Design and Fabrication of Micro Hemispheric Shell Resonator with Annular Electrodes

Abstract

:1. Introduction

2. Design and Simulation

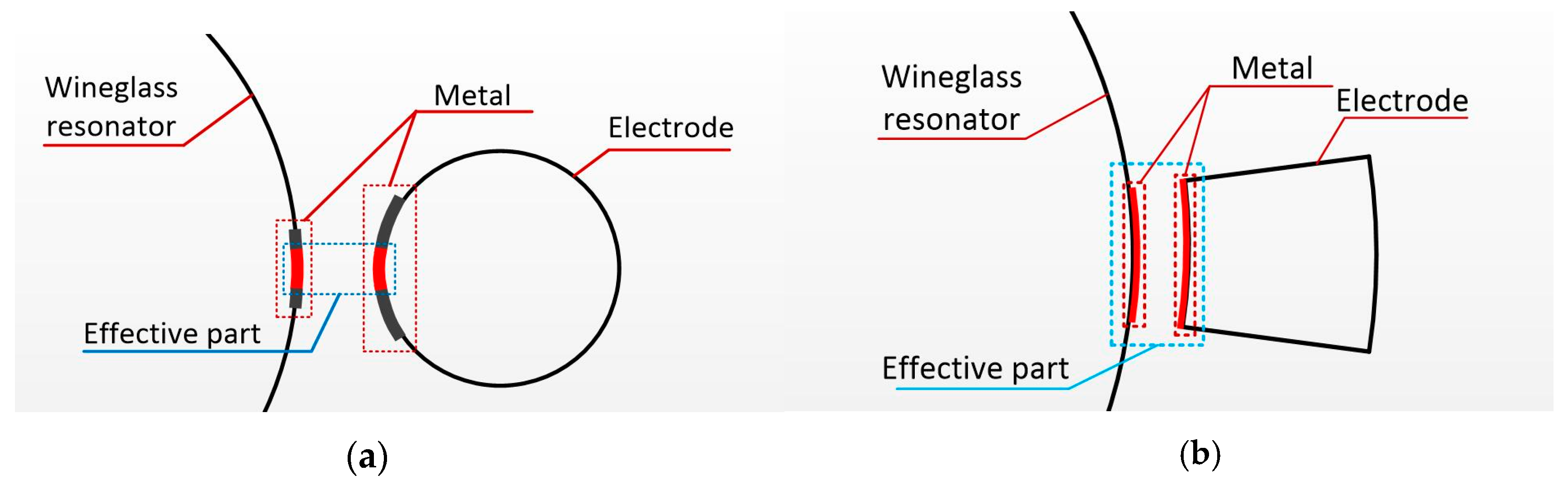

2.1. The Relationship between Driving Force and Electrode Gap

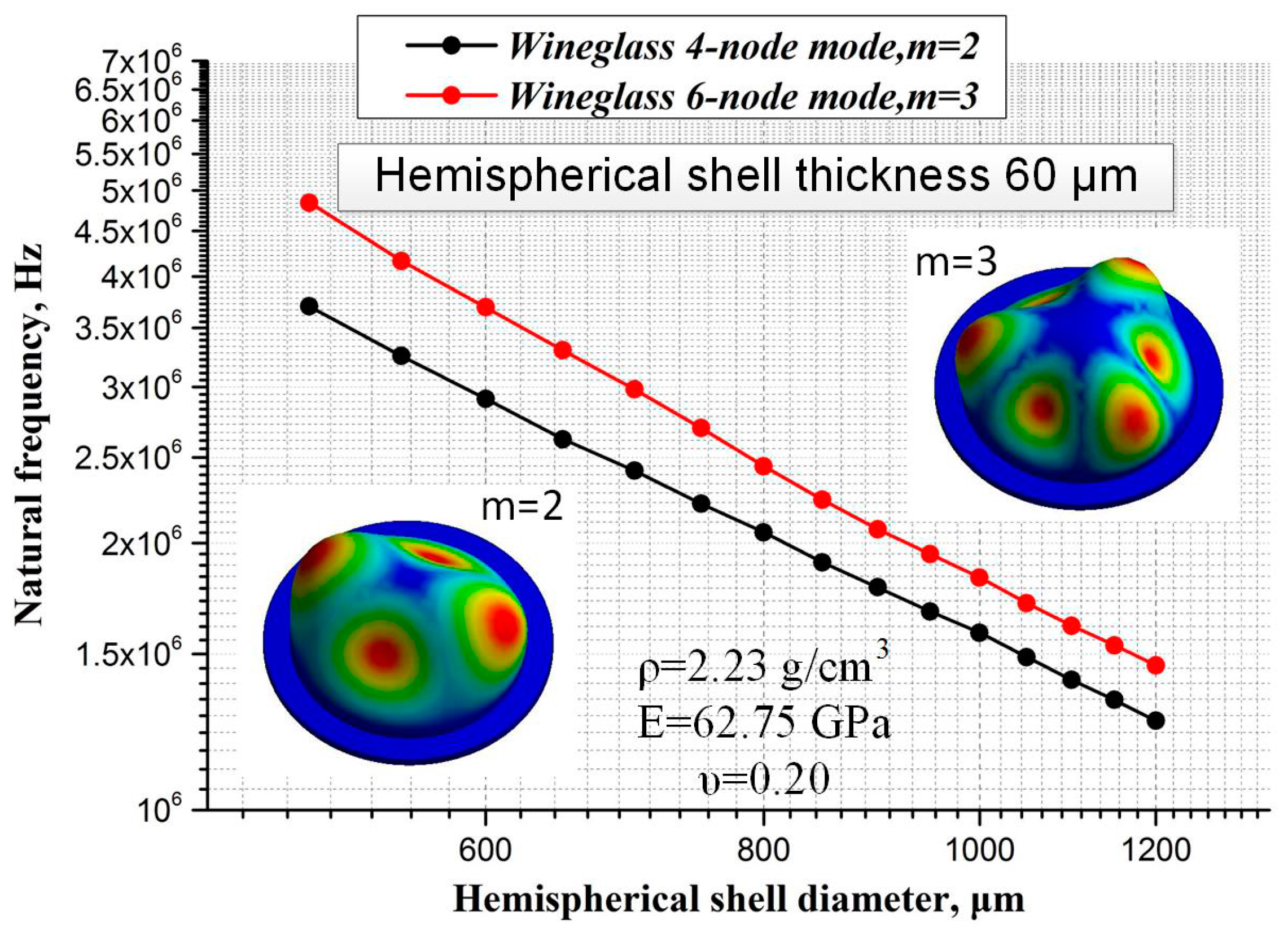

2.2. The Parameters Simulation of the Hemispherical Shell

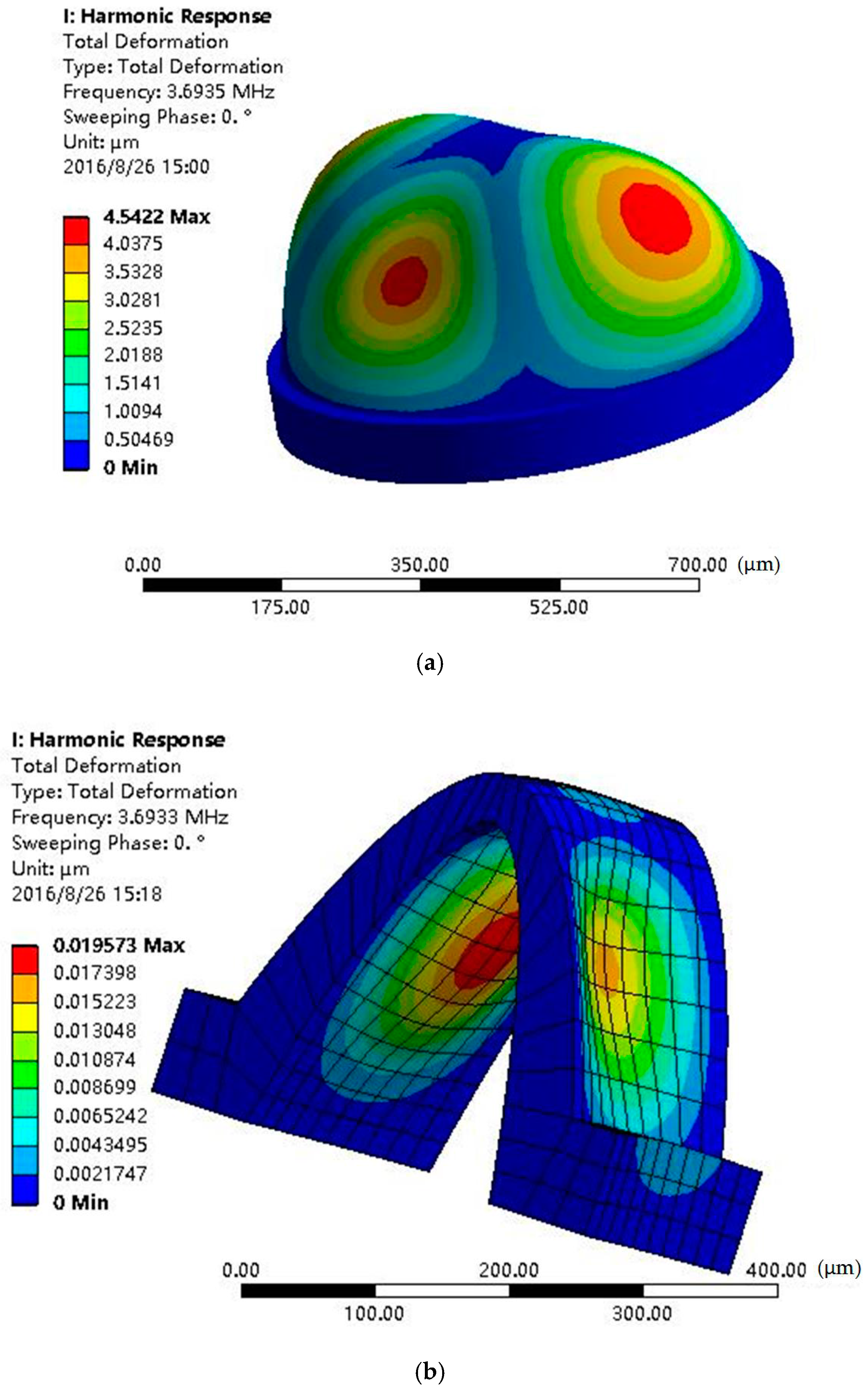

2.3. The Interaction of Hemispherical Shell and Annular Electrodes

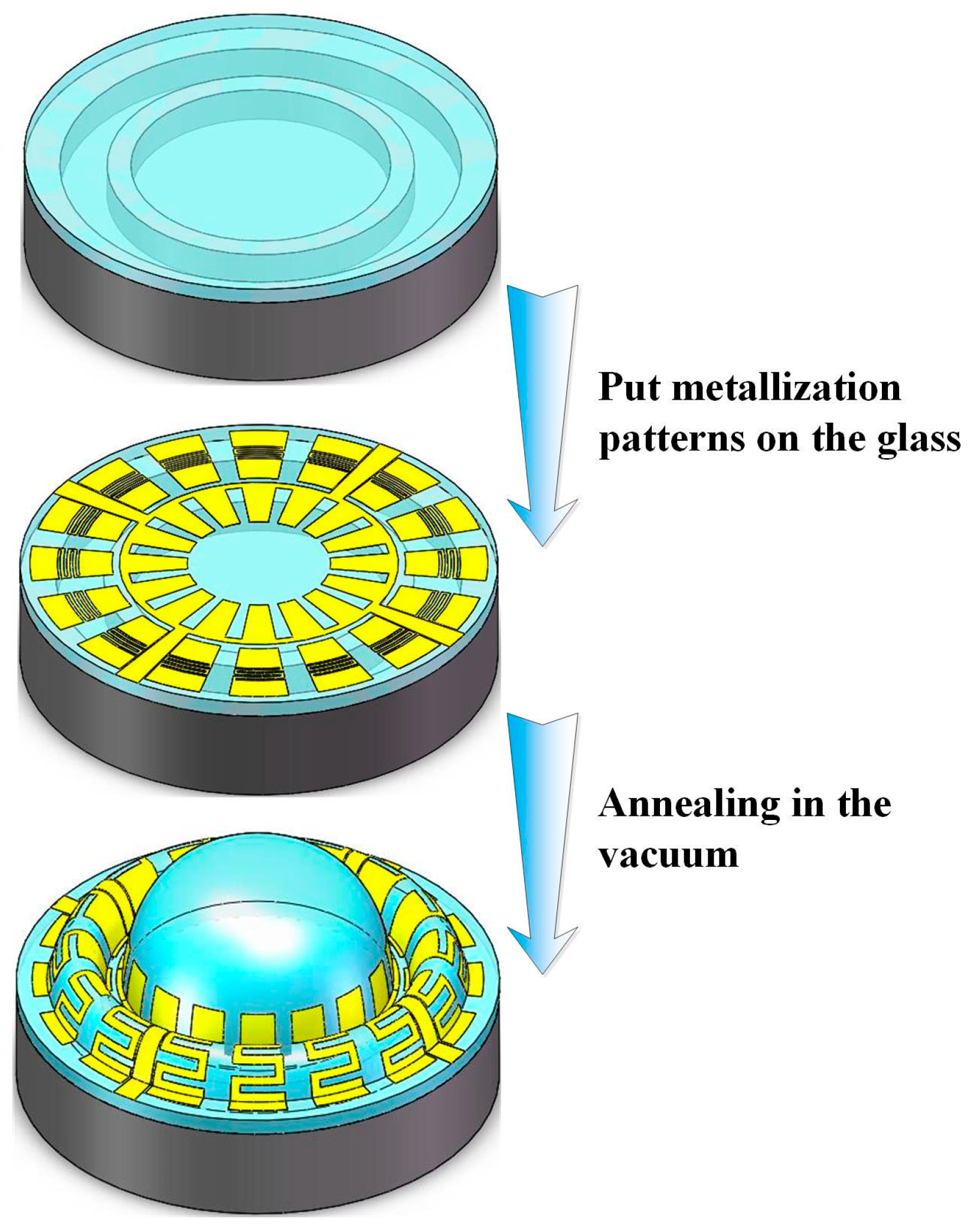

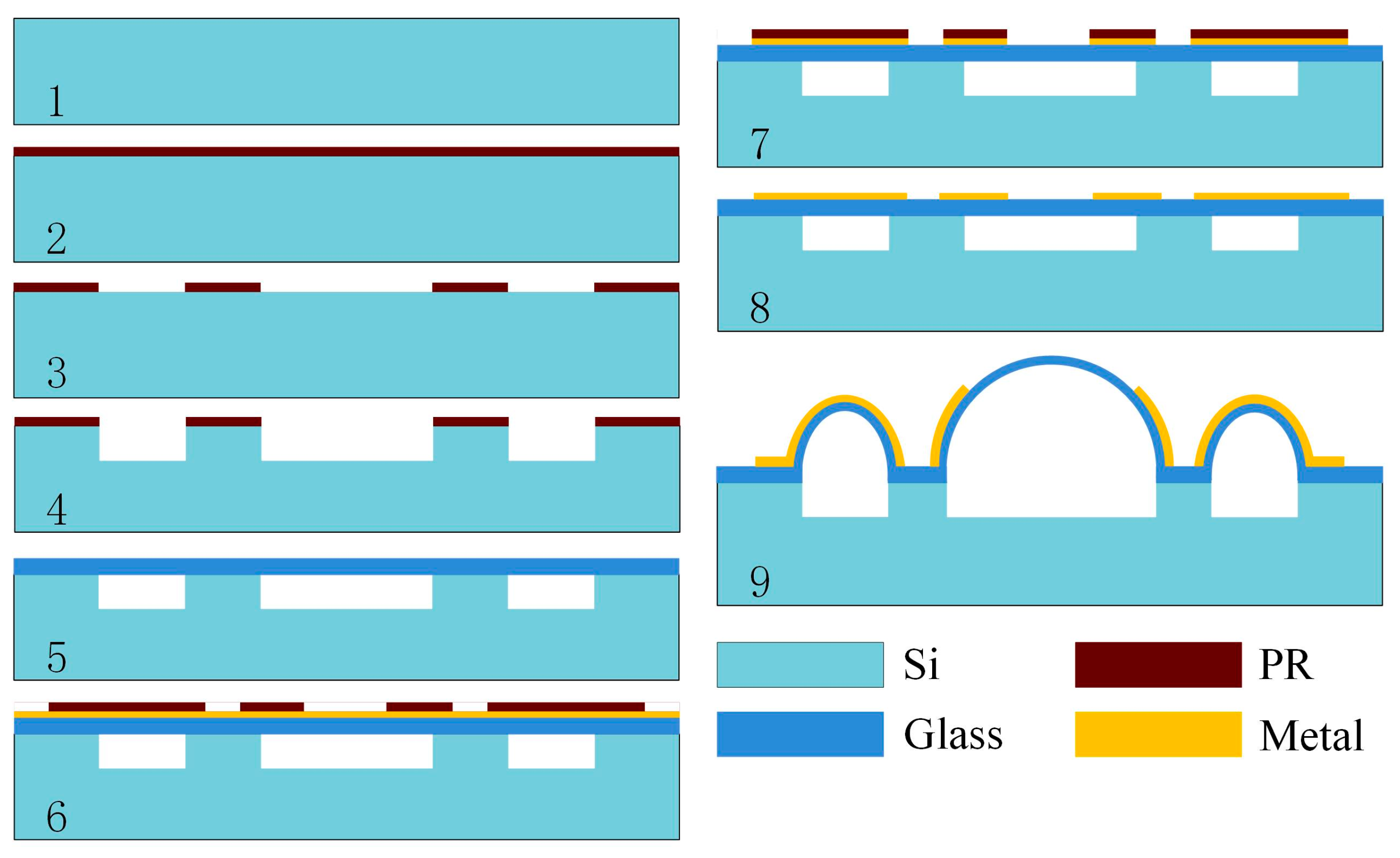

3. Fabrication

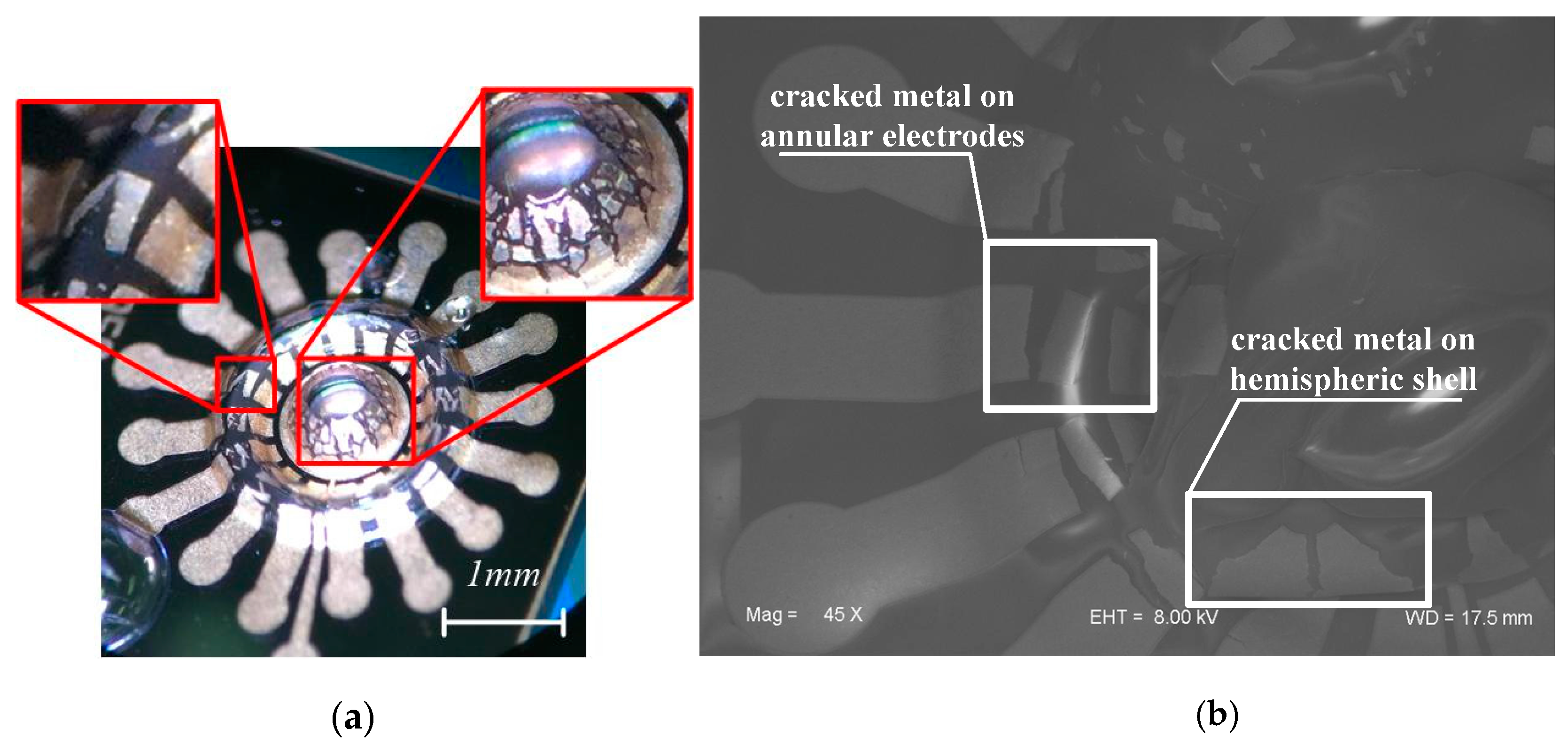

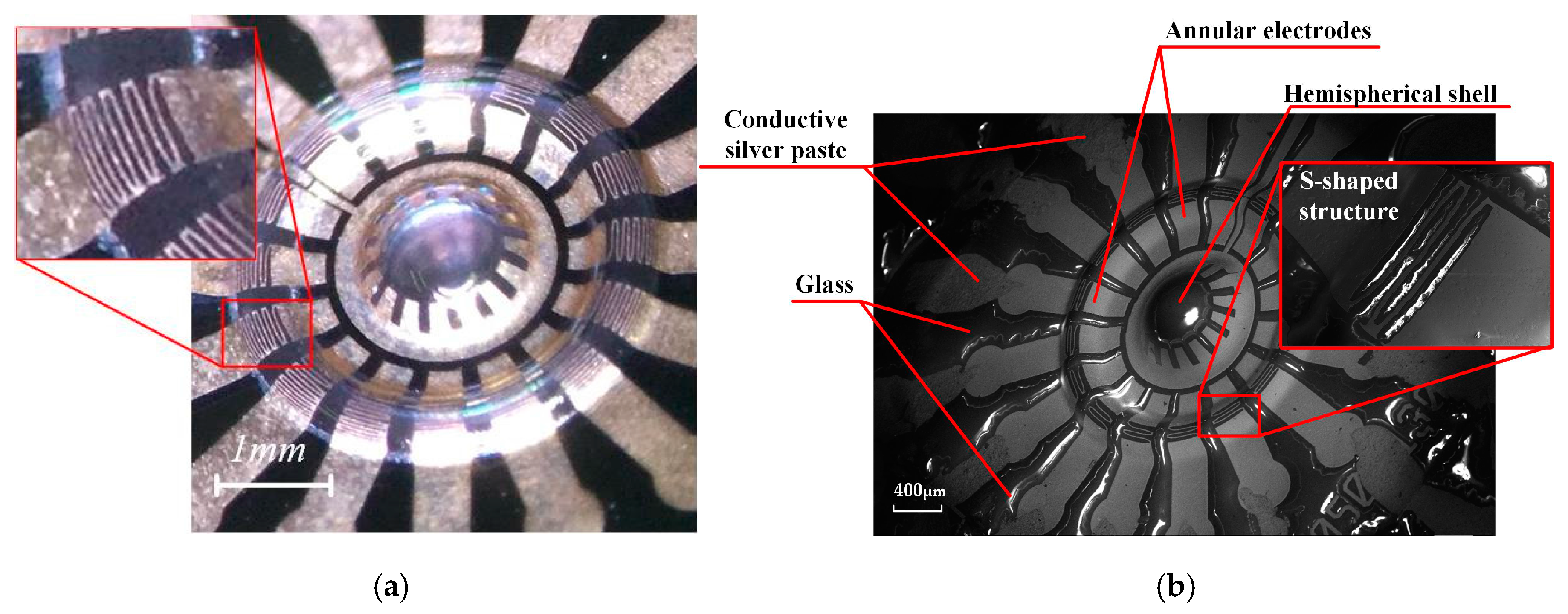

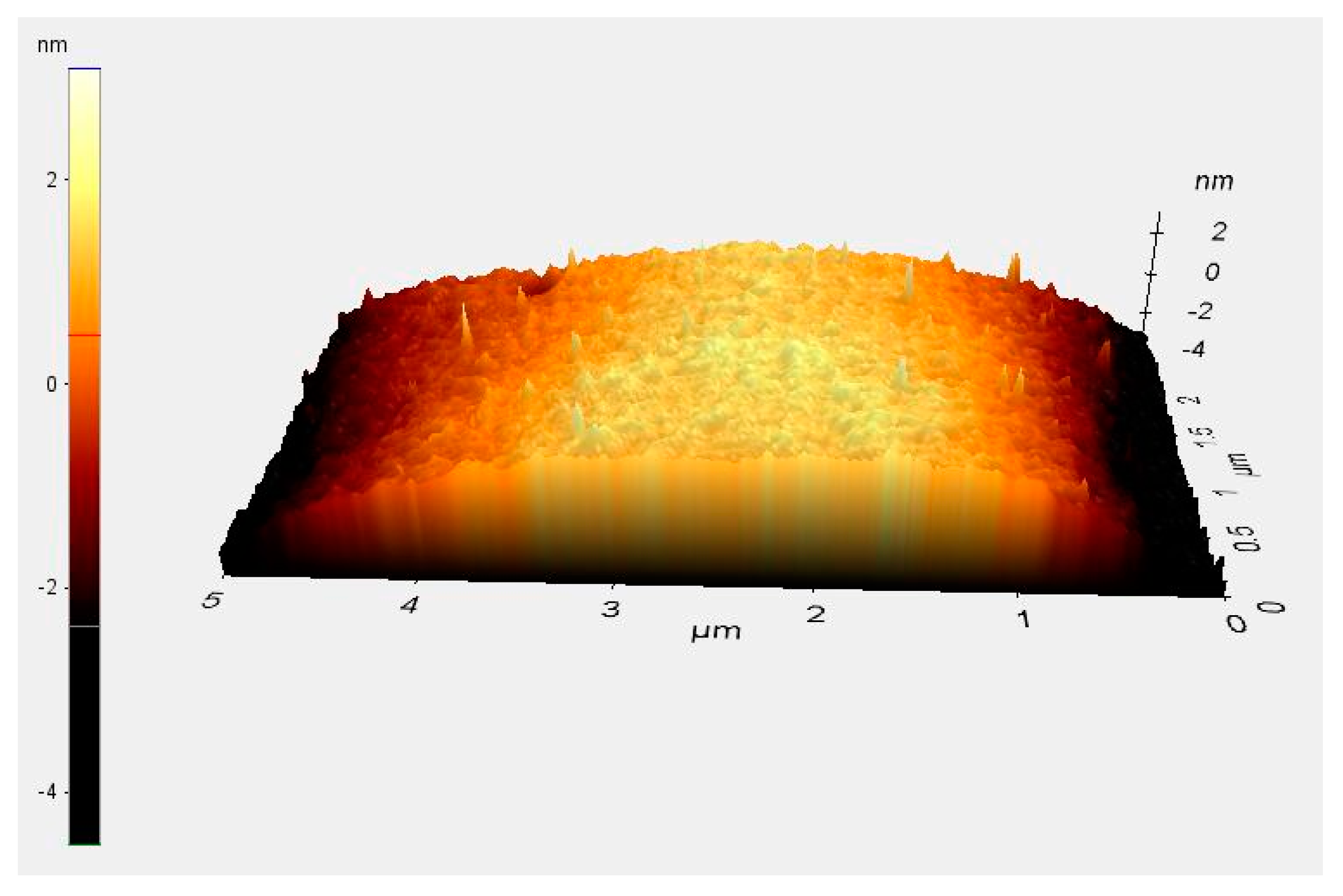

4. Results and Discussions

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Luo, B.; Shang, J.; Zhang, Y. Hemipherical wineglass shells fabricated by a Chemical Foaming Process. In Proceedings of the 2015 IEEE 16th International Conference on Electronic Packaging Technology, Changsha, China, 11–14 August 2015.

- Luo, B.; Shang, J.; Zhang, Y. Hemispherical glass shell resonators fabricated using Chemical Foaming Process. In Proceedings of the 2015 IEEE 65th Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 26–29 May 2015.

- Rozelle, D.M. The Hemispherical Resonator Gyro: From wineglass to the planets. Adv. Astronaut. Sci. 2009, 134, 1157–1178. [Google Scholar]

- Lynch, D. Hemispherical resonator gyro. IEEE Trans. Aerosp. Electron. Syst. 1984, 20, 432–433. [Google Scholar]

- Eklund, E.J.; Shkel, A.M. Glass blowing on a wafer level. J. Microelectromech. Syst. 2007, 16, 232–239. [Google Scholar] [CrossRef]

- Prikhodko, I.P.; Zotov, S.A.; Trusov, A.A.; Shkel, A.M. Microscale glass-blown three-dimensional spherical shell resonators. J. Microelectromech. Syst. 2011, 20, 691–701. [Google Scholar] [CrossRef]

- Cho, J.Y.; Woo, J.K.; Yan, J.; Peterson, R.L. Fused-silica micro birdbath resonator gyroscope (-BRG). J. Microelectromech. Syst. 2014, 23, 66–77. [Google Scholar] [CrossRef]

- Sorenson, L.; Gao, X.; Ayazi, F. 3-D micromachined hemispherical shell resonators with integrated capacitive transducers. In Proceedings of the 2012 IEEE 25th International Conference on Micro Electro Mechanical Systems (MEMS), Paris, France, 29 January–2 February 2012; pp. 168–171.

- Shao, P.; Tavassoli, V.; Mayberry, C.L.; Ayazi, F. A 3D-HARPSS polysilicon microhemispherical shell resonating gyroscope: Design, fabrication, and characterization. IEEE Sens. J. 2015, 15, 4974–4985. [Google Scholar] [CrossRef]

- Pai, P.; Chowdhury, F.K.; Pourzand, H.; Tabib-Azar, M. Fabrication and testing of hemispherical MEMS wineglass resonators. In Proceedings of the 2013 IEEE 26th International Conference on Micro Electro Mechanical Systems (MEMS), Taipei, Taiwan, 20–24 January 2013; pp. 677–680.

- Bernstein, J.J.; Bancu, M.G.; Cook, E.H.; Chaparala, M.V.; Teynor, W.A.; Weinberg, M.S. A MEMS diamond hemispherical resonator. J. Micromech. Microeng. 2013, 23, 125007–125014. [Google Scholar] [CrossRef]

- Senkal, D.; Ahamed, M.J.; Trusov, A.A.; Shkel, A.M. Achieving sub-Hz frequency symmetry in micro-glassblown wineglass resonators. J. Microelectromech. Syst. 2014, 23, 30–38. [Google Scholar] [CrossRef]

- Senkal, D.; Ahamed, M.J.; Trusov, A.A.; Shkel, A.M. High temperature micro-glassblowing process demonstrated on fused quartz and ULE TSG. Sens. Actuators A Phys. 2013, 201, 525–531. [Google Scholar] [CrossRef]

- Ghavanini, F.A.; Rödjegård, H.; Enoksson, P. An easy-to-implement method for evaluation of capacitive resonant sensors. J. Micromech. Microeng. 2006, 16, S156–S160. [Google Scholar] [CrossRef]

- Hernando, A.; Vazquez, M.; Barandiaran, J.M. Metallic glasses and sensing applications. J. Phys. E Sci. Instrum. 1988, 21, 1129–1139. [Google Scholar] [CrossRef]

- Senkal, D.; Ahamed, M.J.; Ardakani, M.H.A.; Askari, S.; Shkel, A.M. Demonstration of 1 million-factor on microglassblown wineglass resonators with out-of-plane electrostatic transduction. J. Microelectromech. Syst. 2015, 24, 29–37. [Google Scholar] [CrossRef]

- Zotov, S.A.; Trusov, A.A.; Shkel, A.M. Three-dimensional spherical shell resonator gyroscope fabricated using wafer-scale glassblowing. J. Microelectromech. Syst. 2012, 21, 509–510. [Google Scholar] [CrossRef]

- Heidari, A.; Chan, M.L.; Yang, H.A.; Jaramillo, G. Micromachined polycrystalline diamond hemispherical shell resonators. In Proceedings of the 17th IEEE International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS & EUROSENSORS XXVII), Barcelona, Spain, 16–20 June 2013; pp. 2415–2418.

- Rahman, M.M.; Xie, Y.; Mastrangelo, C.; Kim, H. 3-D hemispherical micro glass-shell resonator with integrated electrostatic excitation and capacitive detection transducers. In Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems, San Francisco, CA, USA, 26–30 January 2014; pp. 672–675.

- Senkal, D.; Raum, C.R.; Trusov, A.A.; Shkel, A.M. Titania silicate/fused quartz glassblowing for 3-D fabrication of low internal loss wineglass micro-structures. In Proceedings of the Solid-State Sensors, Actuators, and Microsystems Workshop, Hilton Head Island, SC, USA, 3–7 June 2012; pp. 267–270.

- Zotov, S.A.; Prikhodko, I.P.; Trusov, A.A.; Shkel, A.M. 3-D micromachined spherical shell resonators with integrated electromagnetic and electrostatic transducers. In Proceedings of the Solid-State Sensors, Actuators, and Microsystems Workshop, Hilton Head Island, SC, USA, 6–10 June 2010.

- Cho, J.Y.; Yan, J.; Gregory, J.A.; Eberhart, H.W. 3-dimensional blow torch-molding of fused silica microstructures. J. Microelectromech. Syst. 2013, 22, 1276–1284. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, R.; Bai, B.; Feng, H.; Ren, Z.; Cao, H.; Xue, C.; Zhang, B.; Liu, J. Design and Fabrication of Micro Hemispheric Shell Resonator with Annular Electrodes. Sensors 2016, 16, 1991. https://doi.org/10.3390/s16121991

Wang R, Bai B, Feng H, Ren Z, Cao H, Xue C, Zhang B, Liu J. Design and Fabrication of Micro Hemispheric Shell Resonator with Annular Electrodes. Sensors. 2016; 16(12):1991. https://doi.org/10.3390/s16121991

Chicago/Turabian StyleWang, Renxin, Bing Bai, Hengzhen Feng, Ziming Ren, Huiliang Cao, Chenyang Xue, Binzhen Zhang, and Jun Liu. 2016. "Design and Fabrication of Micro Hemispheric Shell Resonator with Annular Electrodes" Sensors 16, no. 12: 1991. https://doi.org/10.3390/s16121991

APA StyleWang, R., Bai, B., Feng, H., Ren, Z., Cao, H., Xue, C., Zhang, B., & Liu, J. (2016). Design and Fabrication of Micro Hemispheric Shell Resonator with Annular Electrodes. Sensors, 16(12), 1991. https://doi.org/10.3390/s16121991