A Multimodal Feature Fusion-Based Deep Learning Method for Online Fault Diagnosis of Rotating Machinery

Abstract

1. Introduction

2. Review of Deep Learning Theory

3. Differential Geometric Feature Fusion-Based Deep Neural Network Fault Diagnosis Method

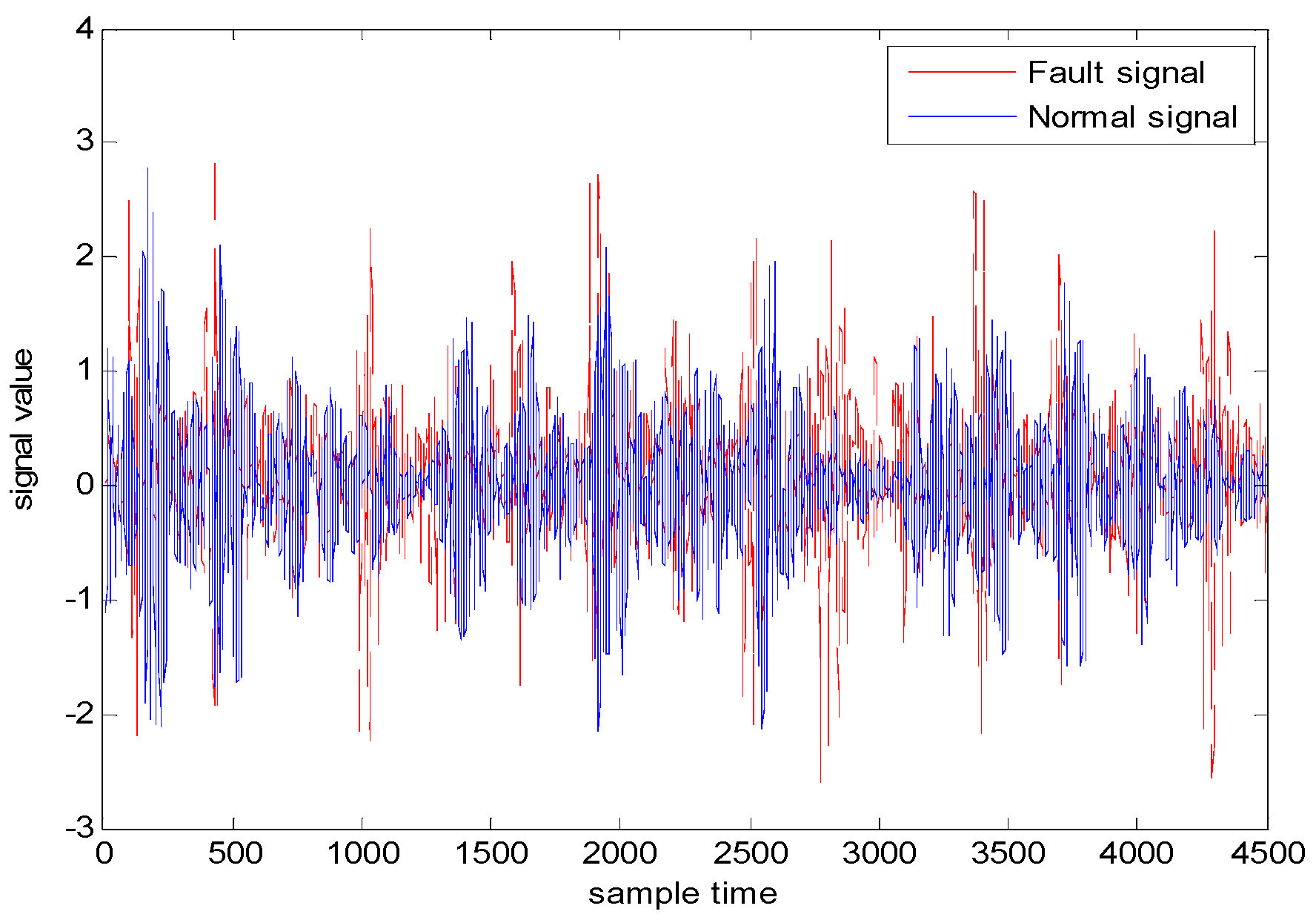

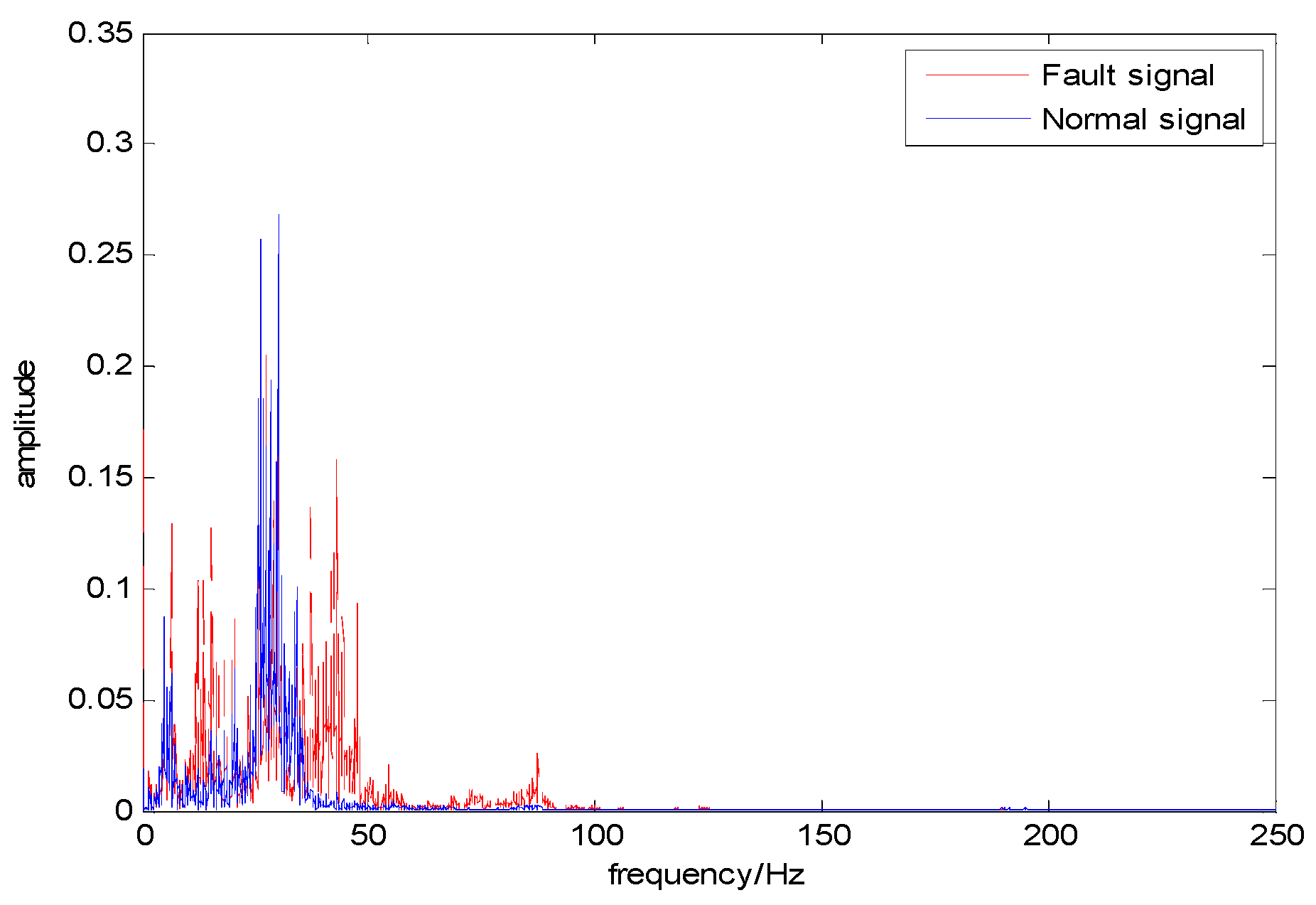

3.1. Frequency-Type Fault Analysis

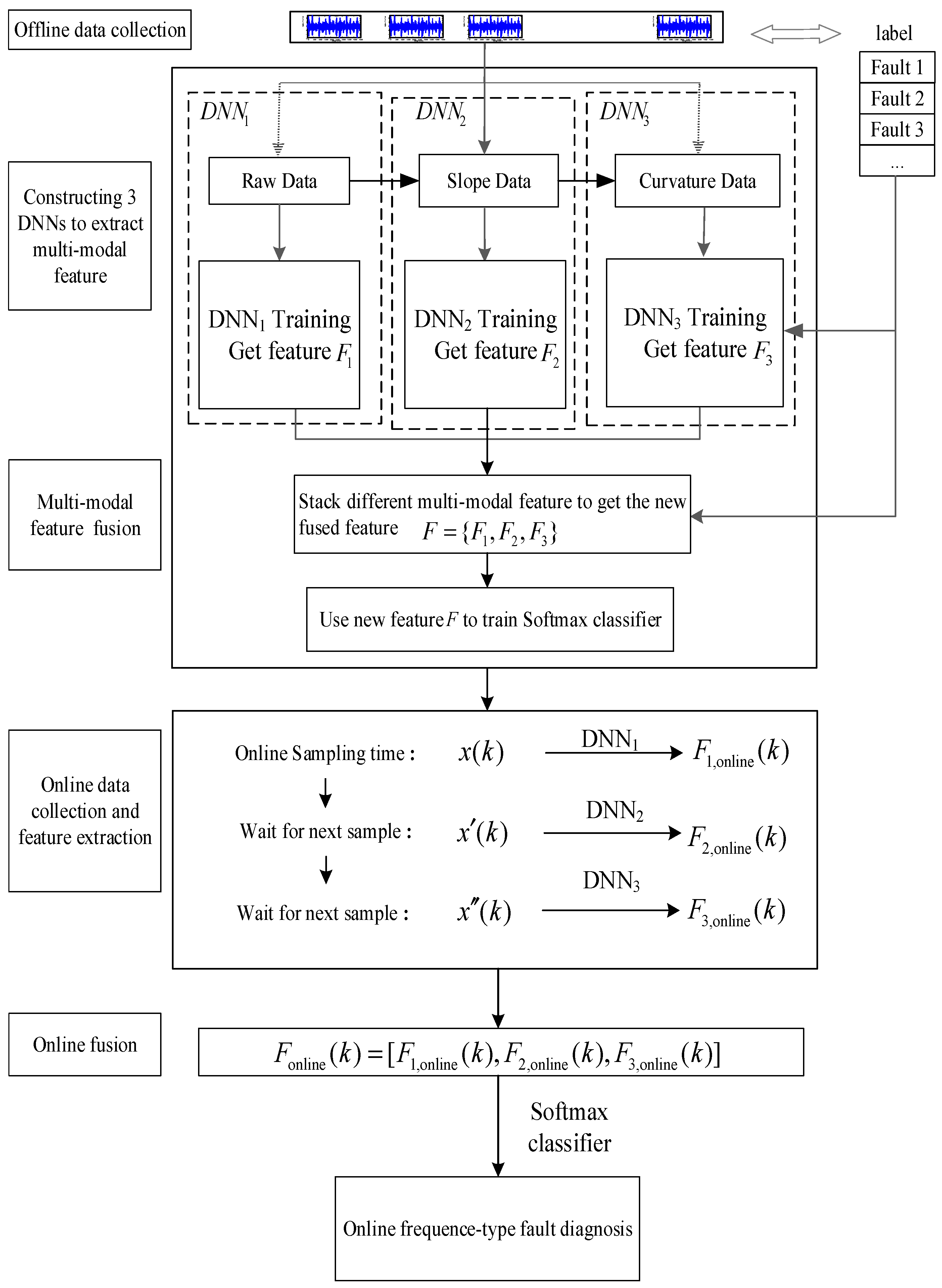

3.2. Differential Geometric Feature Fusion-Based Deep Neural Network-Based Online Fault Diagnosis Methods

3.2.1. Multimodal Differential Feature Extraction

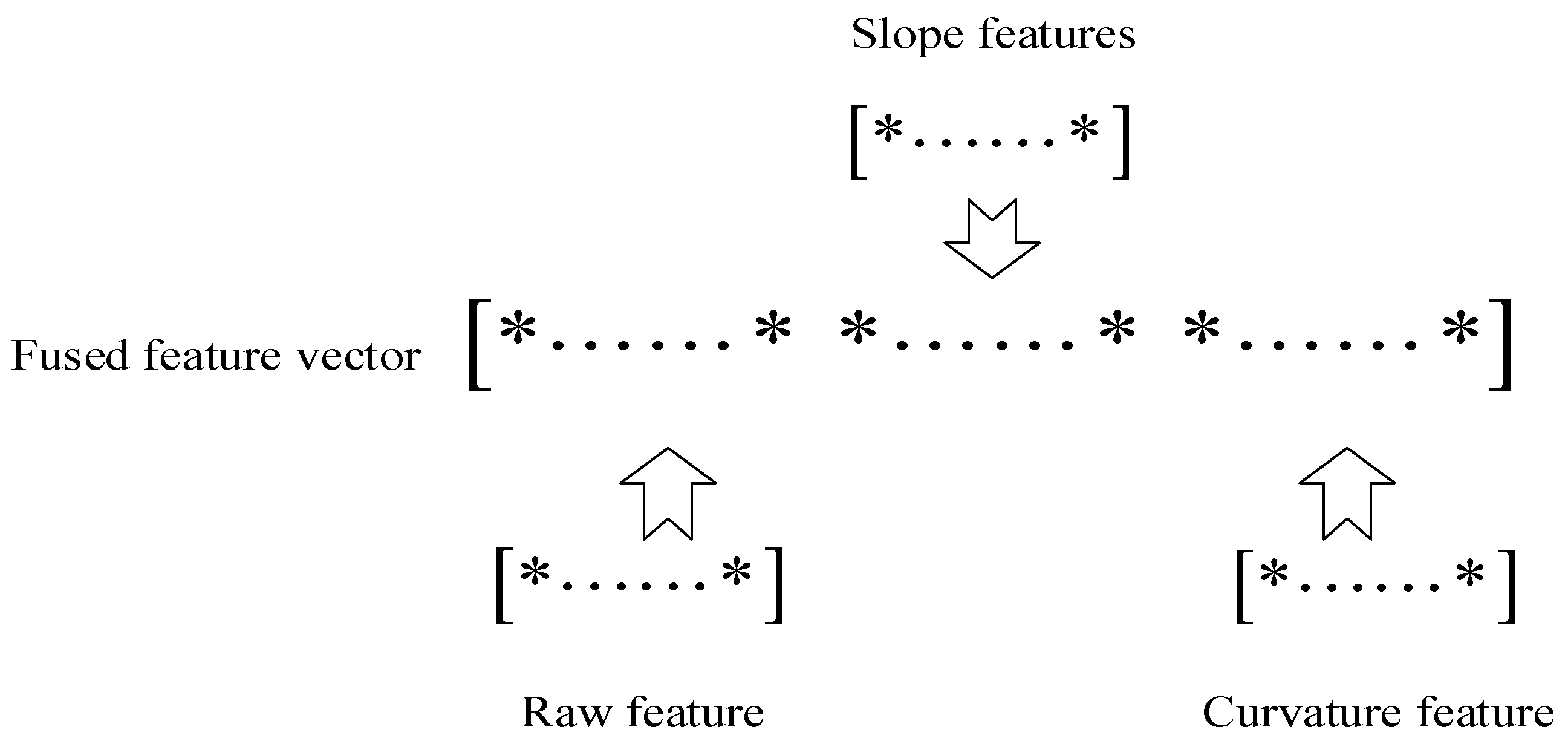

3.2.2. Multimodal Differential Feature Fusion

3.2.3. Online Diagnosis

4. Experiment and Analysis

4.1. Simulation Study

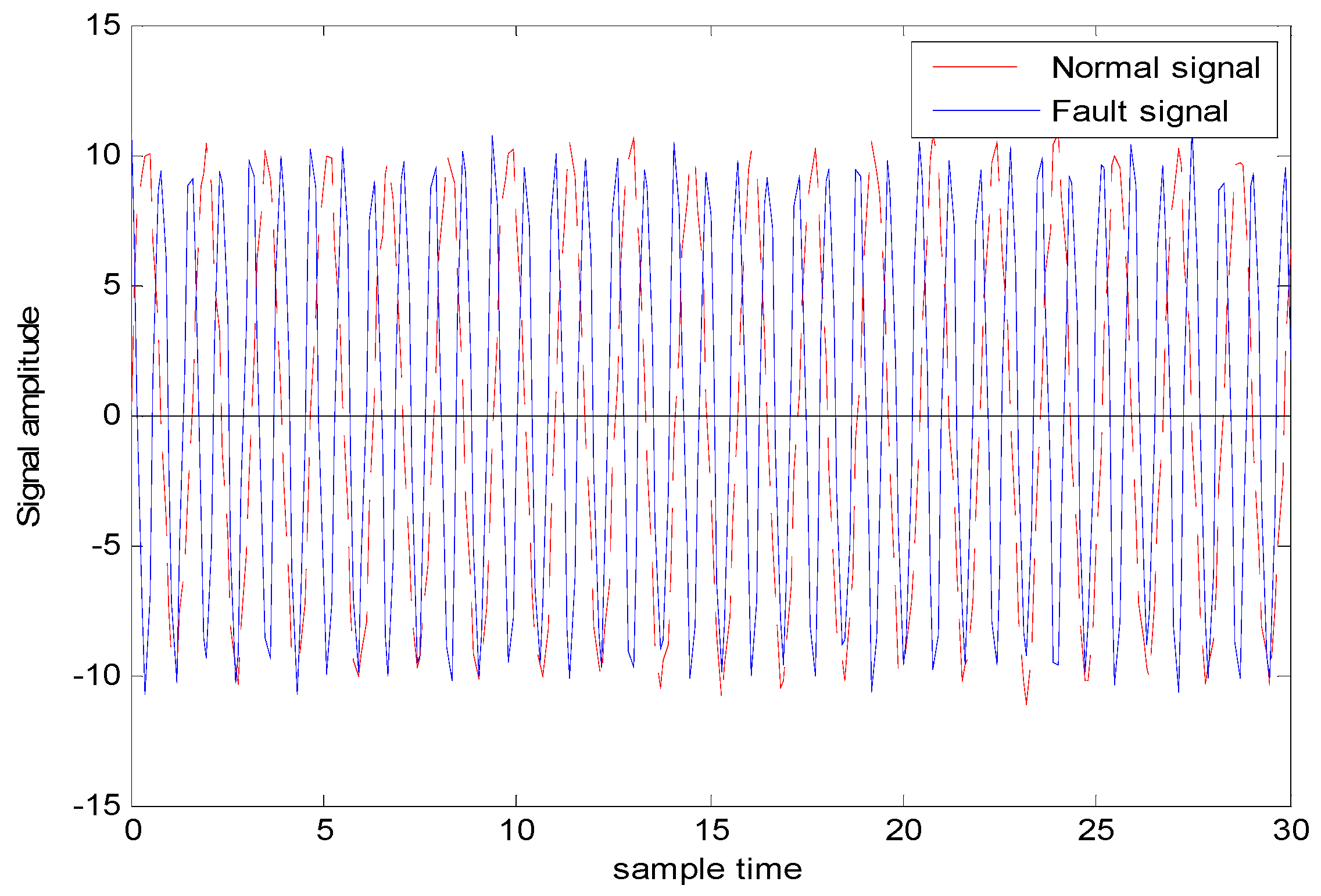

4.1.1. Description of Simulation Experimental Data

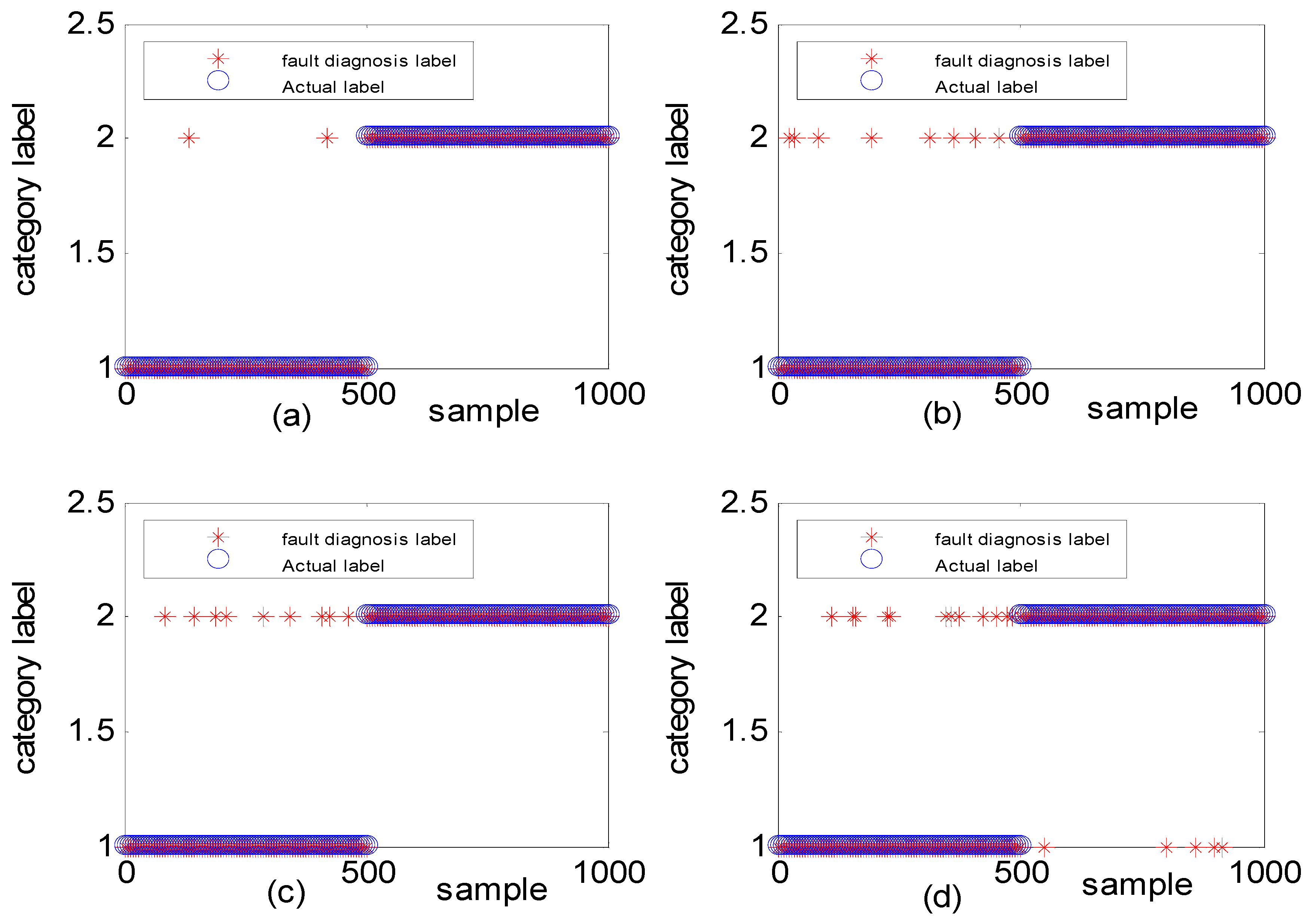

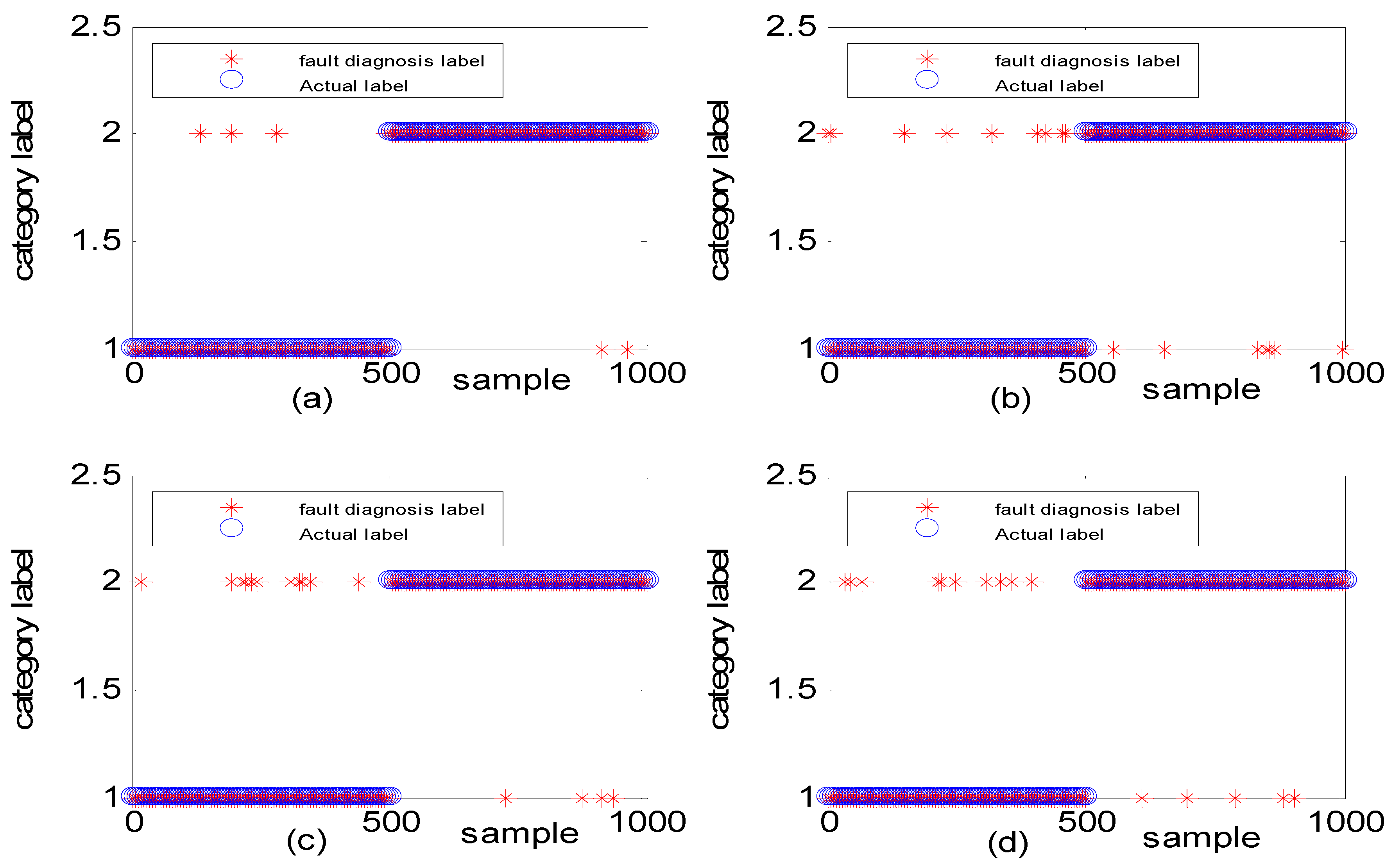

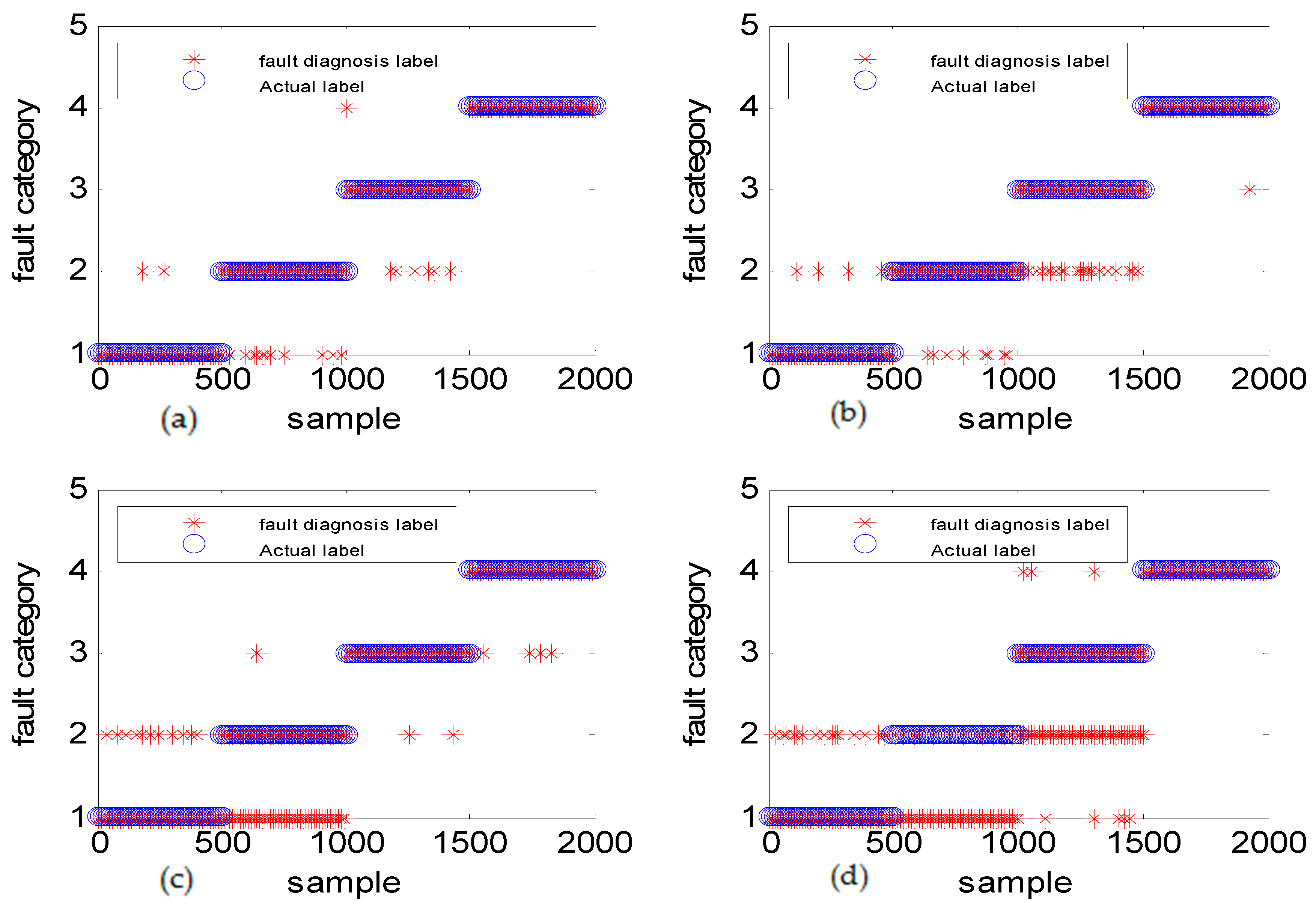

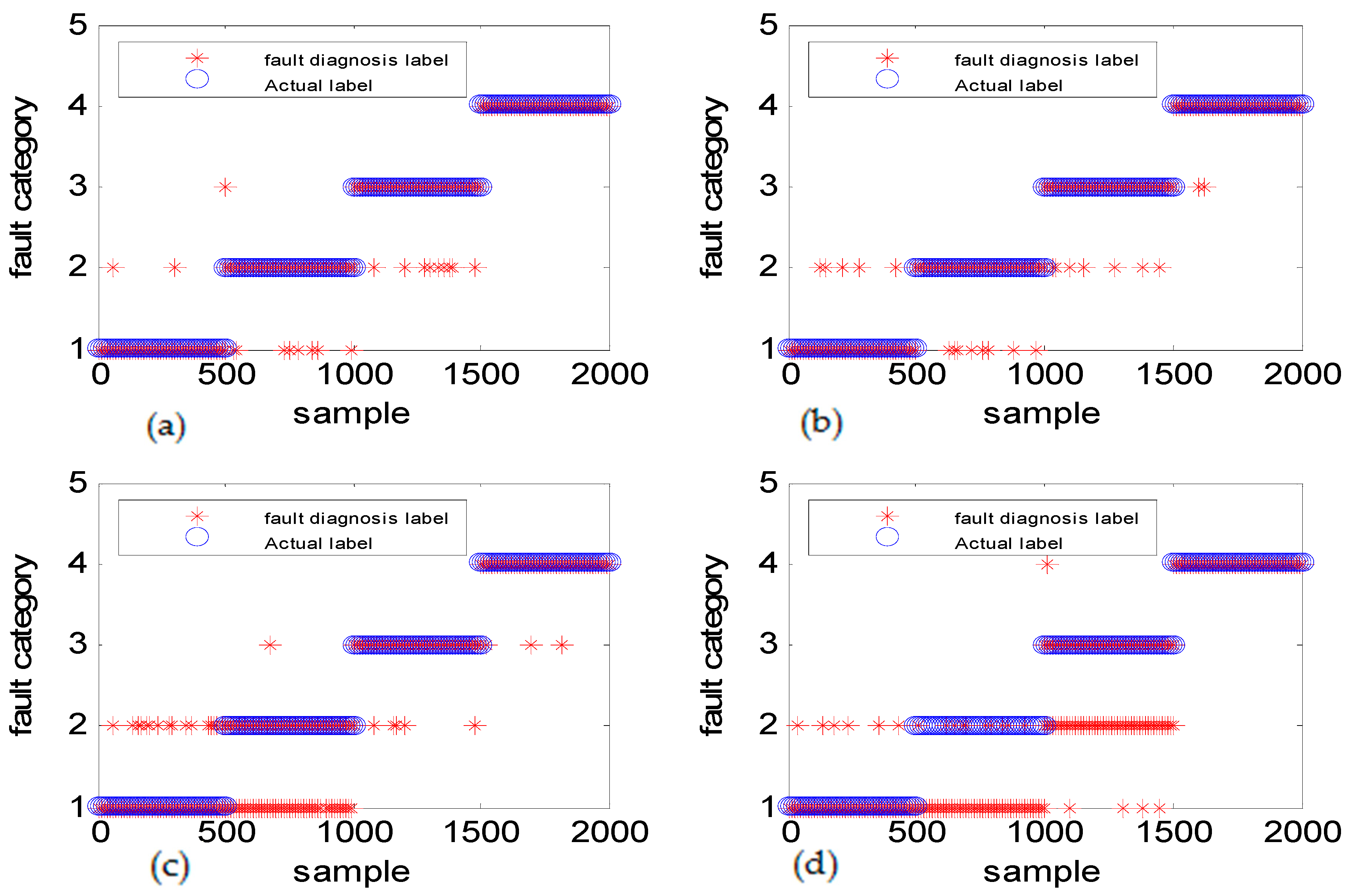

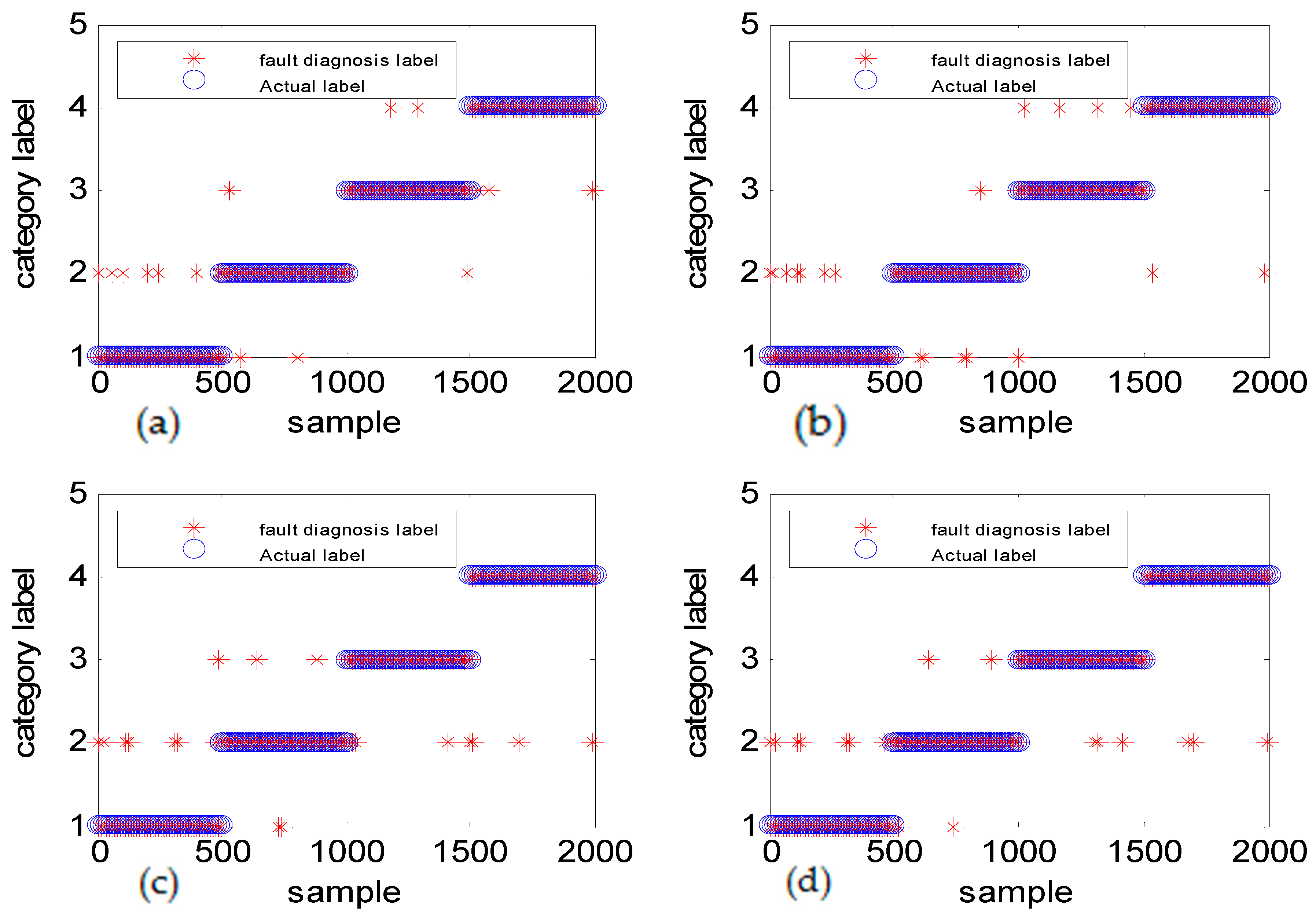

4.1.2. Analysis of Simulation and Experiment Results

4.2. Case Study

4.2.1. Description of the Experimental Platform

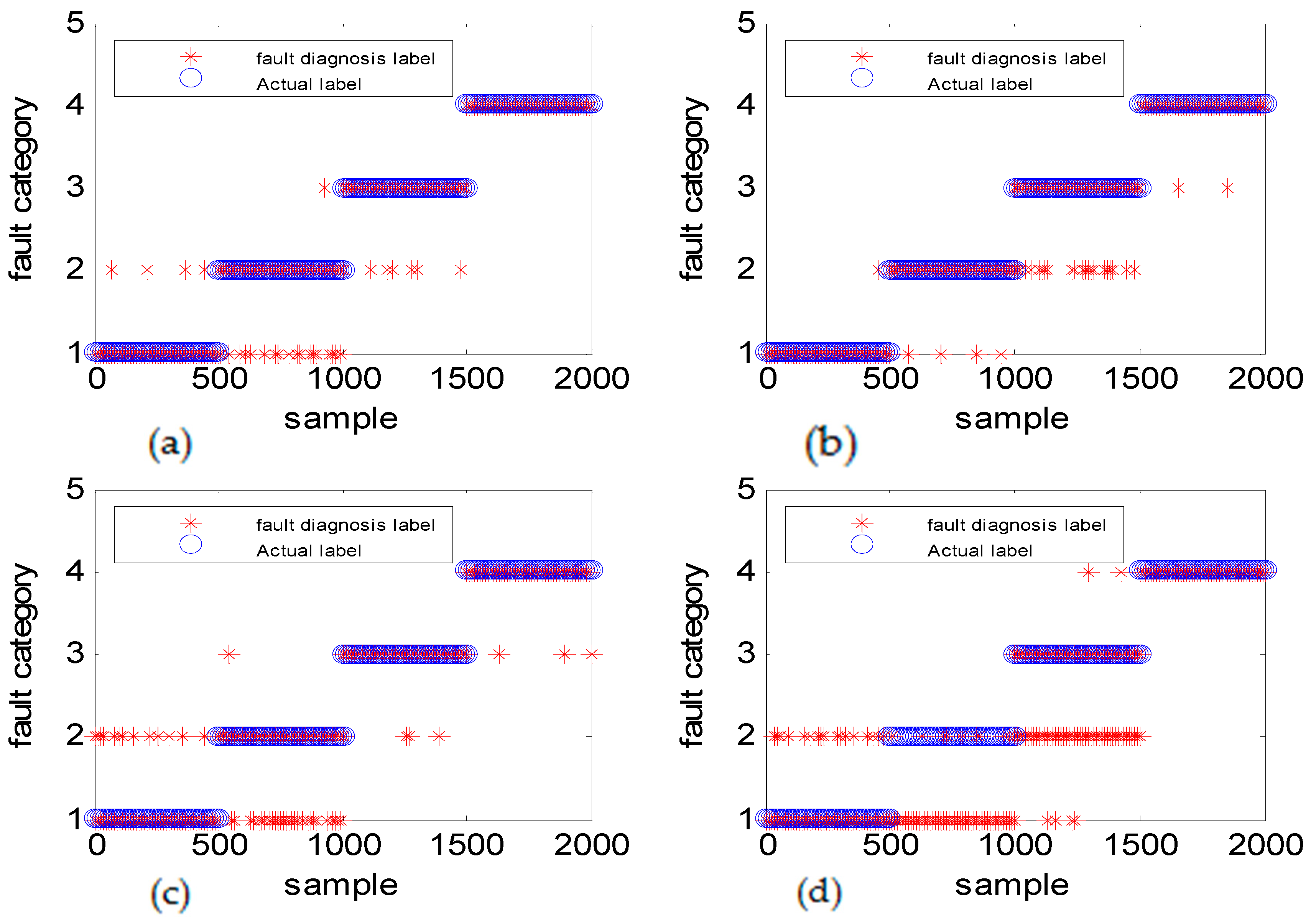

4.2.2. Case Study Result Analysis

4.2.3. Benchmark Dataset Testing

5. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Cao, H.; Fan, F.; Zhou, K.; He, Z. Wheel-bearing fault diagnosis of trains using empirical wavelet transform. Measurement 2016, 82, 439–449. [Google Scholar] [CrossRef]

- Lei, Y.G.; He, Z.J.; Zi, Y.Y. A new approach to intelligent fault diagnosis of rotating machinery. Expert. Syst. Appl. 2008, 35, 1593–1600. [Google Scholar] [CrossRef]

- Sun, W.; Shao, S.; Yan, R. Induction motor fault diagnosis based on deep neural network of sparse auto-encoder. J. Mech. Eng. 2016, 52, 65–71. [Google Scholar] [CrossRef]

- Qin, F.W.; Bai, J.; Yuan, W.Q. Research on intelligent fault diagnosis of mechanical equipment based on sparse deep neural networks. J. Vibroeng. 2017, 19, 2439–2455. [Google Scholar] [CrossRef]

- Ji, Y.; Wang, H.; Zhu, L.B. Review on operation state assessment and prognostics for mechanical equipment based on hidden markov model. J. Mech. Strength 2017, 3, 511–517. [Google Scholar]

- Gao, H.; Liang, L.; Chen, X.; Xu, G. Feature extraction and recognition for rolling element bearing fault utilizing short-time fourier transform and non-negative matrix factorization. Chin. J. Mech. Eng. 2015, 28, 96–105. [Google Scholar] [CrossRef]

- Wu, F.J.; Qu, L.S. Diagnosis of subharmonic faults of large roating machinery based on EMD. Mech. Syst. Signal Process. 2009, 23, 467–475. [Google Scholar] [CrossRef]

- Zhou, F.N.; Wen, C.L.; Leng, Y.B.; Chen, Z.G. A data-driven fault propagation analysis method. J. Chem. Ind. Eng. 2010, 8, 1993–2000. [Google Scholar]

- Frosini, L.; Harlisca, C.; Szabo, L. Induction machine bearing fault detection by means of statistical processing of the stray flux measurement. IEEE Trans. Ind. Electron. 2015, 62, 1846–1854. [Google Scholar] [CrossRef]

- Feng, Z.; Chen, X.; Wang, T. Time-varying demodulation analysis for rolling bearing fault diagnosis under variable speed conditions. J. Sound Vib. 2017, 400, 71–85. [Google Scholar] [CrossRef]

- Yi, C.; Lv, Y.; Ge, M.; Xiao, H.; Yu, X. Tensor Singular Spectrum Decomposition Algorithm Based on Permutation Entropy for Rolling Bearing Fault Diagnosis. Entropy 2017, 19, 139. [Google Scholar] [CrossRef]

- Wang, Y.; He, Z.; Zi, Y. A comparative study on the local mean decomposition and empirical mode decomposition and their applications to rotating machinery health diagnosis. J. Vib. Acoust. 2010. [Google Scholar] [CrossRef]

- Li, Z.; He, Z.J.; Zi, Y.Y.; Chen, X.F. Bearing condition monitoring based on shock pulse method and improved redundant lifting scheme. Math. Comput. Simul. 2008, 79, 318–338. [Google Scholar]

- Liu, F.; Shen, C.; He, Q.; Zhang, A.; Liu, Y.; Kong, F. Wayside bearing fault diagnosis based on a data-driven doppler effect eliminator and transient model analysis. Sensors 2014, 14, 8096–8125. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Chen, J.; Dong, G.; Xiao, W.; Zhou, X. The fault detection and diagnosis in rolling element bearings using frequency band entropy. J. Mech. Eng. Sci. 2012, 27, 87–99. [Google Scholar] [CrossRef]

- Ng, S.S.Y.; Tse, P.W.; Tsui, K.L. A One-Versus-All Class Binarization Strategy for Bearing Diagnostics of Concurrent Defects. Sensors 2014, 14, 1295–1321. [Google Scholar] [CrossRef] [PubMed]

- Zhu, D.; Bai, J.; Yang, S.X. A Multi-Fault Diagnosis Method for Sensor Systems Based on Principle Component Analysis. Sensors 2010, 10, 241–253. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Li, Q.; Cui, J.; Xi, J. Rolling bearing fault classification based on higher-order cumulants and BP neural network. In Proceedings of the 27th Chinese Control and Decision Conference (2015 CCDC), Qingdao, China, 23–25 May 2015; pp. 2664–2667. [Google Scholar]

- Zhang, N.; Che, L.Z.; Wu, X.J. Present Situation and Prospect of Data-driven Based Fault Diagnosis Technique. Comput. Sci. 2017, 44, 37–43. [Google Scholar]

- Wen, L.; Li, X.; Gao, L.; Zhang, Y. A New Convolutional Neural Network Based Data-Driven Fault Diagnosis Method. IEEE Trans. Ind. Electron. 2018, 65, 5990–5998. [Google Scholar] [CrossRef]

- Rashidi, B.; Singh, D.; Zhao, Q. Data-driven root-cause fault diagnosis for multivariate non-linear processes. Control Eng. Pract. 2017, 70, 134–147. [Google Scholar] [CrossRef]

- Zhang, F.; Zong, S.; Ling, Z. Fault diagnosis using kernel principal component analysis for hot strip mill. J. Eng. 2017, 2017, 527–535. [Google Scholar] [CrossRef]

- Widodo, A.; Yang, B.S. Application of nonlinear feature extraction and support vector machines for fault diagnosis of induction motors. Expert Syst. Appl. 2007, 33, 241–250. [Google Scholar] [CrossRef]

- Zhou, S.; Qian, S.; Chang, W.; Xiao, Y.; Cheng, Y. A Novel Bearing Multi-Fault Diagnosis Approach Based on Weighted Permutation Entropy and an Improved SVM Ensemble Classifier. Sensors 2018, 18, 1934. [Google Scholar] [CrossRef] [PubMed]

- Santos, P.; Villa, L.F.; Reñones, A.; Bustillo, A.; Maudes, J. An SVM-Based Solution for Fault Detection in Wind Turbines. Sensors 2015, 15, 5627–5648. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Q.; Shen, Y.; Li, H.; Xu, F. New Fault Recognition Method for Rotary Machinery Based on Information Entropy and a Probabilistic Neural Network. Sensors 2018, 18, 337. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Cheng, G.; Pang, Y.; Kuai, M. Planetary Gear Fault Diagnosis via Feature Image Extraction Based on Multi Central Frequencies and Vibration Signal Frequency Spectrum. Sensors 2018, 18, 1735. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Cheng, G.; Chen, X.; Pang, Y. Planetary gears feature extraction and fault diagnosis method based on VMD and CNN. Sensors 2018, 18, 1523. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, N.; Li, J.; Wang, G. Application of wavelet packet in motor fault diagnosis. J. Changchun Univ. Technol. 2013, 34, 387–391. [Google Scholar]

- Sohaib, M.; Kim, C.-H.; Kim, J.-M. A Hybrid Feature Model and Deep-Learning-Based Bearing Fault Diagnosis. Sensors 2017, 17, 2876. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Guo, Y.; Lin, W.; Yu, S.; Ji, Y. A Weighted Deep Representation Learning Model for Imbalanced Fault Diagnosis in Cyber-Physical Systems. Sensors 2018, 18, 1096. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Liu, G.; Tang, X.; Lu, J.; Hu, J. An Ensemble Deep Convolutional Neural Network Model with Improved D-S Evidence Fusion for Bearing Fault Diagnosis. Sensors 2017, 17, 1729. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Sánchez, R.-V.; Zurita, G.; Cerrada, M.; Cabrera, D. Fault Diagnosis for Rotating Machinery Using Vibration Measurement Deep Statistical Feature Learning. Sensors 2016, 16, 895. [Google Scholar] [CrossRef] [PubMed]

- Dhital, A.; Bancroft, J.B.; Lachapelle, G. A New Approach for Improving Reliability of Personal Navigation Devices under Harsh GNSS Signal Conditions. Sensors 2013, 13, 15221–15241. [Google Scholar] [CrossRef] [PubMed]

- Jing, L.; Wang, T.; Zhao, M.; Wang, P. An Adaptive Multi-Sensor Data Fusion Method Based on Deep Convolutional Neural Networks for Fault Diagnosis of Planetary Gearbox. Sensors 2017, 17, 414. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Peng, Z.; Wu, L.; Yao, B.; Guan, Y. Fault Diagnosis from Raw Sensor Data Using Deep Neural Networks Considering Temporal Coherence. Sensors 2017, 17, 549. [Google Scholar] [CrossRef] [PubMed]

- Lecun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 436, 521–7553. [Google Scholar] [CrossRef] [PubMed]

- Hinton, G.E.; Salakhutdinov, R.R. Reducing the Dimensionality of Data with Neural Networks. Science 2006, 313, 504–507. [Google Scholar] [CrossRef] [PubMed]

- Lu, C.; Wang, Z.Y.; Qin, W.L.; Ma, J. Fault diagnosis of rotary machinery components using a stacked denoising autoencoder-based health state identification. Signal Process. 2017, 130, 377–388. [Google Scholar] [CrossRef]

- Jia, F.; Lei, Y.G.; Lin, J.; Zhou, X.; Lu, N. Deep neural networks: A promising tool for fault characteristic mining and intelligent classification of rotating machinery with massive data. Mech. Syst. Signal Process. 2016, 72, 303–315. [Google Scholar] [CrossRef]

- Gan, M.; Wang, C.; Zhu, C. Construction of hierarchical diagnosis network based on deep learning and its application in the fault pattern recognition of rolling element bearings. Mech. Syst. Signal Process. 2016, 72–73, 92–104. [Google Scholar] [CrossRef]

- Li, C.; Sanchez, R.V.; Zurita, G.; Cerrada, M.; Cabrera, D.; Vásquez, R.E. Multimodal deep support vector classification with homologous features and its application to gearbox fault diagnosis. Neurocomputing 2015, 168, 119–127. [Google Scholar] [CrossRef]

- Pan, J.; Zi, Y.; Chen, J.; Zhou, Z.; Wang, B. Lifting Net A Novel Deep Learning Network with Layerwise Feature Learning from Noisy Mechanical Data for Fault Classification. IEEE Trans. Ind. Electron. 2018, 65, 4973–4982. [Google Scholar] [CrossRef]

- Zhao, M.; Kang, M.; Tang, B.; Pecht, M. Deep Residual Networks with Dynamically Weighted Wavelet Coefficients for Fault Diagnosis of Planetary Gearboxes. IEEE Trans. Ind. Electron. 2018, 65, 4290–4300. [Google Scholar] [CrossRef]

- Zhang, S.M.; Wang, F.L.; Tan, S.; Wang, S. A fully automatic onine mode identiflcation method for multi-mode processes. Acta Autom. Sin. 2016, 42, 60–80. [Google Scholar]

- Antoni, J.; Bonnardot, F.; Raad, A.; El Badaoui, M. Cyclostationary modelling of rotating machine vibration signals. Mech. Syst. Signal Process. 2004, 18, 1285–1314. [Google Scholar] [CrossRef]

- Jun-Qing, F.U.; Liao, K.P.; Shen, Z.W. Comparison studies on sampling method of rotating machine vibration signals in time and angular domain. J. Changsha Commun. Univ. 2007, 1, 015. [Google Scholar]

- Du, B.; Li, M.; Zhang, J.M. Implementation of Rotating Machine Vibration Signals Acquisition System. Instrum. Technol. 2004, 4, 38–39. [Google Scholar]

- Saimurugan, M.; Ramachandran, K.I. A comparative study of sound and vibration signals in detection of rotating machine faults using support vector machine and independent component analysis. Int. J. Data Anal. Tech. Strat. 2014, 6, 188–204. [Google Scholar] [CrossRef]

- Zhao, J.J.; Yang, G.Y.; Zhou, A.R.; Xiang, M.M. Kalman Filtering and Fault Diagnosis of Rotating Machines Vibration Signal. Instrum. Tech. Sens. 2014, 39, 80–83. [Google Scholar]

- Dai, H.H.; Zhou, J.Z.; Yu, J. Wavelet signal filtering and extracting characteristic of rotating machines vibration signal. Inf. Technol. 2004, 28, 4–7. [Google Scholar]

- Chen, Z.; Deng, S.; Chen, X.; Li, C.; Sanchez, R.V.; Qin, H. Deep neural networks-based rolling bearing fault diagnosis. Microelectron. Reliabil. 2017, 75, 327–333. [Google Scholar] [CrossRef]

- Haroun, S.; Seghir, A.N.; Touati, S. Short Time Zero Crossing Rate of Vibration Signal and Self-Organizing Map for Bearing Faults detection and Diagnosis. Int. Conf. Autom. Control Telecommun. Signals 2017, 65, 364–376. [Google Scholar]

- Bearing Data Centre, Western Reserve University. Available online: http://csegroups.case.edu/bearingdatacenter/home (accessed on 10 May 2018).

| Different Experimental Cases | Sampling Interval | Normal Observation | Fault Observation |

|---|---|---|---|

| Different amplitudes with different frequencies | 0.1 | ||

| Different amplitudes with the same frequencies | 0.1 | ||

| Different frequency with the same amplitudes | 0.1 |

| Training Parameter | |||

|---|---|---|---|

| Hidden layers | 6 | 4 | 5 |

| Number of neurons | 500/400/200/100/50/10 | 500/100/50/20/10 | 500/200/100/50/20/10 |

| Max number of epochs | 1000 | 1000 | 1000 |

| Learning rate | 0.01 | 0.02 | 0.01 |

| Data | DGFFDNN | DNN | DGFFBP | BP |

|---|---|---|---|---|

| Different amplitudes with different frequencies | 98.40 | 94.24 | 92.36 | 90.86 |

| Same frequency with different amplitudes | 94.34 | 92.01 | 90.69 | 87.04 |

| Same amplitudes with different frequencies | 93.06 | 73.54 | 62.87 | 54.36 |

| DGFFDNN | DNN | DGFFBP | BP | DNN with FFT | |

|---|---|---|---|---|---|

| Henan University Bearing Platform | |||||

| Different fault diameters (0.007, 0.014, 0.021, 0) | 98.54% | 90.14% | 88.16% | 80.13% | 99.37% |

| Different fault types (inner race, ball, out race, normal) | 97.63% | 89.53% | 86.42% | 70.84% | 99.24% |

| Case Western Reserve University Bearing Platform | |||||

| Different fault diameters (0.007, 0.014, 0.021, 0) | 97.73% | 89.52% | 86.37% | 60.24% | 99.16% |

| Different fault types (inner race, ball, out race, normal) Online diagnosis | 98.06% Yes | 89.52% Yes | 87.73% Yes | 73.56% Yes | 99.22% No |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, F.; Hu, P.; Yang, S.; Wen, C. A Multimodal Feature Fusion-Based Deep Learning Method for Online Fault Diagnosis of Rotating Machinery. Sensors 2018, 18, 3521. https://doi.org/10.3390/s18103521

Zhou F, Hu P, Yang S, Wen C. A Multimodal Feature Fusion-Based Deep Learning Method for Online Fault Diagnosis of Rotating Machinery. Sensors. 2018; 18(10):3521. https://doi.org/10.3390/s18103521

Chicago/Turabian StyleZhou, Funa, Po Hu, Shuai Yang, and Chenglin Wen. 2018. "A Multimodal Feature Fusion-Based Deep Learning Method for Online Fault Diagnosis of Rotating Machinery" Sensors 18, no. 10: 3521. https://doi.org/10.3390/s18103521

APA StyleZhou, F., Hu, P., Yang, S., & Wen, C. (2018). A Multimodal Feature Fusion-Based Deep Learning Method for Online Fault Diagnosis of Rotating Machinery. Sensors, 18(10), 3521. https://doi.org/10.3390/s18103521