A Low-Cost System Based on Image Analysis for Monitoring the Crystal Growth Process

Abstract

:1. Introduction

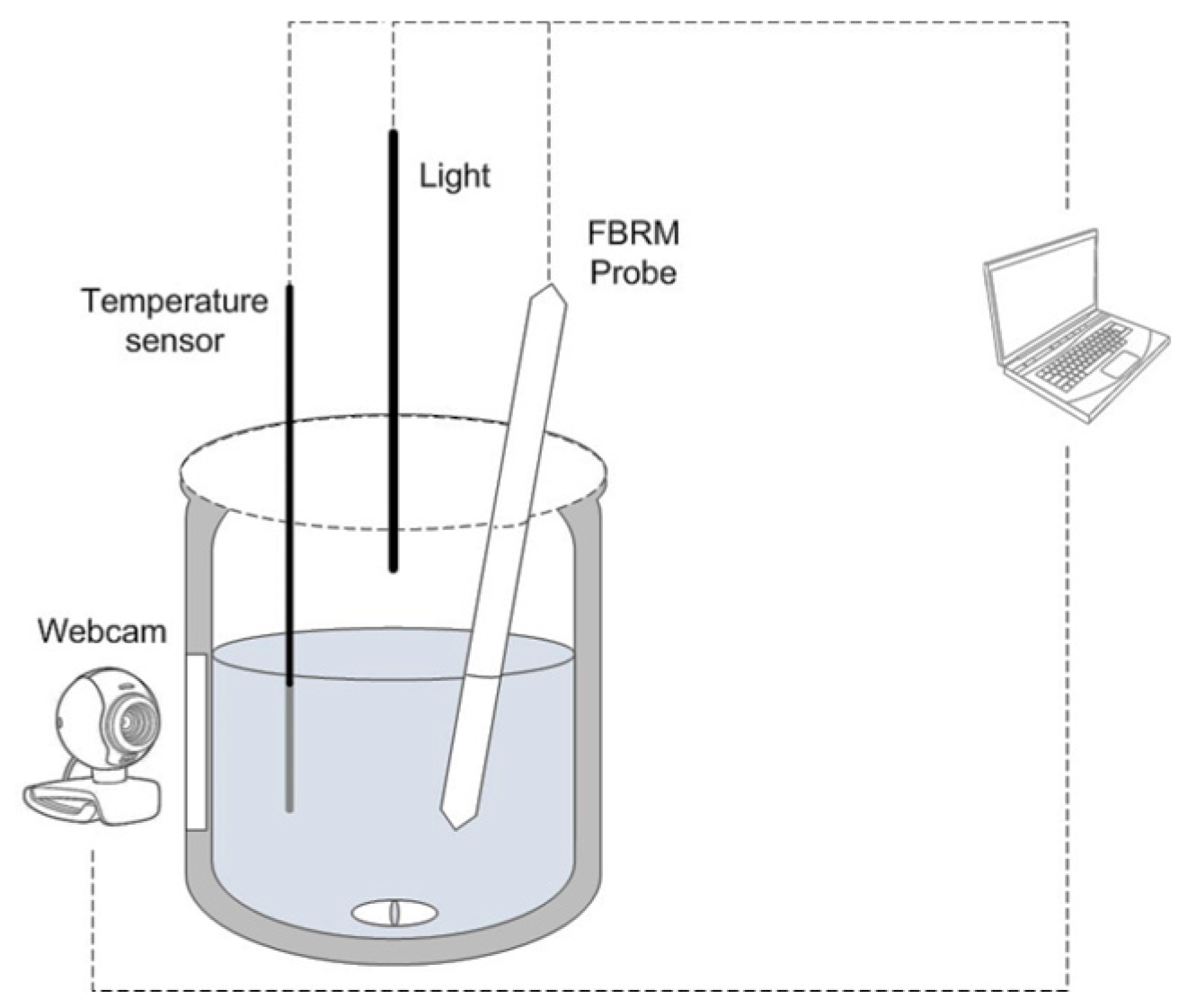

2. Materials and Methods

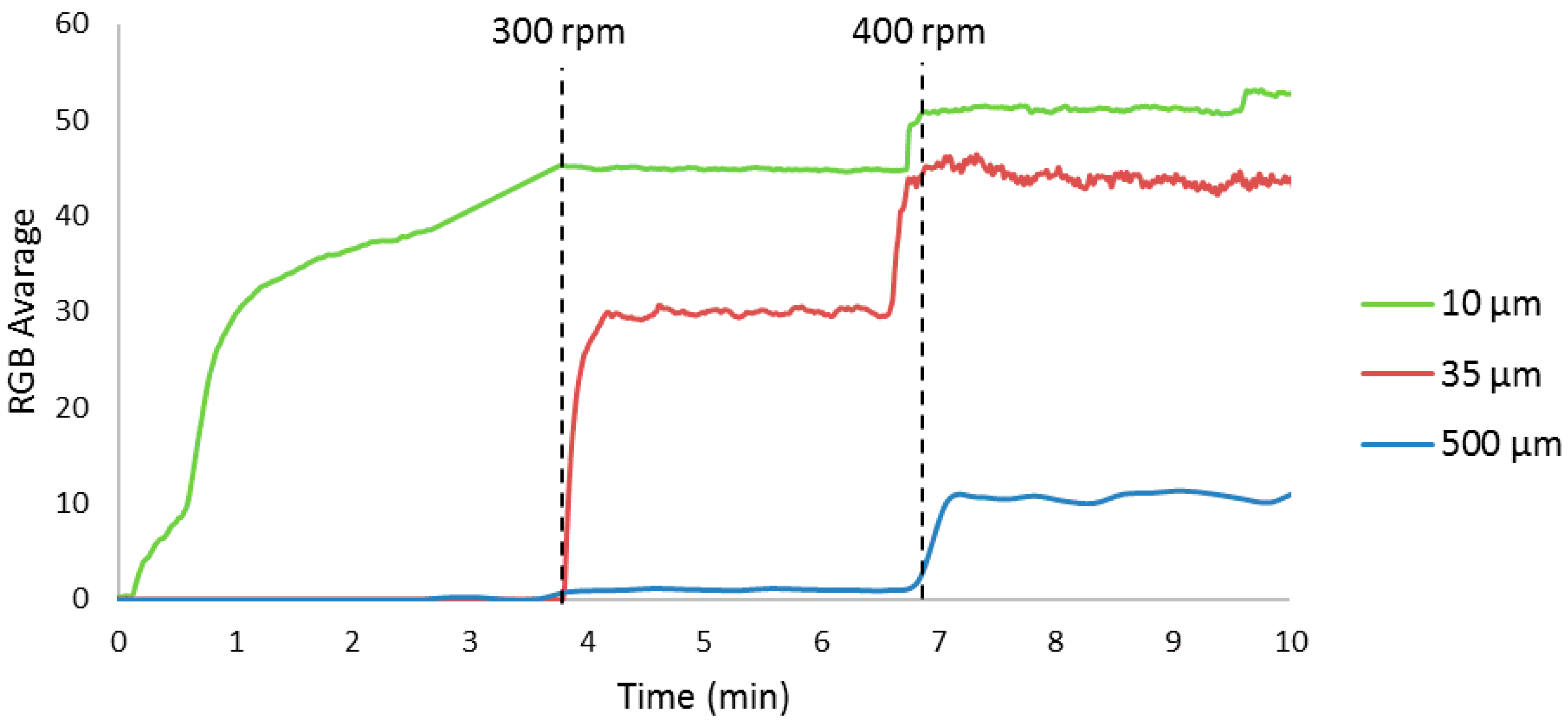

2.1. Influence of Different Particle Sizes on the Imaging System

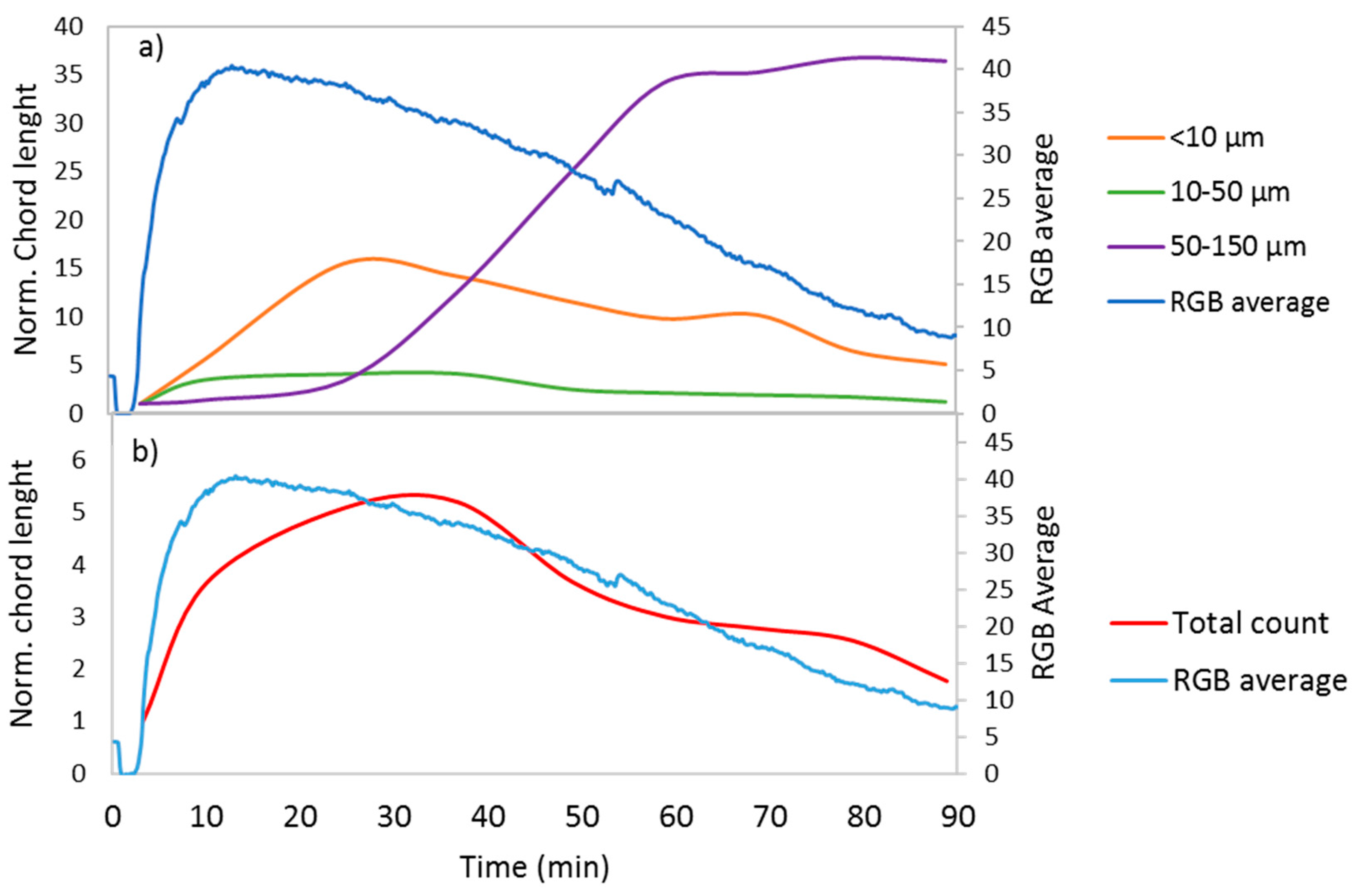

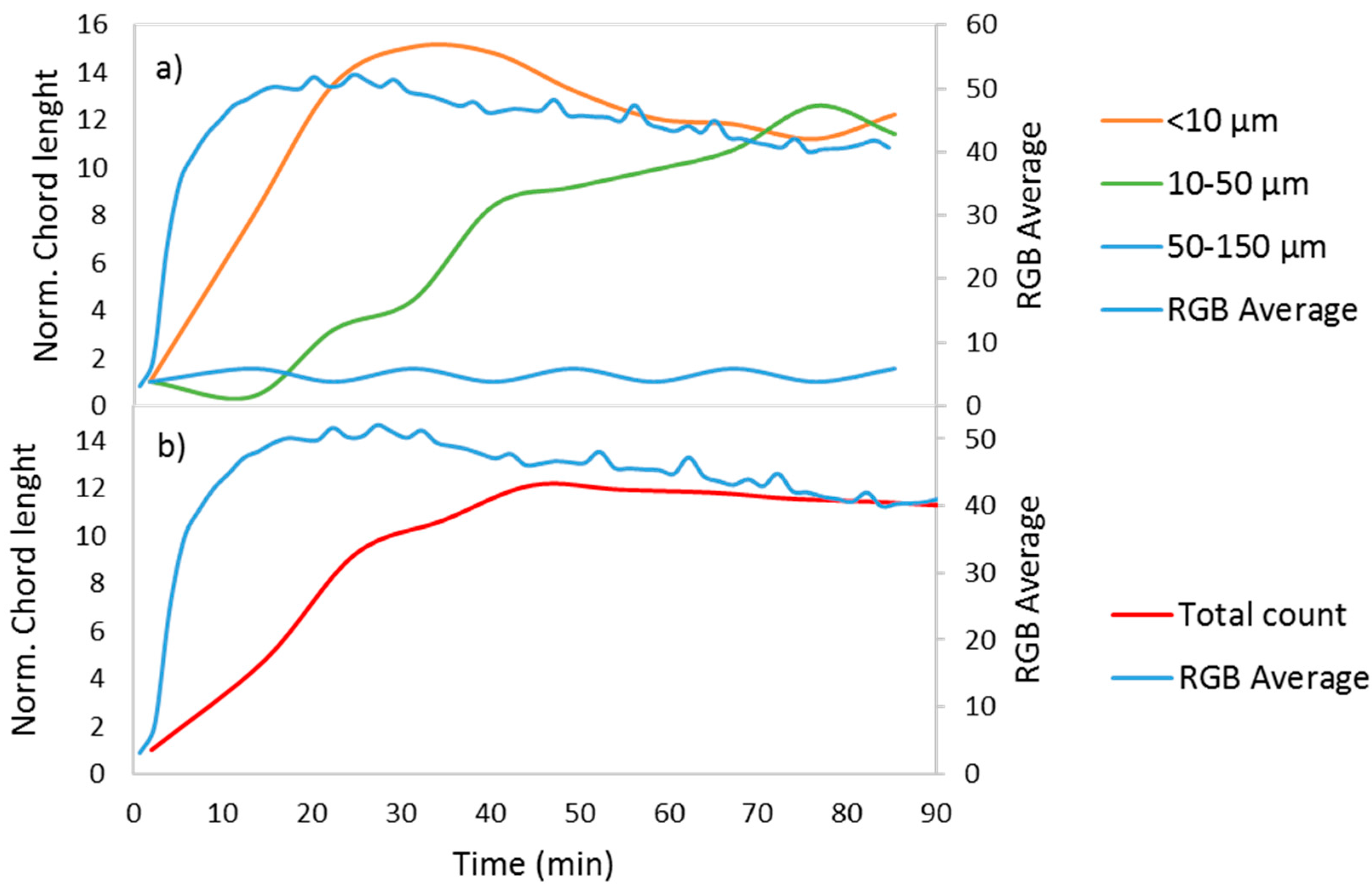

2.2. Calcium Carbonate Crystal Growth Experiments

3. Results and Discussion

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nagy, Z.K.; Fevotte, G.; Kramer, H.; Simon, L.L. Recent advances in the monitoring, modelling and control of crystallization systems. Chem. Eng. Res. Des. 2013, 91, 1903–1922. [Google Scholar] [CrossRef]

- Verma, S.; Shlichta, P.J. Imaging techniques for mapping solution parameters, growth rate, and surface features during the growth of crystals from solution. Prog. Cryst. Growth Charact. Mater. 2008, 54, 1–120. [Google Scholar] [CrossRef]

- Al Nasser, W.N.; Al Salhi, F.H. Kinetics determination of calcium carbonate precipitation behavior by inline techniques. Powder Technol. Part B 2015, 270, 548–560. [Google Scholar] [CrossRef]

- Tadayyon, A.; Rohani, S. Control of fines suspension density in the fines loop of a continuous KCl crystallizer using transmittance measurement and an fbrm® probe. Can. J. Chem. Eng. 2000, 78, 663–673. [Google Scholar] [CrossRef]

- Al Nasser, W.N.; Shaikh, A.; Morriss, C.; Hounslow, M.J.; Salman, A.D. Determining kinetics of calcium carbonate precipitation by inline technique. Chem. Eng. Sci. 2008, 63, 1381–1389. [Google Scholar] [CrossRef]

- Borchert, C.; Sundmacher, K. Crystal aggregation in a flow tube: Image-based observation. Chem. Eng. Technol. 2011, 34, 545–556. [Google Scholar] [CrossRef]

- El Arnaout, T.; Cullen, P.J.; Sullivan, C. A novel backlight fiber optical probe and image algorithms for real time size-shape analysis during crystallization. Chem. Eng. Sci. 2016, 149, 42–50. [Google Scholar] [CrossRef]

- Larsen, P.A.; Rawlings, J.B.; Ferrier, N.J. Model-based object recognition to measure crystal size and shape distributions from in situ video images. Chem. Eng. Sci. 2007, 62, 1430–1441. [Google Scholar] [CrossRef]

- Schorsch, S.; Ochsenbein, D.R.; Vetter, T.; Morari, M.; Mazzotti, M. High accuracy online measurement of multidimensional particle size distributions during crystallization. Chem. Eng. Sci. 2014, 105, 155–168. [Google Scholar] [CrossRef]

- Wang, X.Z.; Roberts, K.J.; Ma, C. Crystal growth measurement using 2d and 3d imaging and the perspectives for shape control. Chem. Eng. Sci. 2008, 63, 1173–1184. [Google Scholar]

- Zhou, Y.; Srinivasan, R.; Lakshminarayanan, S. Critical evaluation of image processing approaches for real-time crystal size measurements. Comput. Chem. Eng. 2009, 33, 1022–1035. [Google Scholar] [CrossRef]

- Simon, L.L.; Nagy, Z.K.; Hungerbuhler, K. Endoscopy-based in situ bulk video imaging of batch crystallization processes. Organ. Process Res. Dev. 2009, 13, 1254–1261. [Google Scholar] [CrossRef]

- Silva, A.D.M.; Oliveira, P.B.; Bandini, T.B.; Barreto, A.G.; Sena, R.C.; Silva, J.F.C. Low-cost system based on image analysis to determine solubility curves. Sens. Actuators B Chem. 2013, 177, 1071–1074. [Google Scholar] [CrossRef]

- Simon, L.L.; Nagy, Z.K.; Hungerbuhler, K. Comparison of external bulk video imaging with focused beam reflectance measurement and ultra-violet visible spectroscopy for metastable zone identification in food and pharmaceutical crystallization processes. Chem. Eng. Sci. 2009, 64, 3344–3351. [Google Scholar] [CrossRef]

- Sena, R.C.; Soares, M.; Oliveira Pereira, M.L.; Domingues da Silva, R.C.; Rosario, F.F.; Cajaiba da Silva, J.F. A simple method based on the application of a ccd camera as a sensor to detect low concentrations of barium sulfate in suspension. Sensors 2011, 11, 864–875. [Google Scholar] [CrossRef] [PubMed]

- Flaten, E.M.; Seiersten, M.; Andreassen, J.P. Polymorphism and morphology of calcium carbonate precipitated in mixed solvents of ethylene glycol and water. J. Cryst. Growth 2009, 311, 3533–3538. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Venâncio, F.; Rosário, F.F.d.; Cajaiba, J. A Low-Cost System Based on Image Analysis for Monitoring the Crystal Growth Process. Sensors 2017, 17, 1248. https://doi.org/10.3390/s17061248

Venâncio F, Rosário FFd, Cajaiba J. A Low-Cost System Based on Image Analysis for Monitoring the Crystal Growth Process. Sensors. 2017; 17(6):1248. https://doi.org/10.3390/s17061248

Chicago/Turabian StyleVenâncio, Fabrício, Francisca F. do Rosário, and João Cajaiba. 2017. "A Low-Cost System Based on Image Analysis for Monitoring the Crystal Growth Process" Sensors 17, no. 6: 1248. https://doi.org/10.3390/s17061248

APA StyleVenâncio, F., Rosário, F. F. d., & Cajaiba, J. (2017). A Low-Cost System Based on Image Analysis for Monitoring the Crystal Growth Process. Sensors, 17(6), 1248. https://doi.org/10.3390/s17061248