An Intelligent Fault Diagnosis Method for Bearings with Variable Rotating Speed Based on Pythagorean Spatial Pyramid Pooling CNN

Abstract

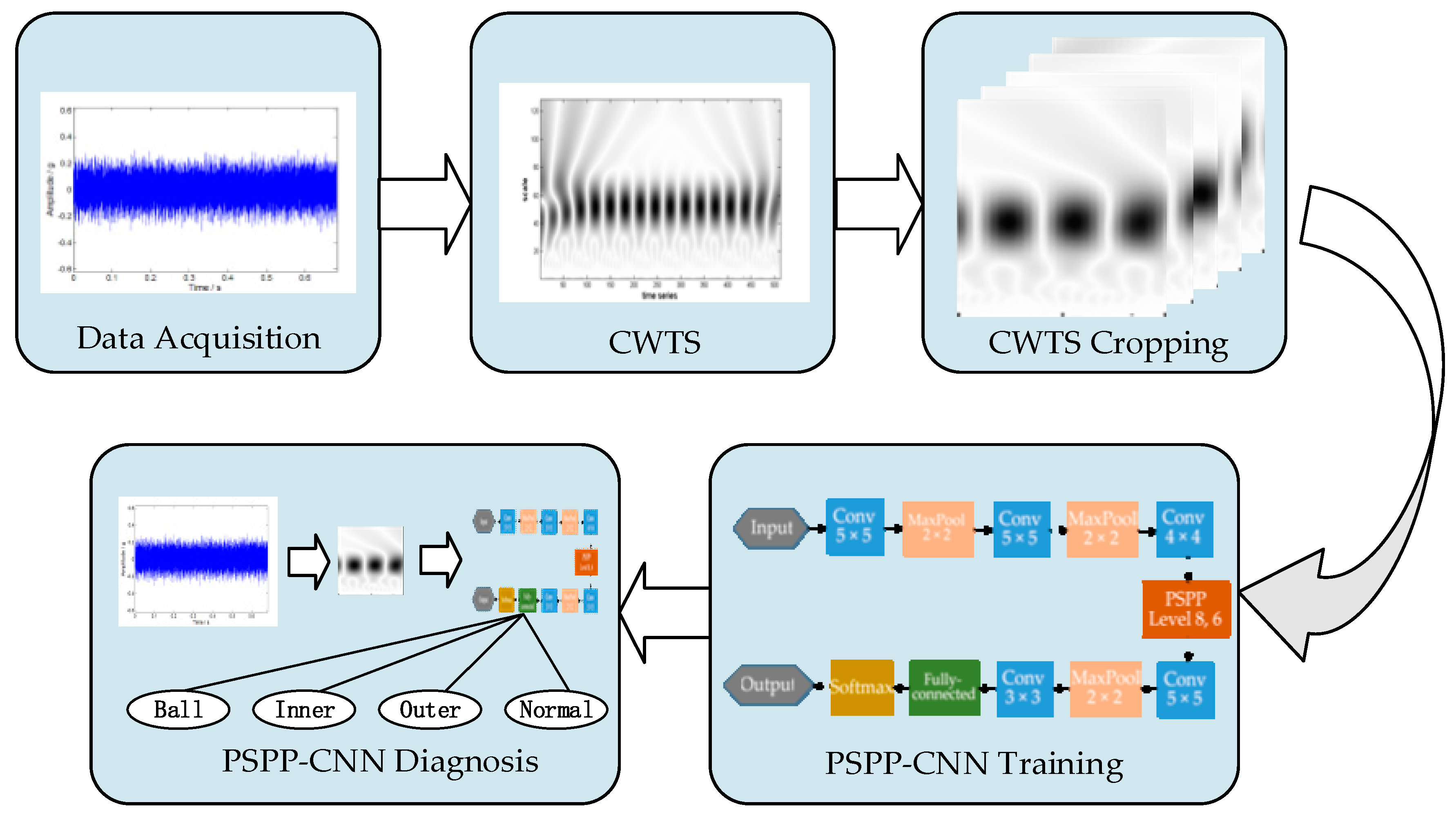

1. Introduction

- (1)

- Compared with features extraction method used before when dealing with continuous wavelet transform coefficients, using a two-dimensional CWTS for fault diagnosis directly can retain the complete time-frequency domain information of signal and avoid the loss of fault information.

- (2)

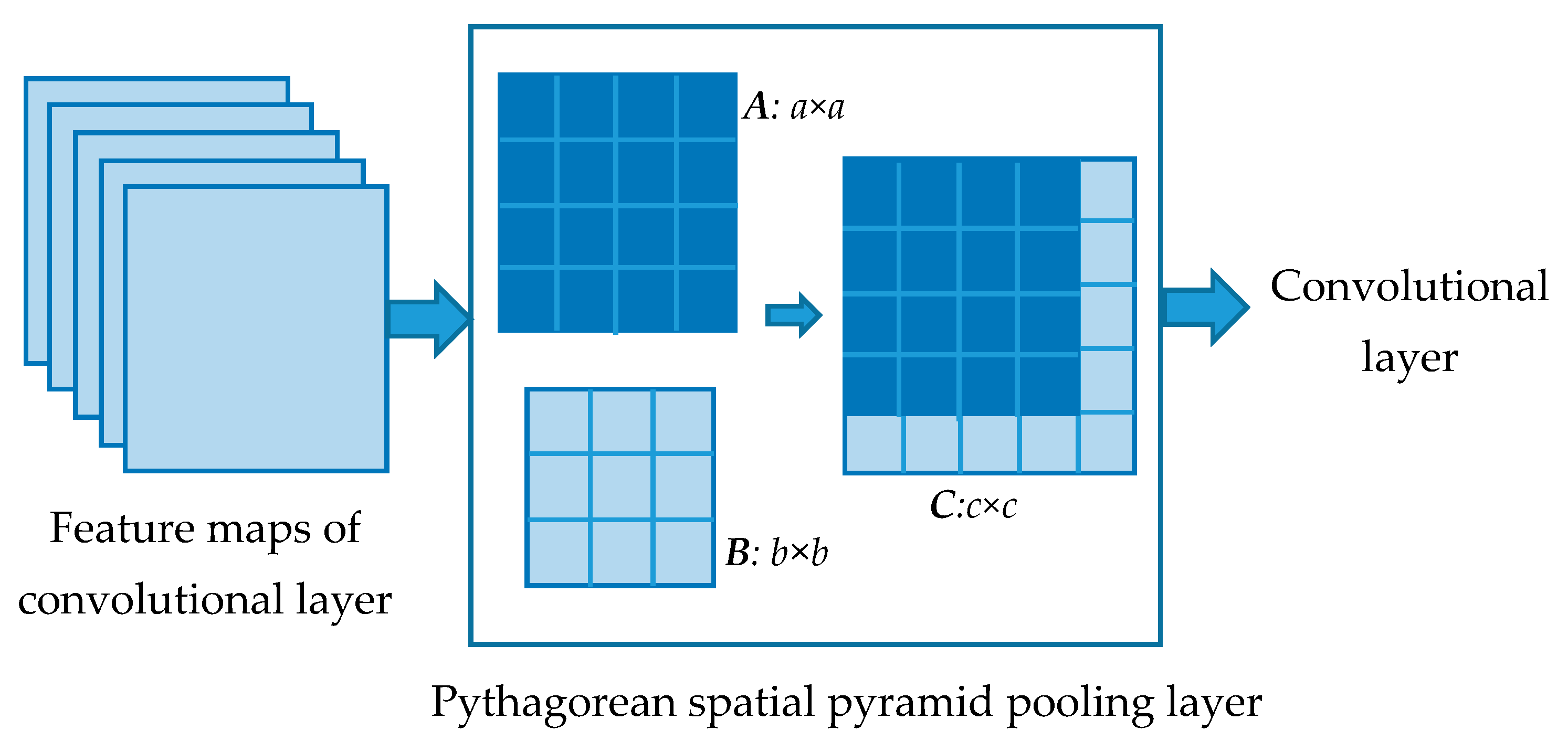

- A PSPP layer is proposed based on the SPP layer. In contrast with SPP-CNN, PSPP-CNN can place convolutional layers after the PSPP layer for further feature extraction. A PSPP layer can also retain position information of input feature maps. Experiment results show that PSPP-CNN performs better than SPP-CNN.

- (3)

- A CWTS cropping method is presented to crop CWTSs to different sizes according to rotating speed and sample frequency. The objects recognition using CNN is concerned with the shape of the object. However, in signal processing area, the location of the signal features should also be paid attention to. The cropped CWTSs have the same frequency and time domain range. It helps the PSPP-CNN to achieve a more accurate and faster convergence.

- (4)

- The proposed method can process data in different rotating speeds using a single CNN without complex parameter selection. PSPP-CNN trained by data at some rotating speeds can be used to diagnose bearing fault in full working speed. The experiments provide a good result.

2. Proposed Method

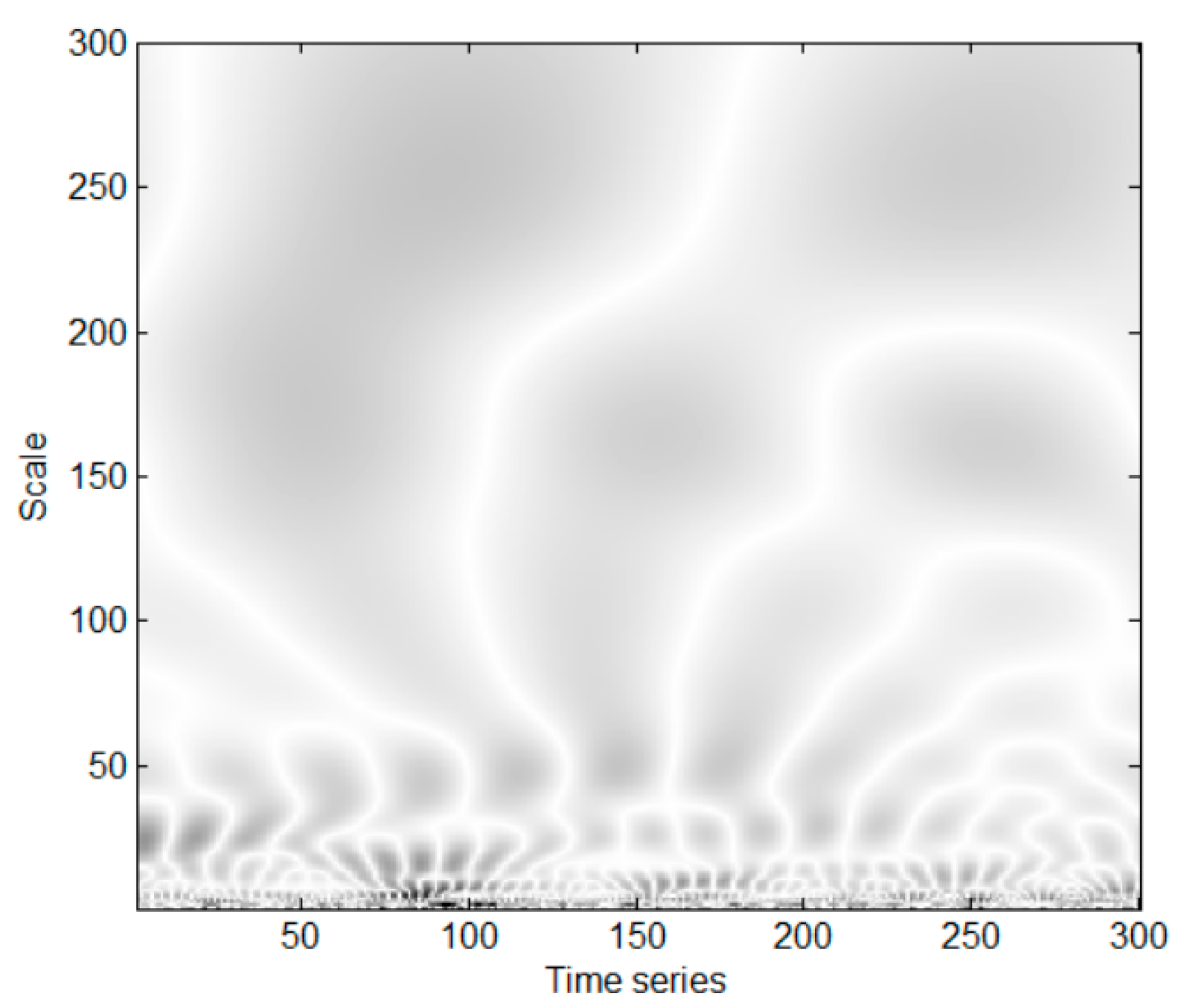

2.1. Continuous Wavelet Transform Scalogram

2.2. Continuous Wavelet Transform Scalogram Cropping

2.3. Pythagorean Spatial Pyramid Pooling Convolutional Neural Network Training

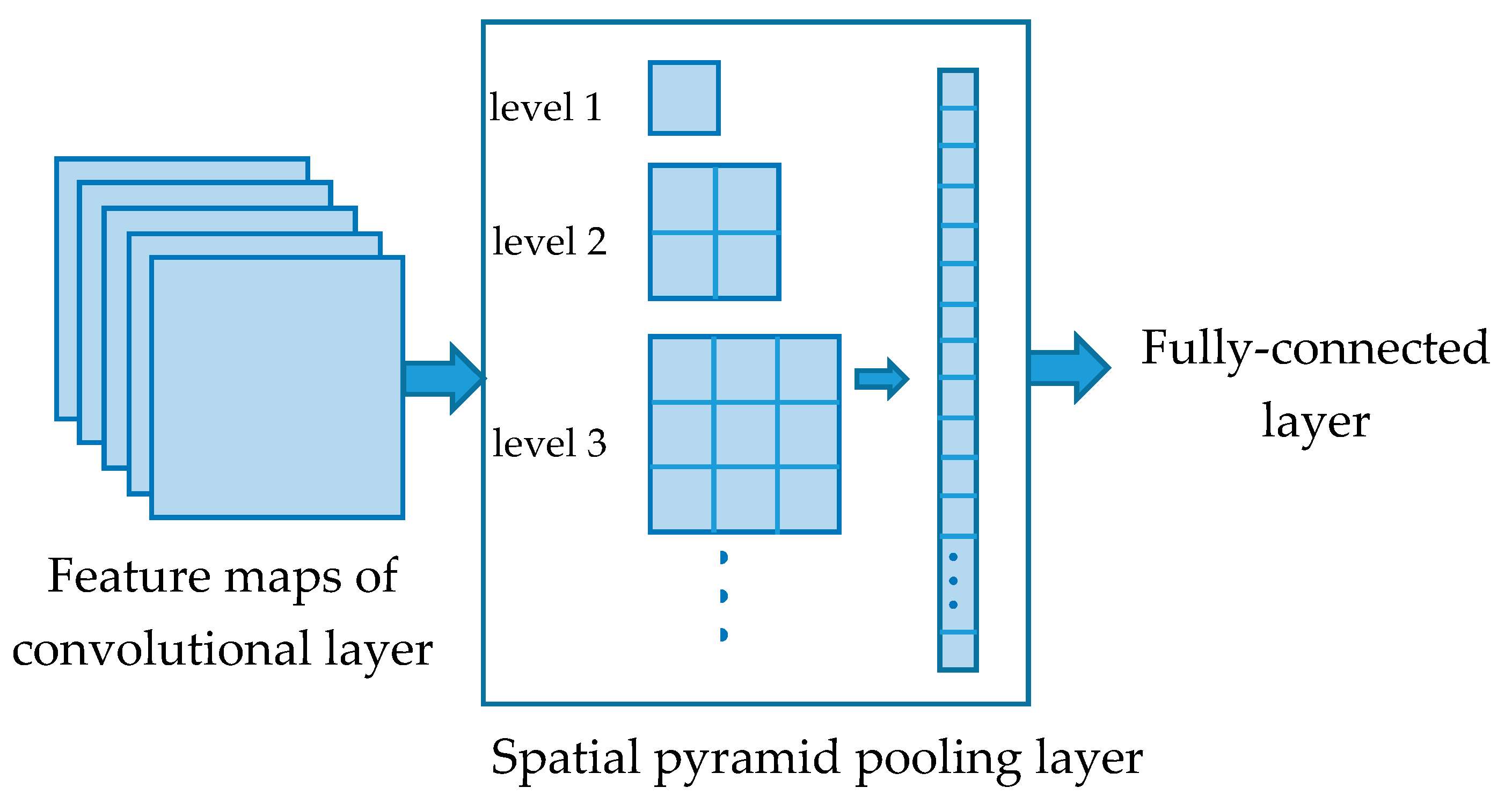

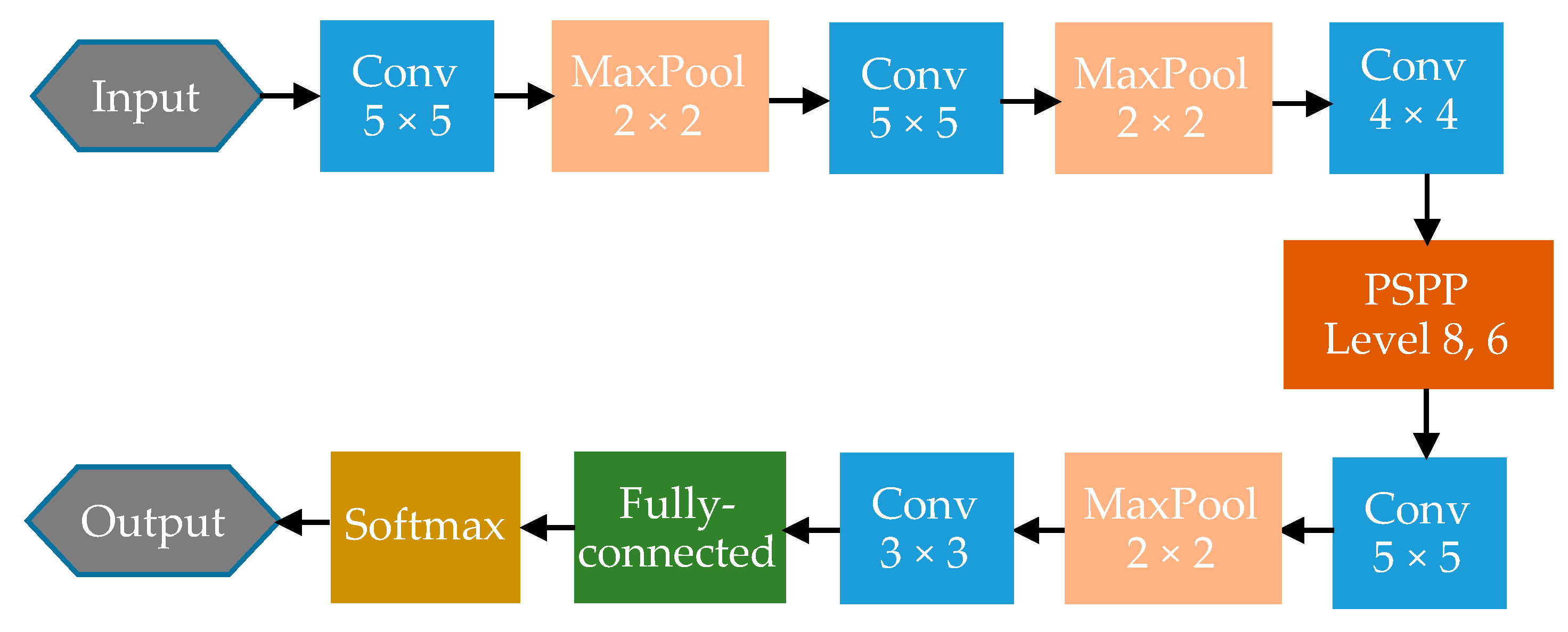

2.3.1. Pythagorean Spatial Pyramid Pooling Convolutional Neural Network

2.3.2. Pythagorean Spatial Pyramid Pooling Convolutional Neural Network Training Method

3. Experiment

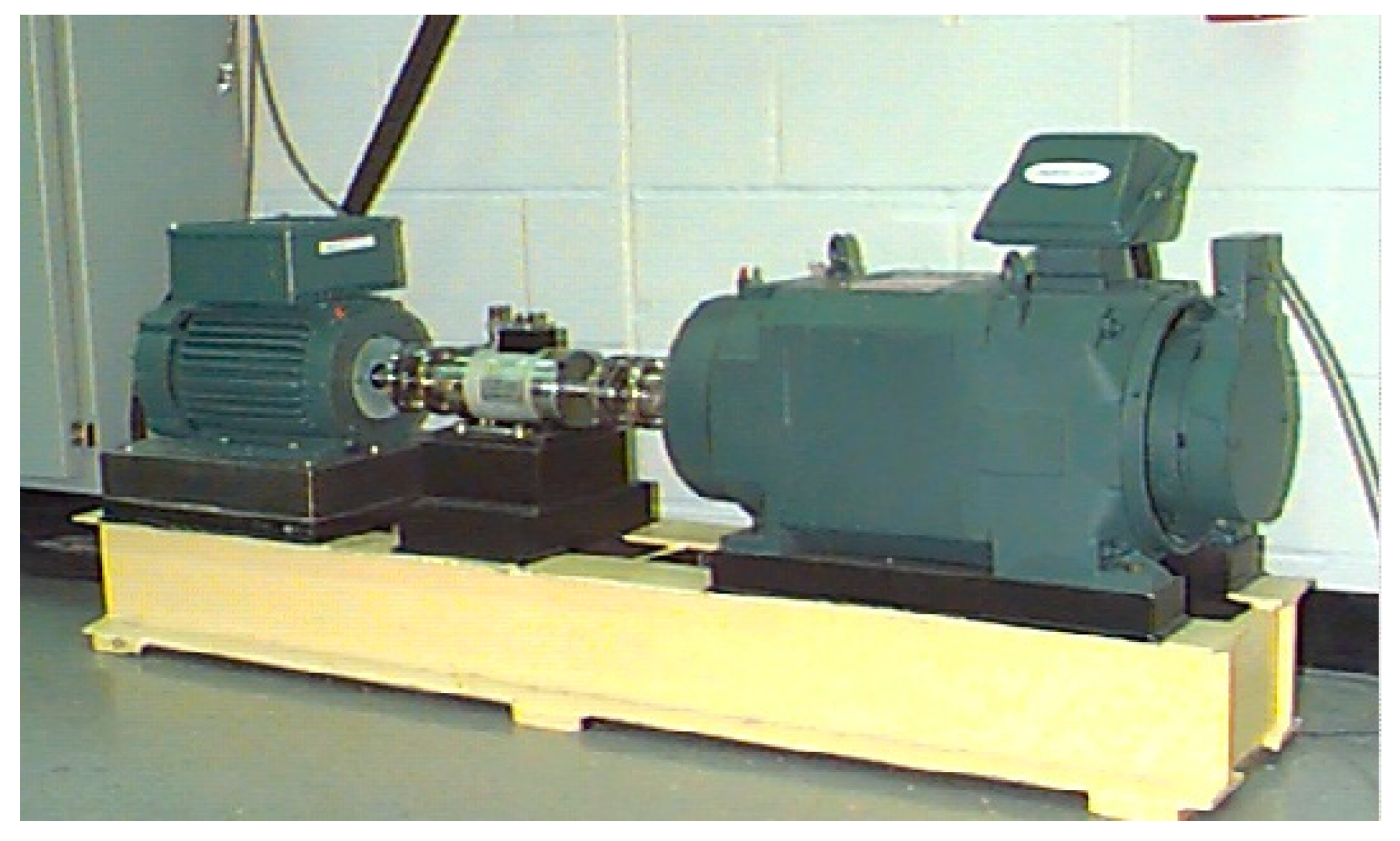

3.1. Constant Rotating Speed Data

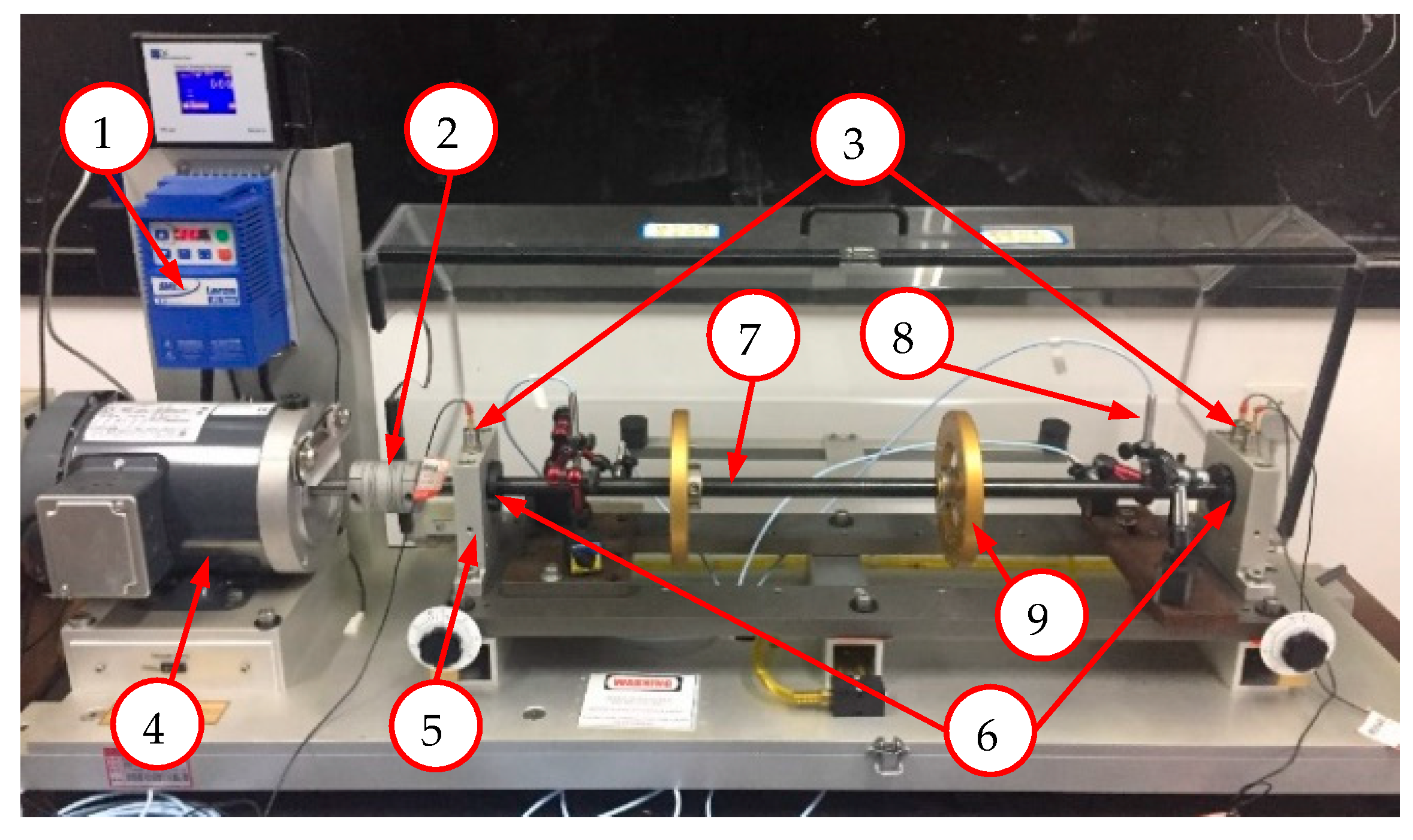

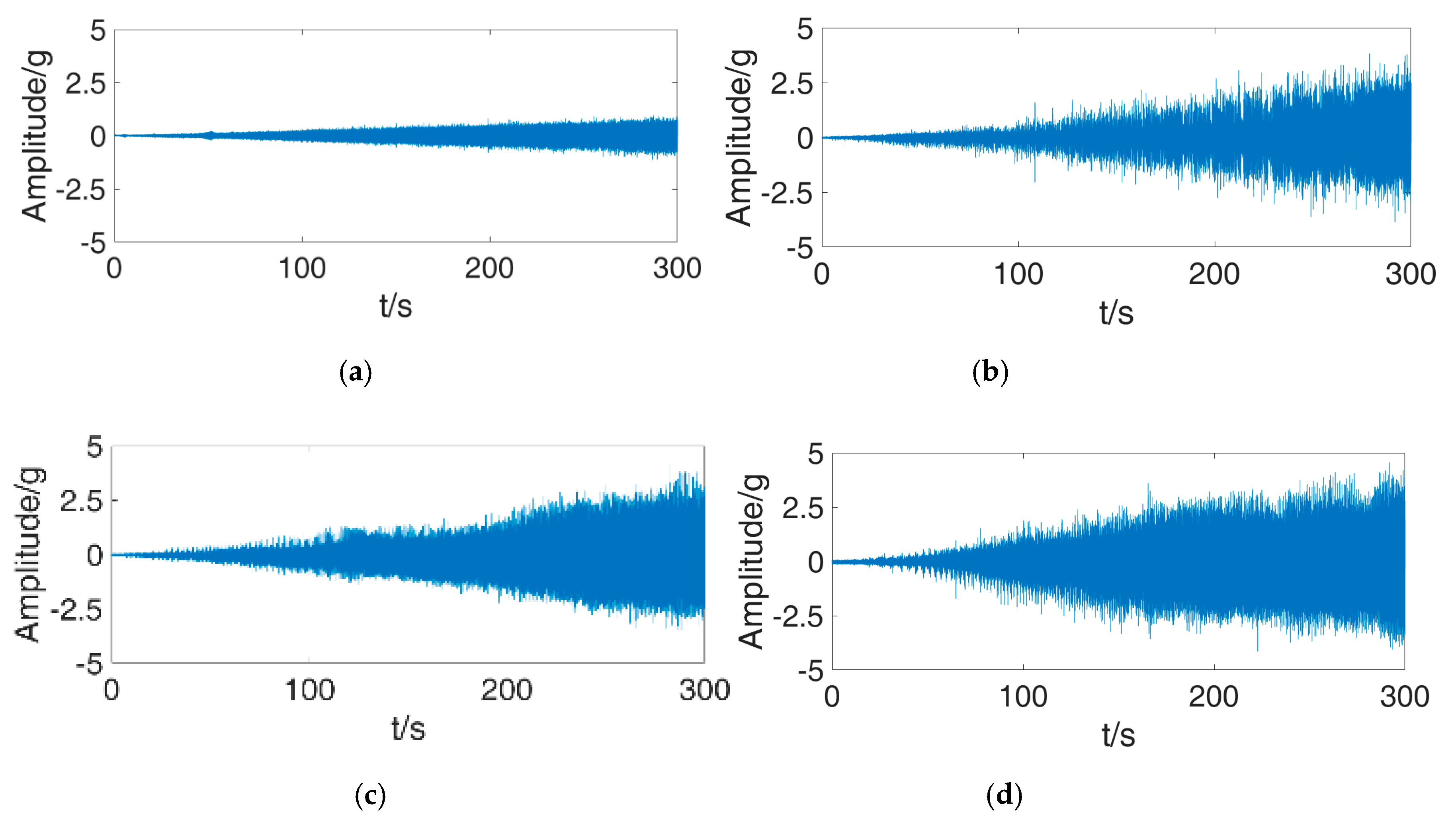

3.2. Variable Rotating Speed Data

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ali, J.B.; Fnaiech, N.; Saidi, L.; Chebel-Morello, B.; Fnaiech, F. Application of empirical mode decomposition and artificial neural network for automatic bearing fault diagnosis based on vibration signals. Appl. Acoust. 2015, 89, 16–27. [Google Scholar]

- Zhang, B.; Sconyers, C.; Byington, C.; Patrick, R.; Orchard, M.E.; Vachtsevanos, G. A Probabilistic Fault Detection Approach: Application to Bearing Fault Detection. IEEE Trans. Ind. Electron. 2011, 58, 2011–2018. [Google Scholar] [CrossRef]

- Tian, Y.; Ma, J.; Lu, C.; Wang, Z. Rolling bearing fault diagnosis under variable conditions using LMD-SVD and extreme learning machine. Mech. Mach. Theory 2015, 90, 175–186. [Google Scholar] [CrossRef]

- Li, Y.; Xu, M.; Wei, Y.; Huang, W. A new rolling bearing fault diagnosis method based on multiscale permutation entropy and improved support vector machine based binary tree. Measurement 2016, 77, 80–94. [Google Scholar] [CrossRef]

- Zhang, B.; Sconyers, C.; Orchard, M.; Patrick, R.; Vachtsevanos, G. Fault progression modeling: An application to bearing diagnosis and prognosis. In Proceedings of the 2010 American Control Conference, Baltimore, MD, USA, 30 June–2 July 2010; pp. 6993–6998. [Google Scholar]

- Hoochang, S.; Roth, H.R.; Gao, M.; Lu, L.; Xu, Z.; Nogues, I.; Summers, R.M. Deep Convolutional Neural Networks for Computer-Aided Detection: CNN Architectures, Dataset Characteristics and Transfer Learning. IEEE Trans. Med. Imaging 2016, 35, 1285. [Google Scholar]

- Abdulnabi, A.H.; Wang, G.; Lu, J.; Jia, K. Multi-Task CNN Model for Attribute Prediction. IEEE Trans. Multimed. 2015, 17, 1949–1959. [Google Scholar] [CrossRef]

- Ren, S.; He, K.; Girshick, R.; Sun, J. Faster R-CNN: Towards Real-Time Object Detection with Region Proposal Networks. IEEE Trans. Pattern Anal. Mach. Intell. 2017, 39, 1137–1149. [Google Scholar] [CrossRef] [PubMed]

- Kalchbrenner, N.; Grefenstette, E.; Blunsom, P. A Convolutional Neural Network for Modelling Sentences. arxiv, 2014; arXiv:1404.2188. [Google Scholar]

- Kamnitsas, K.; Ledig, C.; Newcombe, V.F.; Simpson, J.P.; Kane, A.D.; Menon, D.K.; Rueckert, D.; Glocker, B. Efficient multi-scale 3D CNN with fully connected CRF for accurate brain lesion segmentation. Med. Image Anal. 2016, 36, 61. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Georgoulas, G.; Orchard, M.; Saxena, A.; Brown, D.; Vachtsevanos, G.; Liang, S. Rolling element bearing feature extraction and anomaly detection based on vibration monitoring. In Proceedings of the 2008 16th Mediterranean Conference on Control and Automation, Ajaccio, France, 25–27 June 2008; pp. 1792–1797. [Google Scholar]

- Zhang, W.; Peng, G.; Li, C.; Chen, Y.; Zhang, Z. A New Deep Learning Model for Fault Diagnosis with Good Anti-Noise and Domain Adaptation Ability on Raw Vibration Signals. Sensors 2017, 17, 425. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.; Yao, B.; Zeng, N.; Chen, B.; He, Y.; Cao, X.; He, W. An Intelligent Gear Fault Diagnosis Methodology Using a Complex Wavelet Enhanced Convolutional Neural Network. Materials 2017, 10, 790. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Cai, Z.; Cai, Z.; Wang, Y. An intelligent fault diagnosis system for process plant using a functional HAZOP and DBN integrated methodology. Eng. Appl. Artif. Intell. 2015, 45, 119–135. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, X.; Zhang, B.; Zhang, G.; Niu, G.; Hu, C. Bearing Health Condition Prediction Using Deep Belief Network. In Proceedings of the Annual Conference of Prognostics and Health Management Society, Orlando, FL, USA, 2–5 October 2017. [Google Scholar]

- Bruin, T.D.; Verbert, K.; Babuška, R. Railway Track Circuit Fault Diagnosis Using Recurrent Neural Networks. IEEE Trans. Neural Netw. Learn. Syst. 2017, 28, 523–533. [Google Scholar] [CrossRef] [PubMed]

- Xia, M.; Li, T.; Xu, L.; Liu, L.; de Silva, C.W. Fault Diagnosis for Rotating Machinery Using Multiple Sensors and Convolutional Neural Networks. IEEE/ASME Trans. Mechatron. 2018, 23, 101–110. [Google Scholar] [CrossRef]

- Liu, R.; Meng, G.; Yang, B.; Sun, C.; Chen, X. Dislocated Time Series Convolutional Neural Architecture: An Intelligent Fault Diagnosis Approach for Electric Machine. IEEE Trans. Ind. Inform. 2017, 13, 1310–1320. [Google Scholar] [CrossRef]

- Wang, Y.; He, Z.; Zi, Y. Enhancement of signal denoising and multiple fault signatures detecting in rotating machinery using dual-tree complex wavelet transform. Mech. Syst. Signal Process. 2010, 24, 119–137. [Google Scholar] [CrossRef]

- Shen, C.; Wang, D.; Kong, F.; Peter, W.T. Fault diagnosis of rotating machinery based on the statistical parameters of wavelet packet paving and a generic support vector regressive classifier. Measurement 2013, 46, 1551–1564. [Google Scholar] [CrossRef]

- Hu, Q.; He, Z.; Zhang, Z.; Zi, Y. Fault diagnosis of rotating machinery based on improved wavelet package transform and SVMs ensemble. Mech. Syst. Signal Process. 2007, 21, 688–705. [Google Scholar] [CrossRef]

- YanPing, Z.; ShuHong, H.; JingHong, H.; Tao, S.; Wei, L. Continuous wavelet grey moment approach for vibration analysis of rotating machinery. Mech. Syst. Signal Process. 2006, 20, 1202–1220. [Google Scholar] [CrossRef]

- Zhang, D.; Sui, W.T.; Zhang, Y. Bearing Fault Diagnosis Based on Optimal Morlet Wavelet. Bearing 2009, 10, 48–51. [Google Scholar]

- Yan, R.; Gao, R.X. Base wavelet selection for bearing vibration signal analysis. Int. J. Wavel. Multiresolut. Inf. Process. 2009, 7, 411–426. [Google Scholar] [CrossRef]

- Han, H.; Han, Q.; Li, X.; Gu, J. Hierarchical spatial pyramid max pooling based on SIFT features and sparse coding for image classification. Iet Comput. Vis. 2013, 7, 144–150. [Google Scholar] [CrossRef]

- Malinowski, M.; Fritz, M. Learnable Pooling Regions for Image Classification. arXiv, 2013; arXiv:1301.3516. [Google Scholar]

- Russakovsky, O.; Kai, Y.; Kai, Y.; Fei-Fei, L. Object-Centric spatial pooling for image classification. In European Conference on Computer Vision; Springer: Berlin, Germany, 2012; pp. 1–15. [Google Scholar]

- Wang, G.; Fan, B.; Pan, C. Ordinal pyramid pooling for rotation invariant object recognition. In Proceedings of the IEEE International Conference on Acoustics, Speech and Signal Processing, Brisbane, QLD, Australia, 19–24 April 2015; pp. 1349–1353. [Google Scholar]

- Chen, L.; Zhou, Q.; Fang, W. Spatial Pyramid Pooling in Structured Sparse Representation for Flame Detection. In Proceedings of the International Conference on Internet Multimedia Computing and Service, Xi’an, China, 19–21 August 2016; pp. 310–313. [Google Scholar]

- Ou, Y.; Zheng, H.; Chen, S.; Chen, J. Vehicle logo recognition based on a weighted spatial pyramid framework. In Proceedings of the 17th International IEEE Conference on Intelligent Transportation Systems (ITSC), Qingdao, China, 8–11 October 2014; pp. 1238–1244. [Google Scholar]

- Kawai, Y.; Fujii, M. Semantic Concept Detection based on Spatial Pyramid Matching and Semi-supervised Learning. Ite Trans. Media Technol. Appl. 2013, 1, 190–198. [Google Scholar] [CrossRef]

- Celikkale, B.; Erdem, A.; Erdem, E. Visual Attention-Driven Spatial Pooling for Image Memorability. In Proceedings of the Computer Vision and Pattern Recognition Workshops, Portland, OR, USA, 23–28 June 2013; pp. 976–983. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Spatial Pyramid Pooling in Deep Convolutional Networks for Visual Recognition. IEEE Trans. Pattern Anal. Mach. Intell. 2014, 37, 1904–1916. [Google Scholar] [CrossRef] [PubMed]

- Yue, J.; Mao, S.; Li, M. A deep learning framework for hyperspectral image classification using spatial pyramid pooling. Remote Sens. Lett. 2016, 7, 875–884. [Google Scholar] [CrossRef]

- Toledo, J.I.; Sudholt, S.; Fornés, A.; Cucurull, J.; Fink, G.A.; Lladós, J. Handwritten Word Image Categorization with Convolutional Neural Networks and Spatial Pyramid Pooling. In Joint Iapr International Workshops on Statistical Techniques in Pattern Recognition; Springer International Publishing: Cham, Switzerland, 2016; pp. 543–552. [Google Scholar]

- Wang, P.; Cao, Y.; Shen, C.; Liu, L.; Shen, H.T. Temporal Pyramid Pooling Based Convolutional Neural Network for Action Recognition. IEEE Trans. Circuits Syst. Video Technol. 2017, 27, 2613–2622. [Google Scholar] [CrossRef]

- Xiong, Q.; Zhang, W.; Lu, T.; Mei, G.; Liang, S. A Fault Diagnosis Method for Rolling Bearings Based on Feature Fusion of Multifractal Detrended Fluctuation Analysis and Alpha Stable Distribution. Shock Vib. 2015, 2016, 1–12. [Google Scholar] [CrossRef]

- Guo, S.; Yang, T.; Gao, W.; Zhang, C. A Novel Fault Diagnosis Method for Rotating Machinery Based on a Convolutional Neural Network. Sensors 2018, 18, 1429. [Google Scholar] [CrossRef] [PubMed]

- Vedaldi, A.; Lenc, K. Matconvnet: Convolutional neural networks for Matlab. In Proceedings of the 23rd ACM International Conference on Multimedia, Brisbane, Australia, 26–30 October 2015; pp. 689–692. [Google Scholar]

| Input Size | Level | Filter | Stride | Output Size | Output Length |

|---|---|---|---|---|---|

| 15 × 15 | 1 | 15 | 15 | 1 × 1 | 30 |

| 2 | 8 | 7 | 2 × 2 | ||

| 3 | 5 | 5 | 3 × 3 | ||

| 4 | 4 | 3 | 4 × 4 | ||

| 20 × 20 | 1 | 20 | 20 | 1 × 1 | 30 |

| 2 | 10 | 10 | 2 × 2 | ||

| 3 | 7 | 6 | 3 × 3 | ||

| 4 | 5 | 5 | 4 × 4 |

| Method | Training Steps | Convergence Time/Min | Time of Each Step/Min | Accuracy/% |

|---|---|---|---|---|

| 1 | 63 | 324 | 5.14 | 92.43 |

| 2 | 51 | 263 | 5.16 | 92.52 |

| Fault | None (NO) | Ball (BA) | Inner Race (IR) | Outer Race (OR) | Total | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Diameters/in | 0 | 0.007 | 0.014 | 0.021 | 0.028 | 0.007 | 0.014 | 0.021 | 0.028 | 0.007 | 0.014 | 0.021 | |

| Training set size | 24720 | 10080 | 10080 | 10080 | 3360 | 10080 | 10080 | 10080 | 3360 | 30240 | 10080 | 30240 | 162480 |

| Test set size | 12360 | 5040 | 5040 | 5040 | 1680 | 5040 | 5040 | 5040 | 1680 | 15120 | 5040 | 15120 | 81240 |

| Layer | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CNN | Conv 5 × 5 × 1 50 | MaxPool 2 × 2 | Conv 5 × 5 × 50 50 | MaxPool 2 × 2 | Conv 4 × 4 × 50 100 | MaxPool 2 × 2 | Conv 5 × 5 × 100 100 | MaxPool 2 × 2 | Conv 4 × 4 × 100 200 | MaxPool 3 × 3 | FC |

| SPP-CNN | Conv 5 × 5 × 1 50 | MaxPool 2 × 2 | Conv 5 × 5 × 50 50 | MaxPool 2 × 2 | Conv 4 × 4 × 50 100 | MaxPool 2 × 2 | Conv 5 × 5 × 100 100 | SPP 5 | FC | ||

| PSPP-CNN | Conv 5 × 5 × 1 50 | MaxPool 2 × 2 | Conv 5 × 5 × 50 50 | MaxPool 2 × 2 | Conv 4 × 4 × 50 100 | PSPP (8,6) | Conv 5 × 5 × 100 100 | MaxPool 2 × 2 | Conv 3 × 3 × 100 200 | FC |

| Model | Number of Parameters | Training Steps | Convergence Time/Min | Accuracy/% |

|---|---|---|---|---|

| CNN | 1.1e6 | 38 | 208 | 97.86% |

| SPP-CNN | 1.5e6 | 48 | 281 | 97.23% |

| PSPP-CNN | 5.8e5 | 44 | 211 | 97.79% |

| Fault | None | Ball | Inner Race | Outer Race | Total | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Diameters/in | 0 | 0.007 | 0.014 | 0.021 | 0.028 | 0.007 | 0.014 | 0.021 | 0.028 | 0.007 | 0.014 | 0.021 | |

| Accuracy/% | 99.98 | 95.32 | 95.99 | 91.03 | 99.64 | 99.94 | 94.17 | 99.01 | 99.88 | 98.09 | 96.96 | 99.31 | 97.79 |

| Labels | NO 1800 rpm | IR 1800 rpm | OR 1800 rpm | BA 1800 rpm | NO 2400 rpm | IR 2400 rpm | OR 2400 rpm | BA 2400 rpm | NO 2900 rpm | IR 2900 rpm | OR 2900 rpm | BA 2900 rpm | Accuracy % |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NO | 2631 | 0 | 0 | 48 | 2686 | 1 | 0 | 17 | 2688 | 3 | 0 | 31 | 99.27 |

| IR | 0 | 2687 | 7 | 0 | 0 | 2685 | 5 | 3 | 0 | 2678 | 8 | 25 | 99.83 |

| OR | 0 | 1 | 2681 | 0 | 0 | 2 | 2683 | 0 | 0 | 7 | 2680 | 69 | 99.75 |

| BA | 57 | 0 | 0 | 2640 | 2 | 0 | 0 | 2668 | 0 | 0 | 0 | 2563 | 97.61 |

| Accuracy% | 97.88 | 99.96 | 99.74 | 98.21 | 99.93 | 99.89 | 99.81 | 99.26 | 100 | 99.63 | 99.70 | 95.35 | 99.11 |

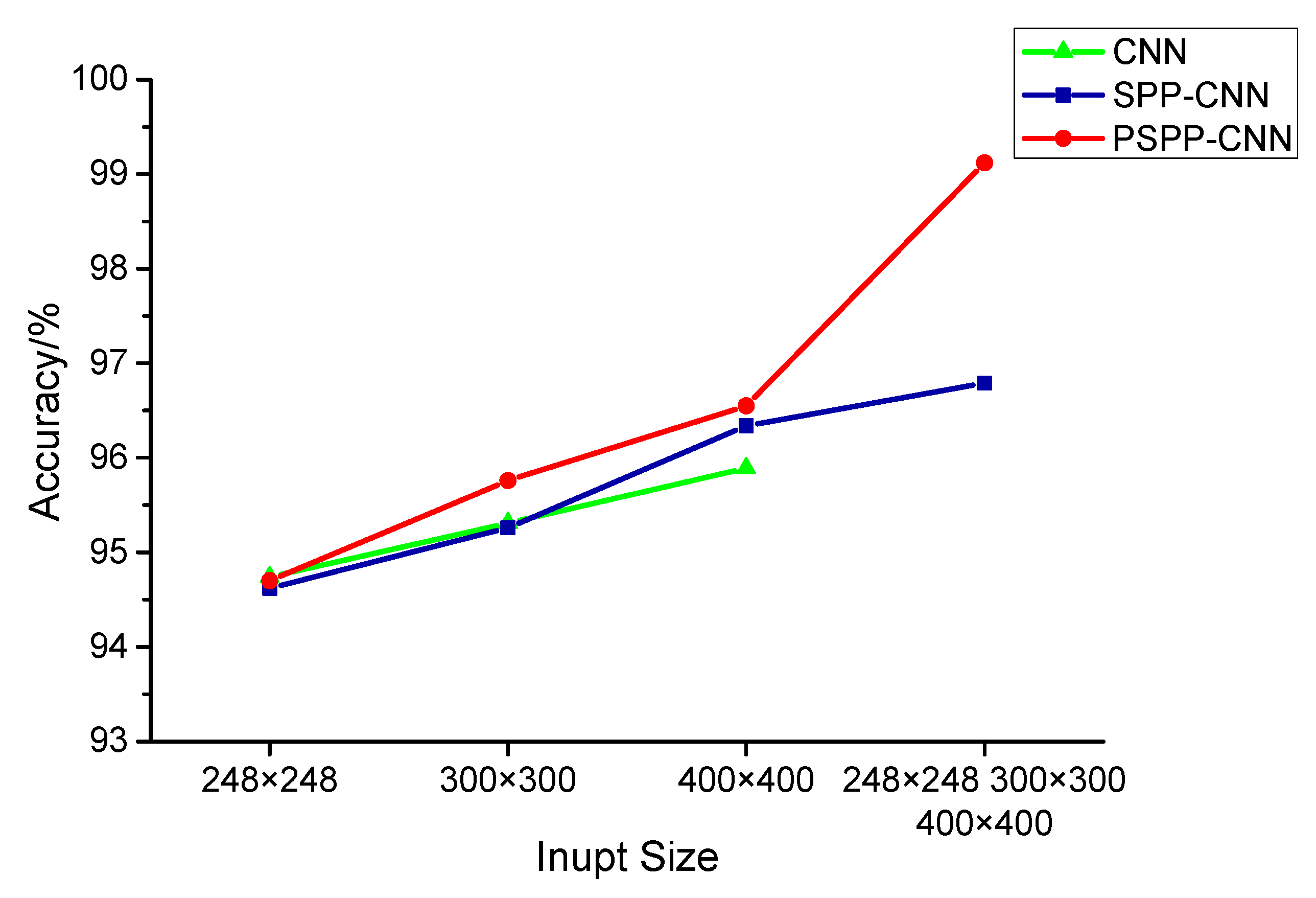

| Input Size | CNN | SPP-CNN | PSPP-CNN |

|---|---|---|---|

| 248 × 248 | 94.74 | 94.62 | 94.70 |

| 300 × 300 | 95.31 | 95.26 | 95.76 |

| 400 × 400 | 95.89 | 96.34 | 96.55 |

| 400 × 400, 300 × 300, 248 × 248 | 96.79 | 99.11 |

| Model | Deep Convolution Neural Network with Wide first-layer kernels | Dislocated Time Series Convolutional Neural Network | Resample-CNN | PSPP-CNN |

|---|---|---|---|---|

| Accuracy/% | 97.76 | 96.20 | 98.15 | 99.11 |

| Fault | None | Ball | Inner race | Outer race | Total |

|---|---|---|---|---|---|

| Accuracy/% | 90.23 | 91.82 | 92.05 | 92.95 | 91.76 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, S.; Yang, T.; Gao, W.; Zhang, C.; Zhang, Y. An Intelligent Fault Diagnosis Method for Bearings with Variable Rotating Speed Based on Pythagorean Spatial Pyramid Pooling CNN. Sensors 2018, 18, 3857. https://doi.org/10.3390/s18113857

Guo S, Yang T, Gao W, Zhang C, Zhang Y. An Intelligent Fault Diagnosis Method for Bearings with Variable Rotating Speed Based on Pythagorean Spatial Pyramid Pooling CNN. Sensors. 2018; 18(11):3857. https://doi.org/10.3390/s18113857

Chicago/Turabian StyleGuo, Sheng, Tao Yang, Wei Gao, Chen Zhang, and Yanping Zhang. 2018. "An Intelligent Fault Diagnosis Method for Bearings with Variable Rotating Speed Based on Pythagorean Spatial Pyramid Pooling CNN" Sensors 18, no. 11: 3857. https://doi.org/10.3390/s18113857

APA StyleGuo, S., Yang, T., Gao, W., Zhang, C., & Zhang, Y. (2018). An Intelligent Fault Diagnosis Method for Bearings with Variable Rotating Speed Based on Pythagorean Spatial Pyramid Pooling CNN. Sensors, 18(11), 3857. https://doi.org/10.3390/s18113857