Concrete Crack Identification Using a UAV Incorporating Hybrid Image Processing

Abstract

1. Introduction

2. Background

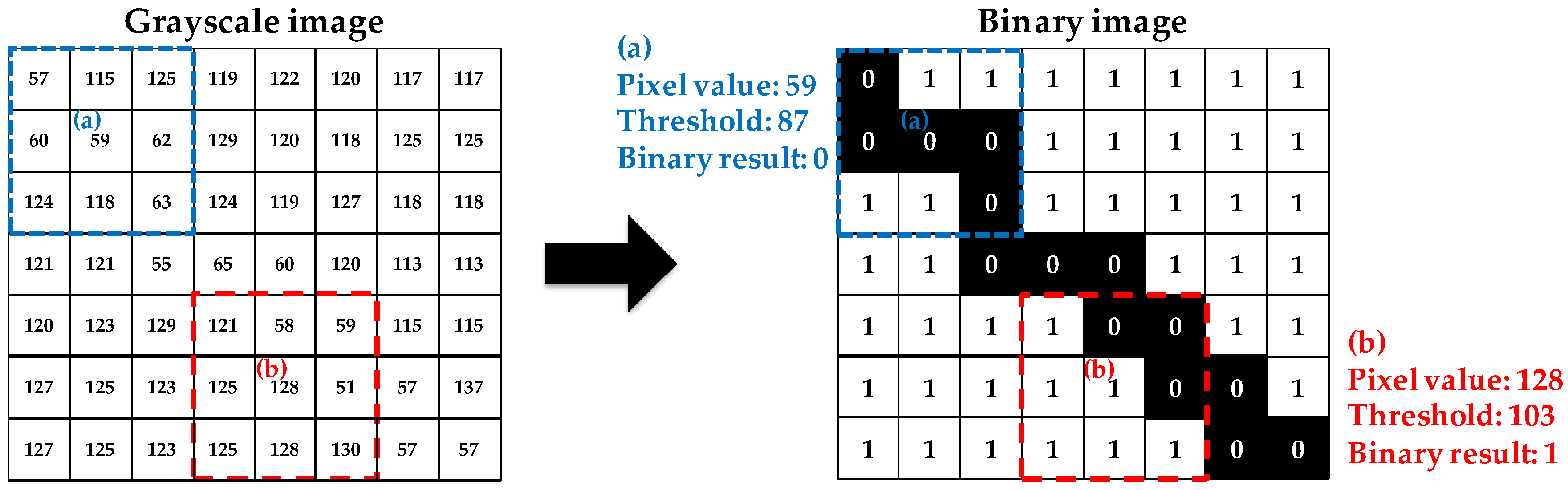

2.1. Crack Width Estimation via Image Binarization

2.2. Issues in Image Binarization for Crack Identification

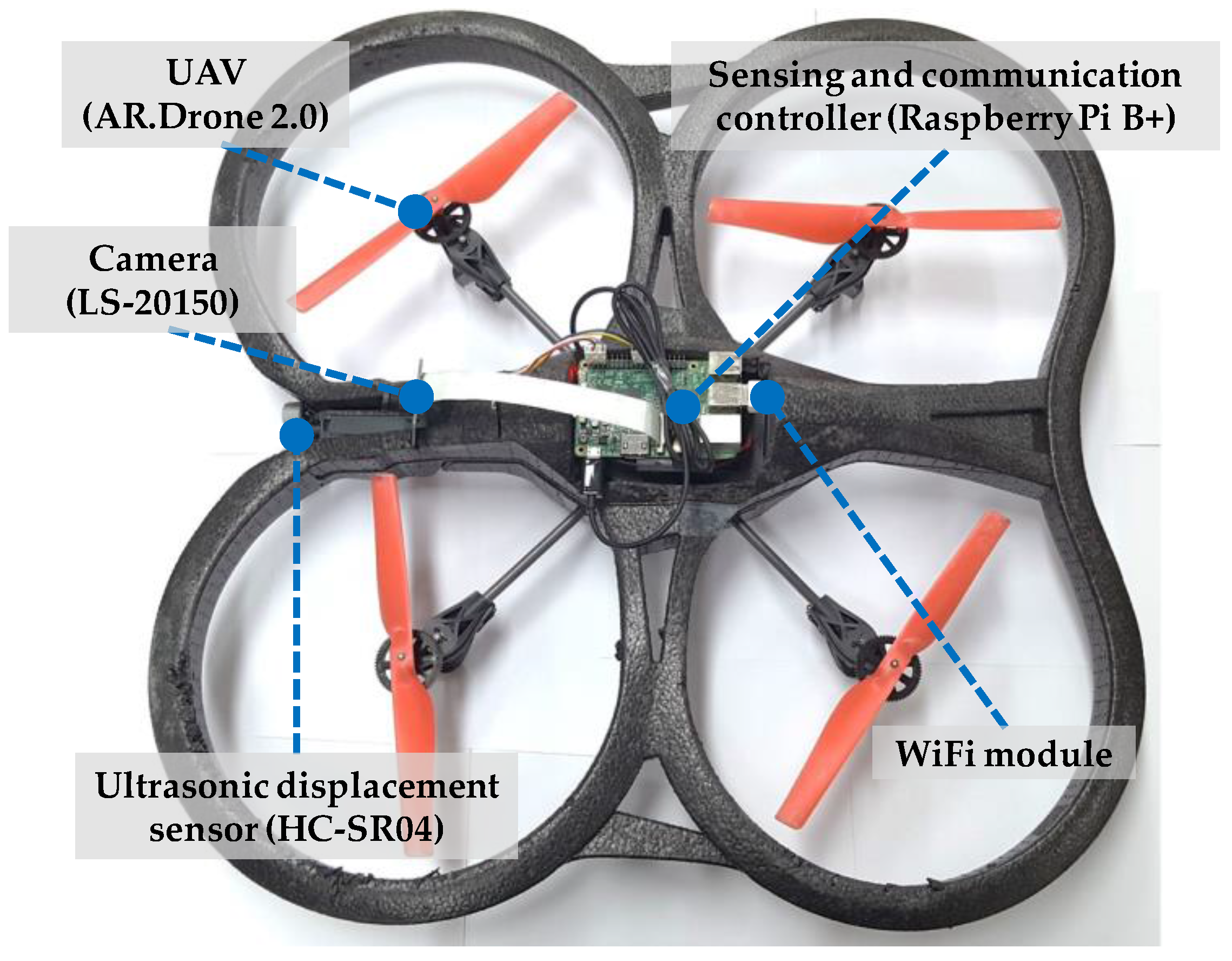

3. Hardware Configuration for Crack Information Acquisition

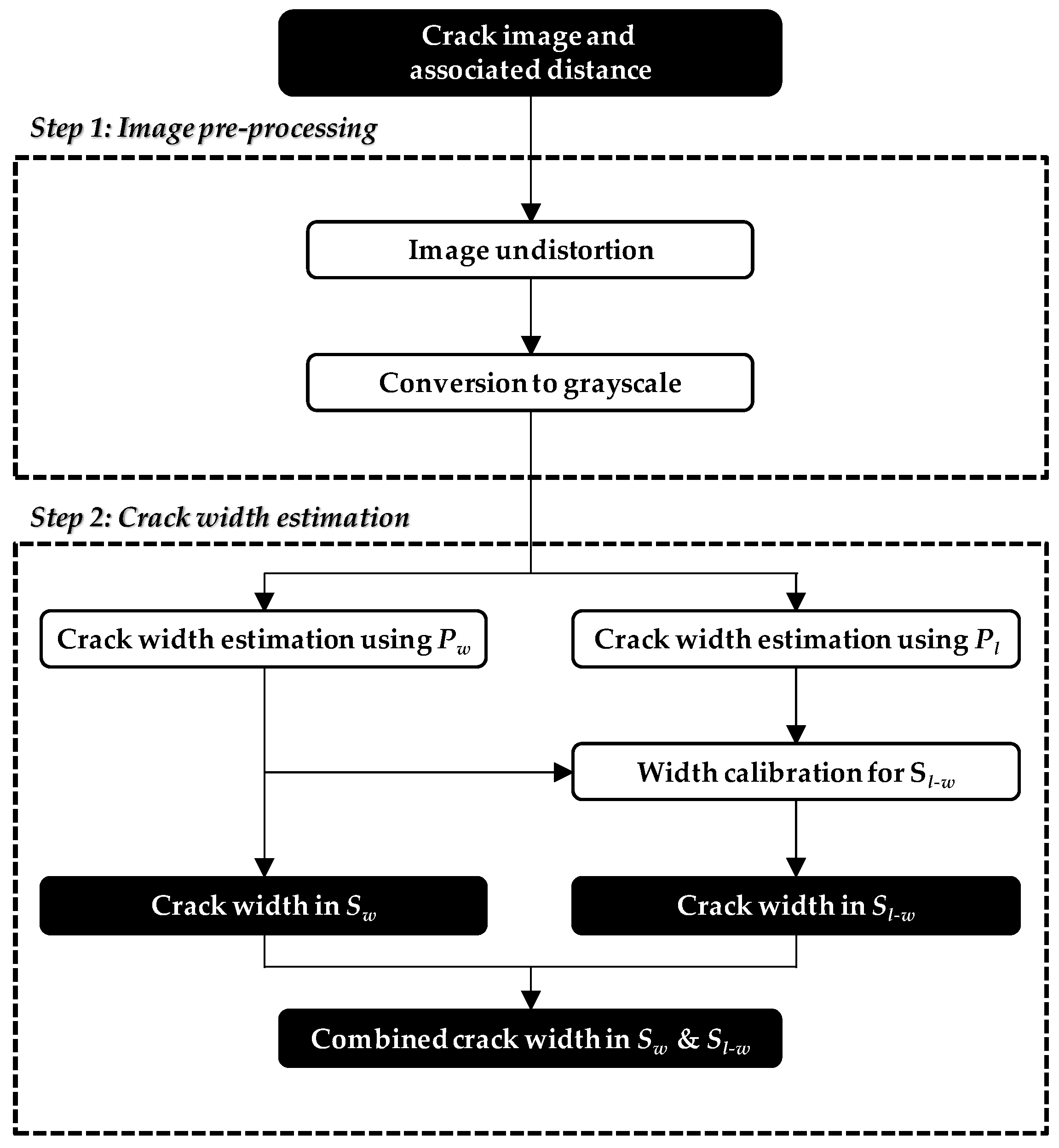

4. Hybrid Image Processing Strategy for Crack Identification

4.1. Image Pre-Processing

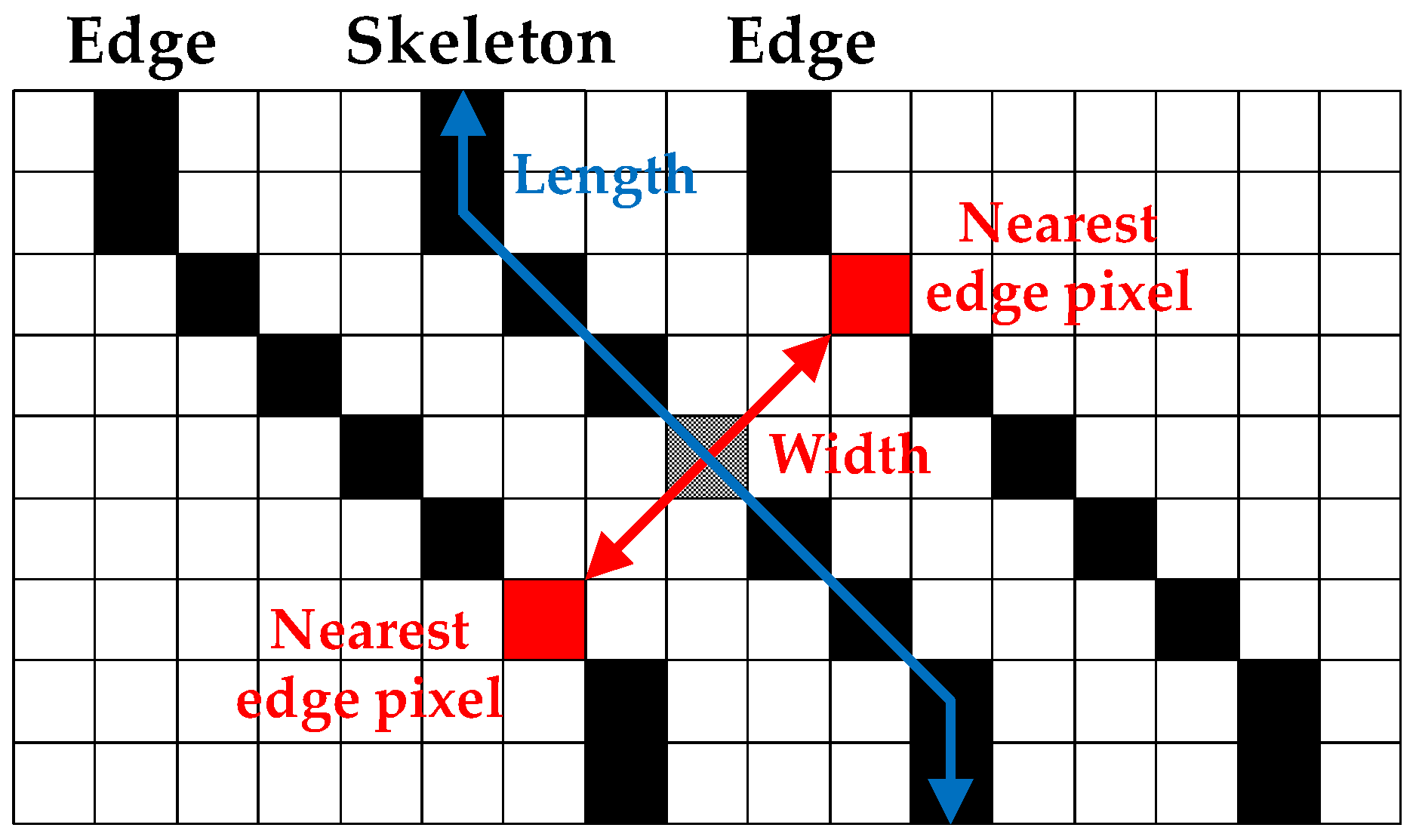

4.2. Crack Width Estimation

- Pw: optimal parameters minimizing estimation errors in crack width; and

- Pl: optimal parameters minimizing estimation errors in crack length.

- Sw: set of skeleton pixels obtained using Pw;

- Sl: set of skeleton pixels obtained using Pl; and

- w(P, S): crack width at location S obtained using P.

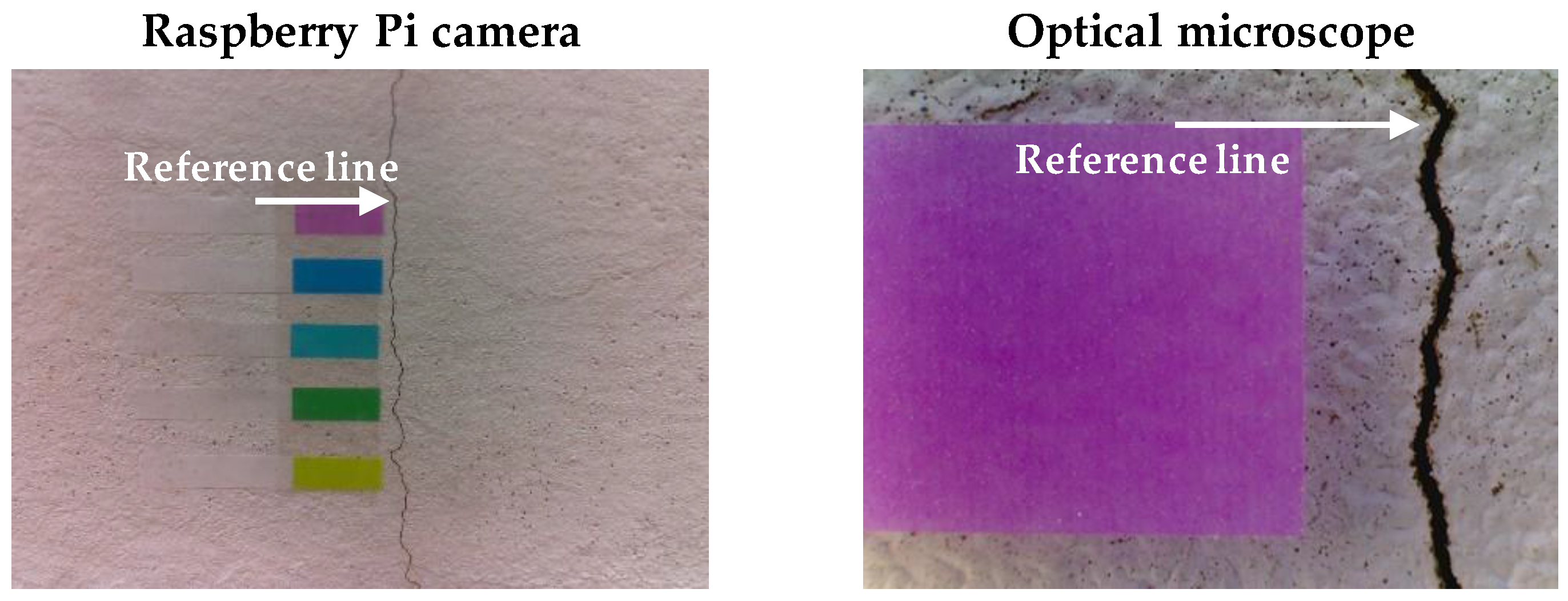

5. Experimental Validation

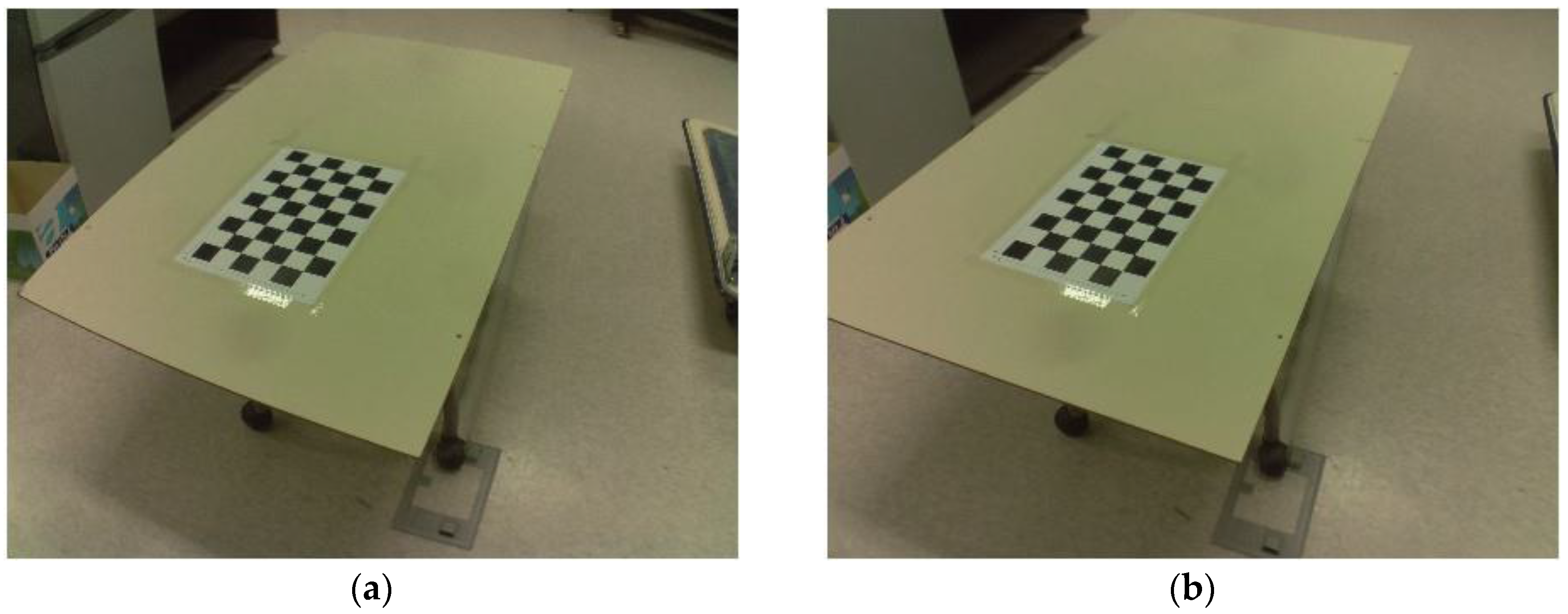

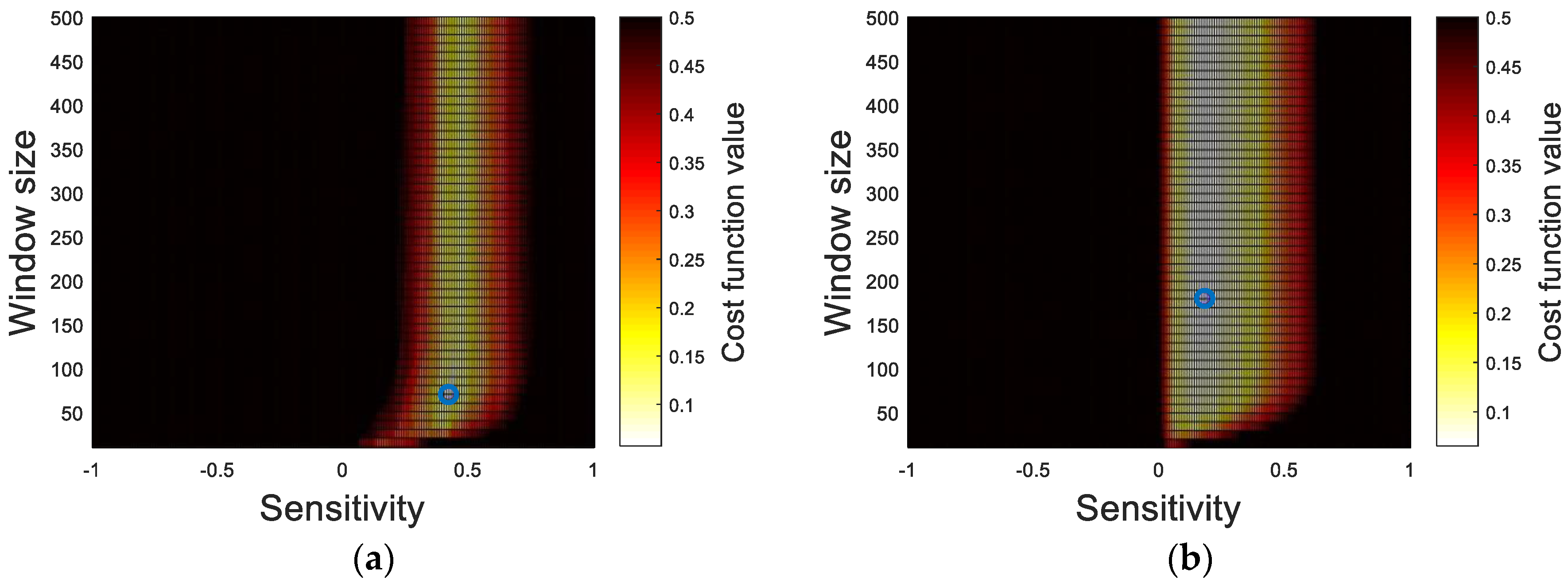

5.1. Determination of Optimal Parameters

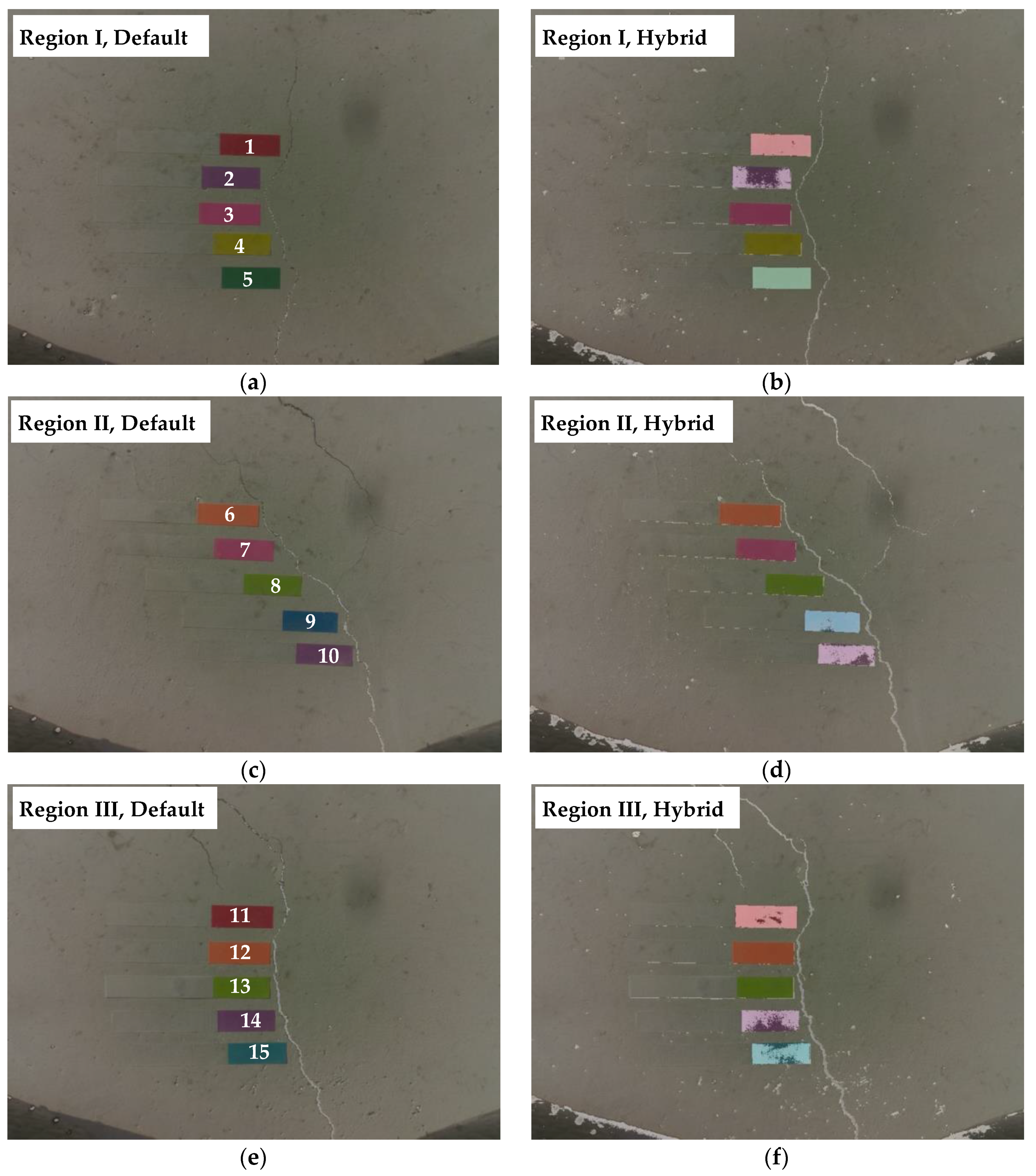

5.2. Crack Identification Using the Hybrid Image Processing Strategy

5.3. Discussion

6. Conclusions

- (1)

- While the crack widths less than 0.25 mm were typically unidentified or underestimated in case of the default values, the proposed hybrid method measured all ranges of crack widths reliably.

- (2)

- The maximum length estimation errors were 7.3% and 52.3% for the hybrid method and Sauvola’s binarization with the default parameters, respectively, proving significant performance improvement by the hybrid method.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Colomina, I.; Molina, P. Unmanned aerial systems for photogrammetry and remote sensing: A review. ISPRS J. Photogramm. Remote Sens. 2014, 92, 79–97. [Google Scholar] [CrossRef]

- Nex, F.; Remondino, F. UAV for 3D mapping applications: A review. Appl. Geomat. 2014, 6, 1–15. [Google Scholar] [CrossRef]

- Campos, I.S.; Nascimento, E.R.; Freitas, G.M.; Chaimowicz, L. A height estimation approach for terrain following flights from monocular vision. Sensors 2016, 16, 2071. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Laefer, D.F.; Mangina, E. State of technology review of civilian UAVs. Recent Pat. Eng. 2016, 10, 160–174. [Google Scholar] [CrossRef]

- Gonzalez, L.F.; Montes, G.A.; Puig, E.; Johnson, S.; Mengersen, K.; Gaston, K.J. Unmanned Aerial Vehicles (UAVs) and artificial intelligence revolutionizing wildlife monitoring and conservation. Sensors 2016, 16, 97. [Google Scholar] [CrossRef] [PubMed]

- Sampedro, C.; Bavle, H.; Sanchez-Lopez, J.L.; Fernández, R.A.S.; Rodríguez-Ramos, A.; Molina, M.; Campoy, P. A flexible and dynamic mission planning architecture for UAV swarm coordination. In Proceedings of the International Conference on Unmanned Aircraft Systems (ICUAS), Arlington, TX, USA, 7–10 June 2016. [Google Scholar]

- Vetrella, A.R.; Fasano, G.; Accardo, D.; Moccia, A. Differential GNSS and vision-based tracking to improve navigation performance in cooperative multi-UAV systems. Sensors 2016, 16, 2164. [Google Scholar] [CrossRef] [PubMed]

- Zongjian, L.I.N. UAV for mapping—Low altitude photogrammetric survey. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2008, 37, 1183–1186. [Google Scholar]

- Remondino, F.; Barazzetti, L.; Nex, F.; Scaioni, M.; Sarazzi, D. UAV photogrammetry for mapping and 3d modeling–current status and future perspectives. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2011, 38, 25–31. [Google Scholar] [CrossRef]

- Siebert, S.; Teizer, J. Mobile 3D mapping for surveying earthwork projects using an Unmanned Aerial Vehicle (UAV) system. Autom. Constr. 2014, 41, 1–14. [Google Scholar] [CrossRef]

- Byrne, J.; O’Keeffe, E.; Lennon, D.; Laefer, D.F. 3D Reconstructions using unstabilized video footage from an unmanned aerial vehicle. J. Imaging 2017, 3, 15. [Google Scholar] [CrossRef]

- Chen, S.E.; Rice, C.; Boyle, C.; Hauser, E. Small-format aerial photography for highway-bridge monitoring. J. Perform. Constr. Facil. 2011, 25, 105–112. [Google Scholar] [CrossRef]

- Zhang, C.; Elaksher, A. An unmanned aerial vehicle-based imaging system for 3D measurement of unpaved road surface distresses1. Comput.-Aided Civ. Infrastruct. Eng. 2012, 27, 118–129. [Google Scholar] [CrossRef]

- Díaz-Vilariño, L.; González-Jorge, H.; Martínez-Sánchez, J.; Bueno, M.; Arias, P. Determining the limits of unmanned aerial photogrammetry for the evaluation of road runoff. Measurement 2016, 85, 132–141. [Google Scholar] [CrossRef]

- Srinivasan, S.; Latchman, H.; Shea, J.; Wong, T.; McNair, J. Airborne traffic surveillance systems: Video surveillance of highway traffic. In Proceedings of the ACM 2nd International Workshop on Video Surveillance and Sensor Networks, New York, NY, USA, 10–16 October 2004. [Google Scholar]

- Puri, A. A Survey of Unmanned Aerial Vehicles (UAV) for Traffic Surveillance; Technical Report; Department of Computer Science and Engineering, University of South Florida: Tampa, FL, USA, 2005. [Google Scholar]

- Heintz, F.; Rudol, P.; Doherty, P. From images to traffic behavior-a uav tracking and monitoring application. In Proceedings of the 10th International Conference on Information Fusion, Quebec City, QC, Canada, 9–12 July 2007. [Google Scholar]

- Eschmann, C.; Kuo, C.-M.; Kuo, C.-H.; Boller, C. High-resolution multisensor infrastructure inspection with unmanned aircraft systems. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2013, 1, 125–129. [Google Scholar] [CrossRef]

- Choi, S.-S.; Kim, E.-K. Building crack inspection using small UAV. In Proceedings of the 17th International Conference on Advanced Communication Technology, PyeongChang, Korea, 1–3 July 2015. [Google Scholar]

- Pereira, F.C.; Pereira, C.E. Embedded image processing systems for automatic recognition of cracks using UAVs. IFAC-PapersOnLine 2015, 48, 16–21. [Google Scholar] [CrossRef]

- Sankarasrinivasan, S.; Balasubramanian, E.; Karthik, K.; Chandrasekar, U.; Gupta, R. Health monitoring of civil structures with integrated UAV and image processing system. Procedia Comput. Sci. 2015, 54, 508–515. [Google Scholar] [CrossRef]

- Ellenberg, A.; Kontsos, A.; Moon, F.; Bartoli, I. Bridge related damage quantification using unmanned aerial vehicle imagery. Struct. Control Health Monit. 2016, 23, 1168–1179. [Google Scholar] [CrossRef]

- Abdel-Qader, I.; Abudayyeh, O.; Kelly, M.E. Analysis of edge-detection techniques for crack identification in bridges. J. Comput. Civ. Eng. 2003, 17, 255–263. [Google Scholar] [CrossRef]

- Hutchinson, T.C.; Chen, Z. Improved image analysis for evaluating concrete damage. J. Comput. Civ. Eng. 2006, 20, 210–216. [Google Scholar] [CrossRef]

- Zhao, H.; Qin, G.; Wang, X. Improvement of canny algorithm based on pavement edge detection. In Proceedings of the 3rd International Congress on Image and Signal Processing, Yantai, China, 16–18 October 2010. [Google Scholar]

- Liu, Y.; Cho, S.; Spencer, B.F., Jr.; Fan, J. Automated assessment of cracks on concrete surfaces using adaptive digital image processing. Smart Struct. Syst. 2014, 14, 719–741. [Google Scholar] [CrossRef]

- Liu, Y.F.; Cho, S.; Spencer, B.F., Jr.; Fan, J. Concrete crack assessment using digital image processing and 3D scene reconstruction. J. Comput. Civ. Eng. 2016, 30, 1–19. [Google Scholar] [CrossRef]

- Sinha, S.K.; Fieguth, P.W. Segmentation of buried concrete pipe images. Autom. Constr. 2006, 15, 47–57. [Google Scholar] [CrossRef]

- Giakoumis, I.; Nikolaidis, N.; Pitas, I. Digital image processing techniques for the detection and removal of cracks in digitized paintings. IEEE Trans. Image Process. 2006, 15, 178–188. [Google Scholar] [CrossRef] [PubMed]

- Cha, Y.J.; Choi, W.; Büyüköztürk, O. Deep learning-based crack damage detection using convolutional neural networks. Comput.-Aided Civ. Infrastruct. Eng. 2017, 32, 361–378. [Google Scholar] [CrossRef]

- Jahanshahi, M.R.; Kelly, J.S.; Masri, S.F.; Sukhatme, G.S. A survey and evaluation of promising approaches for automatic image-based defect detection of bridge structures. Struct. Infrastruct. Eng. 2009, 5, 455–486. [Google Scholar] [CrossRef]

- Kim, H.; Ahn, E.; Cho, S.; Shin, M.; Sim, S.-H. Comparative analysis of image binarization methods for crack identification in concrete structures. Cem. Concr. Res. 2017, 99, 53–61. [Google Scholar] [CrossRef]

- Bernsen, J. Dynamic thresholding of grey-level images. In Proceedings of the 8th International Conference on Pattern Recognition, Paris, France, 27–31 October 1986. [Google Scholar]

- Niblack, W. An Introduction to Digital Image Processing, 1st ed.; Prentice Hall: Englewood Cliffs, NJ, USA, 1986. [Google Scholar]

- Sauvola, J.; Pietikäinen, M. Adaptive document image binarization. Pattern Recognit. 2000, 33, 225–236. [Google Scholar] [CrossRef]

- Wolf, C.; Jolion, J.M. Extraction and recognition of artificial text in multimedia documents. Pattern Anal. Appl. 2004, 6, 309–326. [Google Scholar] [CrossRef]

- Khurshid, K.; Siddiqi, I.; Faure, C.; Vincent, N. Comparison of Niblack inspired binarization methods for ancient documents. In Proceedings of the 16th International Conference on Document Recognition and Retrieval, San Jose, CA, USA, 19–21 January 2010. [Google Scholar]

- Lam, L.; Lee, S.-W.; Suen, C.Y. Thinning methodologies—A comprehensive survey. IEEE Trans. Pattern Anal. Mach. Intell. 1992, 14, 869–885. [Google Scholar] [CrossRef]

- Canny, J. A computational approach to edge detection. IEEE Trans. Pattern Anal. Mach. Intell. 1986, 6, 679–698. [Google Scholar] [CrossRef]

- Kim, H.; Sim, S.-H. Concrete crack assessment using unmanned aerial vehicle. In Proceedings of the 24th Australasian Conference on the Mechanics of Structures and Materials, Perth, Australia, 6–9 December 2016. [Google Scholar]

- Bouguet, J.Y. Camera Calibration Toolbox for Matlab. Available online: http://www.vision.caltech.edu/bouguetj/calib_doc/ (accessed on 11 August 2017).

- Laefer, D.F.; Gannon, J.; Deely, E. Reliability of crack detection methods for baseline condition assessments. J. Infrastruct. Syst. 2010, 16, 129–137. [Google Scholar] [CrossRef]

- ACI 224R-90. Control of Cracking in Concrete Structures; America Concrete Institute: Farmington Hills, MI, USA, 1990. [Google Scholar]

- Byrne, J.; Laefer, D.F.; O’Keeffe, E. Maximizing feature detection in aerial unmanned aerial vehicle datasets. J. Appl. Remote Sens. 2017, 11, 025015. [Google Scholar] [CrossRef]

| Component | Model | Specification |

|---|---|---|

| UAV | Parrot AR.Drone 2.0 | Dimensions: 58 cm × 13 cm × 58 cm |

| Weight: 1.8 kg | ||

| Sensing and communication controller | Raspberry Pi B+ | CPU: 700 MHz single-core |

| Memory: 512 MB | ||

| Weight: 45 g | ||

| Camera | LS-20150 | Resolution: 2592 pixels × 1944 pixels |

| Focal length: 2.8 mm | ||

| F-number: 2.8 | ||

| Weight: 10.3 g | ||

| Ultrasonic displacement sensor | HC-SR04 | Measurable distance: 2 cm–4 m |

| Resolution 0.3 cm | ||

| Weight: 8.5 g |

| Sensitivity | Window Size | Cost Function | |

|---|---|---|---|

| Pw | 0.42 | 70 | 0.057 |

| Pl | 0.18 | 180 | 0.065 |

| Region | Total Crack Length Calculation (mm) | ||

|---|---|---|---|

| Default (Error) | Hybrid (Error) | Manual | |

| I | 37.49 (52.3%) | 72.86 (7.3%) | 78.57 |

| II | 79.18 (42.0%) | 128.75 (5.7%) | 136.50 |

| III | 95.01 (18.8%) | 115.99 (0.9%) | 117.02 |

| Region | Location | Crack Width Calculation (mm) | ||

|---|---|---|---|---|

| Default (Difference) | Hybrid (Difference) | Microscope | ||

| I | 1 | N/A * | 0.14 (0.02) | 0.12 |

| 2 | N/A * | 0.14 (0.02) | 0.12 | |

| 3 | 0.15 (−0.07) | 0.20 (−0.02) | 0.22 | |

| 4 | 0.15 (−0.08) | 0.20 (−0.03) | 0.23 | |

| 5 | N/A * | 0.13 (−0.01) | 0.14 | |

| II | 6 | N/A * | 0.22 (0.03) | 0.19 |

| 7 | 0.20 (−0.03) | 0.25 (0.02) | 0.23 | |

| 8 | 0.30 (−0.02) | 0.30 (−0.02) | 0.32 | |

| 9 | 0.25 (0.01) | 0.25 (0.01) | 0.24 | |

| 10 | 0.35 (−0.04) | 0.40 (0.01) | 0.39 | |

| III | 11 | N/A * | 0.22 (0.03) | 0.19 |

| 12 | 0.49 (−0.04) | 0.49 (−0.04) | 0.53 | |

| 13 | 0.49 (−0.01) | 0.49 (−0.01) | 0.50 | |

| 14 | 0.59 (0.04) | 0.59 (0.04) | 0.55 | |

| 15 | 0.59 (0.04) | 0.59 (0.04) | 0.55 | |

| Exposure Condition | Tolerable Crack Width (mm) |

|---|---|

| Dry air protective membrane | <0.40 |

| Humidity, moist air, soil | <0.30 |

| Deicing chemicals | <0.18 |

| Seawater and seawater spray; Wetting and drying | <0.15 |

| Water retaining structures | <0.10 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.; Lee, J.; Ahn, E.; Cho, S.; Shin, M.; Sim, S.-H. Concrete Crack Identification Using a UAV Incorporating Hybrid Image Processing. Sensors 2017, 17, 2052. https://doi.org/10.3390/s17092052

Kim H, Lee J, Ahn E, Cho S, Shin M, Sim S-H. Concrete Crack Identification Using a UAV Incorporating Hybrid Image Processing. Sensors. 2017; 17(9):2052. https://doi.org/10.3390/s17092052

Chicago/Turabian StyleKim, Hyunjun, Junhwa Lee, Eunjong Ahn, Soojin Cho, Myoungsu Shin, and Sung-Han Sim. 2017. "Concrete Crack Identification Using a UAV Incorporating Hybrid Image Processing" Sensors 17, no. 9: 2052. https://doi.org/10.3390/s17092052

APA StyleKim, H., Lee, J., Ahn, E., Cho, S., Shin, M., & Sim, S.-H. (2017). Concrete Crack Identification Using a UAV Incorporating Hybrid Image Processing. Sensors, 17(9), 2052. https://doi.org/10.3390/s17092052