Microwave Non-Destructive Inspection and Prediction of Modulus of Rupture and Modulus of Elasticity of Engineered Cementitious Composites (ECCs) Using Dual-Frequency Correlation

Abstract

:1. Introduction

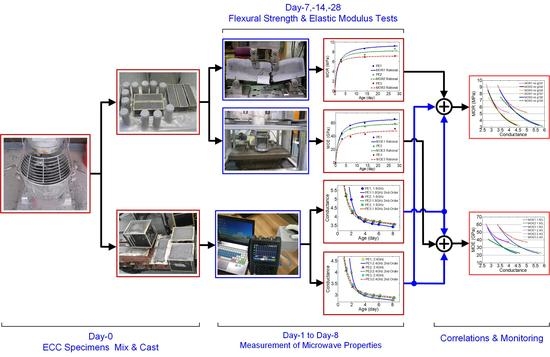

2. Parallel Experimental Programs

2.1. ECC Mixes Design

2.2. Microwave Near-Field Test

2.3. Four-Point Bending Test

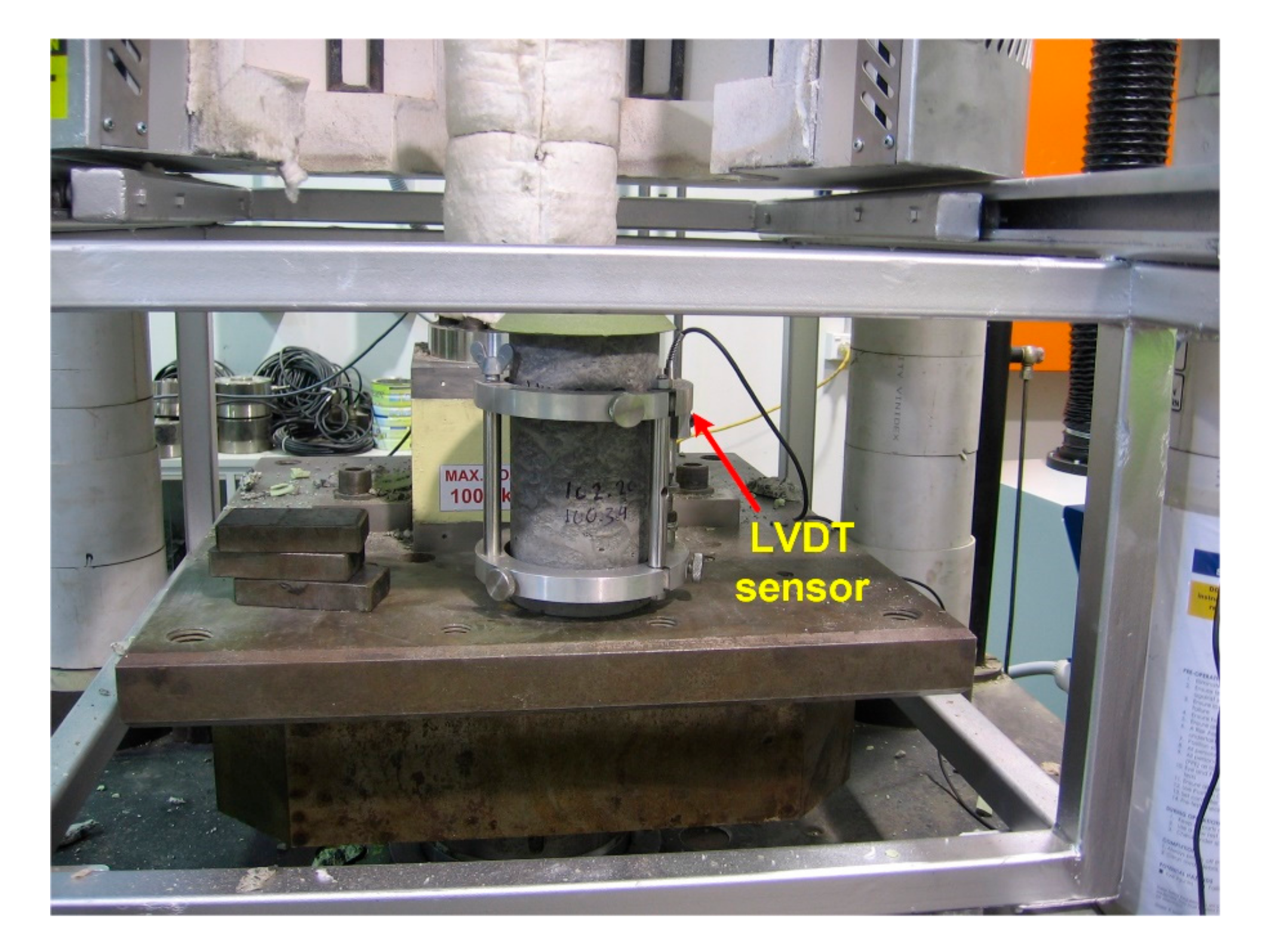

2.4. Modulus of Elasticity Measurement

3. Experimental Results and Mathematical Modeling

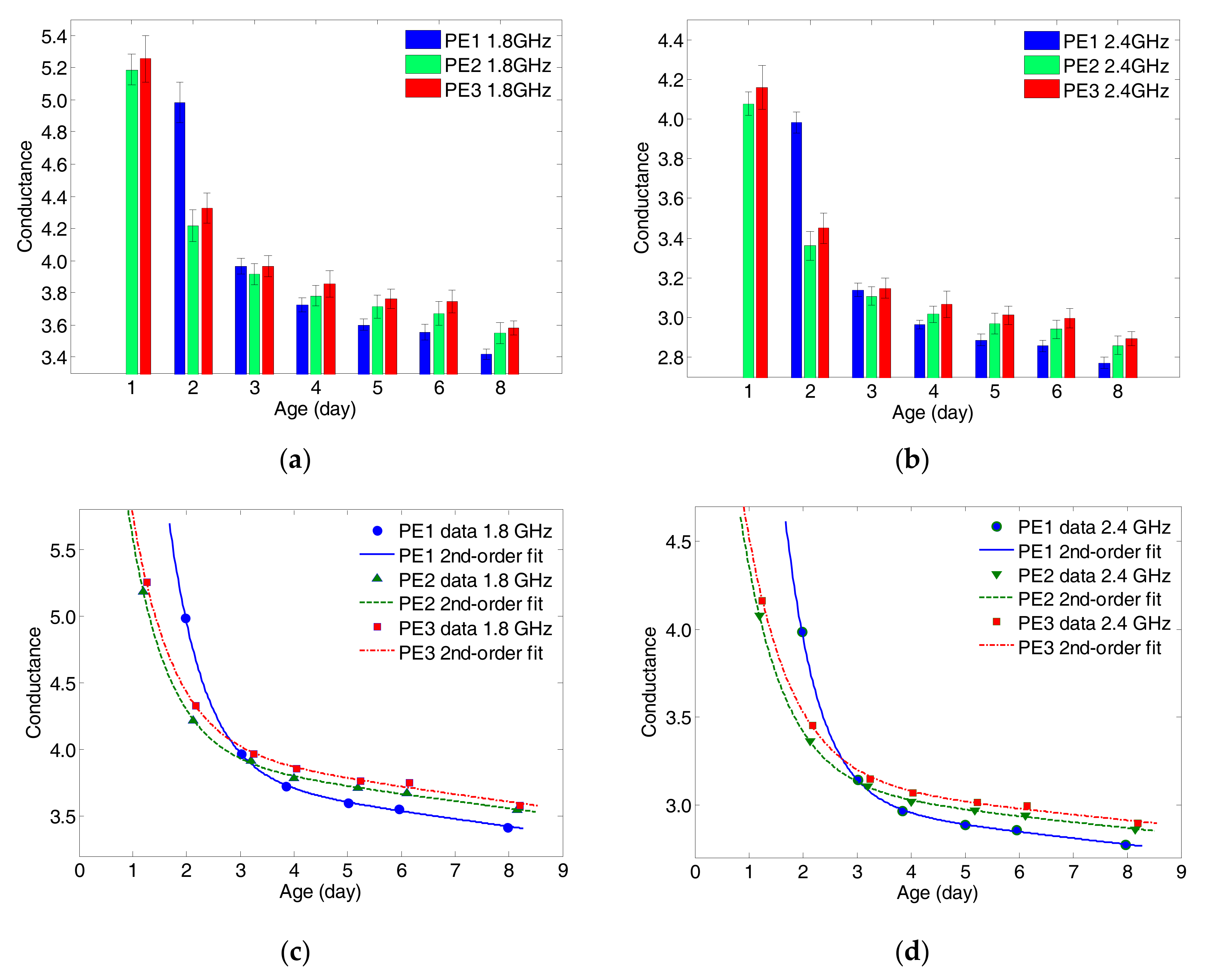

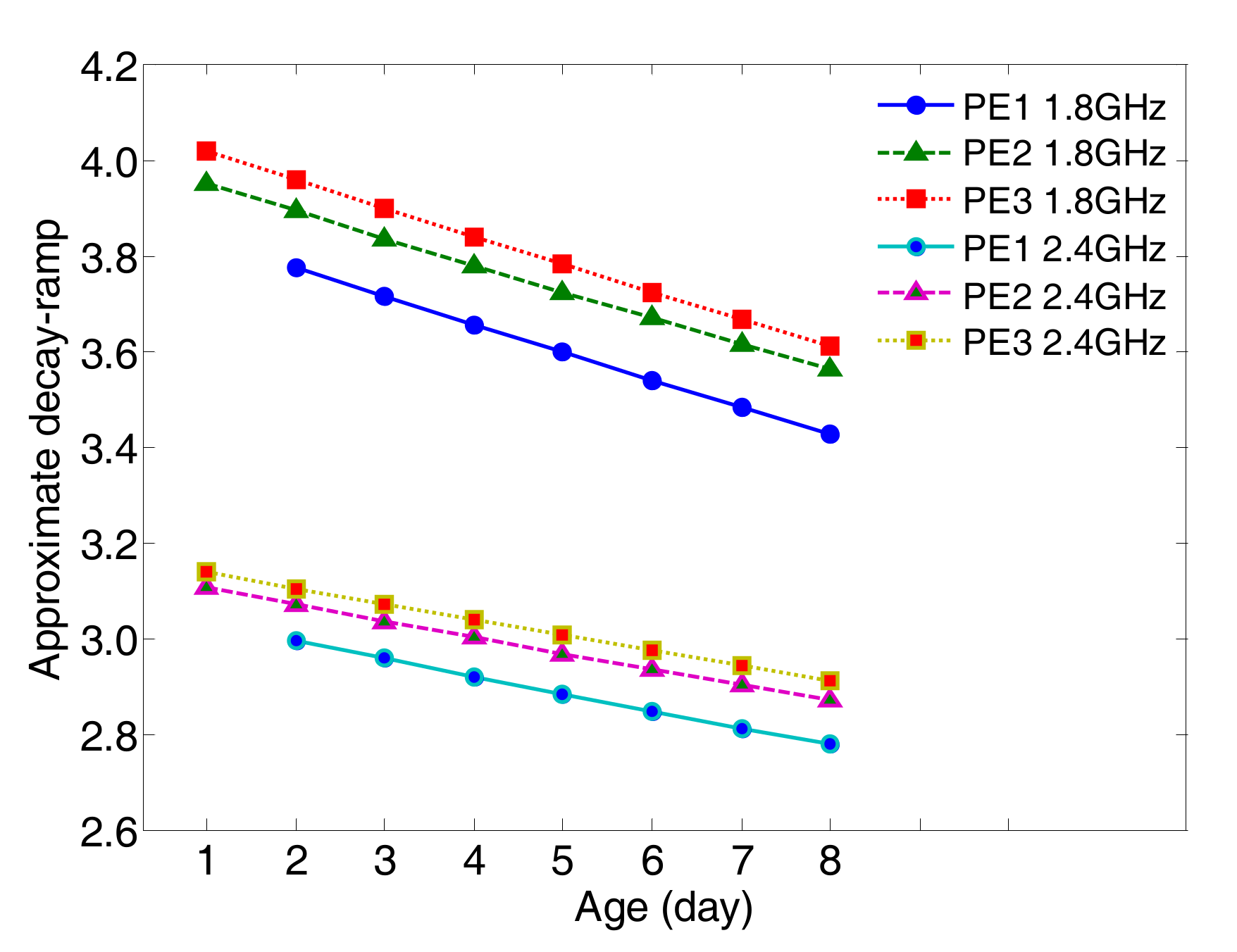

3.1. Modeling of Measured Microwave Properties

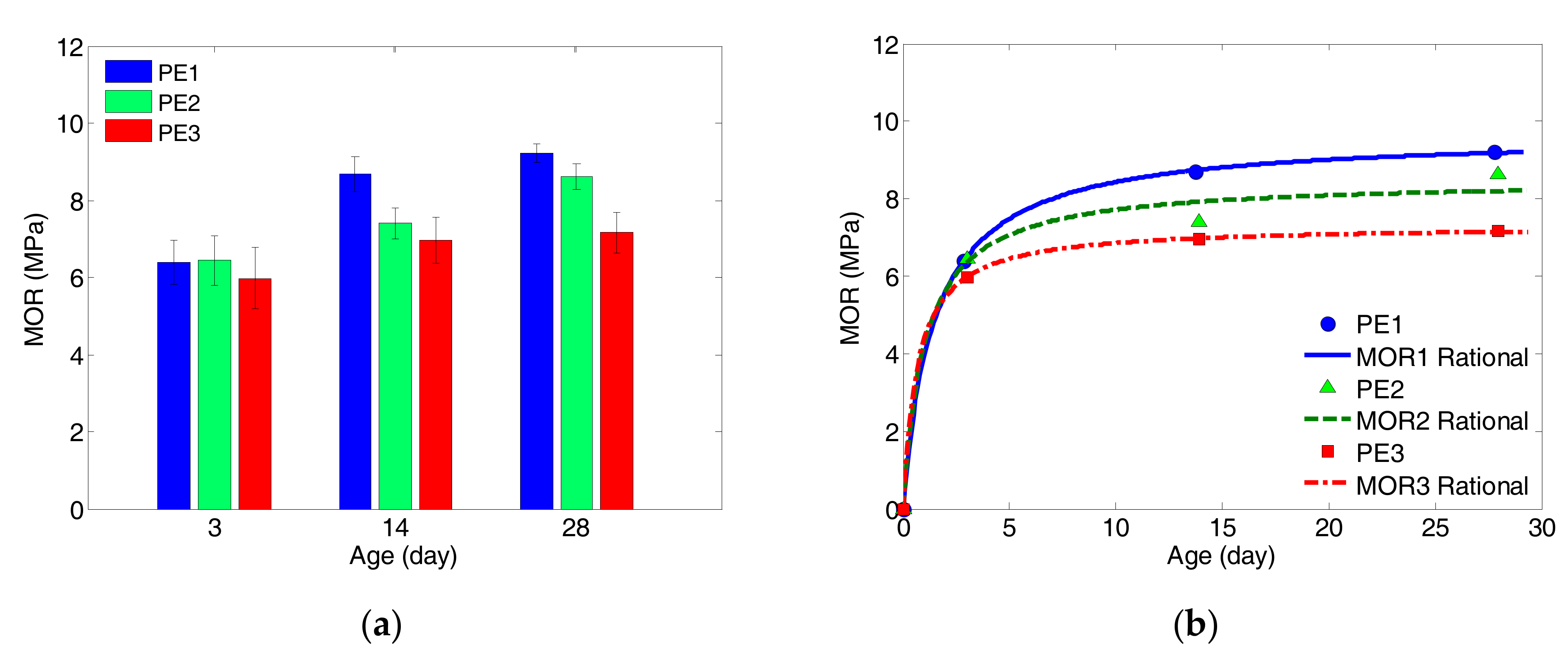

3.2. Modeling of Measured Modulus of Rupture

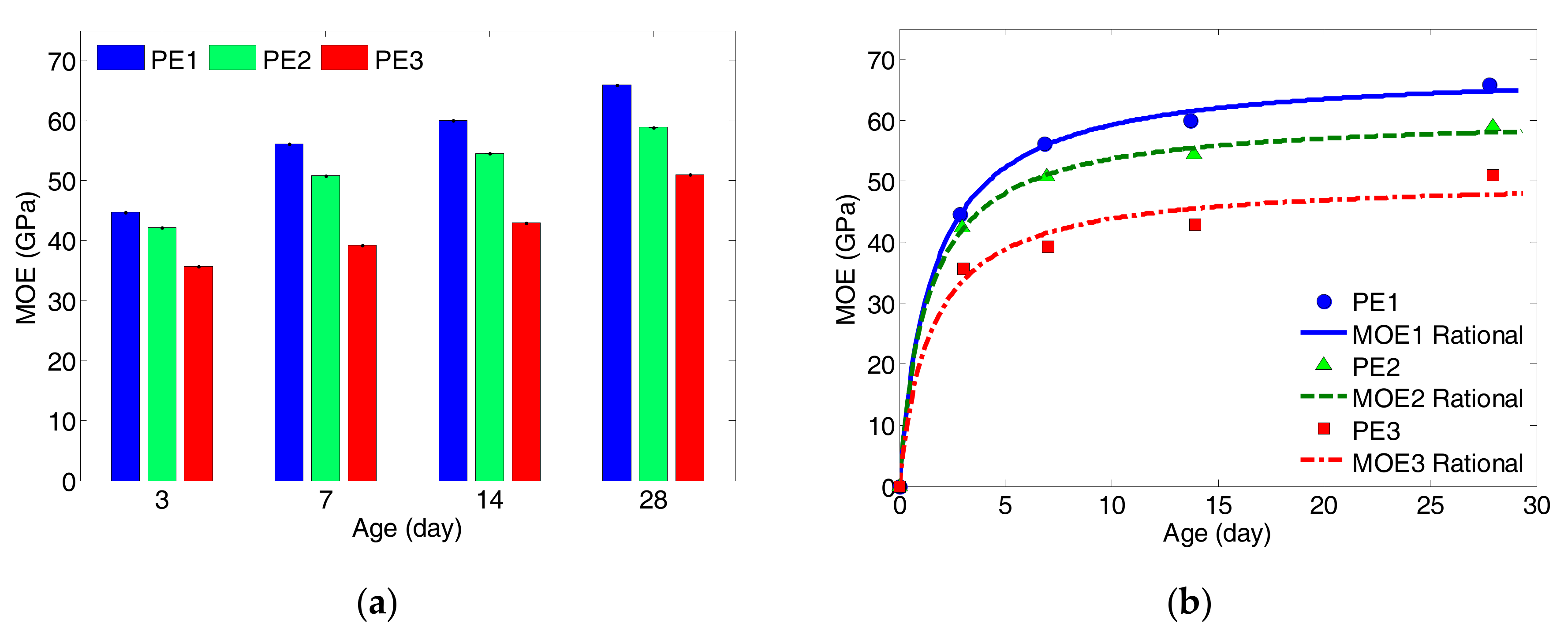

3.3. Modeling of Measured Modulus of Elasticity

4. Correlation and Prediction Models

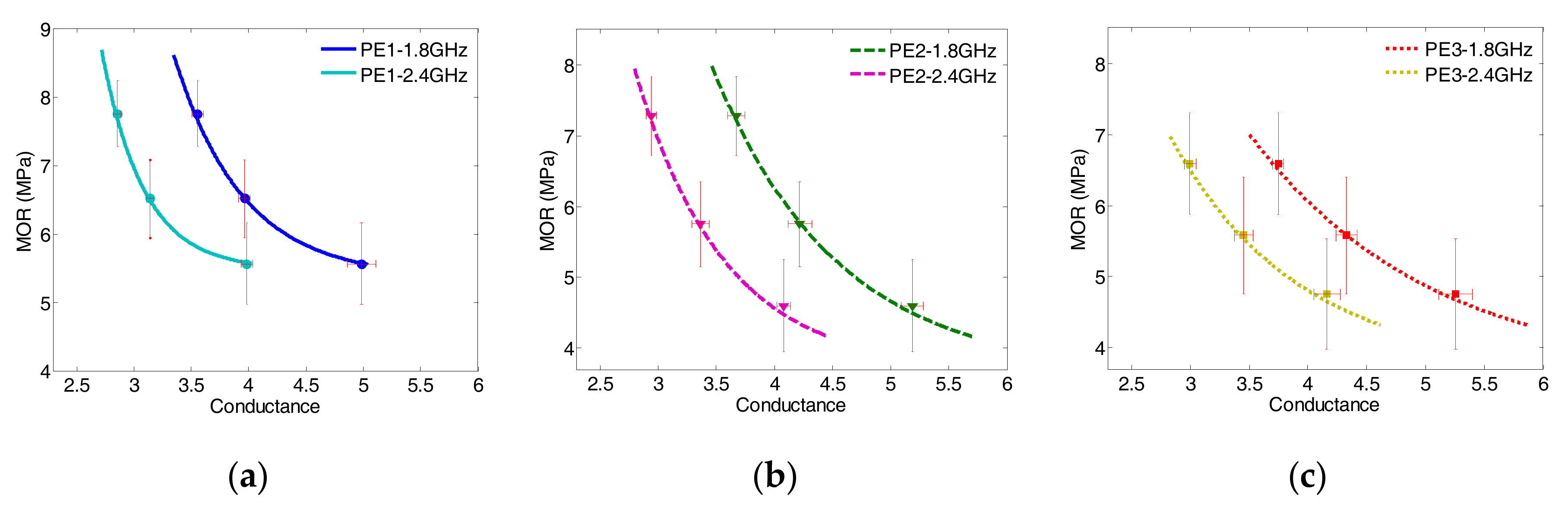

4.1. Correlation between MOR and Conductance

4.2. Correlation Model between MOE and Conductance

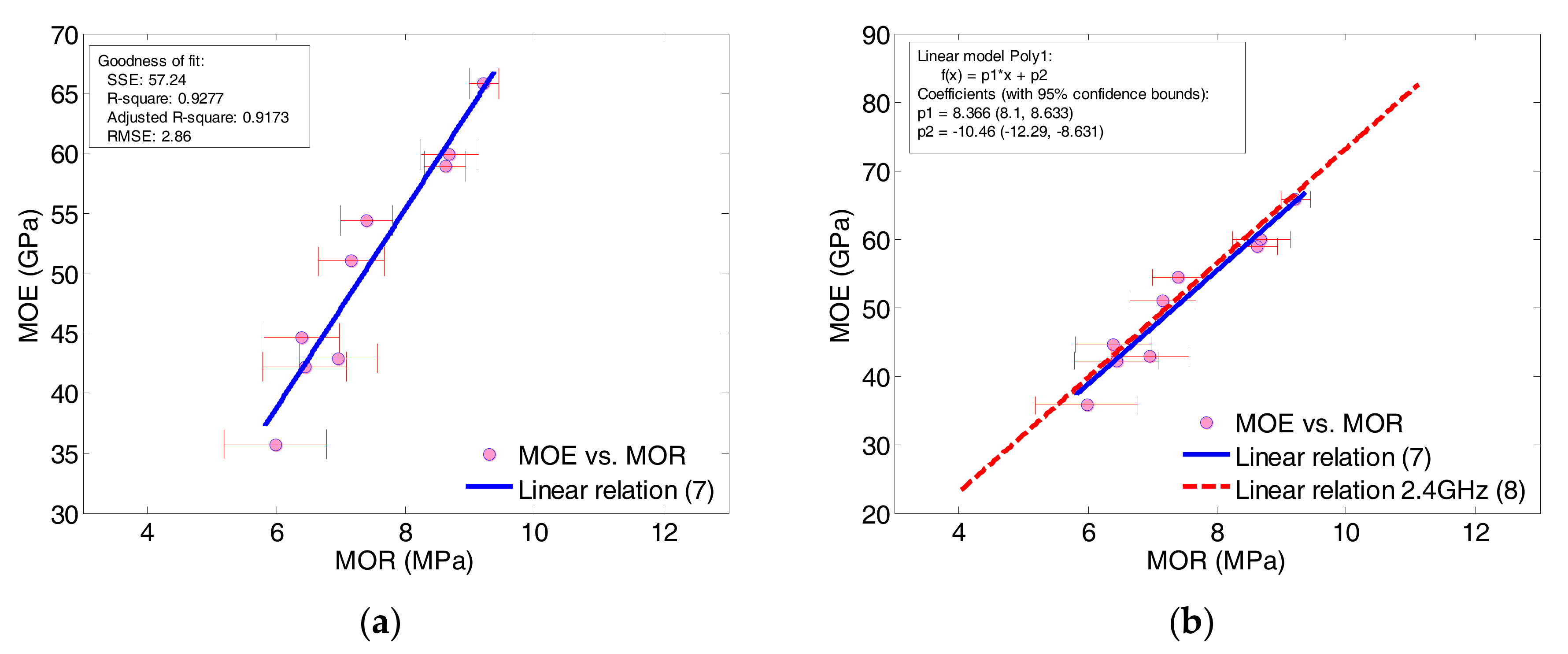

4.3. Relation between MOE and MOR

5. Conclusions

- It was found that the first-order rational function is well-suited for the growth modeling of MOR and MOE of ECC specimens as a function of curing age and w/b ratio.

- The growing rates and the mature values of MOR and MOE are decreasing with the increasing w/b, which can be effectively inspected and predicted by using microwave conductance.

- The achieved correction models indicate that both the MOR and MOE of ECC specimens developed as a function of conductance at dual frequency, which can be used for structural health monitoring, not just for prediction but also for a verification purpose. This is the key advantage of using dual-frequency correlations.

- The linear relation between MOR and MOE is obtained by their predicting functions, which demonstrate the reliability of the microwave technique in monitoring comparing with the measured data.

- It is feasible to monitor and predict the working performance of ECC or CBMs in on-site engineering projects by using handheld VNA via means of microwave nondestructive technique.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- International Atomic Energy Agency (IAEA). Guidebook on Non-Destructive Testing of Concrete Structures; International Atomic Energy Agency: Vienna, Austria, 2002. [Google Scholar]

- Gu, H.; Song, G.B.; Dhonde, H.; Mo, Y.L.; Yan, S. Concrete early-age strength monitoring using embedded piezoelectric transducers. Smart Mater. Struct. 2006, 15, 1837–1845. [Google Scholar] [CrossRef]

- Kim, J.; Lee, C.; Park, S. Artificial neural network-based early-age concrete strength monitoring using dynamic response signals. Sensors 2017, 17, 1319. [Google Scholar] [CrossRef] [PubMed]

- Qin, L.; Li, Z. Monitoring of cement hydration using embedded piezoelectric transducers. Smart Mater. Struct. 2008, 17, 055005. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J.W.; Lee, C.; Park, S. Development of embedded EM sensors for estimating tensile forces of PSC girder bridges. Sensors 2017, 17, 1989. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.T.; Lin, T.F. The stress effect on the ultrasonic velocity variations of concrete under repeated loading. Mater. J. 1998, 95, 519–524. [Google Scholar]

- Selleck, S.F.; Landis, E.N.; Peterson, M.L.; Shah, S.P.; Achenbach, J.D. Ultrasonic investigation of concrete with distributed damage. Mater. J. 1998, 95, 27–36. [Google Scholar]

- Lafhaj, Z.; Goueygou, M.; Djerbi, A.; Kaczmarek, M. Correlation between porosity, permeability and ultrasonic parameters of mortar with variable water/cement ratio and water content. Cem. Concr. Res. 2006, 36, 33–625. [Google Scholar] [CrossRef]

- Yusuf, I.T.; Jimoh, Y.A.; Salami, W.A. An appropriate relationship between flexural strength and compressive strength of palm kernel shell concrete. Alex. Eng. J. 2016, 55, 1553–1562. [Google Scholar] [CrossRef]

- Hoła, J.; Schabowicz, K. State-of-the-art non-destructive methods for diagnostic testing of building structures-anticipated development trends. Arch. Civ. Mech. Eng. 2010, 10, 5–18. [Google Scholar] [CrossRef]

- Lencioni, J.W.; Lima, M.G.D. A study of the parameters that affect the measurements of superficial electrical resistivity of concrete. In Nondestructive Testing of Materials and Structures; Güneş, O., Akkaya, Y., Eds.; Springer: Dordrecht, The Netherlands, 2013; pp. 271–276. [Google Scholar]

- Lataste, J.F.; Sirieix, C.; Breysse, D.; Frappa, M. Electrical resistivity measurement applied to cracking assessment on reinforced concrete structures in civil engineering. NDT E Intern. 2003, 36, 383–394. [Google Scholar] [CrossRef]

- Ferreira, R.M.; Jalali, S. NDT measurements for the prediction of 28-day compressive strength. NDT E Intern. 2010, 43, 55–61. [Google Scholar] [CrossRef]

- Xiao, L.; Li, Z. Early-age hydration of fresh concrete monitored by non-contact electrical resistivity measurement. Cem. Concr. Res. 2008, 38, 312–319. [Google Scholar] [CrossRef]

- Wei, X.; Xiao, L.; Li, Z. Prediction of standard compressive strength of cement by the electrical resistivity measurement. Constr. Build. Mater. 2012, 31, 341–346. [Google Scholar] [CrossRef]

- Zoughi, R.; Nowak, P.S. Strength-Related Testing of Concrete Using Microwave Signals. U.S. Patent 05,939,889, 17 August 1999. [Google Scholar]

- Zoughi, R.; Cone, G.L.; Nowak, P.S. Microwave non-destructive detection of rebars in concrete slabs. Mater. Eval. 1991, 49, 8–1385. [Google Scholar]

- Bois, K.; Benally, A.; Nowak, P.; Zoughi, R. Cure-state monitoring and water-to-cement ratio determination of fresh Portland cement-based materials using near-field microwave techniques. IEEE Trans. Instrum. Meas. 1998, 47, 628–637. [Google Scholar] [CrossRef]

- Mubarak, K.; Bois, K.J.; Zoughi, R. A simple, robust, and on-site microwave technique for determining water-to-cement ratio of fresh Portland cement-based materials. IEEE Trans. Instrum. Meas. 2001, 50, 1255–1263. [Google Scholar] [CrossRef]

- Bois, K.; Benally, A.; Zoughi, R. Microwave near-field reflection property analysis of concrete for material content determination. IEEE Trans. Instrum. Meas. 2000, 49, 49–55. [Google Scholar] [CrossRef]

- Al-Mattarneh, H.M.A.; Ghodgaonkar, D.K.; Majid, M.B.W.A.W. Microwave sensing of moisture content in concrete using open-ended rectangular waveguide. Surf. Sens. Technol. Appl. 2001, 2, 377–390. [Google Scholar] [CrossRef]

- Peer, S.; Case, J.T.; Gallaher, E.; Kurtis, K.E.; Zoughi, R. Microwave reflection and dielectric properties of mortar subjected to compression force and cyclically exposed to water and sodium chloride solution. IEEE Trans. Instrum. Meas. 2003, 52, 111–118. [Google Scholar] [CrossRef]

- Hasar, U.C. Non-destructive testing of hardened cement specimens at microwave frequencies using a simple free-space method. NDT E Int. 2009, 42, 550–557. [Google Scholar] [CrossRef]

- Jamil, M.; Hassan, M.K.; Al-Mattarneh, H.M.A.; Zain, M.F.M. Concrete dielectric properties investigation using microwave nondestructive techniques. Mater. Struct. 2013, 46, 77–87. [Google Scholar] [CrossRef]

- Chung, K.L.; Kharkovsky, S. Monitoring of microwave properties of early-age concrete and mortar specimens. IEEE Trans. Instrum. Meas. 2015, 64, 1196–1203. [Google Scholar] [CrossRef]

- Castro, A.F.; Valcuende, M.; Vidal, B. Using microwave near-field reflection measurements as a non-destructive test to determine water penetration depth of concrete. NDT E Int. 2015, 75, 26–32. [Google Scholar] [CrossRef]

- Hashemi, A.; Horst, M.; Kurtis, K.E.; Donnell, K.M.; Zoughi, R. Comparison of alkali–silica reaction gel behavior in mortar at microwave frequencies. IEEE Trans. Instrum. Meas. 2015, 64, 1907–1915. [Google Scholar] [CrossRef]

- Kim, S.; Kang, J.; Lee, S.H.; Ahn, Y.H. Effect of chlorides on conductivity and dielectric constant in hardened cement mortar: NDT for durability evaluation. Adv. Mater. Sci. Eng. 2016, 6, 1–9. [Google Scholar] [CrossRef]

- Shen, P.; Lu, L.; He, Y.; Wang, F.; Hu, S. Hydration monitoring and strength prediction of cement-based materials based on the dielectric properties. Constr. Build. Mater. 2016, 126, 179–189. [Google Scholar] [CrossRef]

- Chung, K.L.; Luo, J.; Yuan, L.; Zhang, C.; Qu, C. Strength correlation and prediction of engineered cementitious composites with microwave properties. Appl. Sci. 2017, 7, 35. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Longman: New York, NY, USA, 1996. [Google Scholar]

- Gonen, T.; Yazicioglu, S. The influence of compaction pores on sorptivity and carbonation of concrete. Constr. Build. Mater. 2007, 21, 1040–1045. [Google Scholar] [CrossRef]

- Li, V.C.; Wu, C.; Wang, S.; Saito, T. Interface tailoring for strain-hardening PVA-ECC. ACI Mater. J. 2002, 99, 463–472. [Google Scholar]

- Li, V.C. Tailoring ECC for special attributes: A review. J. Concr. Struct. Mater. 2012, 6, 135–144. [Google Scholar] [CrossRef]

- Li, V.C. Engineered cementitious composites (ECC)-material, structural, and durability performance. In Concrete Construction Engineering Handbook; Nawy, E., Ed.; CRC Press: Boca Raton, FL, USA, 2008; Chapter 24. [Google Scholar]

- Ma, H.; Qian, S.; Zhang, Z. Effect of self-healing on water permeability and mechanical property of medium-early-strength engineered cementitious composites. Constr. Build. Mater. 2014, 68, 92–101. [Google Scholar] [CrossRef]

- Chung, K.L.; Ghannam, M.; Zhang, C. Effect of specimen shapes on compressive strength of engineered cementitious composites (ECCs) with different values of water-to-binder ratio and PVA fiber. Arab. J. Sci. Eng. 2017, 2, 1–13. [Google Scholar] [CrossRef]

- Yang, Y.; Gao, X.; Deng, H.; Yu, P.; Yao, Y. Effects of water/binder ratio on the properties of engineered cementitious composites. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2010, 25, 298–302. [Google Scholar] [CrossRef]

- Cong, L.; Leung, C.K.Y. Theoretical evaluation of fiber orientation and its effects on mechanical properties in engineered cementitious composites (ECC) with various thicknesses. Cem. Concr. Res. 2017, 95, 240–246. [Google Scholar]

- Lu, C.; Leung, C.K.Y.; Li, V.C. Numerical model on the stress field and multiple cracking behavior of engineered cementitious composites (ECC). Constr. Build. Mater. 2017, 133, 118–127. [Google Scholar] [CrossRef]

- Zhou, J.; Qian, S.; Ye, G.; Copuroglu, O.; Breugel, K.V.; Li, V.C. Improved fiber distribution and mechanical properties of engineered cementitious composites by adjusting the mixing sequence. Cem. Concr. Compos. 2012, 34, 342–348. [Google Scholar] [CrossRef]

- Soe, K.T.; Zhang, Y.X.; Zhang, L.C. Impact resistance of hybrid-fiber engineered cementitious composite panels. Compos. Struct. 2013, 104, 320–330. [Google Scholar] [CrossRef]

- Nurdeen, M.A.; Johari, M.A.M.; Hashim, S.F.S. Flexural performance of green engineered cementitious composites containing high volume of palm oil fuel ash. Constr. Build. Mater. 2012, 37, 518–525. [Google Scholar]

- Yildirim, G.; Keskin, O.K.; Keskin, S.B.; Sahmaran, M.; Lachemi, M. A review of intrinsic self-healing capability of engineered cementitious composites: Recovery of transport and mechanical properties. Constr. Build. Mater. 2015, 101, 10–21. [Google Scholar] [CrossRef]

- Martínez-Molina, W.; Torres-Acosta, A.A.; Jáuregui, J.C.; Chávez-García, H.L.; Alonso-Guzmán, M.; Graff, E.M.; Arteaga-Arcos, J.C. Predicting concrete compressive strength and modulus of rupture using different NDT techniques. Adv. Mater. Sci. Eng. 2014, 2014, 1–15. [Google Scholar] [CrossRef]

- Yoshitake, I.; Rajabipour, F.; Yoichi, M.; Andrew, S. A prediction method of tensile Young’s modulus of concrete at early age. Adv. Civ. Eng. 2012, 2012, 391214. [Google Scholar] [CrossRef]

- Tian, Z.; Bian, C. Numerical modeling of elastic modulus for cement paste using homogenization method. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2013, 28, 751–760. [Google Scholar] [CrossRef]

- Wu, L.; Yan, B.; Lei, B. Prediction of elastic modulus of cement-based materials based on power’s volume model. Appl. Mech. Mater. 2013, 253, 474–477. [Google Scholar] [CrossRef]

- Yapici, F.; Ozcifci, A.; Akbulut, T.; Bayir, R. Determination of modulus of rupture and modulus of elasticity on flakeboard with fuzzy logic classifier. Mater. Des. 2009, 30, 2269–2273. [Google Scholar] [CrossRef]

- Tiryaki, S.; Hamzacebi, C. Predicting modulus of rupture (MOR) and modulus of elasticity (MOE) of heat treated woods by artificial neural networks. Measurement 2014, 49, 266–274. [Google Scholar] [CrossRef]

- Keysight Technologies. N9923A FieldFox RF Vector Network Analyzer Data Sheet; 5990-5363EN; Keysight Technologies, Inc.: Santa Clara, CA, USA, 2016. [Google Scholar]

- Chung, D.D.L. Structural health monitoring by electrical resistance measurement. Smart Mater. Struct. 2001, 10, 624. [Google Scholar] [CrossRef]

| Fiber | Tensile Strength (MPa) | Elastic Modulus (GPa) | Specific Gravity | Diameter (μm) | Length (mm) | Shape | Color |

|---|---|---|---|---|---|---|---|

| PVA | 1600 | 40 | 1.3 | 38 | 8 | straight | white |

| Constituent | FS (% wt) | PC (% wt) | FA-F (% wt) |

|---|---|---|---|

| CaO | - | 58.1 | - |

| SiO2 | 95.6 | 24.7 | 76.3 |

| Al2O3 | 1.9 | 6.4 | 20.2 |

| SO3 | 0.3 | 3.5 | - |

| MgO | - | 2.4 | - |

| FeO | 0.3 | 2.2 | 0.4 |

| TiO2 | 0.9 | - | 0.9 |

| K2O | - | 0.5 | 0.4 |

| LOI | 1.0 | 2.2 | 1.8 |

| ECC | w/b | Cement | Fly Ash | Water | Sand | HRWR | PVA (%vol) |

|---|---|---|---|---|---|---|---|

| PE1 | 0.200 | 618 | 742 | 272 | 494 | 9.83 | 2 |

| PE2 | 0.255 | 578 | 694 | 324 | 462 | 9.19 | 2 |

| PE3 | 0.300 | 544 | 654 | 359 | 435 | 8.66 | 2 |

| Test | Standard | Shape | Sizes (mm) | No. of Test Specimens/Type |

|---|---|---|---|---|

| Microwave near-field Test | custom | cube | 200 × 200 × 200 | 1 |

| Four-point bending Test | AS1012.8.2 | rectangular prism | 100 × 100 × 400 | 3 |

| Modulus of elasticity Test | AS 1012.9 | cylinder | Ø100, H200 | 1 |

| 1.8 GHz | w/b | K1 | m | K2 | n | R2 |

|---|---|---|---|---|---|---|

| PE1 | 0.200 | 24.17 | 0.664 | 3.90 | 61.73 | 0.9998 |

| PE2 | 0.255 | 6.65 | 0.718 | 4.01 | 67.55 | 0.9995 |

| PE3 | 0.300 | 6.39 | 0.773 | 4.08 | 65.64 | 0.9984 |

| 2.4 GHz | w/b | K1 | m | K2 | n | R2 |

|---|---|---|---|---|---|---|

| PE1 | 0.200 | 24.57 | 0.619 | 3.07 | 79.73 | 0.9999 |

| PE2 | 0.255 | 4.54 | 0.781 | 3.14 | 88.42 | 0.9998 |

| PE3 | 0.300 | 4.58 | 0.843 | 3.17 | 93.43 | 0.9991 |

| ECC | MORav (Day-3) | MORstd (Day-3) | MORav (Day-14) | MORstd (Day-14) | MORav (Day-28) | MORstd (Day-28) | a | b | R2 |

|---|---|---|---|---|---|---|---|---|---|

| PE1 | 6.39 | 0.58 | 8.68 | 0.45 | 9.22 | 0.23 | 0.756 | 0.518 | 0.9999 |

| PE2 | 6.44 | 0.65 | 7.40 | 0.40 | 8.62 | 0.32 | 0.468 | 0.462 | 0.9898 |

| PE3 | 5.98 | 0.80 | 6.96 | 0.60 | 7.16 | 0.52 | 0.308 | 0.456 | 1.000 |

| ECC | MOE (Day-3) | MOE (Day-7) | MOE (Day-14) | MOE (Day-28) | c | d | R2 |

|---|---|---|---|---|---|---|---|

| PE1 | 44.6 | 56.0 | 59.9 | 65.8 | 0.113 | 0.073 | 0.9987 |

| PE2 | 42.2 | 50.8 | 54.4 | 58.9 | 0.086 | 0.065 | 0.9991 |

| PE3 | 35.7 | 39.2 | 42.9 | 51.0 | 0.099 | 0.066 | 0.9831 |

| ECC | w/b | A18 | C18 | m18 | R2 |

|---|---|---|---|---|---|

| PE1 | 0.200 | 880.9 | 26.8 | 0.598 | 0.998 |

| PE2 | 0.255 | 111.2 | 14.25 | 1.068 | 0.998 |

| PE3 | 0.300 | 33.62 | 11.96 | 1.532 | 0.999 |

| ECC | w/b | A24 | C24 | m24 | R2 |

|---|---|---|---|---|---|

| PE1 | 0.200 | 5238 | 27.38 | 0.367 | 0.998 |

| PE2 | 0.255 | 162 | 14.43 | 0.768 | 0.998 |

| PE3 | 0.300 | 44.67 | 12.32 | 1.082 | 0.997 |

| ECC | w/b | G18 | H18 | k18 | R2 |

|---|---|---|---|---|---|

| PE1 | 0.200 | 6960 | 185.4 | 0.589 | 0.9982 |

| PE2 | 0.255 | 1310 | 88.69 | 0.940 | 0.9982 |

| PE3 | 0.300 | 905.8 | 57.4 | 1.013 | 0.9984 |

| ECC | w/b | G24 | H24 | k24 | R2 |

|---|---|---|---|---|---|

| PE1 | 0.200 | 42170 | 189.5 | 0.362 | 0.9979 |

| PE2 | 0.255 | 2052 | 90.08 | 0.673 | 0.9979 |

| PE3 | 0.300 | 1466 | 59.58 | 0.711 | 0.9969 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chung, K.L.; Zhang, C.; Li, Y.; Sun, L.; Ghannam, M. Microwave Non-Destructive Inspection and Prediction of Modulus of Rupture and Modulus of Elasticity of Engineered Cementitious Composites (ECCs) Using Dual-Frequency Correlation. Sensors 2017, 17, 2831. https://doi.org/10.3390/s17122831

Chung KL, Zhang C, Li Y, Sun L, Ghannam M. Microwave Non-Destructive Inspection and Prediction of Modulus of Rupture and Modulus of Elasticity of Engineered Cementitious Composites (ECCs) Using Dual-Frequency Correlation. Sensors. 2017; 17(12):2831. https://doi.org/10.3390/s17122831

Chicago/Turabian StyleChung, Kwok L., Chunwei Zhang, Yuanyuan Li, Li Sun, and Mohamed Ghannam. 2017. "Microwave Non-Destructive Inspection and Prediction of Modulus of Rupture and Modulus of Elasticity of Engineered Cementitious Composites (ECCs) Using Dual-Frequency Correlation" Sensors 17, no. 12: 2831. https://doi.org/10.3390/s17122831

APA StyleChung, K. L., Zhang, C., Li, Y., Sun, L., & Ghannam, M. (2017). Microwave Non-Destructive Inspection and Prediction of Modulus of Rupture and Modulus of Elasticity of Engineered Cementitious Composites (ECCs) Using Dual-Frequency Correlation. Sensors, 17(12), 2831. https://doi.org/10.3390/s17122831