LED-CT Scan for pH Distribution on a Cross-Section of Cell Culture Medium

Abstract

:1. Introduction

2. Materials and Methods

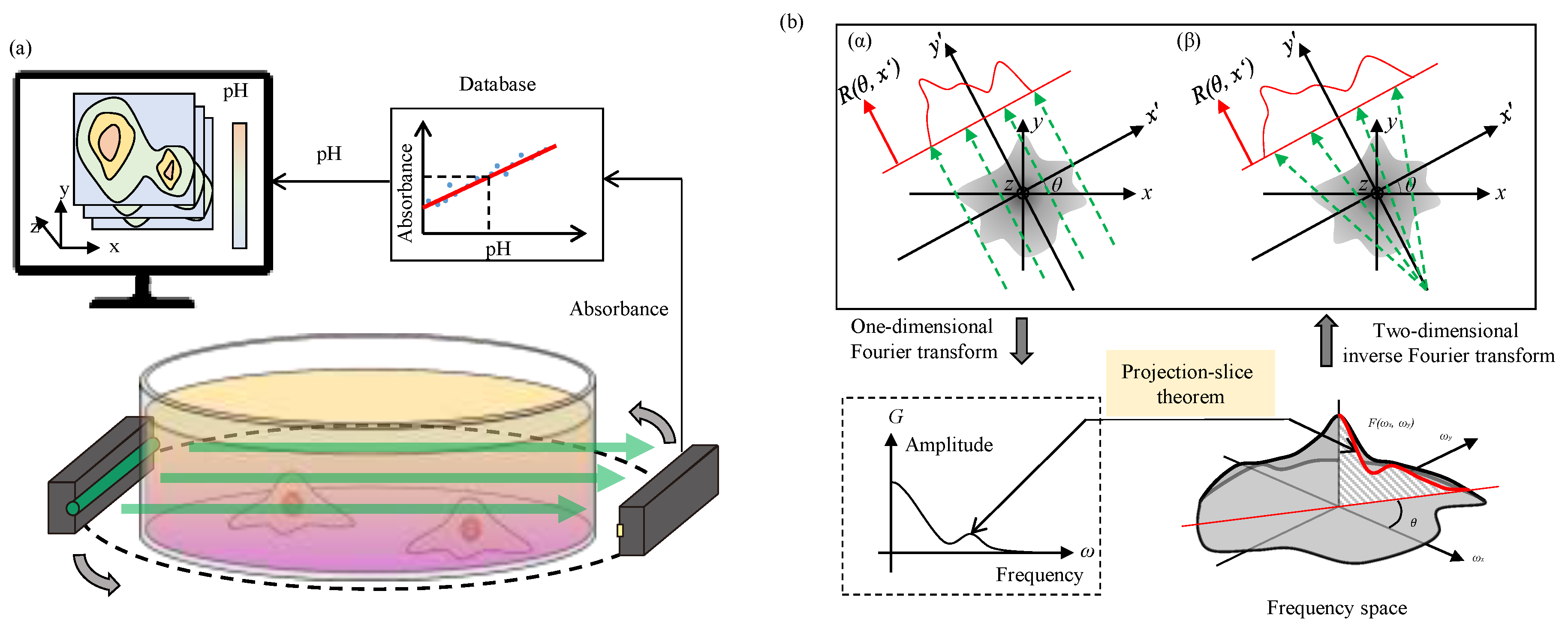

2.1. Basic Principle of CT Scan

2.2. Experimental Procedure

- The intensity of the light along x′ axis is measured without placing any object. This data is used as the background for calibration and is represented by I0(x′).

- A target object, such as a container with different pH liquid, is placed inside the sensing area, and the intensities along the x′ axis at different angles θ are measured. The data is denoted as I(θ, x′).

- The absorbance data R(θ, x′) is processed by Equation (7).

- Fourier-transformation of R(θ, x′) is applied for obtaining G(θ, ω) with Equations (2) and (7).

- The distribution of absorbance f(x, y) is obtained by Equation (6). We use “ifanbeam” function in MatLab to regenerate f(x, y) for the data analysis.

2.3. Experimental Setup

2.4. Response Speed

3. Results

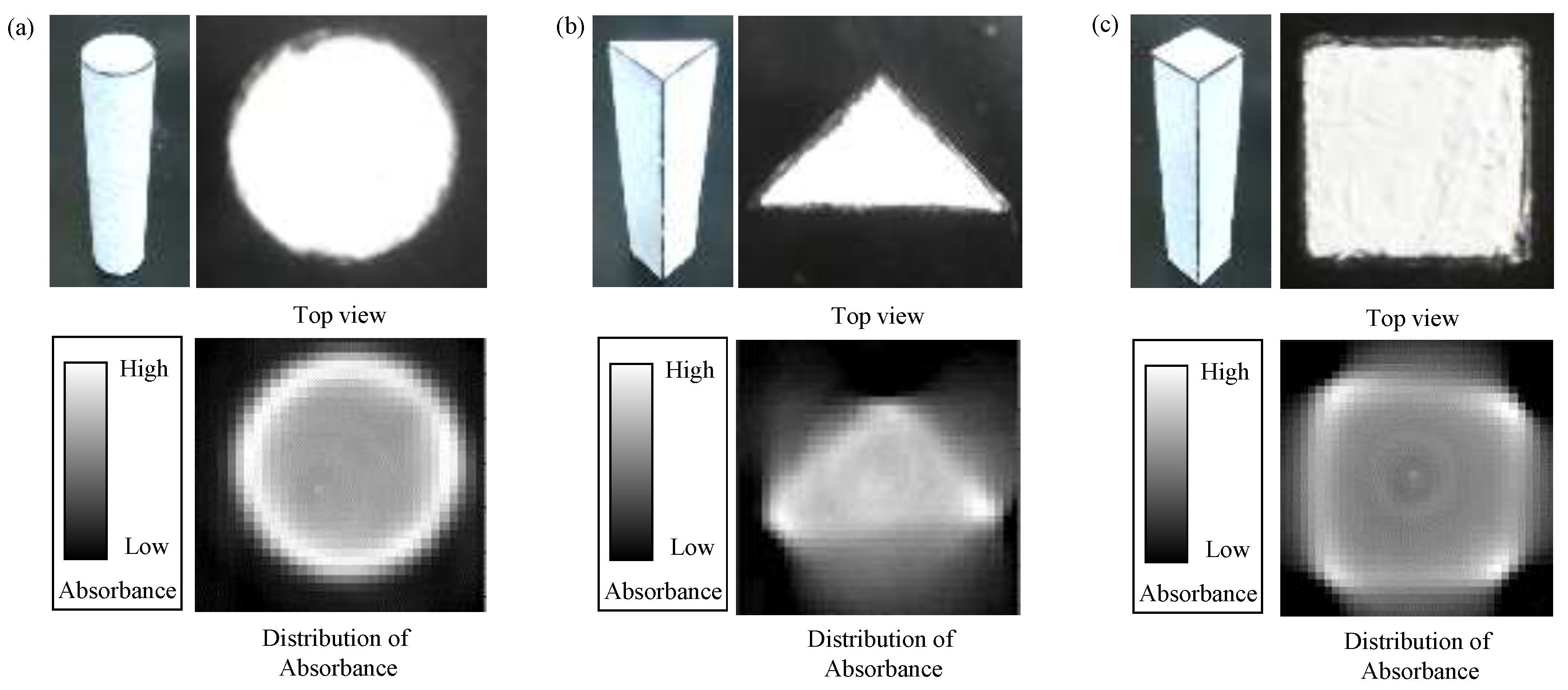

3.1. In Case of 100% Absorbance at the Surface

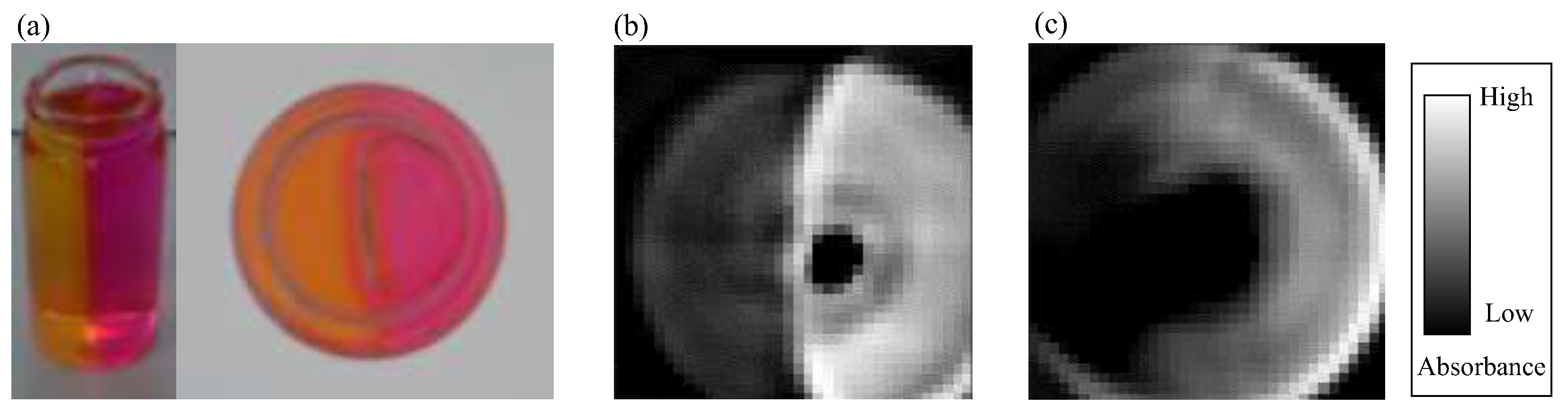

3.2. Application to pH Measurement

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

Appendix B

Appendix C

References

- Yokoyama, U.; Tonooka, Y.; Koretake, R.; Akimoto, T.; Gonda, Y.; Saito, J.; Umemura, M.; Fujita, T.; Sakuma, S.; Arai, F.; et al. Arterial graft with elastic layer structure grown from cells. Sci. Rep. 2017, 7, 140. [Google Scholar] [CrossRef] [PubMed]

- Horade, M.; Tsai, C.D.; Ito, H.; Higashino, N.; Akai, T.; Yokoyama, U.; Ishikawa, Y.; Sakuma, S.; Arai, F.; Kaneko, M. On-Chip Cell Gym. In Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems, Las Vegas, NV, USA, 22–26 January 2017; pp. 603–604. [Google Scholar]

- McAdams, T.A.; Miller, W.M.; Papoutsakis, E.T. Variations in culture pH affect the cloning efficiency and differentiation of progenitor cells in ex vivo haemopoiesis. Br. J. Haematol. 1997, 97, 889–895. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.L.; Tang, J.S.; Chiu, T.H.; Yang, Y.R. Influence of external and intracellular pH on propofol-induced responses in rat locus coeruleus neurons. Eur. J. Pharmacol. 2006, 545, 115–122. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Miller, W.M.; Papoutsakis, E.T. Higher pH promotes megakaryocytic maturation and apoptosis. Stem Cells 2002, 20, 320–328. [Google Scholar] [CrossRef] [PubMed]

- Teo, A.; Mantalaris, A.; Lim, M. Influence of culture pH on proliferation and cardiac differentiation of murine embryonic stem cells. Biochem. Eng. J. 2014, 90, 8–15. [Google Scholar] [CrossRef]

- Oura, M.; Kubo, H.; Yamamori, S.; Takeda, S.; Shimizu, T.; Okano, T. Development of Cell Culture Monitoring System and Novel Non-Contact pH Measurement. In Proceedings of the International Conference of the IEEE Engineering in Medicine and Biology Society, Boston, MA, USA, 30 August–3 September 2011; pp. 22–25. [Google Scholar]

- Rogge, C.; Zinn, S.; Prosposito, P.; Francini, R.; Foitzik, A.H. Transmitted light pH optode for small sample volumes. J. Sens. Sens. Syst. 2017, 6, 351–359. [Google Scholar] [CrossRef]

- Chen, H.; Wang, X.; Song, X.; Zhou, T.; Jiang, Y.; Chen, X. Colorimetric optical pH sensor production using a dual-color system. Sens. Actuators B Chem. 2010, 146, 278–282. [Google Scholar] [CrossRef]

- Capel-Cuevas, S.; Cuéllar, M.; de Orbe-Payá, I.; Pegalajar, M.; Capitán-Vallvey, L. Full-range optical pH sensor based on imaging techniques. Anal. Chim. Acta 2010, 681, 71–81. [Google Scholar] [CrossRef] [PubMed]

- Wolfbeis, O.S.; Rodriguez, N.V.; Werner, T. LED-compatible fluorosensor for measurement of near-neutral pH values. Microchim. Acta 1992, 108, 133–141. [Google Scholar] [CrossRef]

- Petersosn, J.I.; Goldstein, S.R.; Fitzgerald, R.V.; Buckhold, D.K. Fiber Optic pH Probe for Physiological Use. Anal. Chem. 1980, 52, 864–869. [Google Scholar] [CrossRef]

- Kostov, Y.; Tzonkov, S.; Yotova, L.; Krystev, M. Membranes for optical pH sensors. Anal. Chim. Acta 1993, 280, 15–19. [Google Scholar] [CrossRef]

- Brooks, R.A.; Di Chiro, G. Principles of computer assisted tomography (CAT) in radiographic and radioisotopic imaging. Phys. Med. Biol. 1976, 21, 689–732. [Google Scholar] [CrossRef] [PubMed]

- Reigber, A.; Moreira, A. First Demonstration of Airborne SAR Tomography Using Multibaseline L-Band Data. IEEE Trans. Geosci. Remote Sens. 2000, 38, 2142–2152. [Google Scholar] [CrossRef]

- Sauer, K.; Bouman, C. A local update strategy for iterative reconstruction from projections. IEEE Trans. Signal Process. 1993, 41, 534–548. [Google Scholar] [CrossRef]

- Bracewell, R.N.; Riddle, A.C. Inversion of Fan-Beam Scans in Radio Astronomy. Astrophys. J. 1967, 150, 427–434. [Google Scholar] [CrossRef]

- Horn, B.K.P. Fan-Beam Reconstruction Methods. Proc. IEEE 1979, 67, 1616–1623. [Google Scholar] [CrossRef]

- Malkaj, P.; Dalas, E.; Vitoratos, E.; Sakkopoulos, S. pH electrodes constructed from polyaniline/zeolite and polypyrrole/zeolite conductive blends. Appl. Polym. 2006, 101, 1853–1856. [Google Scholar] [CrossRef]

- Kawaguchi, T.; Hishida, K.; Maeda, M. Three dimensional CT measurement of CO2 gas dissolution into liquid by pH laser absorption. J. Vis. Soc. Jpn. 2003, 23, 169–170. (In Japanese) [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Higashino, N.; Takayama, T.; Ito, H.; Horade, M.; Yamaguchi, Y.; Dylan Tsai, C.-H.; Kaneko, M. LED-CT Scan for pH Distribution on a Cross-Section of Cell Culture Medium. Sensors 2018, 18, 191. https://doi.org/10.3390/s18010191

Higashino N, Takayama T, Ito H, Horade M, Yamaguchi Y, Dylan Tsai C-H, Kaneko M. LED-CT Scan for pH Distribution on a Cross-Section of Cell Culture Medium. Sensors. 2018; 18(1):191. https://doi.org/10.3390/s18010191

Chicago/Turabian StyleHigashino, Nobuya, Toshio Takayama, Hiroaki Ito, Mitsuhiro Horade, Yasutaka Yamaguchi, Chia-Hung Dylan Tsai, and Makoto Kaneko. 2018. "LED-CT Scan for pH Distribution on a Cross-Section of Cell Culture Medium" Sensors 18, no. 1: 191. https://doi.org/10.3390/s18010191

APA StyleHigashino, N., Takayama, T., Ito, H., Horade, M., Yamaguchi, Y., Dylan Tsai, C.-H., & Kaneko, M. (2018). LED-CT Scan for pH Distribution on a Cross-Section of Cell Culture Medium. Sensors, 18(1), 191. https://doi.org/10.3390/s18010191