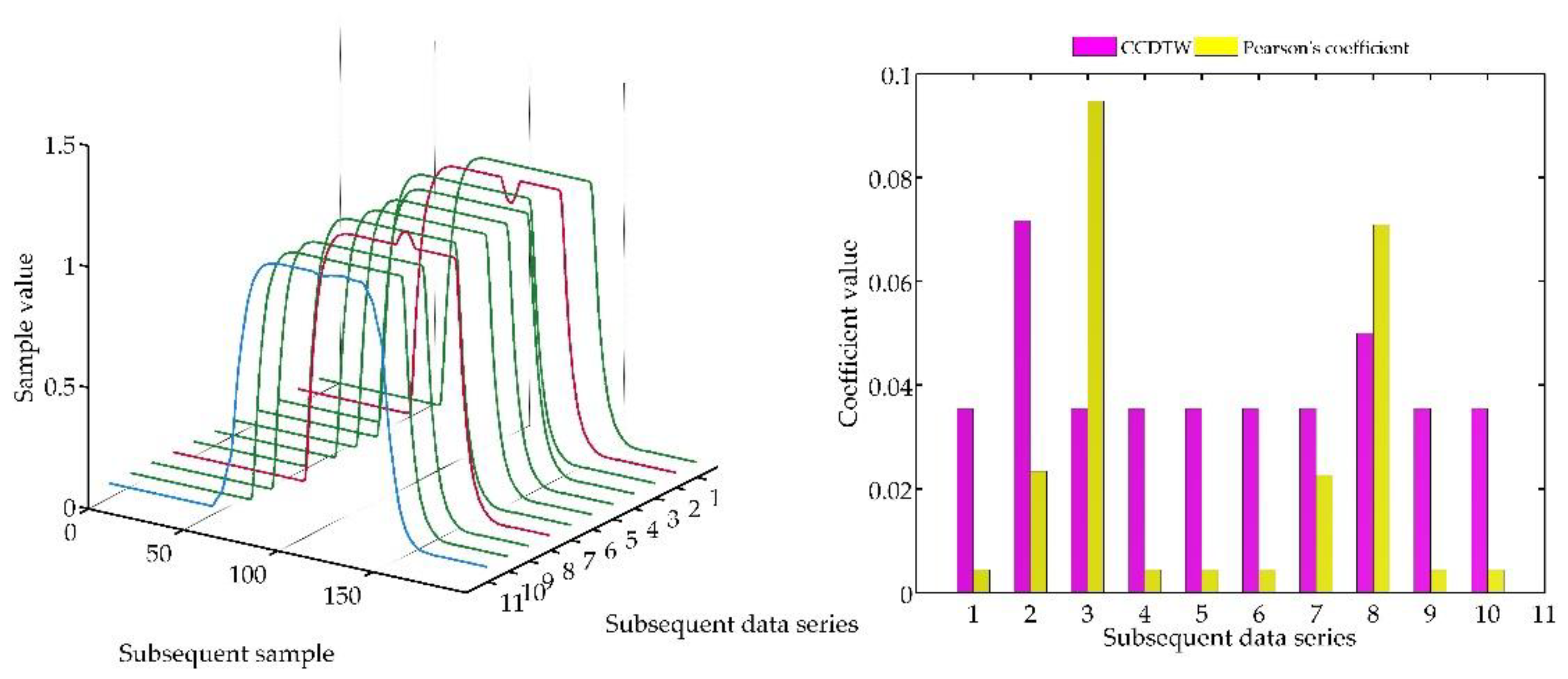

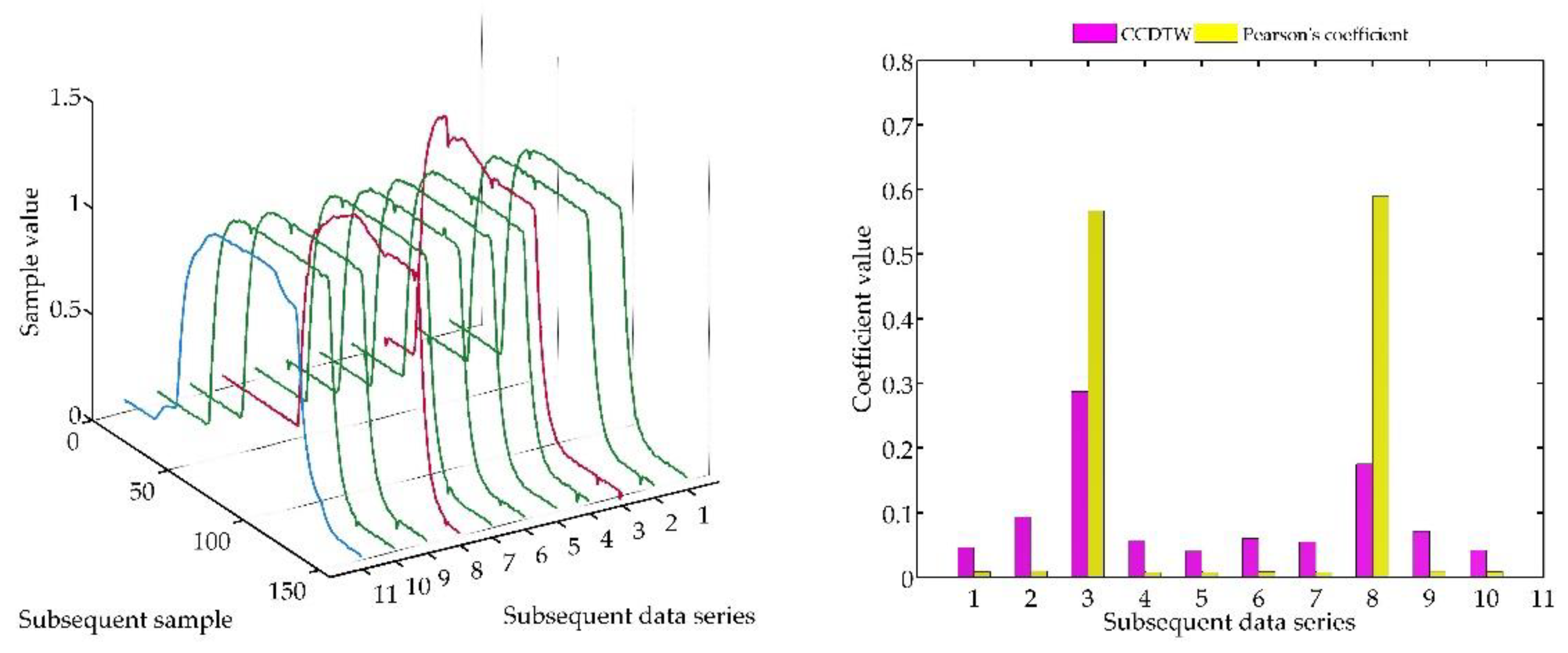

5.5. Simulation Results Based on Real Experiment of the Weight Sensor Data Comparison of Pearson’s Correlation Coefficient Method vs. Calibration-by-Comparison Dynamic Time Warping

6. Discussion

Funding

Conflicts of Interest

References

- Valcu, A.; Baicu, S. Analysis of the results obtained in the calibration of electronic analytical balances. In Proceedings of the 2012 International Conference and Exposition on Electrical and Power Engineering, Iasi, Romania, 25–27 October 2012; pp. 861–866. [Google Scholar]

- Davidson, S.; Fritsch, K.; Grum, M.; Malengo, A.; Medina, N.; Popa, G.; Schnell, N. Guidelines on the Calibration of Non-Automatic Weighing Instruments EURAMET Calibration Guide No. 18. Available online: www.euramet.org (accessed on 2 October 2018).

- OIML R 76-1: 2006. Non-Automatic Weighing Instruments Part 1: Metrological and Technical Requirements—Tests. Available online: https://www.oiml.org/en/files/pdf_r/r076-1-e06.pdf (accessed on 2 October 2018).

- NIST: National Institute of Standards and Technology. Available online: https://www.nist.gov/ (accessed on 2 October 2018).

- Butcher, T.G.; Crown, L.D.; Harshman, R.A. Specifications, Tolerances, and Other Technical Requirements for Weighing and Measuring Devices. Available online: https://doi.org/10.6028/NIST.HB.44-2018 (accessed on 2 October 2018).

- Valcu, A.; Baicu, S.; Taina, A.; Todor, R. Comparative measurements on an electronic weighing instrument. In Proceedings of the 2016 International Conference and Exposition on Electrical and Power Engineering (EPE), Iasi, Romania, 20–22 October 2016; pp. 581–586. [Google Scholar]

- Hoffmann, K. An Introduction to Stress Analysis using Strain Gauges. Available online: www.hbm.com (accessed on 25 October 2018).

- Vanwalleghem, J.; De Baere, I.; Loccufier, M.; Van Paepegem, W. Dynamic Calibration of a Strain Gauge Based Handlebar Force Sensor for Cycling Purposes. Procedia Eng. 2015, 112, 219–224. [Google Scholar] [CrossRef]

- Fujii, Y. Toward dynamic force calibration. Measurement 2009, 42, 1039–1044. [Google Scholar] [CrossRef]

- Florez, J.A.; Velasquez, A. Calibration of force sensing resistors (fsr) for static and dynamic applications. In Proceedings of the 2010 IEEE ANDESCON, Bogota, Colombia, 15–17 September 2010; pp. 1–6. [Google Scholar]

- Hsieh, H.-J.; Lu, T.-W.; Chen, S.-C.; Chang, C.-M.; Hung, C. A new device for in situ static and dynamic calibration of force platforms. Gait Posture 2011, 33, 701–705. [Google Scholar] [CrossRef] [PubMed]

- OIML R 111-1: 2004. Weights of Classes Part 1: Metrological and Technical Requirements. Available online: www.oiml.org (accessed on 5 October 2018).

- Beamex’s White Paper. Weighing Scale Calibration—How to Calibrate Weighing Instruments. Available online: www.beamex.com (accessed on 4 October 2018).

- Laurila, H. Weighing Scale Calibration—How to Calibrate Weighing Instruments. Available online: https://blog.beamex.com/weighing-scale-calibration-how-to-calibrate-weighing-instruments (accessed on 4 October 2018).

- Kumme, R. Investigation of the comparison method for the dynamic calibration of force transducers. Measurement 1998, 23, 239–245. [Google Scholar] [CrossRef]

- Zhang, Y.; Zu, J.; Zhang, H.-Y. Dynamic calibration method of high-pressure transducer based on quasi-δ function excitation source. Measurement 2012, 45, 1981–1988. [Google Scholar] [CrossRef]

- Walendziuk, W.; Idźkowski, A. Comparative research on the uroflowmetry system based on a weight transducer. Prz. Elektrotechniczny 2014. [Google Scholar] [CrossRef]

- Perng, C.-S.; Wang, H.; Zhang, S.R.; Parker, D.S. Landmarks: A New Model for Similarity-Based Pattern Querying in Time Series Databases. In Proceedings of the 16th International Conference on Data Engineering, San Diego, CA, USA, 29 February–3 March 2000. [Google Scholar]

- Cassisi, C.; Montalto, P.; Aliotta, M.; Cannata, A.; Pulvirenti, A. Similarity Measures and Dimensionality Reduction Techniques for Time Series Data Mining. In Advances in Data Mining Knowledge Discovery and Applications; InTech: Rijeka, Croatia, 2012. [Google Scholar]

- JCGM. Evaluation of Measurement Data-Guide to the Expression of Uncertainty in Measurement Évaluation des données de mesure—Guide pour l’expression de l’incertitude de mesure. Available online: https://www.bipm.org/utils/common/documents/jcgm/JCGM_100_2008_E.pdf (accessed on 18 October 2018).

- European Accreditation Laboratory Committee. EA-4/02 M: 2013—Evaluation of the Uncertainty of Measurement in Calibration. Available online: www.european-accreditation.org (accessed on 2 October 2018).

- Grubbs, F.E. Procedures for Detecting Outlying Observations in Samples. Technometrics 1969, 11, 1–21. [Google Scholar] [CrossRef]

- Grubbs, F.E.; Beck, G. Extension of Sample Sizes and Percentage Points for Significance Tests of Outlying Observations. Technometrics 1972, 14, 847. [Google Scholar] [CrossRef]

- Shapiro, S.S.; Wilk, M.B. An Analysis of Variance Test for Normality (Complete Samples). Biometrika 1965, 52, 591. [Google Scholar] [CrossRef]

- Henderson, A.R. Testing experimental data for univariate normality. Clin. Chim. Acta 2006, 366, 112–129. [Google Scholar] [CrossRef] [PubMed]

- Boddy, R.; Smith, G. Statistical Methods in Practice: For Scientists and Technologists; Wiley: Hoboken, NJ, USA, 2009; ISBN 9780470746646. [Google Scholar]

- Lileikyte, R.; Telksnys, L. Quality Estimation Methodology of Speech Recognition Features. Electron. Electr. Eng. 2011, 110, 113–116. [Google Scholar] [CrossRef]

- Kovacs-Vajna, Z.M. A fingerprint verification system based on triangular matching and dynamic time warping. IEEE Trans. Pattern Anal. Mach. Intell. 2000, 22, 1266–1276. [Google Scholar] [CrossRef]

- Petitjean, F.; Inglada, J.; Gancarski, P. Satellite Image Time Series Analysis under Time Warping. IEEE Trans. Geosci. Remote Sens. 2012, 50, 3081–3095. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, T.; Ao, X.; Yuan, H. A Vehicle Speed Estimation Algorithm Based on Dynamic Time Warping Approach. IEEE Sens. J. 2017, 17, 2456–2463. [Google Scholar] [CrossRef]

- Markevicius, V.; Navikas, D.; Idzkowski, A.; Andriukaitis, D.; Valinevicius, A.; Zilys, M. Practical Methods for Vehicle Speed Estimation Using a Microprocessor-Embedded System with AMR Sensors. Sensors 2018, 18, 2225. [Google Scholar] [CrossRef] [PubMed]

- Jablonski, B. Quaternion Dynamic Time Warping. IEEE Trans. Signal Process. 2012, 60, 1174–1183. [Google Scholar] [CrossRef]

- Lauwers, O.; De Moor, B. A Time Series Distance Measure for Efficient Clustering of Input/Output Signals by Their Underlying Dynamics. IEEE Control Syst. Lett. 2017, 1, 286–291. [Google Scholar] [CrossRef]

- Walendziuk, W.; Idźkowski, A.; Gołębiowski, J. Reconfigurable two-current source supplied signal conditioner for resistive sensors. Elektronika ir Elektrotechnika 2016. [Google Scholar] [CrossRef]

- Walendziuk, W.; Gołębiowski, J.; Idźkowski, A. Comparative evaluation of the two current source supplied strain gauge bridge. Elektronika ir Elektrotechnika 2016. [Google Scholar] [CrossRef]

- Walendziuk, W.; Idźkowski, A. Portable acquisition system for domiciliary uroflowmetry. J. Vibroeng. 2009, 11, 592–596. [Google Scholar]

- Vignoli, G. Noninvasive Urodynamics. In Urodynamics; Springer International Publishing: Cham, Switzerland, 2017; pp. 59–80. [Google Scholar]

- Alothmany, N.; Mosli, H.; Shokoueinejad, M.; Alkashgari, R.; Chiang, M.; Webster, J.G. Critical Review of Uroflowmetry Methods. J. Med. Biol. Eng. 2018, 38, 685–696. [Google Scholar] [CrossRef]

- Jarvis, T.R.; Chan, L.; Tse, V. Practical uroflowmetry. BJU Int. 2012, 110, 28–29. [Google Scholar] [CrossRef] [PubMed]

- SM6000-Magnetic-Inductive Flow Meter-Ifm Electronic. Available online: https://www.ifm.com/ch/en/product/SM6000 (accessed on 18 October 2018).

| Parameter | Value |

|---|---|

| Measuring range | 0.10 ÷ 25.00 L/min |

| Accuracy | ±(2% MW + 0.5% MEW) |

| Resolution | 0.05 L/min |

| Repeatability | ±0.2% MEW |

| Analog output | 4 ÷ 20 mA, 0 ÷ 10 V |

| Calculated Parameter | Value |

|---|---|

| Limiting error of mass measurement in ambient temperature | 0.500 g |

| Standard uncertainty (type B) | 0.290 g |

| Combined uncertainty of flow measurement | 4.080 g/s |

| Coverage factor kp | 2.327 |

| Expanded uncertainty of flow measurement | 9.500 g/s |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Walendziuk, W. Dynamic Outlier Detection in the Calibration by Comparison Method Applied to Strain Gauge Weight Sensors. Sensors 2018, 18, 4200. https://doi.org/10.3390/s18124200

Walendziuk W. Dynamic Outlier Detection in the Calibration by Comparison Method Applied to Strain Gauge Weight Sensors. Sensors. 2018; 18(12):4200. https://doi.org/10.3390/s18124200

Chicago/Turabian StyleWalendziuk, Wojciech. 2018. "Dynamic Outlier Detection in the Calibration by Comparison Method Applied to Strain Gauge Weight Sensors" Sensors 18, no. 12: 4200. https://doi.org/10.3390/s18124200

APA StyleWalendziuk, W. (2018). Dynamic Outlier Detection in the Calibration by Comparison Method Applied to Strain Gauge Weight Sensors. Sensors, 18(12), 4200. https://doi.org/10.3390/s18124200