Investigation on Eigenfrequency of a Cylindrical Shell Resonator under Resonator-Top Trimming Methods

Abstract

:1. Introduction

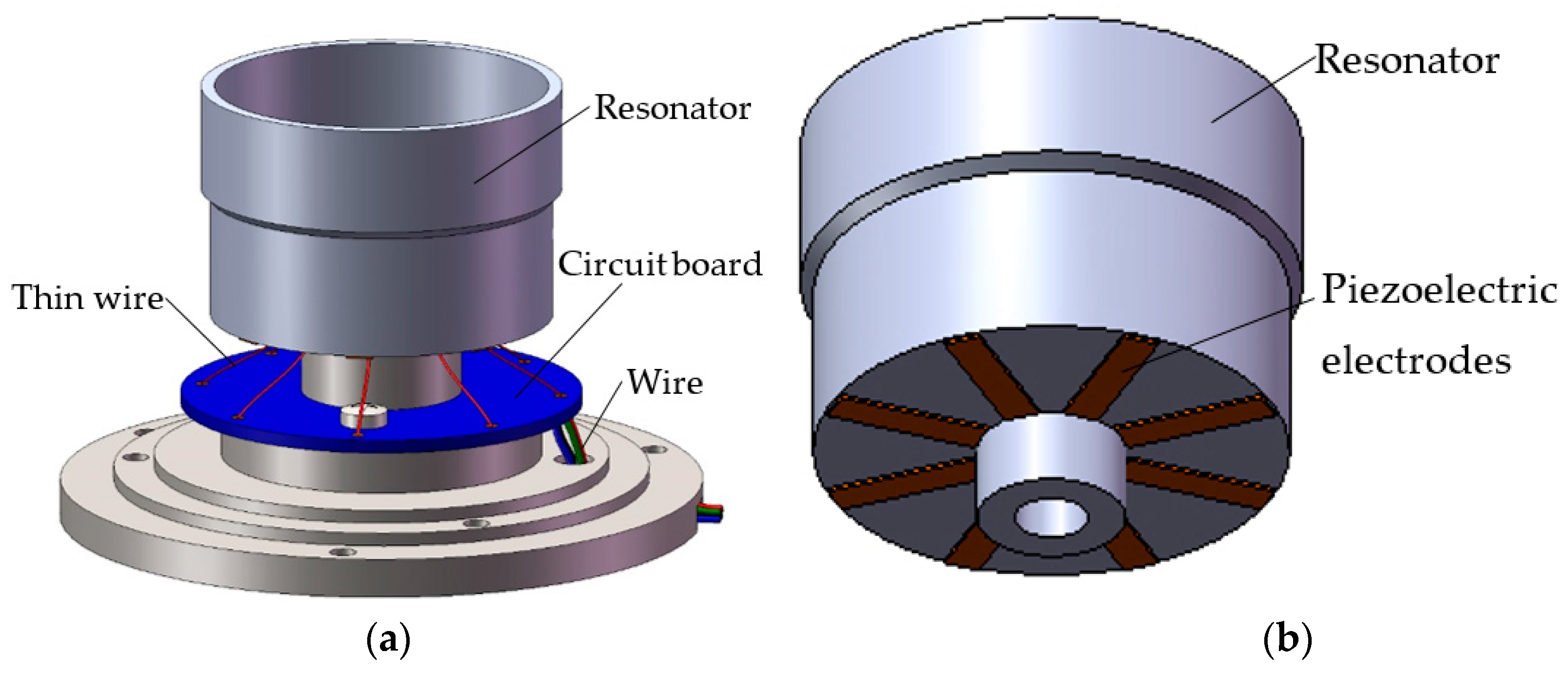

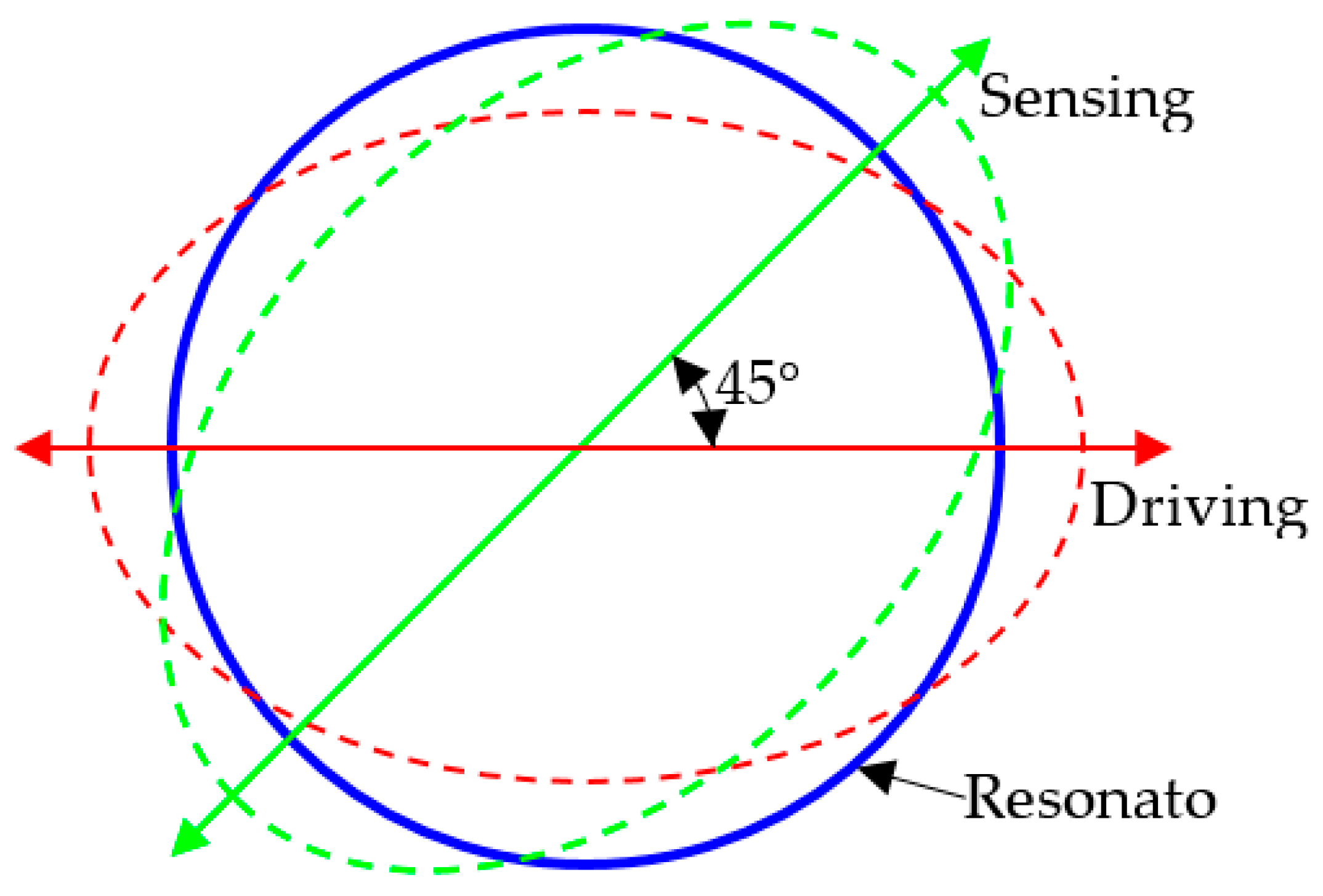

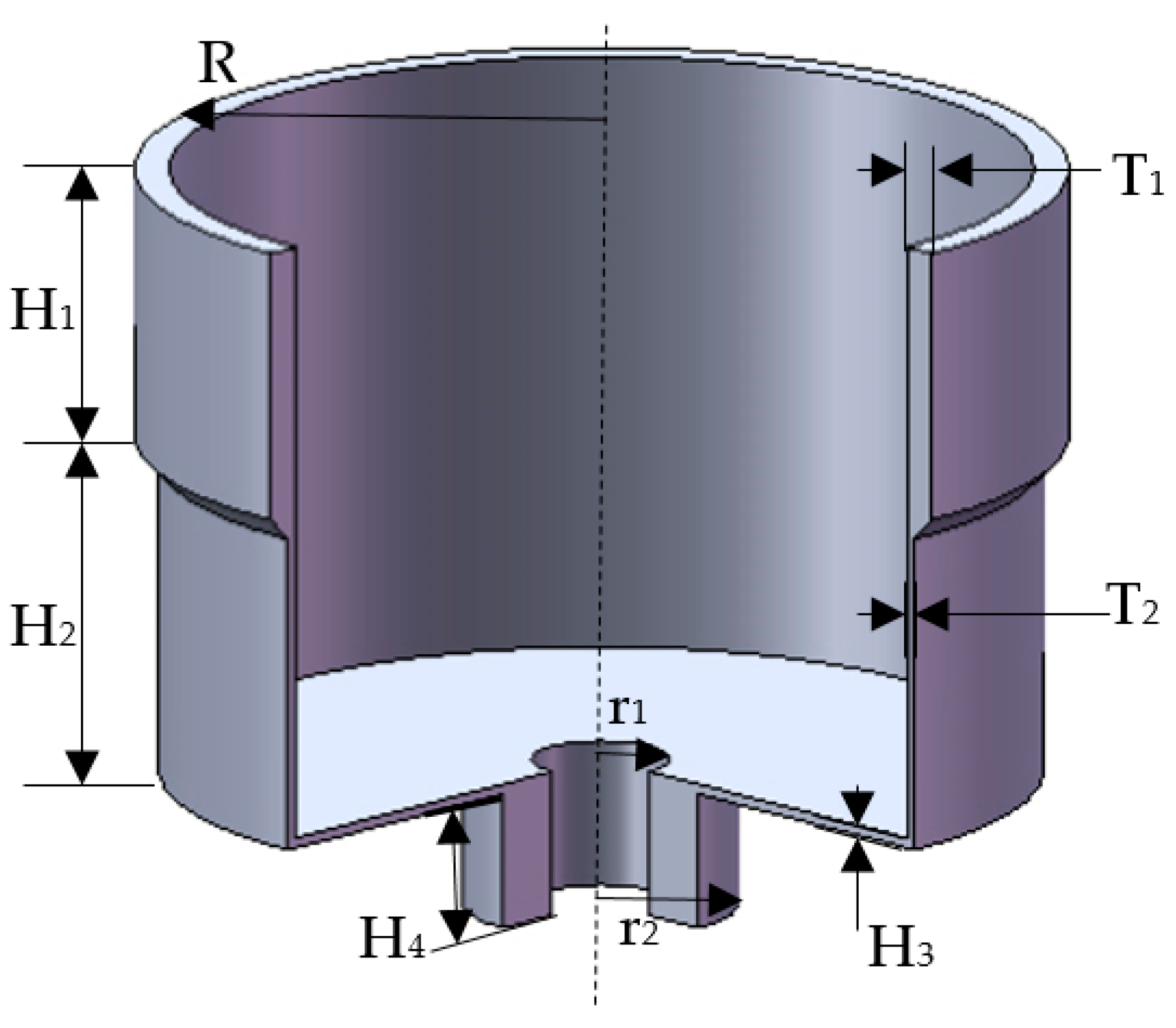

2. Structure and Working Principle

3. Simulation

3.1. Finite Element Modeling

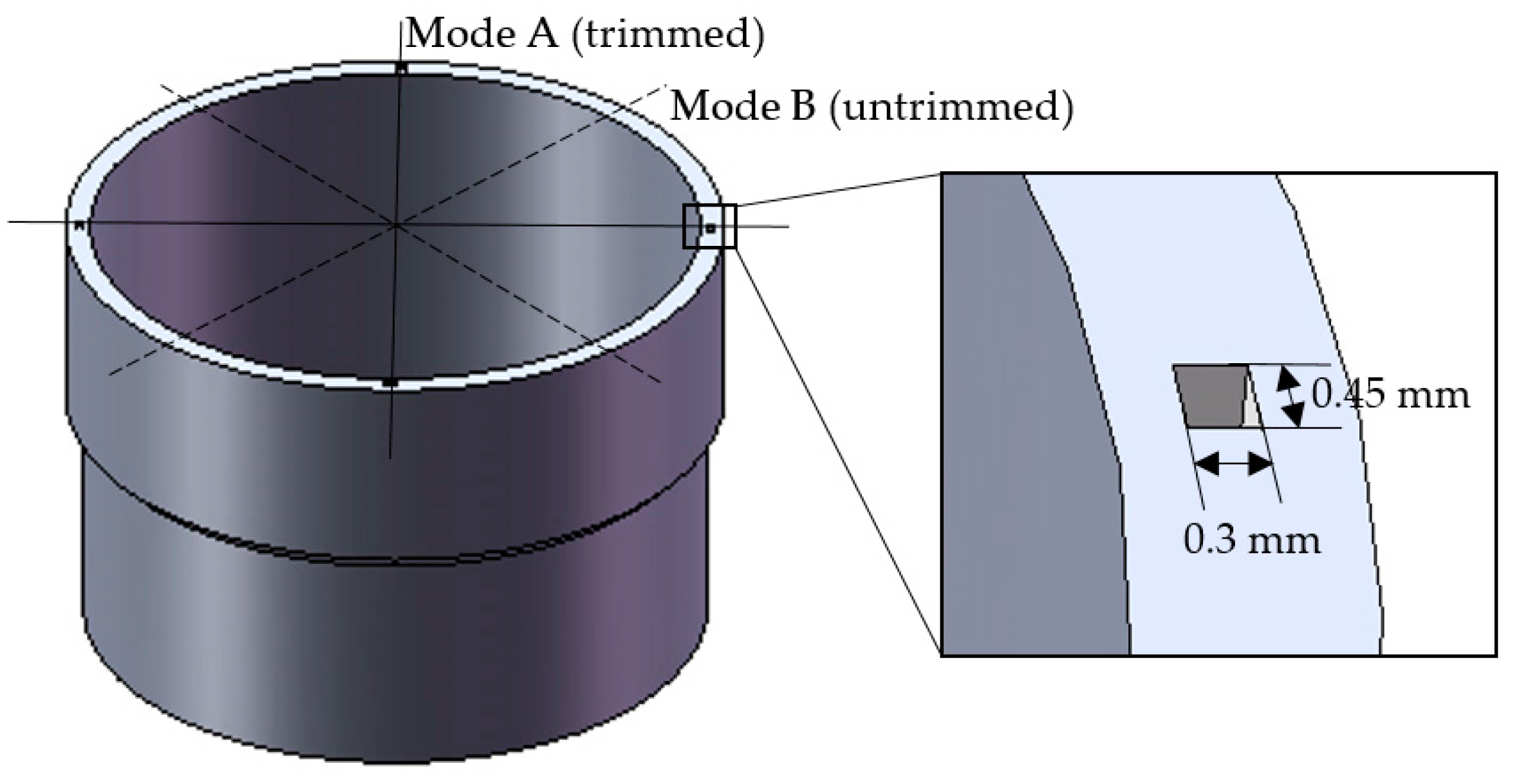

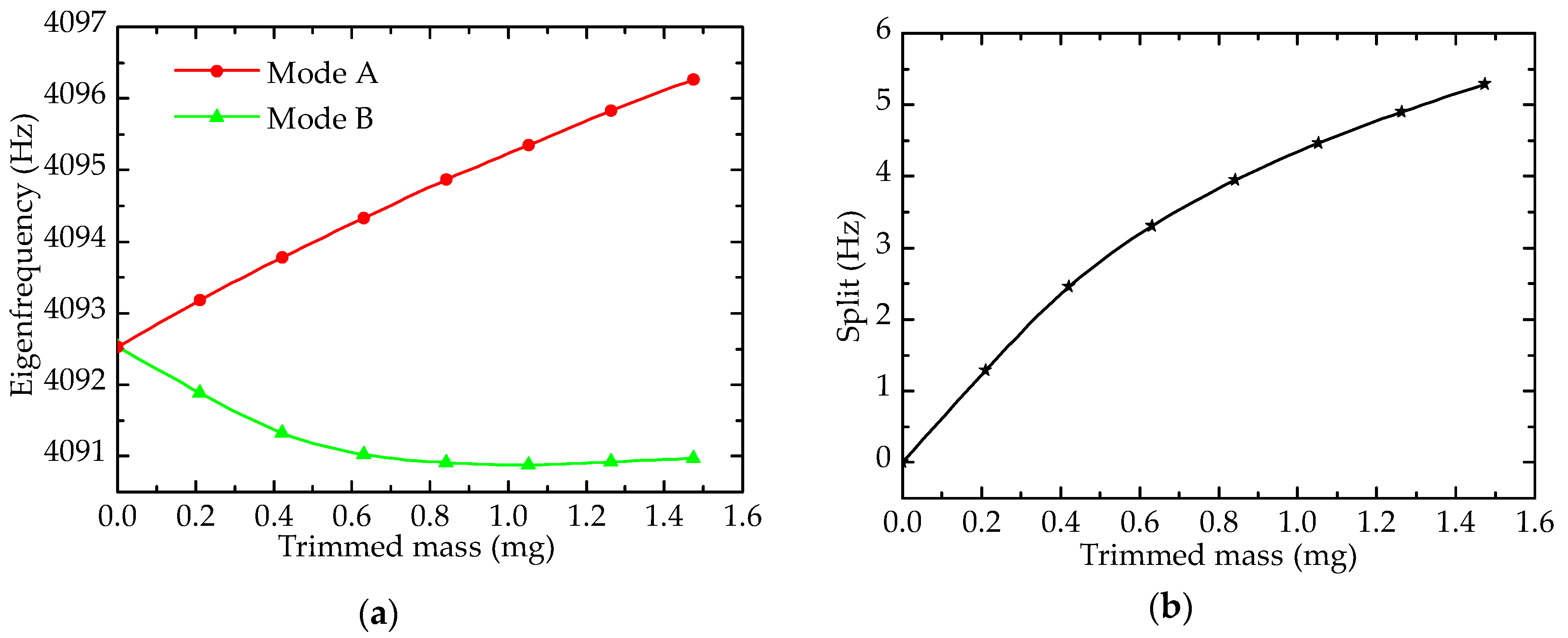

3.2. Effect of Holes-Trimming on Eigenfrequency

3.3. Effect of Grooves-Trimming on Eigenfrequency

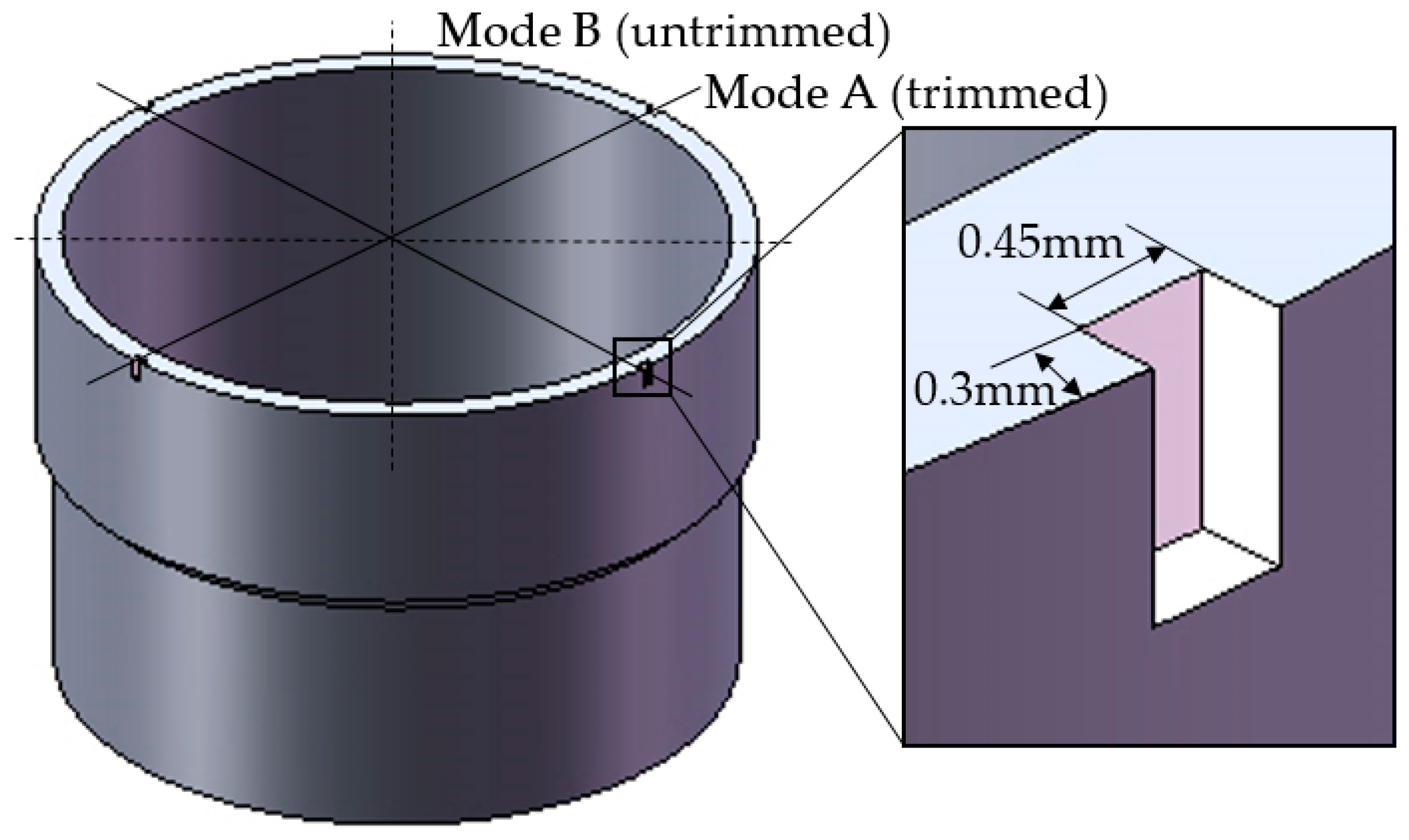

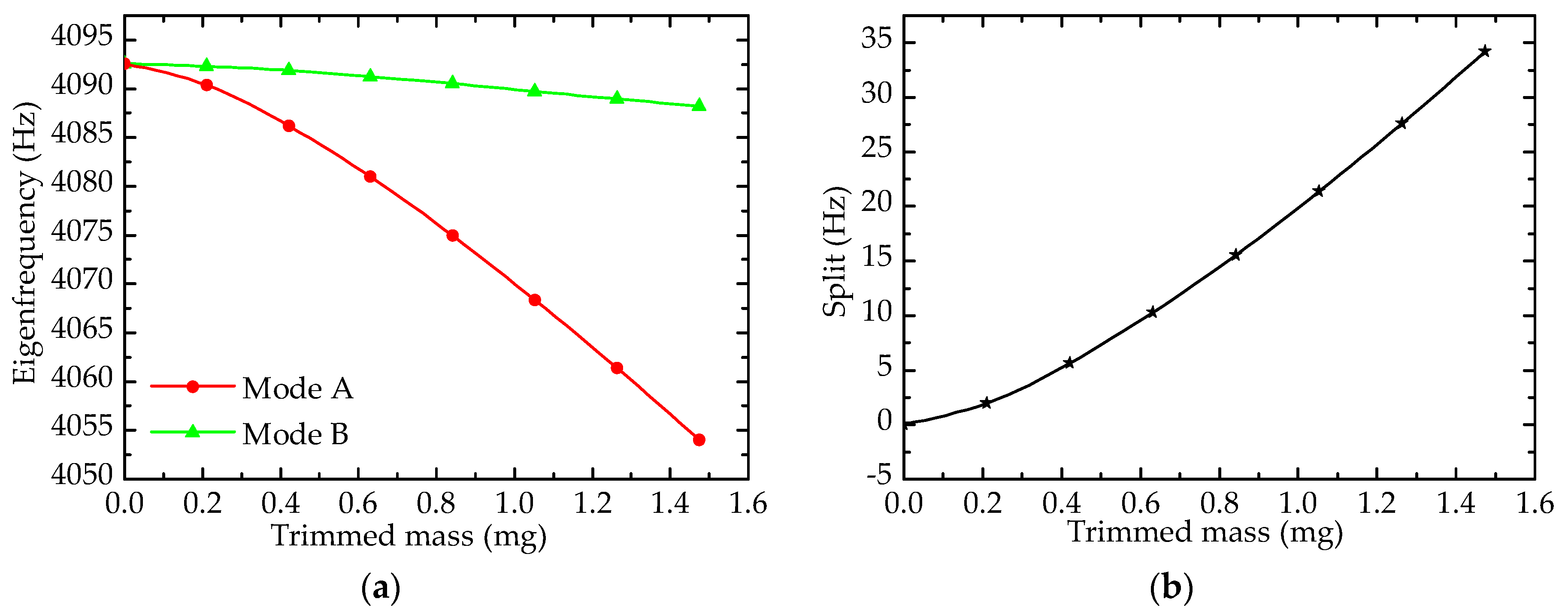

3.3.1. Effect of Forming Grooves on Eigenfrequency

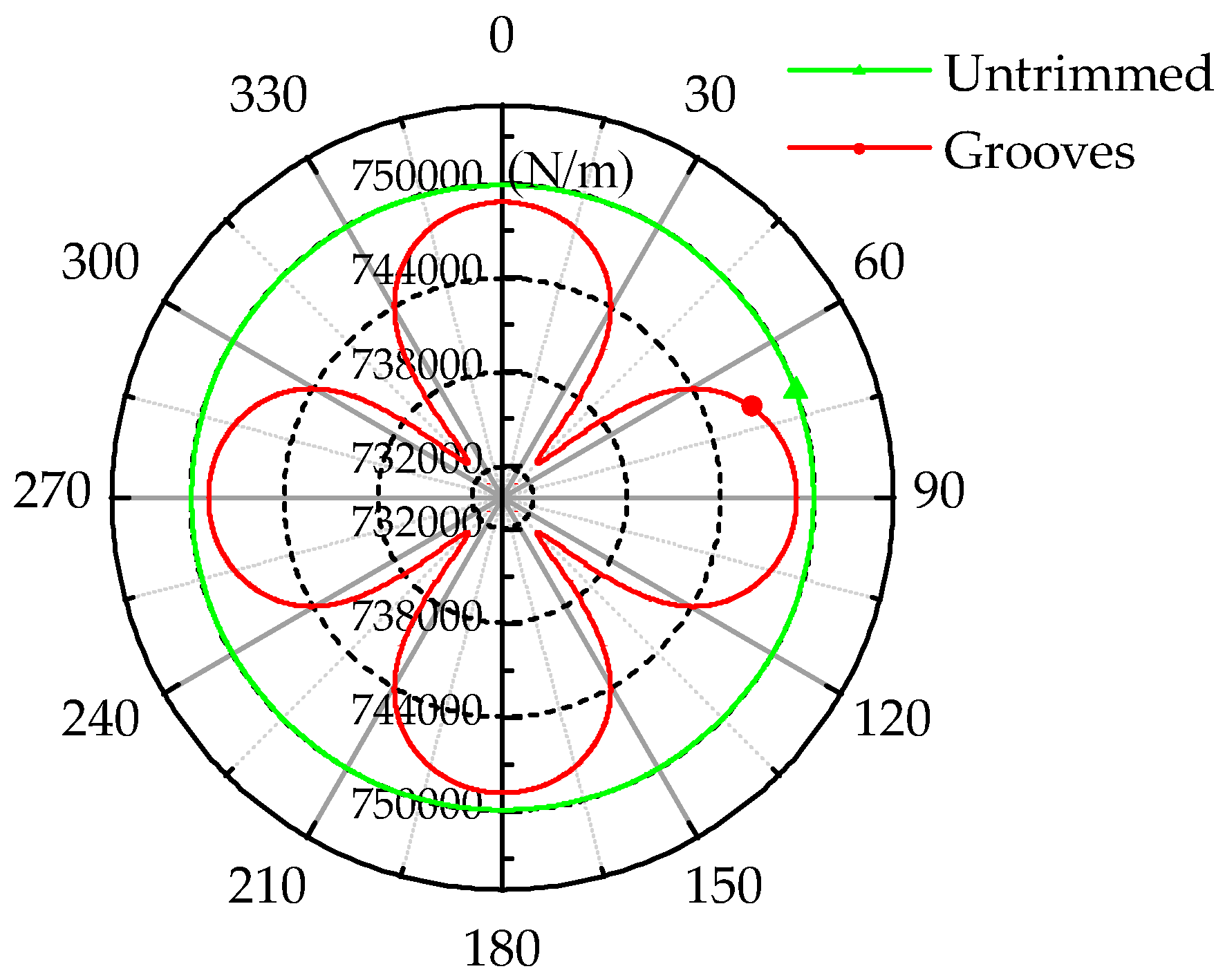

3.3.2. Rigidity Condition

3.4. Comparison and Trimming Process

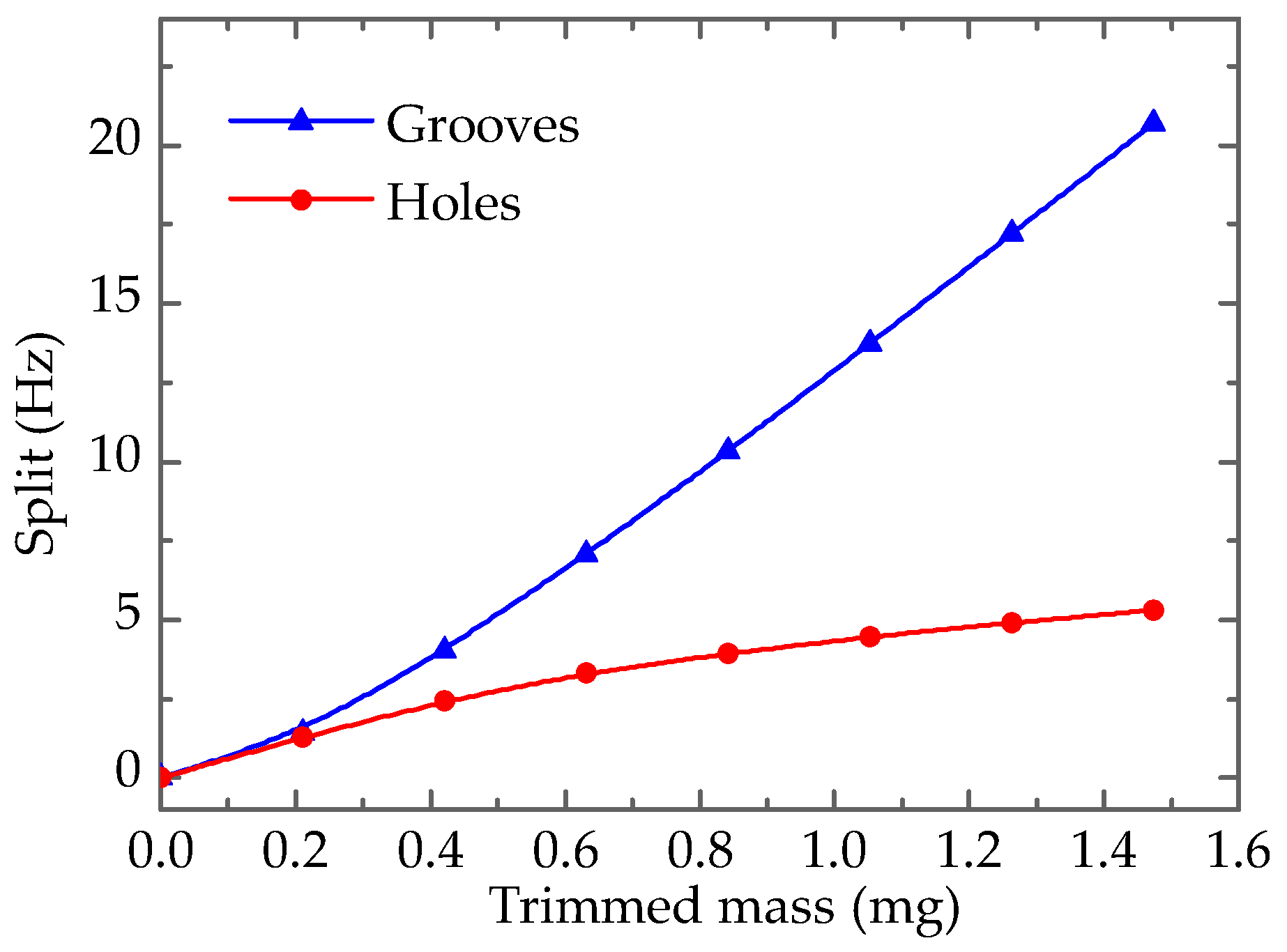

3.4.1. Comparison of Split under Different Trimming Methods

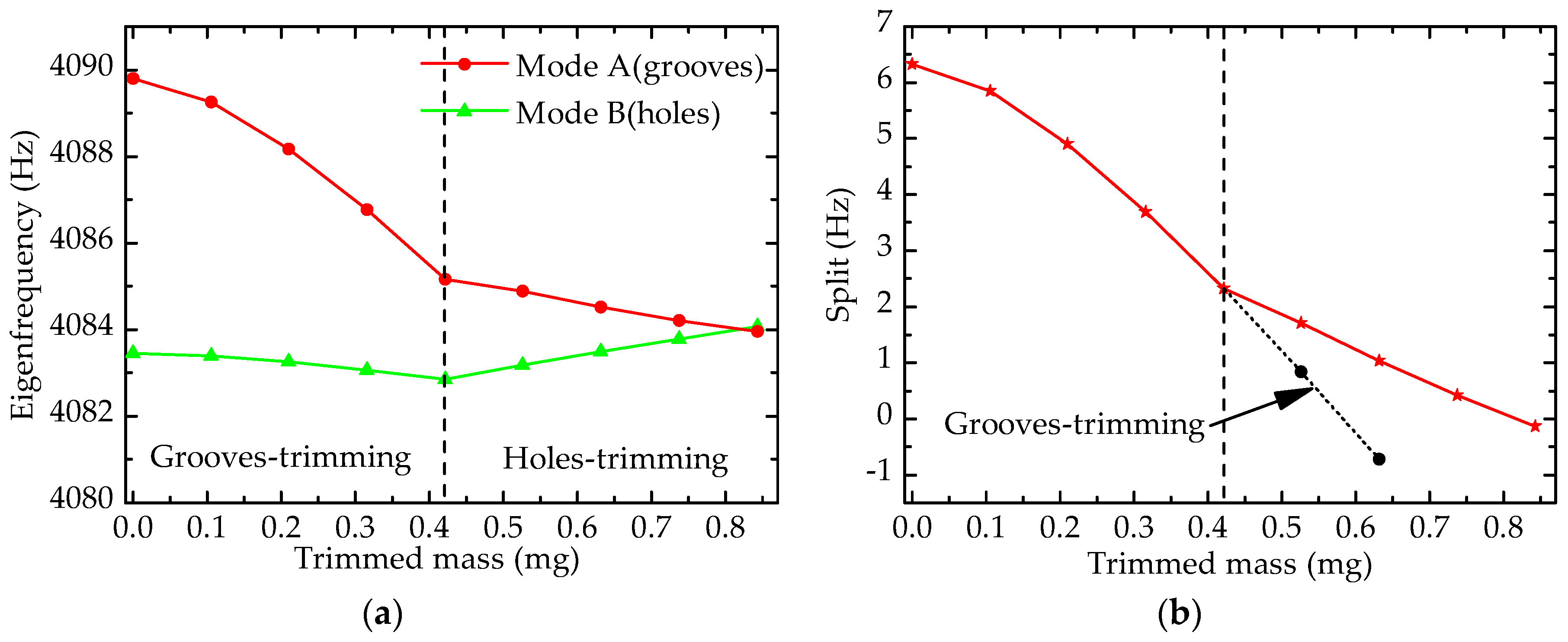

3.4.2. Trimming Process

4. Experiments

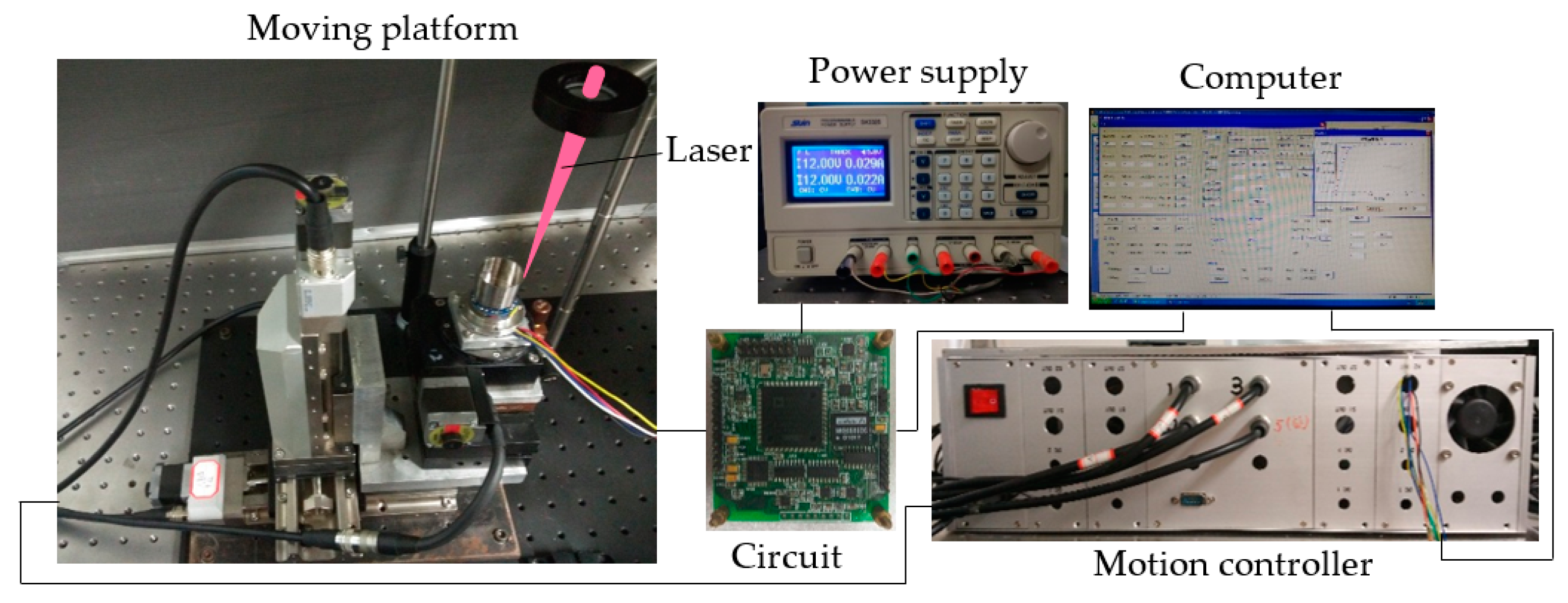

4.1. Experimental Equipment

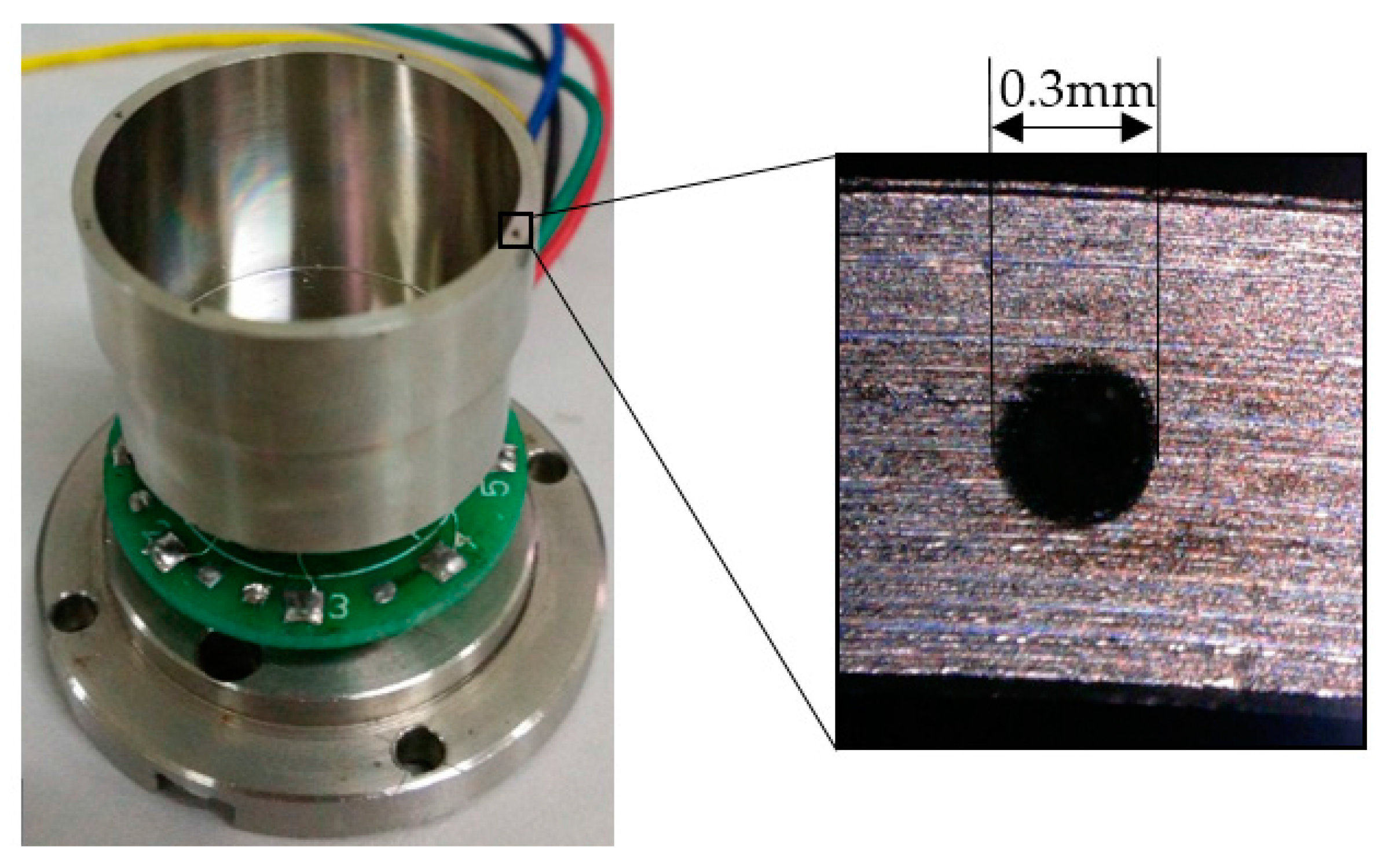

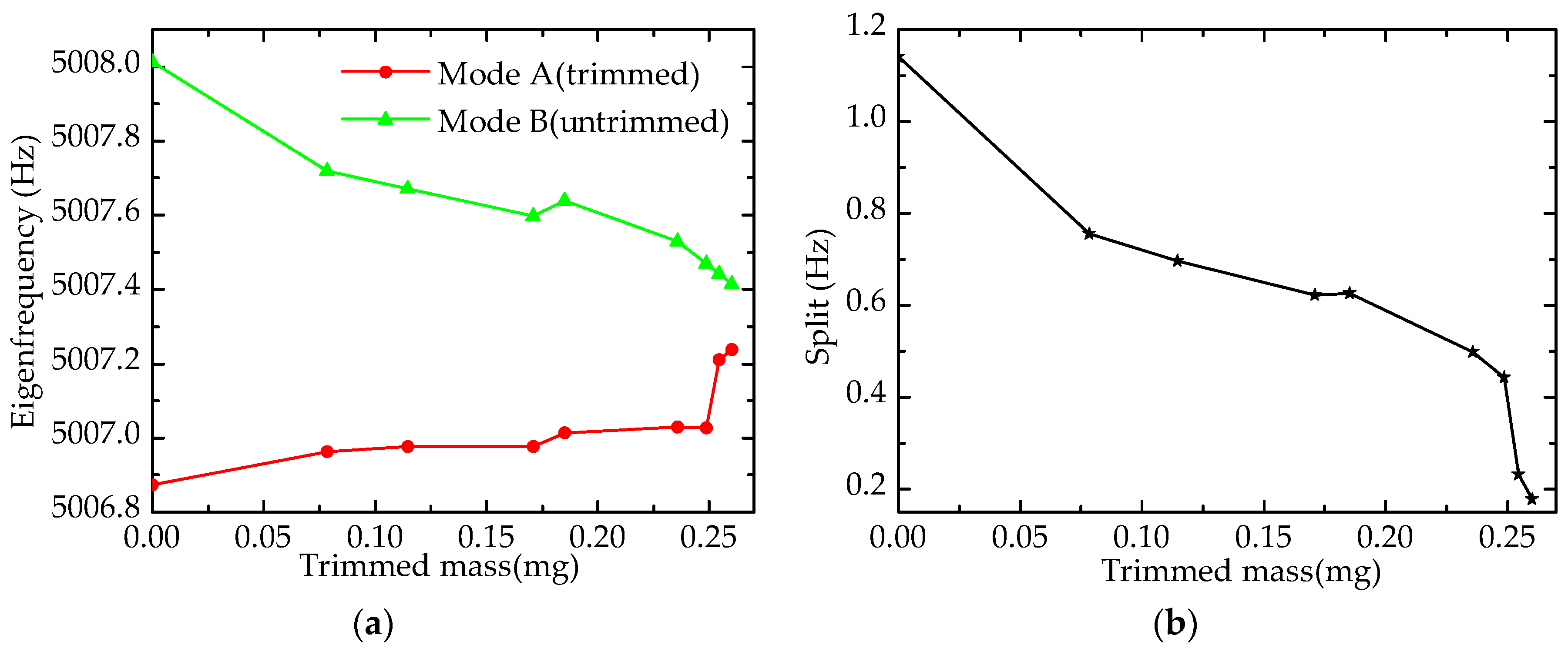

4.2. Effect of Holes on Eigenfrequency

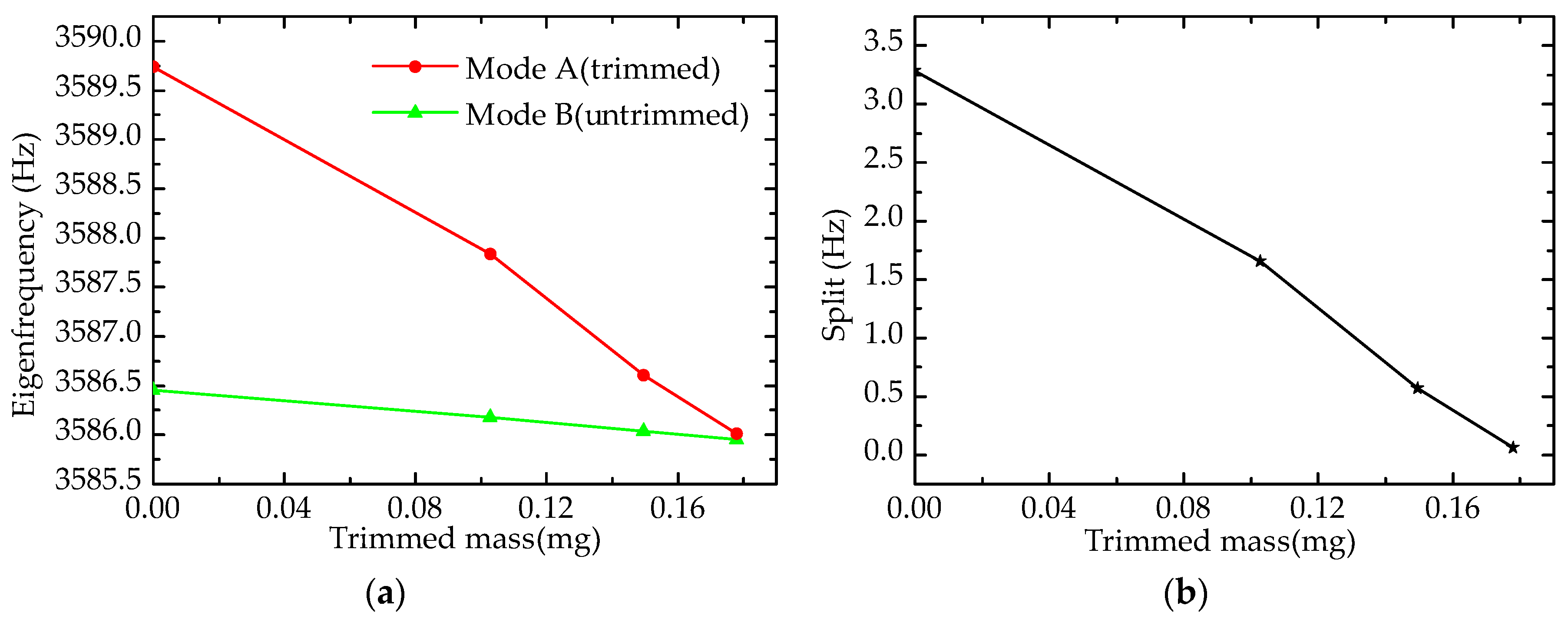

4.3. Effect of Grooves on Eigenfrequency

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Langaid, C. Vibrating structure gyroscopes. Sens. Rev. 1996, 16, 14–17. [Google Scholar] [CrossRef]

- Chikovani, V.V.; Okon, I.M.; Barabashov, A.S.; Barabashov, A.S.; Tewksbury, P. A set of high accuracy low cost metallic resonator CVG. In Proceedings of the IEEE/ION Position, Location & Navigation Symposium, Monterey, CA, USA, 5–8 May 2008; pp. 238–243. [Google Scholar]

- Singh, A.K. Piezoelectric Gyro Sensor Technology. Def. Sci. J. 2007, 57, 95–103. [Google Scholar] [CrossRef]

- John, A.M.; Shreyes, N.M. Modeling of Deformation of Ring Shaped Workpieces Due to Chucking and Cutting Forces. J. Manuf. Sci. Eng. 2004, 126, 141–147. [Google Scholar] [CrossRef]

- Bisegna, P.; Caruso, G. Frequency split and vibration localization in imperfect rings. J. Sound Vibr. 2007, 306, 691–711. [Google Scholar] [CrossRef]

- Xi, X.; Wu, Y.; Wu, X.; Tao, Y.; Wu, X. Investigation on standing wave vibration of the imperfect resonant shell for cylindrical gyro. Sens. Actuator A 2012, 179, 70–77. [Google Scholar] [CrossRef]

- Gallacher, B.J.; Hedley, J.; Burdess, J.S.; Harris, A.J.; Rickard, A.; King, D.O. Electrostatic correction of structural imperfections present in a microring gyroscope. J. Microelectromech. Syst. 2005, 14, 221–234. [Google Scholar] [CrossRef]

- Hu, Z.X.; Gallacher, B.J.; Burdess, J.S.; Fell, C.P.; Townsend, K. Precision mode matching of MEMS gyroscope by feedback control. In Proceedings of the 2011 IEEE Sensors, Limerick, Ireland, 28–31 October 2011; pp. 16–19. [Google Scholar]

- Tao, Y.; Xi, X.; Xiao, D.; Tan, Y.; Cui, H. Precision balance method for cupped wave gyro based on cup-bottom trimming. Chin. J. Mech. Eng. 2012, 25, 63–70. [Google Scholar] [CrossRef]

- Rourke, A.K.; Mcwilliam, S.; Fox, C.H.J. Multi-mode trimming of imperfect rings. J. Sound Vibr. 2001, 248, 695–724. [Google Scholar] [CrossRef]

- Rourke, A.K.; Mcwilliam, S.; Fox, C.H.J. Multi-mode trimming of imperfect thin rings using masses at pre-selected locations. J. Sound Vibr. 2002, 256, 319–345. [Google Scholar] [CrossRef]

- Xi, X. Study on Drift Mechanism and Its Suppressing Techniques of the Cupped Wave Gyroscope. Ph.D. Thesis, National University of Defense Technology, Changsha, China, 2014. [Google Scholar]

- Xi, X.; Wu, Y.; Wu, X.; Tao, Y.; Wu, X. Modeling and analysis of the stress effects for trimmed cupped resonator under varying temperature. Sens. Actuator A 2013, 189, 429–440. [Google Scholar] [CrossRef]

- Xi, X.; Wu, X.; Zhang, Y.; Zhou, X.; Wu, X.; Wu, Y. A study on Q, factor of the trimmed resonator for vibratory cupped gyroscopes. Sens. Actuator A 2014, 218, 23–32. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, Y.; Xi, X.; Zhang, Y.; Wu, X. Analysis on Node Position of Imperfect Resonators for Cylindrical Shell Gyroscopes. Sensors 2016, 16, 1206. [Google Scholar] [CrossRef] [PubMed]

- Shirk, M.D.; Molian, P.A. A review of ultrashort pulsed laser ablation of materials. J. Laser Appl. 1998, 10, 18–28. [Google Scholar] [CrossRef]

- Küper, S.; Stuke, M. Ablation of uv-transparent materials with femtosecond uv excimer laser pulses. MRS Proc. 1988, 129, 475–480. [Google Scholar] [CrossRef]

- Joglekar, A.P.; Liu, H.H.; Meyhofer, E.; Mourou, G.; Hunt, A.J. Optics at critical intensity: Applications to nanomorphing. Proc. Natl. Acad. Sci. USA 2004, 101, 5856–5861. [Google Scholar] [CrossRef] [PubMed]

- Chichkov, B.N.; Momma, C.; Nolte, S.; Alvensleben, F.; Tunnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A 1996, 63, 109–115. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Young’s modulus E | 210 GPa |

| Poisson’s ratios μ | 0.3 |

| Density ρ | 7800 kg/m3 |

| Parameter | Value (mm) |

|---|---|

| Height and thickness of resonant ring H1 and T1 | 8 and 1 |

| Height and thickness of suspension ring H2 and T2 | 10 and 0.3 |

| External radius of resonator R | 13.5 |

| Thickness of bottom H3 | 0.3 |

| Internal, external, and height of substrate r1, r2, and H4 | 2, 4 and 4 |

| Trimming Method | Trimmed Mass (mg) | Eigenfrequency (Hz) | Split (Hz) | |

|---|---|---|---|---|

| Mode A (Grooves) | Mode B (Holes) | |||

| Grooves-trimming | 0 | 4089.791 | 4083.461 | 6.330 |

| 0.105 | 4089.245 | 4083.399 | 5.846 | |

| 0.211 | 4088.159 | 4083.260 | 4.899 | |

| 0.316 | 4086.766 | 4083.074 | 3.692 | |

| 0.421 | 4085.169 | 4082.850 | 2.319 | |

| Holes-trimming | 0.526 | 4084.885 | 4083.177 | 1.708 |

| 0.632 | 4084.516 | 4083.489 | 1.027 | |

| 0.737 | 4084.201 | 4083.789 | 0.412 | |

| 0.842 | 4083.950 | 4084.080 | −0.130 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, K.; Hu, Y.; Deng, G.; Sun, X.; Su, W.; Lu, Y.; Duan, J. Investigation on Eigenfrequency of a Cylindrical Shell Resonator under Resonator-Top Trimming Methods. Sensors 2017, 17, 2011. https://doi.org/10.3390/s17092011

Zeng K, Hu Y, Deng G, Sun X, Su W, Lu Y, Duan J. Investigation on Eigenfrequency of a Cylindrical Shell Resonator under Resonator-Top Trimming Methods. Sensors. 2017; 17(9):2011. https://doi.org/10.3390/s17092011

Chicago/Turabian StyleZeng, Kai, Youwang Hu, Guiling Deng, Xiaoyan Sun, Wenyi Su, Yunpeng Lu, and Ji’an Duan. 2017. "Investigation on Eigenfrequency of a Cylindrical Shell Resonator under Resonator-Top Trimming Methods" Sensors 17, no. 9: 2011. https://doi.org/10.3390/s17092011

APA StyleZeng, K., Hu, Y., Deng, G., Sun, X., Su, W., Lu, Y., & Duan, J. (2017). Investigation on Eigenfrequency of a Cylindrical Shell Resonator under Resonator-Top Trimming Methods. Sensors, 17(9), 2011. https://doi.org/10.3390/s17092011