Prestress Monitoring of a Steel Strand in an Anchorage Connection Using Piezoceramic Transducers and Time Reversal Method

Abstract

1. Introduction

2. Principle for the Detection of Steel Strand Tightness Based on Time Reversal

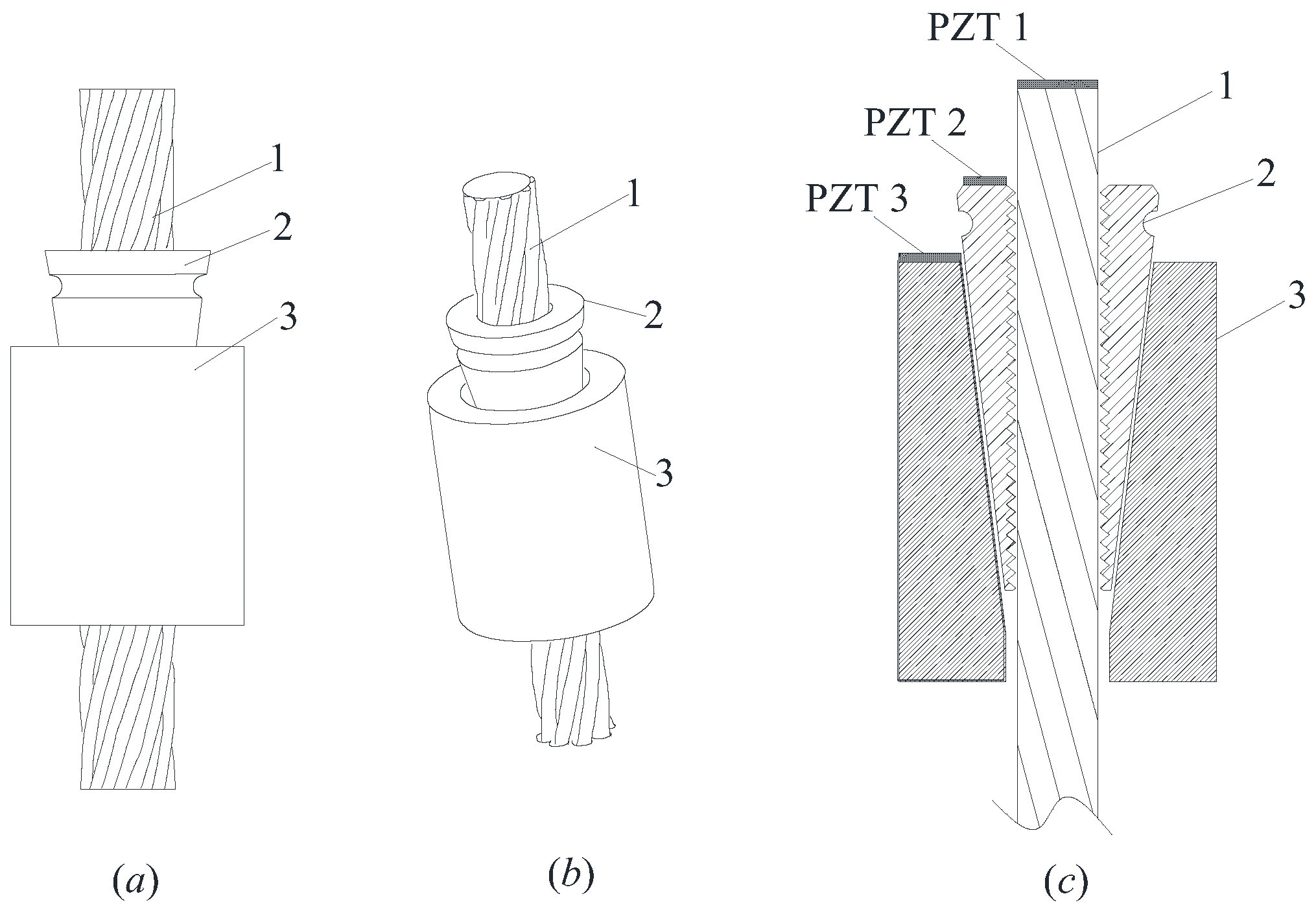

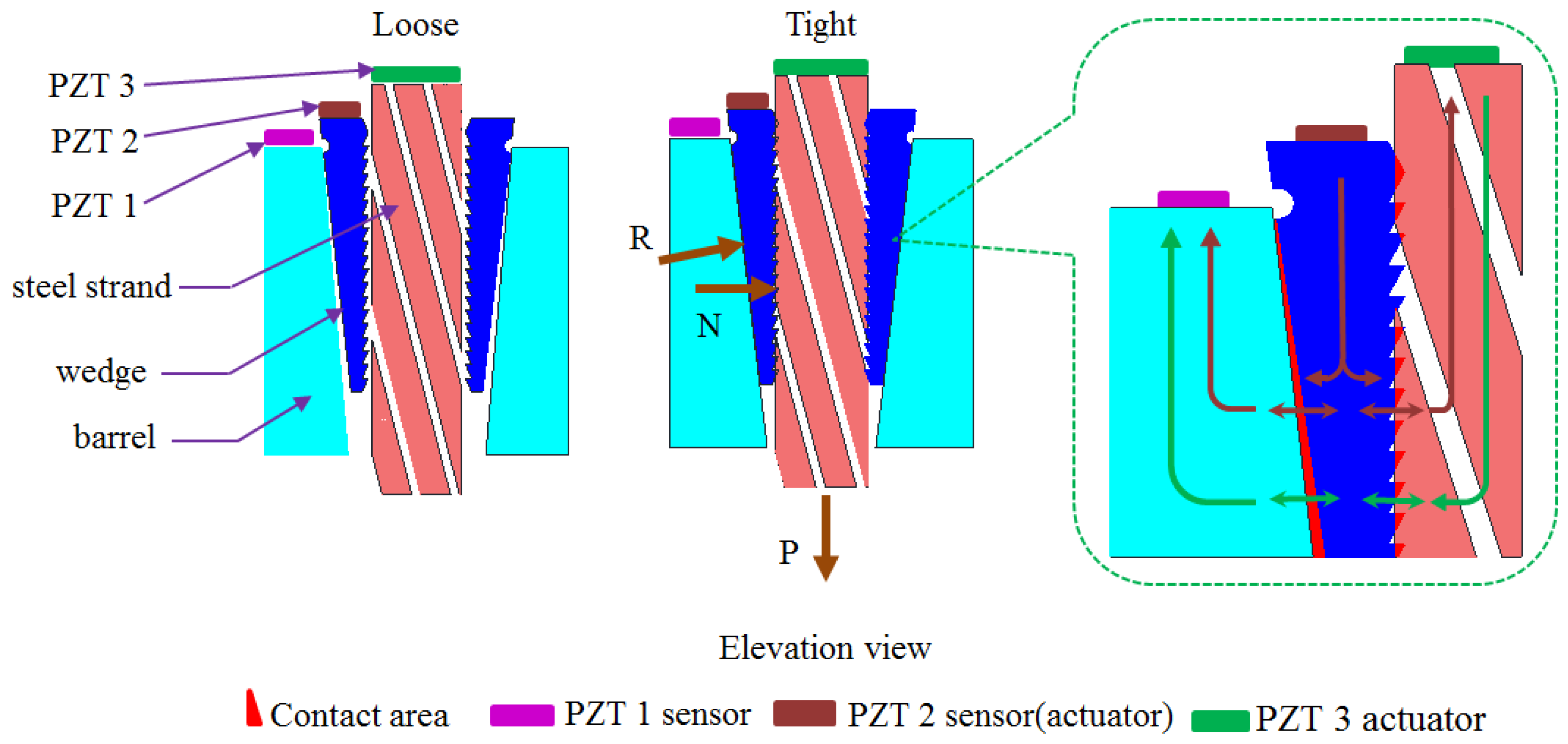

2.1. Wedge Anchorage System Structure

2.2. Active Sensing Monitoring Principle Using Piezoelectric Transducers

2.3. Detection Principle for Steel Strand Connection Based on Time Reversal

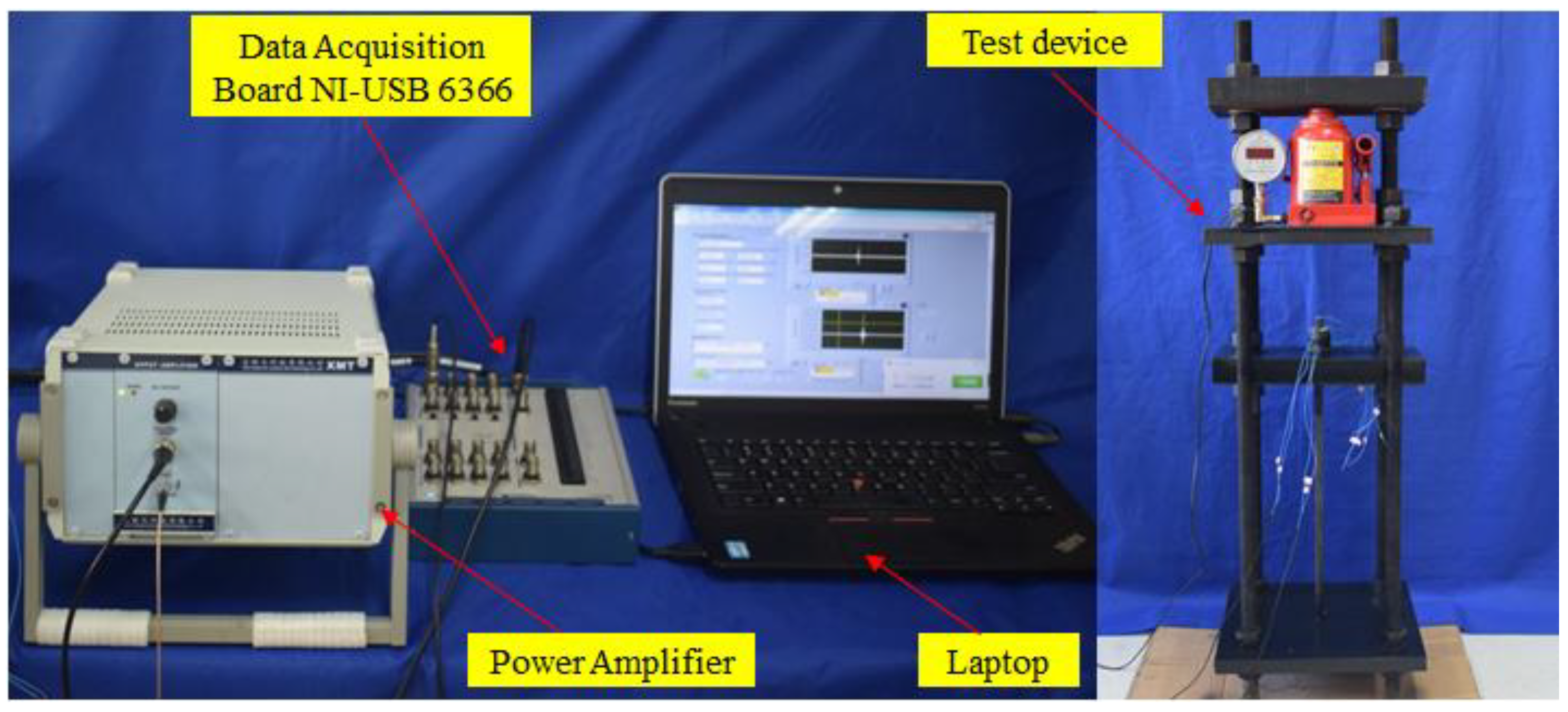

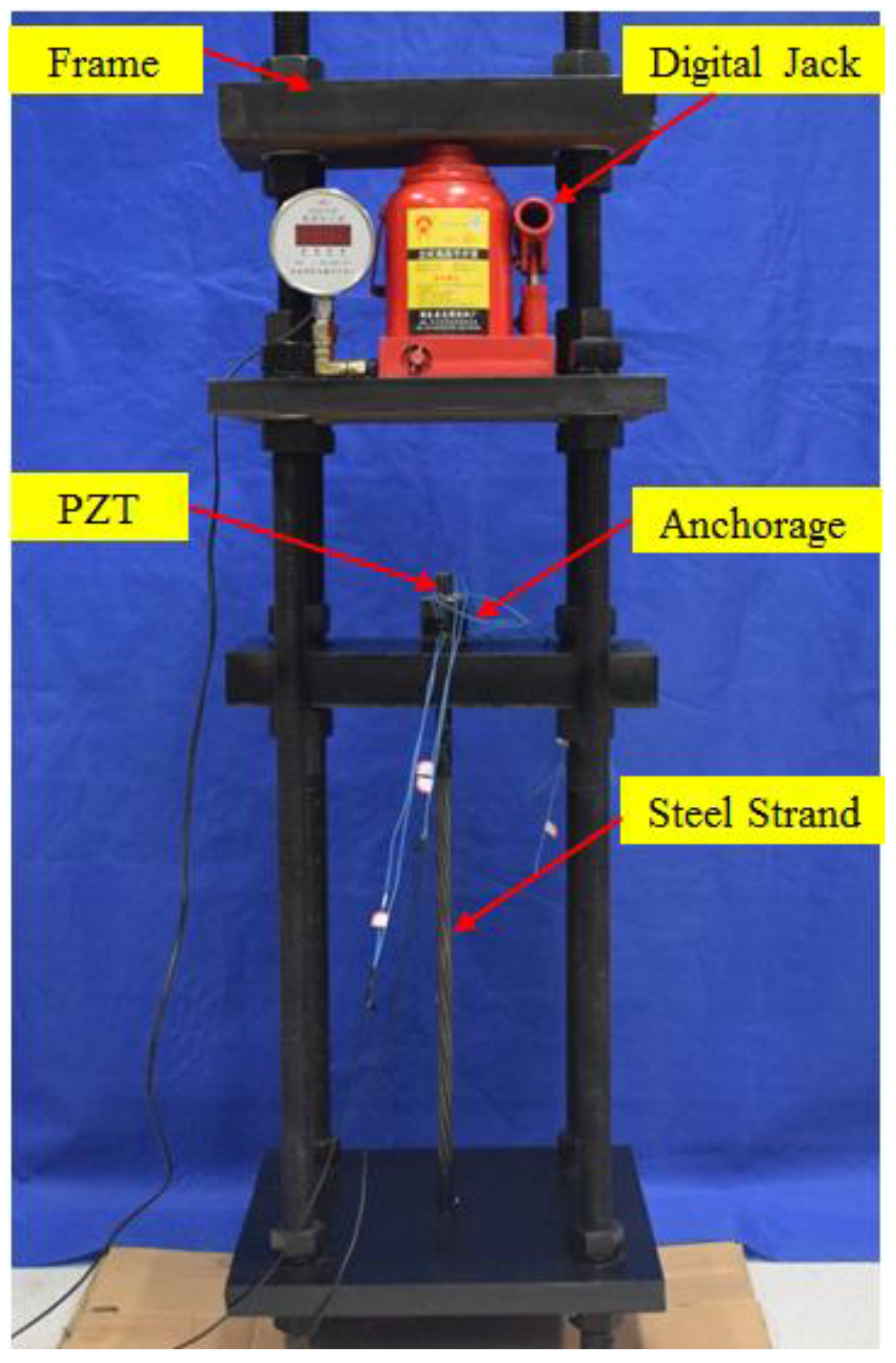

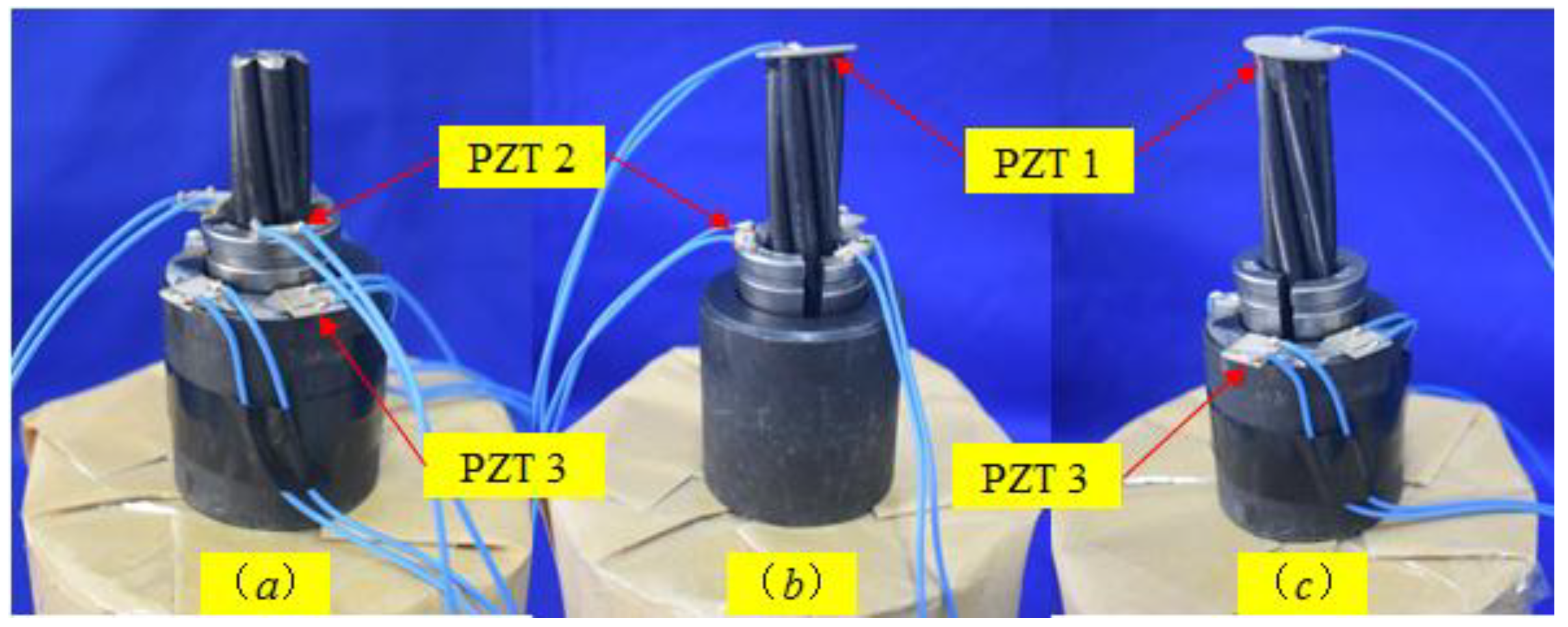

3. Experimental Setup

4. Experimental Procedure, Results and Analyses

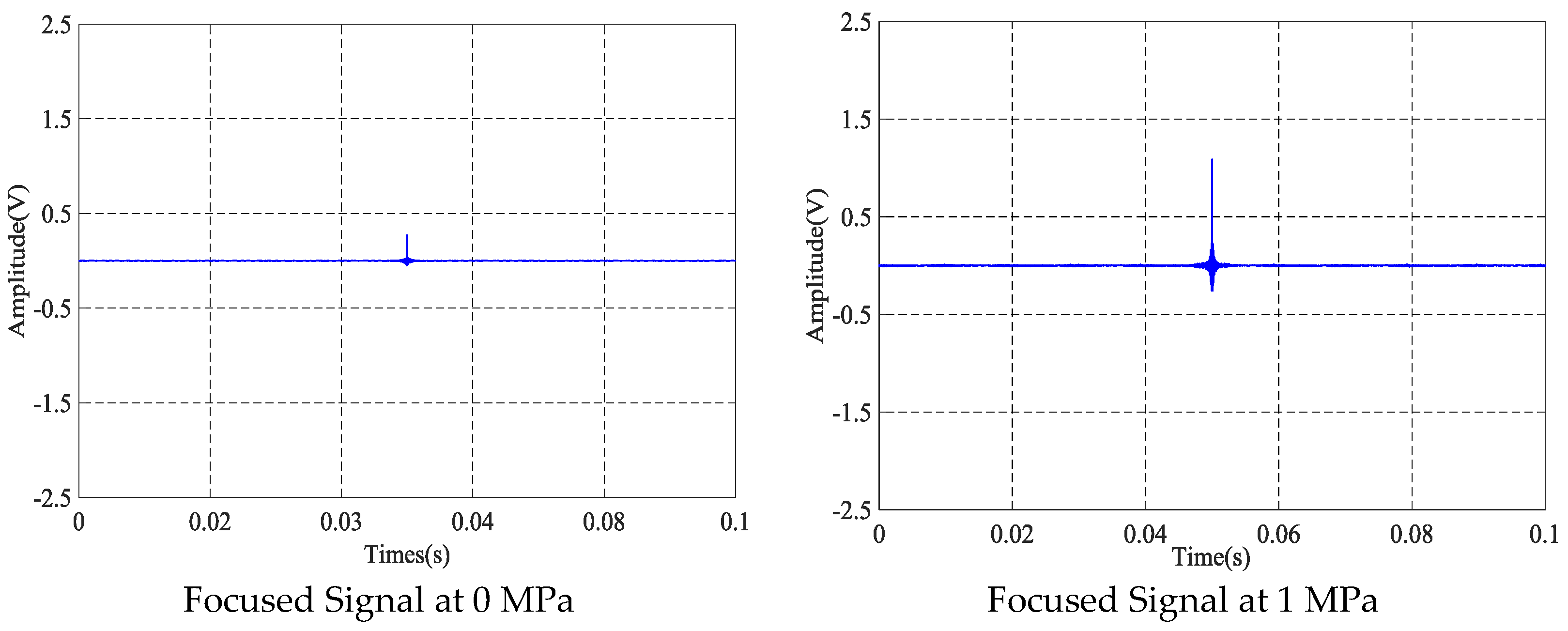

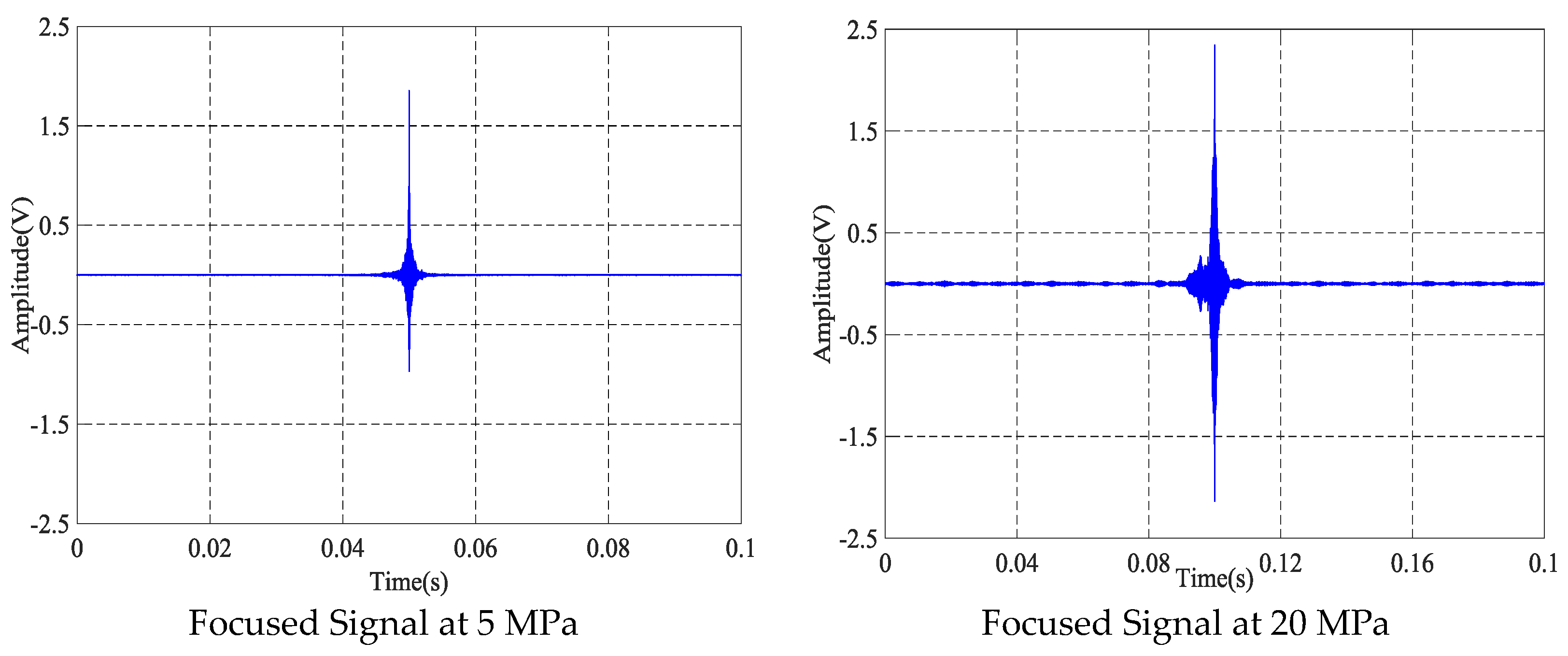

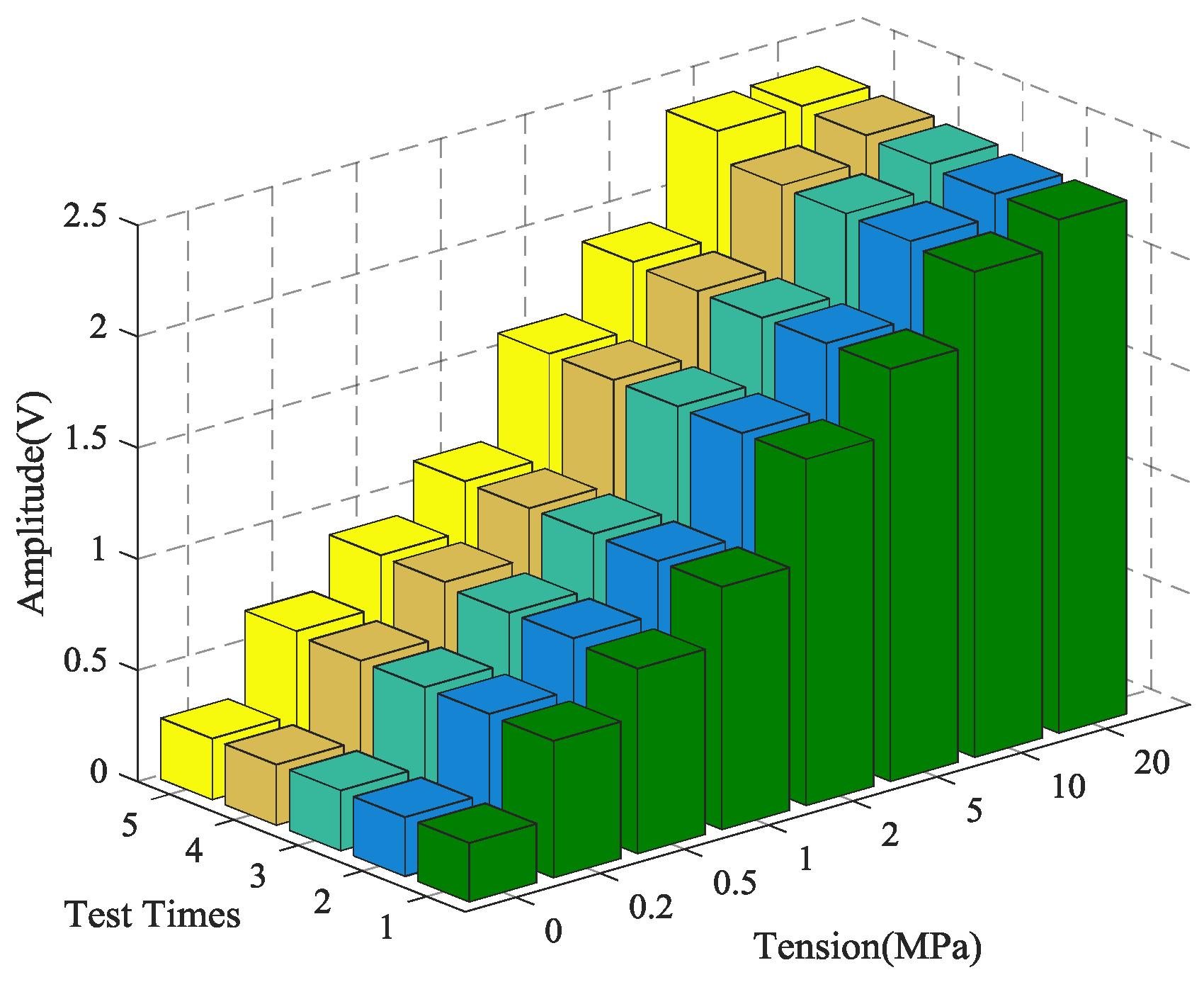

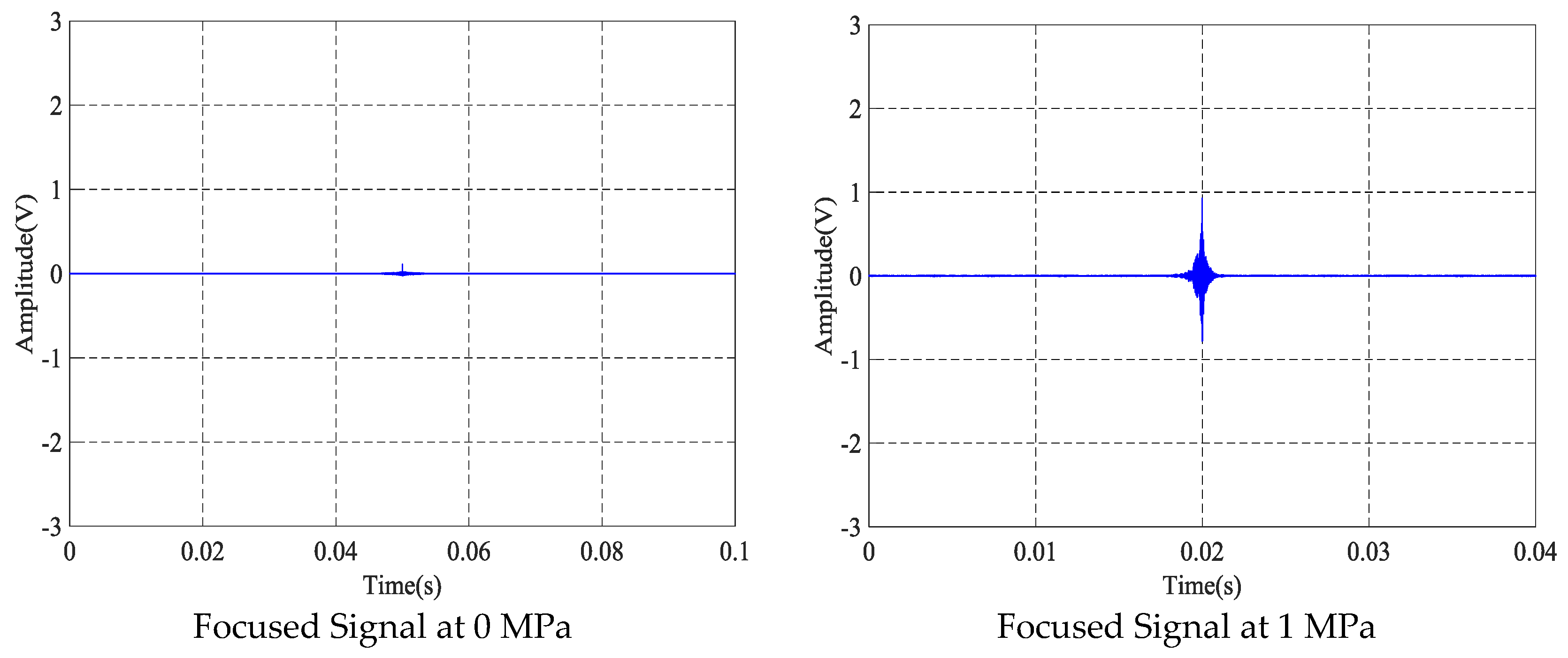

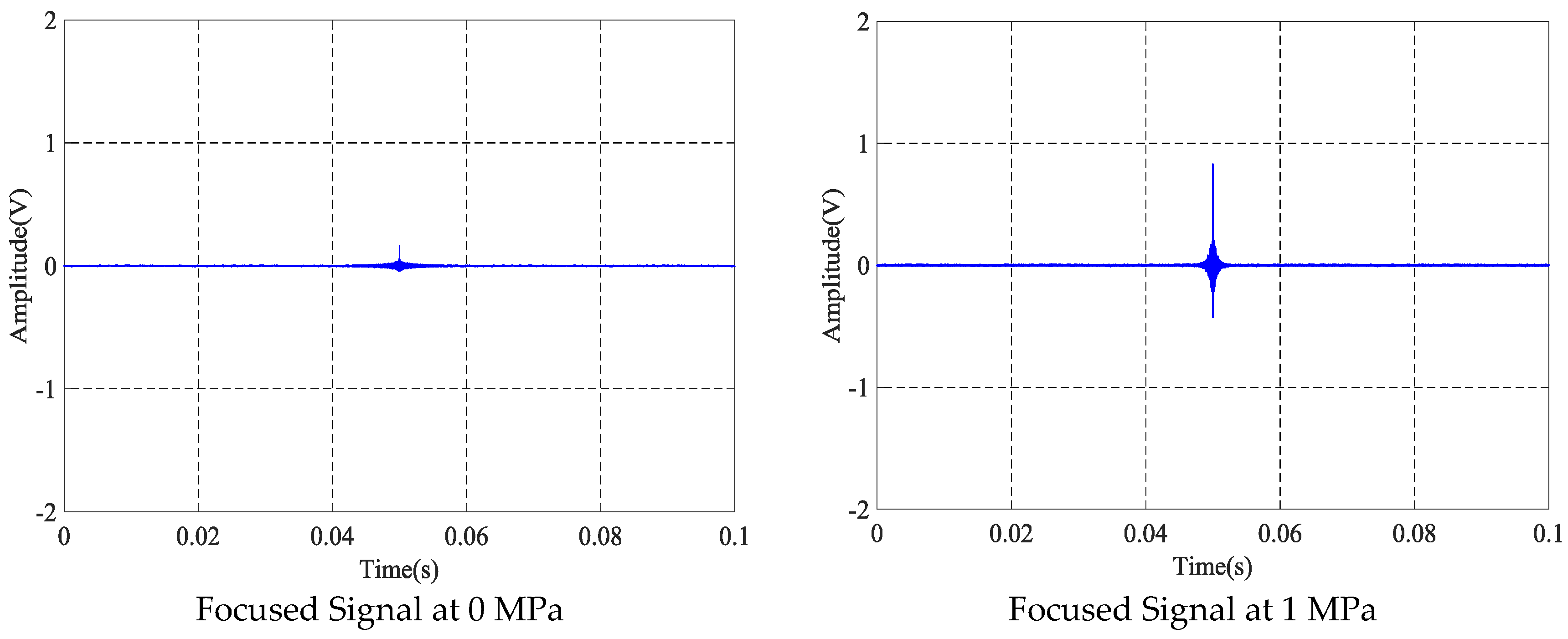

4.1. The Time-Reversal Test Between Steel Strand and Wedges

4.2. The Time-Reversal Test Between Steel Strands and Barrel

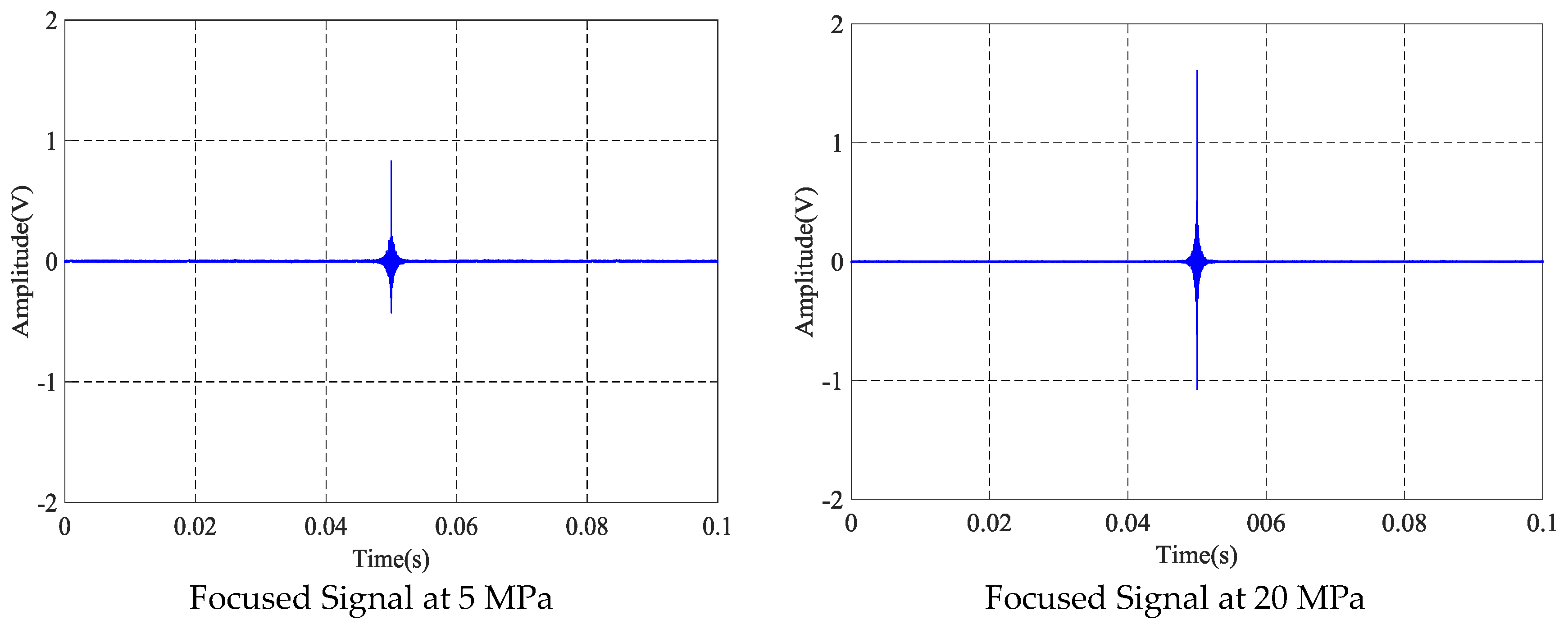

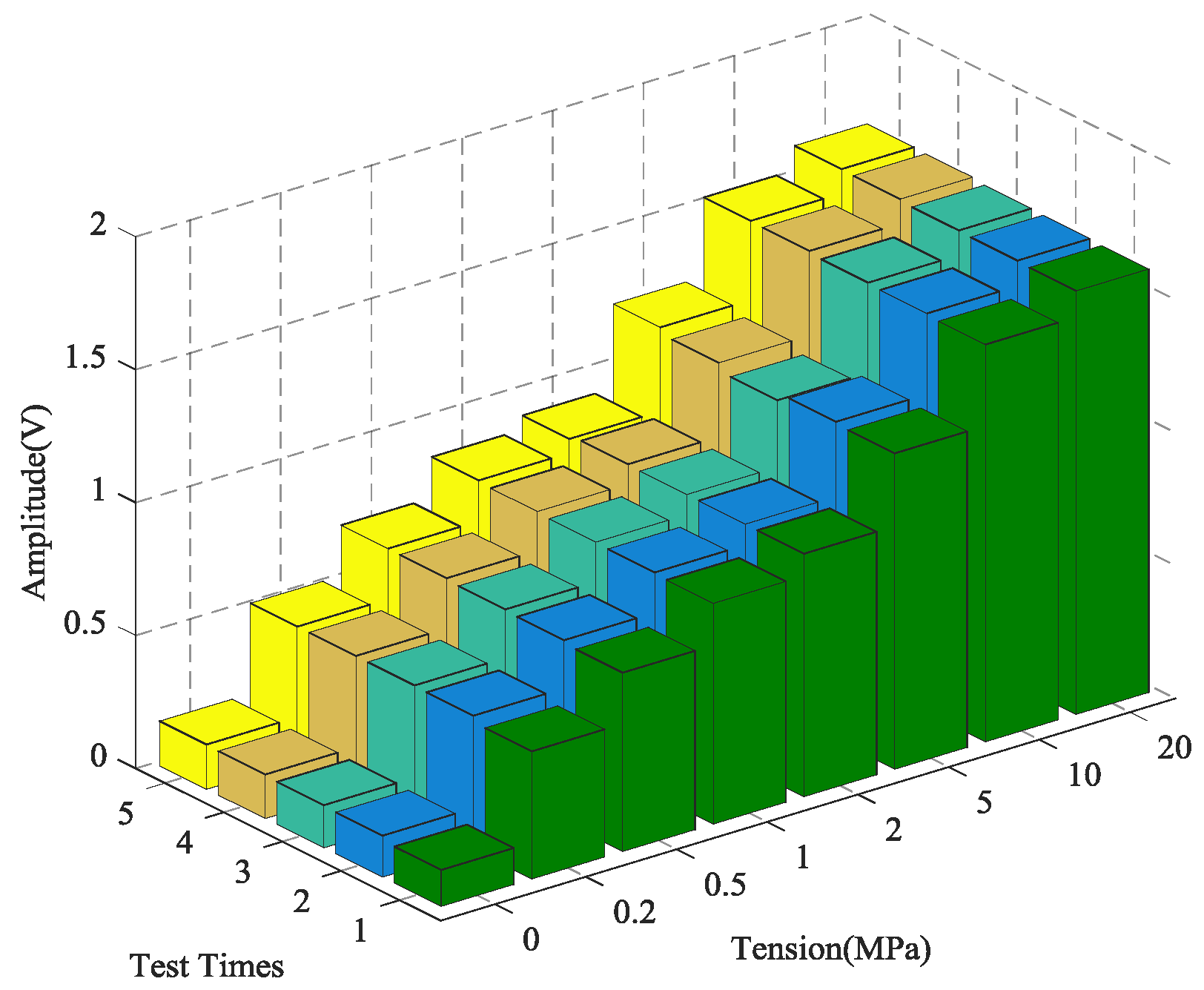

4.3. The Time-Reversal Test Between Wedges and Barrel

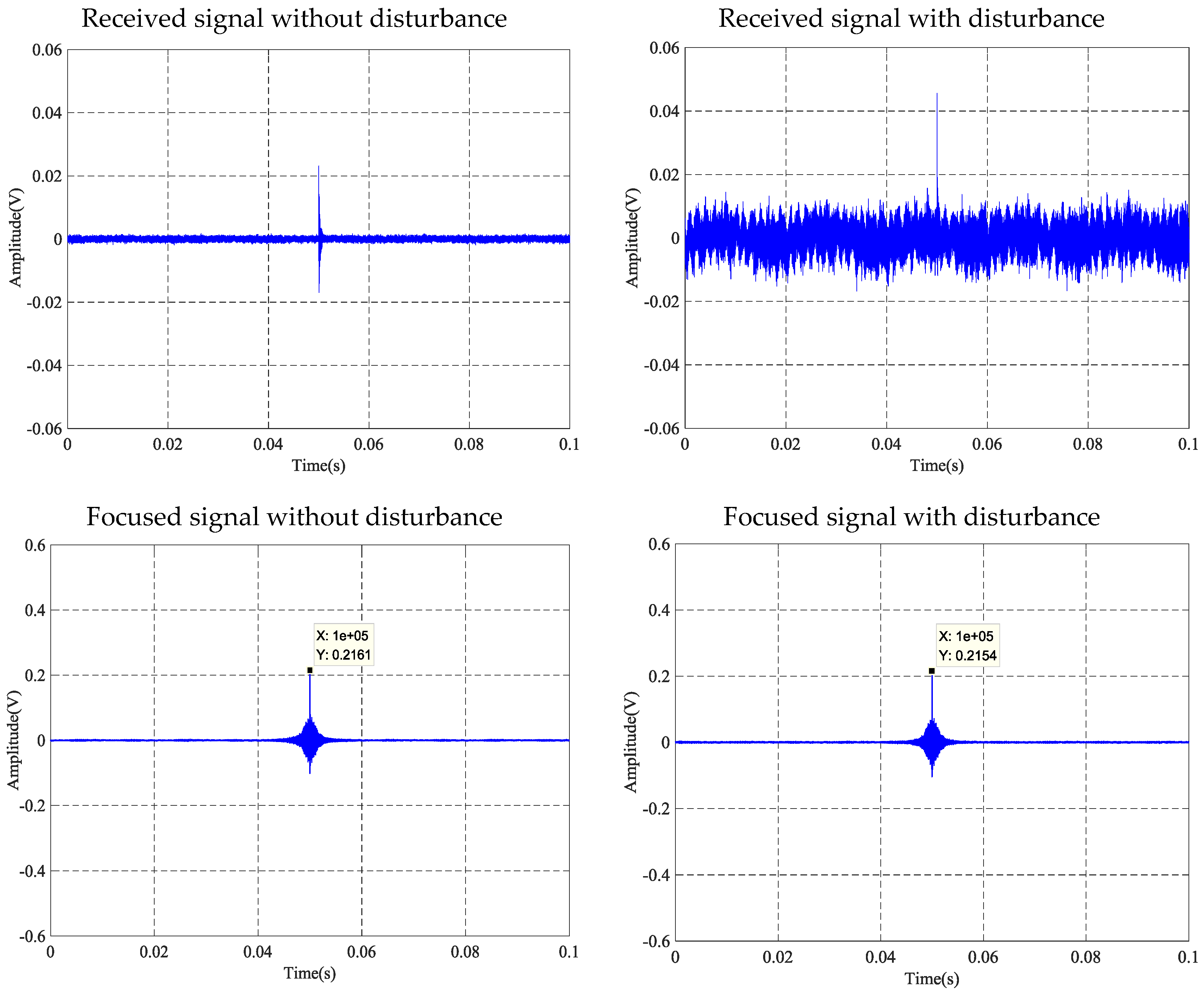

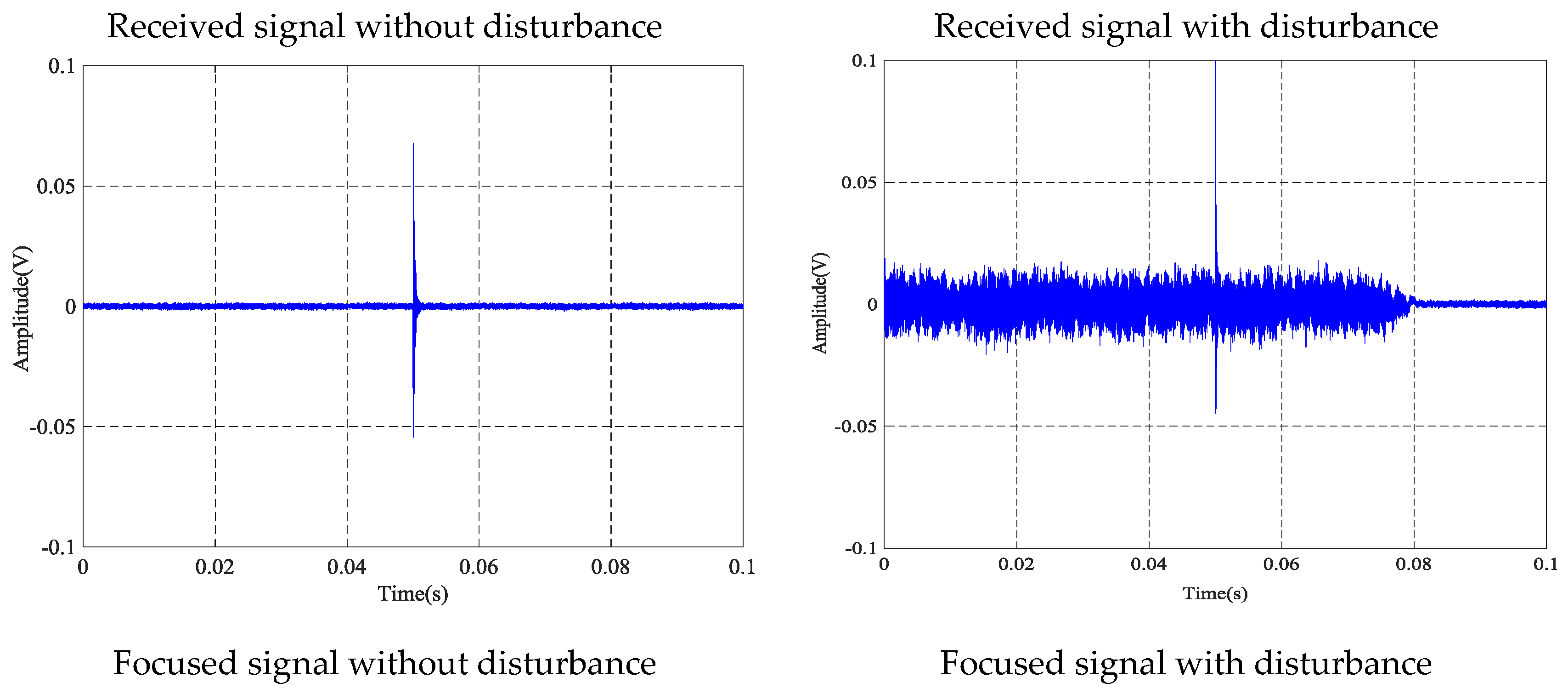

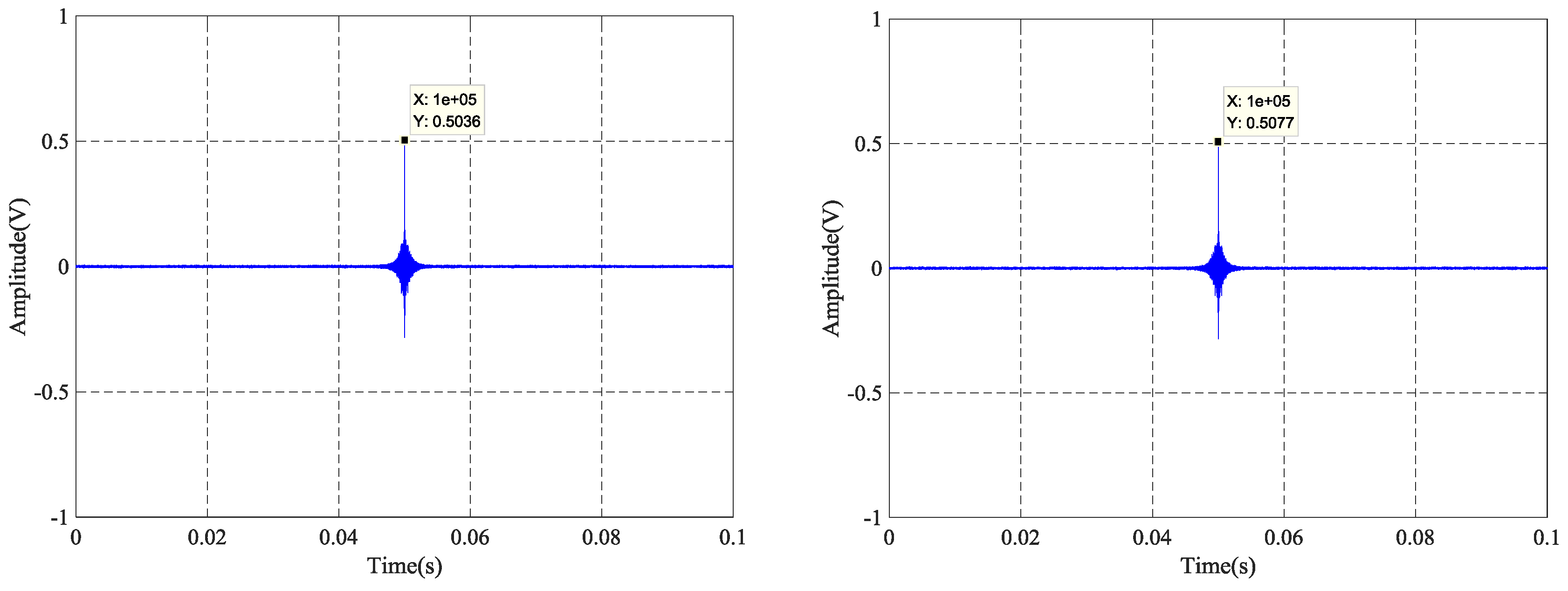

4.4. Anti-Disturbance Ability Results and Analyses

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Darmawan, M.; Stewart, M. Spatial time-dependent reliability analysis of corroding pretensioned prestressed concrete bridge girders. Struct. Saf. 2007, 29, 16–31. [Google Scholar] [CrossRef]

- Guo, T.; Chen, Z. Deflection control of long-span PSC box-girder bridge based on field monitoring and probabilistic FEA. J. Perform. Constr. Facil. 2016, 30, 04016053. [Google Scholar] [CrossRef]

- Robertson, I. Prediction of vertical deflections for a long-span prestressed concrete bridge structure. Eng. Struct. 2005, 27, 1820–1827. [Google Scholar] [CrossRef]

- Darmawan, M.; Stewart, M. Effect of pitting corrosion on capacity of prestressing wires. Mag. Concr. Res. 2007, 59, 131–139. [Google Scholar] [CrossRef]

- Guiglia, M.; Taliano, M. Experimental analysis of the effective pre-stress in large-span bridge box girders after 40 years of service life. Eng. Struct. 2014, 66, 146–158. [Google Scholar] [CrossRef]

- Tong, T.; Wendner, R.; Strauss, A.; Wang, W.; Yu, Q. Effects of concrete creep and its randomness on long-term deflection of prestressed box girder. In Proceedings of the 4th International Symposium on Life-Cycle Civil Engineering (IALCCE 2014), Tokyo, Japan, 16–19 November 2014; CRC Press/Balkema: Boca Raton, FL, USA, 2015; pp. 477–483. [Google Scholar]

- Akl, A.; Saiid, S.; Vosooghi, A. Deflection of in-span hinges in prestressed concrete box girder bridges during construction. Eng. Struct. 2017, 131, 293–310. [Google Scholar] [CrossRef]

- Solomos, G.; Berra, M. Testing of anchorages in concrete under dynamic tensile loading. Mater. Struct. 2006, 39, 695–706. [Google Scholar] [CrossRef]

- Ma, Z.; Jiang, Y.; Yang, Y.; Zhang, K. Slip mechanism of wedge and barrel anchorages under dynamic disturbance. J. Rock Mech. Eng. 2016, 35, 3042–3050. [Google Scholar] [CrossRef]

- Qin, H.; Zhu, W.; Zhang, H.; Zhou, Z.; Ou, J. Manufacturing and performance analysis of intelligent steel strand embedded with prepressure large scale fiber Bragg grating sensor. J. Lasers 2017, 44, 0410001. [Google Scholar] [CrossRef]

- Liu, T.; Jiang, J.; Li, X.; Li, E.; Liu, L.; Wang, Y.; Zhang, Y. Application of Fiber Bragg Grating sensor on measurement of tensile stress in a seven-wire prestressed steel strand. J. Optoelectron. Laser 2005, 16, 1235–1238. [Google Scholar]

- Kim, Y.; Kwon, Y. Review of magnetostrictive patch transducers and applications in ultrasonic nondestructive testing of waveguides. Ultrasonics 2015, 62, 3–19. [Google Scholar] [CrossRef] [PubMed]

- Chaki, S.; Bourse, G. Guided ultrasonic waves for non-destructive monitoring of the stress levels in prestressed steel strands. Ultrasonics 2009, 49, 162–171. [Google Scholar] [CrossRef] [PubMed]

- Joh, C.; Lee, J.; Kwahk, I. Feasibility study of stress measurement in prestressing tendons using villari effect and induced magnetic field. Int. J. Distrib. Sens. Netw. 2013, 2013, 249829. [Google Scholar] [CrossRef]

- Chang, P.; Flatau, A.; Liu, S. Health monitoring of civil infrastructure. Struct. Health Monit. 2003, 2, 257–267. [Google Scholar] [CrossRef]

- Song, G.; Wang, C.; Wang, B. Structural Health Monitoring (SHM) of Civil Structures. Appl. Sci. 2017, 7, 789. [Google Scholar] [CrossRef]

- Kong, Q.; Robert, R.; Silva, P.; Mo, Y. Cyclic crack monitoring of a reinforced concrete column under simulated pseudo-dynamic loading using piezoceramic-based smart aggregates. Appl. Sci. 2016, 6, 341. [Google Scholar] [CrossRef]

- Wang, D.; Song, H.; Zhu, H. Numerical and experimental studies on damage detection of a concrete beam based on PZT admittances and correlation coefficient. Constr. Build. Mater. 2013, 49, 564–574. [Google Scholar] [CrossRef]

- Providakis, C.; Stefanaki, K.; Voutetaki, M.; Tsompanakis, Y.; Stavroulaki, M. Damage detection in concrete structures using a simultaneously activated multi-mode PZT active sensing system: Numerical modelling. Struct. Infrastruct. Eng. 2014, 10, 1451–1468. [Google Scholar] [CrossRef]

- Hu, X.; Zhu, H.; Wang, D. A study of concrete slab damage detection based on the electromechanical impedance method. Sensors 2014, 14, 19897–19909. [Google Scholar] [CrossRef] [PubMed]

- Karayannis, C.; Voutetaki, M.; Chalioris, C.; Providakis, C.; Angeli, G. Detection of flexural damage stages for RC beams using Piezoelectric sensors (PZT). Smart Struct. Syst. 2015, 15, 997–1018. [Google Scholar] [CrossRef]

- Giurgiutiu, V.; Zagrai, A.; Bao, J. Piezoelectric wafer embedded active sensors for aging aircraft structural health monitoring. Struct. Health Monit. 2002, 1, 41–61. [Google Scholar] [CrossRef]

- Yan, S.; Ma, H.; Li, P.; Song, G.; Wu, J. Development and application of a structural health monitoring system based on wireless smart aggregates. Sensors 2017, 17, 1641. [Google Scholar] [CrossRef] [PubMed]

- Duan, W.; Wang, Q.; Quek, S. Applications of piezoelectric materials in structural health monitoring and repair: Selected research examples. Materials 2010, 3, 5169–5194. [Google Scholar] [CrossRef] [PubMed]

- Song, G.; Li, H.; Bosko, G.; Zhou, W.; Chen, P.; Gu, H. Wind turbine blade health monitoring with piezoceramic-based wireless sensor network. Int. J. Smart Nano Mater. 2013, 4, 150–166. [Google Scholar] [CrossRef]

- Song, G.; Mo, Y.; Otero, K.; Gu, H. Health monitoring and rehabilitation of a concrete structure using intelligent materials. Smart Mater. Struct. 2006, 15, 309–314. [Google Scholar] [CrossRef]

- Song, G.; Gu, H.; Mo, Y.; Hsu, T.; Dhonde, H. Concrete structural health monitoring using embedded piezoceramic transducers. Smart Mater. Struct. 2007, 16, 959–968. [Google Scholar] [CrossRef]

- Song, G.; Gu, H.; Mo, Y. Smart aggregates: Multi-functional sensors for concrete structures—A tutorial and a review. Smart Mater. Struct. 2008, 17, 033001. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Y.; Huang, Y.; Jiang, J.; Ho, S. A feasibility study on timber moisture monitoring using piezoceramic transducer-enabled active sensing. Sensors 2018, 18, 3100. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Chen, D.; Zhou, L.; Huo, L.; Ma, H.; Song, G. Evaluation of the effect of fly ash on hydration characterization in self-compacting concrete (SCC) at very early ages using piezoceramic transducers. Sensors 2018, 18, 2489. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Li, Y.; Du, G.; Song, G. Damage detection of L-shaped concrete filled steel tube (L-CFST) columns under cyclic loading using embedded piezoceramic transducers. Sensors 2018, 18, 2171. [Google Scholar] [CrossRef] [PubMed]

- Qiu, L.; Yuan, S.; Zhang, X.; Wang, Y. A time reversal focusing based impact imaging method and its evaluation on complex composite structures. Smart Mater. Struct. 2011, 20, 105014. [Google Scholar] [CrossRef]

- Song, G.; Olmi, C.; Gu, H. An overheight vehicle–bridge collision monitoring system using piezoelectric transducers. Smart Mater. Struct. 2007, 16, 462–468. [Google Scholar] [CrossRef]

- Zhu, J.; Ho, S.; Patil, D.; Wang, N.; Hirsch, R.; Song, G. Underwater pipeline impact localization using piezoceramic transducers. Smart Mater. Struct. 2017, 26, 107002. [Google Scholar] [CrossRef]

- Zhu, J.; Ho, S.; Kong, Q.; Patil, D.; Mo, Y.; Song, G. Estimation of impact location on concrete column. Smart Mater. Struct. 2017, 26, 055037. [Google Scholar] [CrossRef]

- Xu, K.; Deng, Q.; Cai, L.; Ho, S.; Song, G. Damage detection of a concrete column subject to blast loads using embedded piezoceramic transducers. Sensors 2018, 18, 1377. [Google Scholar] [CrossRef] [PubMed]

- Fink, M. Time reversal of ultrasonic fields. I. Basic principles. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1992, 39, 555–566. [Google Scholar] [CrossRef] [PubMed]

- Fink, M.; Prada, C. Acoustic time-reversal mirrors. Inverse Probl. 2001, 17, 1–38. [Google Scholar] [CrossRef]

- Gangadharan, R.; Murthy, C.; Gopalakrishnan, S.; Bhat, M. Time reversal technique for health monitoring of metallic structure using Lamb waves. Ultrasonics 2009, 49, 696–705. [Google Scholar] [CrossRef] [PubMed]

- Du, G.; Kong, Q.; Wu, F.; Ruan, J.; Song, G. An experimental feasibility study of pipeline corrosion pit detection using a piezoceramic time reversal mirror. Smart Mater. Struct. 2016, 25, 037002. [Google Scholar] [CrossRef]

- Parvasi, S.; Ho, S.; Kong, Q.; Mousavi, R.; Song, G. Real time bolt preload monitoring using piezoceramic transducers and time reversal technique—A numerical study with experimental verification. Smart Mater. Struct. 2016, 25, 085015. [Google Scholar] [CrossRef]

- Cai, J.; Shi, L.; Yuan, S.; Shao, Z. High spatial resolution imaging for structural health monitoring based on virtual time reversal. Smart Mater. Struct. 2011, 20, 055018. [Google Scholar] [CrossRef]

- Chalioris, C.; Papadopoulos, N.; Angeli, G.; Karayannis, C.; Liolios, A.; Providakis, C. Damage evaluation in shear-critical reinforced concrete beam using piezoelectric transducers as smart aggregates. Open Eng. 2015, 1, 373–384. [Google Scholar] [CrossRef]

- Karayannis, C.; Chalioris, C.; Angeli, G.; Papadopoulos, N.; Favvata, M.; Providakis, C. Experimental damage evaluation of reinforced concrete steel bars using piezoelectric sensors. Constr. Build. Mater. 2016, 105, 227–244. [Google Scholar] [CrossRef]

- Voutetaki, M.; Papadopoulos, N.; Angeli, G.; Providakis, P. Investigation of a new experimental method for damage assessment of RC beams failing in shear using piezoelectric transducers. Eng. Struct. 2016, 114, 226–240. [Google Scholar] [CrossRef]

- Chaliorisa, C.; Karayannisa, C.; Angelia, G.; Papadopoulosa, N.; Favvataa, M.; Providakisb, C. Applications of smart piezoelectric materials in a wireless admittance monitoring system (WiAMS) to Structures-Tests in RC elements. Case Stud. Constr. Mater. 2016, 5, 1–18. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, C.; Song, G. Health status monitoring of cuplock scaffold joint connection based on wavelet packet analysis. Shock Vibrat. 2015. [Google Scholar] [CrossRef]

- Ai, D.; Zhu, H.; Luo, H.; Wang, C. Mechanical impedance based embedded piezoelectric transducer for reinforced concrete structural impact damage detection: A comparative study. Constr. Build. Mater. 2018, 165, 472–483. [Google Scholar] [CrossRef]

- Wang, T.; Song, G.; Wang, Z.; Li, Y. Proof-of-concept study of monitoring bolt connection status using a piezoelectric based active sensing method. Smart Mater. Struct. 2013, 22, 087001. [Google Scholar] [CrossRef]

- Ji, Q.; Ho, M.; Zheng, R.; Ding, Z.; Song, G. An exploratory study of stress wave communication in concrete structures. Smart Struct. Syst. 2015, 15, 135–150. [Google Scholar] [CrossRef]

- Watkins, R.; Jha, R. A modified time reversal method for Lamb wave based diagnostics of composite structures. Mech. Syst. Signal Process. 2012, 31, 345–354. [Google Scholar] [CrossRef]

- Jun, Y.; Lee, U. Computer-aided hybrid time reversal process for structural health monitoring. J. Mech. Sci. Technol. 2012, 26, 53–61. [Google Scholar] [CrossRef]

- Vigoureux, D.; Guyader, J. A simplified Time Reversal method used to localize vibrations sources in a complex structure. Appl. Acoust. 2012, 73, 491–496. [Google Scholar] [CrossRef]

- Ciampa, F.; Meo, M. Acoustic emission localization in complex dissipative anisotropic structures using a one-channel reciprocal time reversal method. J. Acoust. Soc. Am. 2011, 130, 168–175. [Google Scholar] [CrossRef] [PubMed]

- Ciampa, F.; Meo, M. Impact detection in anisotropic materials using a time reversal approach. Struct. Health Monit. 2012, 11, 43–49. [Google Scholar] [CrossRef]

- Damme, B.; Abeele, K.; Matar, O. The vibration dipole: A time reversed acoustics scheme for the experimental localisation of surface breaking cracks. Appl. Phys. Lett. 2012, 100, 084103. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, C.; Huo, L.; Song, G. Health monitoring of cuplok scaffold joint connection using piezoceramic transducers and time reversal method. Smart Mater. Struct. 2016, 25, 035010. [Google Scholar] [CrossRef]

- Narayanan, S.; Balamurugan, V. Finite element modelling of piezolaminated smart structures for active vibration control with distributed sensors and actuators. J. Sound Vib. 2003, 262, 529–562. [Google Scholar] [CrossRef]

- Song, G.; Qiao, P.; Binienda, W.; Zou, G.P. Active vibration damping of composite beam using smart sensors and actuators. J. Aerosp. Eng. 2002, 15, 97–103. [Google Scholar] [CrossRef]

- Sethi, V.; Song, G. Multimodal vibration control of a flexible structure using piezoceramic sensor and actuator. J. Intell. Mater. Syst. Struct. 2008, 19, 573–582. [Google Scholar] [CrossRef]

- Pai, P.; Wen, B.; Naser, A.; Schulz, M. Structural vibration control using PZT patches and non-linear phenomena. J. Sound Vib. 1998, 215, 273–296. [Google Scholar] [CrossRef]

- Gu, H.; Song, G. Active vibration suppression of a flexible beam with piezoceramic patches using robust model reference control. Smart Mater. Struct. 2007, 16, 1453–1459. [Google Scholar] [CrossRef]

- Sethi, V.; Franchek, M.; Song, G. Active multimodal vibration suppression of a flexible structure with piezoceramic sensor and actuator by using loop shaping. J. Vib. Control 2011, 17, 1994–2006. [Google Scholar] [CrossRef]

- Gurses, K.; Buckham, B.; Park, E. Vibration control of a single-link flexible manipulator using an array of fiber optic curvature sensors and PZT actuators. Mechatronics 2009, 19, 167–177. [Google Scholar] [CrossRef]

- Song, G.; Zhou, X.; Binienda, W. Thermal deformation compensation of a composite beam using piezoelectric actuators. Smart Mater. Struct. 2004, 13, 30–37. [Google Scholar] [CrossRef]

- Sodano, H.; Park, G.; Inman, D. Estimation of electric charge output for piezoelectric energy harvesting. Strain 2004, 40, 49–58. [Google Scholar] [CrossRef]

- Wang, G. Analysis of bimorph piezoelectric beam energy harvesters using Timoshenko and Euler–Bernoulli beam theory. J. Intell. Mater. Syst. Struct. 2013, 24, 226–239. [Google Scholar] [CrossRef]

- Bryant, M.; Garcia, E. Energy harvesting: A key to wireless sensor nodes. In Proceedings of the Second International Conference on Smart Materials and Nanotechnology in Engineering, Weihai, China, 8–11 July 2009. [Google Scholar] [CrossRef]

- Jiang, T.; Zheng, J.; Huo, L.; Song, G. Finite element analysis of grouting compactness monitoring in a post-tensioning tendon duct using piezoceramic transducers. Sensors 2017, 17, 2239. [Google Scholar] [CrossRef] [PubMed]

- Jiang, T.; Kong, Q.; Patil, D.; Luo, Z.; Huo, L.; Song, G. Detection of debonding between fiber reinforced polymer bar and concrete structure using piezoceramic transducers and wavelet packet analysis. IEEE Sens. J. 2017, 17, 1992–1998. [Google Scholar] [CrossRef]

- Feng, Q.; Kong, Q.; Huo, L.; Song, G. Crack detection and leakage monitoring on reinforced concrete pipe. Smart Mater. Struct. 2015, 24, 115020. [Google Scholar] [CrossRef]

- Luo, M.; Li, W.; Hei, C.; Song, G. Concrete infill monitoring in concrete-filled FRP tubes using a PZT-based ultrasonic time-of-flight method. Sensors 2016, 16, 2083. [Google Scholar] [CrossRef] [PubMed]

- Feng, Q.; Kong, Q.; Jiang, J.; Liang, Y.; Song, G. Detection of interfacial debonding in a Rubber–Steel-Layered structure using active sensing enabled by embedded piezoceramic transducers. Sensors 2017, 17, 2001. [Google Scholar] [CrossRef] [PubMed]

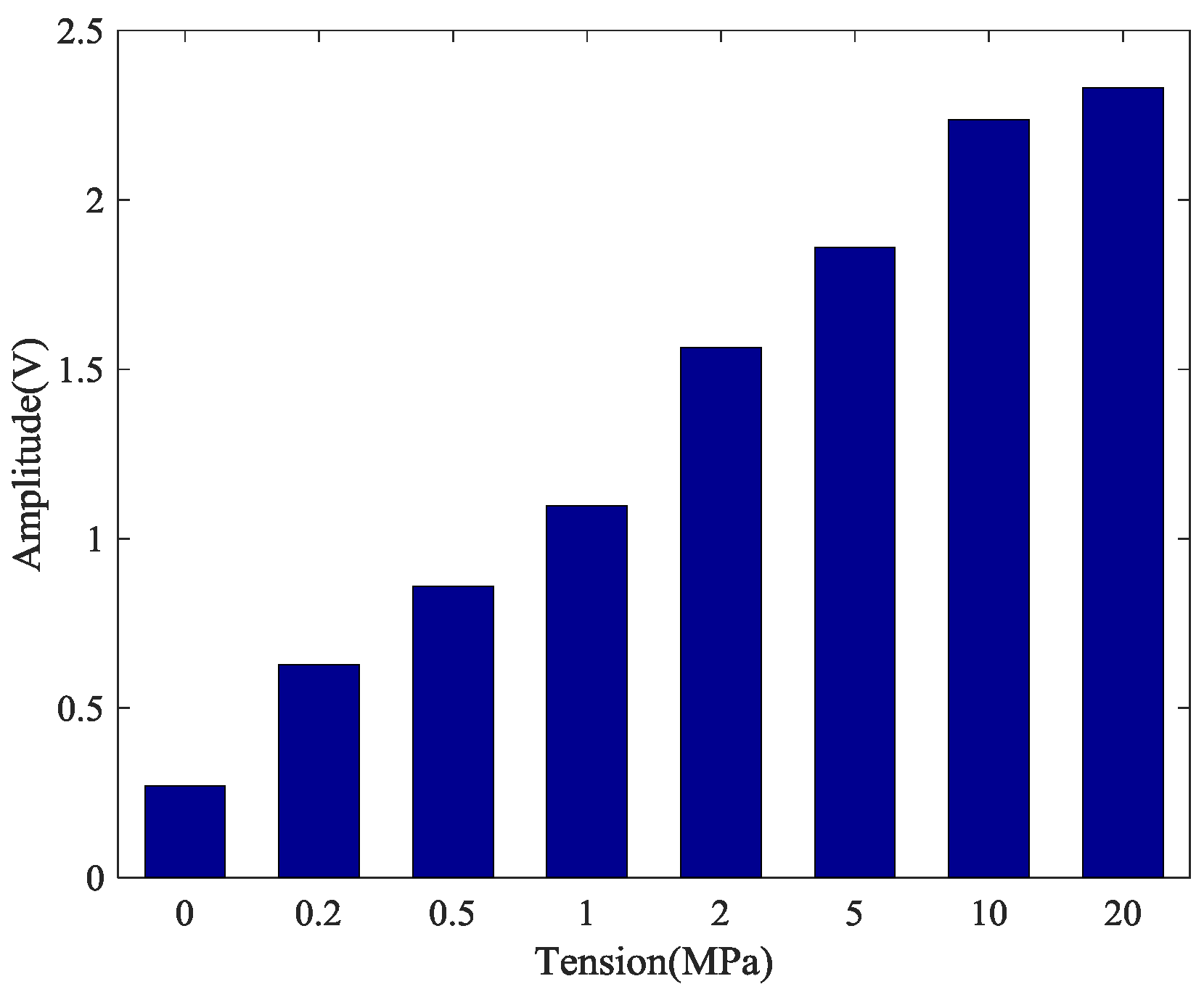

| MPa | 0 | 0.2 | 0.5 | 1 | 2 | 5 | 10 | 20 |

|---|---|---|---|---|---|---|---|---|

| kN | 0 | 0.276 | 0.69 | 1.38 | 2.76 | 6.9 | 13.8 | 27.6 |

| Tension/MPa | Tension/kN | Min/V | Max/V | μ/V | σ/μ/(10−2) |

|---|---|---|---|---|---|

| 0 | 0 | 0.264558 | 0.274446 | 0.269632 | 1.419444 |

| 0.2 | 0.276 | 0.615164 | 0.6491 | 0.628855 | 1.826525 |

| 0.5 | 0.69 | 0.832016 | 0.881979 | 0.859474 | 2.088011 |

| 1 | 1.38 | 1.090825 | 1.106081 | 1.097808 | 0.506306 |

| 2 | 2.76 | 1.556926 | 1.571639 | 1.563922 | 0.348047 |

| 5 | 6.9 | 1.854132 | 1.875389 | 1.859441 | 0.439823 |

| 10 | 13.8 | 2.182169 | 1.875389 | 2.236725 | 2.734821 |

| 20 | 27.6 | 2.308493 | 2.359761 | 2.330045 | 0.844448 |

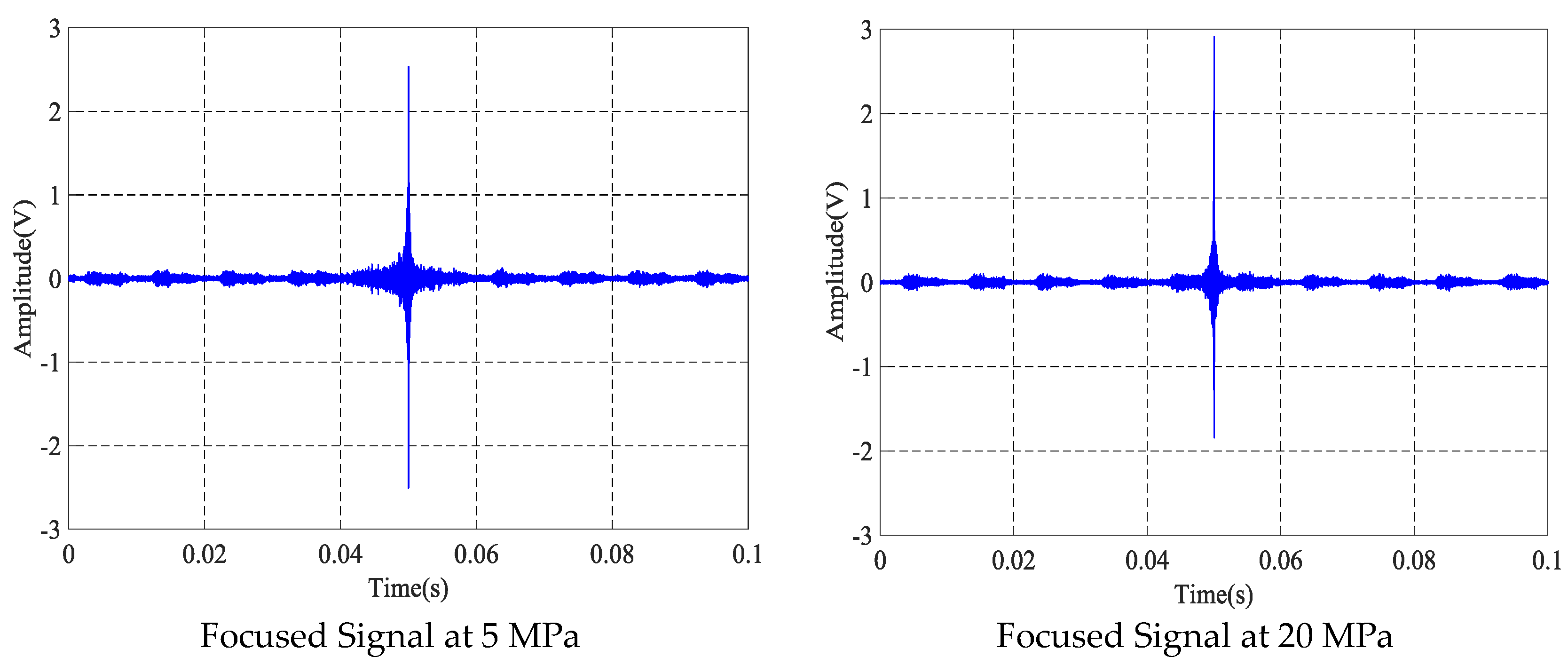

| Tension/MPa | Tension/kN | Min/V | Max/V | μ/V | σ/μ/(10−2) |

|---|---|---|---|---|---|

| 0 | 0 | 0.11208 | 0.113996 | 0.112921 | 0.612221 |

| 0.2 | 0.276 | 0.209888 | 0.216627 | 0.214014 | 1.195999 |

| 0.5 | 0.69 | 0.386678 | 0.434445 | 0.422541 | 4.277936 |

| 1 | 1.38 | 0.927317 | 0.962595 | 0.94467 | 1.329268 |

| 2 | 2.76 | 1.296668 | 1.317607 | 1.307192 | 0.651326 |

| 5 | 6.9 | 2.535705 | 2.604062 | 2.569132 | 0.979111 |

| 10 | 13.8 | 2.840649 | 2.914029 | 2.875087 | 1.093778 |

| 20 | 27.6 | 2.812053 | 3.006242 | 2.873273 | 2.597293 |

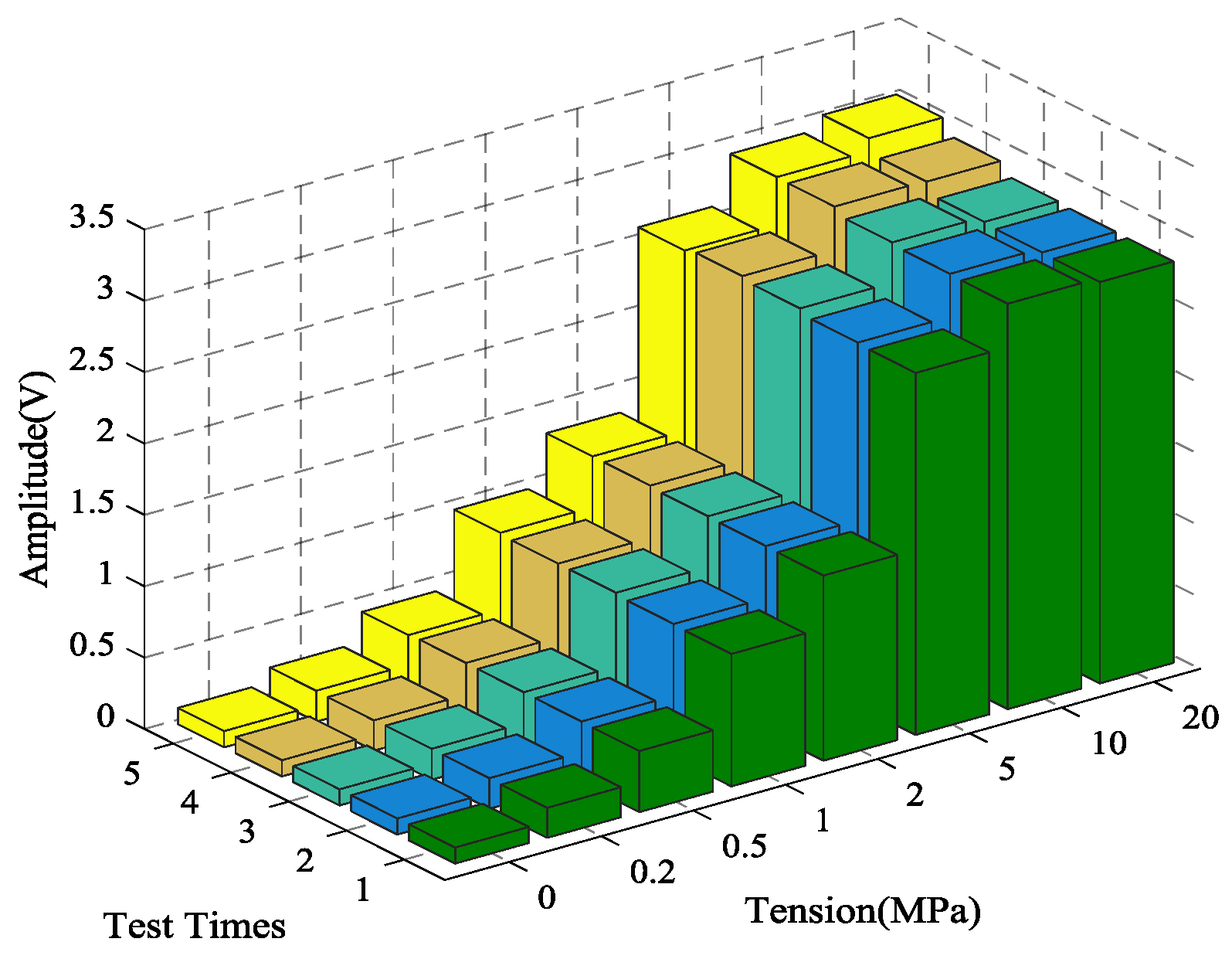

| Tension/MPa | Tension/kN | Min/V | Max/V | μ/V | σ/μ/(10−2) |

|---|---|---|---|---|---|

| 0 | 0 | 0.136850 | 0.168320 | 0.157398 | 7.086028 |

| 0.2 | 0.276 | 0.479997 | 0.508538 | 0.501667 | 2.189873 |

| 0.5 | 0.69 | 0.672501 | 0.698786 | 0.688785 | 1.399519 |

| 1 | 1.38 | 0.830159 | 0.852215 | 0.840823 | 0.895999 |

| 2 | 2.76 | 0.905172 | 0.920107 | 0.914026 | 0.53849 |

| 5 | 6.9 | 1.167486 | 1.221231 | 1.194364 | 1.452056 |

| 10 | 13.8 | 1.494013 | 1.519024 | 1.507248 | 0.616488 |

| 20 | 27.6 | 1.592577 | 1.610284 | 1.601367 | 0.413511 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhang, L.; Liu, L.; Huo, L. Prestress Monitoring of a Steel Strand in an Anchorage Connection Using Piezoceramic Transducers and Time Reversal Method. Sensors 2018, 18, 4018. https://doi.org/10.3390/s18114018

Zhang X, Zhang L, Liu L, Huo L. Prestress Monitoring of a Steel Strand in an Anchorage Connection Using Piezoceramic Transducers and Time Reversal Method. Sensors. 2018; 18(11):4018. https://doi.org/10.3390/s18114018

Chicago/Turabian StyleZhang, Xiaoyu, Liuyu Zhang, Laijun Liu, and Linsheng Huo. 2018. "Prestress Monitoring of a Steel Strand in an Anchorage Connection Using Piezoceramic Transducers and Time Reversal Method" Sensors 18, no. 11: 4018. https://doi.org/10.3390/s18114018

APA StyleZhang, X., Zhang, L., Liu, L., & Huo, L. (2018). Prestress Monitoring of a Steel Strand in an Anchorage Connection Using Piezoceramic Transducers and Time Reversal Method. Sensors, 18(11), 4018. https://doi.org/10.3390/s18114018